Ingersoll-Rand UP6 20 HP, UP6 15HP, UP6 25 HP, UP6 30 HP Option Manual

UP6 15, UP6 20, UP6 25, UP6 30

OPTIONS MANUAL

Intellisys Option

Dryer Option

High Dust Option

Outdoor Module Option

PORO Option

60Hz

This manual contains

important safety information

and must be made available

to personnel who operate and

maintain this machine.

C.C.N. : 80445174

REV : B

DATE : JANUARY 2009

CONTENTS & ABBREVIATIONS

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

1

CONTENTS

1 CONTENTS

2 FOREWORD

3 DECALS

6 SAFETY

8 INTELLISYS OPTION

31 DRYER OPTION

47 HIGH DUST FILTER OPTION

48 OUT DOOR MODULE OPTION

49 PORO OPTION – ELECTRO–PNEUMATIC

53 PORO OPTION – INTELLISYS

ABBREVIATIONS & SYMBOLS

#### Contact Ingersoll Rand for serial number

–>#### Up to Serial No.

####–> From Serial No.

* Not illustrated

{ Option

NR Not required

AR As required

SM Sitemaster/Sitepack

HA High ambient machine

WC Watercooled machine

AC Aircooled machine

ERS Energy recovery system

T.E.F.C. Totally enclosed fan cooled motor (IP55)

O.D.P. Open drip proof (motor)

2

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

FOREWORD

This manual is provided to cover instructions and technical data

for additional options to the standard UP compressor range. It is

provided as a SUPPLEMENT to the standard operators and parts

manuals and should NOT be used for the operation of the

complete machine.

The contents of this manual are considered to be proprietary and

confidential to Ingersoll Rand and should not be reproduced without

the prior written permission of Ingersoll Rand.

Nothing contained in this document is intended to extend any

promise, warranty or representation, expressed or implied, regarding

the Ingersoll Rand products described herein. Any such warranties or

other terms and conditions of sale of products shall be in accordance

with the standard terms and conditions of sale for such products, which

are available upon request.

This manual contains instructions and technical data to cover

routine operation and scheduled maintenance tasks by operation and

maintenance staff. Major overhauls are outside the scope of this

manual and should be referred to an authorized Ingersoll Rand service

department.

All components, accessories, pipes and connectors added to the

compressed air system should be:

. of good quality, procured from a reputable manufacturer and,

wherever possible, be of a type approved by Ingersoll Rand.

. clearly rated for a pressure at least equal to the machine maximum

allowable working pressure.

. compatible with the compressor lubricant/coolant.

. accompanied with instructions for safe installation, operation and

maintenance.

Details of approved equipment are available from Ingersoll Rand

Service departments.

The use of non–genuine spare repair parts other than those

included within the Ingersoll Rand approved parts list may create

hazardous conditions over which Ingersoll Rand has no control.

Therefore Ingersoll Rand does not accept any liability for losses

caused by equipment in which non–approved repair parts are installed.

Standard warranty conditions may be affected.

The intended uses of this machine are outlined below and examples

of unapproved usage are also given, however Ingersoll Rand cannot

anticipate every application or work situation that may arise.

IF IN DOUBT CONSULT SUPERVISION.

This machine has been designed and supplied for use only in the

following specified conditions and applications:

. Compression of normal ambient air containing no known or

detectable additional gases, vapors, or particles

. Operation within the ambient temperature range specified in the

GENERAL INFORMATION section of this manual.

The use of the machine in any of the situation types listed in

table 1:–

a) Is not approved by Ingersoll Rand,

b) May impair the safety of users and other persons, and

c) May prejudice any claims made against Ingersoll Rand.

TABLE 1

Use of the machine to produce compressed air for:

a) direct human consumption

b) indirect human consumption, without suitable filtration and purity

checks.

Use of the machine outside the ambient temperature range

specified in the GENERAL INFORMATION SECTION of this manual.

Use of the machine where there is any actual or foreseeable risk of

hazardous levels of flammable gases or vapors.

THIS MACHINE IS NOT INTENDED AND MUST NOT BE

USED IN POTENTIALLY EXPLOSIVE ATMOSPHERES,

INCLUDING SITUATIONS WHERE FLAMMABLE GASES OR

VAPOURS MAY BE PRESENT.

Use of the machine fitted with non Ingersoll Rand approved

components.

Use of the machine with safety or control components missing or

disabled.

The company accepts no responsibility for errors in translation of

this manual from the original English version.

Ingersoll Rand reserves the right to make changes and

improvements to products without notice and without incurring any

obligation to make such changes or add such improvements to

products sold previously.

INTELLISYS is a registered trademark of Ingersoll Rand

Company USA.

¤ COPYRIGHT 2008

INGERSOLL RAND

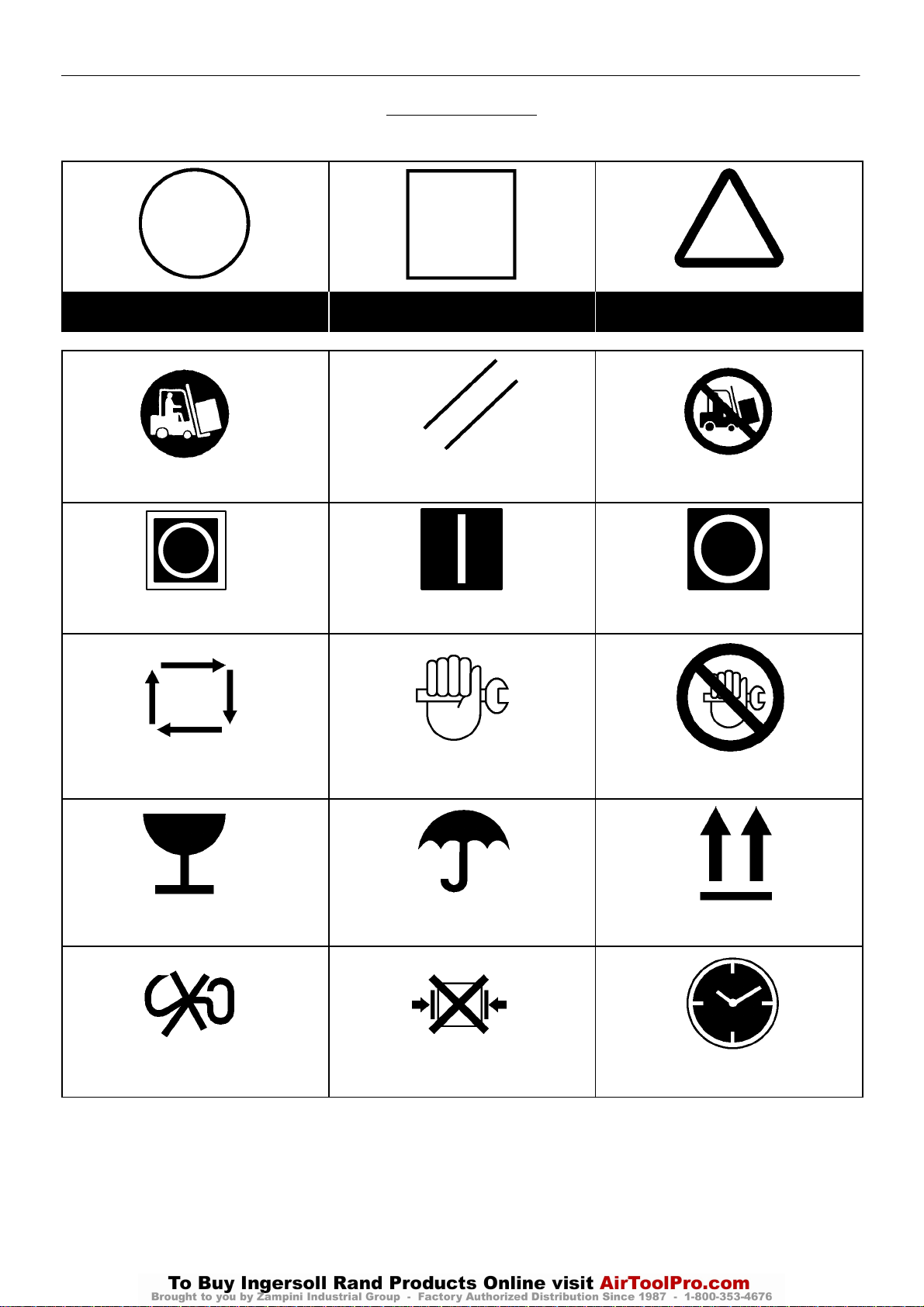

DECALS 3

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

ISO SYMBOLS

GRAPHIC FORM AND MEANING OF ISO SYMBOLS

Prohibition / Mandatory Information / Instructions Warning

Use fork lift truck from this side only. RESET Do not use fork lift truck from this side.

Emergency stop. On (power). Off (power).

AUTOMATIC RESTART MAINTENANCE MAINTENANCE PROHIBITED

FRAGILE KEEP DRY THIS WAY UP

USE NO HOOKS NO SIDE CLAMPS HOURS

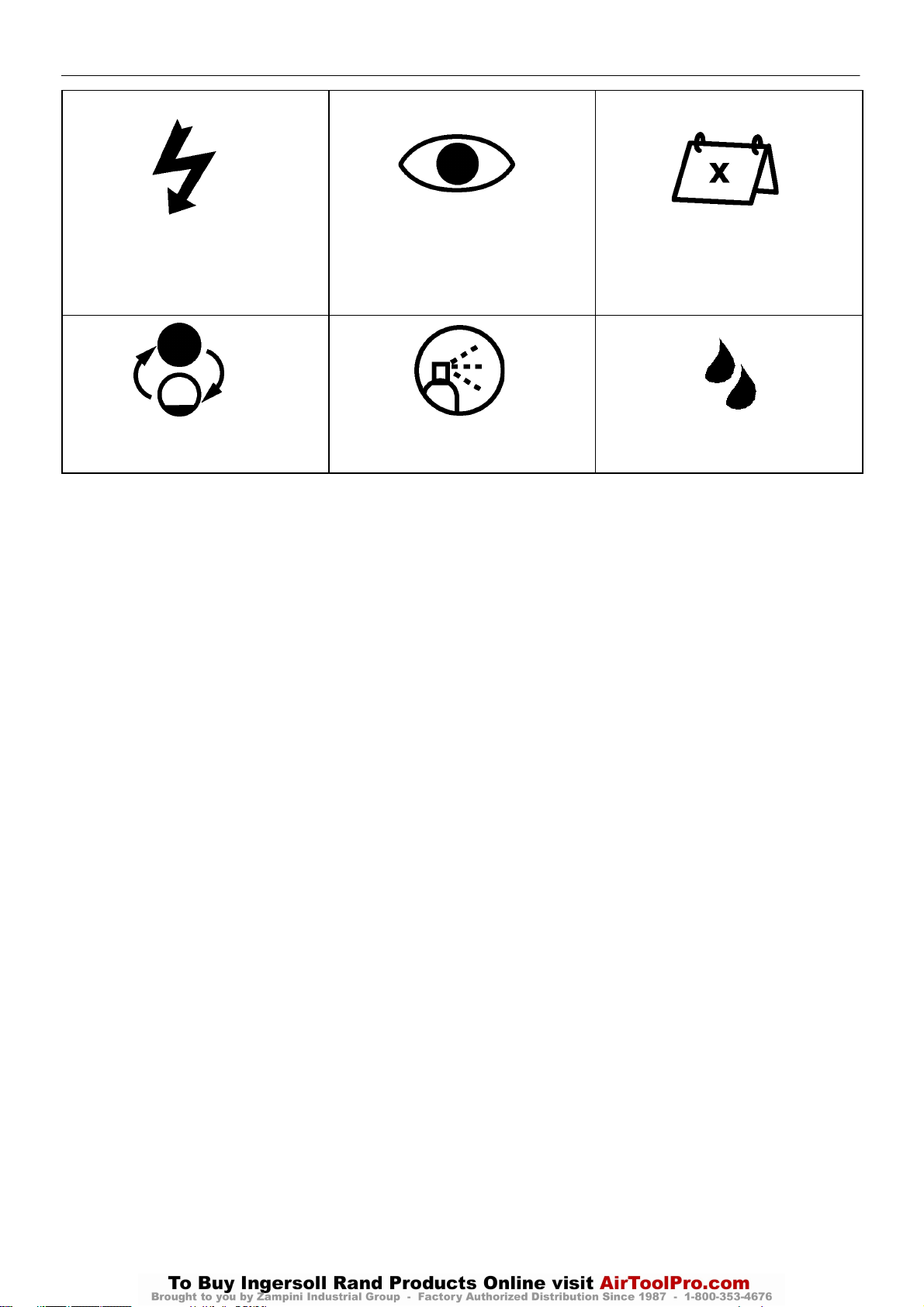

DECALS4

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

POWER INSPECT

CHANGE / REPLACE CLEAN

Every X months, if sooner than required by

operating hours

MOISTURE

DECALS 5

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

ANSI SYMBOLS

GRAPHIC FORM AND MEANING OF ANSI SYMBOLS

DANGER

INTAKE AIR. Can contain carbon monoxide or other contaminants. Will cause serious injury or death. Ingersoll Rand

air compressors are not designed, intended or approved for breathing air. Compressed air should not be used for

breathing air applications unless treated in accordance with all applicable codes and regulations.

