Page 1

!

This dryer configuration includes equipment

options as selected (X) below:

EMS OPTION

LDP OPTION

3V OPTION

More Than Air. Answers.

Online answers: http://www.air.irco.com

Phone : 1-800-526-3615

Form: APDD 792

CCN: 38019683

Z103146 Rev. 10

Page 2

Page 3

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

FOREWORD

Reading this user manual will fully familiarize you with the Ingersoll-Rand adsorption

dryer. You will be better able to run this equipment in accordance with its intended use.

This manual contains important information for safe, proper and economic dryer

installation, start-up, operation and maintenance. Always keep it within reach where the

adsorption dryer is being used.

It is necessary to follow all instructions as written. Careful reading will avert danger,

avoid unnecessary downtime, and minimize work for yourself and wear on the

equipment.

In addition to carefully reading this technical manual in its entirety, you must understand

your National, State and local rules and regulations regarding safety in the workplace,

their necessary precautions and procedures.

Each person responsible for the set-up, start-up, operation, maintenance or repair of

this adsorption dryer must have first read and understood this user manual – including

all the safety tips.

NOTE: Ingersoll-Rand recommends that installation, start-up and maintenance

be carried out by its factory-trained technicians in a regularly scheduled,

site-dedicated program. This will ensure the safety of personnel, the

integrity of equipment and the surety of warranty coverage.

i

Page 4

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

ii

Page 5

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

TABLE OF CONTENTS

1. INTRODUCTION ..................................................................................................................................................1

1.1 GENERAL.............................................................................................................................................................1

1.2 PRODUCT INFORMATION......................................................................................................................................1

1.2.1 Pressure Vessel Regulations ........................................................................................................................2

1.2.2 Leak Test......................................................................................................................................................2

1.3 SAFETY INSTRUCTIONS........................................................................................................................................2

1.3.1 Identification of Signs and Symbols in this Manual.....................................................................................2

1.3.2 General Safety Tips for Assembly, Inspection and Maintenance.................................................................3

1.4 TECHNICAL DATA SHEET ....................................................................................................................................4

1.4.1 Models TZE400 to TZE820 ..........................................................................................................................4

1.4.2 Models TZE1000 to TZE1800......................................................................................................................5

1.4.3 Models TZE2100 to TZE3500......................................................................................................................6

1.4.4 Dryer Flow Capacities ................................................................................................................................7

1.5 OVERLOADING ....................................................................................................................................................8

1.6 TRANSPORT .........................................................................................................................................................8

1.7 STORAGE .............................................................................................................................................................8

1.8 USE OF A PREFILTER AND AFTERFILTER..............................................................................................................8

2. INSTALLATION....................................................................................................................................................9

2.1 GENERAL.............................................................................................................................................................9

2.2 MECHANICAL ASSEMBLY....................................................................................................................................9

2.3 FILTER INSTALLATION.......................................................................................................................................10

2.3.1 Prefilter Installation (Shipped Loose) .......................................................................................................10

2.3.2 Afterfilter Installation (Shipped Loose) .....................................................................................................11

2.3.3 Filter Skid with 3 Valve Bypass (If Dryer Includes 3V Option).................................................................11

2.4 ELECTRICAL CONNECTION ................................................................................................................................11

2.5 EMS CONTROL CONNECTION ...........................................................................................................................12

3. EQUIPMENT OPERATION ..............................................................................................................................13

3.1 GENERAL OPERATING PRINCIPLES ....................................................................................................................13

3.1.1 Dryer Program Steps .................................................................................................................................14

3.2 OPERATOR CONTROLS / LOW-VOLTAGE CONTROL PANEL ...............................................................................16

3.2.1 Dryer Status ...............................................................................................................................................18

3.2.2 Alarm Information .....................................................................................................................................19

3.2.3 Dryer Operation Modes.............................................................................................................................20

3.2.4 Heater Sheath Information ........................................................................................................................20

3.2.5 Heater Outlet Information .........................................................................................................................21

3.2.6 Regeneration Outlet Information ...............................................................................................................21

3.2.7 Dryer Off, Dryer On, EMS On – 3-Position Switch..................................................................................21

3.2.8 Status Lamps..............................................................................................................................................22

3.2.9 Pressure Gages ..........................................................................................................................................22

3.3 INITIAL START-UP.............................................................................................................................................22

3.3.1 Pressurizing Dryer.....................................................................................................................................22

3.3.2 Energizing Dryer Controls ........................................................................................................................23

3.3.3 Pressure Switch Adjustment.......................................................................................................................24

3.3.4 EMS Start Up.............................................................................................................................................24

3.4 SHORT-TERM SHUTDOWN.................................................................................................................................26

3.5 SHUTDOWN IN CASE OF A FAULT OR FOR MAINTENANCE .................................................................................26

3.6 RESTARTING......................................................................................................................................................26

4. MAINTENANCE..................................................................................................................................................27

4.1 CHECKLIST ........................................................................................................................................................27

iii

Page 6

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

4.1.1 Daily Check ...............................................................................................................................................27

4.1.2 Weekly Check..............................................................................................................................................27

4.1.3 Quarterly Check (Every Three Months) ....................................................................................................27

4.1.4 Annual Check.............................................................................................................................................28

4.2 CHANGING THE FILTER ELEMENT......................................................................................................................28

4.3 REPLACEMENT OF THE DESICCANT ...................................................................................................................29

5. PARTS LISTINGS ...............................................................................................................................................31

5.1 PARTS LIST FOR TZE400 TO TZE650................................................................................................................31

5.2 PARTS LIST FOR TZE820 TO TZE1225..............................................................................................................32

5.3 PARTS LIST FOR TZE1500 TO TZE2100............................................................................................................33

5.4 PARTS LIST FOR TZE2500 TO TZE3500.............................................................................................................34

6. FAULTS AND TROUBLESHOOTING .............................................................................................................38

6.1 DEWPOINT HAS DETERIORATED .............................................................................................................38

6.2 HIGH HUMIDITY ALARM OR SENSOR FAILURE ...................................................................................39

6.3 PRESSURE DROP TOO HIGH .......................................................................................................................39

6.4 SWITCHING FAILURE ALARM ...................................................................................................................39

7. DRAWINGS..........................................................................................................................................................42

iv

Page 7

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

1. INTRODUCTION

1.1 GENERAL

This adsorption dryer includes the latest technology and safety features. Its use,

however, can endanger life and limb and can lead to considerable damage to the

equipment and other material assets if:

• it is operated by personnel not instructed in its use,

• it is improperly used,

• it is improperly maintained or serviced.

Furthermore, ignorance of its use and proper service can result in the loss of any claim

for damage.

This adsorption dryer is designed for neutral media (such as air or nitrogen) which is

free of aggressive water, oil and solid elements. Ingersoll-Rand accepts no liability for

corrosion damage or malfunctions caused by aggressive media.

Applications other than those mentioned in this manual must be agreed to by IngersollRand and confirmed in writing.

Ingersoll-Rand reserves the right to make changes at any time as may be necessary for

increasing safety or efficiency, or In the interests of further product development.

1.2 PRODUCT INFORMATION

The adsorption dryer is used for the purpose of drying compressed air and other gases

according to its contracted design. Depending on certain conditions at the inlet, it

provides pure, dry and oil-free compressed air or gases. The standard model of

adsorption dryer is equipped with two desiccant vessels and a prefilter and afterfilter.

This specific model of dryer includes an Energy Management System (EMS) that

provides automatic monitoring and control of the work/regeneration cycle to optimize

equipment efficiency. This manual includes references to optionally available Low Dew

Point (LDP) and 3-valve bypass (3V) systems/assemblies which may or may not be

provided. Selected options included with this dryer are indicated on the cover page by

an “X” mark in the box.

1

Page 8

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

1.2.1 PRESSURE VESSEL REGULATIONS

The pressure vessels are designed and built to meet the American Society of

Mechanical Engineers (ASME) standards. They fulfill the test of the certifying procedure

and carry the ASME symbols U or UM.

RANGE OF APPLICATION

Design Pressure Max: 150 psig

Design Temperature

Max: 500 °F (260 °C)

Min: -20 °F (-29 °C)

1.2.2 LEAK TEST

Each Ingersoll-Rand adsorption dryer is subjected to, and passes, a leak test prior to

shipment.

1.3 SAFETY INSTRUCTIONS

This manual contains basic tips which must be followed during set-up, operation and

servicing. It is of utmost importance that it be read by the assembly technician before

installation and start-up as well as by the specialist/operator in charge. It must always

be within reach at the place where the adsorption dryer is being used.

1.3.1 IDENTIFICATION OF SIGNS AND SYMBOLS IN THIS MANUAL

The safety tips contained in this manual, whose disregard could endanger people and

equipment, are indicated by a general danger sign and the additional markings Danger!

or Attention! or Warning!

Danger! / Attention!

Safety sign in accordance with DIN 4844 - W9

Warning – high voltage!

Safety sign in accordance with DIN 4844 - W8

Safety tips printed directly on the adsorption dryer must be heeded at all times and must

be kept completely legible.

2

Page 9

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

1.3.2 GENERAL SAFETY TIPS FOR ASSEMBLY, INSPECTION AND MAINTENANCE

The purchaser is to ensure that all assembly, maintenance and inspection work is

carried out by personnel qualified to do it.

The personnel involved in assembly, operation, maintenance and inspection must have

the corresponding qualifications to do this work. Areas of responsibility and supervision

of the personnel must be clearly established by the purchaser. Should the personnel

not possess the necessary knowledge, then they must be instructed. If need be, this

training may be carried out by the manufacturer/supplier at the request of the purchaser.

Further, the purchaser is to ensure that all personnel completely understand and follow

the content of this manual.

Attention!

• Never make structural changes to the adsorption dryer

• Only use recommended spare parts as listed in section 5

• Never weld on a pressure vessel or change it in any way

• Carry out maintenance only when the adsorption dryer is OFF,

depressurized and disconnected from the electric power supply.

Danger!

• Review the Material Safety Data Sheet (MSDS) provided with the

desiccant

• Wear protective clothing and goggles when working with the

desiccant

• If desiccant comes into contact with the eyes, rinse eyes

immediately with a lot of clear water

• If the desiccant is spilled, clean up without causing swirls of dust

• In case of fire, there is no restriction on the use of fire extinguishing

material; the reaction with water and foam is defined as strong

• A mask must be worn whenever handling desiccant.

