Ingersoll-Rand NM2304A-X-X User Manual

OPERATOR’S MANUAL NM2304A-X-X

SPECIFICATIONS, SERVICE KITS, GENERAL INFORMATION, TROUBLESHOOTING

INCLUDE MANUALS: 67151-X Lower Pump End (pn 97999-763), 6691X Air Motor (pn 97999-748) & S-632 General Information Manual (pn 97999-624)

3” AIR MOTOR

4:1 RATIO

3” STROKE

TWO BALL PUMP SERIES

NM2304A-X1-X11

CARBON STEEL

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

RELEASED: 1-2-98

REVISED: 6-1-10

(REV. G)

SERVICE KITS

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 637316 for repair of air motor section.

• 637176 for repair of 67151-X-311and -X-511 lower pump section.

for repair of 67151-X-C11 lower pump section.

637228

SPECIFICATIONS

Model Series (refer to option chart) NM2304A-X1-X11.........

Type Air Operated, Two Ball..........................

Ratio 4:1..........................

Air Motor 66913.......................

Motor Repair Kit 637316................

Motor Diameter 3” (7.62 cm)................

Stroke (Double Acting) 3” (7.62 cm)...........

Air Inlet (female) 1/4 - 18 N.P.T.F. - 1................

Lower Pump End Series

NM2304A-11-C11 67151-1-C11..............

NM2304A-11-311 67151-1-311..............

NM2304A-11-511 67151-1-511..............

NM2304A-41-C11 67151-4-C11.............

NM2304A-41-311 67151-4-311..............

NM2304A-41-511 67151-4-511..............

NM2304A-81-311 67151-8-311..............

NM2304A-91-311 67151-9-311..............

NM2304A-A1-C11 67151-A-C11.............

NM2304A-A1-311 67151-A-311..............

NM2304A-A1-511 67151-A-511..............

NM2304A-B1-311 67151-B-311..............

Material Inlet

NM2304A-1

NM2304A-4

Material Outlet (female) 3/4 - 14 N.P.T.F. - 1..........

Air Inlet Pressure Range 0 - 150 p.s.i. (0 - 10.3 bar).........

Fluid Pressure Range 0 - 600 p.s.i. (0 - 41.4 bar)...........

Maximum Rec’d Cycles / Minute 125.....

Displacement In

Volume / Cycle 4.54 oz. (134.3 ml)...................

Cycles Per Gallon 28.2................

Flow @ 60 Cycles / Minute 2.1 g.p.m. (8.06 l.p.m.)..........

Noise Level @ 100 p.s.i. 85 db(A) *............

Accessories Available 61113 Wall Mount Bracket...........

* The pump sound pressure level has been updated to an Equivalent Continuous Sound

Level (L

Aeq

microphone locations.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

1-X11, -81-, -B1- (female) 1-1/2 - 11-1/2 N.P.T.F. - 1

1-X11, -91-X11, -A1-X11 Immersed Inlet

PERFORMANCE

3

Per Cycle 8.2.........

