Ingersoll-Rand M801P080BU48AA, M801P100CU48AA, M801P060AU36AA, M801P140DU60AA, M801P120DU60AA Installer's Manual

...

18-CD34D1-5-EN

INSTALLER’S GUIDE

Upflow/Horizontal — Downflow/Horizontal, Gas-Fired Furnaces,

“Fan Assisted Combustion System”

M801P040AU24AA

M801P060AU24AA

M801P060AU36AA

M801P080BU36AA

M801P080BU48AA

ALL phases of this installation must comply with

IMPORTANT — This Document is customer property and is to

remain with this unit. Please return to service

information pack upon completion of work.

M801P100BU36AA

M801P100CU48AA

M801P100CU60AA

M801P120DU60AA

M801P140DU60AA

M801P060AD24AA

M801P060AD36AA

M801P080BD45AA

M801P100CD48AA

M801P100CD60AA

M801P120DD60AA

M801P140DD60AA

NATIONAL, STATE AND LOCAL CODES

For VENT SIZING INFORMATION see:

USA —

National Fuel Gas Code ANSI Z223.1/ NFPA 54 (latest version)

CANADA—

Natural Gas Installation Code CAN/ CGA-B149.1 (latest version)

Propane Installation Code CAN/ CGA-B149.2 (latest version)

OPTIONAL ACCESSORIES

Model Number Description

BAYBASE205 Downflow subbase for downflow models

only

BAYFLTR200 External side filter rack

BAYFLTR203 Filter kit horizontal for 17.5" cabinet

BAYFLTR204 Filter kit horizontal for 21" cabinet

BAYFLTR205 Filter kit horizontal for 24.5" cabinet

BAYFLTR317 Cleanable filter for 17.5" cabinet upflow

only

BAYFLTR321 Cleanable filter for 21" cabinet upflow

only

BAYFLTR324 Cleanable filter for 24.5" cabinet upflow

only

BAYLPKT210B Propane conversion kit

BAYLPSS210B LP kit with stainless steel burners

BAYRACK960A Internals filter rack kit for upflow models

BAYVENT800B Masonry chimney vent kit for upflow only

KIT09224 Filter clip kit

BAYBRCKFLT10 Downflow bracket kit

FLR01185 Filter for 14-1/2" cabinet downflow only

FLR01186 Filter for 17-1/2", 21", 24-1/2" cabinet

downflow only

Upflow/ Horizontal* Downflow/ Horizontal*

*Horizontal Conversion for these furnaces may be left

or right side rotation.

A341789P12

INSTALLER’S GUIDE

WARNING

SAFETY SECTION

The following safety practices and precautions must be followed

during the installation, servicing, and operation of this furnace.

1. Use only with the type of gas approved for this furnace.

Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specied in “Location and Clearances” in this document.

3. Provide adequate combustion and ventilation air to the

furnace space as specied in “Air for Combustion and

Ventilation” in this document.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specied in the “Venting” section in this document.

5. Never test for gas leaks with an open ame. Use a

commercially available soap solution made specically

for the detection of leaks to check all connections, as

specied in “Gas Piping” in this document.

6. Always install the furnace to operate within the furnace’s

intended temperature-rise range with a duct system

which has an external static pressure within the allowable

range, as specied on the unit rating plate. Airow with

temperature rise for CFM versus static is shown in this

document.

7. When a furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled

by a duct(s) sealed to the furnace casing and terminating

outside the space containing the furnace.

8. A gas-red furnace for installation in a residential

garage must be installed as specied in “Location and

Clearances” section in this document.

9. The furnace may be used for temporary heating of

buildings or structures under construction only when the

following conditions have been met:

a. The furnace venting system must be complete and

installed per manufacturer’s instructions.

b. The furnace is controlled only by a room thermostat

(no eld jumpers).

c. The furnace return air duct must be complete and

sealed to the furnace and clean air lters are in place.

d. The furnace input rate and temperature rise must be

veried to be within nameplate marking.

e. 100% of the furnace combustion air requirement must

come from outside the structure.

f. The furnace return air temperature range is between

55 and 80 degrees Fahrenheit.

g. Clean the furnace, duct work, and components upon

substantial completion of the construction process,

and verify furnace operating conditions including

ignition, input rate, temperature rise and venting,

according to the manufacturer’s instructions.

