Page 1

03529245

Form P6432

Edition 2

May, 1981

OPERATOR AND MAINTENANCE MANUAL

MODEL ML25K

MODEL ML50K

MODEL ML100K

1 - Ton Air Chain Hoist

i

WARNING

DO NOT USE THIS HOIST FOR

LIFTING CR LOWERING PEOPLE.

ALWAYS OPERATE, INSPECT AND MAINTAIN

THIS HOIST IN ACCORDANCE WITH AMERICAN

NATIONAL STANDARDS INSTITUTE

STANDARDS 830.16 .

READ ALL THE ENCLOSED INSTRUCTIONS BEFORE

INSTALLING, OPERATING OR REPAIRING THIS

HOIST.

SAFETY

Refer All Communications to the Nearest

Ingersoll-Rand Office or Distributor.

Printed in U.S.A.

AIR HOISTS

Page 2

Page 3

HOW TO ORDER REPAIR PARTS FOR YOUR HOIST

Your Hoist is designed and constructed to give you long, trouble-free service. In time it may become necessary to order

and install new parts to replace those that have been subjected to wear. For prompt service and genuine Ingersoll-Rand parts,

place orders with your nearest Ingersoll-Rand Distributor. The use of other than genuine Ingersoll-Rand replacement parts

may result in decreased Hoist performance, and may, at the Company’s option, invalidate all warranties.

When ordering parts, give your Distributor the following data:

1. Complete model number of the Hoist as it appears on the nameplate.

2. Complete part number, part description and quantity needed as shown on the pages of this manual.

If it becomes necessary to return the complete Hoist or certain parts to the factory, contact the Distributor from whom

you purchased the Hoist, or the nearest Ingersoll-Rand Distributor in your locality.

INSTALLING THE HOIST

Make certain your Hoist is properly installed. A little extra time and effort in so doing can contribute a lot toward prevent-

ing accidents and helping you get the best service possible.

Always make certain the supporting member from which the Hoist is suspended is strong enough to support the weight of

the Hoist plus the weight of a maximum rated load plus a generous factor of at least 500% of the combined weights.

When installing a Fabric Chain Container on an MLK Hoist refer to the illustration on Page 30. Note: Make certain to ad-

just the balance chain so that the Container does not contact the load chain.

If the Hoist is suspended by a Top Hook, the supporting member should rest completely within the saddle of the Hook

and be centered directly above the hook shank. Do not use a supporting member that cants the Hoist to one side or the other.

For installing a Trolley on a beam measure the beam flange and temporarily install the Trolley on the Hoist to determine

to 6.35 mm) greater than the width of the beam flange. The number of spacers between the Trolley side plate and the mounting lug on the Hoist must be the same in all four locations in order to keep the Hoist centered under the I-beam. The remaining spacers must be equally distributed on the outside of the side plate.

When installing the Hoist and Trolley on the beam, make certain the side plates are parallel and vertical. After installation,

operate the Trolley over the entire length of the beam with a capacity load suspended a few inches off the floor.

Page 4

LUBRICATION SPECIFICATION

Whenever a Series MLK Hoist is disassembled for overhaul or replacement of parts, lubricate as follows:

Coat all motor parts with a light film of Ingersoll-Rand Pneu-Lube@Medium Oil No. 50 or a good quality SAE 20 or

1.

20W motor oil before assembling.

Apply a coating of Ingersoll-Rand No. 11 Grease to the Planet Gear Bearings (83) and the Brake Driver Bearing (87) be-

2.

fore assembly.

Lubricate each link of the load chain weekly using a good quality SAE 50 to 90W EP oil. Lubricate the chain more fre-

3.

quently depending on the severity of service.

OPERATION

Always use an air line filter and lubricator with an MLK Hoist. The diameter of the air passage must be at least 1/2” (13

mm). We recommend using No. NFLRU-8 Filter-Lubricator-Regulator installed as close to the inlet of the Hoist as practical.

If quick disconnect fittings are used at the inlet of the Hoist, they must have at least a

3/8"

(9.5 mm) air passage. Use of

smaller fittings will reduce performance.

OPERATING PRACTICES

The two most important aspects of Hoist operation are: (1) Allow only qualified people to operate a Hoist, and (2) Sub-

ject each Hoist to a regular inspection and maintenance procedure.

A qualified operator must be physically competent. He must have no health condition which might affect his ability to react, and he must have good hearing, vision and depth perception. The qualified Hoist operator must be carefully instructed in

his duties and must understand the operation of the Hoist, including a study of the manufacturer’s literature. He must thoroughly understand proper methods of hitching loads. He should have a good attitude regarding safety and should refuse to

operate under unsafe conditions.

Proper use of a Hoist begins before a load is lifted. Make certain to:

a. Check to see that the Hoist is directly over the load. Do not lift the load at an angle.

b. Check to see that the Hoist is securely connected to the overhead crane, monorail, trolley or supporting member.

c. Check to see that the load is securely inserted in the hook.

Regular inspection procedures should be set up, rigidly adhered to and recorded by or under the direction of a qualified

person. On Hoists in continuous service, inspection should be made at the beginning of each shift. The items to be checked

include, but are not limited to:

a. Lubrication according to the instructions above.

b. Brakes: Lift a capacity or near capacity load a few inches off the floor and check ability of braking system to stop and

hold the load and without excessive drift.

c. Chain and Hooks: Visually inspect the load chain for cleanliness and lubrication as well as wear or other damage. Note:

Excessive wear may not be apparent upon casual observation. The only positive check is to gauge it according to manufacturer’s instructions. Refer to CHAIN REPLACEMENT on page 7. Never operate a Hoist with dry, dirty, worn, damaged

or kinked chain.

Page 5

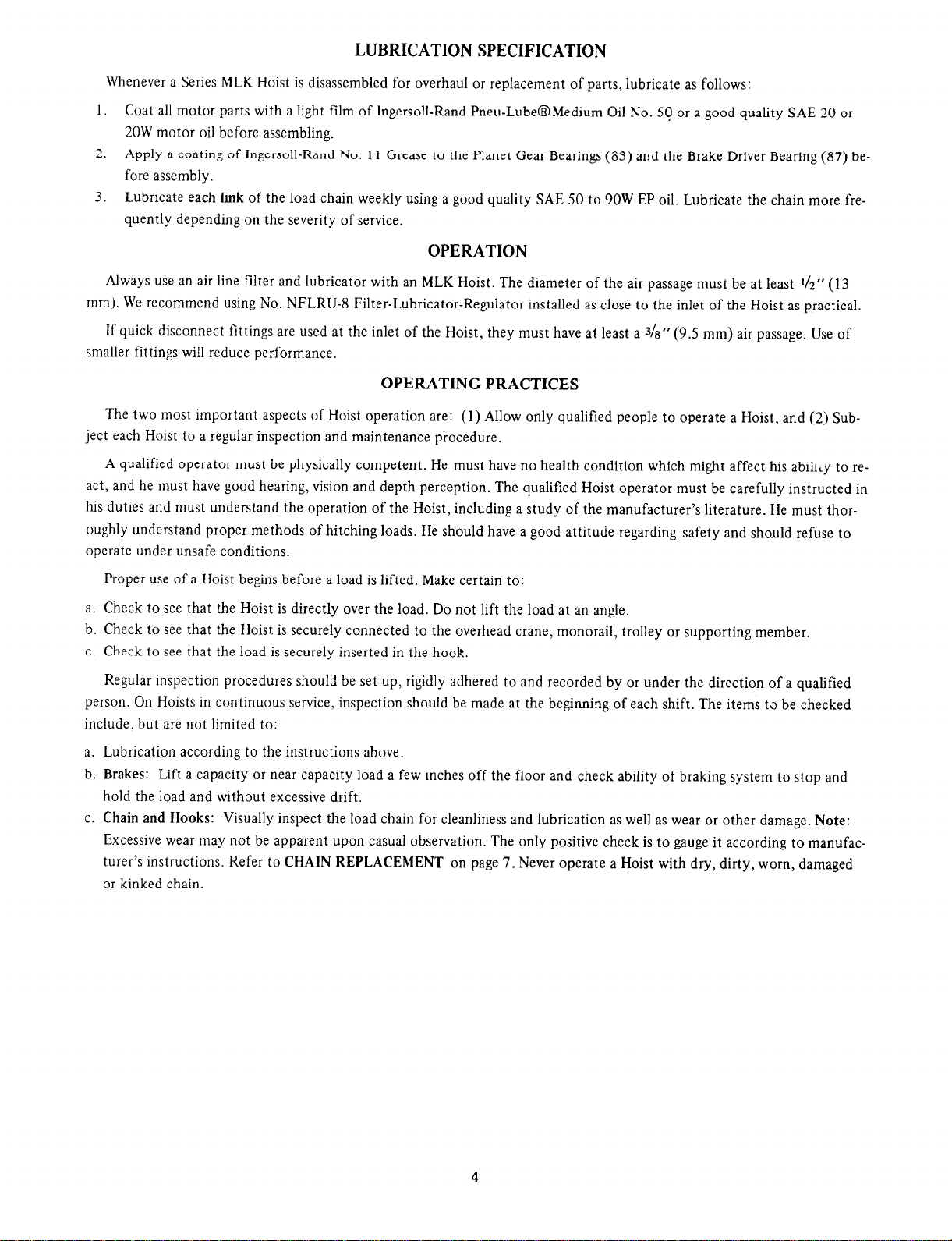

Hooks should be checked for wear. increase in throat opening, and bending.

