Ingersoll-Rand P-130 SD, P-130 WD Operating & Maintenance Manual With Spare Parts List

INGERSOll-RAND

Doosan purchased Bobcat Company from Ingersoll-Rand Company in

2007. Any reference to Ingersoll-Rand Company or use of trademarks,

service marks, logos, or other proprietary identifying marks belonging

to Ingersoll-Rand Company in this manual is his torical or nominative

in nature, and is not meant to suggest a current affiliation between

Ingersoll-Rand C

ompany and Doosan

Company or the products of

e

ith

er.

OPERATING & MAINTENANCE MANUAL

wilh spare paris IIsl

MANUAL O'UTILISATION ET O'ENTRETIEN

avec calalogue de pieces delachees

BEDIENUNGS-UND WARTUNGSANLEITUNG

mil ersalzlelllisle

L1BRO

D'USO E MANUTENZIONE

con IIsla rlcambl

MANUAL DE MANEJO Y MANTENIMIENTO

con

L1sla

U~I,

SERIAL No. RANGE

J.e ....

J

l.:AJ1

eW

FROM TO

__

3_00_0_0_1

de Repueslos

J-:.I,)

~Li

~_I

e-e

1_--,-32_1-,-9_99_-1

INGERSOLL-RAND

Revised (09-12)

OPERATING & MAINTENANCE MANUAL

MANUAL D'UTILISATION ET D'ENTRETIEN

BEDIENUNGS-UND WARTUNGSANLEITUNG

c

o IIl6ERSOUfWlD'

L1BRO

MANUAL

PARTS BOOK C.P.N. 92789320

D'USO E MANUTENZIONE

DE

MANEJO Y MANTENIMIENTO

ISSUE

No.4

DATE:

JUNE 1990

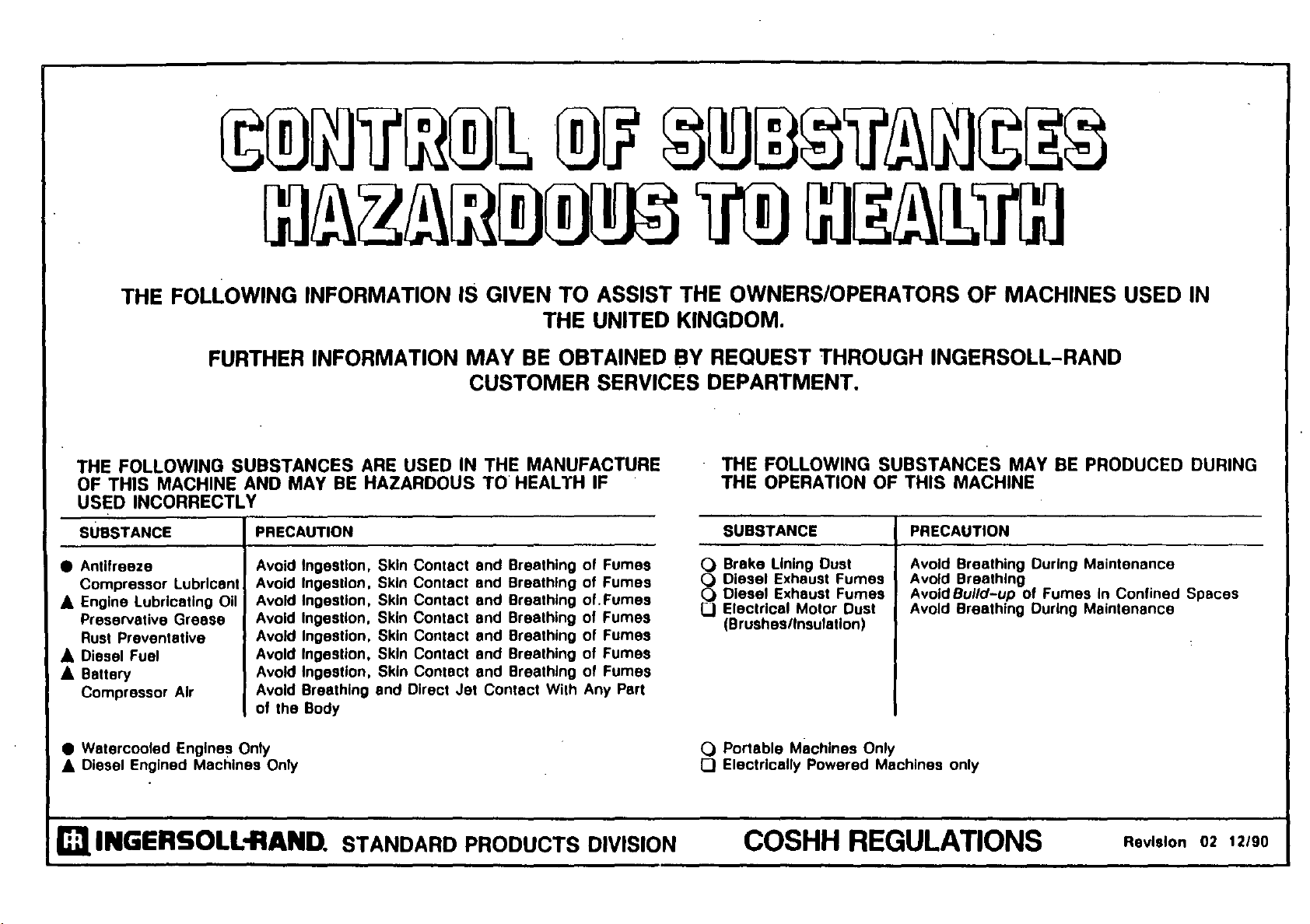

THE FOLLOWING INFORMATION IS GIVEN

TO

ASSIST THE OWNERS/OPERA TORS OF MACHINES USED IN

THE UNITED KINGDOM.

FURTHER INFORMATION

THE

FOLLOWING

OF

THIS

USED

SUBSTANCE

• Antifreeze

Compressor Lubricant

A Engine Lubricating

Preservative Grease

Rusl Preventative

MACHINE

INCORRECTLY

A Diesel Fuel

A Ballery

Compressor Air

• Watercooled Engines Only

A Diesel Englned Machines Only

SUBSTANCES

AND

PRECAUTION

Avoid Ingestion, Skin Contact end Breathing of Fumes

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion, Skin Contact and Breathing of.Fumes

011

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion. Skin Contacl and Breathing

Avoid Ingestion, Skin Contact and Breathing of Fumes

Avoid Breathing and Direct Jet Contact With Any Part

01

the Body

MAY

ARE

USEDINTHE

BE

HAZARDOUS

MAY

BE OBTAINED BY REQUEST THROUGH INGERSOLL-RAND

CUSTOMER SERVICES DEPARTMENT.

THE

MANUFACTURE

TO

HEALTH

IF

FOLLOWING

THE

OPERATION

SUBSTANCE

o Brake Lining Dust

01

01

of

01

Fumes

Fumes

Fumes

Fumes

o Diesel Exheust Fumes

o Diesel Exhaust Fumes

a Eleclrlcal Molor Dust

(Brushesllnsulatlon)

o Portable Machines Only

o Electrically Powered Machines only

SUBSTANCES

OF

THIS

MACHINE

PRECAUTION

Avoid Breathing During Maintenance

Avoid Breethlng

Avoid

Build-Up

Avoid Breethlng During Maintenance

MAY

BE

PRODUCED

01

FumesInConlined Spaces

DURING

mlINGER50LL-RAND. STANDARD PRODUCTS DIVISION

COSHH

REGULATIONS

Revision 02

12/90

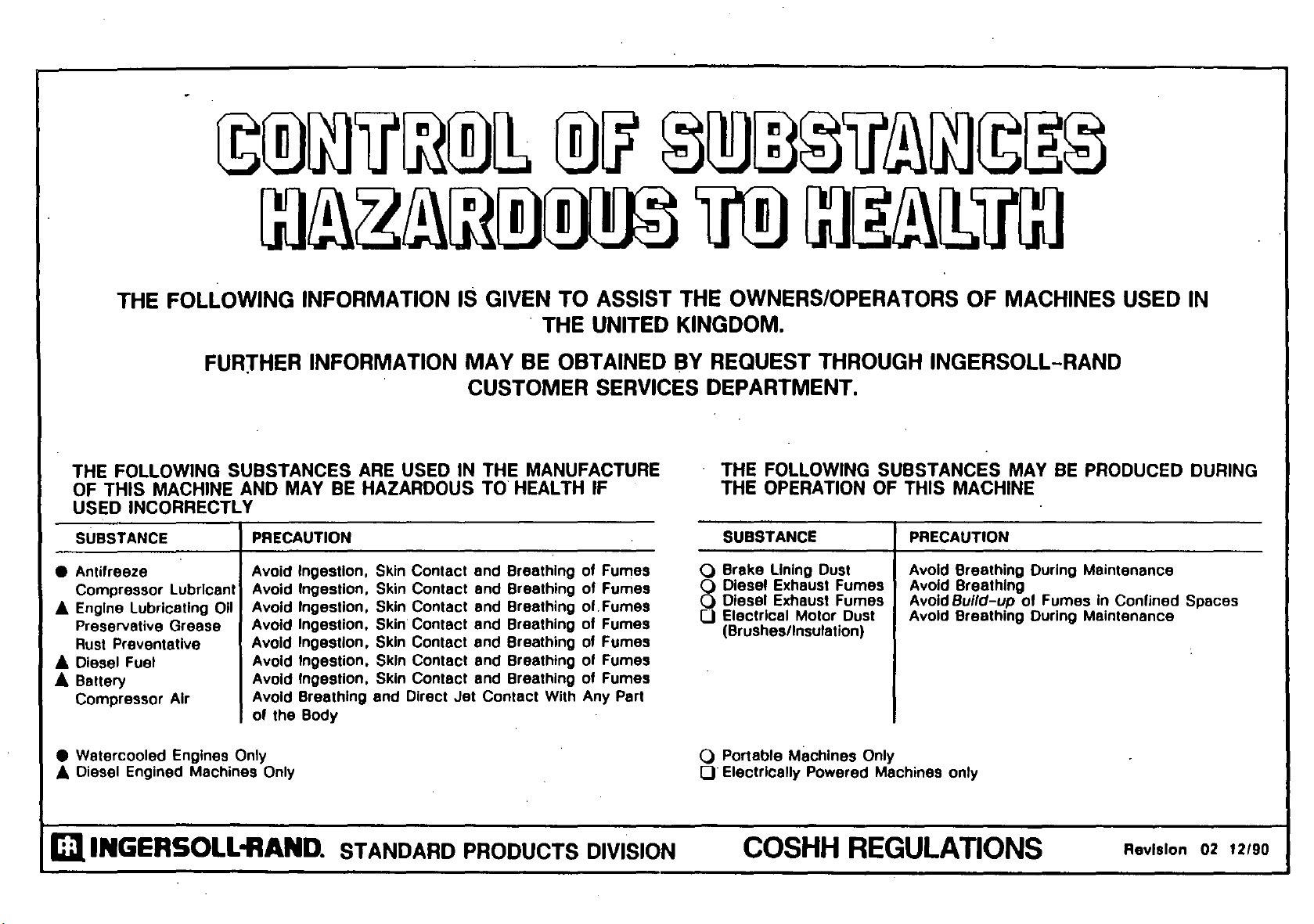

THE FOLLOWING INFORMATION IS GIVEN

. THE UNITED KINGDOM.

TO

ASSIST THE OWNERS/OPERATORS

OF

MACHINES USED

IN

FURTHER INFORMATION

THE

FOLLOWING

OF

THIS

USED

SUBSTANCE

• Antilreeze

Compressor

... Engine

Preservative Grease

Rust

... Diesel Fuel

...

Ballery

Compressor Air

• Watercooled Engines Only

... Diesel Englned Machines Only

MACHINE

INCORRECTLY

lubricant

lubricating

Preventative

SUBSTANCES

AND

PRECAUTION

Avoid Ingestion, Skin Contact and Breathing01Fumes

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion, Skin Contact and Breathing ol.Fumes

011

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion, Skin Contact and Breathing

Avoid Ingestion, Skin Contacl and Breathing of Fumes

Avoid Ingestion, Skin Contact and Breathing

Avoid Breathing and Direct Jet Contact With Any Part

01

the Body

MAY

ARE

USED

BE

HAZARDOUS

MAYBE

OBTAINED BY REQUEST THROUGH INGERSOLL-RAND

CUSTOMER SERVICES DEPARTMENT.

THE

IN

THE

MANUFACTURE

TO

HEALTH

IF

FOLLOWING

THE

OPERATION

SUBSTANCE

o Brake Lining Dust

01

01

01

01

Fumes

Fumes

Fumes

Fumes

o Diesel Exhaust Fumes

o Diesel Exhaust Fumes

o Eleclrlcal Molor Dust

(Brushesllnsulatlon)

o Portable Machines Only

O·

Electrically Powered Machines only

SUBSTANCES

OF

THIS

MACHINE

PRECAUTION

Avoid Breathing During Maintenance

Avoid Breathing

Build-up

Avoid

Avoid Breathing During Maintenance

MAY

BE

PRODUCED

01

FumesInConfined Spaces

DURING

IIlINGERSOLL-RAND.