WARNING

HAZARDOUS VOLTAGE. Can cause serious injury or death. Disconnect power and bleed pressure from tank before

servicing. Lockout/Tagout machine. Compressor must be connected to properly grounded circuit. See Grounding

Instructions in manual. Do not operate compressor in wet conditions. Store indoors.

RISK OF FIRE OR EXPLOSION. Electrical arcing from compressor components can ignite flammable liquids and

vapors which can result in serious injury. Never operate the compressor near flammable liquids or vapors. If used to

spray flammable materials, keep compressor at least 20ft away from the spray area.

HIGH PRESSURE AIR. Rusted tanks can cause explosion and severe injury or death. Receiver under pressure.

Operator should relieve tank pressure before performing maintenance. In addition to automatic drain, operate manual

drain valve weekly. Manual drain valve located at bottom of the tank.

MOVING PARTS. Can cause serious injury. Do not operate with guards removed. Machine may start automatically.

Disconnect power before servicing. Lockout/Tagout machine.

HOT SURFACES. Can cause serious injury. Do not touch. Allow to cool before servicing. Do not touch hot

compressor or tubing.

EXPOSED MOVING BELTS AND SHEAVES.

Can cause severe injury or death.

Do not operate without guard in place. Disconnect power before servicing.

Lockout/Tagout machine.

Air flow exhaust may contain flying debris.

Safety protection should be worn at all times.

6

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

SAFETY

DANGER!

Hazard that WILL cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions must be followed precisely to

avoid injury or death.

WARNING!

Hazard that CAN cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions which must be followed

precisely to avoid injury or death.

CAUTIONS!

Cautions call attention to instructions which must be followed

precisely to avoid damaging the product, process or its surroundings.

NOTES

Notes are used for supplementary information.

BREATHING AIR PRECAUTION

Ingersoll Rand air compressors are not designed, intended or

approved for breathing air. Compressed air should not be used for

breathing air applications unless treated in accordance with all

applicable codes and regulations.

General Information

Ensure that the operator reads and understands the decals and

consults the manuals before maintenance or operation.

Ensure that the Operation and Maintenance manual is not removed

permanently from the machine.

Ensure that maintenance personnel are adequately trained,

competent and have read the Maintenance Manuals.

Do not point air nozzles or sprayers toward anyone.

Compressed air and electricity can be dangerous. Before

undertaking any work on the compressor, ensure that the electrical

supply has been isolated and the compressor has been relieved of all

pressure.

Wear eye protection when operating or servicing compressor.

All persons positioned near to operating machinery should be

equipped with hearing protection and given instructions on its use in

accordance with workplace safety legislation.

Make sure that all protective covers are in place and that the

canopy/doors are closed during operation.

The specification of this machine is such that the machine is not

suitable for use in flammable gas risk areas.

Installation of this compressor must be in accordance with

recognized electrical codes and any local Health and Safety Codes.

The use of plastic bowls on line filters can be hazardous. Their

safety can be affected by either synthetic lubricants, or the additives

used in mineral oils. Ingersoll Rand recommends that only filters with

metal bowls should be used on a pressurized system.

Compressed air

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

All air pressure equipment installed in or connected to the machine

must have safe working pressure ratings of at least the machine rated

pressure.

If more than one compressor is connected to one common

downstream plant, effective isolation valves must be fitted and

controlled by work procedures, so that one machine cannot accidently

be pressurized / over pressurized by another.

Compressed air must not be used for a direct feed to any form of

breathing apparatus or mask.

The discharged air contains a very small percentage of compressor

lubricant and care should be taken to ensure that downstream

equipment is compatible.

If the discharged air is to be ultimately released into a confined

space, adequate ventilation must be provided.

When using compressed air always use appropriate personal

protective equipment.

All pressure containing parts, especially flexible hoses and their

couplings, must be regularly inspected, be free from defects and be

replaced according to the Manual instructions.

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

Avoid bodily contact with compressed air.

All safety valves located in the separator tank must be checked

periodically for correct operation.

Do not over–pressurize the receiver tank or similar vessels beyond

design limits.

Do not use a receiver tank or similar vessels that fail to meet the

design requirements of the compressor. Contact your distributor for

assistance.

Do not drill into, weld or otherwise alter the receiver tank or similar

vessels.

Materials

The following substances are used in the manufacture of this

machine and may be hazardous to health if used incorrectly:

. preservative grease

. rust preventative

. compressor coolant

AVOID INGESTION, SKIN CONTACT AND INHALATION OF

FUMES

Transport

When loading or transporting machines ensure that the specified

lifting and tie down points are used.

Lifting equipment must be properly rated for the weight of the

compressor.

Do not work on or walk under the compressor while it is suspended.

WARNING

Imposing a normal or emergency stop on the compressor will

only relieve presure upstream of the minimum pressure valve on

top of the separator tank.

If maintenance work is required downstream of this valve, ensure

that all pressure is relieved at the process vent point external to

the compressor

Ensure that the machine is operating at the rated pressure and that

the rated pressure is known to all relevant personnel.

Electrical

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

Keep all parts of the body and any hand–held tools or other

conductive objects, away from exposed live parts of the compressor

electrical system. Maintain dry footing, stand on insulating surfaces

and do not contact any other portion of the compressor when making

adjustments or repairs to exposed live parts of the compressor

electrical system.

WARNING

Any electrical connections or adjustments should only be

made by a suitably qualified electrician

Close and lock all access doors when the compressor is left

unattended.

Do not use extinguishers intended for Class A or Class B fires on

electrical fires. Use only extinguishers suitable for class BC or class

ABC fires.

Attempt repairs only in clean, dry, well lighted and ventilated areas.

Connect the compressor only to electrical systems that are

compatible with its electrical characteristics and that are within it’s rated

capacity.

Condensate disposal

As waste water regulations vary by country and region it is the

responsibility of the user to establish the limitations and regulations in

their particular area. Ingersoll Rand and its associated distributors are

happy to advise and assist in these matters.

For further information, consult Material Data

80440043 MSDS, Ultra Coolant English

80440068 MSDS, Ultra Coolant Spanish

80440050 MSDS, Ultra Coolant Portuguese

80442254 MSDS, Xtend Food Grade Coolant English

SAFETY

7

8

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

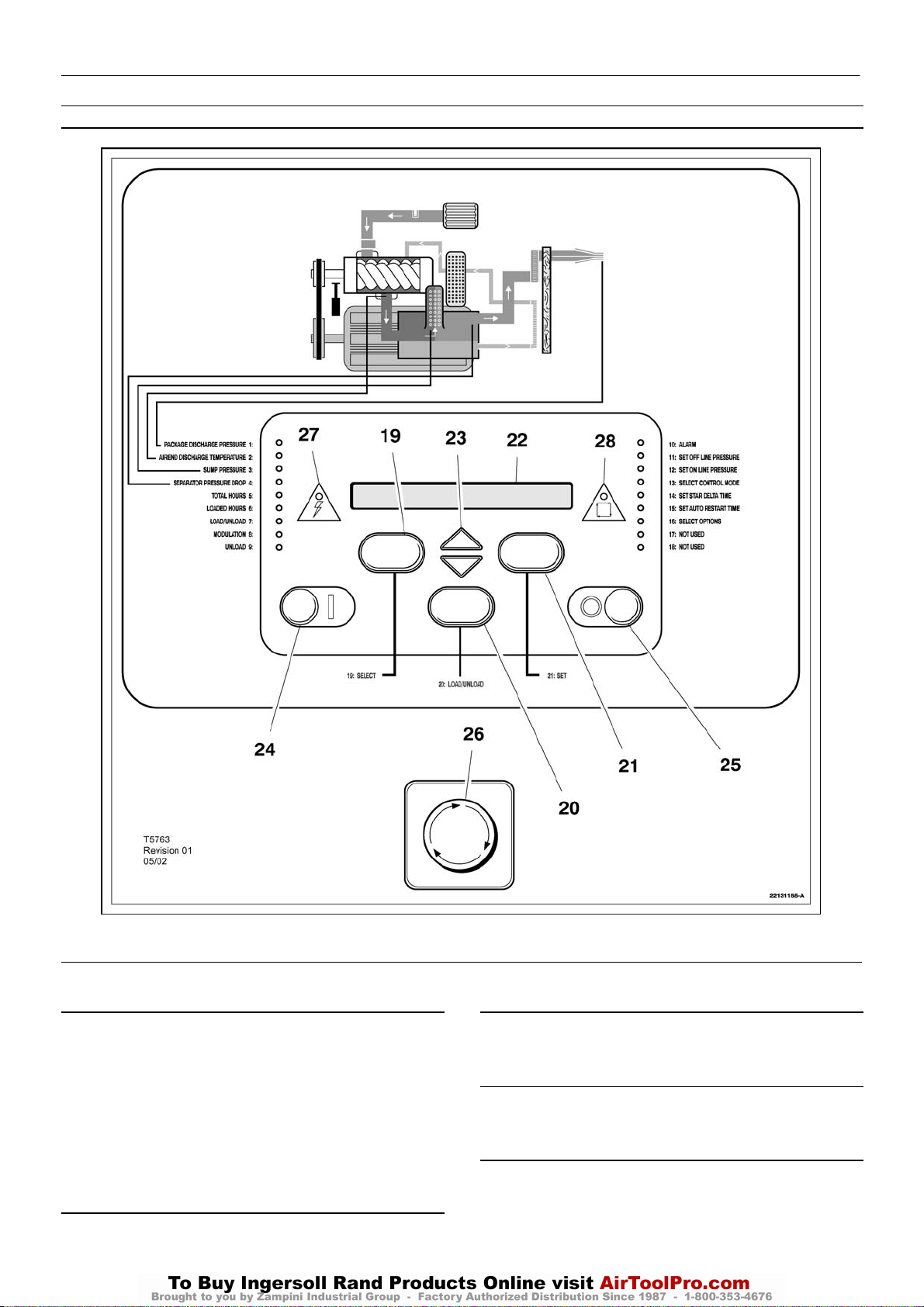

INTELLISYS CONTROL AND INSTRUMENTATION

INTELLISYS OPTION

PRIOR TO STARTING

1. Check coolant level. Add if necessary.

2. Make sure main discharge valve is open.

3. Turn on electrical isolator. The power L.E.D. will illuminate and the

display will indicate ‘Ready to start’.

WARNING

Make sure that all protective covers are in place.

STARTING

Press ‘Start’ [24]. The compressor will start and then load

automatically.

POWER OUT RESTART (Optional)

If this setting is set to ON, the compressor will automatically restart

when power is returned to the compressor if it was operating when

power was removed.

POWER OUT RESTART TIME

If the power out restart setting is set to ON, this is the number of

seconds from the time power is restored until the compressor starts.

The power out restart horn will sound during this time.

NORMAL STOPPING

1. Press ‘Unloaded Stop’[25]. The compressor will unload then stop.

2. Turn off electrical isolator.

INTELLISYS OPTION

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

9

EMERGENCY STOP

1. Press ‘Emergency stop button’ [26] and the compressor will stop

immediately.

2. Turn off electrical isolator.

INSTRUMENT PANEL FUNCTION

1 PACKAGE DISCHARGE PRESSURE L.E.D.

This will illuminate when the display indicates the package

discharge pressure.

2 AIREND DISCHARGE TEMPERATURE L.E.D.

This will illuminate when the display indicates the airend discharge

temperature.

3 SUMP PRESSURE L.E.D.

This will illuminate when the display indicates the sump pressure.

4 SEPARATOR PRESSURE DROP L.E.D.

This will illuminate when the display indicates the separator

pressure drop.

5 TOTAL HOURS L.E.D.

This will illuminate when the display indicates the total compressor

running hours.

6 LOADED HOURS L.E.D.

This will illuminate when the display indicates the total loaded

compressor hours.

7 LOAD/UNLOAD L.E.D.

This will illuminate when the compressor is running onload.

15 L.E.D.–Set auto restart time.

16 L.E.D.–Select options.

17 L.E.D.–Not used.

18 L.E.D.–Not used.

19 DISPLAY SELECT BUTTON

Press to index through compressor operating conditions. The

corresponding L.E.D. will illuminate adjacent to display.

This is used to select alternative status displays (after

approximately 5 minutes, the display defaults to the package discharge

pressure). Depressing this button in the set point routine will cause exit

to checking machine for 2 seconds, then ready to start.

20 LOAD/UNLOAD BUTTON

These are used to manually switch the compressor between a

loaded control mode (e.g. on/off line) and unloaded running.

See L.E.D.

21 SET BUTTON

Depressing this button when the compressor is stopped will enable

entry into the set point routine. When in the set point routine, depressing

this button will cause the controller to move on to the next set point

setting, saving the new value if one has been entered.

A warning reset is obtained by depressing this button (while the

machine is running). An alarm reset is obtained by depressing this

button twice within 3 seconds (the alarm condition will remain if the

indicated fault has not been rectified).

22 LIQUID CRYSTAL DISPLAY

This indicates the status of the compressor, set up parameters and

warning/alarm messages. When the compressor is running, the

display will normally show the package discharge pressure.

8 MODULATION L.E.D.

This will illuminate when the compressor is running in modulation

mode. (Note: capacity modulation will occur only if the appropriate

regulation pneumatics are fitted to the compressor).