10. This product must be gas piped by a Licensed Plumber

or Gas Fitter in the Commonwealth of Massachusetts.

Safety signal words are used to designate a degree or level of

seriousness associated with a particular hazard. The signal

words for safety markings are WARNING and CAUTION.

b. WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

c. CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It is also used to alert against unsafe practices

and hazards involving only property damage.

GENERAL INSTALLATION INSTRUCTIONS

The manufacturer assumes no responsibility for equipment

installed in violation of any code or regulation. It is recommended

that Manual J of the Air Conditioning Contractors Association

(ACCA) or A.R.I. 230 be followed in estimating heating

requirements. When estimating heating requirements for

installation at Altitudes above 2000 ft., remember the gas input

must be reduced (See GAS INPUT ADJUSTMENT).

Material in this shipment has been inspected at the factory

and released to the transportation agency without known

damage. Inspect exterior of carton for evidence of rough

handling in shipment. Unpack carefully after moving

equipment to approximate location. If damage to contents

is found, report the damage immediately to the delivering

agency.

Codes and local utility requirements governing the installation of

gas red equipment, wiring, plumbing, and ue connections must

be adhered to. In the absence of local codes, the installation must

conform with latest edition of the National Fuel Gas Code ANSI

Z223.1 • National Installation Code, CAN/CGA B149.1. The

latest code may be obtained from the American Gas Association

Laboratories, 400 N. Capitol St. NW, Washington D.C. 20001,

1-800-699-9277 or www.aga.org

These furnaces have been classied as Fan Assisted Combustion

system CATEGORY I furnaces as required by ANSI Z21.47

“latest edition” and CAN/CGA 2.3. Therefore they do not require

any special provisions for venting other than what is indicated in

these instructions.

!

▲

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death or property damage.

Improper servicing could result in dangerous

operation, serious injury, death, or property

damage.

© 2015 Ingersoll Rand — All Rights Reserved 18-CD34D1-5-EN

WARNING

INSTALLER’S GUIDE

!

▲

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for

each appliance connected to the venting system

being placed into operation could result in carbon

monoxide poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

Seal any unused openings in the venting

system.

1. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the CAN/CGA B149

Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause

an unsafe condition.

2. As far as practical, close all building doors and

windows and all doors between the space in which

the appliance(s) connected to the venting system are

located and other deficiencies which could cause an

unsafe condition.

3. Close fireplace dampers.

4. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they are operating at maximum speed. Do not

operate a summer exhaust fan.

5. Follow the lighting instructions. Place the appliance

be-ing inspected into operation. Adjust the thermostat

so appliance is operating continuously.

6. If improper venting is observed during any of the

above tests, the venting system must be corrected

in accordance with the National Fuel Gas Code,

ANSI Z221.1/NFPA 54 and/or CAN/CGA B149

Installation Codes.

7. After it has been determined that each appliance

connected to the venting system properly vents where

tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas

-fired burning appliance to their previous conditions

of use.

Contents

Safety Section ..................................................................2

General Installation Instructions ....................................... 2

Location and Clearances .................................................. 4

Outline Drawings ..............................................................5

Upflow Installation ............................................................7

Downflow Installation ........................................................ 7

Horizontal Installation ....................................................... 7

Air for Combustion and Ventilation .................................... 8

Duct Connections ........................................................... 10

Return Air Filter .............................................................. 11

General Venting Instructions ........................................... 12

Venting into a Masonry Chimney .................................... 13

Field Wiring Diagrams .................................................... 15

Electrical Connections .................................................... 16

Gas Piping ...................................................................... 17

Sequence of Operation ...................................................17

Start-up and Adjustment ................................................. 17

Combustion and Input Check .........................................17

High Altitude Derate .......................................................19

Lighting Instructions ....................................................... 20

Control and Safety Switch Adjustment ...........................20

Operating Information ..................................................... 20

Integrated Furnace Control Error flash Codes ................ 21

Periodic Servicing Requirements ...................................22

Airflow Tables .................................................................. 23

18-CD34D1-5-EN 3

INSTALLER’S GUIDE

CAUTION

WARNING

!

