Ingersoll-Rand HC-3, HC-6, HC-7, HC-9, HC-14 User Manual

...

U

U

s

s

err

e

M

M

a

a

n

n

u

u

all

a

SERIES HC

Heat-of-Compression

Compressed Air Dryer

Models HC-3 – HC-239

IMPORTANT! BEFORE INSTALLING AND

OPERATING THE DRYER, IT IS

RECOMMENDED THAT THIS

MANUAL BE STUDIED AND

CLEARLY UNDERSTOOD.

THIS DRYER IS DESIGNED TO BE

USED ONLY WITH A NONLUBRICATED COMPRESSOR.

USE WITH A LUBRICATED

COMPRESSOR WILL VOID ALL

WARRANTIES AND MAY CAUSE

SEVERE DAMAGE.

Information

When making inquiries,

please provide the following

information:

1) Equipment Model Number

2) Equipment Serial Number

3) Equipment Operating

Pressure

4) Equipment Operating

Temperature

5) Approximate time in

service

6) Nature of Problem

For information, parts,

or service, contact your

local IInnggeerrssoollll--RRaanndd

Service provider or

reach us at

www.air.irco.com

USER MANUAL

Series HC

Reference IR - 222 Rev 3

Page 2 10/17/2013

USER MANUAL

Series HC

PREFACE

SECTION 1: INTRODUCTION

1.1 General Information

1.2 Safety Instructions

1.3 Personnel Qualification

1.4 Product Information

SECTION 2: INSTALLATION

2.1 Set-up and installation

1.2.1 Identification of signs and symbols in this manual

1.2.2 Safety tips for maintenance, inspection & assembly work

1.4.1 Theory of operation

1.4.2 Pressure vessel regulations

1.4.3 Airtightness test

1.4.4 Overloading

1.4.5 Technical data sheet

1.4.6 Dryer flow capacities

1.4.7 Transport

1.4.8 Storage

1.4.9 Use of a pre and afterfilter

2.1.1 Mechanical installation

2.1.2 Preventative maintenance prior to start-up

2.1.3 Filter installation

2.1.4 Electrical installation

INDEX

Reference IR - 222 Rev 3

Page 3 10/17/2013

USER MANUAL

Series HC

SECTION 3: START UP AND OPERATION

3.1 Start-up

3.1.1 Pressurizing dryer

3.2 Operator interface

SECTION 4: MAINTENANCE

4.1 Suggested preventive maintenance schedule

4.1.1 Introduction

4.1.2 Periodic maintenance schedule

4.2 Replacement / Disposal of the desiccant

4.2.1 For first time fill-up

4.2.2 To replace used desiccant

4.3 Dew point meter maintenance (DPDS Option only)

4.4 Afterfilter

4.4.1 General comments and use

4.4.2 Function

4.4.3 Assembly and installation

4.4.4 Maintenance

4.4.5 Changing of afterfilter elements

4.5 Filter Accessories

Reference IR - 222 Rev 3

Page 4 10/17/2013

USER MANUAL

Series HC

SECTION 5: TROUBLESHOOTING AND FAULTS

5.1 Introduction

5.2 High Dew Point

5.2.1 Changed operating conditions

5.2.2 Old desiccant

5.2.3 Towers not reversing

5.2.4 Cooler discharge air temperature too high

5.2.5 Dew point indication in error

5.2.6 Two-way valve leakage

5.3 Fail-to-shift

5.3.1 Solenoid valve failed to operate

5.3.2 Pilot air tubing leakage

5.3.3 Two-way switching valve actuator leakage

5.4 Primary Drain Failure

5.4.1 Plugging or sticking due to foreign matter

5.5 Secondary Drain Failure

5.5.1 Solenoid valve failure

5.5.2 Liquid level probe failure

5.6 Short-term shut-down

5.7 Shut-down in case of a fault or for maintenance

SECTION 6: SPECIFICATIONS, PARTS LIST(S), & DATA REPORTS

SECTION 7: AUXILIARY MANUALS (IF APPLICABLE)

SECTION 8: CUT SHEETS

SECTION 9: DRAWINGS

Reference IR - 222 Rev 3

Page 5 10/17/2013

USER MANUAL

Series HC

PREFACE:

This technical manual from IInnggeerrssoollll--RRaanndd®® is an aid in getting to know the adsorption

dryer better and in utilizing its possibilities for application in accordance with its

intended use. Furthermore, this manual contains important information for safe,

proper and economic operation.