(Note:

Increased throat opening or a bent

hook indicates overloading or abuse). Replace hooks having a 15% increase in throat opening or 10% bend. If the hook latch

snaps past the tip of the hook, the hook is sprung and must be replaced. Check hook support bearings for lubrication or damage. See that they swivel easily and smoothly.

(Dwg. TPD450)

Hoist Size

For ML25K and

MLS0K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

For ML100K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

in mm

1-1/6

I-1/4

“T” Throat Opening

New Hook Discard Hook

27.0

31.8

in

l-7/32

l-7/16 36.5

mm

31.0

Observe the action of Chain feeding through the Hoist. Do not operate a Hoist unless the Chain feeds through the Hoist

and Hook Block smoothly and without audible clicking or other evidence of binding or malfunctioning.

d. Controls: See that the controls function properly and return to neutral when released, Check the functioning of up and

down stops by running the empty hook slowly to both extremes of travel. If the hook does not stop in its normal position,

do not operate the Hoist until the cause of the trouble is located and corrected.

e. General: Check to see that suspension fastenings are secure, unworn and undamaged. On trolley-mounted Hoists, check

that trolley wheels track the rail properly and that wheels and rail are not excessively worn. Be alert for unusual visual or

audible signs which could indicate a defect. Do not operate the Hoist until the defect has been determined and corrected.

Periodically, depending upon severity of service, the following items should also be inspected. These are in addition to

those previously listed.

a. Check all load-supporting members, including Chain, Pocket Wheel and Chain Guides, for excessive wear or damage.

b. Inspect top and bottom hooks with a magnetic particle or other suitable crack detector.

c. Hook retaining nuts or collars along with their locking members and support bearings should be inspected. Proper inspec-

tion will require disassembly.

d. Check and clean the brake parts each time the Hoist is disassembled. Replace the brake disc if the thickness is less than

.090 in (2.286 mm).

e. At least once yearly disassemble the Hoist and check for worn gearing, bearings and shafts. The parts should be cleaned,

lubricated and reassembled. Replace worn parts.

f. Check all Trolleys for smoothness of operation and for wear on supporting members.

g. Check for excessive wear in the fabric in a Fabric Chain Container. and check for loose mounting bolts and nuts on Fabric

and Metal Chain Containers.

5

Page 6

OPERATING INSTRUCTIONS

1.

Read the manufacturer’s operating instructions before operating the Hoist.

Never lift a load greater than the rated capacity of the Hoist.

2.

Never use the load chain as a sling.

3.

4.

Never operate the Hoist with twisted, kinked or damaged chain.

Be certain the load is properly seated in the saddle of the hook. Faulty loading leads to spreading of the hook.

5.

6.

Do not use load chains as a ground for welding. Do not attach a welding electrode to a Hoist or sling chain.

Do not use the up and down stops as means of stopping a Hoist-these are emergency devices only. Keep hands and

7.

clothing free from the throttle lever.

8.

Do not leave a load suspended for any extended period.

9.

Always stand clear of the load.

Never use the Hoist for lifting or lowering people, and never stand on a suspended load.

10.

11.

Never carry loads over people.

12.

Before each shift, check the Hoist for wear or damage. Check brakes, limit stops, etc.

13.

Periodically inspect the Hoist thoroughly and replace worn or damaged parts.

14.

Follow the lubrication instructions.

15.

Do not attempt to repair load chain or hooks. Replace them when they become worn or damaged.

16.

Never operate a Hoist when the load chain is not centered under the hook. Do not “side pull” or “yard”.

17.

Always rig the Hoist properly and carefully.

18.

Ease the slack out of the load chain when starting a lift. Do not jerk the Hoist.

19.

Keep the load chain clean and well lubricated. Do not drag the load chain or hook on the floor.

20.

Be certain there are no objects in the way of a load or hook when moving the Hoist.

21.

Be certain the air supply is shut off before performing maintenance work on the Hoist.

22.

Avoid swinging the load when moving the Hoist.

23.

Keep the load block overhead when not in use.

24.

Properly secure an outdoor Hoist before leaving it unattended.

25.

Do not allow unqualified personnel to operate a Hoist.

26.

Avoid collision or bumping of Hoists. Do not swing a suspended load.

27.

Do not operate a Hoist if you are not physically fit to do so.

28.

Do not do anything that you feel may be unsafe.

Pay attention to the load at all times when operating a Hoist.

29.

30.

Never splice a hoist chain by inserting a bolt between links or by any other means.

Do not force a chain or hook into place by hammering, and never insert the point of the hook into a chain link.

31.

Do not allow the chain to be exposed to extremely cold weather. Do not apply sudden loads to a cold chain.

32.

6

Page 7

CHAINLUBRICATION

The load chain and chain attachment pins must, be kept clean and lubricated at all times. Unlubricated Chain will wear out

in a very few capacity lifts. Failure to maintain clean lubricated Chain will void the Manufacturer’s Warranty and cause chain

wear which will make operation of the Hoist hazardous. Use an open chain lubricant or any good EP gear oil. Several excellent types of open chain lubricants are available and can be purchased in convenient aerosol cans.

CHAINREPLACEMENT

Excessive Chain wear cannot be detected by casual observation. The Chain is case hardened to a depth of .0l0” to .012”,

and once this case is worn through, wear will progress rapidly and the strength of the Chain will be considerably reduced. Further, the Chain will no longer fit the Chain Wheel properly, greatly increasing the chance of malfunction and Chain breakage.

Periodically, as experience dictates, examine the Chain for wear. Be certain to inspect that portion of the Chain which reg-

ularly passes over the Chain Wheel, since this is the portion that suffers the greatest wear. Check the individual links for stria-

tion-that is, minute parallel lines indicating excessive stress or wear.