STANDARD PRODUCTS DIVISION

COSHH

REGULATIONS

Ravlslon 02 12190

0.0

The

contentsofthis

consideredtobe

and confidential

Ingersoll-Rand

be

reproduced

without

consent

Company

Nothing

document

extend

or

representation,

or

implied,

products

Any

such

terms

and

products shall

accordance

Ingersoll-Rand's standard

terms

and

such

available

FOREWORD

I

manual

proprietary

and

should

for

the

of

Limited.

contained

any

described herein.

warrantiesorother

conditionsofsale

distribution

prior

Ingersoll-Rand

is

intended

promise,

expressed

regarding the

conditionsofsale

products,

upon

which

reQuest.

written

in

warranty

be

Ingersoll-Rand Company

Limited

make

improvements

without

incurring

make

such

products

The

than

Ingersoll-Rand

list

conditions

Ingersoll-Rand

limited

Therefore

Company

held

equipment

non-approved

reserves

changes

notice

any

such

changesoradd

improvements

sold

previously.

useofrepair

those

included

may

approved

create

over

has

Ingersoll-Rand

limited

responsible

repair

the

right

or

to

products

and

without

obligation

parts

within

hazardous

Company

no

control.

cannot

in

parts

other

parts

which

which

installed.

COPYRIGHTC 1988

AVANT·PROPOS VORWORT

are

Le

consid~r~

Ingersoll·Rand

to

not

confidentielelne

reprodui!

consentement

soci~!~

contenudece

comme

pour

Ingerson-Rand

appartenanl

el

doil

distribution

ecr~

prealable

manuel

comme

pas

sans

Company

~tre

de

limited

Aucun

this

to

of

in

with

for

are

to

add

to

to

the

be

for

are

elementducontenu

document

representant

garan~e.nirepresenta~on.

explicile~

produits

garantiesdecelte

autres

des

auxtermesetcondilionsstandard

la

vente

conditions

sur

La

n'est

entendu

aucune

ni

implici!e~

quiysonl

termesetconditions

produits

dewont

soci~!~

Ingersoll-Rand

desdits

produits,

que

demande.

soci~te

I'on

Ingerson-Rand

limitedsereserveIedroil

des

modificationsoud'ajouter

perfectionnemenls

sans

preavisetsans

quoi

que

ce

d'apporterdetelles

d'ajoulerdeleis

aux

proouils

L'utilisation

autres

que

dansIensle

approlN<!es

engendrer

dangereuses

soc;el~

Ingerson-Rand

limited

n'a

consequent,

Ingersoll-randnepeut

comme

equipemenls

monte

des

soit

modifications

pertedionnemenls

vendus

anterieuremenl

de

pi~es

celles

qui

des

pi~ces

par

Ingersoll-rand

des

sur

aucun

la

responsable

sur

lesquels

piecesdereparation

de

comme

promesse,

eu

!!gard

decr~s

natureoutaus

litre

aux

Toules

de

vente

conformes

pour

termes

poorra

oblenir

Company

d'apporter

aux

de

sont

des

proouits

encourir

I'obligation

reparation

induses

qui

sont

paul

conditions

lesquelles

Company

contr61e.

pas

par

soci~t~

etre

lenue

des

~

est

non

homologuees.

est

Die

a

Handbuch

Ingersoll-Rand

Inhalt

Ie

Informationen

Ie

vOfherige,

der

limited

weitergegeben

ce

Es

beschriebenen

ni

erlei

leislungen

k1arungen

implizierter

eistungen

mongen

de

Verkaufvan

la

den

et

und

von

Ingersoll-Rand

die

kOnnen.

Ingersoll-Rand

behalt

en

vorherigen

verandern

ni

enlsleht

hierdurch

salche

Verbesserungen

bereits

vQfzunehmen.

Der

der

la

migten

sind,

zur

EinfluB

Company

kelnerlei

Maschinenteile

die

eingebaut

Eigentumerrechteandiesem

sind

der

Firma

varbehalten.

enthal!

schriftliche

Ingersoll-Rand

vervielfaltigt

enthaltinBezug

Versprechen,

ausdriicklicher

Natur.

oder

und

Bedingungen

Produkten

A1lgemeinen

Bedingungen

Produklen

vertrauliche

und

darf

nicht

Einwilligung

Company

oderanllrille

werden.

aul

Ptodukte

oder

Garantieer-

Aile

andere

miissen

Bestimmungen

liir

den

der

ohne

die

darin

kein-

Gewahr-

oder

Gewahr-

Bestim·

fOr

Verkauf

Firma

iibereinstimmen,

bei

Bedart

sich

angelordert

Company

var,

ihre

werden

Ptodukle

Limited

ohne

Ankiindigung

oderzuverbessern.

der

keinerlel

Veranderungen

Gesellschaft

Verpflichtung,

oder

nachtraglich

verkauften

Einbau

von

van

Ingersoll-Rand

Ersatzteilliste

kann

gefahrliche

Folge

haben,

van

Limited

Verantwortung

nicht

genehmigle

worden

Produkten

Teilen,

die

nlcht

geneh-

enthalten

Situationen

die

sich

Ingersoll-Rand

kann

liir

Gbernehmen,

solche

Ersatztetle

sind.

dem

daher

PREFAZIONE

II

contenulo di questa Manuale

II

di proprielA privata della

Ingersoll-Rand e

Der

essere

riprodotto

distribuito

.

permesso

senza

Ingersoll-Rand Company

Limited

Nonsidave

nessuna

contenute

documento

estendere

garanzia0rappresentazione,

implicita

dei prodotti qui descritti.

den

garanzie,

mit

condizioni

prodotti

normali

delle

qualsiasi

0

esplicita.

0

di

saranno

TerminieCondizioni

Vendita della Ingersollper

tali prodalii, che sana

disponibiliarischiesta.

La

Ingersoll-Rand Company

LimitedsiriservaIIdiritlo

apportare

zu

miglioramentlaiprodolll senza

Es

dame

sanza

cambiamenti

previo

incorrereinqualsiasi

obbligo di dover apportare tali

cambiamentl0miglioramenti

an

ai

prodolli che sana giil stati

vend

uti.

Riparazionl falle can parti

in

differenti da quelle incluse

nella

lista

delle parti approvate

dalla Ingersoll-Rand

controllo. Pertanto,possono

creare

condiaioni

su

cui

la

Ingersoll-

Company limited

in

responsabile

apparecchiatureincui

state

installate parti che non

sono

del

tipo

approvalo.

non

per

essere

iI

scritto

presumere

in

sia

altri

previa

informazioni

questa

data

premessa,

a

riguardo

termini

vendita

conforml

Rand

awertimento

non

pericolose

Rand

non

per

siano

dave

della

che

per

Tali

dei

di

ha

Ie

PREFACIO

EI

contenidodeeste

propiedad de Ingersoll-Rand y

no

puede

parasudistribuci6n

consentimiento

ser

escritodela

Ingersoll-Rand Company

Lim~ed.

Nada de10contenidoeneste

documento

de

garantfa

expresa0insinuada,

a

los

mismo. Todas

otros

de venta de productos estaran

0

de

acuerdo

condiciones

ai

Ingersoll-Rand paralaventa

di

de

tales

se

ofrecen

su

solicitud.

significa

cualquier

0

representaci6n,

productos descritosenel

las

tllrminos0condiciones

con

los

standard

produetos,

disponibles

Ingersoll-Rand Company

Limitedsereservaelderecho

cambiar

0

a productos vendldos

previa

e

EI

Quenosean

listadepiezas

oanadir

mente.

usadepiezas

las

tales

de reparaci6n

incluidasenla

aprobada por

Ingersoll-Rand puede originar

condiciones

las

cualesnotiene

peligrosas

Ingersoll-Rand Company. Asl

pues,

Companynose

de

eQuiposenlos

han

instalado

Ingersoll-Rand

responsabiliza

reparaci6nnoaprobadas.

II

manual

reproducido

sin

previo

extensi6n

promesa,

referente

garanll..u

tllrminos

de

las

cuales

previa

mejoras

sobre

control

cuales

piezas

se

de

es

la

y

4"iL,.;1

)lJ.>.1

Jl.>,

~

a

.;,..

ctl;.t:-'-

i.L...:..l1

....

-lJ1) _J

<S

;r

c;--

t,.,t.,:.J lSl.

j".,t'i

J""";'I

UrJu,..J1

i.r-:J'

' -lJ1) - J

J

~J...,

~j;:ll

<..,,~I

. i'J..bJ1

~;-5-;

•

..;

"I

JI

~~;1~

~L:.,

JI

.;..~~«I~I

.;..~I

,l,JrJI

C7

......

,

.:r--4"-

to'

r~

J

l!l-i

J ",I

,l,JrJ

'Ii ";;J

~I)

. .,.u.J1 ,J;s. i}I;:11

i,

J.L>J.\

~I)

._

JI.;.JI~~'

~J.L

.;..~I'y';"l;,..t

'I

.;..l.I}Ji

<....;L.,.;I

.,oJ1

JI

.;..L,.::.I.I~.;..t...:,.....:.J1

~I

&-'ll

)l>

»l,;:

..;l;;

........

,....s;;1

r

)L;:-I

j;f:

<JJ';"" i'J..bJi

__

I..;

.bi

o.-S

c-

.-.J'''''

•

.1...

.;.Jl:!~

........

~\

U A

..,.;~

~

wl)l

~i)_J

....

.c...ll

il.

.:r-"=<

...

JAW

.1.A.iJ1

JI

r::--<r>

'

. .,;

<:.,11

.;..~\

r~1

iT'

lA~

~~

............

- J....

~'i

«,WI

';"~I

J

........

~I

U r

Jl>.,)\

~

JU:.i

«t.;

4:)1

~J""J

.;..I~I

d'i

~

'~

JI.--:--I

WLiJ<..:.....;;ll

J.i

.LI)_

J....

~'i

<Sri)"""

'I

~lJJ

. uJ..bJ1

~I)_J~i

-,.;

-

.;..1

r"

.

i...t..:-~

.J'?U

~

~i

'J

~

j

ctl;

~I

«I

~I

;r

"I

-

INDEX

OPERATION &

TABLE DES MATERIERES

UTILISATION & ENTRETIEN

INHALTSVERZEICHNIS

UNO

BETRIEB

WARTUNG

IN

DICE

MANUTENZIONE

IN

DICE

FUNCIONAMIENTO Y

MAINTENANCE MANTENIMIENTO

Forward

0.0

Operation

2.0

Lubrication

3.0

Maintenance

4.0

Speed&Pressure

5.0

Fault

6.0

7.0

Eloctrical

SPARE

PARTS

Running

7.1.0

Engino/Airend

7.2.0

Enclosure

7.3.0

Air

7.4.0

Oil

7.5.0

Fuel

7.6.0

Regulation

7.7.0

Electrical

7.8.0

7.9.0

Decals

Options

7.10.0

Recommended

7.t1.0

,

Index-Fasteners

7.12.0

Index·

7.13.0

0.0 Avant-propos 0.0

Utilisation

2.0

Graissage 3.0

3.0

Entretien

4.0

5.0

Regulation

Finding

Regulation

de

6.0 Detection

7.0 Systeme electrique 7.0 Elekrisches System

pression

des

de

vitesse

delau!s

at

System

LIST

Gear 7.1.0

Assembly

Intake/Exhaust

System/Lilting Bail

Assembly

LISTE

RECHANGE

7.2.0

7.3.0

7.4.0 Ensemble 7.5.0

DES

PIECES

Trainderoulement

Ensemble

cOte

air/mateur

Enveloppe

amenagement de

levage/systeme

DE

Cooler/Separator d'echappemenV 7.6.0

Tank/Oil&Air

System

Parts/Maintenance 7.9.0

Service

Parts

System

System

Kits

Piping

Spare

prise

d'air 7.7.0

Refroidisseur

7.5.0

reservoir

tuyauterie

7.6.0

Circuitdecombustible

Systeme

7.7.0

Systeme

7.8.0

Oecalcomanies

7.10.0 Options

7.11.0

Piecesderecharge

recommandeesl

trousses

d'huile/ 7.8.0

separateur/ 7.9.0

huile&air

de

regulation

electrique 7.12.0

d'entretien

atdeservice

Index-Fixations

7.12.0

7.

t3.0 Index - Pieces

EinfUhrung

2.0 Betrieb

Schmierung

4.0 Wartung

5.0 Geschwindigkeits·

und

6.0

Druckvorschritten

Fehlersuche

ERSATZTEIL-VERZEICHNIS

7.1.0 Fahrwerk

7.2.0

Bausatz

Motor/Kompressor

7.3.0 Gehause

7.4.0 Luftansaugung/Abgas

Bausalz

Kraftstoffsystem

Regelsystem

Elektrisches

Schilder

7.10.0

7.11.0 Emplohlener Ersatzteill

Inhalsverzeichnis

Olklihler/

Abscheider TanklOI-

und

Luftrohrleitungen

System

Sonderausrustungen

Wartungsalz

-

VerschlUsse

7.13.0

Inhaltsvezeichnis

-

Teila

Introduzione

0.0

Funzionamento

2.0

3.0

Lubrificazione

4.0

Manutenzione

Regolazione

5.0

e

6.0

Ricerca

Impianto

7.0

ELENCO

Pressione

PARTI

Velocilll 4.0

Gausti

Elettrico

01

RICAMBIO

7.1.0 Parti Mobili

7.2.0

Montaggio

del

Motore/Compressore

Contenitore

7.3.0

7.4.0

Presa

Ariallmpianto

SCappamento/

Montaggio

Manici

Sollevamento

7.5.0 Raffreddamento

Separatoreffubature

OlioedAria

7.6.0

Impianto

Alimentazione

Impianto

7.7.0

Impianto Elettrico

7.8.0

7.9.0 Calcomanie

7.10.0

Opzioni

7.11.0

PartidiRicambio

Consigliate/Kit 7.9.0 Calcomanlas

Regolazione

Servizo/Mantenzione

Indice-Dispositivi

7.12.0

Fissaggio

7.13.0 Indice-Parti

Olio/

di

0.0

2.0

3.0

5.0

6.0

7.0

LISTADEPIEZAS

REPUESTO

7.1.0

7.2.0

di

7.3.0

7.4.0

7.5.0

7.6.0

7.7.0

7.10.0 Opcionea

7.11.0

Prefacio

Funcionamiento

Lubricaci6n

Mantenimiento

Regulaci6n

Velocidad y

Presi6n

localizaci6ndeaverias

Sistema electrico

Tren

rodante

Conjunto

extremodeaire

Envuelta

Sistemadeadmisi6n1

escapedeairel

Conjuntodela

de

levantamiento

Refrigerador

tanque

tuberiadeaceite y

aire

Sistema

Sistema

Juegosdeservicio/

del

combustible

electrico

mantenimianto

piezasderepuesto

recomendades

Indice-Sujetadores

7.12.0

Indice-Piezas

7.13.0

de

DE

motor/

barra

de aceite/

separador/

y

FOREWORD

In

preparing this multilanguage

pUblication, every effort has

been

sufficient information to permit

made

to

provide

an operator to perform his

duties so

as'

to receive

maximum performance and

trouble froe service from the

compressor.