All instructions must be followed as written in order to avoid danger and damages

which could cause downtime and premature wear and tear on the adsorption dryer.

In addition to the technical manual and the accident prevention regulations which are

valid in the particular location where the dryer is being used, the recognized special

rules for safe and proper working procedures must also be followed.

Each person involved with the set-up, start-up, operation, maintenance and repair of

the adsorption dryer in the User Company must have first read and understood the

technical manual and especially the safety tips.

Reference IR - 222 Rev 3

Page 6 10/17/2013

USER MANUAL

Series HC

Prior to installation and start-up of this dryer,

please read and implement this section.

SECTION 1

INTRODUCTION

Reference IR - 222 Rev 3

Page 7 10/17/2013

USER MANUAL

Series HC

SECTION 1:

1.1 GENERAL INFORMATION

The adsorption dryer of the HC-3 – HC-239 series is built according to the latest

technological developments and recognized safety rules. Its use, however, can

endanger life and limb of the user or of third parties and can lead to considerable

damage to the adsorption dryer and other material assets if:

it is operated by personnel not trained or instructed in its use,

it is improperly used,

It is improperly maintained or serviced.

INTRODUCTION

This can result in the loss of all damage claims.

This adsorption dryer is designed for neutral media (gas) free of aggressive water,

oil and solid elements. IInnggeerrssoollll--RRaanndd®® accepts no liability for corrosion damage and

malfunctions caused by aggressive media.

Applications other than those mentioned in this manual must be agreed to by

IInnggeerrssoollll--RRaanndd®

® and confirmed in writing.

In the interest of further development, IInnggeerrssoollll--RRaanndd®® reserves the right to make

changes at any time, which, in keeping with the essential characteristics of the

adsorption dryer described here, may be necessary for increasing efficiency or for

reasons relating to safety or to normal business practice.

1.2 SAFETY INSTRUCTIONS

This technical manual contains basic tips, which must be followed during set-up,

operation and servicing. It is of utmost importance that it be read by the assembly

technician before installation and start-up, as well as by the specialist / operator in

charge, and it must always be within reach at the place where the adsorption dryer

is being used.

Reference IR - 222 Rev 3

Page 8 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

1.2.1 Identification of signs and symbols in this technical manual

The safety tips contained in this technical manual, whose disregard could endanger

people and machines, are indicated by a general danger sign and the additional

markings Danger! or Attention!

Danger! / Attention!

Warning against electrical voltage!

Safety tips printed directly on the adsorption dryer must also be followed at all times

and must be kept completely legible.

Advice: This sign refers to a procedure or sequence of particular

interest or importance. All tips must be followed to ensure

proper use of this adsorption dryer.

This dot refers to working or operational steps. The steps are to be carried out in

the order of their appearance from top to bottom.

- The sign of a hyphen marks enumerations.

Reference IR - 222 Rev 3

Page 9 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

1.2.2 Safety tips for maintenance, inspection and assembly work

The operator is to make sure that all maintenance, inspection and assembly work is

carried out by special personnel who are authorized and qualified, and who are

adequately informed through careful study of the technical manual. For this reason,

special attention should be paid to the following attention and danger sign:

Attention!

Never make structural changes to the adsorption dryer that are

not specifically authorized by Ingersoll-Rand!

Only use original spare and accessory parts!

Carry out maintenance work only when the adsorption dryer is

switched off, depressurized, and disconnected from the electric

power supply!