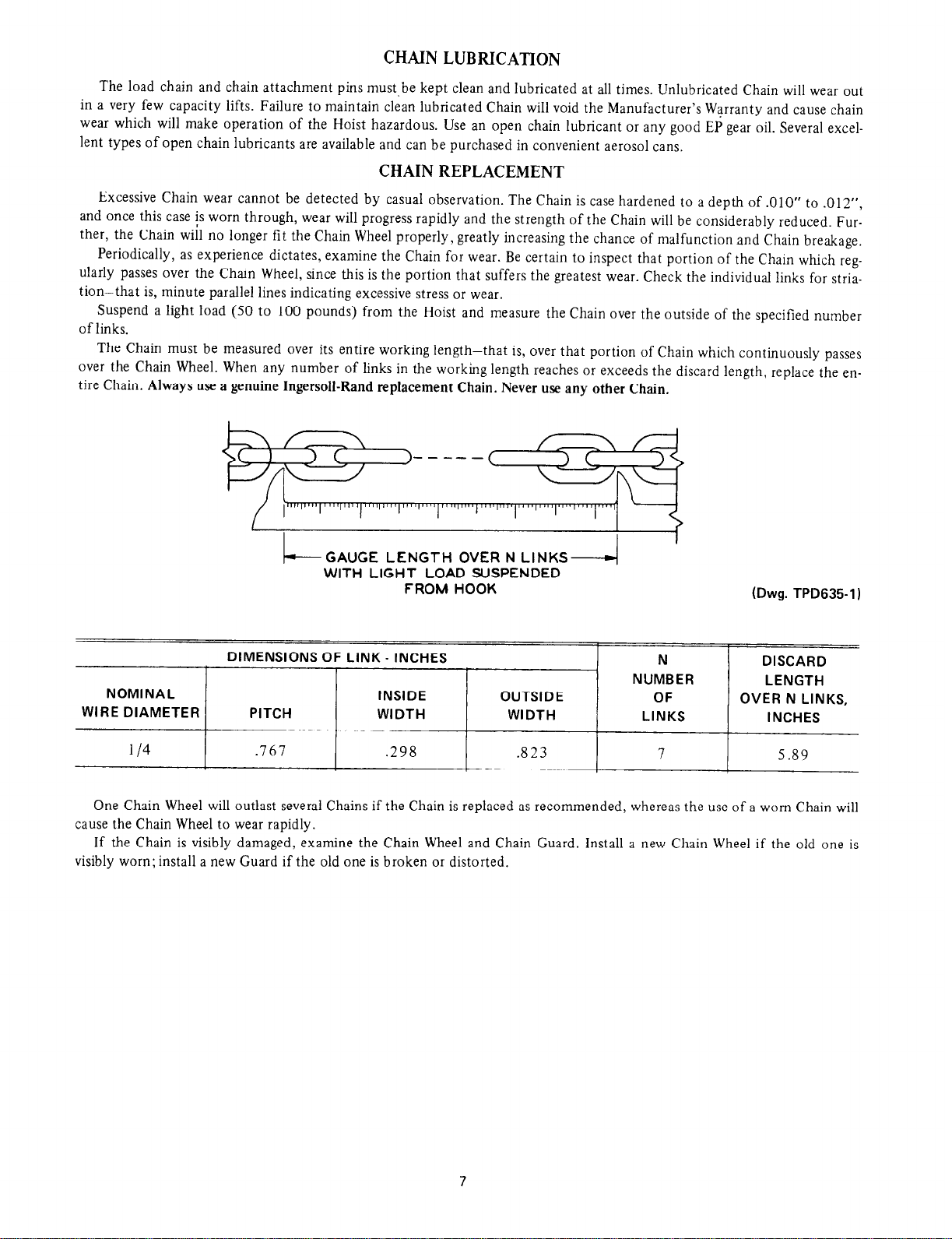

Suspend a light load (SO to 100 pounds) from the Hoist and measure the Chain over the outside of the specified number

of links.

The Chain must be measured over its entire working length-that is, over that portion of Chain which continuously passes

over the Chain Wheel. When any number of links in the working length reaches or exceeds the discard length, replace the entire Chain. Always use a genuine Ingersoll-Rand replacement Chain. Never use any other Chain.

GAUGE LENGTH OVER N LINKS

WITH LIGHT LOAD SUSPENDED

NOMINAL

WIRE DIAMETER

1/4

FROM HOOK

DIMENSIONS OF LINK - INCHES

INSIDE OUTSIDE OF

PITCH

.767 .298 .823

WIDTH WIDTH LINKS

N

NUMBER LENGTH

7

(Dwg. TPD635-1)

DISCARD

OVER N LINKS,

INCHES

5.89

One Chain Wheel will outlast several Chains if the Chain is replaced as recommended, whereas the use of a worn Chain will

cause the Chain Wheel to wear rapidly.

If the Chain is visibly damaged, examine the Chain Wheel and Chain Guard. Install a new Chain Wheel if the old one is

visibly worn; install a new Guard if the old one is broken or distorted.

7

Page 8

CHAIN REPLACEMENT (Continued)

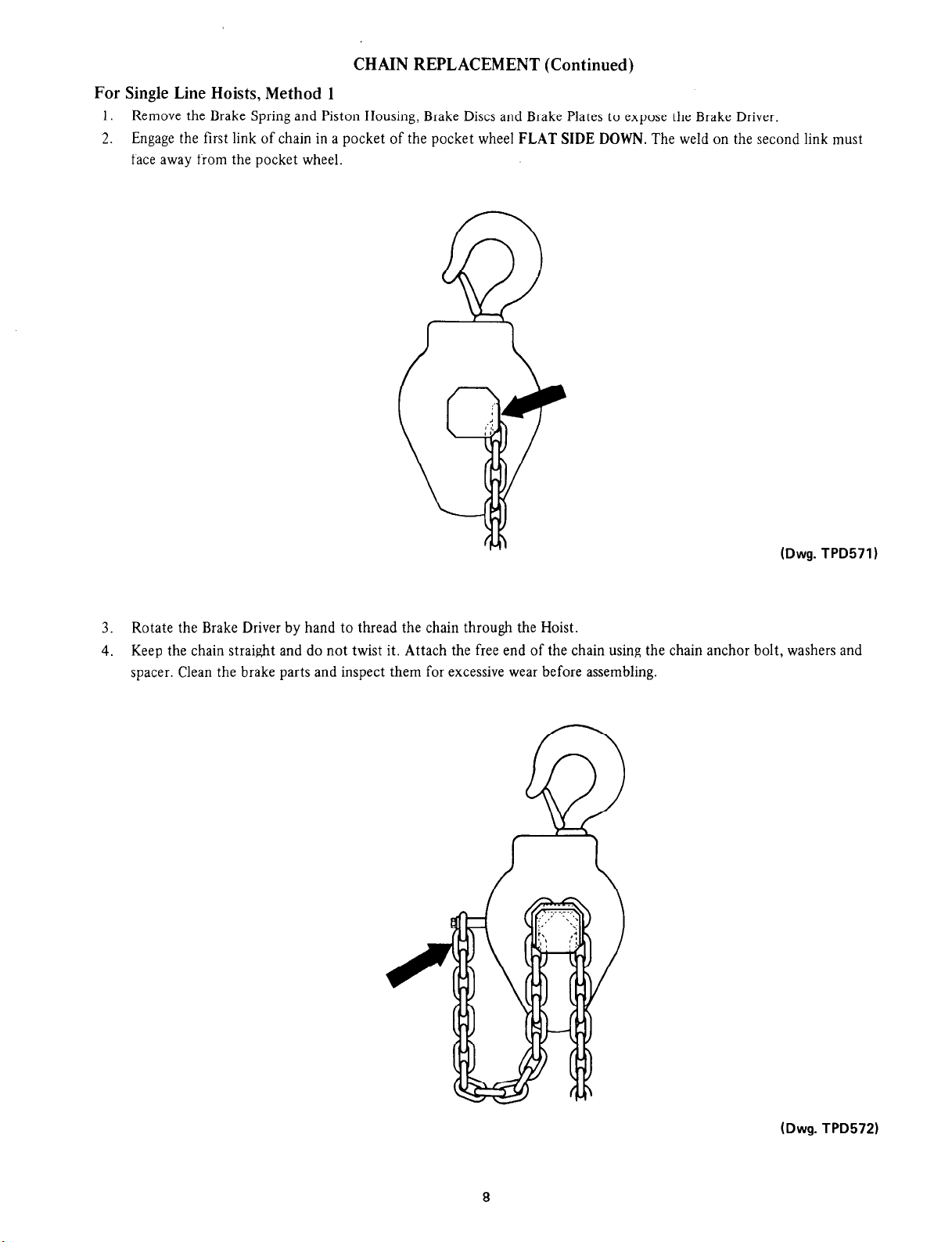

For Single Line Hoists, Method 1

1. Remove the Brake Spring and Piston Housing, Brake Discs and Brake Plates to expose the Brake Driver.

2. Engage the first link of chain in a pocket of the pocket wheel

face away from the pocket wheel.

FLAT SIDE DOWN.

The weld on the second link must

(Dwg. TPD571)

3. Rotate the Brake Driver by hand to thread the chain through the Hoist.

4. Keep the chain straight and do not twist it. Attach the free end of the chain using the chain anchor bolt, washers and

spacer. Clean the brake parts and inspect them for excessive wear before assembling.