9 UNLOAD L.E.D.

This will illuminate when the compressor is running in unload mode.

10 ALARM L.E.D.

This will flash when a warning condition exists. The warning

detected will be displayed and the compressor will continue to run. The

warning can be reset by depressing set [21].

It will illuminate when an alarm condition has occurred. The

compressor will shutdown immediately. The alarm can be reset by

depressing set [21] twice within 3 seconds.

OTHER L.E.D.s

These will illuminate during the set point routine to indicate which

function is being adjusted.

11 L.E.D.–Set off line pressure.

12 L.E.D.–Set on line pressure.

13 L.E.D.–Select control mode.

14 L.E.D.–Set star delta time.

23 ARROW KEYS

These are used to index through warning and alarm messages. In

the set point routine, these buttons are used to increase/decrease set

point values and enable/disable some operation conditions.

The arrow keys are also used to select pressure bands 1 (Y) or 2

(B) during normal operation of the compressor.

24 START BUTTON

This button when depressed will cause the compressor to start and

load automatically, provided that the controller detects a demand for air.

When pressed in the display mode, it will cause exit to checking

machine for 2 seconds, then ready to start.

25 UNLOADED STOP

This button when depressed while the compressor is running, will

unload the compressor (if not already unloaded) for 10 seconds and

then stop. This is the normal method for stopping the compressor. If the

compressor is already stopped, it will execute an L.E.D. check (all the

L.E.D.s should illuminate) and display the controller software revision.

26 EMERGENCY STOP

This button when depressed will stop the compressor immediately

and display an emergency stop alarm message.

10

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

INTELLISYS OPTION

27 POWER L.E.D.

This will illuminate when the 8V controller supply is available.

28 AUTOMATIC RESTART L.E.D.

This will illuminate when the machine has shutdown due to low air

demand. The compressor will restart and load automatically as soon

as the demand for air resumes.

DISPLAY MESSAGES

When the compressor is running normally, the display will indicate

the package discharge pressure and illuminate the corresponding

L.E.D. [1]. An arrow will also appear in the far right of the display

indicating pressure band selection. Pressing display select [19] will

change the display value and the corresponding L.E.D. will illuminate.

The controller monitors all aspects of the compressor while running and

will display warnings or in severe conditions execute an emergency

stop and display alarm conditions.

MACHINE CONTROL MODES

CAPACITY CONTROL

The compressor is designed to work with two types of capacity

control, to suit the individual plant requirements. These controls are:–

A. On line – Off line. (Fitted as standard)

B. On line – Off line, with Upper Range Modulation. (Optional extra)

Either is available by selection at the control panel.

ON LINE – OFF LINE CONTROL

For applications that require a widely varying air demand, this

mode of control will deliver air at full capacity or zero capacity with

low receiver pressure.

This mode of operation is controlled by the pressure transducer

responding to changes in plant air pressure. This sensorenergizes

the load solenoid valve which in turn operates the venting valve

(blowdown) and the closing of the atmospheric vent opening in the

air inlet valve.

The compressor then delivers full capacity air to the plant

system. If the air pressure in this system rises to the upper set point

of the pressure setting, the load solenoid valve is de–energized

allowing the inlet valve to close. At the same time, the venting valve

opens allowing the receiver pressure to drop.

The pressure setting has a range of 12 psi (0.83 bar) between

its upper and lower set points.The upper set point is set at 3 psi (0.2

bar) above the compressor rated discharge pressure.

UPPER RANGE MODULATION CONTROL (Optional Extra)

For plants having a relatively high and constant air demand,

Upper Range Modulation is the recommended mode of control.

Upper range modulation retains the features of On line – Off line

control but provides the throttling of the inlet air flow as the line

pressure rises to the upper set point of the off–line pressure setting.

AUTOMATIC START/STOP

For plants that have a widely varying plant air demand, larger air

storage capacity, and/or want automatically available stand–by air

capacity, Automatic Start–Stop Control Option is available.

During periods of low demand, if the line pressure rises to the off line

air pressure set point of the lntellisys® , a timer is energized and begins

to time out. The automatic restart time is adjustable in a 2–60 minute

range. The timer will continue to operate as long as the plant line

pressure remains above the on line set point of the Intellisys® . If the

timer continues to operate for as long as its adjusted time setting, a

contact in the lntellisys opens to de–energize the compressor starter

coils. At the same time, a yellow Automatic Restart light on the

lntellisys® panel is lit and the message AUTO RESTART will be

displayed to indicate the compressor has shut down automatically and

will restart automatically.

The automatic restart will take place when the line pressure drops

to the online set point of the Intellisys® .

To operate in the automatic start/stop mode, proceed with the

following steps:

1. Press the SET button until the message AUTO S/S OFF is

displayed.

2. Push the up or down arrows to select the auto start/stop function (on

or off). AUTO S/S OFF in the display indicates auto start/stop is

disabled (off). AUTO S/S ON in the display indicates auto start/stop is

enabled (on). Press the SET button to store function. The display will

flash to acknowledge and then display AUTO S/S 10 MIN.

3. Press the up or down arrows to select the desired automatic restart

time (2–60 min. range). The default value is 10 minutes. Press SET

button to store the value.The display will flash to acknowledge. Press

the DISPLAY SELECT button or wait 30 seconds for the controller to

automatically exit the set routine.The display returns to READY TO

START.

4. Start the compressor and adjust the isolation valve to allow the unit

to slowly reach the offline pressure and unload.The compressor should

run for a minimum of 10 min. and unloaded for the pre–set time and then

shut down.

5. The compressor should restart automatically when the system air

pressure drops below the online air pressure setting.

CONTROLLER WARNING MESSAGES

In the event of a warning, the controller will display a message and

thealarm L.E.D. [10] will flash. The warning message will alternate with

the normal display every 4 seconds, the compressor will continue to run

but the fault should be rectified as soon as possible. The arrow keys

[23] should be used to index the display for any additional warning

messages. A warning message may be reset by depressing set [21]

once.

NOTE:

The warning will recur if the fault has not been rectified. The

following warning messages may be displayed:

SEPARATOR ELEMENT

The separator element is dirty or blocked and should be replaced.

By bleeding off a small amount from the regulator valve, which

energises the Modulate Solenoid Valve, a reduction in the air signal

to the pneumatic cylinder on the inlet valve allows the cylinder to

‘trim’ the inlet valve position as dictated by changing line pressure.

Modulation begins when the compressor reaches about 94% of the

rated line pressure and is factory set to modulate down to

approximately70% of rated capacity.

If the air demand decreases to a level below the 70% modulated

output, the line pressure will increase slightly to the upper limit of the

pressure setting, when the compressor then changes to the Off line

control position and operates with the receiver vented.

AIREND TEMPERATURE

The airend temperature reaches 97% of the high airend

temperatureset point (i.e. 223 F (106 C)).

INTELLISYS OPTION

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

11

CONTROLLER ALARMS

In the event of an alarm, the controller will execute an emergency

stop, the alarm L.E.D. [10] will illuminate and an alarm message will be

displayed. The arrow keys [23] should be used to index the display for

any additional alarm messages. An alarm is reset by depressing set

[21] twice within a 3 second period after the fault has been rectified. The

compressor will restart only when all alarm conditions have been

rectified. The following alarm messages may be displayed (For fault

correction see the Fault Finding section):

STARTER FAULT

The contactor sequence during start or stop is incorrect.

AIREND TEMPERATURE

The airend discharge temperature is above the high temperature

set point.

MOTOR OVERLOAD

The motor overload contacts are open. The motor overload must be

reset before the controller can be reset.

REVERSE ROTATION

No sump pressure is detected after the first 2 seconds of running.

Isolate the machine and reverse the mains supply connections before

resuming.

OVER PRESSURE

The line pressure is 15 psi (1 bar) greater than the rated discharge

pressure.

TEMPERATURE SENSOR 1

The airend temperature sensor/ connecting cable has failed.

TEMPERATURE SENSOR 2

The separator tank temperature sensor/connecting cable has

failed.

PRESSURE SENSOR

Indicates pressure transducer failure / connecting cable fault.

FIELD OPTION/S

Before installation and operation of this option, these instructions

should be studied carefully to obtain a clear knowledge of the option

and its application to the compressor.

REMOTE START/STOP

The Remote Start/Stop Option allows the operator to control the

compressor from a remote mounted start/stop station.Terminal points

are provided in connector J1 in the top of the lntellisys controller; one

a connection for a normally closed stop switch (terminals 3 and 4), and

one for a normally open, momentary contact start switch (terminals 5

and 6). Refer to the compressor wiring schematic for specific

connection points.

For safety, a selection is available in the lntellisys set–points to

disable the remote start and stop function.This allows the compressor

to be fully controlled by the lntellisys and not from the remote

start/stop station.

If the remote start switch is momentarily closed, the lntellisys

starts the compressor.The remote stop switch is normally closed. If the

remote stop switch opens, the compressor will unload and stop.The

compressor cannot restart until the remote stop switch has been reset

to a closed position. (EMERGENCY STOP will display on the

lntellisys if the stop switch is not closed).

To operate in the remote start/stop mode, proceed with the

following steps:

1. Press the SET button until the message REMOTE S/S OFF is

displayed.

2. Push the up or down arrows to select the remote start/stop function

(on or off). REMOTE S/S OFF in the display indicates remote start/stop

is disabled (off). REMOTE S/S ON in the display indicates remote

start/stop in enabled (on). Press the SET button to store the function.

The display will flash to acknowledge. Press the DISPLAY SELECT

button or wait 30 seconds for the controller to automatically exit the set

routine.The display returns to READY TO START.

3. Start the compressor with the Start button on the Intellisys control

panel.The compressor must be started locally first before the Remote

Start/Stop buttons are activated by the lntellisys.

FAILED CALIBRATION

During calibration routine, a 10% of scale error has been detected.

Ensure that the separator is completely blowndown and repeat

calibration.

CONTROL POWER LOSS

The 48Vac signal is not present at the controller.

REMOTE START FAILURE

Momentary remote start has not disengaged before star–delta

transition. This alarm is active only if the remote start/stop is enabled.

REMOTE STOP FAILURE

The momentary remote stop switch has not disengaged when the

start signal is received. This alarm is active only if the remote start/stop

is enabled.

EMERGENCY STOP

The emergency stop button is engaged.

LOW SUMP PRESSURE

The sump pressure drops below 15 psi (1 bar) during normal

operation.