Attention!

Multiple power sources may exist in the electrical panel. All

possible power sources must be disconnected before servicing

dryer.

Advice: Refer to the desiccant material safety data sheet (MSDS) when

installing or disposing of desiccant, which can be found in

Section 8 of this User Manual.

Danger!

Wear protective goggles and mask when working with the desiccant!

Advice for protection:

If desiccant comes into contact with the eyes, rinse eyes immediately with large

amounts of clear water.

If the desiccant is spilled, clean up with effort to minimize the formation of dust.

In case of fire, there is no restriction on the use of fire extinguishing material.

A small dust mask must be worn.

Reference IR - 222 Rev 3

Page 10 10/17/2013

Danger!

Do not attempt to service or maintain dryer while system is hot!

USER MANUAL

Series HC

SECTION 1: (Continued)

1.3 PERSONNEL QUALIFICATION

The personnel involved in operation, maintenance, inspection, and assembly must

have the corresponding qualifications to do this work. Areas of responsibility and

supervision of the personnel must be precisely established by the operator. Should

the personnel not possess the necessary knowledge, then they must be trained and

instructed. If need be, this training may be carried out by the manufacturer / supplier

at the request of the operator of the adsorption dryer. Further, the operator is to

make sure that the personnel completely understand the contents of the technical

manual.

1.4 PRODUCT INFORMATION

The adsorption dryer is used for the purpose of drying compressed air and other

gases according to its respective design. As a "standard model" the adsorption dryer

is equipped with two desiccant vessels and, depending on certain conditions,

provides pure, dry and oil-free compressed air or gases.