(Dwg. TPD572)

Page 9

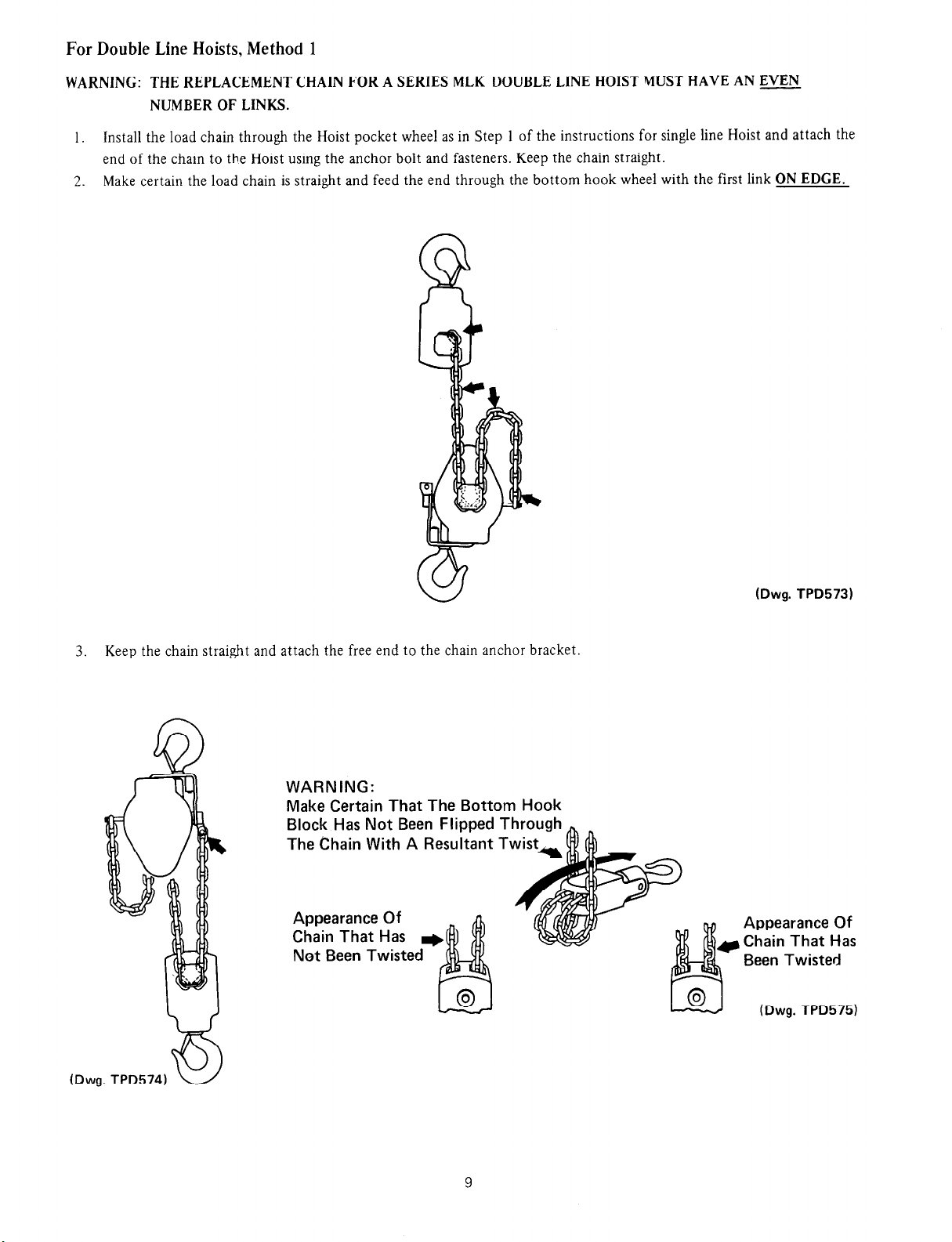

For Double Line Hoists, Method 1

WARNING: THE REPLACEMENT CHAIN FOR A SERIES MLK DOUBLE LINE HOIST MUST HAVE AN EVEN

NUMBER OF LINKS.

1. Install the load chain through the Hoist pocket wheel as in Step 1 of the instructions for single line Hoist and attach the

end of the chain to the Hoist using the anchor bolt and fasteners. Keep the chain straight.

2. Make certain the load chain is straight and feed the end through the bottom hook wheel with the first link ON EDGE.

3. Keep the chain straight and attach the free end to the chain anchor bracket.

WARNING:

Make Certain That The Bottom Hook

Block Has Not Been Flipped Through

The Chain With A Resultant Twist+

Appearance Of

Chain That Has

(Dwg. TPD573)

Appearance Of

Chain That Has

Been Twisted

(Dwg. TPD575)

(Dwg. TPD574)

9

Page 10

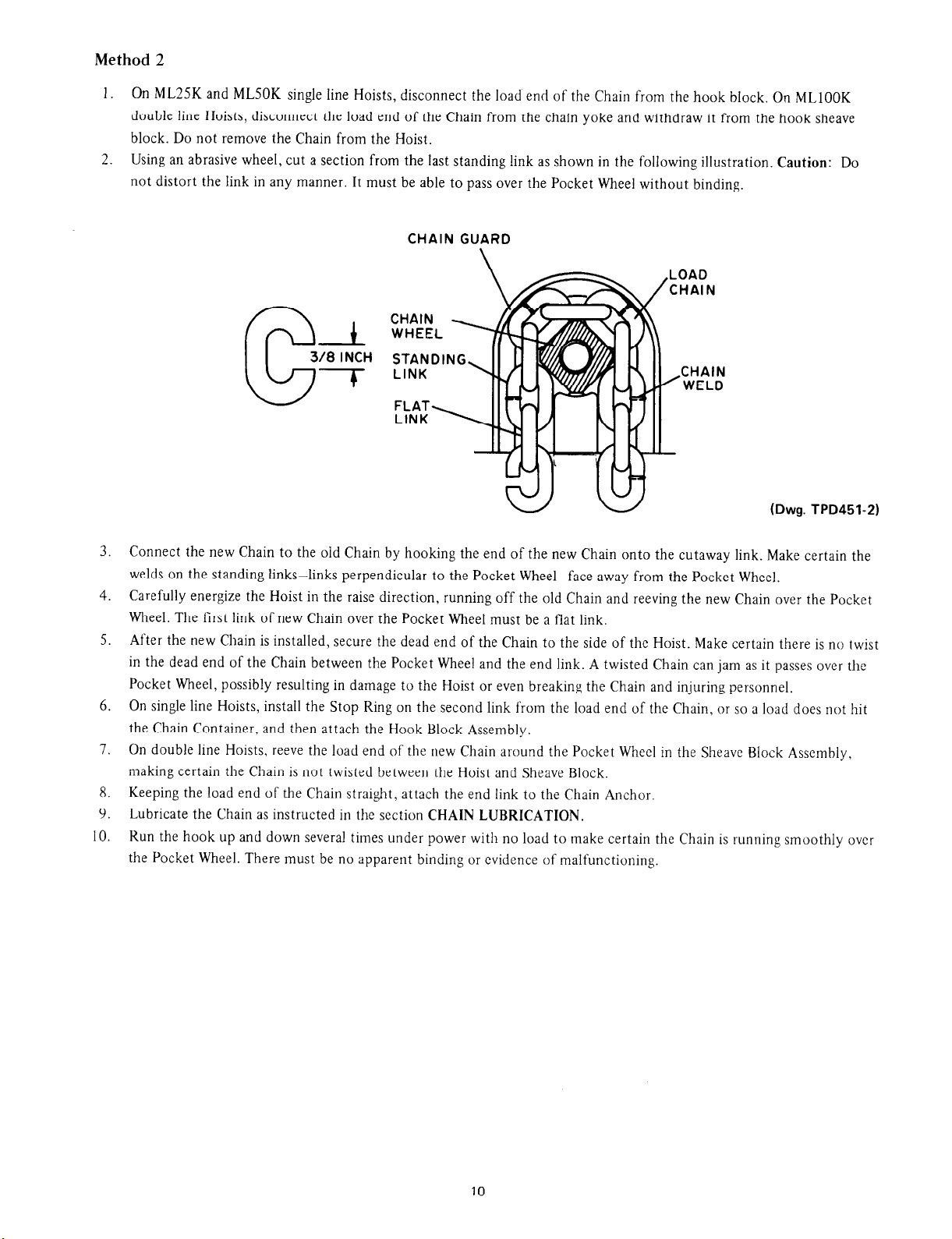

Method 2

On ML25K and MLS0K single line Hoists, disconnect the load end of the Chain from the hook block. On ML100K

1.

double line Hoists, disconnect the load end of the Chain from the chain yoke and withdraw it from the hook sheave

block. Do not remove the Chain from the Hoist.