12

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

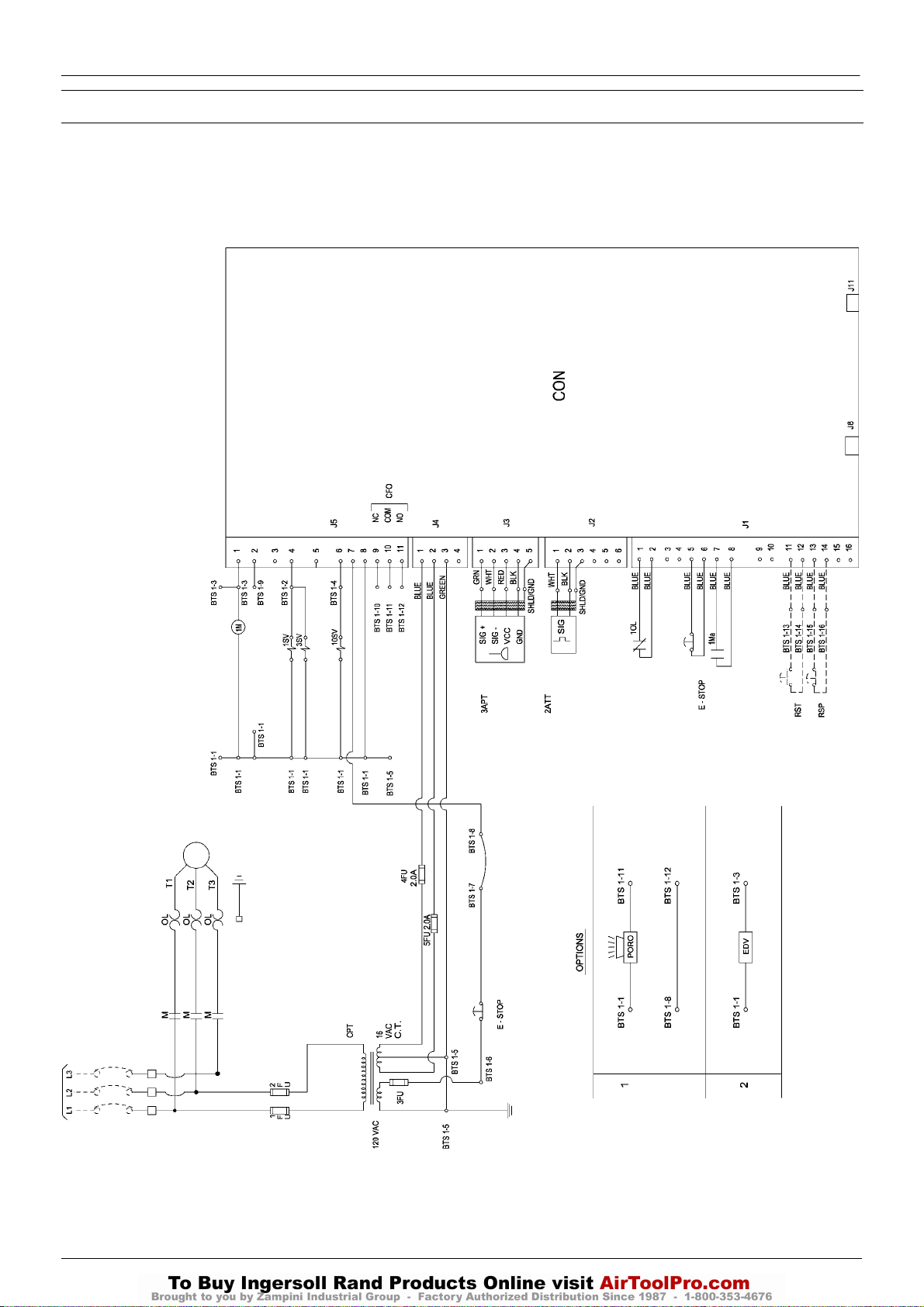

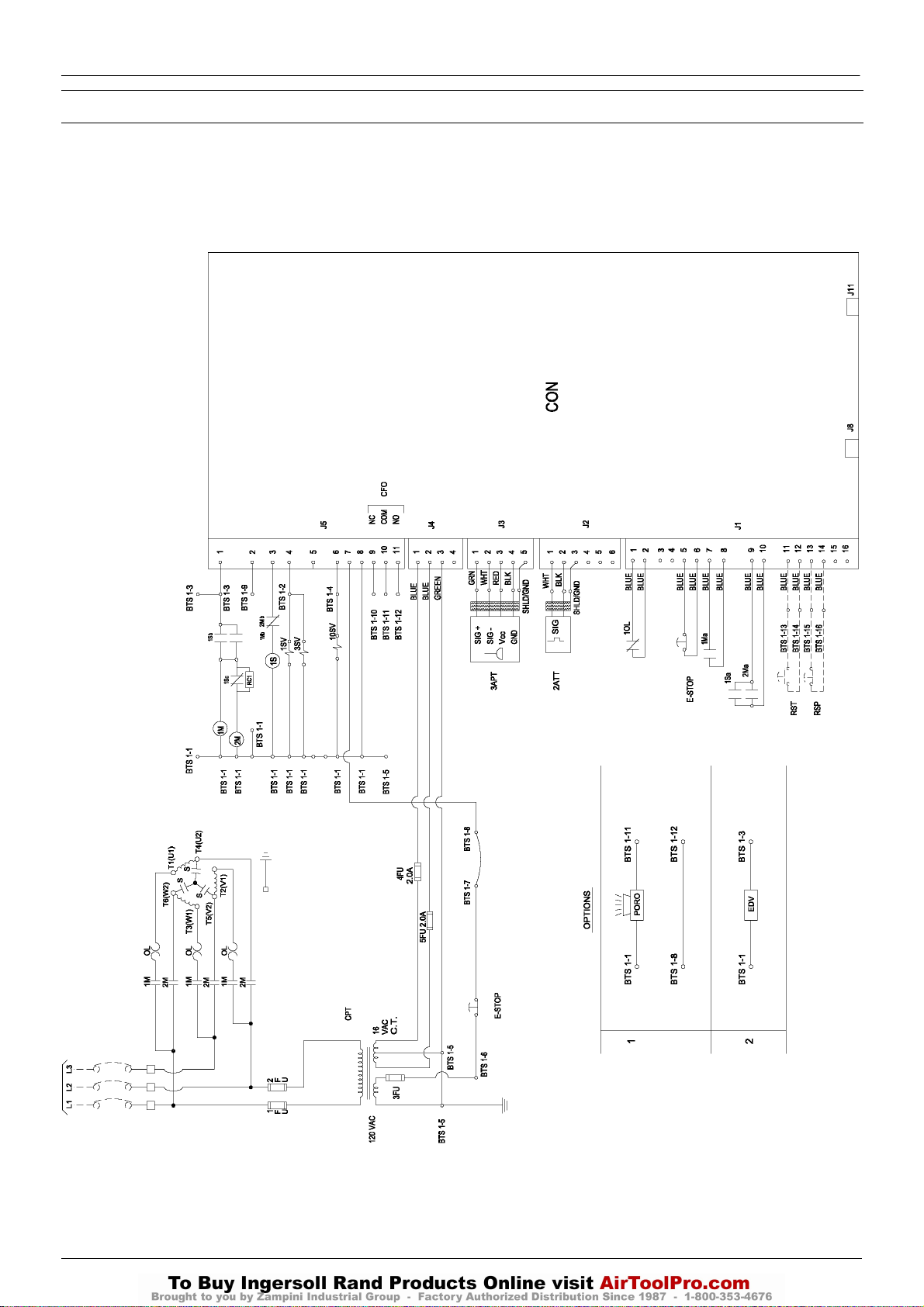

ELECTRICAL SCHEMATIC – DOL WITH INTELLISYS CONTROL

INTELLISYS OPTION

INTELLISYS – DOL

32343956

Revision D

KEY

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

INTELLISYS OPTION

13

CON Controller, INTELLISYS

CPT Transformer, control

EDV Valve, electric drain

E–STOP Button, emergency stop

FU Fuse

M Contactor (main)

1M Coil, motor starter

OL Overload, motor starter

1SV Valve, solenoid (load) N.C

3SV Valve, solenoid (blowdown) N.O

10SV Valve, solenoid (line / sump) N.C

RST Remote start

(Optional)

RSP Remote stop

(Optional)

CFO Common fault output

PORO Power out restart (Optional)

2ATT Temperature sensor

3APT Pressure sensor

NOTES

1. Approved fused disconnect or circuit breaker per code

requirements must be provided by customer.

2. Dashed lines represent wiring by customer.

3. Sizing of electrical components not supplied by Ingersoll Rand is

the responsibility of the customer and should be done in

accordance with the information on the compressor data plate

and local electrical codes.

4. Unit will not restart automaticlly after power outage, except with

additional PORO option.

5. Circuit shown in normal position de–energized.

6. All wiring to be in accordance with local codes.

14

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

ELECTRICAL SCHEMATIC – STAR DELTA WITH INTELLISYS CONTROL

INTELLISYS OPTION

INTELLISYS – STAR DELTA

32343931

Revision E

KEY

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

INTELLISYS OPTION

15

CON Controller, INTELLISYS

CPT Transformer, control

EDV Valve, electric drain

E–STOP Button, emergency stop

FU Fuse

1M Contactor (main)

2M Contactor (delta)

OL Overload, motor starter

1SV Valve, solenoid (load) N.C

3SV Valve, solenoid (blowdown) N.O

10SV Valve, solenoid (line / sump) N.C

RST Remote start

(Optional)

RSP Remote stop

(Optional)

CFO Common fault output

PORO Power out restart (Optional)

2ATT Temperature sensor

3APT Pressure sensor

1S Contactor (wye / star)

NOTES

1. Approved fused disconnect or circuit breaker per code

requirements must be provided by customer.

2. Dashed lines represent wiring by customer.

3. Sizing of electrical components not supplied by Ingersoll Rand is

the responsibility of the customer and should be done in

accordance with the information on the compressor data plate

and local electrical codes.

4. Unit will not restart automaticlly after power outage, except with

additional PORO option.

5. Circuit shown in normal position de–energized.

6. All wiring to be in accordance with local codes.

7. Blue – 16 Volts AC

16

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

INTELLISYS OPTION

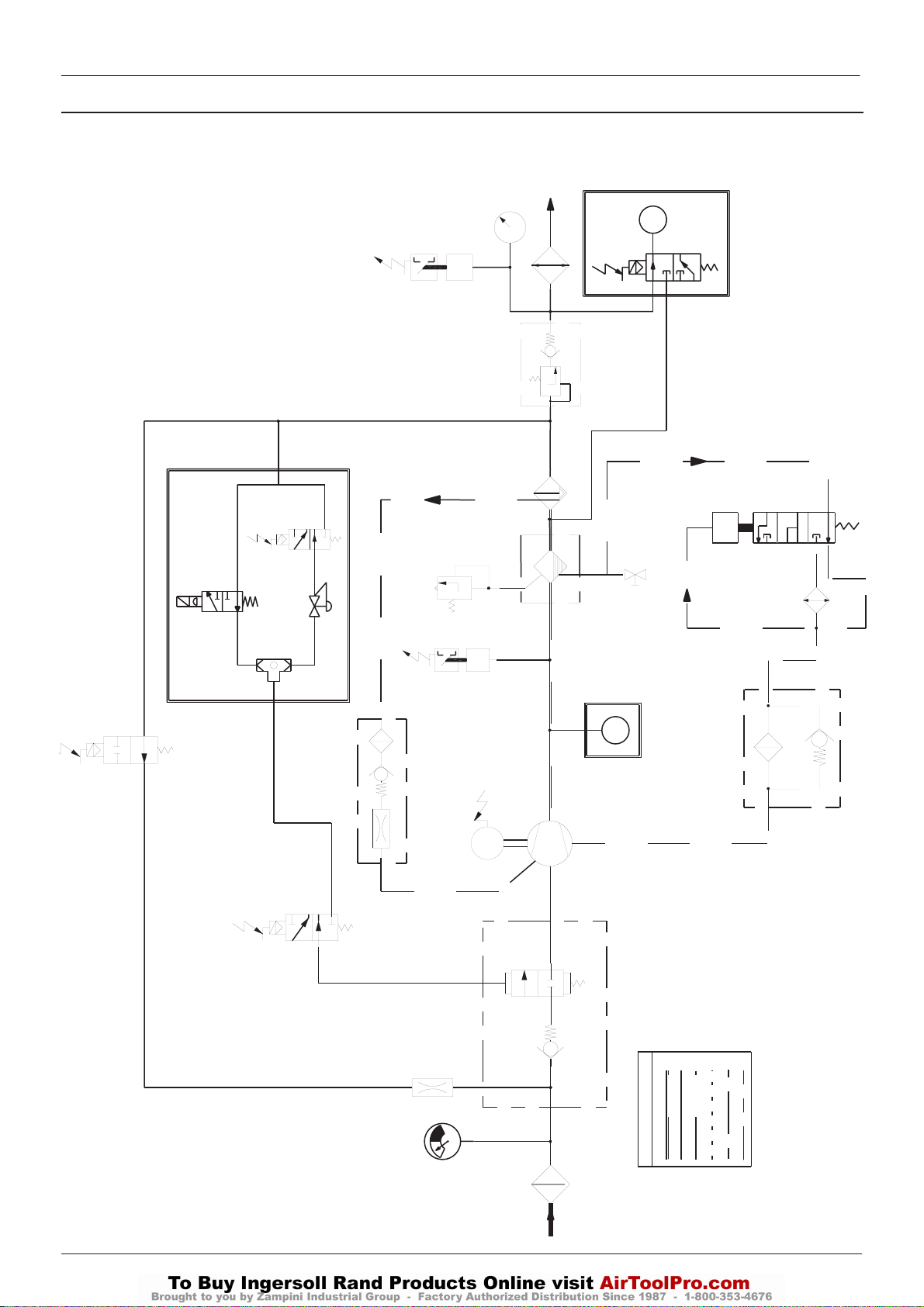

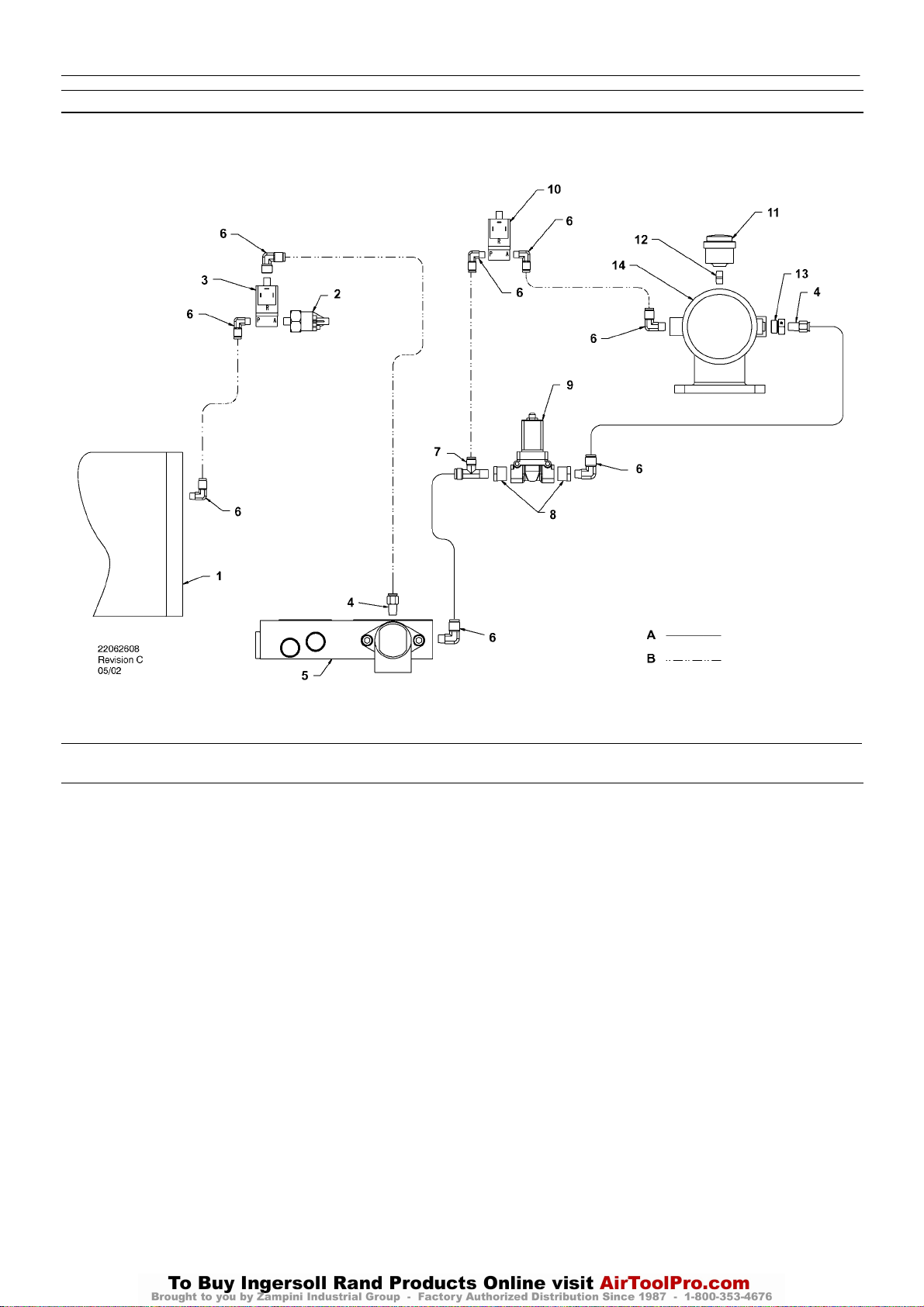

PIPING AND INSTRUMENTATION WITH INTELLISYS CONTROL

6SV

33

32

10SV

85584282

Revision D

INTELLISYS (OPTION)