66073-1 Air Line Connection Kit

) to meet the intent of ANSI S1. 13-1971, CAGI-PNEUROP S5.1 using four

© 2010

CCN 99695199

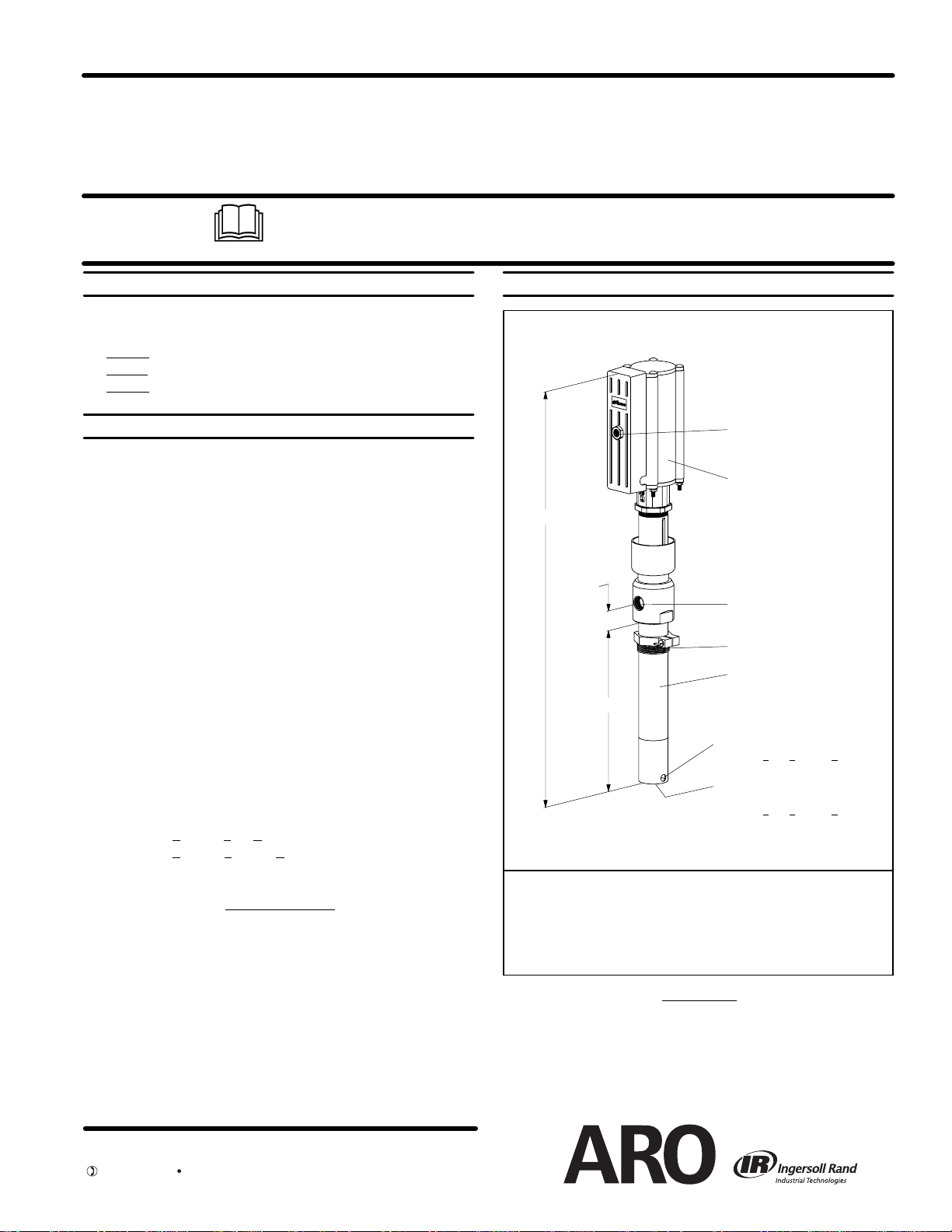

PUMP DATA

MODEL NM2304A-X1-X11

Air Inlet (female)

1/4 - 18 N.P.T.F. - 1

Air Motor 66913

(see manual 6691X)

“A”

1-7/16”

(36.5 mm)

“B”

Figure 1

NOTE: Dimensionsare shown in inches and (mm), supplied for reference only and are

typically rounded up to the nearest 1/16 inch.

Model Number “A” (mm) “B” (mm) Weight (kg)

NM2304A-11-X11 30-11/32” (770.3) 11-23/32” (297.7) 32 lbs (14.5)

NM2304A-41-X11 55-23/32” (1414.9) 37-3/32” (942.2) 46 lbs (20.9)

NM2304A-81-X11 30-11/32” (770.3) 11-23/32” (297.7) 31.4 lbs (14.3)

NM2304A-91-X11 55-23/32” (1414.9) 37-3/32” (942.2) 45.4 lbs (20.6)

NM2304A-A1-X11 29 -21/32” (752.9) 11-1/32” (280.2) 31.0 lbs (14.1)

NM2304A-B1-X11 30-11/32” (770.3) 11-23/32” (297.7) 32 lbs (14.5)

IMPORTANT

This is one of the four documents which support the pump. Replacement copies of these forms are available upon request.

= NM2304A-X-X Model Operator’s Manual (pn 97999-749)

- S-632 General Information - Industrial Piston Pumps (pn 97999-624)

- 67151-X Lower Pump End Operator’s Manual (pn 97999-763)

- 6691X Air Motor Operator’s Manual (pn 97999-748)

Material Outlet (female)

3/4 - 14 N.P.T.F. - 1

2-11-1/2N.P.T.