All classes of

equipment, regardless of how

well built, require a certain

amount of aMentian. The

purpose of this publication is

acquaint an operator with the

functions, oporation and

servicing of the various

components. which were

built

with the very best of materials

and workmanship. to obtain

maximum

compressor.

Before starting the compressor,

the instructions

carefully read to obtain a

thorough

duties to be performed. Take

pride in the compressor, keep

it

clean, and in

mechanical

major

this publication,

nearest Ingersoll·Rand

Company

distributor from

compcssor

Correspondence

office.

always specify the serial

numberofthe

well as the model.

IHe

knowledge

servicing,

condition. For

Branch

was purchased.

or

distributor,

from the

should

of

not

covered

consult

office,orthe

whom

with a

branch

compressor

be

the

good

your

the

must

as

AVANT·

Dans

publication

ont

suffisammentd'informations

permettreaun

ses

meilleures

service

compresseur.

materiel,

leur

certain

to

publication a

I'utilisateur

I'utilisationetI'entretien

organes,

les

conformement

praliques

puisse

utileducompresseur.

AvantdemettreIecompresseur

marche,ily a

instructions

acquerir

fondie

convient

deIemaintenitenparfait

propreteetbon

Pour

in

caraclere

couvertes

consulterIebureaudela

la

PROPOS

la

preparation

muttilingue,

ete

accomplis

fonctions

construction,

les

plus

operateurderemplir

afin

performances

sans

Toutes

quelle

que

niveau

pour

avec

qui

ont

meilleures

d'execution,

obtenirIe

maximumdeduree

soigneusemenl

une

connaissance

des

fonctionsaremplir.

d'efre

fierducompresseur,

operationsdeservice

majeur

dans

proche

Ingersoll-Rand

concessionnaire

compresseuraete

correspondance

d'une

succutsale

concesslonnaire

specifierIenumaradeserie

compresseur

aussi

modele.

de

tous

efforts

pour

presenter

d'obtenir

el

incident

les

dasses

soilla

qualite

demandent

d'attention.

butdefamiliariser

les

lonctions,

des

oonstruits

malieres

meilleures

alin qu'il

de

mecanique.

publication,

succutsale

divers

lire

appro-

elat

ete

aux

lieu

elal

quinesont

cetle

delasoaete

au

aUpft3S

duquel

achete.

au

bien

Toute

avec

toujours

que

avecIebureau

do~

VORWART

cette

Diese metHsprachige Anlei-

tung soli dem Sedienungs-

personal alles Wissenswerte

pour

Gber

die

storungsfreien Betrieb vermit·

Ies

teln. Die einzelnen

un

Beschreibungen

du

Funktion.

de

Wartung vertraut machen,

de

eine optimale Leistung

un

Cette

lange Lebensdauer

Gerates zu gewahrleisten.

Die Anleitung so lite

Inbetriebnahme

avec

sors sorgfaltig gelesen

et

werden,

Bedienung

Wartung genau kennenzulernen.

Vor

en

pressors

les

Anweisungen sorgfaltig

pour

durchzulesen,

gena

II

leistenden Aufgaben erhalten

wird. Man sollte

de

Kompressor stolz sein, ihn

sauber und

de

gutem Zustand halten. GroBe

pas

Wartungen,

Wartung

um

dem

Anlassen

uses Sild

Such nichl behandell werden,

bitte an

Ingersoll-Rand Dienststelle

Ie

oder

Ie

un

du

Ie

beim Fachandler, bei

dem

det

wurde, besprechen.

Korres- pondenz

Zweigstelle

Fachhandler muB stets

Seriennummer

i..iber

Kompressor bezogen

das

Modell enthalten.

und

sollen

Sedienung

des

Kompres-

die

erforderliche

und

fachgerechte

des

sind

damit

i..iber

mechanisch

die

in diesem

der

mit

oder

und

einen

mit

der

und

um

und

des

vor

der

Kom-

die

ein

die

zu

auf

den

nachsten

Jegliche

einer

dem

die

Angaben

PREFAZIONE

sforzo

scopo

di

piu

per

condizioni

che

linguesefatto

sia, richiede

Nella stesura

blicazione in

agni

6peratore tutte Ie informazioni

necessarie per ottenere

macchina Ie migliori

prestazioncon

rispetto delle

e manutenzione.

Ogni macchina,

castruita

sempre sicure elementari

operazioni di manutenzione.

Lo

pubblicazione e di

familiarizzare I'operatore

la

manutenzione

macchina, la lubrificazione di

tutti i suoi

con

assemblati

qualificata, H tutto al fine di

ottenere la massirna durata

Vostro compressore.

Prima

compressore

leggere attentamente Ie

istruzione al fine di

in

sufficientemente

ptestazione a caratteristiche

della macchina. Cercate di

curare

mantenetelo pulito e in buone

condizione meccaniche. Per

ulteriori e

sulla manutenzione

riportati su

blicazione, consultate il

rappresentante 0

Ingersoll-Rand

qualsiasi contatto

corrispondenza

rappresentante Ingersoll-Rand

si

modello della

suo

componenti

materiali selezionati ed

de

di

awiare

e

il Vostro compressore,

piu precisi consigli

questa

piu

con

dovra sempre specificare il

numero

macchina

di matricola.

questa pub-

dare

all

dalla

iI

massmo

d'uso

per

ben

di questa

con

della

costruiti

manodopera

del

opportuno

conoscere

Ie

reali

non

pub-

filiale

vicina. Per

Ie filiali 0 il

e il

PREFACIO

ha

preparado

Se

con

sumo

cuidado

de

prop6sito

toda la informaci6n necesaria

el

para

sin averias,

Todo equipo,

mejor

daraloperario

rendimiento

del

aunque

fabricaci6n, exige

alenci6n.EIobjelo

publicaci6n, es el

COnocer al

funciones,

mantenimiento

componentes,

side fabricados

y

manodeobradeprimera

calidad,

maximolavida

Antesdela

delamaquina

atenci6n las instrucciones,

asi

para

conocim

hay

que

il

debe estar

compresor,

un

estado

limpieza ydefuncionamiento.

Cuando

un servicio

no

incluida

opera

las

operaciones

de

los

can

para

asi

prolongar

del

puestaenmarcha

hay

tener

ientodelas

que

sea

un

tamar.EIopera

orgulloso

manteniendolo

impecable

necesario

de

revisi6n mayor,

publicaci6n, se debe consullar

a la Oficina de Ingersoll-Rand

mas pr6xima, 0aldistribuidor

donde

compresor.

haga

correspondencia

especificar tanto el

COmoelnumerodeserie

0

compresor.

se

una

compr6

Cada

consulta

este

manual

con

maximo,

compresor.

seadela

de

esta

de

hacer

rio las

los distintos

cuales

compresor.

que

en

vez

y el

han

elementos

leer

can

perfecto

med

idas

de

realizar

esta

Que se

debe

modelo

del

,1.1;1

".w

, '......,

t'"

el

y

al

rio

su

en

de

t:!ili ,

-=...~l

r

......

;,~

J'-Wl

J.<

\..AJI

;ro

<,JL:l-1

$1

t:

wL;.,.!

ijl.S

~J

O,)~

~

)a..:.ll

..,.;

"..J

IJ.

"\;..j

I

J...'-'ll

~r-'

yo

~

J

.I;...e-

~I

4-'-"

"rc

.1,;.,-1

;ro

~l,.;..Al1

Q..c;,!,<

~

Js-

~I

Ut..-

J~!

•

.Lo

-r~

",.ill

.u.....lr.J:.s-J .

<J->"L

J"Jo1

, ....

\..AJI

J"..,.,...u

"IJ.,

.

1",,;,..

<}J

t...i,l;;

U'"

~

to

JL::;

'Y

~

..,,';";1

tj}1JI-"I)-

....

J-,=

cfl

.Ji..A..I

1..1

<.<l'

1S.WJ\

~.i,

o~J.d1

i.rJl

~l>J1

~I...,.wl

~

-:..,...,

",~I

;ro)oU

.

..,...1:.1.1

-..J.J""I-!

' .,;.,Lult

;roIJoU

, t,..;."

;

pJ

I •

.Lo

.....ill

...;sUo

d'

J '

lo=---'"

-

"}'

J.>il

J

\..AJI

r-'<;,I

....

•

.wl

~

1,(.;

;'Y

r41L

<;';'

....

J

.

;~

<,s:.,;i¥

<,..,J".\I ...

e:-""')

,;pJl

J"...

jel

......

...::....";";\

$1

I

"

.J;~b~tj}IJI-r;JI~1

JI

ijL..;

'YL

....

w..u

J-Lli

el

la

. J<,}I

.liJ

olA

J.-...,

....,;1

;ro

;ro

>-<

J

;ro

.}.-I

<}

J-'J

;.I}

ij.r"