3

Page 10

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

1.4 TECHNICAL DATA SHEET

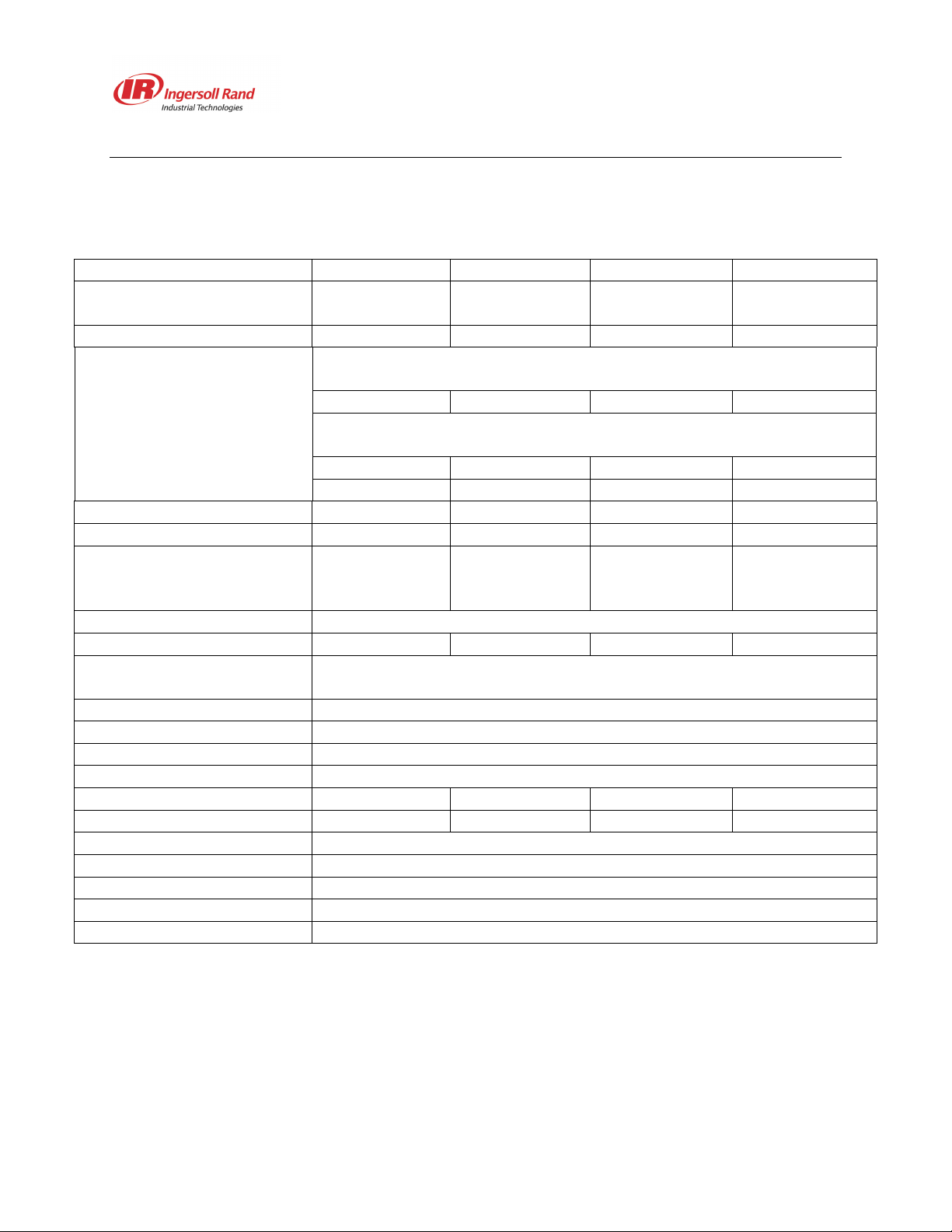

1.4.1 MODELS TZE400 TO TZE820

Model TZE400 TZE500 TZE650 TZE820

Rated flow @ 100 psig &

100°F inlet conditions

Chamber Outer Diameter 18 inches 18 inches 18 inches 20 inches

Desiccant Bed

Composition & Pounds

per Chamber

Inlet Connection 2-in NPT 2-in NPT 2-in NPT 3-in RF FLG

Outlet Connection 2-in NPT 2-in NPT 2-in NPT 3-in RF FLG

Recommended Prefilter

Recommended Afterfilter

Pilot Air Filter

Standard Electric Rqmt 460 Vac/3-phase/60 Hz

Heater 6 kW 6 kW 8 kW 12 kW

Cycle Time

Outlet Pressure Dewpoint -40°F PDP (-100°F LDP)

EMS Control Setting -40°F PDP (-100°F LDP)

High Humidity Alarm -35°F PDP (-95°F LDP)

Pressure Switch Setpoints

Purge Pressure Setting 70 psig 65 psig 55 psig 55 psig

Low Purge Alarm Setpoint

Heater Outlet Setpoint 425°F

End Heating Temperature

End Cooling Temperature 120°F

Heater Sheath Alarm 1000°F

Flow Directions Downward Drying – Upward Regeneration

400 scfm 500 scfm 650 scfm 820 scfm

Standard (no LDP option):

100% Activated Alumina

272 350 433 660

With LDP option – Layered:

33% Mol Sieve (bottom), 67% Activated Alumina (top).

1st MS: 90 1st MS: 115 1st MS: 143 1st MS: 218

2nd AA: 182 2nd AA: 235 2nd AA: 290 2nd AA: 442

HE563

DP563

AR-0003G/B

HE563

DP563

AR-0003G/B

HE 706

DP 706

AR-0003G/B

HE 1100

DP 1100

IR-DP19

8-Hour Cycle –

4 Hours Drying / 4 Hours Regeneration

PSL – 10 psig / PSH – 30 psig below line pressure

60 psig 55 psig 45 psig 45 psig

180°F

4

Page 11

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

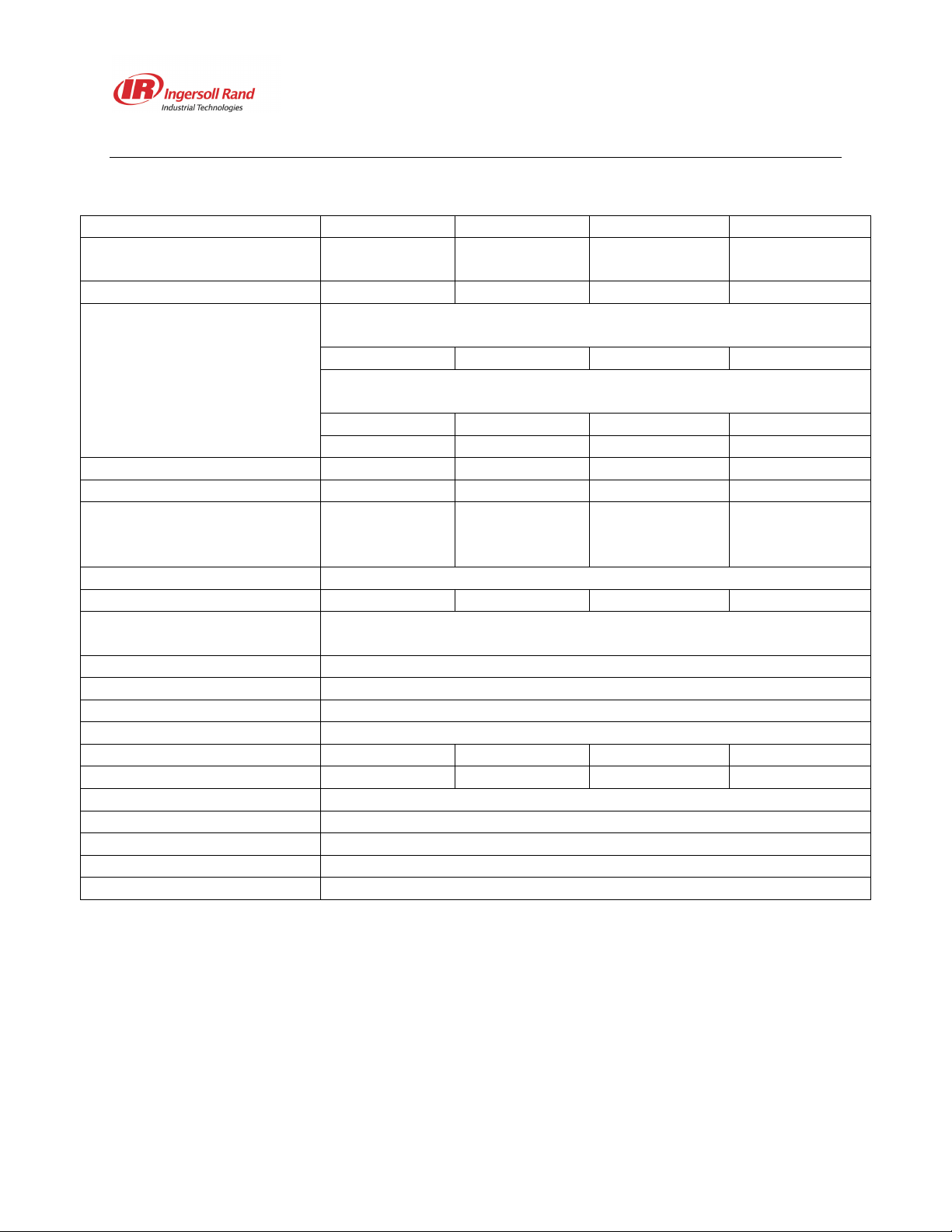

1.4.2 MODELS TZE1000 TO TZE1800

Model TZE1000 TZE1225 TZE1500 TZE1800

Rated flow @ 100 psig &

100°F inlet conditions

Chamber Outer Diameter 24 inches 24 inches 28 inches 28 inches

Desiccant Bed

Composition & Pounds per

Chamber

Inlet Connection 3 in RF FLG 3 in RF FLG 3 in RF FLG 4 in RF FLG

Outlet Connection 3 in RF FLG 3 in RF FLG 3 in RF FLG 4 in RF FLG

Recommended Prefilter

Recommended Afterfilter

Pilot Air Filter

Standard Electric Rqmt 460 Vac/3-phase/60 Hz

Heater 17 kW 21 kW 25 kW 28 kW

Cycle Time

Outlet Pressure Dewpoint -40°F PDP (-100°F LDP)

EMS Control Setting -40°F PDP (-100°F LDP)

High Humidity Alarm -35°F PDP (-95°F LDP)

Pressure Switch Setpoints

Purge Pressure Setting 70 psig 60 psig 65 psig 70 psig

Low Purge Alarm Setpoint

Heater Outlet Set Point 425°F

End Heating Temperature 180°F

End Cooling Temperature 120°F

Heater Sheath Alarm 1000°F

Flow Directions Downward Drying - Upward Regeneration

1000 scfm 1225 scfm 1500 scfm 1800 scfm

Standard (no LDP option):

100% Activated Alumina

825 990 1055 1320

With LDP option – Layered:

33% Mol Sieve (bottom), 67% Activated Alumina (top).