REPLACES 10 AND 11

5SV

10

CONTINUED IN NEXT PAGE

11

P

39

9

8

7

T

6

40

42

41

17

18

12

T

14

15

3SV

20

19

MODULATION (OPTION)

3

1SV

16

5

21

4

M

34

INTELLISYS (OPTION)

REPLACES 12

B

A

2

PIPING LEGEND

13

F

E

C

D

22

1

INTELLISYS OPTION

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

17

FROM PREVIOUS PAGE

KEY

1. Filter, air

2. Valve, inlet

3. Valve, solenoid (load)

4. Airend assembly

5. Motor

6. Tank, separator, Coarse

7. Separator, Fine

8. Valve, minimum pressure

9. Aftercooler

10.Gauge, pressure

11.Switch, discharge pressure

12.Switch, temperature

13.Filter, coolant

14.Thermostat

15.Cooler

16.Relay, overload Motor

17. Valve, safety

18 . Valve, Drain

19 . Screen, Scavenge

20 . Valve, Solenoid 3sv (Blowdown)

21 . Orifice

22 . Indicator, Air Filter Restriction

23 .Refrigerant Compressor

24.Evaporator

25 .Condenser

27

26

M

35

24

37 38

23

29

25

36

28

INTEGRAL DRYER (OPTION)

26.Filter, Refrigerant

27.Expansion Valve

28 .Indicator, Dew Point

29.Condensate Drain Valve

30.Receiver, Air

31.Auto Drain Valve

32.Valve, Solenoid 10sv (Line/Sump)

33.Transducer, Pressure

34.Sensor, Temperature

35.Moisture Separator

36.Filter, Air

37.3 Way Valve, Bypass

38.Valve, Isolation

39.Valve, Solenoid 5sv (Modulation)

40.Valve, Solenoid 6sv (Modulation)

41.Valve, Shuttle

42.Valve, Modulation

A Air/Coolant

B Air

C Coolant

D Condensate

E Component boundary

F Refrigerant

G Option

30

31

AIR RECEIVER (OPTION)

18

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

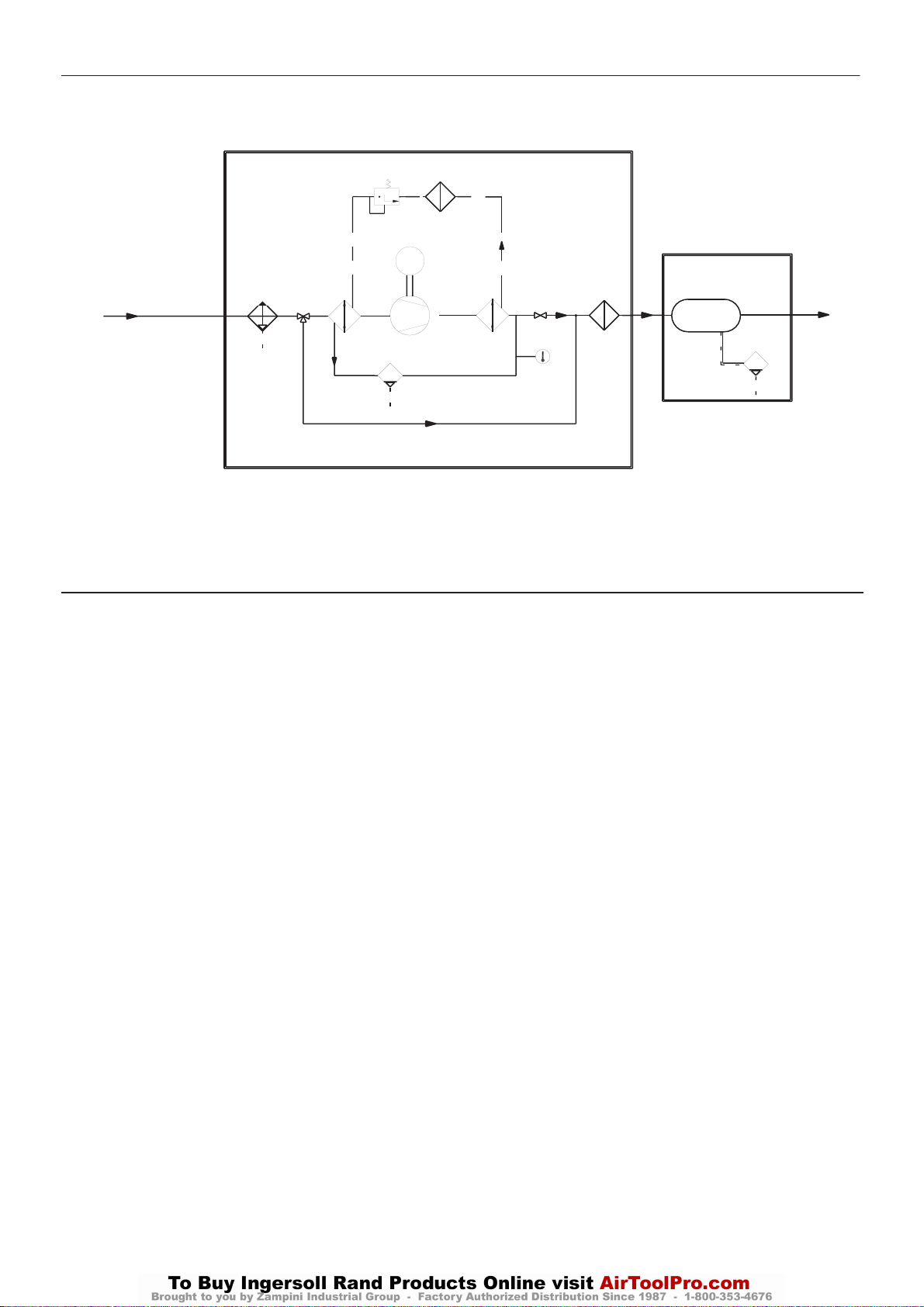

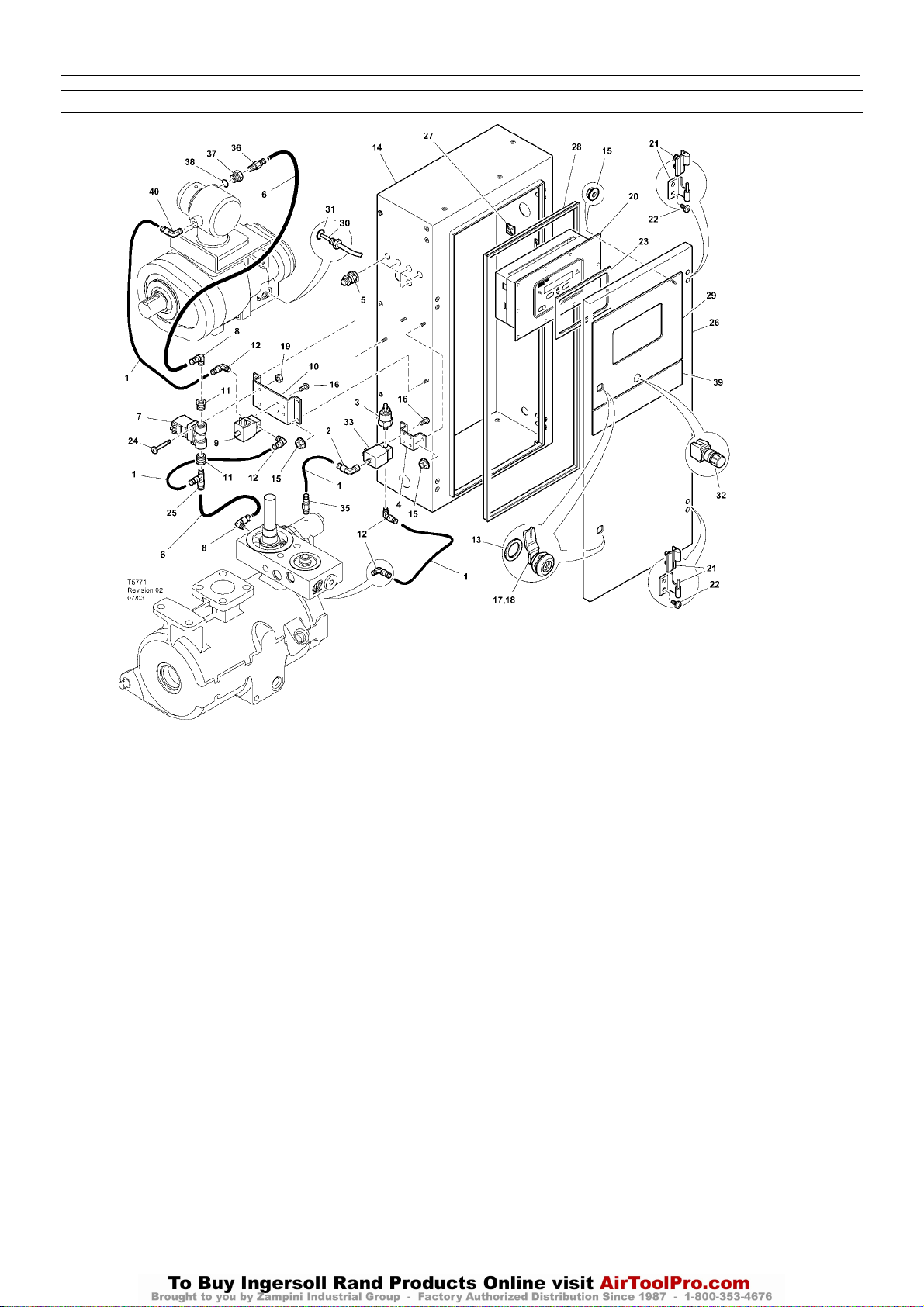

INTELLISYS CONTROL AND INSTRUMENTATION DIAGRAM

INTELLISYS OPTION

KEY

1. Tank, separator

2. Transducer, pressure

3. Valve, solenoid (Line / Sump)

4. Connector

5. Combination block

6. Elbow

7. Tee, male run

8. Reducer bushing

9. Valve, solenoid (Blowdown)

10.Valve, solenoid (Load)

11.Indicator air filter

12.Nipple

13.Adaptor

14.Intake valve assembly

NOTES:

A. Tubing 3/8 inch

B. Tubing 1/4 inch

INTELLISYS PARTS – INSTRUMENTATION AND ELECTRICAL SYSTEM

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

INTELLISYS OPTION

19

Item ccn Qty. Description Item ccn Qty. Description

1 39124813 AR Tube (Nylon)

2 39155460 1 Elbow

3 39853809 1 Transducer

4 22107833 1 Bracket

5 92877018 5 Gland, cable

6 39124821 AR Tube (Nylon)

7 54654652 1 Valve, solenoid (Blowdown)

8 39155650 2 Elbow

9 54774302 1 Valve, solenoid (Load)

10 54755426 1 Bracket

11 95944625 2 Bushing

12 39155577 4 Elbow

13 93492072 2 Seal

14 22177174 1 Cabinet

15 96737564 14 Nut

16 96743182 8 Screw

17 85584340 4 Latch

*18 92829308 1 Key

19 96703756 2 Nut

20 22128763 1 Controller, INTELLISYS

21 22091193 2 Hinge

22 96743992 4 Screw

23 39495874 1 Gasket

24 96742754 2 Screw

25 22055909 1 Tee

26 22177190 1 Cabinet door

27 39133467 3 Mount

28 22177315 1 Gasket, door

29 22131155 1 Decal, controller

30 22137848 1 Sensor, temperature

31 39404157 1 ‘O’ Ring

32 22113344 1 Button, emergency stop

33 22289797 1 Valve, solenoid (line/sump)