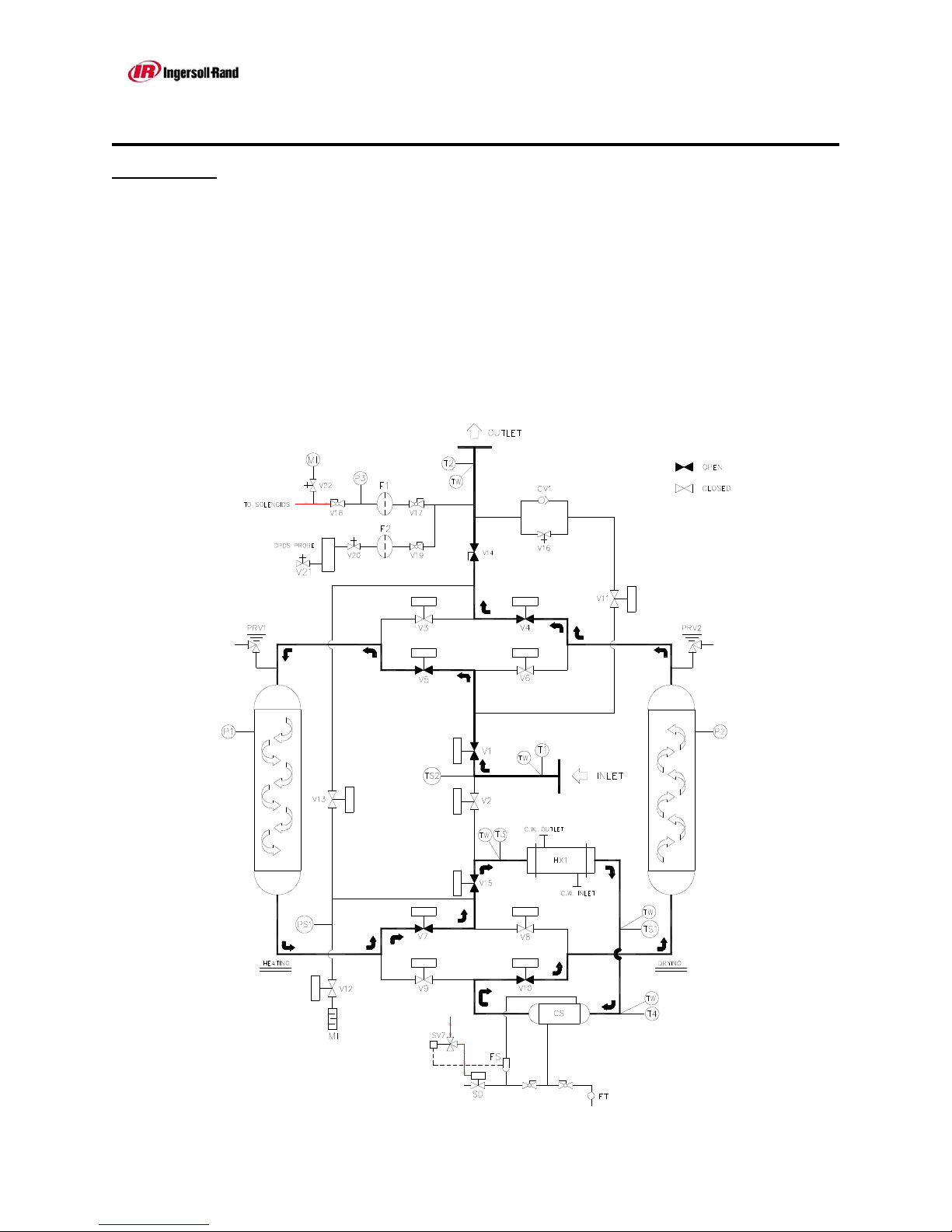

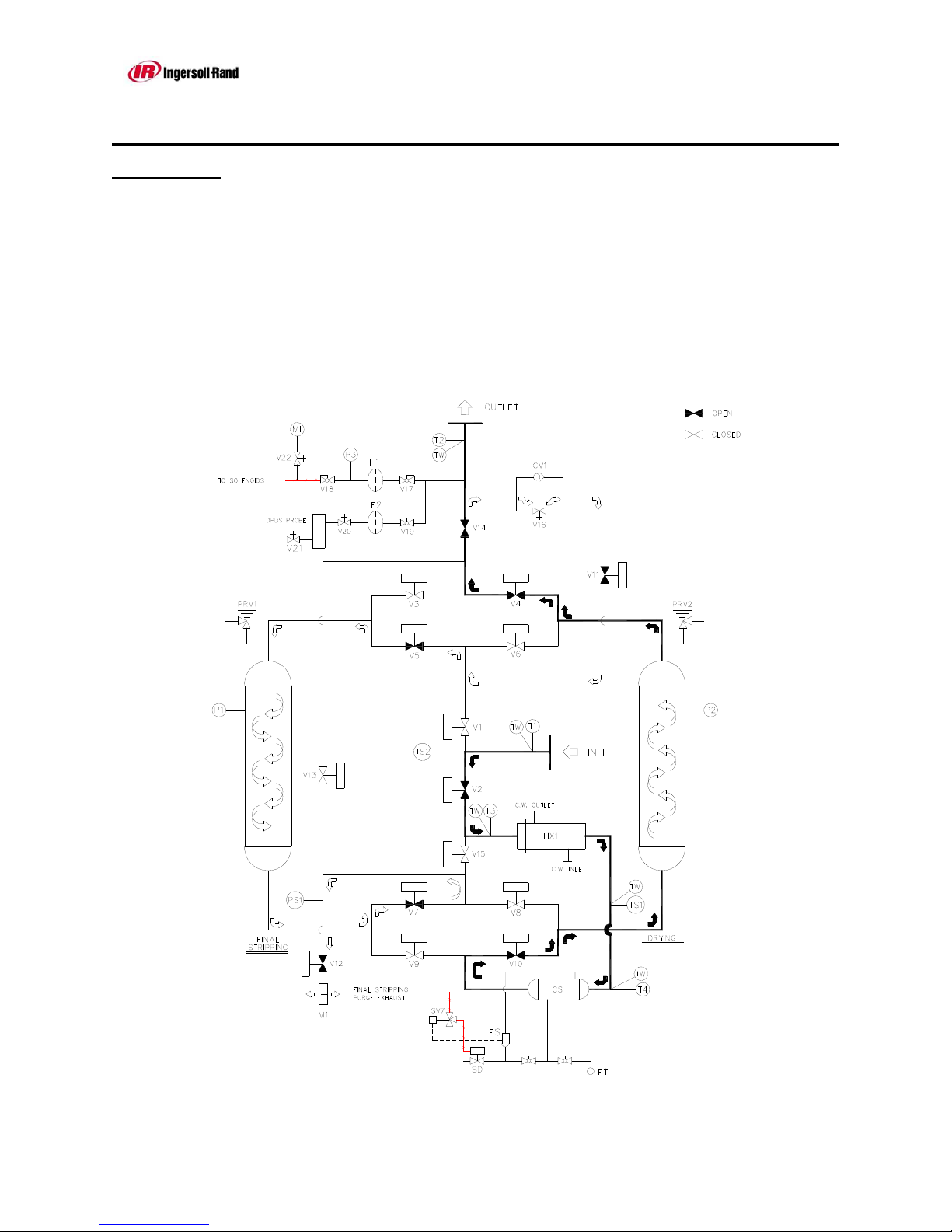

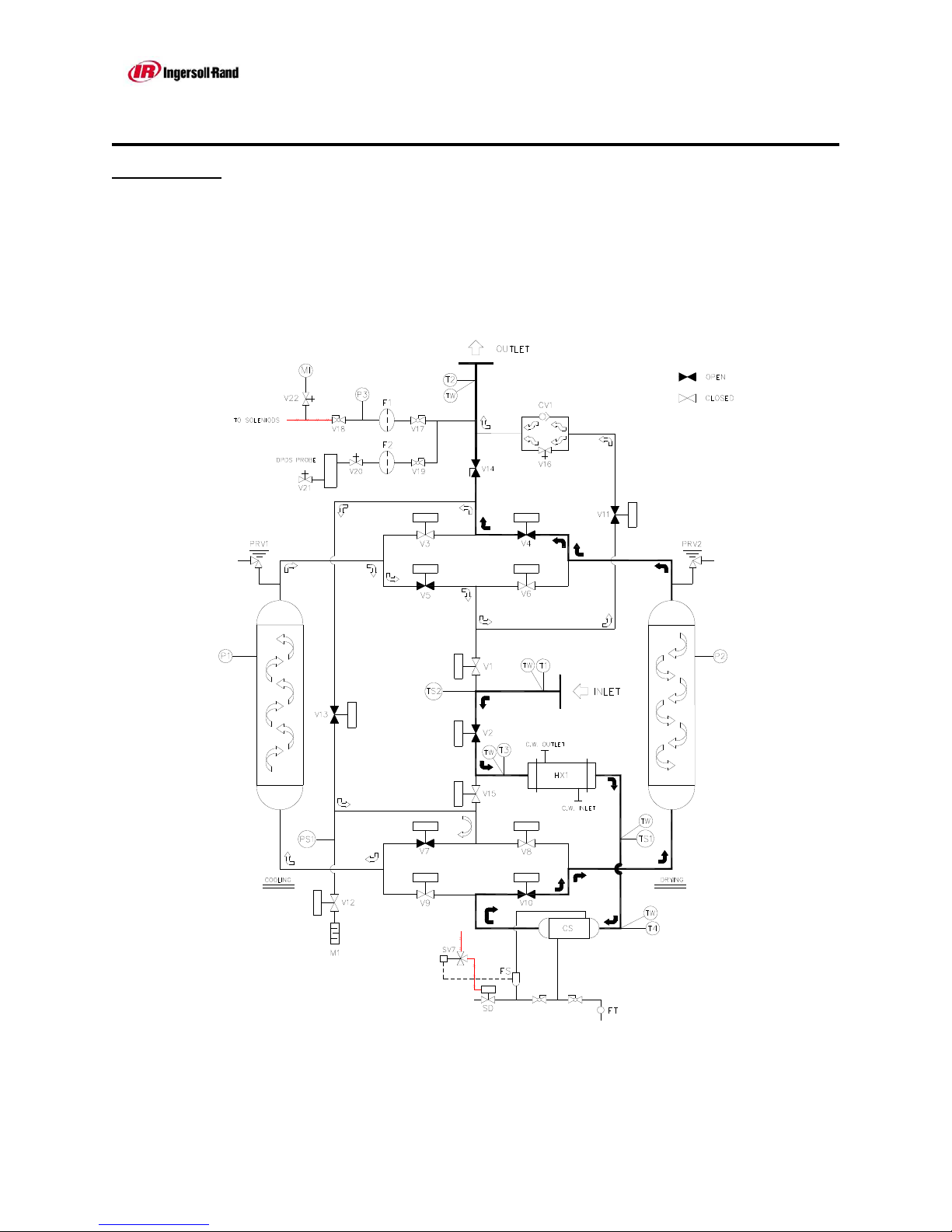

1.4.1 Theory of Operation

The HC heat-of-compression dryer uses the hot air from the compressor to

regenerate the desiccant. Each tower is sized for a minimum of 4 hours online,

but may be extended by use of the optional DPDS which will allow the dryer to

switch towers based on water load rather than time.

The DPDS (Dew Point Demand System) is optional equipment and may or may

not be present on this particular air dryer. If the dryer is equipped with the DPDS,

see the associated DPDS Instruction Manual included in Section 7 for more

operational details.

The regeneration cycle is split up into three functions.

Reference IR - 222 Rev 3

Page 11 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

A. Regeneration Cycles

1. Heating. Hot air directly from the compressor enters the inlet of the HC

and is directed by the inlet 2-way valves into the regenerating tower. This

hot, thirsty air regenerates the bulk of the water from the desiccant. The

air is then directed into the aftercooler where it is cooled, the coalescing