1st MS: 272 1st MS: 327 1st MS: 348 1st MS: 436

2nd AA: 553 2nd AA: 663 2nd AA: 707 2nd AA: 884

HE1100

DP1100

IR-DP19

HE 1380

DP 1380

IR-DP19

HE 2100

DP 2100

IR-DP19

HE 2100

DP 2100

IR-DP19

8 Hour Cycle –

4 Hours Drying / 4 Hours Regeneration

PSL – 10 PSIG / PSH – 30 PSIG below line pressure

60 psig 50 psig 55 psig 60 psig

5

Page 12

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

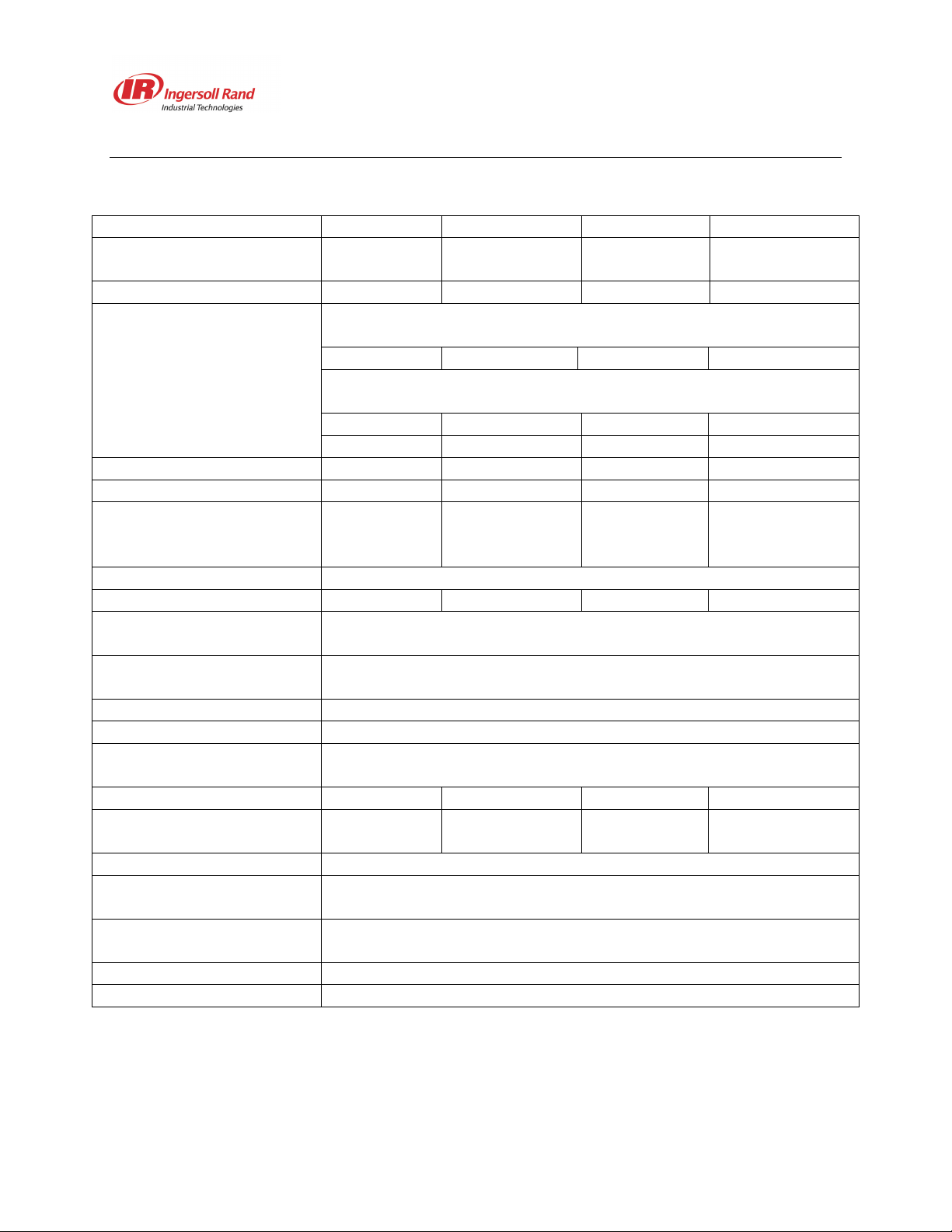

1.4.3 MODELS TZE2100 TO TZE3500

Model TZE2100 TZE2500 TZE3000 TZE3500

Rated flow @ 100 psig &

100°F inlet conditions

Chamber Outer Diameter 30 inches 36 inches 40 inches 40 inches

Desiccant Bed

Composition & Pounds

per Chamber

Inlet Connection 4-in RF FLG 4-in RF FLG 6-in RF FLG 6-in RF FLG

Outlet Connection 4-in RF FLG 4-in RF FLG 6-in RF FLG 6-in RF FLG

Recommended Prefilter

Recommended Afterfilter

Pilot Air Filter

Standard Voltage 460 Vac/3-phase/60 Hz

Heater 30 kW 36 kW 43 kW 50 kW

Cycle Time

Outlet Pressure

Dewpoint

EMS Control Setting -40°F PDP (-100°F LDP)

High Humidity Alarm -35°F PDP (-95°F LDP)

Pressure Switch Set

Points

Purge Pressure Setting 60 psig 70 psig 65 psig 60 psig

Low Purge Alarm Set

Point

Heater Outlet Set Point 425°F

End Heating

Temperature

End Cooling

Temperature

Heater Sheath Alarm 1000°F

Flow Directions Downward Drying - Upward Regeneration

2100 scfm 2500 scfm 3000 scfm 3500 scfm

Standard (no LDP option):

100% Activated Alumina

1485 1722 2310 2805

With LDP option – Layered:

33% Mol Sieve (bottom), 67% Activated Alumina (top).

1st MS: 490 1st MS: 568 1st MS: 762 1st MS: 926

2nd AA: 995 2nd AA: 1154 2nd AA: 1548

HE 2100

DP 2100

IR-DP19

HE 2750

DP 2750

IR-DP19

HE 4100

DP 4100

IR-DP19

2nd AA: 1879

HE 4100

DP 4100

IR-DP19

8-Hour Cycle –

4 Hours Drying / 4 Hours Regeneration

-40°F PDP (-100°F LDP)

PSL – 10 psig / PSH – 30 PSIG below line pressure

50 psig 60 psig 55 psig 50 psig

180°F

120°F

6

Page 13

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

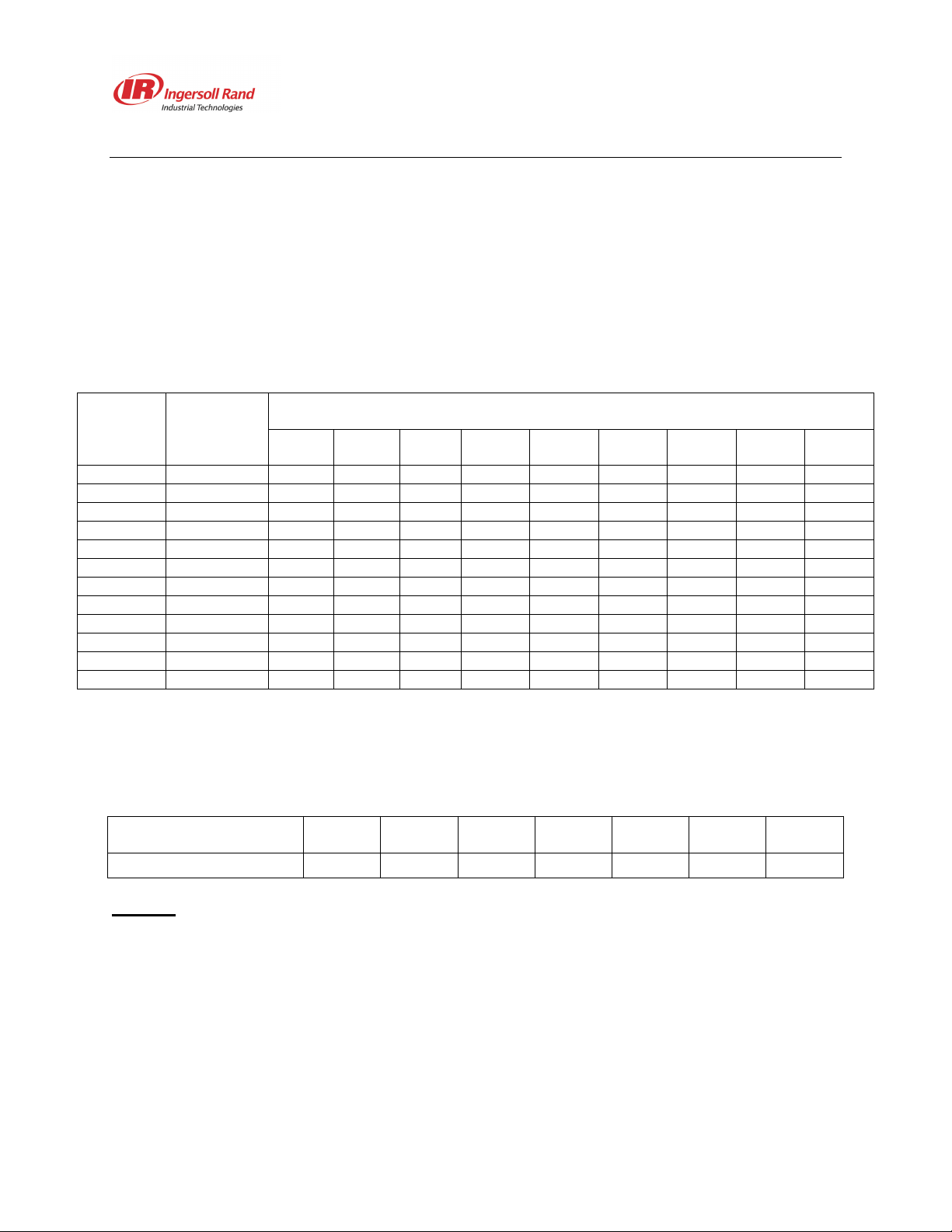

1.4.4 DRYER FLOW CAPACITIES

The specific size/model of your dryer was selected to meet performance requirements

based on an analysis of air supply and demand capacities. The model selection chart

provided following should confirm that this dryer remains suitable for its intended use.