*34 39192000 4 Grommet

35 39156393 1 Connector

36 39156419 1 Connector

37 54774997 1 Bush

38 39404165 1 ‘O’ Ring

39 22131148 1 Decal

40 39155478 1 Elbow

* Not illustrated

20

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

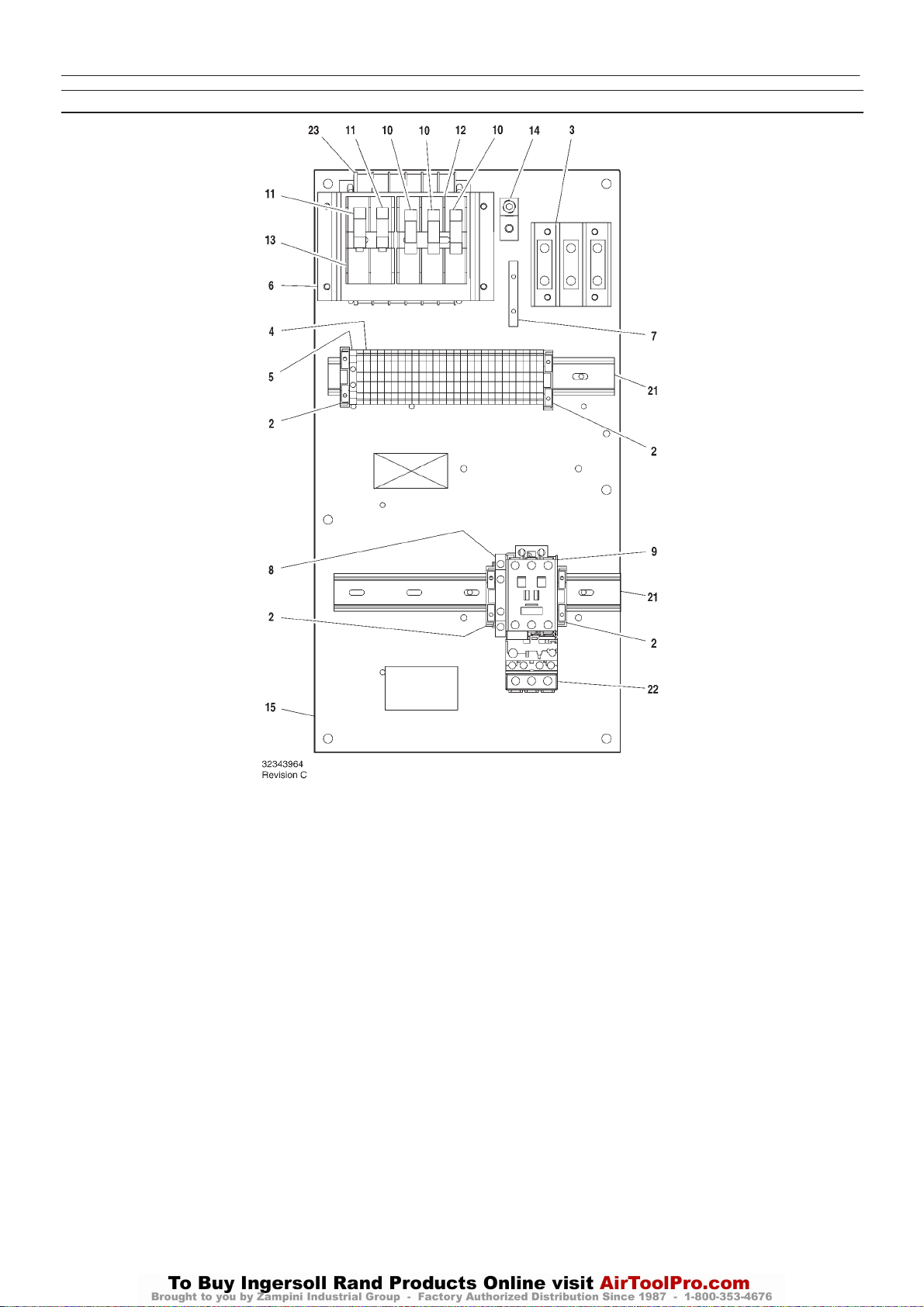

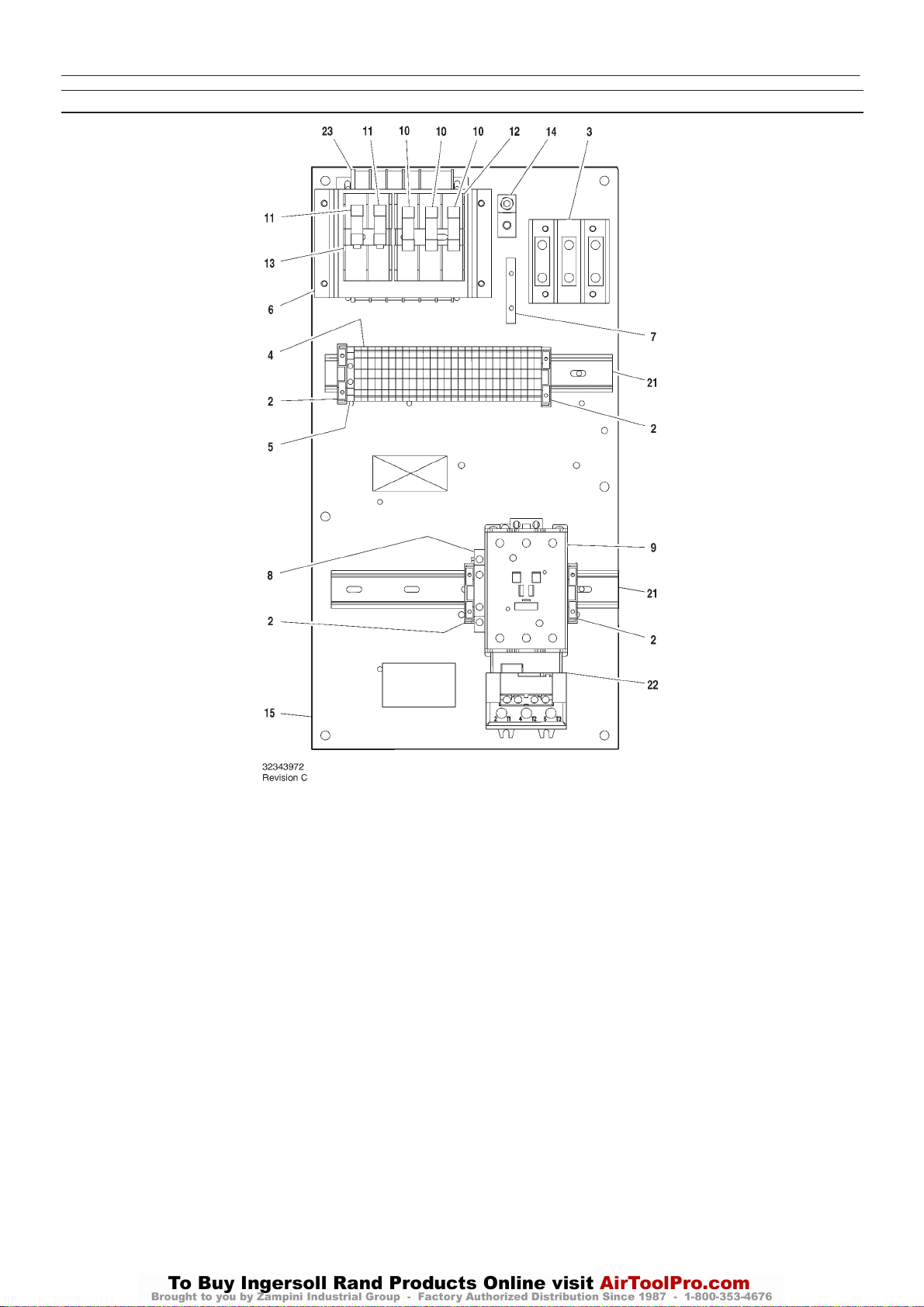

INTELLISYS PARTS – C37 FULL VOLTAGE – DOL 60Hz – 575V 15/30hp

INTELLISYS OPTION

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 27 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 1 Contact, auxilliary

9 39251061 1 Contactor – C37

10 22074033 3 Fuse

2.0A 125–250V

11 32342099 2 Fuse

1.5A 600V

12 39479035 1 Fuse, holder

13 39480504 1 Fuse, holder

14 32342123 1 Lug, power grounding

15 22113351 1 Panel

*16 39191648 1 Plug

11 position

*17 39191655 1 Plug

16 position

*18 39186101 1 Plug

4 position

*19 39191630 1 Plug

5 position

*20 39186093 1 Plug

6 position

21 22056741 2 Rail

22 23053754 1 Relay, overload

23 39491519 1 Transformer

* Not illustrated

INTELLISYS PARTS – C43 FULL VOLTAGE – DOL 60Hz – 230/460V 15hp

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

INTELLISYS OPTION

21

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 27 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 1 Contact, auxilliary

9 39250998 1 Contactor – C43

10 22074033 3 Fuse

2.0A 125–250V

11 32342099 2 Fuse

1.5A 600V

12 39479035 1 Fuse, holder

13 39480504 1 Fuse, holder

14 32342123 1 Lug, power grounding

15 22113351 1 Panel

*16 39191648 1 Plug

11 position

*17 39191655 1 Plug

16 position

*18 39186101 1 Plug

4 position

*19 39191630 1 Plug

5 position

*20 39186093 1 Plug

6 position

21 22056741 2 Rail

22 23053754 1 Relay, overload

23 39491519 1 Transformer

* Not illustrated

22

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

INTELLISYS PARTS – C85 FULL VOLTAGE – DOL 60Hz – 200V 15–25hp / 230/460 20–30hp

INTELLISYS OPTION

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 27 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 1 Contact, auxilliary