\..AJ~

$1

.rJ

r')1

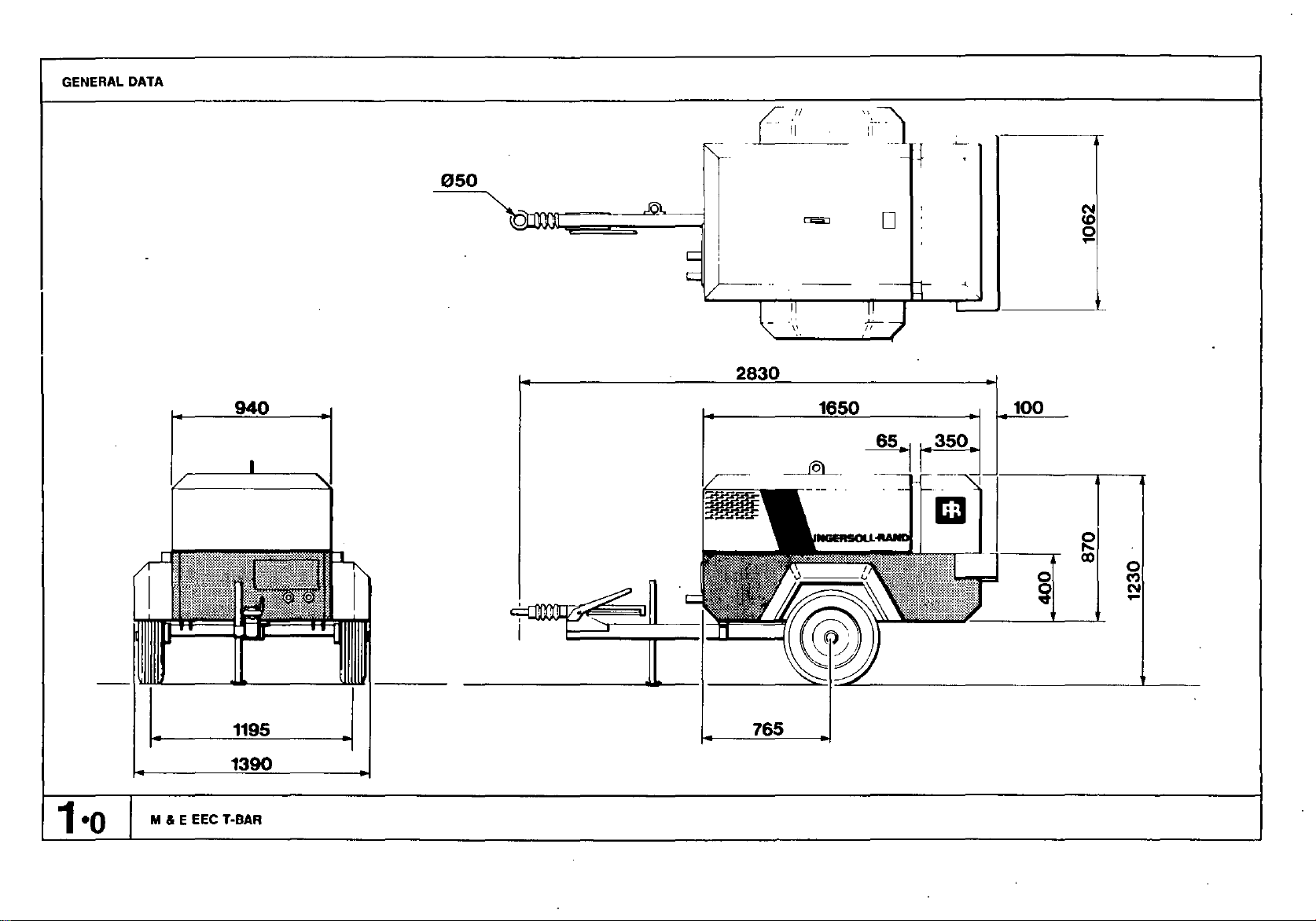

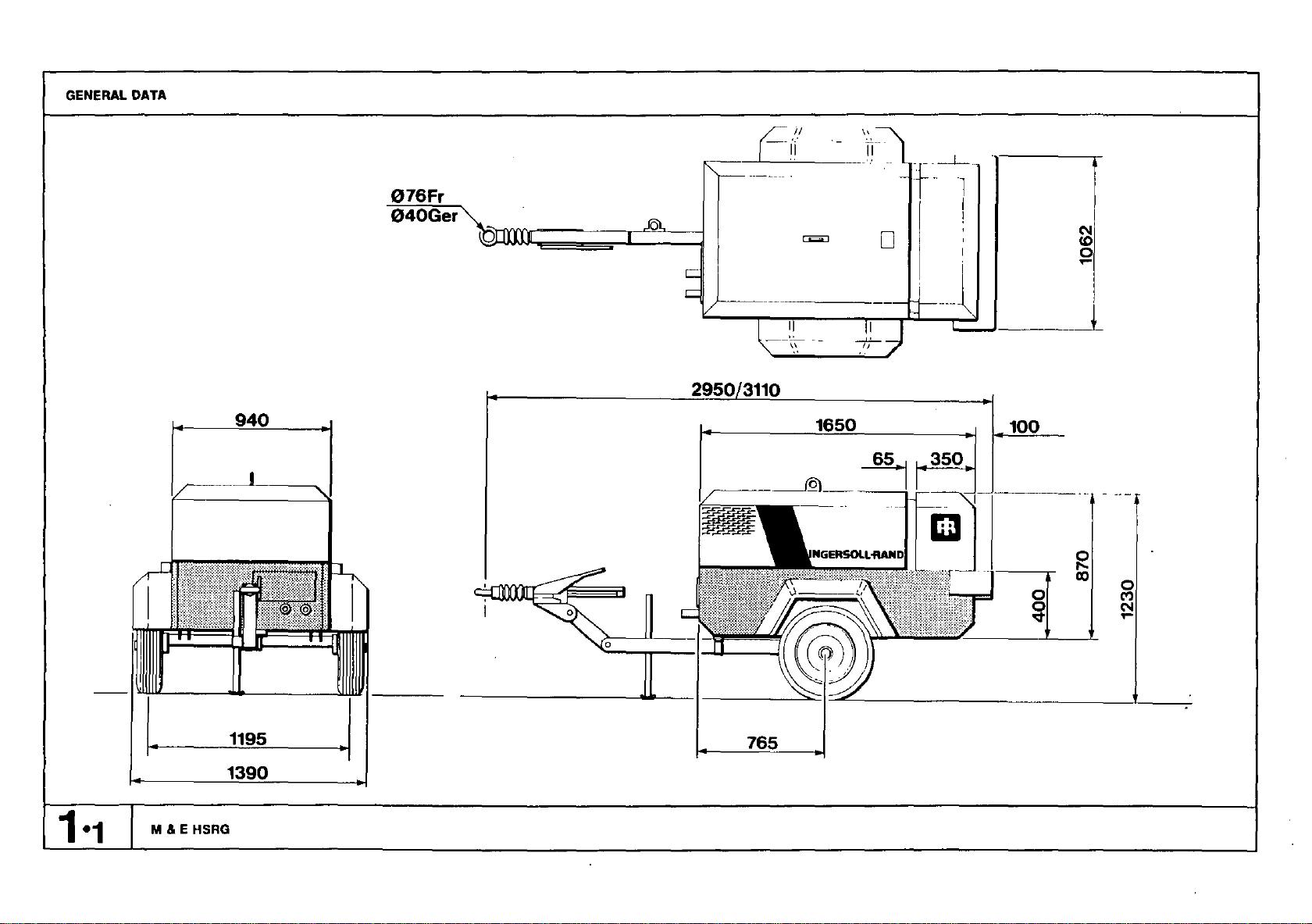

GENERAL DATA

050

~

.a

-

--

I"

~

c::

~L-.--

2830

II

II

~

" "

c=J

~_

..

II

--+

D

--

~}

tt

-~.-

"

-

,

10

'"

0

...

1-0

940

[

1390

M " E EEC T·BAR

100

....

I

"I

I'

~

~

765

@

.65>11_

350

mI

j

I

R

CIO

0

0

~

C')

...

'"

GENERAl DATA

076Fr

040Ger")s

IQl

-

~~f,f

(:=J

[;:

c::

1/

'\~

rt

-

0

0-

f--L

··1

I

!

,

I

i

i

..

_-~

('II

co

0

....

I.

_9-'-40_-----..'1

1195

1390

.1

--------oUo-_I

~-~,-

29503110

.

_-lQ)

I

~

o

o

-

765

-_

~

:s:::::.

Jl...~

Ii

1650

65'II·350~--j~

.....

NGERSOlL-ftAND

:::;,,~~.

_.

---

tJ

100

__

o

~

o

C'l

('II

....

----L------;-

1-1

M

&E

HSRG

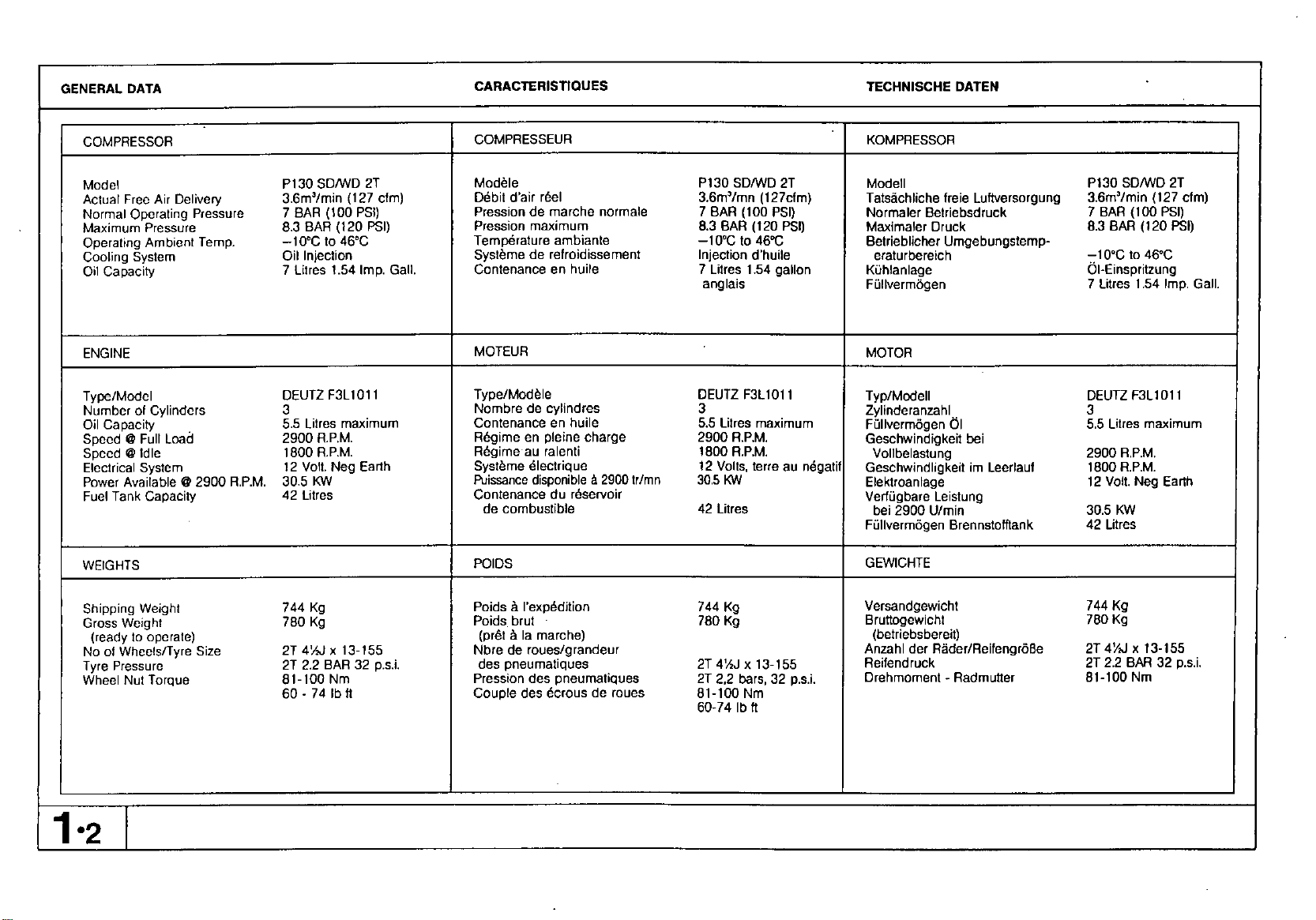

GENERAL DATA

CARACTERISTIQUES

TECHNISCHE

DATEN

COMPRESSOR

Model

Actual

Free

Air

Normal

Maximum

Operating Ambient Temp.

Cooling

Oil

Capacity

ENGINE

Type/Model

Delivery

Operating

Pressure

System

Pressure

Number01Cylinders

Oil Capacity

Speed @ Full Load

Speed @ tdle

Electrical

Power Available @ 2900

Fuel

WEIGHTS

Tank

System

Capacity

R.P.M.

P130 SDIWD 2T

3.6m'/min (127 elm)

7 BAR (100

8.3 BAR (120

-1

DoC

Oil Injection

7 Litres 1.54 Imp. Gall.

DEUTZ F3L1011

3

5.5

Litres

2900

1800

12 Volt. Neg Earth

30.5

42

Litres

PSI)

PSI)

to 46°C

maximum

R.PM

R.PM

KW

COMPRESSEUR

Modele P130 SDIWD 2T

Debil d'air reel 3.6m'/mn (127e1m)

Pression

Pression

Temperature

Systeme

Contenanceenhuile

de marcha

maximum

ambiante

de

refroidissement

normale

7 BAR (100

8.3 BAR (120

-1

DoC1046"C

Injeelion d'huile

7 Litres 1.54 gallon

PSI)

PSI)

anglais

MOTEUR

Type/Modele

Nombre de cylindres

Contenanceenhulle

Regime en pleine charge 2900 R.PM.

Regime-auralenti

Systeme

Puissance

electrique

disponiblea2900

tr/mn

DEUTZ F3L

3

5.5

1800 R.PM.

12 Volts, terre au negatil

30.5

Litres

f'N>I

1011

maximum

Contenancedureservoir

de

combustible

POIDS

42

Litres

KOMPRESSOR

Modell

Tatsachliche Ireie Luftversorgung

Normaler

Maximaler

Belrieblicher Umgebungstemp-

Betriebsdruck

Druck

eraturbereich

Kuhlanlage

FOllvermogen

MOTOR

Typ/Modell

Zylinderanzahl 3

FGllvermogen

Gesehwindigkeit bei

Vollbelastung

01

GeschwindligkeitimLeerlauf

Elektroanlage

Verfugbare

bei 2900 U/min

FUllverm6gen

GEWICHTE

Leistung

Brennstofftank

P130 SDIWD 2T

3.6m'/min (127 elm)

7 BAR (100

8.3 BAR (120

-1

DoC

PSI)

PSI)

to 46°C

OI·Einspritzung

7 Litres 1.54 Imp. Gall.

DEUTZ

F3L1011

5.5

Litres

maximum

2900

R.P.M.

1800

R.P.M.

12 Volt. Neg Earth

30.5

KW

42

Litres

Shipping Weight

Gross

(ready to operate)

NoofWheels/Tyre

Tyre

Pressure

Wheel

1-2

Weight

Nut

Torque

Size

744

Kg

780

Kg

2T

4\\J

2T

81-100Nm

60-74

x 13-155

2.2 BAR 32

Ib It

p.s.i.

PoidsaI'expedition

Poids brut 780 Kg

(pret Ii la marche)

744 Kg

Nbrederoues/grandeur

des

pneumatiques

Pression

Couple

des

pneumatiques

des

ecrousderoues

2T

4\\J

2T

2,2 bars, 32

81-100 Nm

60-74 Ib It

x 13-155

p.sJ.

Versandgewichl

Bruttogewicht

(betriebsbereit)

Anzahl der Rader/ReifengroBe

Reifendruck

Drehmoment-Radmutter

744 Kg

780 Kg

2T4Y,Jx

2T 2.2 BAR 32

81-100 Nm

13-155

p.s.i.