separator where liquid water is removed through the drain trap system,

then into the drying tower where the air is actually dried to its final low

dew point. The heating cycle lasts 90 minutes.

Reference IR - 222 Rev 3

Page 12 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

2. Stripping. At the end of heating, the inlet valves shift position, directing

the hot inlet air directly into the aftercooler, separator, and drying tower.

We now begin stripping. The stripping phase of regeneration lasts 90

minutes. At the beginning of stripping, the regenerating tower is

depressurized through a muffler. During stripping, a small adjustable flow

of dry air is used to remove the last little bit of moisture from the

regenerating tower. If dryer is equipped with optional trim heater,

reference operational instructions in Addendum at back of manual.

Reference IR - 222 Rev 3

Page 13 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

3. Cooling. At the end of stripping, the regenerating tower is repressurized.

The cooling cycle valves open and cooling begins. The cooling cycle lasts

60 minutes. During cooling, a portion of the dry outlet air is directed into

the regenerating tower to reduce the temperature of the bed prior to

tower shift.

Reference IR - 222 Rev 3

Page 14 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

1.4.2 Pressure vessel regulations

The pressure vessels are designed according to the standard technical

requirements. They fulfill the test of the certifying procedure and carry the “U”,

“UM” ASME Symbol.

Range of Application:

Type HC-3 – HC-239

Operating overpressure

Operating temperature

1.4.3 Airtightness test

All adsorption dryers are subjected to an airtightness test prior to shipment using

compressed air.

1.4.4 Overloading

Max. 150 PSIG

10.34 Bar(g)

Max.

Min.

500°F

260°C

20°F

-6.67°C

Attention!

Never weld on or alter a pressure vessel in any

way!

Reference IR - 222 Rev 3

Page 15 10/17/2013

Attention!

Protect the adsorption dryer from overloads!

The adsorption dryer can become overloaded, if:

The inlet flow is too high,

The temperature of the air at the discharge of the

aftercooler is too high,

The min. operating pressure is too low,

The temperature of the air at the discharge of the

compressor is too low.