The table following is based on -40oF PDP, 8-hour cycle, activated alumina and average

inlet air flow for non-LDP-equipped dryers with EMS. Consult our factory for rated air

flows on LDP-equipped dryers.

Design Inlet

MODEL

TZE400 150 220 265 310 355 400 440 480 520 550

TZE500 150 305 355 400 460 500 550 590 645 680

TZE650 150 360 435 505 580 650 705 790 850 905

TZE820 150 460 550 640 735 820 905 990 1070 1150

TZE1000 150 615 715 805 920 1000 1140 1255 1325 1420

TZE1225 150 690 825 955 1100 1225 1360 1490 1610 1735

TZE1500 150 785 960 1150 1275 1500 1600 1730 1875 2010

TZE1800 150 1010 1210 1405 1610 1800 1995 2190 2375 2535

TZE2100 150 1095 1345 1600 1835 2100 2275 2500 2700 2890

TZE2500 150 1480 1735 1985 2270 2500 2820 3100 3355 3585

TZE3000 150 1685 2015 2340 2680 3000 3330 3645 3960 4235

TZE3500 150 1900 2300 2700 3095 3500 3845 4195 4570 4890

Air Pressure

(psig)

60 70 80 90 100 110 120 130 140

Rated inlet air flow (scfm) at given pressures (psig)

(Based upon 100oF inlet air temperature)

Higher pressures are optionally available. Consult factory.

To correct for an inlet temperature other than 100oF, multiply dryer capacity by the

temperature correction factor listed below.

CORRECTION FACTOR FOR INLET TEMPERATURE

TEMPERATURE

DEGREES F

Correction Factor

Example: To size for an inlet flow of 950 SCFM @ 105 F and 110 psig.

1. Select model that produce at least 950 SCFM at 110 psig. This case would be the TZE1000 which

can dry 1140 SCFM.

2. Multiply pressure corrected flow by the temperature correction factor to obtain the flow of the dryer

corrected for pressure and temperature:

1140 X (0.85) = 969 SCFM

3. Confirm model selection. Model TZE1000 can flow 969 SCFM at the inlet conditions specified;

requirements of 950 SCFM are less: TZE1000 is correct.

80 90 100 105 110 115 120

1.1 1.1 1.0 0.85 0.69 0.565 0.455

7

Page 14

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

NOTE: Settings for EMS: Standard Dryers: EMS Control -40°F (-40°C)

High Humidity -35°F (-35°C)

LDP Dryers: EMS Control -100°F (-74°C)

High Humidity -95°F (-69°C).

1.5 OVERLOADING

Attention! Protect the adsorption dryer from overloads!

The adsorption dryer can become overloaded if:

• The flow volume of the medium to be dried increases

• The temperature of the air at entry and, correspondingly, its

humidity increases

• The minimum operating pressure decreases

• The prefiltration and separation of impurities are not sufficient or the

filter drain fails

• Introduction of oil into the air stream.

1.6 TRANSPORT

Immediately upon delivery of the adsorption dryer, it must be checked for any damage

that may have occurred during transport. If necessary, the damage must be recorded

on the shipping waybill/receipt. Liability for such damage usually rests with the shipper.

Contact Ingersoll-Rand to arrange for any required service or replacement parts.

Attention!

For transport within your company site, only the skids of the adsorption

dryer may be used. Lifting at any other points on the equipment will void

the warranty and damage the equipment.

1.7 STORAGE

If the adsorption dryer is to be stored for a long period of time, its place of storage must

be dry and free of dust. The ambient temperature cannot go below 33°F (+1°C).

1.8 USE OF A PREFILTER AND AFTERFILTER

In order to prevent droplets of condensate, oil and dirt from getting into the desiccant, a

Ingersoll-Rand prefilter must be installed upstream of the adsorption dryer. An oil film

on the desiccant reduces the drying capacity and the dewpoint. In order to prevent

breakdown in downstream consumers caused by material that has been abraded from

the desiccant bed, a Ingersoll-Rand afterfilter must be mounted behind the adsorption

dryer. Since no condensate accumulates in the afterfilter, this filter is always equipped

with a manual vent valve.

8

Page 15

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

Both filters are equipped with a differential pressure indicator to ensure a direct display

of the degree of contamination of the filter elements.

2. INSTALLATION

2.1 GENERAL

Ensure that the installation site is free of dust, dirt and litter. The site floor must be level

and strong enough to support the equipment. The site itself must be an heated

environment (minimum 50°F) to ensure proper operation and warranty protection.

Ensure that the Ingersoll-Rand adsorption dryer is carried only by its skid base frame.

The adsorption dryer must be positioned so that the side from which it is to be operated

is easily accessible. The piping is to be connected at a slightly downward slope. Install

isolation valves on the inlet and outlet sides of the adsorption dryer. Also, a bypass

pipe with an additional isolation valve should be mounted onto the adsorption dryer to

allow for an uninterrupted supply of compressed air in case the adsorption dryer

requires maintenance or repair. The bypass assembly is optionally provided (see

paragraph 1.2) or can be customer furnished. If vibrations occur at the installation site,

the adsorption dryer skid frame is to be placed onto vibration dampers.

2.2 MECHANICAL ASSEMBLY

• The equipment should be located in an area with adequate clearances for

service. An overhead clearance of not less than two feet above each desiccant

tower is required for loading of the desiccant.

• Remove all protective shipping crates, flange covers, etc.

• Using the mounting holes provided on the skid, anchor the dryer to a solid, level

foundation designed to support the equipment.

• Do not hydrostatically test the pressure vessels. All TZE dryer pressure vessels

and welded piping are hydrostatically tested at one and one-half times the design

pressure after fabrication and before assembly.

• Desiccant for models TZE820 and up is shipped loose and must be installed on

site. Refer now to paragraph 4.3 for instructions on installing the desiccant.

• If the equipment is installed in a high traffic area, protective barriers may be

required to prevent possible damage of equipment and to prevent contact with

hot surfaces.

• Due to vibration during shipping some tube fittings may have loosened.

Therefore, inspect all connections and tighten if required.

9

Page 16

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

• Ensure that the inlet and outlet connections to and from the dryer are made using

the correctly rated fittings and piping to meet the design conditions.

NOTE: System isolation and by-pass valves should be installed. If not supplied

by Ingersoll-Rand as part of the equipment package (i.e., 3V option – see

paragraph 1.2), they should be supplied and installed by others. Ensure

that this bypass facility is installed so that future servicing of the dryer

system off-line may take place.

• Full flow relief valves to protect the system from over-pressure must be

customer-provided in accordance with local regulations.

• The purge exhaust on the TZE650 and smaller dryers is equipped with an

exhaust muffler. If required, the muffler can be removed and purge exhaust can

be connected to a vent header. Follow recommendations for pipe sizing listed

below.

• The purge exhaust connection on the TZE820 and larger dryers must be

connected to a vent header. To ensure satisfactory regeneration of the desiccant

chambers, the purge exhaust piping should be sized as follows to prevent backpressure build up.

EXTENDED LENGTH PIPE SIZE REQUIRED

TO 10 FEET SAME SIZE AS DRYER EXHAUST

TO 25 FEET 1 SIZE LARGER THAN DRYER EXHAUST

TO 50 FEET 2 SIZES LARGER THAN DRYER EXHAUST

TO 100 FEET 3 SIZES LARGER THAN DRYER EXHAUST

Caution!

The noise at the outlet of the exhaust header may exceed 100 dBa, and

the flow velocity will be high. Exhaust must be piped to an area where

these flow velocities and noise levels can be safely tolerated.

2.3 FILTER INSTALLATION

2.3.1 PREFILTER INSTALLATION (SHIPPED LOOSE)

• Mount prefilter in such a way as to allow clearance for the element installation

and removal.

• Locate the prefilter as close to the dryer inlet connection as possible.

• The filter must be piped so that the correct flow direction indicated on the filter is

followed.

10

Page 17

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

• Ensure that all piping and valves are equivalent or larger in size to the dryer inlet

connection.

• Connect drain port to a condensate collector. Use an easily visible collector to

aid in operational inspection.

2.3.2 AFTERFILTER INSTALLATION (SHIPPED LOOSE)

• Mount afterfilter in such a way as to allow clearance for the element installation

and removal.

• The filter must be piped so that the correct flow direction indicated on the filter is

followed.

• Ensure that all piping and valves are equivalent or larger in size to the dryer inlet

connection.

2.3.3 FILTER SKID WITH 3 VALVE BYPASS (IF DRYER INCLUDES 3V OPTION)

• Filters skid should be located as close to dryer as possible. Use the skid bolt

holes to secure the assembly.

• Ensure that the skid is located such that the 3-valve bypass will bypass the dryer

and filters when in use.

• Check the flow direction of each filter to ensure the prefilter is connected to the

inlet pipe of the dryer and afterfilter is connected to the outlet pipe of the dryer.