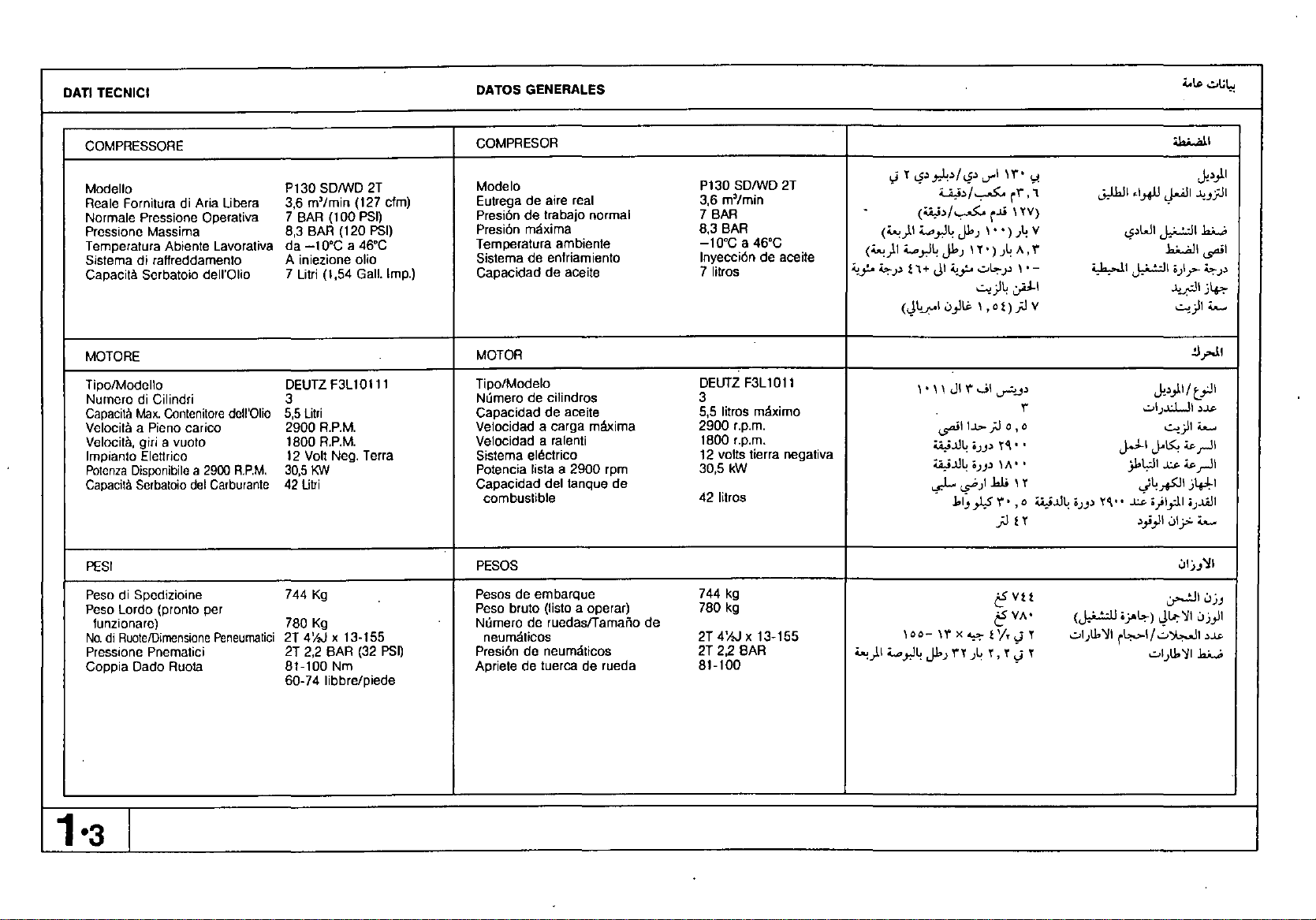

DATI

TECNICI

DATOS GENERALES

.t.\$~l;~

COMPAESSOAE

Madella

Reale

FornituradiAria

Normale

Prcssionc

Temperatura

SistemadiraHreddamento

Capacita

MOTOAE

Tipo/Madella

NumcrodiCilindri

Capacita

VelocilaaPiano

Velocila,

Impianto

Potenza

CapacJta

PESI

PesodiSpodizioine

Peso

funzionaro)

No.diRuolelDimensione

Pressione

Coppia

Pressione

Massima

Abienle

Scrbatoio

Max.

Contenitore

giriavuoto

Elettrico

Disponibilea2900

Serbaloio

Lordo

(pronto

Pnematici

Dado Auota

Operativa

Lavorativa

dell'Olio

carico

del

Carburante

per

Peneumatici

Libera

dcll'Olio

R.P.M.

P130 SDIWD 2T

3,6

m'/min

(100

BAA

R.PM

R.PM

i<N'I

Kg

BAA

(127 elm)

PSI)

(120

PSI)

a

46'C

olio

F3L10111

(32

Nm

PSI)

7 BAA

8,3

da

-W'C

A

iniezione

7 Lilr; (1,54 Gall, Imp,)

DEUTZ

3

5,5

Litri

2900

1800

12

Volt Neg, Terra

30,5

42

Utri

744

780 Kg

2T 4/'.1 x 13-155

2T 2,2

81-100

60-74Iibbre/piede

COMPAESOA

Modelo

Eutregadeaire real

Presi6ndeIrabajo normal

Presi6n

Temperatura

Sistemadeentriamiento

Capacidad de

MOTOA

Tipo/Modelo

Numeradecilindros

Capacidaddeaceite

Velocidadacarga

Velocidadaralenti

Sistema

Potencia

Capaeidad

PESOS

PesosdeembarQue

Peso

NumeroderuedaslTamano

Presi6ndeneumaticos

Aprietedetuercaderueda

maxima

electrico

lista

combustible

bruto

neumaticos

ambiente

aceite

maxima

a 2900

tanque

rpm

de

del

(Iistoaoperar)

de

P130 SDIWD 2T

3,6

m3/min

7 BAR

8,3

BAA

-10'Ca46'C

Inyecci6ndeaceite

71itros

DEUTZ

F3L1011

3

5,5

lilros

r,p,m,

volts

maximo

tierra

13-155

BAA

negativa

2900

1800 r,p,m.

12

30,5 kW

42 Iilras

744 kg

780 kg

2T 4i'.J x

2T 2,2

81-100

.,;

.

("-<)1

(,,-<)1

~;....

~),)

,,-<)1

......,JL

y

~'~'/~'crl

~,/..,..s:..

(;;,,;,/

~

......,JL

.....

.,JL

JIo)

t1+

J'

...

..;..

(<J~10)~'

'1"'

r1""

r.Ji

'TV)

JIo)

'''»)4

,Y'»)L

";"'~J,)

"",,)4~1

,ot);J

, 'IIJI1"';1 u-"-J'

~II.J.>-

U:iJJ4

U:iJJ4

.r-

0))-'

0))-'

cr';I

11).AS

;J

.b.l;

0

,.~

'A'

'(.

;J

e'Vt!

e'VA'

'00-

,'(x~tY'J"

JIo)

n)L

Y,

Y~Y

A,

,.-

1"

,0

..

•

'Y

,0

t Y

Yo

V

1"

~1~loir'''~J,)

V

U:iJJ4

0))-'

(~'f'",")

"-'1;11

u.w.J.1

J,lhll .I.*J J--'ll

~,WI

~I

J,,;,.AJI

.L"plj~

""")1 ......

J')I/tfll

..:..o1).x..LJl

~)l~

J-J-I

Jots:,

jkl.,:Jl

J;;

.;4.,.p:JIj

,.~

••

..l.:.&-

ojl?1

,,,;)101j" ......

~'j)'.il

~10jJ

<J"''j10j)1

'jl

rL,...-1/"-')l.,..J1

"-'1)1k

...

~

;)..wl

'jl

J,)I

-,<J;JI

J,,;.,.;

~I

!lr-l

,)Js.

;-31

;-31

4-J:-1

'J.>

J,,;.,.;

l

1-3

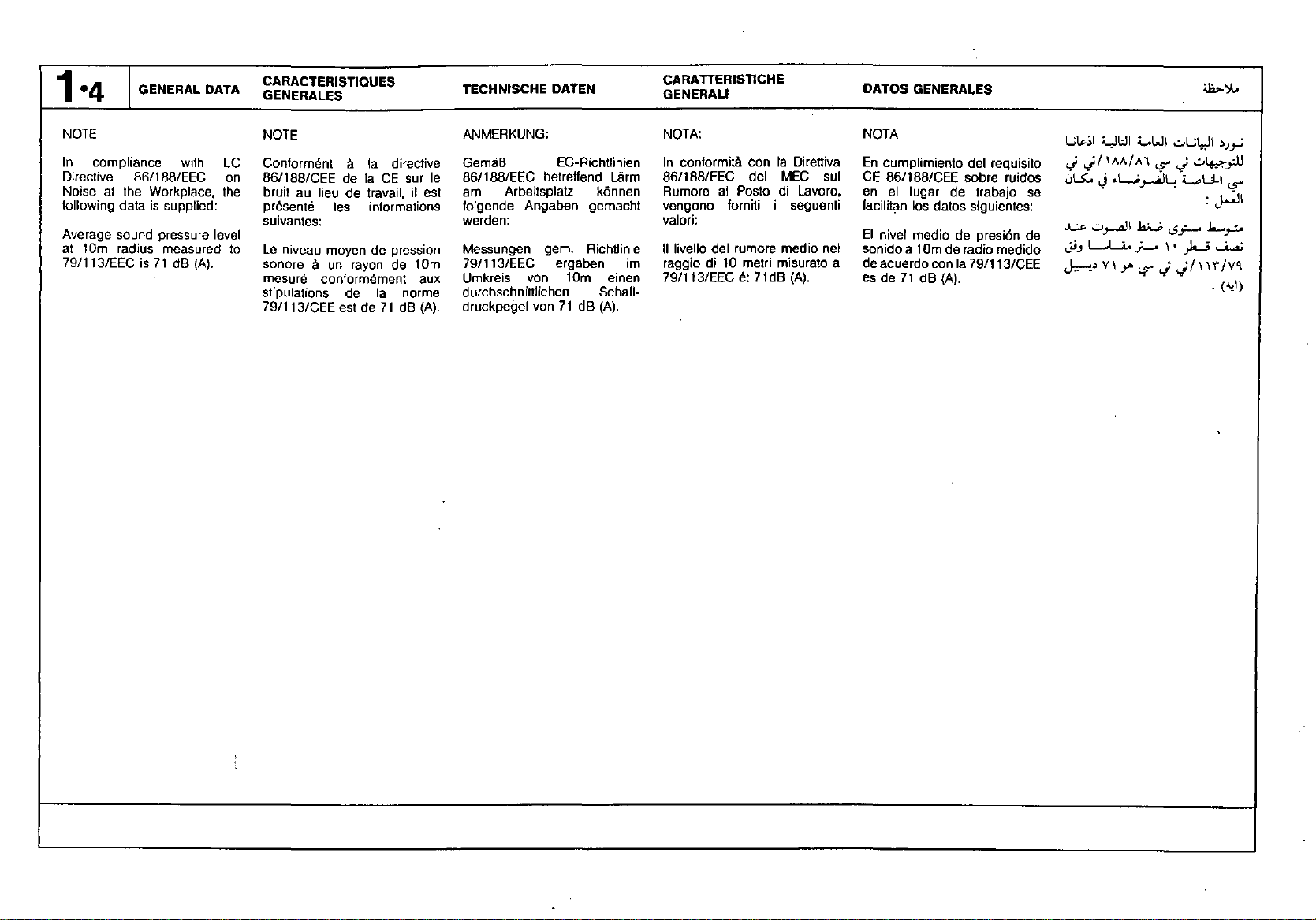

GENERAL DATA

CARACTERISTIQUES

GENERALES

TECHNISCHE DATEN

CARATTERlsnCHE

GENERAL!

DATOS GENERALES

NOTE

In

compliance

Direclive

Noise al Ihe Workplace, Ihe

following

Average

at

791113/EEGis71dB(A).

dataissupplied:

sound

10m radius measured

with

861188/EEG

pressure

EC

on

level

NOTE

Conferment

861188/GEEdela

bruit au

presents

suivantes:

to

La

niveau moyen de pression

sonOreaun

masura conformement aux

stipulations de

79/113/GEE esl de71dB

a.

lieudetravail,ilest

les

rayon

la

directive

GE

sur

informations

de

10m

la

norma

(A).

ANMERKUNG:

GemaB

86/188/EEG belreffend Liirm

Ie

am Arbeitsplatz

lolgende Angaben gemachl

EG-Richtlinien

werden:

Messungen gem. Richtlinie

79/113/EEG ergaben

Umkreis

durchschninlichen Schalldruckpegel

von

von71dB

10m

kennan

im

einen

(A).

NOTA:

In

conformitA

86/188/EEG del

RumorealPostadiLavero,

vengono

conlaDirettiva

MEG

sui

fornitiiseguenti

valeri:

II

livello

del

raggio

di

79/113/EEG

rumore

10

metri

e:

71dB

media

misurato

(A).

nel

NOTA

En

cumplimiento

GE

86/188/GEE sabre ruidos

en

el

lugar de trabajo se

faciljt~n

EI

los

nivel

media de presi6n de

sonidoa10mderadio

a

de

acuerdo can

esde71dB(A).

datos

del

requisito

siguienles:

medido

la

79/113/GEE

L.;~;I

<...,JI:II

....

d

d/

IM/

A1

,:;~

.J

•L..;.,...;.jL., -

.J...;<

~.......,JI

Ju...;

~

J

L-L..i.o;'--

c.h--<'

V,

yo

<r

Wl

~L.;t"J1

<S"

d

~4?-rU

LAiL

<.SJ'-'

,.

)W

..; ..;

/ ,

'J"";

1

<S"

:~I

k...-,""

.....;.,.;

,r

/Y~

.