▲

To prevent shortening its service life, the furnace

should not be used as a “Construction Heater”

during the finishing phases of construction

until the requirements listed in item 9, a-g of the

safety section of this publication have been met.

Condensate in the presence of chlorides and

fluorides from paint, varnish, stains, adhesives,

cleaning compounds, and cement create a

corrosive condition which may cause rapid

deterioration of the heat exchanger.

!

WARNING

▲

These furnaces are not approved or intended for

installation in manufactured (mobile) housing,

trailers, or recreational vehicles. Failure to follow

this warning could result in property damage,

personal injury, or death.

!

CAUTION

▲

Do NOT install the furnace in a corrosive or

contaminated atmosphere.

!

WARNING

▲

Do NOT install the furnace directly on carpeting,

tile or other combustible material other than

wood flooring. For vertical downflow application,

subbase (BAYBASE205) must be used between

the furnace and combustible flooring. When the

downflow furnace is installed vertically with a

cased coil, a subbase is not required.

!

▲

EXPLOSION HAZARD!

PROPANE GAS IS HEAVIER THAN AIR AND MAY

COLLECT IN ANY LOW AREAS OR CONFINED

SPACES. IN ADDITION, ODORANT FADE MAY

MAKE THE GAS UNDETECTABLE EXCEPT WITH

A WARNING DEVICE. IF THE GAS FURNACE IS

INSTALLED IN A BASEMENT, AN EXCAVATED

AREA OR A CONFINED SPACE, IT IS STRONGLY

RECOMMENDED TO CONTACT A GAS SUPPLIER

TO INSTALL A GAS DETECTING WARNING

DEVICE IN CASE OF A GAS LEAK.