• Connect the filter skid piping and dryer skid piping using materials and fabrication

procedures that are suitable for compressed air pressure piping. All flanges are

ANSI B16.5 Class 150 raised face flanges.

2.4 ELECTRICAL CONNECTION

Warning – high voltage!

Be sure that power is removed from the line feed before making

• Connect the dryer to a correctly sized power supply. Refer to the dryer

nameplate or the electrical drawing (see section 7) for the supply voltage and

amperage requirement to properly size the electrical service. Only one electrical

connection is required. All internal wiring was done at the factory.

connection between the site drop and the equipment.

11

Page 18

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

NOTE: A disconnect switch is not provided with the dryer and must be supplied

by the customer in accordance with the local electrical code.

• Ground the frame of the dryer in accordance with the local electrical code.

• It is recommended that the common alarm relay, located in the dryer control

panel, be connected to the control room or operator station so that an immediate

response to the dryer alarm may be given when required.

• Before energizing the electrical circuit, the electrical heater assembly should be

inspected to determine that no moisture has accumulated in the heater enclosure

or terminations. A 1000V meg-ohmmeter should be used to determine the

phase-to-ground insulation resistance for each phase. A minimum value of 500

kOhms should exist.

2.5 EMS CONTROL CONNECTION

• A probe sample line must be run from downstream of the afterfilter.

• A 10-ft length of 1/8-in stainless steel tubing and necessary compression fittings

are provided.

• Tube fittings are to be installed downstream of the afterfilter at the differential

pressure indicator (DPI) port T-fitting on the afterfilter outlet nozzle

• Remove the hexagonal plug from the DPI T-fitting.

• Insert 1/8-in tubing into compression fitting and tighten.

• Run the tubing back to the hygrometer housing. Cut to necessary length and

connect to the upper connection fitting. Tubing is semi-flexible so care must be

taken when bending to ensure the tubing does not kink.

• If the sample port is installed at a distance longer than the tubing supplied,

contact your Ingersoll-Rand distributor for assistance.

12

Page 19

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3. EQUIPMENT OPERATION

3.1 GENERAL OPERATING PRINCIPLES

This dryer model has two parallel adsorption chambers filled with desiccant. While the

medium is being dried flowing top-down in one chamber, regeneration takes place from

the bottom up in the other chamber. The changeover from one chamber to the other is

controlled by the Energy Management System that monitors desiccant performance by

measuring the outlet air dew point. It can operate continuously and is fully automatic.

The standard dryer with EMS has a cycle time of eight hours. Half the cycle time is

dedicated to air drying work and the other half to desiccant regeneration, with one

chamber working to dry the air while the other regenerates. The dryer is configured at

the factory.

Wet air enters the working desiccant chamber (it can be either the left or right) at the

inlet switching valves (top) and is dried as it flows downward through the desiccant bed.

Dry air exits the dryer through the outlet check valve.

The regeneration of the off-line tower begins with a heating cycle. After having

depressurized the off-line tower, the purge orifice allows a portion of the dry outlet air to

flow across the regeneration heater. The heated regeneration air then passes upward

through the desiccant bed where it picks up previously adsorbed moisture from the

desiccant and is then evacuated to atmosphere through the purge exhaust valve.

At the completion of the regeneration heating cycle, the cooling cycle begins. The

regeneration heater is de-energized. The purge orifice allows a portion of the dry outlet

air to flow through the off-line tower. It is then evacuated to atmosphere through the

purge exhaust valve. When the cooling cycle is completed, the purge exhaust valve is

closed and the off-line tower is repressurized. Once at line pressure, the dryer is ready

to switch drying from one tower to the other. Dryer models TZE3000 and 3500 have

purge control valves which close once at line pressure and prior to switching from one

tower to the other.

The purge air is controlled by a purge adjusting valve and purge orifice located in the

purge line. Purge pressure is indicated on the purge pressure gauge.

Ingersoll-Rand high-efficiency prefilters and reverse-flow afterfilters are designed to

remove solids, oil and water condensate from compressed air and other neutral,

compressed gases. These filters provide high flows and low differential pressures.

13

Page 20

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

The prefilter is designed to flow from the inside to the outside. The afterfilter is designed

to flow from the outside to the inside. Solids are filtered out by impact or by the effect of

inertia, whereas oil particles and drops of moisture are filtered out by the effect of

coalescence. The contaminants collect at the bottom of the filter vessel and are drained

automatically or manually.

3.1.1 DRYER PROGRAM STEPS

This automatic dryer is equipped with a PLC which retains last-position data in the event

of a power failure or fast shutdown. The dryer will restart at the last position or can be

manually cycled on the operator interface to reset at step 1.

14

Page 21

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

STEP 1

OPEN LEFT CHAMBER

INLET VALVE

EV-1L & EV-11R (VALVE TO MOVE)

10-SEC TIMER/VALVE TO OPEN

10 SEC PASS, LEFT

CHAMBER ABOVE 60 psig

STEP 8

OPEN RIGHT CHAMBER

INLET VALVE

EV-1R & EV-11L (VALVE TO MOVE)

10-SEC TIMER/VALVE TO OPEN

10 SEC PASS, RIGHT

CHAMBER ABOVE 60 psig

STEP 2

5 SEC PASS

STEP 3

10 SEC PASS AFTER RIGHT

CHAMBER BELOW 30 psig

STEP 4

HEATING TIMER FINISH OR PURGE

OUTLET TEMP ABOVE 200-DEG F

STEP 5

IF COOLING TIMER DONE (100 MINUTES) OR PURGE

OUTLET TEMP BELOW 120-DEG F & 60 MINUTES PASSED

CLOSE RIGHT

CHAMBER INLET VALVE

EV-1L & EV-11R WAIT 5 SEC

FOR VALVE TO CLOSE

DEPRESSURIZE

RIGHT CHAMBER

EV-2R & EV-3R (IF R/C <10 psig)

ENERGIZE EV-1L & EV-11R

RIGHT CHAMBER

HEATING PERIOD

START R/C HEATING MODE

FOR 140 MINUTES MAXIMUM;

ENERGIZE EV-1L AND EV11R

RIGHT CHAMBER

COOLING PERIOD

START R/C COOLING MODE FOR

100 MINUTES MAXIMUM /

60 MINUTES MINIMUM;

ENERGIZE EV-1L & EV-11R

CLOSE LEFT CHAMBER

STEP 9

5 SEC PASS

STEP 10

10 SEC PASS AFTER LEFT

CHAMBER BELOW 30 psig

STEP 11

HEATING TIMER FINISH OR PURGE

OUTLET TEMP ABOVE 200-DEG F

STEP 12

IF COOLING TIMER DONE (100 MINUTES) OR PURGE

OUTLET TEMP BELOW 120-DEG F & 60 MINUTES PASSED

INLET VALVE

EV-1R & EV-11L WAIT 5 SEC FOR

VALVE TO CLOSE

DEPRESSURIZE

LEFT CHAMBER

EV-2L & EV-3L (IF L/C <10 psig)

ENERGIZE EV-1R & EV-11L

LEFT CHAMBER

HEATING PERIOD

START L/C HEATING MODE

FOR 140 MINUTES MAXIMUM

ENERGIZE EV-1R & EV11L

LEFT CHAMBER

COOLING PERIOD

START L/C COOLING MODE FOR

100 MINUTES MAXIMUM /

60 MINUTES MINIMUM

ENERGIZE EV-1R & EV-11L

STEP 6

120 SEC PASS & BOTH

CHAMBERS ARE ABOVE 60 psig

STEP 7

DRYER HALF-CYCLE COMPLETED (240

MINUTES) OR BAD DEWPOINT OR EMS OFF

& BOTH CHAMBERS ARE ABOVE 60 psig

GO TO STEP 8

REPRESSURIZE

RIGHT CHAMBER

ENERGIZE EV-1L & EV-11R

RIGHT CHAMBER

STANDBY

ENERGIZE EV-1L & EV-11R

STEP 13

120 SEC PASS & BOTH

CHAMBERS ARE ABOVE 60 psig

STEP 14

GO TO STEP 1

REPRESSURIZE

LEFT CHAMBER

ENERIZE EV-1R & EV-11L

LEFT CHAMBER

STANDBY

ENERGIZE EV-1R & EV11L

DRYER HALF-CYCLE COMPLETED (240

MINUTES) OR BAD DEWPOINT OR EMS OFF

& BOTH CHAMBERS ARE ABOVE 60 psig

Su

SD

E

FIGURE 1 – DRYER PROGRAMMED STEPS

15

Page 22

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2 OPERATOR CONTROLS / LOW-VOLTAGE CONTROL PANEL

The operator status display and control interface (i.e., monitor) is detailed in Figure 2. It

is provided to allow the operator to manually cycle through the programmed steps, and

to indicate system status. The system operating setpoints cannot be changed at this

panel.

16

Page 23

USER MANUAL

In order to choose one of the next four options, the SHIFT button

must be pressed first. An “s” in the lower right corner indicates the

shing

arrow on the right side of the screen indicates that more information is

available in the direction of the arrow and can be accessed by using

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

TEXT

DISPLAY

F1 – DRYER STATUS

F2 – MANUAL STEP AHEAD (MANUAL MODE ONLY)

F3 – DRYER ALARM STATUS

– ALARM RESET

F4

SHIFT –

upper row is now active.

F5 – DRYER OPERATING MODE MENU

F6 – HEATER SHEATH TEMPERATURE AND SETPOINT

F7 – HEATER OUTLET TEMPERATURE AND SETPOINTS

F8 – REGENERATION OUTLET TEMPERATURE AND SETPOINTS

Arrows allow user to scroll up or down within the display. A fla

the scroll arrows.

ESC – ACCESSES THE MENU MODE (ACCESS IS NOT REQUIRED).

ENTER – NO FUNCTIONALITY FOR THIS BUTTON.