("I)

GENERAL

DATA

CARACTERISTIQUES

GENERALES

TECHNISCHE

DATEN

CARATTERISTICHE

GENERALI

DATOS

TECHNICOS

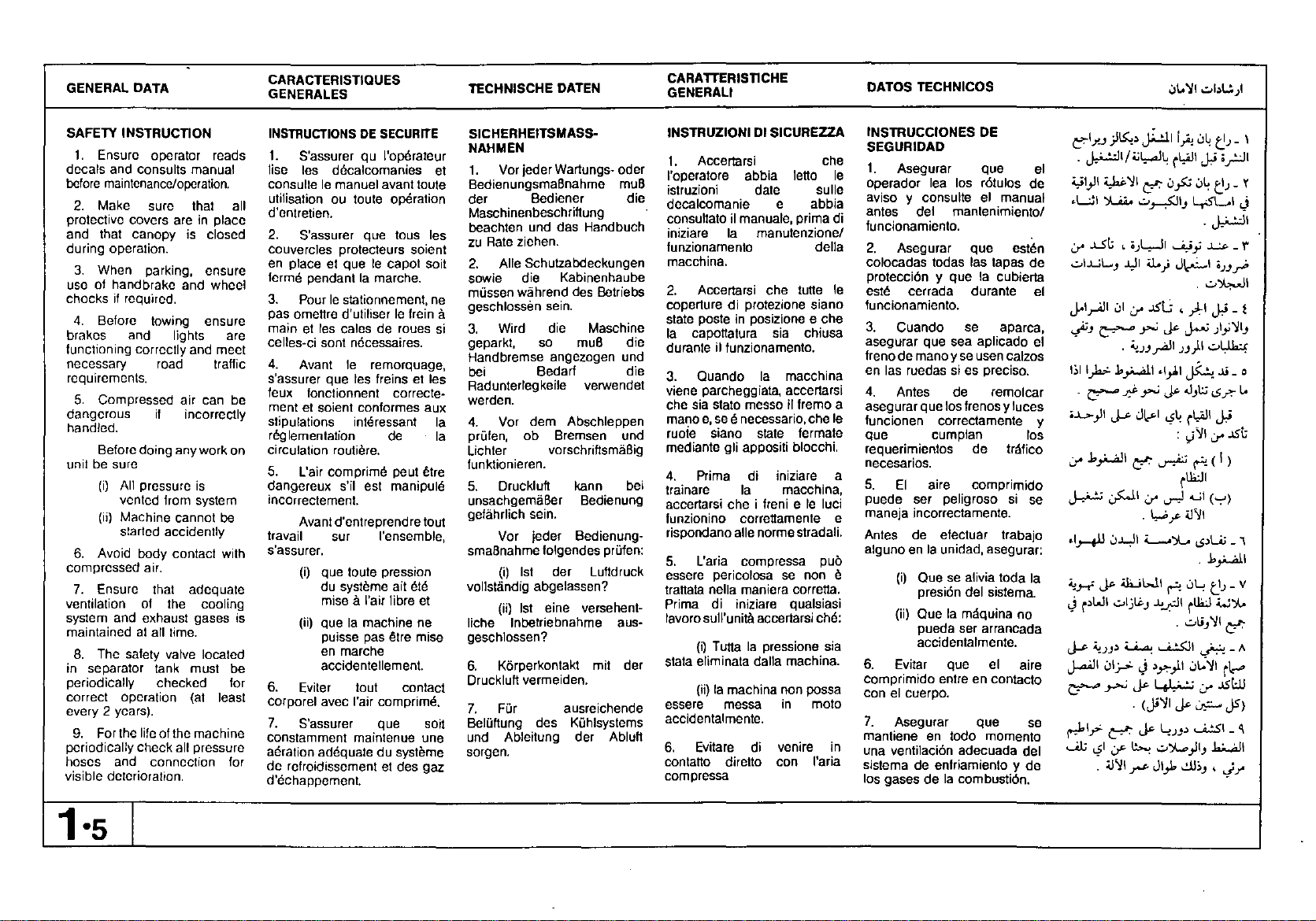

SAFETY

1.

decals and consults manual

before

2.

protective covers are in place

and that canopy is closed

during operation.

3.

usc of handbrake and wheel

chocksjfrequired.

4.

brakes and lights are

functioning

necessary road traffic

requirements.

5.

dangerous

handled.

unit be sure

6.

compressed air.

7.

ventilation of the cooling

system and exhaust gases is

maintainedatall lime.

INSTRUCTION

Ensure operator reads

mainlcnanccloperation.

Make sure Ihat all

When parking, ensure

Before towing ensure

correctly

Compressed air can

Before

doing

(i)

All pressure is

vented

(ii) MaChine

started

Avoid body contact with

Ensure that adequate

and

jf

incorrectly

any

from

cannot

accidently

meet

work

system

be

be

on

8. The safety valve located

in

separator tank must be

periodically checked for

correct operation

every 2 years).

9.

For

the

periodically check all pressure

hoses and connection for

visible deterioration.

life

(at

least

of the machine

INSTRUCTIONSDESECURITE

1.

S'assurer qu l'operateur

lisc les decalcomanies et

consulle

utilisation au toute

d'entretien.

2. S'assurer que taus les

couvercles protecteurs soient

en

ferme pendantlamarche.

3. Pour

pas omettre d'utiliser

main et les cales de roues

celles·ci sont nccessaires.

4.

s'assurer que les freins et les

feux fonctionnent correcte-

ment et soient conformes aux

stipulations interessant

reg

circulation routiere.

5. L'air comprime peut

dangercux s'il est manipule

incorrectement.

travail sur I'ensemble,

s'assurer.

6.

corparel avec I'air comprime.

7.

constamment maintenue une

aeration adequate du systeme

de refroidisscmenl

d'echappement.

Ie

manuel avant toute

place et queIecapot soit

Ie

Avant

lementation

Avant d'cntreprendre tout

(i)

que toute pression

du systeme ait

misea.l'air libre et

(ii)

Quelamachine ne

puisse pas

en

marche

accidentellement.

Eviter tout contact

S'assurer que soit

operation

stationnement, ne

Ie

Ie

frein

remorquage,

de

~tre

ete

~tre

mise

et

des gaz

SICHERHEITSMASSNAHMEN

1.

Vor jeder Wartungs- oder

BedienungsmaBnahma

dar Badiener die

Maschinenbeschriftung

beachten und das Handbuch

zu

Rate

zichen.

2.

Aile Schutzabdeckungen

sowle die Kabinenhaube

massen wahrend des Betriebs

geschlossen sein.

a.

3,

si

la

la

Wird die Maschine

geparkt,

Handbremse angezogen und

bei

Radunterlegkeile verwendet

werden.

4.

prGfen,

Lichter vorschriftsmaBig

funktionieren.

5.

unsachgemaBer

gefahrlich sein.

smaBnahme folgendes prufen:

vollstandig abgelassen?

Iiche Inbetriebnahme ausgeschlossen?

6.

Druckluft vermeiden.

7.

BelUftung des Kuhlsystems

und Ableilung

sorgen.

so

Bedart die

Vor dem Abschleppen

ob Bramsen und

D,uckluft

Vor jeder Bedienung-

(i)

lsi de, Luftdruck

(ii)

1st

eine versehent-

K6rperkantakt mit der

Fur ausreichende

muB

muB

kann bei

de'

die

Bedienung

Abluft

INSTRUZIONI01SICUREZZA

1.

Accertarsi che

I'operatore abbia

istruzioni date sulle

decalcomanie e abbia

cansultato

iniziare

funzionamento della

macchina.

2.

coperture di protezione siano

state poste

la

durante il funzionamento.

il

manuale, prima di

la

Accertarsi che

in

capotlatura sia chiusa

3. Quando

viene parcheggiata, accertarsi

che sia stato messo

mana

e,see necessaria,che

ruoie siano

mediante gli appositi blocchi.

4. Prima di iniziare a

trainare

accertarsi che i freni e

funzionina carretlamente e

rispondano aile normestradali,

5.

essere pericolosa

trauata nella maniera carretta.

Prima di iniziare qualsiasi

lavoro

stata eliminata dalla machina.

essere messa

accidentalmente.

6,

contatto diretto

compressa

la

L'aria compressa pub

sull'unitA accertarsi che:

(i)

Tuualapressione sia

(ii)

la

machina non possa

Evitare di

leUo

manutenzianel

tUUe

posiziane e che

la

macchina

it

fremo a

state

fermate

macchina,

Ie

Iud

se

non e

in

mota

venire in

can I'aria

INsmUCCIONES

SEGURIDAD

1.

Ie

Ie

Ie

Asegu,ar

operador

aviso

antes

funcionamiento.

2.

colocadas

protecci6n y

este cerrada durante el

funcionamiento.

3.

asegurar que sea aplicado

freno demanayseusen calzos

en las ruedas

4. Antes de remolcar

asegurar

fundonen correctamente y

Que

requerimientos de trafico

necesarios.

5.

puede ser peligroso

maneja incorrectamente.

Antes de efectuar trabajo

alguno

6.

comprimido entre en contaeto

can

7.

mantiene

una ventilaci6n adecuada del

sistema de enfriamiento y de

los gases de

lea

y cansulte el manual

Asegurar que esten

Cuando

EI

(i)

(ii) Que

Evitar

el

cuerpo.

Asegurar que

los r6tulos de

del manlenimientol

toclas

Quelacubierta

se

si

es preciso.

Que

los frenos yluces

cumplan los

aire comprimido

enlaunidad, asegurar:

Quesealivia toda la

presi6n del sistema.

la

maQuina no

pueda ser arrancada

accidentalmente.

Que

en

todo momento

la

combusti6n.

DE

Que

las tapas de

aparca,

si

se

el aire

sa

el

el

e--I.>'J

)15:"

y..,.tll;'

.

~1/~1,.AJ4

<,;I}I~'YI

.L;;I

~

..LSt:i

..:-I-'-'L.J.yl

J-I.r-'JI

../'

J

1;1

I)..'

~

'-l.>-}I

i.r' 1

~

.I.,......u

"...."

.j

r,WI ..:-Ij"-J

j...s.

~)J~~~\

J-aAl1

~

~Ir'

..A;

<$

C'"

~

..:-.....,sJIJL,.OL..I

~

ii)~1

u.}

"I i.r'

..\S"l;

~

.,..;

. <')J.r"!1

1.,.;....;l1

.,j-

J>-'

J->-

J~I

~I

C'"

~I

i.r'

. l,..;-'"

"J..,II

<"""")1..,.

J<.

<JuWI"""L

-"...;::II

"I.i-".j'J""}.I

yo;

J<.

.

(~'YI

C::"'"

J<.

1

</

"""

.

~'>'I

r'"

Jly.

.1.,.1

...,...,;:;""(I )

~

..:-)l...,}1J

rL,.il1

,,~

~y

J~I

,

J<.

)J)I

J<.

<$4

:

rUO:JI

..,..,J

.

J<.

L.,)J'

d1;J

J...' }';'YI

,J

..:-uJ'Y1

"4

t!)

-,

jJ'r"1

"L

t!)

_I

.~I

.,L:s.

_ r

')J.r"

.

..:,.,~\

):-1

jJ

_!

..:-1,1·4

A.u

_0

J\;;

<'s.r.

rL,.il1

jJ

,;'>'1

i.r'

..\S"\;

-..;1

(..,..)

~'>'I

<.S,Li;

- ,

.

1.,.;....;l1

t!)

_v

rUO:J

W')(.

C'"

~_A

"t.."'Y1

r~

i.r'

..\S"1:1J

~

J')

~I-~

].;..,;JI

'

.JJ'

.j

J

L.

1-5

1-6

10.

circumstances should the

use

as

Ether be used

this machine.

IGENERAL DATA

CAUTION:

of

Yoltatile

Under

liquids

for

starting

such

CARACTERISTIQUES

GENERALES

no

8.

Verifier perioidiquement

Ie

bon fonctionnement de

soupape de

dansIereservoir separateur

(au mains tous les 2 ans).

9.

Pour tauleladuree utile de

la

periodiquemont tcus les

raccords

BOUS pression pourdeterminer

s'ils presentcnt

deterioration.

10.

utiliser de liquides volatils

com

me

cette machineenmarche.

sOrete

machine,

et

tuyaux flexibles

ATIENTION: Ne jamais

I'ether pour mettre

amEmagee

des

signes

verifier

de

ALLGEMEINES

8.

Das Sicherheitsventil im

SchaUer

la

regelmaBlg auf richtige

Funktion prulen (mindestens

aile 2 Jahre).

..

9

Betriebszeit

Druckluftschlauche und

·anschlOsse auf sichtbare

Schaden Oberprufen.

10.

Umstanden dart eine

atherische oder ahnliche

FlOssigkeit zum Starten dieser

Maschine verwendet werden.

des

Wahrend der gesamten

der

Maschine aile

WARNUNG:

Separators

Unter keinen

CARRATTERISTICHE

GENERALI

7.

Accertarsi che I'impianto

di raffreddamento

scarico abbiano sempre

un'adeguata ventilazione.

8.

La

posta

deve essere contrallata

periodicamente per accertarsi

che funzioni correttamente

(almena agni 2 ann

9.

macchina viene

controllare periodicamente

che

compressa ed

collegamento non abbiano

parti deteriorate.

10.

volatili, come l'Etere non

devono mai essaere usati per

della macchina.

valvola di sicurezza

nel

serbatoio separatore

Duranteilperiodoincui

Ie

ATIENZIONE: Liquidi

ad i gas di

i).

usata,

tubature dell'aria

i lora punti di

DATOS GENERALES

8.

La

situada en

separador debe ser

inspeccionada peri6di-

. camente para asegurar que

funcione correctamente {cada

2

9.

maquina, verificar

peri6dicamente todas

mangueras de presi6n y

la

deteriorovisual de

10.

ningunas circunstancias

deben usarse liquidos volatiles

tales como

en marcha esla maquina.

valvula de seguridad

el

tanque del

anos como mlnimo}.

Durantelavida util de

la

PRECAUCION:

el

eter para poner

la

las

conexion.