Lower Pump 67151-X-X11

(see manual 67151-X)

1/2” (13 mm) thru hole

(NM2304A-11-X, -81-X and -B1-X only)

Material Inlet (female)

1-1 / 2 - 11 - 1 /2 N . P.T.F. - 1

(NM2304A-1

1-X, -81-X and -B1-X only)

PUMP OPTION DESCRIPTION CHART

NM2304A - X 1 - X 1 1

CONTAINER SUITABILITY

PACKING MATERIAL

SPRING ARRANGEMENT

PLUNGER TYPE

CONTAINER SUITABILITY PACKING MATERIAL

1-

Universal (Stub) C-UHMW-PE (upper and lower)

4- 55 Gallon 3- Glass filled PTFE (upper)

8 - Universal (Stub) (without bung) Virgin PTFE (lower)

9 - 55 Gallon (without bung)

A - Stub Follower Plate Virgin PTFE (lower)

B - Universal (Stub) with alternate bung

SPRING ARRANGEMENT PLUNGER TYPE

1- Coil 1- Standard (Carbon Steel)

5- Glass filled PTFE / Leather staggered (upper)

GENERAL DESCRIPTION

The two-ball design provides for easy priming of the lower foot valve.

The double acting feature is standard in all ARO industrial pumps. Material is delivered to the pump discharge outlet on both the up and down

stroke.

The motor is connected to the lower pump end with a spacer tube and

solvent cup. This allows for lubrication of the upper packing gland and to

prevent air motor contamination because of normal wear and eventual

leakage through the material packing gland.

WARNING

mumoperating pressureof 600p.s.i. (41.4bar) at 150 p.s.i. (10.3

bar) inlet air pressure.

INLET PRESSURE TO PUMP MOTOR

Pump ratio is an expression of the relationship between the pump motor area and the

lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure is supplied

to the motor of a 4:1 ratio pump it will develop a maximum of 600 p.s.i. (41.4 bar) fluid

pressure (at no flow) - as the fluid control is opened, the flow rate will increase as the

motor cycle rate increases to keep up with the demand.

WARNING

safety precautions and important information.

NOTICE: Thermal expansion can occur when the fluid in the material lines is exposed to elevated temperatures. Example: Material

lines located in a non-insulated roof area can warm due to sunlight.

Install a pressure relief valve in the pumping system.

Replacement warning label (pn 94520) is available upon request.

HAZARDOUS PRESSURE. Do not exceed maxi-

PUMP RATIO X MAXIMUM PUMP

= FLUID PRESSURE

Refer to general information sheet for additional

Replace the seals as necessary.

Material leakage out of the solvent cup or material appears on the

pump plunger rod.

• Tighten the solvent cup until leakage discontinues. If this procedure

does not aid in stopping the leakage problem, the upper packings

may be worn (see lower pump disassembly). Replace the seals as

necessary.