FIGURE 2 – OPERATOR MONITOR

17

Page 24

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2.1 DRYER STATUS

The F1 key is pressed to display the present status of the dryer. This allows you to see

which step of the program cycle is currently engaged. A message can appear below

the dryer status at any time when in manual mode. A blinking arrow on the right side of

the display will indicate this. To access the messages, press the green arrow on the

right side of the interface.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

SELECT LEFT CHAMBER DRYING

LEFT CHAMBER DRYING

R/C IN DEPRESS MODE

LEFT CHAMBER DRYING

R/C IN HEATING MODE

LEFT CHAMBER DRYING

R/C IN COOLING MODE

LEFT CHAMBER DRYING

R/C IN REPRESS MODE

LEFT CHAMBER DRYING

R/C IN STANDBY MODE

LEFT CHAMBER IN EMS MODE

R/C IN STANDBY MODE

SELECT RIGHT CHAMBER

DRYING

RIGHT CHAMBER DRYING

L/C IN DEPRESS MODE

RIGHT CHAMBER DRYING

L/C IN HEATING MODE

RIGHT CHAMBER DRYING

L/C IN COOLING MODE

RIGHT CHAMBER DRYING

L/C IN REPRESS MODE

RIGHT CHAMBER DRYING

L/C IN STANDBY MODE

RIGHT CHAMBER IN EMS MODE

L/C IN STANDBY MODE

Opening the left chamber (L/C) inlet valve.

Closing the right chamber (R/C) inlet valve.

Depressurizing the right chamber.

Heating the right chamber for regeneration.

Cooling the right chamber.

Pressurizing the right chamber.

Right chamber in standby until the end of the

half cycle.

The dryer is in EMS mode on the left

chamber. This will extend the half cycle for a

maximum of 12 hours or until the outlet

dewpoint goes higher than -40°F.

Opening the right chamber inlet valve.

Closing the left chamber inlet valve.

Depressurizing the left chamber.

Heating the left chamber for regeneration.

Cooling the left chamber.

Pressurizing the left chamber.

Left chamber in standby until the end of the

half cycle.

The dryer is in EMS mode on the right

chamber. This will extend the half cycle for a

maximum of 12 hours or until the outlet

dewpoint goes higher than -40°F.

18

Page 25

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2.2 ALARM INFORMATION

The F3 button is pressed to display the status of the dryer alarms. If there is no alarm,

a NO ALARM message will appear. If more than one alarm is active, a flashing arrow

will appear on the right side of the display. To access the messages, press the green

arrow on the right side of the panel. In order to reset non-active alarms, press the F4

key. When all the alarm conditions have been cleared, the NO ALARM message will

appear.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

HEATER OUTLET OVER TEMPERATURE

THERMOCOUPLE MODULE IN ERROR

THERMOCOUPLE OUT OF RANGE

HEATER FAILURE ALARM

FAIL REACH SETPOINT

OVERSHEATH ALARM

SHEATH TEMPERATURE TOO HIGH

DEPRESS FAILURE ON LEFT CHAMBER

DEPRESS FAILURE ON RIGHT CHAMBER

REPRESS FAILURE ON LEFT CHAMBER

REPRESS FAILURE ON RIGHT CHAMBER

HIGH HUMIDITY ALARM

NO ALARM Indicates no alarm is active.

Heater outlet temperature is above the

setpoint.

Indicates the thermocouple module

has lost it’s 24Vdc supply.

Indicates a thermocouple connected to

the module is defective or open.

The heater has failed to reach the

setpoint temperature within 15

minutes.

The heater sheath temperature is

above the setting.

The left chamber did not reach the low

setting of the pressure switch within

time limit.

The right chamber did not reach the

low setting of the pressure switch

within time limit.

The left chamber did not reach the

high setting of the pressure switch

within time limit.

The right chamber did not reach the

high setting of the pressure switch

within time limit.

Indicates the outlet dewpoint is above

alarm setpoint.

19

Page 26

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2.3 DRYER OPERATION MODES

The F5 button is pressed to display the dryer mode of operation. The actual mode will

be displayed whether it is in automatic or manual mode. To change the actual mode of

the dryer, press F2 when in the dryer mode screen. The actual mode will change from

one to the other each time the F2 button is pressed. If the dryer mode screen is left

unattended for thirty seconds, it will automatically switch to the dryer status screen. In

manual mode, the READY TO STEP AHEAD PRESS F2 TO CONTINUE message

will be shown when the dryer is ready to perform the next step. In order to go to the

next step in manual mode you must not be in the dryer operation mode screen. Failure

to do so will simply change the operating mode of the dryer.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

The dryer is in automatic mode. The dryer

DRYER IN AUTO MODE

DRYER IN MANUAL MODE

READY TO STEP AHEAD

PRESS F2 TO CONTINUE

will perform its cycle without any external

intervention except in case of alarm.

The dryer is in manual mode. The dryer will

need external intervention in order to do to

the following step. If no external intervention

is provided the dryer will stay in that step.

The dryer is ready to go to the next step

when in manual mode. The user must wait

for this signal in order to press F2 for making

the dryer step ahead in its cycle.

3.2.4 HEATER SHEATH INFORMATION

The F6 button accesses heater sheath information. On this screen the actual sheath

temperature in degrees Fahrenheit is displayed and so is the temperature setpoint for

the sheath over-temperature alarm. The setpoint cannot be changed from the panel.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

Displays temperature of the heater sheath

HEATER SHEATH XXXX F

ALARM SETPOINT YYYY F

20

(XXXX) and also at which temperature the

dryer will turn in alarm (YYYY).

Both temperatures are in degrees

Fahrenheit.

Page 27

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2.5 HEATER OUTLET INFORMATION

The F7 button accesses the heater outlet information. On this screen the actual

temperature in degrees Fahrenheit is displayed and so is the temperature setpoint for

the heater outlet over-temperature and heating failure alarm. The setpoint cannot be

changed at the panel.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

Displays the heater outlet temperature

HEATER OUTLET XXXX F

HEAT CONTROL YYYY F

HEATER OUTLET XXXX F

HEAT FAIL AT ZZZZ F

HEATER OUTLET XXXX F

HEAT OVERTEMP VVVV F

(XXXX) and the regulation temperature

setting (YYYY) of the heater.

Both temperatures are in degrees F.

Displays the actual heater outlet temperature

(XXXX) and the heating failure alarm

temperature setting (ZZZZ).

Both temperatures are in degrees F.

Displays the actual heater outlet temperature

(XXXX) and the high outlet temperature

alarm setting (VVVV).

Both temperatures are in degrees F.

3.2.6 REGENERATION OUTLET INFORMATION

The F8 button accesses regeneration outlet information. On this screen the actual

temperature in degrees Fahrenheit is displayed and so are the control setpoints for end

of heating and end of cooling. The setpoints cannot be changed at the panel.

MESSAGE IDENTIFICATION MESSAGE DESCRIPTION

Displays the actual regeneration outlet

REGEN OUTLET XXXX F

HEAT SETPOINT YYYY F

temperature (XXXX) and the end of heating

mode temperature setting (YYYY).

Both temperatures are in degrees F.

Displays the actual regeneration outlet

REGEN OUTLET XXXX F

COOL SETPOINT ZZZZ F

temperature (XXXX) and the end of cooling

mode temperature setting (ZZZZ).

Both temperatures are in degrees F.

3.2.7 DRYER OFF, DRYER ON, EMS ON – 3-POSITION SWITCH

This 3-position switch provides for manual selection of dryer basic functions. Ensure

that the switch is set at DRYER OFF before beginning the initial startup procedure.

21

Page 28

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.2.8 STATUS LAMPS

A green light announces that there is POWER at the control panel when lit. A red light

announces that there is an ALARM condition when lit. Refer to the operator monitor to

determine the cause.

3.2.9 PRESSURE GAGES

Three gages are mounted in a row above the low-voltage control panel. The two

outside read the pressure within each chamber (left side for left chamber, right for right)

and the middle gage shows the purge pressure.

3.3 INITIAL START-UP

Attention!

All pipes and wire connections must be tightened!

Furthermore, before start-up:

• The pipes must be checked for the presence of scale, abraded

material from the threading, or other similar impurities.

• All isolation valves on the prefilter, afterfilter and on the bypass line (if

installed) should be closed.

• The ambient temperature must not be less than 33°F.

NOTE: Breakdown resulting from faulty installation does not fall under the

Ingersoll-Rand warranty obligation.

3.3.1 PRESSURIZING DRYER

Prior to pressurizing the dryer system, verify the following:

• DRYER OFF/DRYER ON/EMS ON switch is in the DRYER OFF position

• System outlet block valve is closed

• Prefilter, afterfilter and pilot air filter vent valves are closed

• Desiccant chamber vent valve is closed

• Pilot air isolation valve is open

• Hygrometer adjustment/isolation valves are closed.

Slightly open the inlet isolation valve to slowly admit compressed air to the system.

When full system operating pressure has been reached, all connections should be soap

22

Page 29

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

bubble tested for leaks. Any leaks should be repaired and retested prior to placing the

equipment in service. If some gas other than the process air will be used for leak

testing, consult Ingersoll-Rand for its compatibility with system components before

proceeding.

Fully open the inlet isolation valve.

When the system is filled with process air and leak tight, slowly open the system outlet

valve to pressurize the downstream piping. During this procedure, ensure that the dryer

system pressure does not fall beyond 95% of its reading prior to opening the system

outlet valve. This will protect the equipment internal components (i.e., filter elements,

desiccant) from gas velocities above design conditions.

When pressurizing is complete, then fully open the system outlet valve to place the

equipment in service.

Verify that the system inlet pressure and temperature are at the design operating levels

(see paragraph 1.4)

Ensure that the pilot pressure regulator is set between 80 and 100 psig.

3.3.2 ENERGIZING DRYER CONTROLS

Turn 3-position switch to the DRYER ON position.

The operator monitor controls the dryer cycle. This should be used as a reference

guide to ensure dryer is cycling. A manual mode is included in the dryer program to

allow for fast cycling to verify to operation of the dryer.

Review the operational program of the dryer (paragraph 3.1.1) and the wiring schematic

(see section 7) before operating the dryer.

NOTE: The hygrometer will signal an open circuit (the ALARM light will

illuminate) until probe cable is connected to hygrometer probe. This

connection is described in paragraph 3.3.4 – leave it as is for now.

While dryer is in purge mode for either chamber, the regeneration pressure setting

should be checked. Refer to paragraph 3.3.3 for the correct blower flow setting.

Warning!

Failure to correctly set the purge pressure can lead to improper

regeneration of the desiccant bed, resulting in a dewpoint failure

when the chamber is returned to service.