En

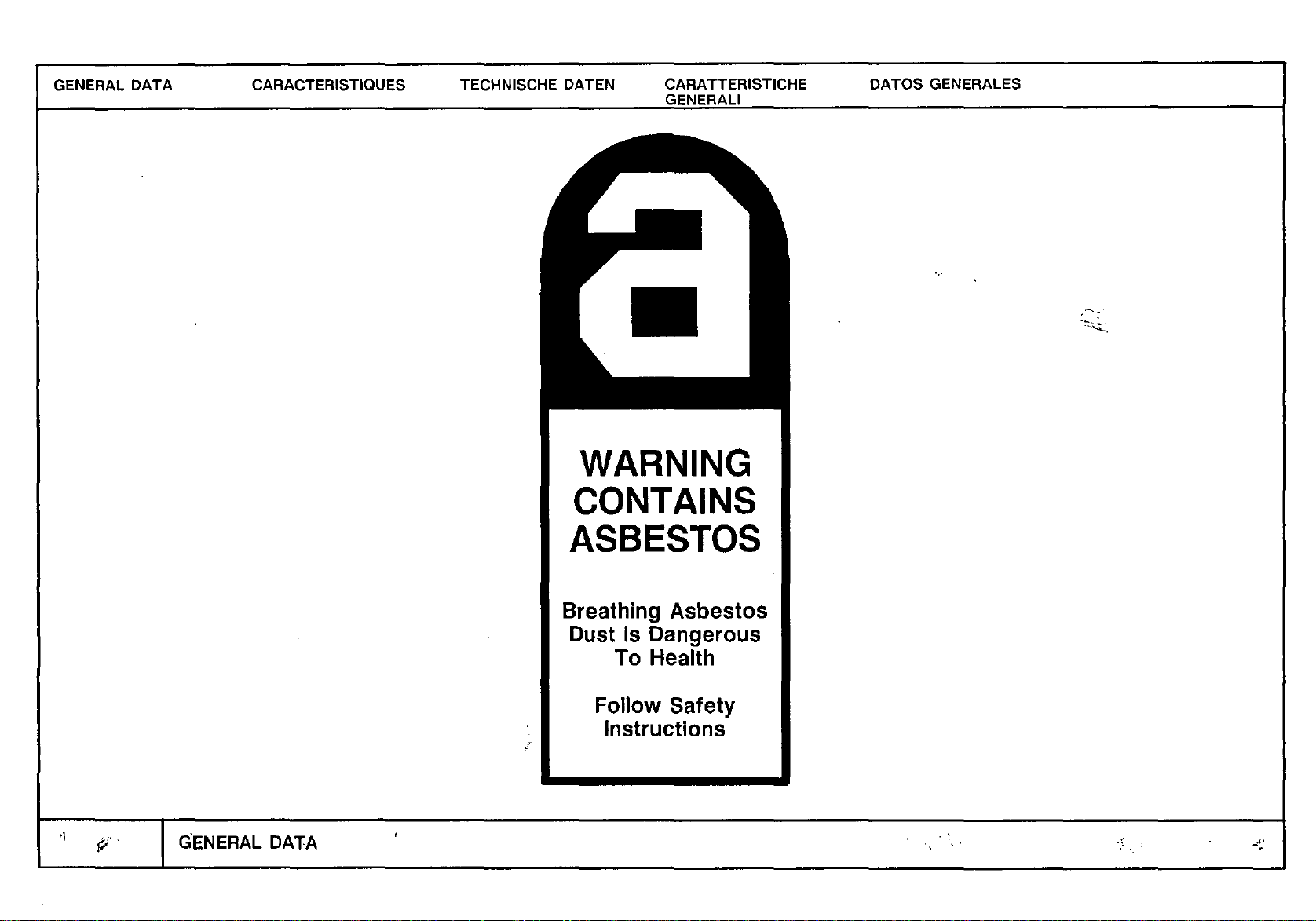

GENERAL DATA CARACTERISTIQUES TECHNISCHE DATEN

WARNING

CONTAINS

CARATTERISTICHE

GENERAL!

DATOS GENERALES

,--.:-~

.

.

~';.::...

ASBESTOS

Breathing Asbestos

Dust is Dangerous

To Health

Follow Safety

Instructions

'1

GENERAL DATA

, ,

.

~

z

o

!i

II:

~

...

/

\

I/'l

o

•

N

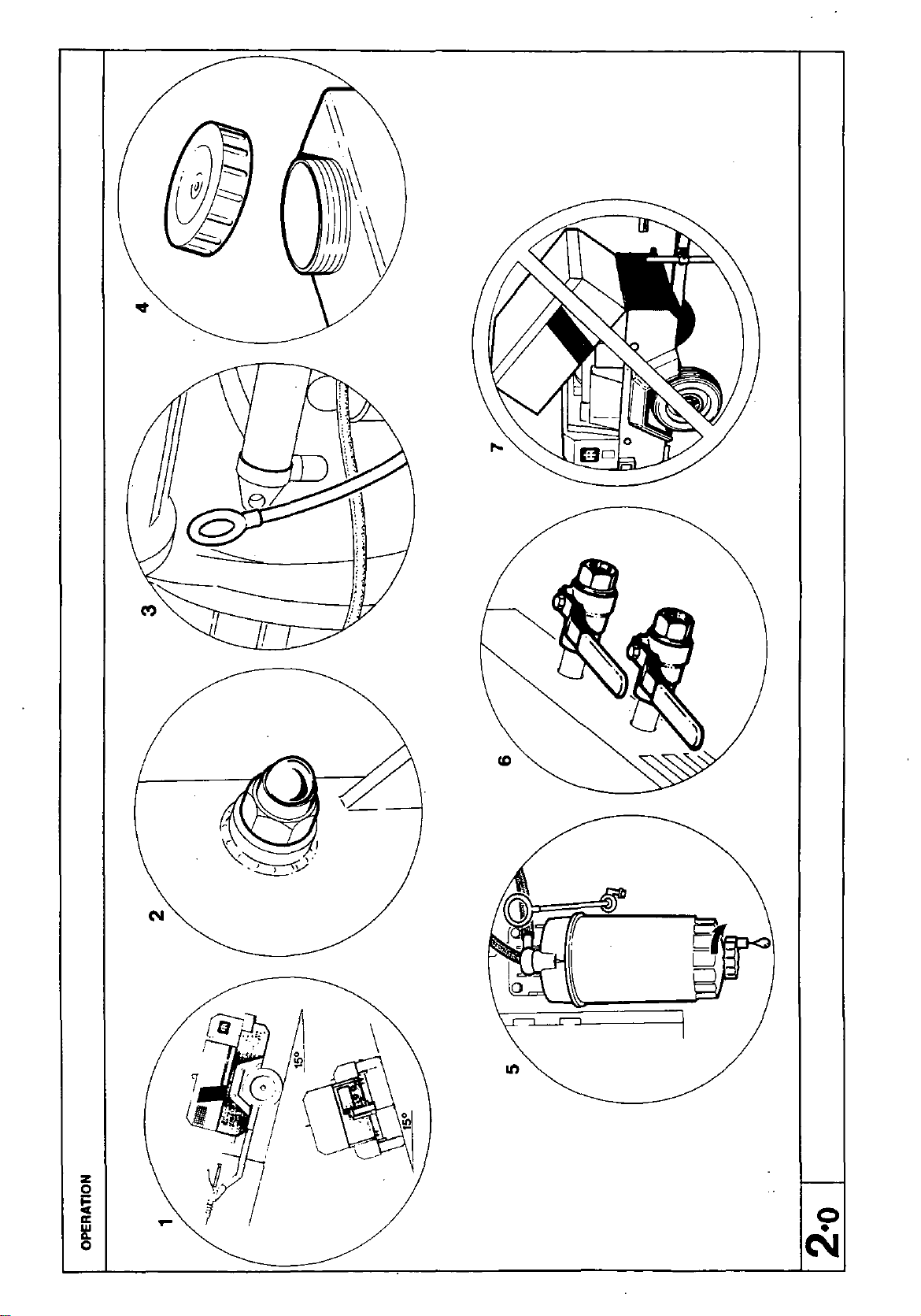

OPERATION

FONCTIONNEMENT

BEOIENUNG

NORME PER

L'USO

FUNCIONAMIENTO

j,.W.:J1

BEFORE STARTING

t.

Place the unit in a position

as level as possible. The

designofthese units permits a

15 degree lengthwise and a 15

degree sideways limit on outof-level operation. The engine,

not

the

compressor,isthe

in

lithe

any case.

DO

unitisto

NOT

be

limiting factor

When tho unitisto be operated

out-ai-levelitis important

keep the engine crankcase oil

level ncar the high level mark

(with Ihe unil level).

overfill either tho engine or the

compressor with oil.

CAUTION:

connected to 8 common

header or together with any

other source01compressed

air:

make sure 8 checkvatve

is

fittedtothe unit

2.

Check the compressor oil

level in sight bubble.

3.

Check the engine

lubricating oilinaccordance

with the operating instructions

of

the

manual.

4.

good rule

shift. This prevents condensation occurring

5.

separator of water daily (where

valve filted).

engine operator's

Check diesel fuel level. A

istotop upafter each

in

fuel tank.

Drain luel filter water

AVANT LE DEMARRAGE

1,

Amener

aussi

construction

permel

par

degres

de15degres

les

compresseur

to

limilablSiI'ensemble

sur

de

carter

niveau

I'horizonlale).NETROP

d'huile

compresseur.

ATIENTION:Si

doit

collecteur commun

toute sutre source d'air

com

soit

de retenue.

2.

campresseuraumoyendela

d'observatian.

3.

moteur

instructions

presentees

I'utilisateurdumoteur.

4.

combustible

pratiQuedefaire

chaQue

formaliondecondensation

reservoirdecombustible.

5

(flJ Sl'r.1IJ!Cur

rrr'hJsJit'>lC

I'ensemble

horizontal

rapportaI'horizontale

dansIesens

cas,

une

denivellation,ilest

maintenirIeniveau

mateur

maximum

itre

prime,

equip'

VerifierIeniveau

Verifier

Verifier

eQuipe.

Vld.lngcr

Que

de

une

c'estIemoteuretnon

ni

ces

inciinaison

laleralement

Qui

canstitueIefacteur

presdurepere

(avec

Ie

moteur,

connecte a

s'assurer qu'il

d'une soupape

I'huiledegraissage

conformement

dansIemanuel

Ie

Diesel.IIestdebonne

Geci

rcau

Quofidicnncment

d'cau

norSQU'.1

surunplan

possible.

ensembles

maximum

longitudinal

Dans

ooit

eire

important

d'huile

rensemble

EMPUR

I'ensemble

d'huile

d'exploitalion

niveau

I'appoint

empeche

dans

du

flkrc a

cst

moniC).

de

lout

utilise

ni

un

ou

fenelre

du

aux

de

du

apras

OEM

VOR

1.

La

waagerecht

Konstruktion

15°

15

15"

et

Grenzwert,

durch

Ie

durch

Betrieb

schragem

aehten,

du

5lellung)

de

Kurbelgehiiu50

a

moglichst

Markierung

Ie

Kampressor

iiberfiil"lt

ACHTUNG : Wenn

pressor an einen gemein-

II

samen Druckkessel

schlossen oder mit anderen

Kompressoren zusammengeschaltet werden

unbedingt ein RUckschlag-

du

ventil eingebaut werden.

2.

Anzeigefenster

3.

Anweisung

kontrollieren.

4.

empfiehll

Betriebsschicht

la

Dies

Ie

Kraltstolftank

5.

Wasscrabscheider

sloffiltcrs

Kallstart-Bausatz

licfcrbar).

ANLASSEN

Kompresscr

NeigunginLangsrichtung

NeigunginOuerrichtung,

Den

MOIor·Olsland

Dieselsland

verhindert

Wenn

aufstellen.

erlaubt

der

letzten

den

Kampressor,

den

Motor

beding!

des

Kompressors

Gelande

daB

(bei

der

nahe

herankommt

NIGHT

Kompressor-Olstand

kontrollieren.

im

sich,

den

wieder

Kondensation

eingebaut,

taglich

mbgllchst

Seine

den

Betrieb

und

einem

Endes

nicht

sondern

wird.

Bei

ist

darauf

waagerechter

Olstand

des

an

kantrol1ieren.

Tank

Motors

die

obere

Motor

u~~

mil

de.

Kom-

ange--

5011,

muB

nach

nach

jeder

aufzufullen.

des

kraft-

entlccrcn.

Wunsch

den

den

Matarhandbuch

(auf

PRIMA01AWIARE

MACCHINA

1.

Porrelamacehinainuna

posizione

bei

possibile.IIrnassima

con5Ontrto

nel

Queno

lallore

usareIamacx::hinainposizione

auf

perfelamente

zu

gruppo

Quandosidebba

im

posiziooe

livello

motare

nella

01

vicinoalsegnadimassimo.

che

motore

A

deve essere collegata ad

collettore comune, 0 lnsieme

ad altre fonti dl aria

compressa,

sulla machinna

non

im

2.

livello

3.

mOlore

I'operatore.

Es

4.

E'

terminediogni

im

formaeione

serbatoio

5.

giorno

filtra

monlalo).

che

sialapiu

dal

senso

posizione

I'olio

TIENZIONE:Se

Controllare

Conlrollare

Conlrallare

buona

Svuotare

del

di5Ognoedi

della

long~udinale.

che

compressore,

0011'0110

(misurato

elo

rltorno.

dell'olia

seguendoIeistruziani

dal

larghezza

limrtalapossibilita

orrrizontale,

non

livellata,

nella

orizzontale)

possa

dal

compressore.

sl

dovra montare

nel

nel

illivello

illevello del"

norma

turna,

di

del

carburante.

l'acQua

separatore

carburante.

LA

orizzontale

dislivello

IS'

sia

che

In

ogni

casa,

non

noneil

maiImatore.

operare

occ:orre

che

coppa

rimanga

Evitare

I'unitil

spia

dell'oIio

evita

volta

del

dal

un

Nel

per

nafta.

al

Ia

nel

al

del

conlamacchina

straboccare

una valvola di

vetrino

compressore.

rabboccare

Questo

condensa

una

dell'acQua

(Seastalo

DE

ANTES

MARCHA

1.

GolocarlamaQuinaenla

posici6n

disenodeestas

un

funcionamiento

in

un'

il

Iongiludinal

di

noelcampresoresel

restrictivoencada

necesario

en

in

importanle

il

acerte

mantenga

superior

No

lIenarniel

COn

excesodeaceite.

ATENCION :Sila

ser conectada auncolector

comun u otra fuente

cualqulers

comprimido, asegurar que

se

instalaenla

valvuladeretencl6n.

2.

Verificarelniveldeaceite

compresorenla

3.

il

Venficarelaceite

motorencanformidad

instrucciones

del

operadar.

4.

Verificar

combustible

medida

tumo

condensaci6nenel

combustible.

5.

Purgar

5Oparadordeagua

combustible

PONER EN

mas

nivelada

limite

de

cemo

quelamaQuina

posici6n

asegurar

del

carter

pr6ximoala

(conlamaQuina

motorniel

dadasenel

diesel.Esuna

reUenarlo

de

trabaja.