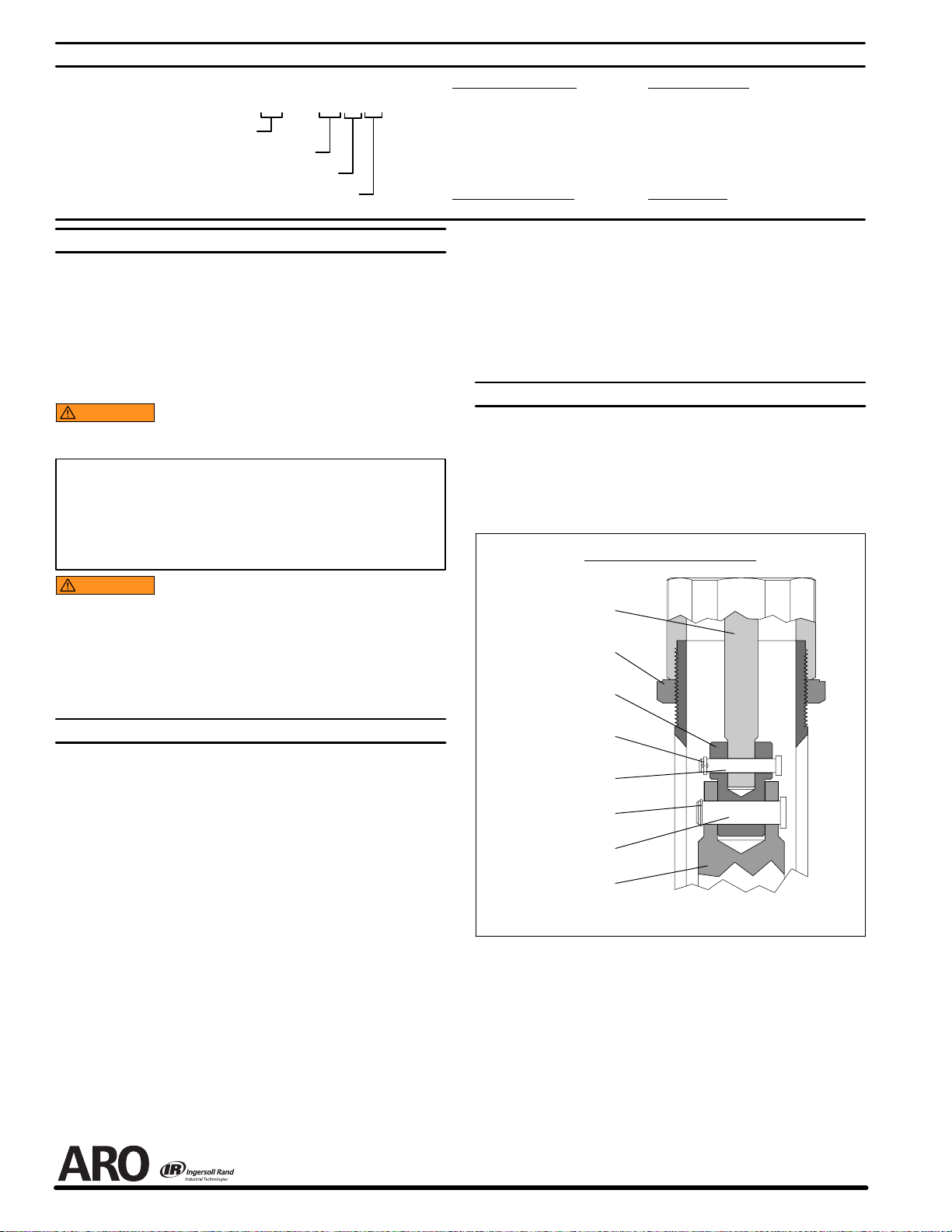

PUMP CONNECTION - UPPER / LOWER

NOTE: All threads are right hand.

1. Loosen (90571) lock nut and unscrew entire pump from the air motor. This will expose (94448) adapter (see figure 2).

2. Remove (Y145-2) retaining ring and (90572) connector pin to remove pump assembly from the air motor.

3. Remove (Y15-21) cotter pin and (94048) clevis pin to remove

(94448) adapter.

PUMP CONNECTOR DETAIL

Pump Motor

Piston Rod

90571 Lock Nut (ref.)

94448 Adapter

TROUBLE SHOOTING

Pump problems can occur in either the air motor section or the lower

pump end section. Use these basic guidelines to help determine which

section is affected. Be sure to eliminate any possible non-pump problems before suspecting pump malfunction.

Pump will not cycle.

• No pressure to the motor. See motor manual.

• Restricted return lines. Clean obstruction.

• Damaged motor. Service motor.

No material at the outlet (pump continually cycles).

• Check the material supply, disconnect or shut off the air supply and

replenish the material, reconnect.

Material on one stroke only (fast downstroke).

• The lower check may not be seating in the foot valve (see lower

pump disassembly). Remove the check from the foot valve, clean

and inspect the valve seat area. If check or foot valve are damaged,

replace.

Material on one stroke only (fast upstroke).

• The middle packings may be worn (see lower pump disassembly).

Y15-21 Cotter Pin

94048 Clevis Pin

Y145-2 Retaining Ring

90572 Connector Pin

Lower Pump Plunger

Figure 2

REASSEMBLY

1. Assemble (94448) adapter to air motor rod, aligning through holes.

2. Assemble (94048) clevis pin through hole, securing adapter.

3. Assemble (Y15-21) cotter pin through clevis pin.

4. Assemble (94448) adapter into (90584) plunger, aligning through

holes.

5. Assemble (90572) connnector pin through hole, securing with

(Y145-2) retaining ring.

6. Screw the lower pump assembly to the air motor.

7. Screw (90571) lock nut against air motor base and tighten to 50 - 60

ft lbs (67.8 - 81.3 Nm).

PN 97999-749

NM2304A-X-X (en)Page2of2

Loading...

Loading...