NOTE: The manufacturer of your furnace does not

test any detectors and makes no representations

regarding any brand or type of detector

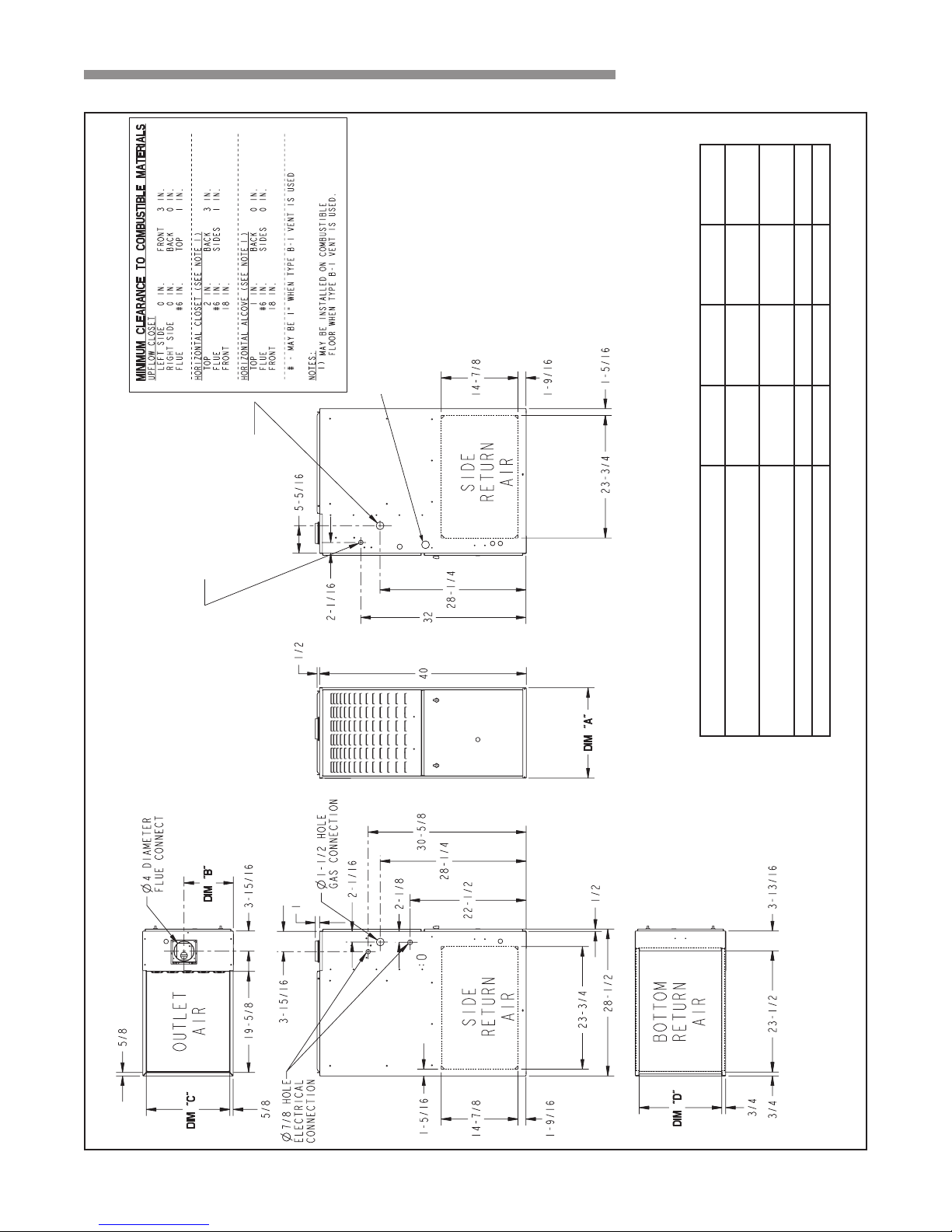

LOCATION AND CLEARANCES

The location of the furnace is normally selected by the architect,

the builder, or the installer. However, before the furnace is moved

into place, be sure to consider the following requirements:

1. Is the location selected as near the chimney or vent and as

centralized for heat distribution as practical?

2. Do all clearances between the furnace and enclosure

equal or exceed the minimums stated in Clearance Table

on the Outline Drawings.

3. Is there sufcient space for servicing the furnace and other

equipment? A minimum of 24 inches front accessibility

to the furnace must be provided. Any access door or

panel must permit removal of the largest component.

4. Are there at least 3 inches of clearance between the

furnace combustion air openings in the front panel and

any closed panel or door provided?

5. Are the ventilation and combustion air openings large

enough and will they remain unobstructed? If outside

air is used, are the openings set above the highest snow

accumulation level? (See the Air for Combustion and

Ventilation section)

6. Allow sufcient height in supply plenum above the

furnace to provide for cooling coil installation, if the

cooling coil is not installed at the time of this furnace

installation.

7. A furnace shall be installed so electrical components are

protected from water.

8. If the furnace is installed in a residential garage, it must

be installed so that the burners, and the ignition source

are located not less than 18 inches above the oor and the

furnace must be located or protected to avoid physical

damage from vehicles.

4 18-CD34D1-5-EN

Ø 1-5/8” HOLE WITH PLUG

INSTALLER’S GUIDE

14-1/2" 9-5/8" 13-1/4" 13"

17-1/2" 9-5/8" 16-1/4" 16"