Using an abrasive wheel, cut a section from the last standing link as shown in the following illustration. Caution: Do

2.

not distort the link in any manner. It must be able to pass over the Pocket Wheel without binding.

CHAIN GUARD

(Dwg. TPD451-2)

Connect the new Chain to the old Chain by hooking the end of the new Chain onto the cutaway link. Make certain the

3.

welds on the standing links-links perpendicular to the Pocket Wheel-face away from the Pocket Wheel.

Carefully energize the Hoist in the raise direction, running off the old Chain and reeving the new Chain over the Pocket

4.

Wheel. The first link of new Chain over the Pocket Wheel must be a flat link.

After the new Chain is installed, secure the dead end of the Chain to the side of the Hoist. Make certain there is no twist

5.

in the dead end of the Chain between the Pocket Wheel and the end link. A twisted Chain can jam as it passes over the

Pocket Wheel, possibly resulting in damage to the Hoist or even breaking the Chain and injuring personnel.

On single line Hoists, install the Stop Ring on the second link from the load end of the Chain, or so a load does not hit

6.

the Chain Container, and then attach the Hook Block Assembly.

On double line Hoists, reeve the load end of the new Chain around the Pocket Wheel in the Sheave Block Assembly,

7.

making certain the Chain is not twisted between the Hoist and Sheave Block.

Keeping the load end of the Chain straight, attach the end link to the Chain Anchor.

8.

9.

Lubricate the Chain as instructed in the section CHAIN LUBRICATION.

Run the hook up and down several times under power with no load to make certain the Chain is running smoothly over

10.

the Pocket Wheel. There must be no apparent binding or evidence of malfunctioning.

I0

Page 11

DISASSEMBLY

WARNING:

DISCONNECT THE AIR SUPPLY HOSE BEFORE PERFORMING MAINTENANCE ON THIS HOIST.

Note: Refer to the illustrations on the following pages. Disassemble the Hoist only as far as necessary to service the worn

or broken component.

1.

The Brake Piston (99) located in the Piston Housing (96) may be serviced by removing the Plate Screws (104). Plate

(103), Shoulder Bolts (105) and Lock Washers (106).

2.

Place the Piston Housing Assembly and Pressure Plate (98) down on a press table. Compress the Springs between the

Pressure Plate and the Housing and remove the Piston Nut (102). WARNING: Release the pressure of the Springs carefully.

3.

Push the Brake Piston (99) from the Housing.

Note: It is necessary to remove the Brake Driver Retainer (67) before the motor components can be removed.

4.

Remove the Muffler Cover Screws (33) and the Valve Chest Cover Screws (45).

5.

Remove the Valve Chest Screws (19) and remove the Valve Chest (16) from the Housing(l). Note: The Throttle Disc

Seals (58) and Seal Expanders (59) are free to fall from the Throttle Disc (57) as the Valve Chest is removed.

ASSEMBLY

Before assembling the Hoist clean and apply a light film of oil or grease where specified, to each part. Apply a thin film of

O-ring lubricant to each O-ring before final assembly. Clean and lubricate the load chain each time maintenance is performed

in addition to the regular maintenance schedule.

Assembly of Valve Chest End

Install the Motor Shaft Front Retaining Ring (66)

1.

(75) Front End Plate (74), bearing diameter first, and Rotor (70) small diameter first, onto the Shaft.

Apply a light film of oil to each Vane (71) slide one Vane into each slot and slide the Cylinder (72) over the Rotor.

2.

Slide the Rear End Plate (69) and Rear End Plate Bearing (68) over the short end of the Motor Shaft and apply the Mo-

3.

tor Shaft Rear Retaining Ring (65).

4.

Align the holes in the Front and Rear End Plates with the dowel hole in the Cylinder and slide a l/8” diameter rod

12” long through the aligned parts.

Place the Motor Retaining Washer (76), dished (concave) side first, over the Front End Plate and engage the dowel hole

5.

with the rod.

6.

Slide the long hub of the Motor Shaft into the Housing(l), insert the guide rod into the pilot hole in the Housing and

seat the motor.

Remove the guide rod and replace it with the Cylinder Dowel (73).

7.

8.

Apply the Housing Gasket (9) onto the motor end of the Housing and apply the Valve Plate (60) over the Gasket.

Apply a heavy film of O-ring lubricant to the Throttle Disc Seals (58) and the Seal Expanders (59). Insert an Expander,

9.

small diameter first, followed by a Seal, into each of the two recesses in the Throttle Disc (57).

10.

With the valve ports oriented as illustrated on Page 20, slide the Throttle Disc over the hub of the Rear End Plate.

With the Throttle Shaft (34) in place in the Housing(l), slide the Limit Gear (36) onto the keyed end of the Shaft and

11.

engage the teeth on the Gear with those on the Throttle Disc.

For Hoists equipped with Pull Chain Throttle, apply the Throttle Shaft Spring (42) into the Valve Plate before install-

12.

ing the Limit Gear.

13.

For Hoists equipped with Pendent Throttle:

a. Install one Pendent Piston Seal (22), cupped side trailing, onto the Pendent Piston (21). Push the Piston through the

bore of the Valve Chest to the opposite side and install the remaining Seal cupped side outward.

b. Apply the Piston Rod Seal (24) to the Piston Rod (23) and slide the Rod into the bore of the Piston so the ends of

the Rod protrude equally beyond the Piston.

c. Slide a Piston Spring Retainer (27), small diameter trailing, followed by a Spring (26) over the ends of the Rod.

d. Align the hole in the Piston with the slot in the back of the Valve Chest.

e. Insert the Piston Drive Pin (25) into the Piston through the slot in the Valve Chest. Install the Piston Cylinder

Caps (28).

onto the Motor Shaft (64) and slide the Front End Plate Bearing

11

Page 12

f. Align the bolt holes in the Valve Chest with those in the Valve Plate (60) and Housing (1) and retain with Valve

Chest Screws (I 9) and Lock Washers (20).

14. Insert the Muffler Inserts and Muffler (31) into the recesses in the top of the Valve Chest and retain them with the Muffler Cover (32) and Screws (33).

15. For Hoists with Pull Chain Throttle:

a. Install a Pipe Plug into each of the three tapped holes in the Valve Chest.

b. Apply the Valve Chest Cover- Grommet and Valve Chest Cover (44) and retain both with the Valve Chest Cover

Screws (45).

I5. For Hoists equipped with Pendent Control:

a. Install an Elbow (221) in each of the tapped holes in the Valve Chest.

b. Slide the Pendent Grommet (231). small diameter first, over the Pendent Bundle.

c. Install the air supply hose from the Hose Bundle to the top center Elbow, the “up” hose to the left Elbow and the

“down” hose to the right Elbow.

d. Insert the Stop Sleeve (227) into the recess in the Valve Chest, align the grooves in the Pendent Grommet with the

slot in the Valve Chest Cover (44) and retain them using the Cover Screw Washers (46) and Valve Chest Cover

Screws (45).

e. Clean the Bundle

Note:

The Stop Sleeve must be firmly crimped onto the Pendent Bundle cable.

and

Grommet to remove all grease and oil.

Assembly of Chain Wheel, Brake and Gearing

1. Apply the Chain Wheel Plain End Washer (79) onto the plain end of the Chain Wheel (77) and press the Bearing (78)

onto the Chain Wheel hub.

2. Similarly install the Splined End Chain Wheel Washer (81) and Bearing (80) on the splined end of the Chain Wheel.

3. Slide the Chain Wheel, plain end first, over the end of the Motor Shaft (64) into the brake end of the Housing (1). Tap

the assembly to seat the Plain End Bearing (78).

4. Install two Planet Gear Bearings (84) into each of the Planet Gears (83) using Bearing Inserting Tool No. 45675.

tion: Lubricate the Bearings as instructed on Page 4 and press only on the hardened stamped end of the Bearing.

5. Install the Planet Gears using the Planet Gear Shaft (86) and Thrust Washers (85).

6. Insert the Brake Driver Bearing (88) in the smooth bore of the Planet Gear Frame (82).

Caution:

Lubricate the Bearing

as instructed on Page 4 and press only on the hardened stamped end.

7. Press the Gear Frame Bearing (87) onto the bearing diameter of the Gear Frame. Lubricate as above.

Cau-

12

Page 13

8.