23

Page 30

USER MANUAL

ADJUSTMENT

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.3.3 PRESSURE SWITCH ADJUSTMENT

On the TZE dryer there are four pressure switches: PSH-1, PSL-1, PSH-2 and PSL-2.

The PSH pressure switches are set at 30 psig below the operating pressure of the

dryer, and use the normally open contact. When the adjustment is done, the contact

between C and NC should close when increasing to the desired pressure.

The PSL switches are set at 10 psig regardless of the operating pressure and use the

normally closed contact. When the adjustment is done, the contact between C and NC

should close when decreasing to the desired pressure.

To increase the pressure, screw the knob toward the pressure switch diaphragm (see

figure 3). To decrease the pressure, turn away from the pressure switch diaphragm.

KNOB

FIGURE 3 – PRESSURE SWITCH ADJUSTMENT

3.3.4 EMS START UP

Refer to the general assembly drawing provided in section 7, and to figure 4.

The EMS hygrometer probe has been shipped inside of its own sealed package to

ensure that the probe does not become saturated with ambient air during storage and

transport. Do not remove probe from the package until dryer system has been started

and probe is to be inserted into the sample cell.

24

Page 31

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

• Check that the sample line is connected from the dryer outlet to the inlet valve on

the humidity probe sample cell.

• Check that the humidity probe is installed into the sample cell.

• Connect the cable to the humidity probe.

• Fully open the inlet valve to the sample cell.

• Partially open the discharge valve of the sample cell to vent off a small amount of

sample air. Do not fully open discharge valve.

• Perform a soap bubble test to check for leaks on all parts of the sample line

connections and the humidity sample cell.

• The digital display will now read the dewpoint of the dryer system. It will take a

short period of time for a humidity probe to be purged of humidity.

FIGURE 4 – HYGROMETER PROBE ASSEMBLY

NOTE: The dryer should be operated in the DRYER ON position at the time of

initial start-up and at all times when the hygrometer or humidity probe are

removed for service.

25

Page 32

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

3.4 SHORT-TERM SHUTDOWN

Follow this sequence when switching off the adsorption dryer:

• First close all the shutoff valves up- and downstream of dryer

• Then immediately switch DRYER OFF.

Danger!

Dryer will remain pressurized.

3.5 SHUTDOWN IN CASE OF A FAULT OR FOR MAINTENANCE

Follow this sequence when switching off the adsorption dryer:

• First switch off the dryer. Make certain dryer is not in heating or cooling mode.

The dryer electrical panel will still have power. The dryer disconnect must be

turned off before opening electrical panel.

• Close all the isolation valves upstream and downstream of the adsorption dryer.

• Depressurize the dryer by using the hand valve mounted at the bottom of the

desiccant chamber.

• Depressurize the filters by opening vent valves at the bottom of each filter vessel.

Danger!

Before any kind of maintenance or repair work is done, the dryer

must be depressurized and disconnected from the power source.

3.6 RESTARTING

• Close the hand valve mounted at the bottom of the afterfilter and at the bottom of

each desiccant chamber

• Slowly open the inlet isolation valve and pressurize the dryer up to the regular

operating pressure by keeping the shutoff valve mounted behind the afterfilter

closed.

• Switch DRYER ON.

NOTE: If the dryer is restarted after a long standstill, proceed as for an initial

start-up (see paragraph 3.3).

26

Page 33

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

4. MAINTENANCE

4.1 CHECKLIST

These checks are to be carried out by the operator during the routine operations cycle.

4.1.1 DAILY CHECK

• Operate prefilter drain ball valve as required to prevent excess accumulation.

This may require frequent exercise depending on line moisture content. If the

drain is automatic, check for functionality and blow down daily to remove

accumulated fluids.

• Check filter differential pressures. A filter differential pressure of 5 to 8 psi (or

pointing in the red field) indicates a dirty filter element and it should be replaced.

Filter elements should last between 6 to 12 months under normal use.

• Check correct purge pressure.

• Ensure dryer is cycling without alarms.

4.1.2 WEEKLY CHECK

• Check all mufflers for backpressure. Replace if clogged or dirty.

• Verify heater operation.

4.1.3 QUARTERLY CHECK (EVERY THREE MONTHS)

• Check operating conditions, purge rate, line pressure, inlet flow.

• Check dryer operating cycle for proper operation of valve operators, solenoid

valves, dump valves, heaters, pressure switches and temperature controller.

• Check the outlet dewpoint.

• Blow down relief valves.

• Check heater outlet temperature is between 400°F and 425°F.

• Verify pressure switch operation.

• Inspect pilot air filter element. If element seems clogged, dirty or damaged,

replace it.

27

Page 34

USER MANUAL

ain pollutants as appropriate to their function.

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

4.1.4 ANNUAL CHECK

• Disassemble, clean and inspect the inlet switching, purge exhaust and

depressurization valves/actuators. Replace all worn or damaged parts.

• Disassemble, clean and inspect the outlet and purge check valves. Replace all

worn or damaged parts.

• Inspect the desiccant through the chamber fill port. Replace desiccant if

degraded or if oil is present (see paragraph 4.3).

• Replace prefilter, afterfilter and pilot air filter elements at least once a year.

• Replace the dewpoint sensor humidity probe.

NOTE: Should the need for spare parts or service arise during work on the

adsorption dryer, the dryer model and its serial number must be

conveyed to Ingersoll-Rand. This information is given on the nameplate

mounted on the control cabinet. Telephone Ingersoll-Rand to arrange for

maintenance support (1-800-526-3615).

4.2 CHANGING THE FILTER ELEMENT

• The filter element within the filter housing must be replaced annually

• Depressurize the dryer and switch DRYER OFF

Danger!

Change filter elements only when the housing is fully depressurized

• Separate the lower part of the housing from the upper part

• Loosen and remove the element by hand

• Install the new filter and the O-ring/gasket, making sure that the filter seats

perfectly

• Refit the filter housing.

NOTE: Filter elements cannot be cleaned or reused.

Attention!

Filters may cont

Dispose of used filters in accordance with your local, state and federal

28

Page 35

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

regulations.

4.3 REPLACEMENT OF THE DESICCANT

Desiccant life is determined by the care with which it is handled, the quality of filtered

inlet air provided and by its time in use. Be careful to not abrade (i.e., wear down) the

desiccant when installing it. Proper filtering of inlet air, and constant pressure and

temperature, will also extend its life. In order to ensure trouble-free operation, we

recommend replacing the desiccant every 10,000 operating hours, or every 3 years.

The following considerations determine the life expectancy of desiccant:

• Care in installation

• Quality of input gas (e.g., air)

• Constancy of flow and temperature

• Whether full-service cycling or low-demand usage

• Time in service.

The following clues will suggest that you examine the desiccant and consider its

replacement:

• Discoloring of desiccant (e.g., oil residue, other contaminants): a brown or yellow

tinge indicates that the adsorbancy capacity of the desiccant has been

diminished

• Frequent afterfilter replacement due to desiccant dust accumulation

• Performance dew point rises.

Refer to paragraph 1.4 to determine the desiccant quantity required for your model of

dryer.

• Close dryer inlet/outlet isolation valves

• Depressurize and switch DRYER OFF

Danger!

• Wear protective equipment and clothing when handling

desiccant.

• Remove the drain plug and empty the old desiccant into a container

29

Page 36

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

4.3 REPLACEMENT OF THE DESICCANT (CONTINUED)

• Screw the plug back in and fill with new desiccant from above (refer to paragraph

• Start up the adsorption dryer in accordance with paragraph 3.3 for initial start-up.

Danger!

• Desiccant may contain pollutants.

• Desiccant is to be disposed of in accordance with local, state

and federal regulations.

1.4 regarding quantities for each chamber)

30

Page 37

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

5. PARTS LISTINGS

5.1 PARTS LIST FOR TZE400 TO TZE650

Description TZE400 TZE500 TZE650

Part # Qty Part # Qty Part # Qty

Consumables

Prefilter ( Element Only )

Afterfilter ( Element Only )

Muffler 38328167 2 38328167 2 38328167 2

Moisture Indicator 38016713 1 38016713 1 38016713 1

Activated Alumina – Pounds 38335253 544 38335253 700 38335253 866

Probe Recalibration

LDP Option

Activated Alumina – Pounds 38335253 364 38335253 470 38335253 580

Molecular Sieve 4A – Pounds

Inlet Valve

Inlet Valve Kit/ 38331666 2 38331666 2 38331666 2

Inlet Valve

Solenoid Block 38331120 1 38331120 1 38331120 1

Gasket Consult factory

Outlet Valve

Valve Kit Consult factory

Check Valve 38015855 2 38015855 2 38015855 2

Gasket 38049490 4 38049490 4 38049490 4

Purge

Purge Valve Kit 38331708 2 38331708 2 38331708 2

Purge Valve 38007076 1 38007076 1 38007076 1

Purge Exhaust Valve 38331716 2 38331716 2 38331716 2

3V Bypass Option

Ball Valve 38049540 3 38049540 3 38049540 3

EMS

Digital Panel Meter 38431730 1 38431730 1 38431730 1

Replacement Parts

Pressure Gauge 38006714 3 38006714 3 38006714 3

PLC 38028759 1 38028759 1 38028759 1

Power Supply 38328357 1 38328357 1 38328357 1

Text Display 38018065 1 38018065 1 38018065 1

Thermocouple 38031001 1 38031001 1 38031001 1

Relief Valve 38007084 2 38007084 2 38007084 2

Temperature Indicator 38006698 2 38006698 2 38006698 2

Heater 38028668 1 38028668 1 38028676 1

Gasket Consult factory

Pressure Regulator 38015145 1 38015145 1 38015145 1

Pressure Switch 38006565 5 38006565 5 38006565 5

Light Bulb 38335212 2 38335212 2 38335212 2

Refer to filter

38049482

38340030 180 38340030 230 38340030 286

38331658 2 38331658 2 38331658 2

1

nameplate or

consult factory

38049482

1

38049482

1

31

Page 38

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

Description TZE400 TZE500 TZE650

Transformer Primary Fuse 38015244 2 38015244 2 38015244 2

Transformer Secondary Fuse 38006870 1 38006870 1 38006870 1

Heater Fuses 38006896 3 38006896 3 38006896 3

Control Fuses 38015236 1 38015236 1 38015236 1

Control Relay Consult factory

Heater contactor 38049367 1 38049367 1 38049367 1

5.2 PARTS LIST FOR TZE820 TO TZE1225

Description TZE820 TZE1000 TZE1225

Part # Qty Part # Qty Part # Qty

Consumables

Prefilter ( Element Only )