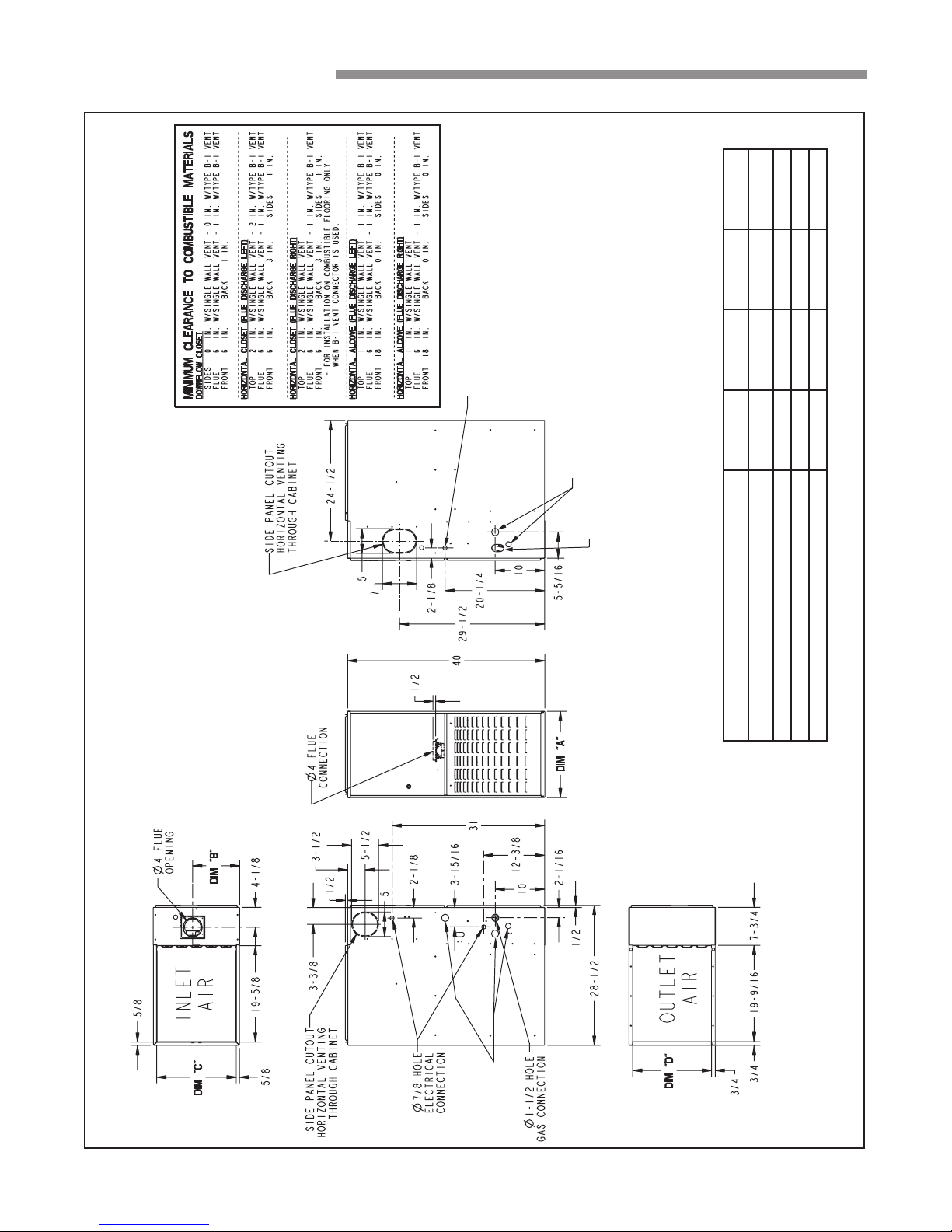

OUTLINE DRAWINGS - UPFLOW/HORIZONTAL

For the M801P Series Furnaces

Ø 7/8” HOLE WITH PLUG

ELECTRICAL CONNECTION

Ø 1-5/8” HOLE WITH PLUG

(ALTERNATE)

MODEL DIM "A" DIM "B" DIM "C" DIM "D"

M801P040AU24AA, M801P060AU24AA

M801P060AU36AA

M801P080BU36AA, M801P080BU48AA

M801P100BU36AA

M801P100CU48AA, M801P100CU60AA 21" 13-1/16" 19-3/4" 19-1/2"