Caution: It is very important that the Planet Gears and Ring Gear (89) be timed when the Gear Frame Assembly is inserted into the Ring Gear. Time the gearing as follows:

a. Align the bolt holes in the Ring Gear and Brake Housing (9 1) and press in the Ring Gear.

b. Stand the Ring Gear and Housing upright.

c. Align the arrows and scribe lines on the faces of the Planet Gears in a straight line as illustrated below.

(Dwg. TPD35-I)

d. Maintain this alignment, insert the Gear Frame Assembly into the Ring Gear and simultaneously press the Planet

Frame Bearing into the Brake Housing.

e. Make certain the Gasket (90) is in place and install the assembled Planet Frame, Ring Gear and Brake Housing over

the Motor Shaft and into the Housing. The Motor Shaft must turn freely by hand. The gear train and Chain Wheel

must rotate smoothly as the shaft is turned.

9. Install the Brake Driver (93) and Brake Driver Retaining Ring (67).

10. Stack the brake components over the Brake Driver and into the Brake Housing as illustrated on Page 16. Align the

notches in the Brake Plates with the bolt holes in the Brake Housing (9 1) and main Housing (1).

11. Assemble the Brake Spring and Piston Housing Assembly as follows:

a. Apply O-ring lubricant to the Large Seal (100) and Small Seal (101) and install them in their respective grooves on

the Brake Piston.

b. Taking care not to cut the Seals (100 and l0l), slide the Piston into the Brake Spring and Piston Housing (96).

c. Place the Spring and Piston Housing (96) on a bench, three spring holes facing upward.

d. Place a Spring (97) in each of the holes and place the Pressure Plate (98), stud first, over the Springs and into the

Brake Piston.

e. Hold the Plate and Housing together and flip the Housing over with the threaded stud up.

f. Press down on the Brake Spring and Piston Housing to force the threaded stud through the Piston. While maintain-

ing this position, tighten the Piston Nut (102) to 50 to 70 in-lb (5.65 to 7.9 1 N m) torque. Note: Make certain the

Piston is fully inserted through the Spring and Piston Housing and that it is in full contact with the Pressure Plate.

g. Install the Plate (103) using the Plate Screws (104).

h. Align the bolt holes in the Brake Spring Housing with those in the Housing (1) and install the Lock Washers (106)

and Shoulder Bolts (105).

13

Page 14

END VIEW OF MLK HOIST WITH

PENDENT THROTTLE

MLK Hoist with Pendent Throttle

(Dwg. TPA715

-2)

Page 15

PART NUMBER FOR ORDERING

t

Housing Assembly ..................

H

1

l

2

3

4

*

*

*

*

l

9

10

11

12

13

*

*

16

17

l

18

19

20

21

l

22

23

l

24

25

26

27

28

l

29

30

31

Housing. .......................

Throttle Shaft Bearing (3).

...........

Vent Plug. ......................

Throttle Shaft Plug ................

Nameplate ......................

Nameplate Screw (4) ...............

Caution Tag. ....................

Caution Tag Screw (4) ..............

lousing Gasket ....................

H

ChainGuide..

....................

Chain Guide Screw (4). ...............

Lck Washer (4). ...................

I

Chain Guard ......................

Guard Retaining Screw (2).

Lock Washer (2). ...................

I

............

Valve Chest. ......................

Valve Chest Inlet Plug ............

Valve Chest Gasket. .................

Valve Chest Screw (5) ................

Lock Washer (5). ...................

I

Pendent Piston. ....................

Pendent Piston Seal (2).

.............

Pendent Piston Rod .................

Piston Rod Seal. ..................

I

Piston Drive Pin ....................

I

Piston Spring (2) ...................

I

Piston Spring Retainer (2)

I

Piston Cylinder Cap (2) ...............

.............

Cylinder Cap Seal (2) ................

Cylinder Cap Screw (8) ...............

Mluffler.

.........................

...

ML50K-A300

ML50K-300

R38M-603

P250-546

ML50K-29

MR-301

R4K-302

TA-147A

9BM-302

ML50K-445

ML-741C

34U-463

4U-58

ML-6A

G57T-634

L0l-67

ML50K-545

GA57-95

ML50K-928

PR22H-548

8U-58

ML50K-A246

ML50K-248

ML50K-A65 5

ROBRC-283

ML50K-256

ML50K-250

ML50K-249

ML50K-238

HRA20A- 117

CEll0-354

ML50K-175

l

l

l

l

l

l

Muffler Insert (2)

31A

Muffler Cover .....................

32

Muffler Cover Screw (4).

33

Throttle Shaft

34

35

36

37

38

39

*

Throttle Shaft Seal

Limit Gear

Throttle Lever.

Throttle Lever Retaining Pin.

Throttle Lever Thrust Washer (2).

S-Hook (for Hoists with Pull Chain

Throttle (4).

*

Pull Chain (for Hoists with Pull Chain

Throttle) (2)

Throttle Shaft Spring (for Hoists with Pull

42

Chain Throttle)

*

l/8” Pipe Plug (for Hoists with Pull Chain

Throttle) (3)

Valve Chest Cover.

44

Valve Chest Cover Screw (4).

45

Cover Screw Washer (4).

46

*

Valve Chest Cover Grommet (for Hoists

...................

..............

.....................

................

.......................

....................

......................

......................

....................

......................

..................

..............

with Pull Chain Throttle).

*

Warning Plate.

*

Warning Plate Fastener (2)

Stop Sleeve

55

Throttle Disc.

57

Throttle Disc Seal (4)

58

Seal Expander (4).

59

Valve Plate

60

Brake Tube.

61

Brake Tube Seal (2)

62

Brake Tube Housing Seal

63

.....................

.......................

.....................

................

..................

.......................

......................

.................

..............

...........

........

...........

.............

.............

ML50K-675

ML50K-342

CEll0-354

ML50K-A255

834-l59

ML50K-25 1

ML50K-556

WF171-15

MR-458

D02-421

MRl0-413-10

ML50K-412

R2-227

ML50K-241

CEll0-354

MF-37

ML50K-377

CA1l0-598

CEll0-4

ML50K-520

ML50K-102

ML50K-5

410-283

ML50K-549

ML50K-40 1

ML50K-21

PS3-67

* Not illustrated.

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one (pair or set) of each part indicated by a

Page 16

\

104

102

103

100

Brake Parts

for MLK Hoist

(Dwg.

TPB613-3)

Motor Parts

(Dwg. TPB702)

for MLK Hoist

I6

Page 17

Gearing for MLK Hoist

(Dwg. TPC396-1)

Sprocket Assembly for MLK Hoist

17

(Dwg. TPC397-I)

Page 18

64

l

65

l

66

67

l

68

69

70

l

71

72

73

74

l

75

76

77

l

78

79

l

80

81

MotorShaft

I

Motor Shaft Rear Retaining Ring.

Motor Shaft Front Retaining Ring

Brake Driver Retainer.

Rear End Plate Bearing

1

Rear End Plate.

1

Rotor

Vane Packet (set of 7 Vanes)

Cylinder

Cylinder Dowel

1

Front End Plate.

1

Front End Plate Bearing.

Motor Retaining Washer.

ChainWheel

Chain Wheel Plain End Bearing

Chain Wheel Plain End Washer

Chain Wheel Splined End Bearing

Chain Wheel Splined End Washer.

.................................................

................................

................................

........................................

.........................................

..............................................

.....................................................

.....................................

...................................................

..............................................

.............................................

........................................

........................................

................................................

....................................

....................................

..................................

..................................

ML50K-316

MLK-120

MLK-119

ML50K-729

R2-24

ML50K-12

MR-53

MR-42-7

MR-3

R3H-434

MR-11

TB-394

MR-207

ML-740B

MR-593

MR-974

MR-988

MR-975

Gear Frame Assembly

for ML25K

for ML50K and ML100K

82

Planet Gear Frame

for MLL25K

for ML50K and ML100K

83

Planet Gear Assembly (2)

for ML25K

for ML50K and MLl00K

84

85

86

87

l

88

89

l

90

91

91A

l

92

93

94

l

95

Planet Gear Bearing (2 for each Gear) ............................

Planet Gear Thrust Washer (4)

Planet Gear Shaft (2).

Gear Frame Bearing.

Brake Driver Bearing

Ring Gear

..................................................

Ring Gear Gasket.

Brake Housing

...............................................

Brake Housing Bolt Seal (4).

Brake Housing Bearing Seal

Brake Driver

................................................