(siseinciuye).

mc1Quinas

desnivelado

15

lateralEImotor

caso.

desnivelada

Queelnivel

del

de

mirilladeburbuja

el

despuesdecada

Esto

diariamente

posible.

permite

tanto

faclor

Cuandosea

funcione

motor

marca

nivelada).

compresor

va e

sire

con

manual

nivel

buena

previene

tanQue

fillro

con

del

del

las

del

del

de

grados

unidad

unidad una

lubricante

del

J-"<

J""--'

c:PJ

<J

EI

wl..L.>-)1

~).:J'o.:JJ.J.>.~~~

""'

y

~J'~rJ.t;

JS

<J

es

~

de

50

'":'}

c:PJ

"4j

J-..-o

LS~

:".lSI;

<J

U;

~I

ci'J'Jj<.<J1

JS

<J

el

ctl;

<"'J'

\0 J <,I)JI

j.

,.boll

c/'J

'..L.>-)I

"JJ.r'JI

~rJ.I~;>

<J

'.I>-)I

"-!)4

1'-

'..L.>-)I

JI ,

~

~

,

j,.....,.i

.

4,i~.,.

~I

J

~;->-11

J

<.,.J.Ll1

• .~rJ.1

"'"

~

rJ.1

~

"'J..L.>-

'.1>-)1

r---'"

01.01>7..

wl"";'il

. ,-",U,I

JoWl~, <b...oll

~

= .

""'

'J'--'.rf

<J

,,-!)I

)

<,IWI

LSy.-l1

J

<b...oll JI~rJ.1 W

.

":';[$

III :

.....,:J

J.,-->

I

.1

J+U

.J"

.rf

iJ,..o

"-!j

LSJ""--'

.

""l.,-)I0!J1

..;,J.i-'

"-! j ..u.;; _r

~I

~

'j)1

LSJ'--'.LUi - !

oJ!

~I

.~..,y

C:'

....;[.:

.

'j)1

c:P

-\

wl"";'il

JL>

c:P

LSJ'--'

<..,.,.

.

<.J=--

ij)l.ll./

J'.U-

...

,-,A

1~........

..,..,s

..u.;; _T

",...,;1

wkW

<J"l'l-I

;JsliJl

""'

I.L..

01j>'

'il

""'

J

'i

;

OPERAnON

o I

II

III

;:.,.:,"

,<

':,~;

~

2

Q

INGER50~::'AND

1

OPERATION

CAunON

diesel fuel

minimum cetene

45

greater

(Refertoengine

manual.)

6.

allow full air pressure which

ensures proper

7.

machine with the canopy open

as

NOTE

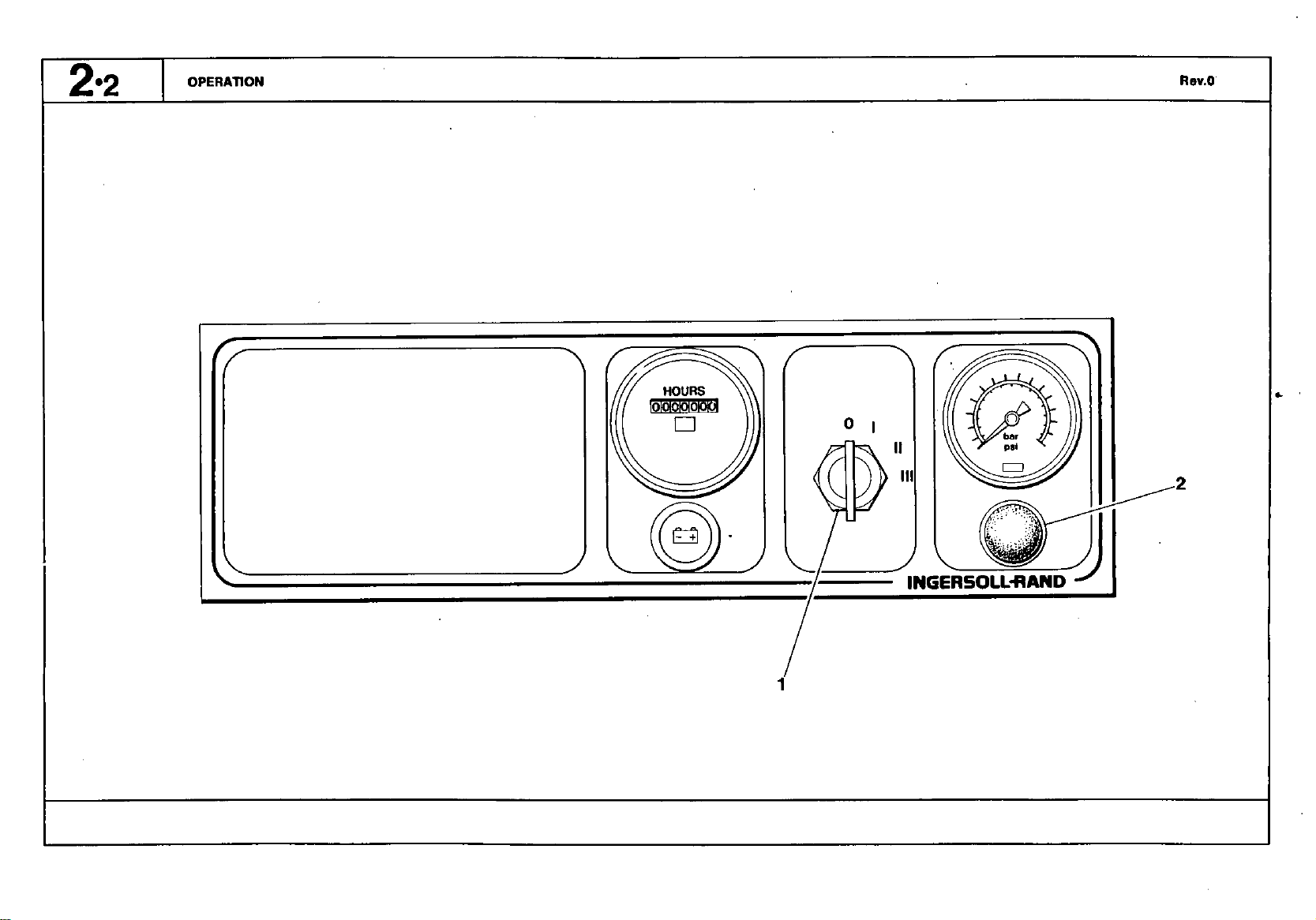

startata reduced load,' a

"start-run" button is located on

the

STARTING

All normal starting functions

are

operaled switch (1).

A.

'1' Battery condition light will

come on. Continue to turn

switch to positon 'Ill' (Engine

slart).

position 'II' when engine starts.

Release

bat1ery

extinguished.

B.

running at reduced speed,

Allow unit

depress start-run button. The

engine will immediately

increase

compressor will soon reach

normal operating pressure.

At

this pointinthe

Ihe unit ilissafe

load to the engine.

:Use onlya No. 2-D

oil

with

and sulphur

number

content

not

than 0.5%.

operators

Close all service valves

oil circulation.

Do not operate the

this may cause overheating.

:In

order to allow unit

control panel

incorporatedinthe key

Turn key switch to position

Then come back to

to

condition light

The

engine will now

to

(2).

UNIT

position 'I' when

to

warm up then

max.

Speed and

operation of

to apply full

FONCT10NNEMENT

ATTENTION : Utiliser

8

seulement un

of

Diesel No.

de

une

n'exclldant

(Voir Ie manuel

I'utilisateurdumoteur).

to

6.

service pour permet1re a

pression d'air maximum

d'assurer une circulation

d'huile adequate.

10

7.

machine avecIecapot ouvert,

car ceci risque de provoquer

un surchauffage.

NOTE:

en marche de I'ensemble sous

une charge raduite,

amanage

"demarrage-marche" sur

tableau des commandes

ENSEMBLE

MARC

Toutes les fonctions normales

is

de mise en marche sont

incorporees

cle. (1).

be

A.

Amener l'interrupteur acIa a

la

position'1'.La

de batterie s'allume. Continuer

de toumer l'interrupteur pour

I'amener

Ie

moteursemet en marche.

Laisser I'interrupteur revenir

la

lampe-temoin de batterie

s'eteint

2~D

clltane

teneur

Fermertous les robinets

Ne pas faire fonctionner

Pour permettrelamise

HE

avec un indiee

minimum

pas

un

DE

a I'interrupteur a

a

la

position

position

'I'

combustible

de

45

en

soufre

a,s%.

il

MISE

'II'

est

(2).

EN

quand

bouton de

lampe-temoin

quand

BEOIENUNG NORME

ACHTUNG : Nur Oie8el61 mn

einer Cetanzahl von

mindestens

SchwelelgehaR von

et

h6chstens

(Siehe

buch).

d.

6.

Zum

qruckes

Olzirkulation aile Ausfritts-

de

ventile 6ffnen.

la

7.

Die Maschine nicht mit

offenen

dieszum HeiBlauf

la

ANMERKUNG:So

Motor unter erleichterter

Belastung starten kann, ist ein

"Slart-Betrieb" Knopfander

Bedienungslafel angebracht

(2)

AN

LASSEN

Ie

Oer

Schiiisselschalter

aIle

normalen Startfunktionen

zustandig.

A Den SchlOssel bis

Nummer "1" drehen, die

Batterieanzeige leuchtet jetzt

auf.

Den Schalter bis zur

Position

drehen. Sobaid der Motor

anspringt, den

Position

Batterieanzeige abschaltet,

den Schalter auf Position "I"

stellen.

B.

Oer

geringerer Drehzahl. Warm·

a

laufen lassen und Start-

la

Betriebsknopt betiiligen.

Motor

Tauren und erreicht bald den

normalen Betriebsdruck.

45

und

elnem

0,5% verwenden.

im

Bedienungshand-

Aufbau des

im

Interesse guter

TOren

betreiben, da

fOhren

daB

OER

EINHEIT

(t)

"III"

(MotoranlaB)

"II"

Molar lauft jetzt mit

18uft

SChalter

drehen. Sobald die

sofort auf volle

Luft-

kann.

der

istfUr

zur

zur

Oer

PER

L'USO

ATTENZIONE : U8are

esclusivamente

2-D, con

pari ad almeno

contenuto

8uperlore

(Vedere II Manuale del

Motore

6.

servizio,

permettere di ottemere

completa pressione dell'aria

necessaria per far circolare

bene

7.

in

capottatura e ancora aperta,

altrimenti

surriscaldamento.

NOTA

I'awiamento della macchina

can

pannello di comando

incluso un pulsante di

Mawiamento-marcia".

OISPOSITIVIO

AWIAMENTO

Tutti

d'awiamento, sono

incorporate

chiavetta

A.

chiavetta nella posizione

spia della condizione della

batteria

a ruolare

alia posizione

un

delfoperatore).

Chiudere

I'olio.

Non metterelamacchina

funzione quando

:

carico parzializzato, sui

Ie

(1).

Ruotareilcommutatore a

si

gasolio

numerodicetano

No.

45 e con

di

zolfo

allo

0.5%.

tutteIevalvole di

in

modo da

si

puo causare un

Per

normali funzioni

nel

commutatore a

illumina. Continuare

iI

commutatore fino

'III'

(Awiamento

non

consentire

(2)

state

'1

'.

La

FUNCIONAMIENTO

ATENCION: Usar

aceite combustible dieselno.

2-D

con un cetanje

de 45 y

azufre no 8uperior

(Vea el manual del

operador).

6.

de servicio para permitir

presi6n maxima deaire,el cual

asegura

la

del aceite.

7.

maquina con la cubierta

abierta,

causar recalentamiento.

la

NOTA:

maquina pueda arrancar a

carga reducida,

OOt6ndeMarranque-

en

el panel de conlrol

UNlOADDEARRAQUE

e

Todas las funciones de

arranque normales

incorporan enelinterruptor

01

accionado par "ave

A Girarelinterruptor de lIava

a

indicadora de estado de

bateria

Continuar girando el

interruptor hasta

(arranquedemotor). Volver a

ia posici6n 'II' cuando

arranqueelmotor. Liberar a

posici6n 'I' cuandoseapague

la

luz indicadora de estado

baterfa.

un

conlenldo

Cerrar todas las valvulas

la

circulaci6n debida

No hacer funcionar

ya

que esto podria

Para

permitir que la

la

posiici6n

se

la

solamenle

mlnimo

al

0,5%.

se

incluye un

marcha"

(2).

(1).

'I'.

La

encendera.

posici6n

se

luz

'III'

de

la

la

,....

}I

.:..,j

,J.;

~

<$.iJ1

.s~

-4:.-<

(!lrJ.1

c.1.-li

"'~I

.r--"<

l!

,1.#

<,.ill

,,;-5.;

~J.L>

~~

i.l>-

II

I"',~

Y.r--

I'

'-'I .

_~

h,LAlI

c:'"

"I"

<Il>-

<S>"

.)

"""

.~

.)"..;..,

U.

.!.A.,;I

's

J..--o-J

k..AJ1 JI

J))

<...-..-J

~

J~~I

J;

JI.lJ1

c.i:;.iI.\

I-L..;

!l;-->--1I)

~..-JI

UL.-

,,;11.,J1

r

~

,..:

~

r c"J- .

lAL,.;1

J-,U

.lW J-.o;-I :

<$'

_ T

'iJ t •

. Z'••.)"

~

",l.~

j-lSOl k..AJ1 'lL.

. .:..,)1..",.

12

<..;,SUI

"":-:-'! .J..j

I

..

c."- .

!ll:..;,'"

~~~-.

~

(')

~I

.

",WI

~1...AlU;J

~J

Jl

;;:JI

.~

J'J);

.)

~\

"I""

JI

....

,..:

. !lrJ.1

<Il>-

J;

!l.,.....11

;J-4

i.l>-}I

~I-

Jl

Jll-I

-"!