M801P120DU60AA, M801P140DU60AA 24-1/2" 15-5/16" 23-1/4" 23"

18-CD34D1-5-EN 5

INSTALLER’S GUIDE

Ø 7/8” HOLE WITH PLUG

ELECTRICAL CONNECTION

(ALTERNATE)

Ø 1-5/8” HOLE WITH PLUG

M801P OUTLINE DRAWING - DOWNFLOW\HORIZONTAL

For the M801P Series Furnaces

1-1/2” X 2-1/2” OVAL

GAS CONNECTION

MODEL DIM "A" DIM "B" DIM "C" DIM "D"

M801P060AD24AA, M801P060AD36AA 14-1/2" 9-5/8" 13-1/4" 13"

M801P080BD45AA 17-1/2" 9-5/8" 16-1/4" 16"

M801P100CD48AA, M801P100CD60AA 21" 13-1/16" 19-3/4" 19-1/2"

M801P120DD60AA, M801P140DD60AA 24-1/2" 15-5/16" 23-1/4" 23"

6 18-CD34D1-5-EN

Ø 1-5/8” HOLE

WITH PLUG (3)

UPFLOW

FURNACE

CASED

COIL

INSTALLER’S GUIDE

UPFLOW INSTALLATION

The coil is always placed downstream of the furnace airow.

Apply gasket material (duct seal eld supplied) to ALL mating

surfaces between the furnace and the coil case.

NOTE: The top flanges on the furnace must be bent

90 degrees upward to allow the coil attachment.