Brake Plate (4).

Brake Disc (2)

...............................................

Brake Spring and Piston Housing Assembly

96

97

98

99

. 100

l

101

102

103

104

105

106

*

* Not illustratea.

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock

Spring and Piston Housing.

Spring (3)

................................................

Pressure Plate

...................................................

Piston

Piston Large Seal.

Piston Small Seal.

Piston Nut

Pate

................................................

....................................................

Plate Screw (2).

Shoulder Bolt (4).

Lock Washer (4).

Chain Anchor Bolt

...

..........................................

................................

..........................................

................................

..........................................

................................

...................................

........................................

.........................................

.........................................

............................................

....................................

......................................

..............................................

............................

.....................................

..............................................

.........................................

.........................................

............................................

............................................

.............................................

............................................

ML25K-A8

ML50K-A8

ML25K-8

ML50K-8

MRS-Al0

ML-A10

ML50K-654

ML50K-361

MR-191

ML50K-97

ML50K-318

ML50K-406

ML50K-3 1

ML50K-346

ML50K-27 1

HRA20A-990

ML50K-842

ML50K-834

ML50K-855

ML50K-A395

ML50K-395

ML50K-832

ML50K-A338

ML50K-A809

R2C-103

R00BR-210

ML50K-394

ML50K-981

CEll0-354

ML50K-7

D02-321

20BM-744

18

Page 19

*

*

*

111

112

113

114

116

117

. 118

. 119

l

120

121

126

127

128

129

130

131

. 132

. 133

. 134

135

136

. 137

l

138

l

139

l

140

141

Lockwasher ................................................

Washer ....................................................

Chain Anchor Bolt Spacer

.......................................

Chain

for ML25K and ML50K with 10’ (3.05 m) maximum lift

for MLl00K with lO’(3.05 m) maximum lift.

lift as specified

.......................................

top Ring Assembly (for ML25K and ML50K).

Stoping Pin

Stop Ring Plug

..............................................

.............................................

.........................

..................

New Style Bottom Hook Assembly (for ML25K and ML50K).

Hook Block (2).

...................................................

Hook

............................................

Hook Latch Kit ...........................................

Hook Bearing

Thrust Race (2).

Hook Block Bolt (2)

Bottom Hook and Block Assembly (for MLl00K)

Sheave Block Assembly (includes bearing) (2).

Sheave Block Screw (3)

Sheave Block Insert (3).

Pocket Wheel

Thrust Spacer (2)

..............................................

...........................................

.........................................

.......................

........................

.......................................

.......................................

..............................................

...........................................

Bottom Hook ..............................................

Hook Latch Kit ...........................................

Hook Bearing.

Thrust Race (2).

.............................................

............................................

Top Hook and Yoke Assembly

for ML25K and ML50K

.................................

for ML100K .........................................

Top Hook Yoke

for ML25K and ML50K

................................

for ML100K .........................................

Top Hook

for ML25K and ML50K

.................................

for ML100K .........................................

Hook Latch Kit

for ML25K and ML50K

.................................

for ML100K .........................................

Hook Retaining Ring

for ML25K and ML50K

.................................

for ML100K .........................................

Hook Bearing

for ML25K and ML50K

.................................

for ML100K .........................................

Thrust Race (2)

for ML25K and ML50K

.................................

for ML100K .........................................

Top Hook Yoke Pin (2).

........................................

...........

...............

L0l-67

B12-265

ML50K-145

CEll0-745

CE120-745

ML-745

MR-A259

34U-215A

502-95

MLK-A463

MLK-463

CE110-KS304

CEll0-S123

R4810-105

CEll0-596

MLK-461

MLl00K-A378

CE120-B378

CE120-312

CE120-38

CE120-380

CE120-80

HRA20A-S377

D0lS-123

CEll0-295

CE120-596

MRI0-AS590A

MLl00K-A590

MRl0-590A

ML20-590A

CElI0-KS304

HRA20A-S377

CEll0-S123

D0I-S123

MRl0-375

HRA20A-375

R4810-105

CEll0-295

CEll0-596

CE120-596

MR-964

* Not illustrated

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock

19

Page 20

28

44

Valve Chest for MLK Hoist

(Dwg. TPA712-2)

Page 21

Bottom Hook and Block Assembly for ML100K Hoist

(Dwg. TPC401)

(Dwg. TPD785)

New Style Bottom Hook for ML25K and ML50K Hoists

(Refer to page 30 for Old Style Bottom Hook)

21

Top Hook and Yoke for MLK Hoists

Page 22

OLD STYLE PENDENT HANDLE ASSEMBLY

n

204

205

\

A

204

(Dwg. TPC394-1)

PART NUMBER FOR ORDERING

Pendent Handle Assembly

200

201

l

202

l

203

204

204A

205

206

207

*

* Not illustrated.

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock

Pendent Handle

Pendent Throttle Valve (2)

Throttle Valve Face.

Pendent Throttle Spring (2).

Pendent Throttle Valve Cap (2)

Valve Cap Gasket (2).

Pendent Throttle Lever (2)

Throttle Lever Pin.

Handle Cover

Handle Cover Screw (4)

..........................................

..............................................

No longer available

.....................................

.......................................

....................................

..................................

........................................

.....................................

.......................................

22

ML50K-A264

R000BR1C-283

ROH-51

R000A2-266

AB025-239

HRA20A-273

508-98

ML50K-270

R2FA-662

Page 23

NEW STYLE PENDENT HANDLE ASSEMBLY

231

NOTE:PLACE GROMMETOVER HOSE

AND STRAIN RELIEF BEFORE MAKING

CONNECTIONS

225

317.

216

24

23

(Dwg. TPB701-I)

Page 24

l

l

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

Pendent and Hose Bundle

for 5 ft length

for length as specified.

Pendent Handle Assembly.

Pendent Handle.

Pendent Throttle Valve (2)

Throttle Valve Face.

Pendent Throttle Spring (2).

Pendent Throttle Valve Cap (2)

Pendent Throttle Lever (2)

Throttle Lever Pin.

Pin Lock Washer (2).

Strain Relief Support.

Relief Support Lock Washer (2).

Handle Screw (4).

l/8-27 NPT to 7/16-20 Tube Male Brass Elbow (3)

........................................

..................................

.....................................

..........................................

...................................

.....................................

..................................

................................

...................................

........................................

.......................................

......................................

...............................

.........................................

.....................

Hose and Strain Relief Bundle Assembly

for 5 ft Pendent

for length as specified.

......................................

..................................

Hose Assembly (3)

for 5 ft Pendent

for length as specified.

Hose Clamp (6).

7 / 16 x 3 / 16 Barbed Female Swivel Fitting (3).

l/8 NPT x 3/16 Barbed Straight Fitting (3)

......................................

..................................

........................................

....................

......................

Strain Relief Assembly

for 5 ft pendent

for length as specified.

Clamping Sleeve

Cable Thimble

Stop Sleeve

Warning Plate

...........................................

............................................

Warning Plate Fastener (2)

......................................

..................................

........................................

.........................................

...................................

Hose Tie (3 for 5 ft Pendent; 2 additional for each additional 5 ft of Pendent)

Grommet .................................................

Bushing ..................................................

MLK-A169-10

MLK-AL169

MLK-A269

MLK-269

MLK-K264

R000BRlC-283

MLK-51

R000A2-266

MLK-273

DLC-120

D02-138

MLK-450

H54U-352

MF-31

MLK-161

ML50K-AH3A-5

ML50K-AL3A

MLK-H3A-5

MLK-LH3A

CA1l0-476A

MLK-162

MLK-170

ML50K-WRJA-5

ML50K-LWR3A

MLK-521

MLK-602

ML50K-520

CA110-598

CE10-4

...

HRE20A-283

ML50K-236

HRA20A-82

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock

24

Page 25

Side View of Rigid Trolley

Sec. A-A

for ML25K and ML5OK

Trolley Parts for MLK Hoists

25

End View of Rigid Trolley

for ML100K

(Dwg.

TPA825-1)

Page 26

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

RIGID TROLLEY PARTS

PART NUMBER FOR ORDERING

I

Rigid Trolley Kit

for operation on I-beam having flanges 2.66” (68 mm) to 5.00” (127 mm) wide

for ML25K and ML50K (3-l/8” dia. wheels)

for operation on I-beam having flanges 3.00” (76 mm) to 5.00” (127 mm) wide

for all Models (4” dia. wheels)

for operation on Flat-Tread Monorail

for all Models (4” dia. wheels)

Trolley Bracket (2)

for MLK-K430

for CE120-K430 and CE120-K430T.