Afterfilter ( Element Only )

Pilot Air Filter Element 38049474 1 38049474 2 38049474 2

Depressurization Muffler 38328167 2 38328167 2 38328167 2

Activated Alumina – Pounds 38335253 1320 38335253 1650

Probe Recalibration 38049482 1 38049482 1 38049482 1

LDP Option

Activated Alumina – Pounds 38335253 882 38335253 1106

Molecular Sieve 4A – Pounds 38340030 436 38340030 542 38340030 654

Inlet Valve

Inlet Valve Kit/ 38438875 2 38438875 2 38438875 2

Inlet Valve

Solenoid Block 38015889 1 38015889 1 38015889 1

Gasket Consult factory

Outlet Valve

Valve Kit 38436879 1 38436879 1 38436879

Check Valve 38015715 2 38015715 2 38015715 2

Gasket 38027769 4 38027769 4 38027769 4

Purge

Purge Valve 38007068 2 38007068 2 38007068 2

Purge Valve Gasket 38049490 4 38049490 4 38049490 4

Exhaust Valve 38331690 2 38331690 2 38331690 2

Exhaust Valve Kit 38331708 2 38331708 2 38331708 2

3V Bypass Option

Manual Butterfly Valve Kit 38049599 3 38049599 3 38049599 3

Gasket, 3-inch 38027769 6 38027769 6 38027769 4

Bypass Valve 38049581 3 38049581 3 38049581 3

EMS

Digital Panel Meter 38431730 1 38431730 1 38431730 1

Replacement Parts

Pressure Gauge 38006714 3 38006714 3 38006714 3

PLC 38028759 1 38028759 1 38028759 1

Power Supply 38328357 1 38328357 1 38328357 1

Refer to filter

38438842 2 38438842 2 38438842 2

nameplate or

consult factory

38335253 1980

38335253 1326

32

Page 39

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

Description TZE820 TZE1000 TZE1225

Text Display 38018065 1 38018065 1 38018065 1

Thermocouple 38031001 1 38031001 1 38031001 1

Relief Valve 38007084 2 38007084 2 38026852 2

Temperature Indicator 38006706 2 38006706 2 38006706 2

Heater 38006953 1 38006938 1 38015475 1

Gasket Consult factory

Pressure Regulator 38015145 1 38015145 1 38015145

Pressure Switch 38006565 1 38006565 5 38006565 5

Light Bulb 38335212 2 38335212 2 38335212 2

Transformer Primary Fuse 38015244 2 38015244 2 38015244 2

Transformer Secondary Fuse 38006870 1 38006870 1 38006870 1

Heater Fuses 38006821 3 38015293 3 38015335 3

Control Fuses 38015236 1 38015236 1 38015236 1

Control Relay Consult factory

Heater Contactor 38049367 1 38049367 1 38049367 1

5.3 PARTS LIST FOR TZE1500 TO TZE2100

Description TZE1500 TZE1800 TZE2100

Part # Qty Part # Qty Part # Qty

Consumables

Prefilter ( Element Only )

Afterfilter ( Element Only )

Pilot Air Filter Element 38049474 1 38049474 2 38049474 2

Depressurization Muffler 38328167 2 38328167 2 38328175 2

Activated Alumina – Pounds 38335253 2110 38335253 2640

Probe Recalibration 38049482 1 38049482 1 38049482 1

LDP Option

Activated Alumina – Pounds

Molecular Sieve 4A – Pounds 38340030 696 38340030 872 38340030 980

Inlet Valve

Inlet Valve Kit/ 38438875 2 38438883 2 38438883 2

Inlet Valve

Solenoid Block 38015871 1 38015871 1 38015871 1

Gasket Consult factory

Outlet Valve

Valve Kit 38436879 1 38437299 1 38437299

Check Valve 38015715 2 38015764 2 38015764 2

Gasket 38027769 4 38329637 4 38329637 4

Purge

Purge Valve 38007019 2 38007019 2 38007019 2

Purge Valve Gasket 38027769 4 38027769 4 38027769 4

Exhaust Valve 38438842 2 38438842 2 38438842 2

Exhaust Valve Kit 38438875 2 38438875 2 38438875 2

3V Bypass Option

Refer to filter

38335253

38438842 2 38438859 2 38438859 2

1414

nameplate or

consult factory

38335253

1768

38335253 2970

38335253

1990

33

Page 40

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

Description TZE1500 TZE1800 TZE2100

Manual Butterfly Valve Kit 38049599 3 38049607 3 38049607 3

Gasket, 3-inch 38027769 6 38329637 6 38329637 4

Bypass Valve 38049581 3 Consult factory 3 Consult factory 3

EMS

Digital Panel Meter 38431730 1 38431730 1 38431730 1

Replacement Parts

Pressure Gauge 38006714 3 38006714 3 38006714 3

PLC 38028759 1 38028759 1 38028759 1

Power Supply 38328357 1 38328357 1 38328357 1

Text Display 38018065 1 38018065 1 38018065 1

Thermocouple 38031001 1 38031001 1 38031001 1

Relief Valve 38026852 2 38026852 2 38026852 2

Temperature Indicator 38006706 2 38006706 2 38006706 2

Heater 38028684 1 38006912 1 38028692 1

Gasket Consult factory

Pressure Regulator 38015145 1 38015145 1 38015145

Pressure Switch 38006565 1 38006565 5 38006565 5

Light Bulb 38335212 2 38335212 2 38335212 2

Transformer Primary Fuse 38015244 2 38015244 2 38015244 2

Transformer Secondary Fuse 38006870 1 38006870 1 38006870 1

Heater Fuses 38015285 3 38006854 3 38006854 3

Control Fuses 38015236 1 38015236 1 38015236 1

Control Relay Consult factory

Heater Contactor 38049383 1 38049409 1 38049409 1

5.4 PARTS LIST FOR TZE2500 TO TZE3500

Description TZE2500 TZE3000 TZE3500

Part # Qty Part # Qty Part # Qty

Consumables

Prefilter ( Element Only )

Afterfilter ( Element Only )

Pilot Air Filter Element 38049474 1 38049474 2 38049474 2

Depressurization Muffler 38328175 2 38328175 2 38328175 2

Activated Alumina – Pounds 38335253 3444 38335253 4620

Probe Recalibration 38049482 1 38049482 1 38049482 1

LDP Option

Activated Alumina – Pounds

Molecular Sieve 4A – Pounds 38340030 1136 38340030 1524

Inlet Valve

Inlet Valve Kit/ 38438883 2 38438891 2 38438891 2

Inlet Valve

Solenoid Block 38015871 1 38332391 1 38332391 1

Gasket Consult factory

Outlet Valve

Refer to filter

38335253

38438859 2 38438867 2 38438867 2

2308

nameplate or

consult factory

38335253

3096

38335253 5610

38335253

38340030 1852

3758

34

Page 41

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

Valve Kit 38437299 1 38437307 1 38437307

Check Valve 38015764 2 38015822 2 38015822 2

Gasket 38329637 4 38329645 4 38329645 4

35

Page 42

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

5.4 PARTS LIST FOR TZE2500 TO TZE3500 (CONTINUED)

Description TZE2500 TZE3000 TZE3500

Purge

Purge Valve 38007019 2 38007035 2 38007035 2

Purge Valve Gasket 38027769 4 38329637 4 38329637 4

Exhaust Valve 38438842 2 38438859 2 38438859 2

Exhaust Valve Kit 38438875 2 38438883 2 38438883 2

3V Bypass Option

Manual Butterfly Valve Kit 38049607 3 Consult factory 3 Consult factory 3

Gasket, 3-inch 38329637 6 Consult factory 6 Consult factory 4

Bypass Valve Consult factory Consult factory Consult factory

EMS

Digital Panel Meter 38431730 1 38431730 1 38431730 1

Replacement Parts

Pressure Gauge 38006714 3 38006714 3 38006714 3

PLC 38028759 1 38028759 1 38028759 1

Power Supply 38328357 1 38328357 1 38328357 1

Text Display 38018065 1 38018065 1 38018065 1

Thermocouple 38031001 1 38031001 1 38031001 1

Relief Valve 38026852 2 38026852 2 38026852 2

Temperature Indicator 38006706 2 38006706 2 38006706 2

Heater 38015467 1 38015418 1 38028700 1

Gasket Consult factory Consult factory Consult factory

Pressure Regulator 38015145 1 38015145 1 38015145

Pressure Switch 38006565 1 38006565 5 38006565 5

Light Bulb 38335212 2 38335212 2 38335212 2

Transformer Primary Fuse 38015244 2 38015244 2 38015244 2

Transformer Secondary Fuse 38006870 1 38006870 1 38006870 1

Heater Fuses 38006862 3 38006847 3 38006847 3

Control Fuses 38015236 1 38015236 1 38015236 1

Control Relay Consult factory Consult factory Consult factory

Heater Contactor 38338786 1 38049391 1 38049391 1

36

Page 43

USER MANUAL

TZE400 to TZE3500 with EMS

REV 10 – 23 February 2006

37

Page 44

USER MANUAL

6. FAULTS AND TROUBLESHOOTING

6.1 DEWPOINT HAS DETERIORATED

POSSIBLE CAUSE REMEDY

Check compressor after cooler and cooling

Incoming air temperature above design

condition.

Incoming air flow too high

Inlet pressure below design pressure.

Liquid water entering dryer

system.

Adjust as necessary to reduce the inlet

temperature to dryer specification.

Problem external to dryer. Verify inlet flow

rate and reduce as necessary to dryer

specification.

Check compressed air system. Correct if

necessary

Check prefilter elements and seals for

damage. Replace if necessary.

Check operation of drain trap. Ensure

proper drainage. Repair or replace drain if

necessary.