1

Seal with field

supplied sealant

or gasket

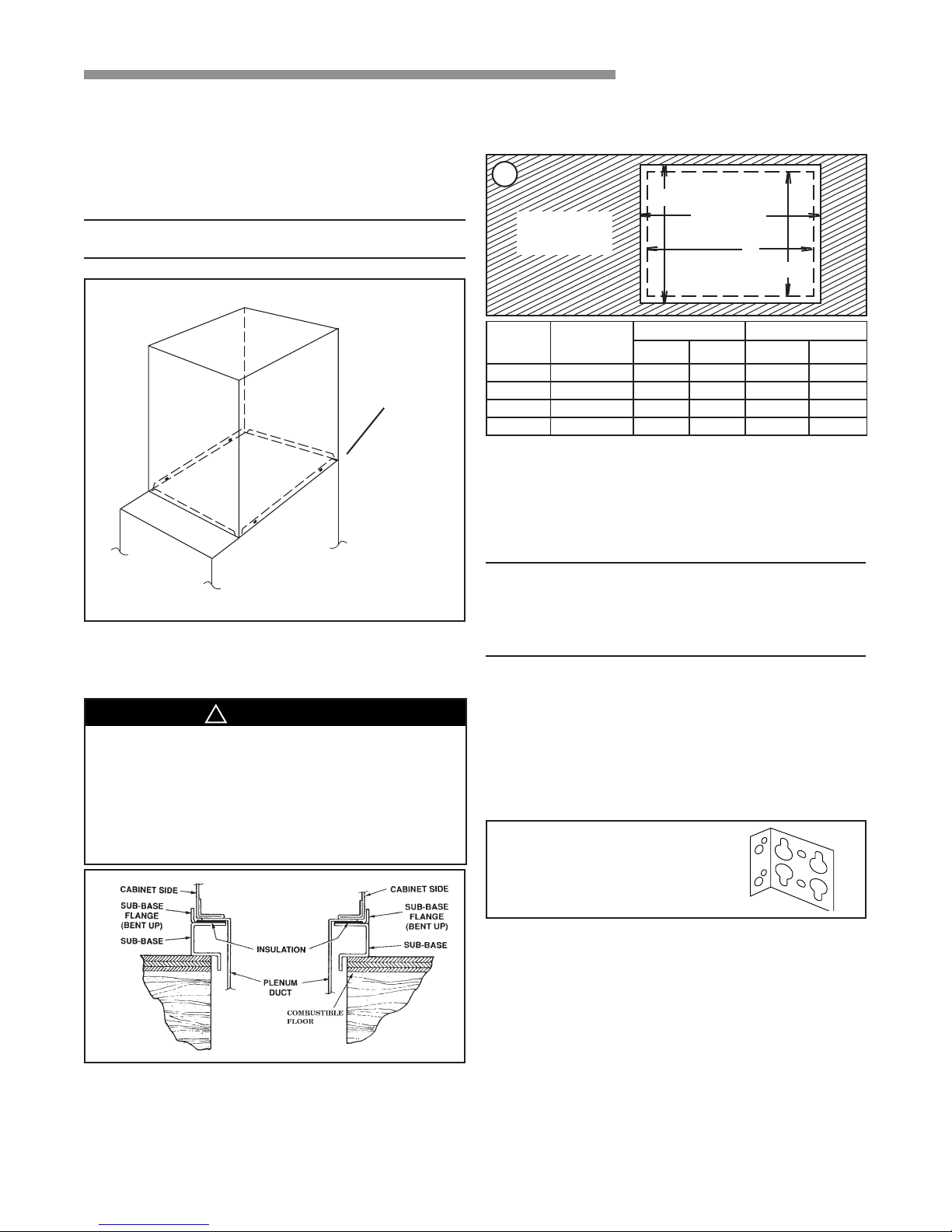

Required floor opening: (DOWNFLOW)

Figure 3 and Table 1

3

A (width)

FURNACE

FRONT

CABINET

WIDTH

14-1/2" 13-1/4" 13-5/8" 20-1/8" 12-5/8" 19-3/8"

17-1/2" 16-1/4" 16-5/8" 20-1/8" 15-5/8" 19-3/8"

21" 19-3/4" 20-1/8" 20-1/8" 19-1/8" 19-3/8"

24-1/2" 23-1/4" 23-5/8" 20-1/8" 22-5/8" 19-3/8"

RETURN

DUCT

WIDTH

FLOOR OPENING PLENUM OPENING

B (depth)

D

C

"A" "B" "C" "D"

HORIZONTAL INSTALLATION

The coil and furnace must be fully supported when used in the

horizontal position. Three brackets (with screws) are included

with downow furnaces for installation to stabilize and secure

the furnace and cased coil in the horizontal position. See Figure 4.

VERTICAL

INSTALLATIONS:

DOWNFLOW INSTALLATION

!

WARNING

▲

Do not install the furnace directly on carpeting,

tile or other combustible material other than

wood flooring. For vertical downflow application,

subbase (BAYBASE205) must be used between

the furnace and combustible flooring. When the

downflow furnace is installed vertically with a

cased coil, a subbase is not required.

2

IMPORTANT: The cased coil must be placed

downstream of the furnace. In horizontal

installations, the apex of the coil may point

either toward or away from the furnace. See the

coil Installer's Guide for more details.

The cased coil is secured to the furnace and both the furnace and

the cased coil must be properly supported. The brackets mount

using the rear screws on the coil case and use the screws provided

to secure the bracket to the furnace. The remaining bracket is

placed as close to center as possible (horizontally) between the

coil case front and the furnace bottom channel (for downow/

horizontal furnace). Use four of the screws provided to secure the

bracket. The upow furnace,

4

CASED COIL CONNECTION

BRACKET FOR DOWNFLOW

FURNACE IN HORIZONTAL

DOWNFLOW ONLY

converted to horizontal, aligns and attaches the coil as in Figure 1.

However, the coil requires additional support. This furnace may

be installed in an attic or crawl space in the horizontal position by

placing the furnace on the left or right side (as viewed from the

front in the upright position). The horizontal furnace installation

in an attic should be on a service platform large enough to allow

for proper clearances on all sides and service access to the front

of the furnace (See Clearance Table on Outline Drawings and

Figure 5).

18-CD34D1-5-EN 7

Loading...

Loading...