9 39251020 1 Contactor – C85

10 22074033 3 Fuse

2.0A 125–250V

11 32342099 2 Fuse

1.5A 600V

12 39479035 1 Fuse, holder

13 39480504 1 Fuse, holder

14 32342123 1 Lug, power grounding

15 22113351 1 Panel

*16 39191648 1 Plug

11 position

*17 39191655 1 Plug

16 position

*18 39186101 1 Plug

4 position

*19 39191630 1 Plug

5 position

*20 39186093 1 Plug

6 position

21 22056741 2 Rail

22 23053770 1 Relay, overload

23 39491519 1 Transformer

* Not illustrated

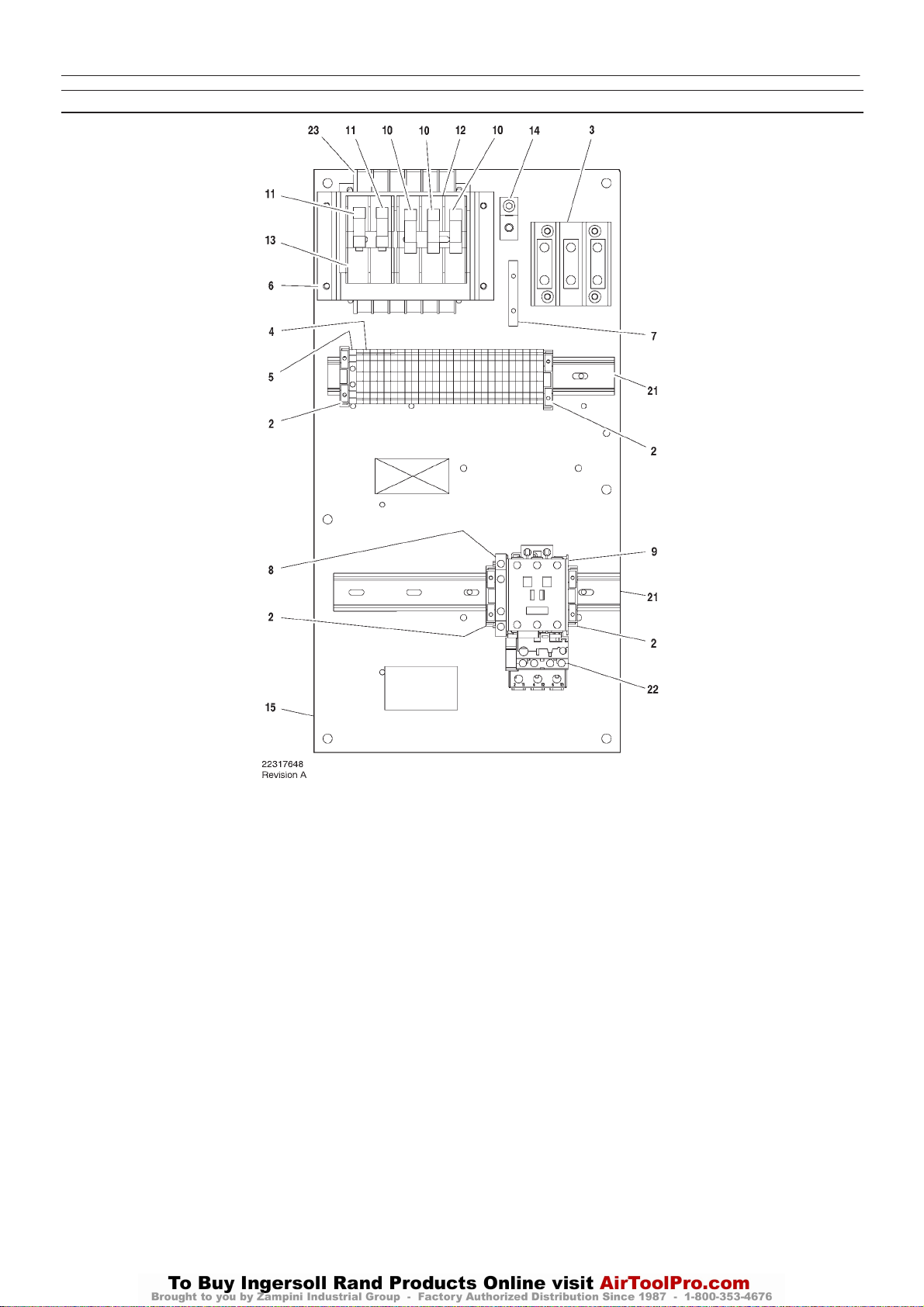

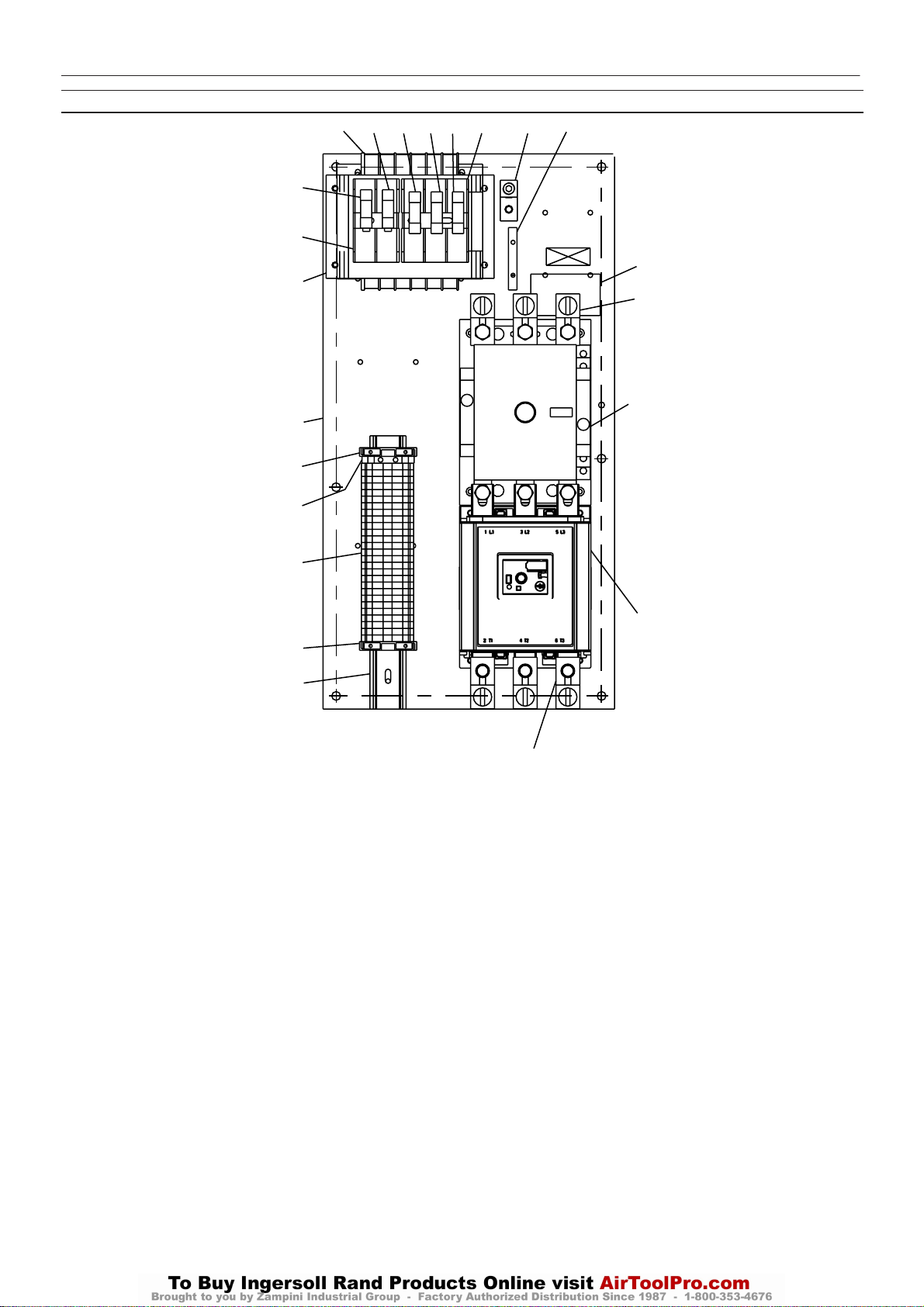

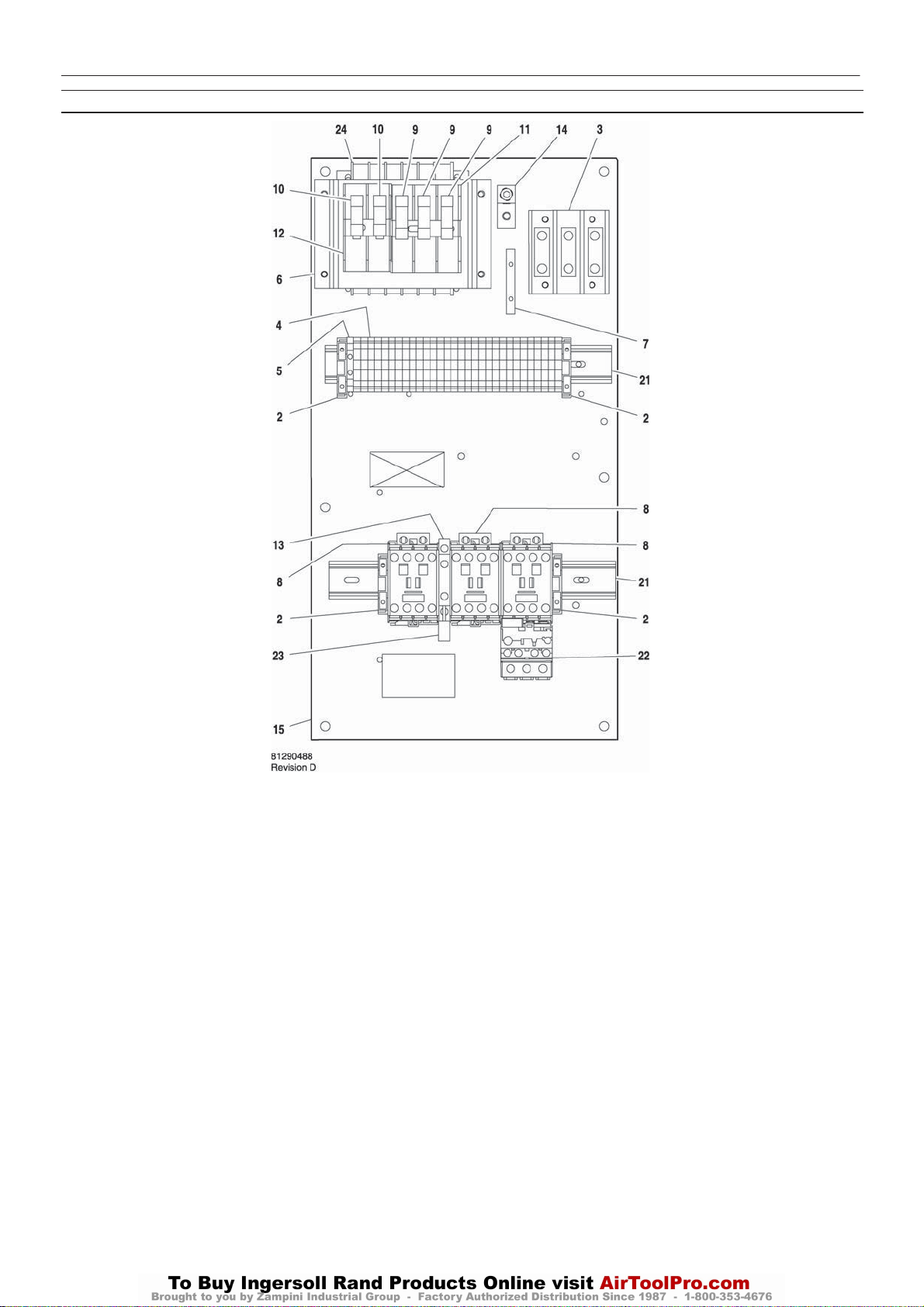

INTELLISYS PARTS – D110 FULL VOLTAGE – DOL 60Hz – 200V 30hp

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

10

24

10

12

6

16

2

9

9

9

INTELLISYS OPTION

11

7

15

13

5

8

23

3

4

23

2

22

Revision D

Item ccn Qty. Description Item ccn Qty. Description

*1 22113344 1

2 39252937 2 Block, end stop

3 39252937 1 Block, terminal ground

4 39252903 27 Block, terminal

5 22630727 1 Kit, terminal

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22264873 1 Contactor – D110

9 22074033 3 Fuse

10 32342099 2 Fuse

11 39479035 1 Fuse, holder

12 39480504 1 Fuse, holder

13 1 Label

Assembly, emergency stop

push button

2.0A 125–250V

1.5A 600V

532343980

*14 39191648 1 Plug

11 pos ition

15 32342123 1 Lug, power grounding

16 22050140 1 Panel

11 pos ition

*17 39191655 1 Plug

16 position

*18 39186101 1 Plug

4position

*19 39191630 1 Plug

5position

*20 39186093 1 Plug

6position

22 22056741 1 Rail

23 39251095 1 Relay,overload

24 39491519 1 Transformer

* Not illustrated

24

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

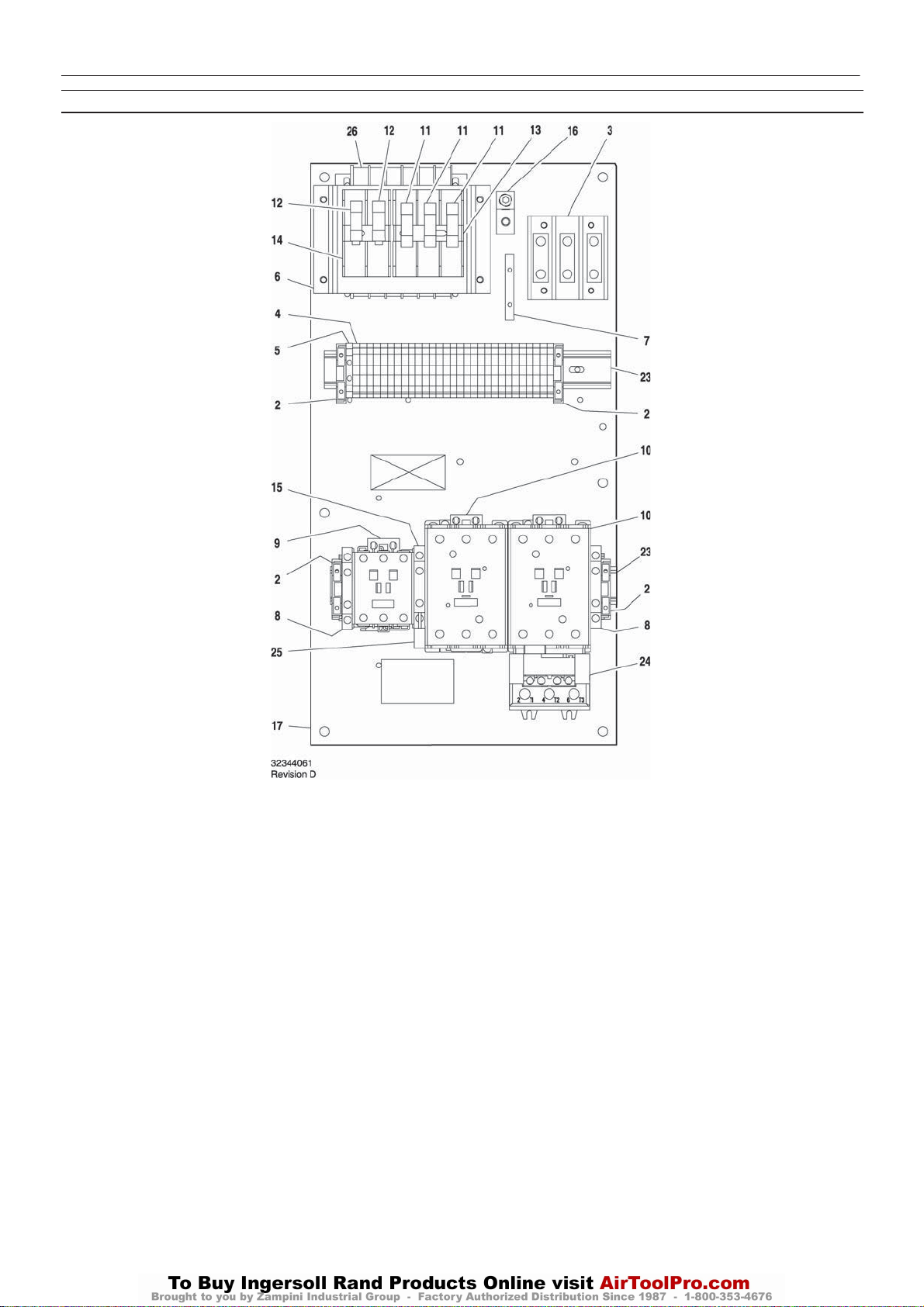

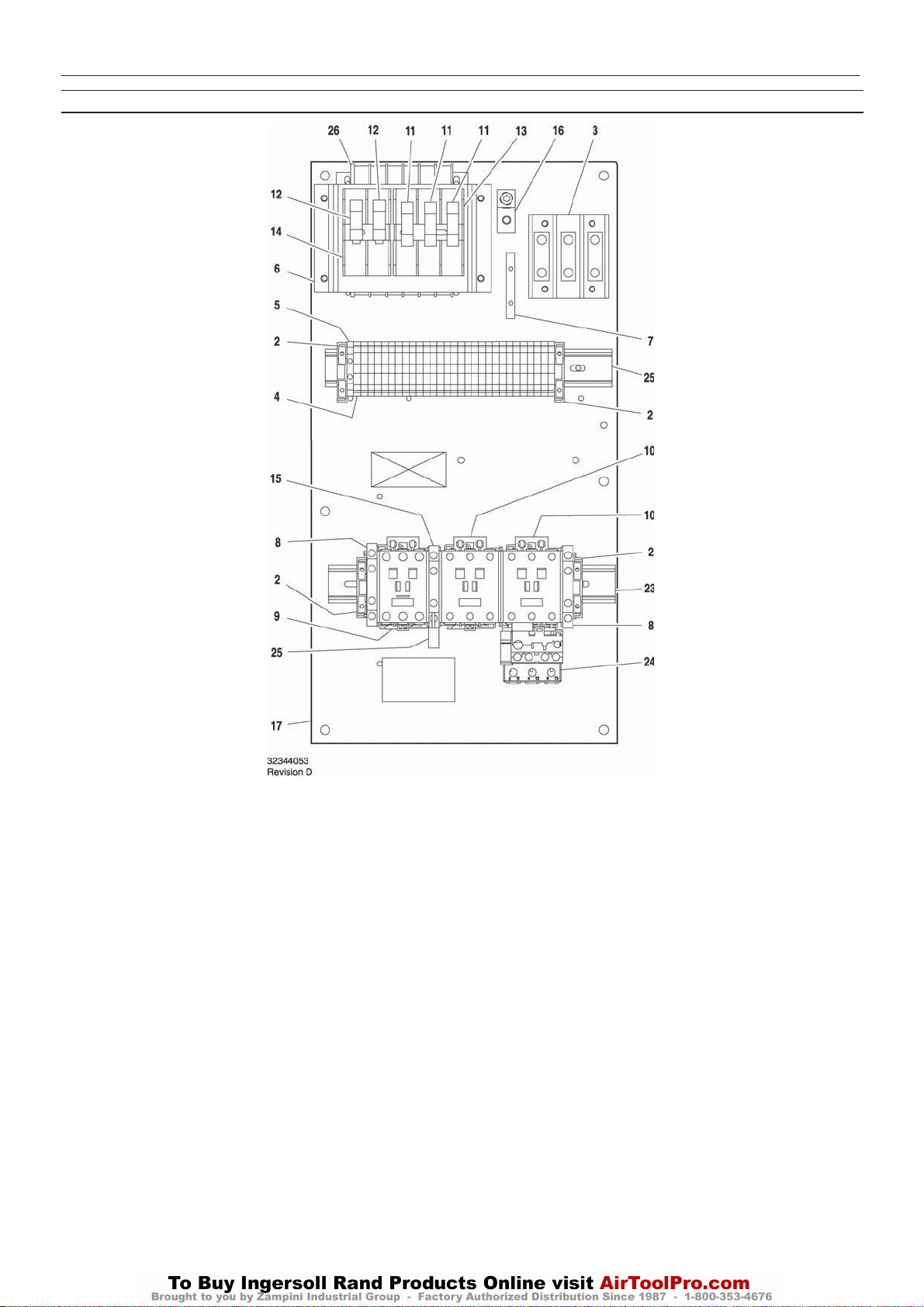

INTELLISYS PARTS – C60/C43 STAR/DELTA – 60Hz – 200V 25/30hp, 220/230V – 30hp

INTELLISYS OPTION

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 29 Block, terminal

5 39252911 1

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 2 Contact, auxilliary

9 39250998 1 Contactor – C43

10 39251004 2 Contactor – C60

11 22074033 3 Fuse

12 32342099 2 Fuse

13 39479035 1 Fuse, holder

14 39480504 1 Fuse, holder

15 39333257 1 Interlock

Block, terminal ground

2.0A 125–250V

1.5A 600V

16 32342123 1 Lug, power grounding

17 22113351 1 Panel

*18 39191648 1 Plug

11 position

*19 39191655 1 Plug

16 position

*20 39186101 1 Plug

4 position

*21 39191630 1 Plug

5 position

*22 39186093 1 Plug

6 position

23 22056741 2 Rail

24 23053770 1 Relay, overload

25 39203443 1 Suppressor

26 39491519 1 Transformer

* Not illustrated

INTELLISYS OPTION

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

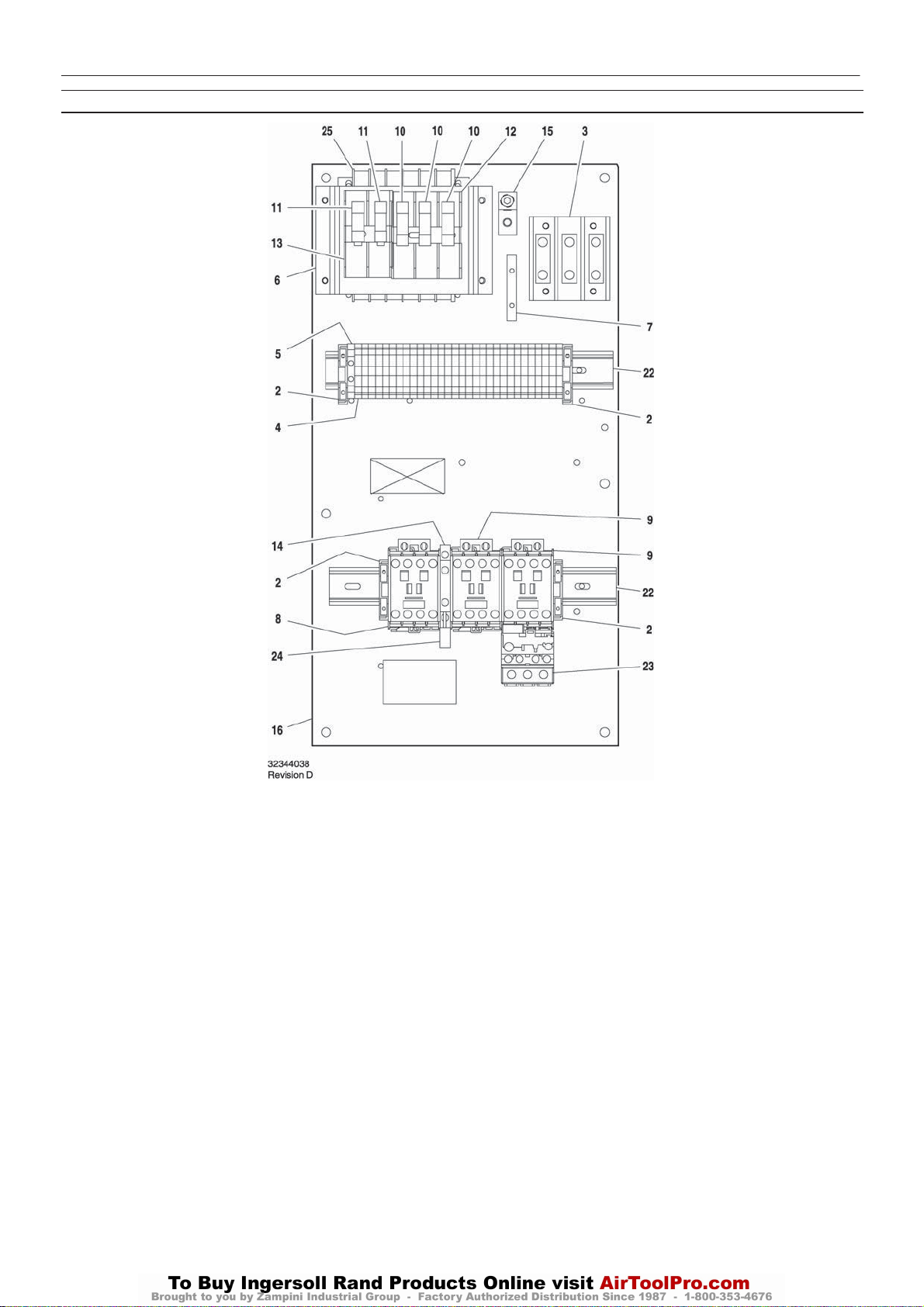

INTELLISYS PARTS – C23/16 STAR/DELTA – 60Hz – 440/460V – 20/25hp, 575V – 25/30hp

25

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 30 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22074413 1 Contactor – C16

9 39252036 2 Contactor – C23

10 22074033 3 Fuse

2.0A 125–250V

11 32342099 2 Fuse

1.5A 600V