Trolley Wheel (4)

for MLK-K430

for CE120-K430.

for CEl20-K430T

Trolley Wheel Spacer (8).

Trolley Wheel Shaft Nut (4)

Trolley Wheel Shaft Lock Washer (4)

Trolley Bracket Bolt (2).

Trolley Bolt Nut (2).

Trolley Bracket Spacer (28) (as required).

Top Lug

for ML25K and ML50K

forMLl00K .........................................

Top Lug Spacer (for MLl00K) (2).

Top Lug Screw (for MLl00K) (2)

L

Lock Washer (for MLl00K) (2).

Top Lug Pin (2).

Link Chain Anchor Pin (for MLl00K)

L

L

Link Chain Anchor Pin Cotter (2) (for MLl00K)

.............................................

.......................................

.......................................

.....................................

.....................................

......................................

....................................

......................................

.........................................

..................................

...................................

.............................

.............................

..............................

...........................

.................................

.................................

...............................

........................

...................

........................

MLK-K430

CE120-K430

CE120-K430T

MLK-430

CE120-430

MRl0-691

MR20-691

MR20-691T

21-748

DU-562

D01-692

D01-694-8

D01-341A

D01-442-l/6

MRl0-425

ML20-425

MR20-446

Dl0-312A

D02-321

MR-964

ML20-962A

D02-524

26

Page 27

Trolley Assembly

for operation on 4” to 12” I-Beam having flanges 2.66” (68 mm) to 5.00”

(127 mm) wide

for ML25K and ML50K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for operation on 5” to 12” I-Beam having flanges 3.00” (76 mm) to 5.00”

(127 mm) wide

for MLl00K.............................................

for operation on Flat Tread Monorail

for ML25K and ML50K . . . . . . . . . . . . . . . . . . . . . . . .

for MLl00K.............................................

Trolley Wheel (4)

for Hook-On Trolley No. MRl0-7927 . . . . . . . . . . . . . . . . . . . . . . . . . .

for Hook-On Trolley No. MR20-7928 . . . . . . . . . . . . . . . . . . . . . . . . .

for Hook-On Trolley No. MRl0-7927T. . . . . . . . . . . . . . . . . . . . .

for Hook-On Trolley No. MR20-7928T . . . . . . . . . . . . . . . . . . . . . . . . . . .

Semi-Rigid Trolley Adapter

for ML25K and ML50K . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . .

for MLl00K.............................................

HOOK-ON TROLLEY PARTS

PART NUMBER FOR ORDERING

MRl0-7927

MR20-7928

MRl0-7927T

MR20-7928T

MRl0-691

MR20-691

MRl0-691T

MR20-691T

MRl0-852

ML20-852

INSTALLATION INSTRUCTIONS FOR FABRIC CHAIN CONTAINER KITS

ML50K-K479-17 AND ML50K-K749-45

WARNING: DISCONNECT THE HOIST FROM THE AIR SUPPLY BEFORE INSTALLING A CHAIN CONTAINER KIT.

Refer to illustrations on Page 28 and install a Fabric Chain Container as follows:

1. Insert a Container Bolt (270) through the boss on the Hoist housing and into the Brackets (266 and 267). Retain the

Container with the Container Bolt Nuts (271). Note: If the Container is to be allowed to swing outward, tighten the

Nuts to within one turn of being fully tight. This will allow the Container to swing away from a load.

2. Apply the Balance Chain (272) to the Container and Hoist using S-Hooks (273). Adjust the length of the Chain to prevent the load chain from rubbing on the Container.

27

Page 28

265

260

__-__

265

266

267

268

269

270

271

272

273

(Dwg. T

Fabric Chain Container

for ML50K-K749-17

for ML50K-K749-45

Left Bracket

Right Bracket

Bracket Bolt (4).

Bracket Bolt Nut (4)

Chain Container Bolt (2)

................................................

...............................................

.............................................

...........................................

........................................

Chain Container Bolt Nut (2)

Balance Chain

...............................................

...................................

...................................

.....................................

S-Hook ....................................................

B699)

(Dwg. TPD717)

Top View of Chain Container for MLK Hoist

PART NUMBER FOR ORDERING

ML50K-749-17

ML50K-749-45

ML50K-748

ML50K-747

R2N-103

ML50K-394

M0V010AA-634

ML50K-394

CA110-240-l/2

D02-421

28

Page 29

KITS AND ACCESSORIES

Fabric Chain Container: Includes Chain Container, Brackets and all hardware necessary for installation on a Hoist

No. ML50K-K749-17 (03551066) for use on an ML25K or ML50K Hoist with up to a 17 ft lift and on an MLl00K

Hoist with up to a 9 ft lift.

No. ML50K-K749- 45 (0355 1074) f or use on an ML25K or ML50K Hoist with up to a 45 ft lift and on an MLl00K

Hoist with up to a 23 ft lift.

Link Chain Metal Containers: One (1) No. FMD2-68 (03 109642) Chain Container Bolt and one ( 1) No. Tll-58 (03 14 1538)

Lock Washer must be ordered with each Chain Container.

No. MLl0-749 (03195336) for use on an ML25K or ML50K Hoist with up to 13 ft lift and on an MLl00K Hoist with up

to 6-l/2 ft lift.

No. ML20-749A (03195369) for use on an ML25K or ML50K Hoist with up to 26 ft lift and on an MLl00K Hoist with

up to 13 ft lift.

No. ML20-749-20 (03195385) for use on an ML25K or ML50K Hoist with up to 40 ft lift and on an ML100K Hoist with

up to 40 ft lift.

Conversion Kits: Include all components necessary to convert a pull chain throttle Hoist to pendent control operation.

No. ML50K-K930-10 (03551 140) for use on any MLK Hoist with 10 ft lift (5 ft pendent length).

No. ML50K-K930 (03551207) for use on any MLK Hoist with other than 10 ft lift. Length of pendent must be specified

when ordering. Pendent bundle length is normally 5 ft shorter than lift.

Trolley Kits

No. CE120-K430 (03510435) Plain Trolley Kit - Includes all Trolley parts for suspending a Hoist equipped with lug

mounting from an I-beam having 3.00” to 5.00” (76 mm to 127 mm) wide flange 4” (102 mm) diameter wheels.

No. CE120-K430T (03510443) Plain Trolley Kit - Includes all Trolley parts for suspending a Hoist equipped with lug

mounting from a flat tread monorail having 2.66” to 5.00” (68 mm to 127 mm) wide flange 4” (102 mm) diameter

wheels.

No. MLK-K430 (03611019) Plain Trolley Kit for use with ML25K and ML50K Hoist. Includes all Trolley parts for suspending a Hoist with lug mounting from an I-beam having 2.66” to 5.00” (68 mm to 127 mm) wide flange 3-l/8” (79

mm) diameter wheels.

Two and Three-Motor Pendents:

No. MLK-AL122 (03622487) - Two-motor pendent and hose assembly (Specify length of hose required).

No. MLK-AL132 (03622495) - Three-motor pendent and hose, assembly (Specify length of hose required.

Cross Mount:

No. ML500K-444 (03613023) for use on ML25K or ML50K.

No. MLl000K-444 (03613031) for use on MLl00K.

29

Page 30

OLD STYLE BOTTOM HOOK FOR ML25K AND ML50K

406

400

401

402

403

404

405

406

*

408

Hook Block (for ML25K and ML50K) .

Hook .......................

Hook Latch Kit.

Hook Bearing.

Thrust Race.

Link Chain Connector.

Connector Swivel Pin

Set Screw (2).

Link Chain Pin.

* Not illustrated.

..............

.................

..................

...........

............

.................

................

PART NUMBER FOR ORDERING

......

......

......

......

. . . . . .

......

......

......

......

......

......

......

......

......

......

......

......

......

........

........

........

........

........

........

........

........

........

(Dwg. TPD577-1)

. . . CEll0-463

. . . CEl10-KS304

. . . CEl10-S123

. . . MRl0-379

. . . CE120-596

. . . MLl0-461

. . .

. . .

. . .

MRl0-462A

R2J-561

MLl0-603

30

Page 31

Page 32

INGERSOLLRAND

9HO

Loading...

Loading...