12 39479035 1 Fuse, holder

13 39480504 1 Fuse, holder

14 39333257 1 Interlock

15 32342123 1 Lug, power grounding

16 22113351 1 Panel

*17 39191648 1 Plug

11 position

*18 39191655 1 Plug

16 position

*19 39186101 1 Plug

4position

*20 39191630 1 Plug

5position

*21 39186093 1 Plug

6position

22 22056741 2 Rail

23 23053747 1 Relay, overload

24 39203443 1 Suppressor

25 39491519 1 Transformer

* Not illustrated

26

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

INTELLISYS PARTS – C23/23 STAR/DELTA – 60Hz – 380V 20hp

INTELLISYS OPTION

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 30 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 39252036 3 Contactor – C23

9 22074033 3 Fuse

2.0A 125–250V

10 32342099 2 Fuse

1.5A 600V

11 39479035 1 Fuse, holder

12 39480504 1 Fuse, holder

13 39333257 1 Interlock

14 32342123 1 Lug, power grounding

15 22113351 1 Panel

*16 39191648 1 Plug

11 position

*17 39191655 1 Plug

16 position

*18 39186101 1 Plug

4position

*19 39191630 1 Plug

5position

*20 39186093 1 Plug

6position

21 22056741 2 Rail

22 23053747 1 Relay, overload

23 39203443 1 Suppressor

24 39313143 1 Transformer

* Not illustrated

INTELLISYS PARTS – C43/37 STAR/DELTA – 60Hz – 200V 20hp, 220/230V – 25hp

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

INTELLISYS OPTION

27

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 29 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 2 Contact, auxilliary

9 39251061 1 Contactor – C37

10 39250998 2 Contactor – C43

11 22074033 3 Fuse

2.0A 125–250V

12 32342099 2 Fuse

1.5A 600V

13 39479035 1 Fuse, holder

14 39480504 1 Fuse, holder

15 39333257 1 Interlock

16 32342123 1 Lug, power grounding

17 22113351 1 Panel

*18 39191648 1 Plug

11 position

*19 39191655 1 Plug

16 position

*20 39186101 1 Plug

4position

*21 39191630 1 Plug

5position

*22 39186093 1 Plug

6position

23 22056741 2 Rail

24 23053754 1 Relay, overload

25 39203443 1 Suppressor

26 39491519 1 Transformer

* Not illustrated

28

UP6 15, UP6 20, UP6 25, UP6 30

http:/air.ingersollrand.com

INTELLISYS PARTS – C37/23 STAR/DELTA – 60Hz – 220/230V – 15–20hp, 440/460V – 30hp

INTELLISYS OPTION

Item ccn Qty. Description Item ccn Qty. Description

1–

2 39252937 4 Block, end stop

3 39164520 1 Block, terminal

4 39252903 29 Block, terminal

5 39252911 1 Block, terminal ground

6 22114623 1 Bracket

7 32342115 1 Bus, grounding

8 22132963 1 Contact, auxilliary

9 39252036 1 Contactor – C23

10 39251061 2 Contactor – C37

11 22074033 3 Fuse

2.0A 125–250V

12 32342099 2 Fuse

1.5A 600V

13 39479035 1 Fuse, holder

14 39480504 1 Fuse, holder

15 39333257 1 Interlock

16 32342123 1 Lug, power grounding

17 22113351 1 Panel

*18 39191648 1 Plug

11 position

*19 39191655 1 Plug

16 position

*20 39186101 1 Plug

4position

*21 39191630 1 Plug

5position

*22 39186093 1 Plug

6position

23 22056741 2 Rail

24 23053754 1 Relay, overload

25 39203443 1 Suppressor

26 39491519 1 Transformer

220/230V & 440/460V

* Not illustrated

Loading...

Loading...