USER MANUAL

Series HC

SECTION 1: (Continued)

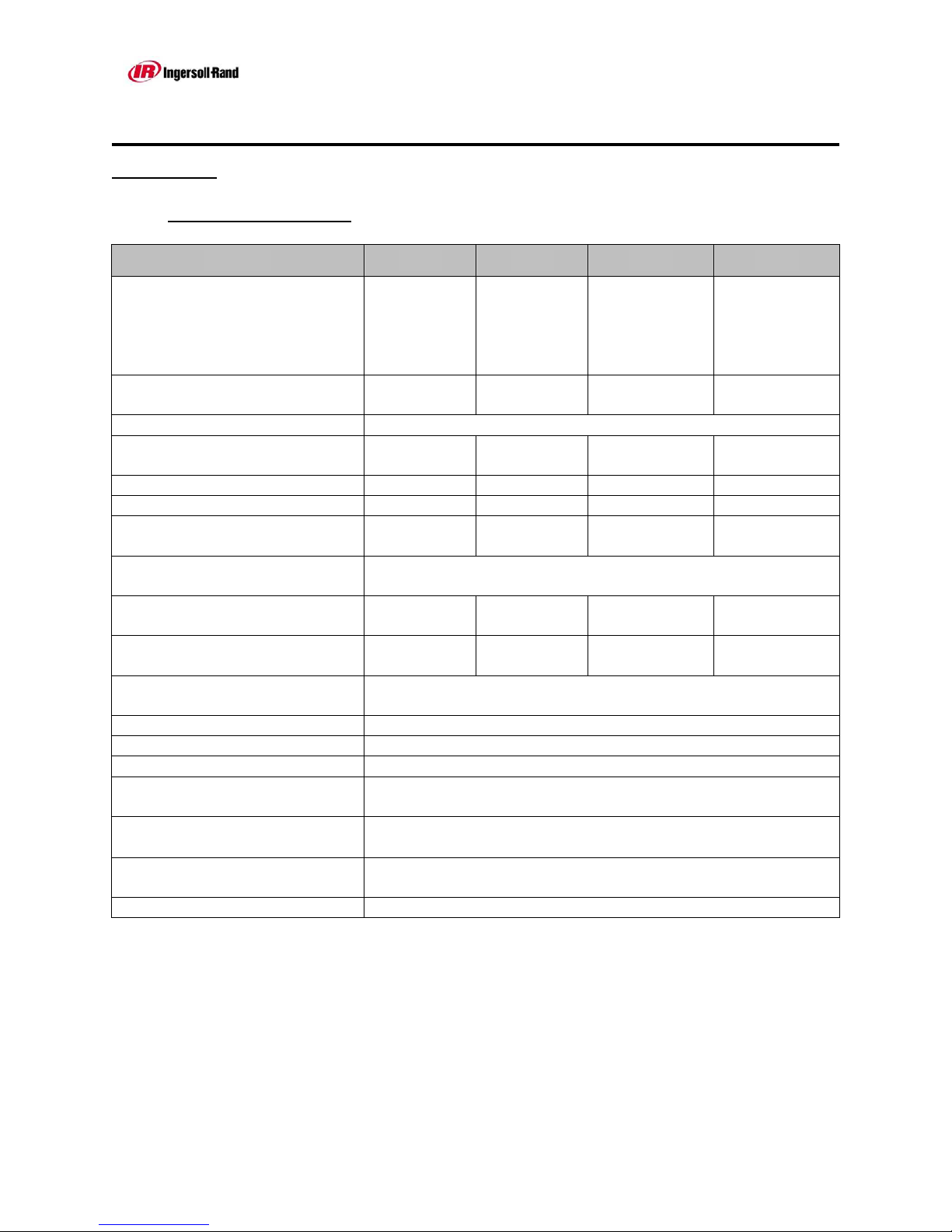

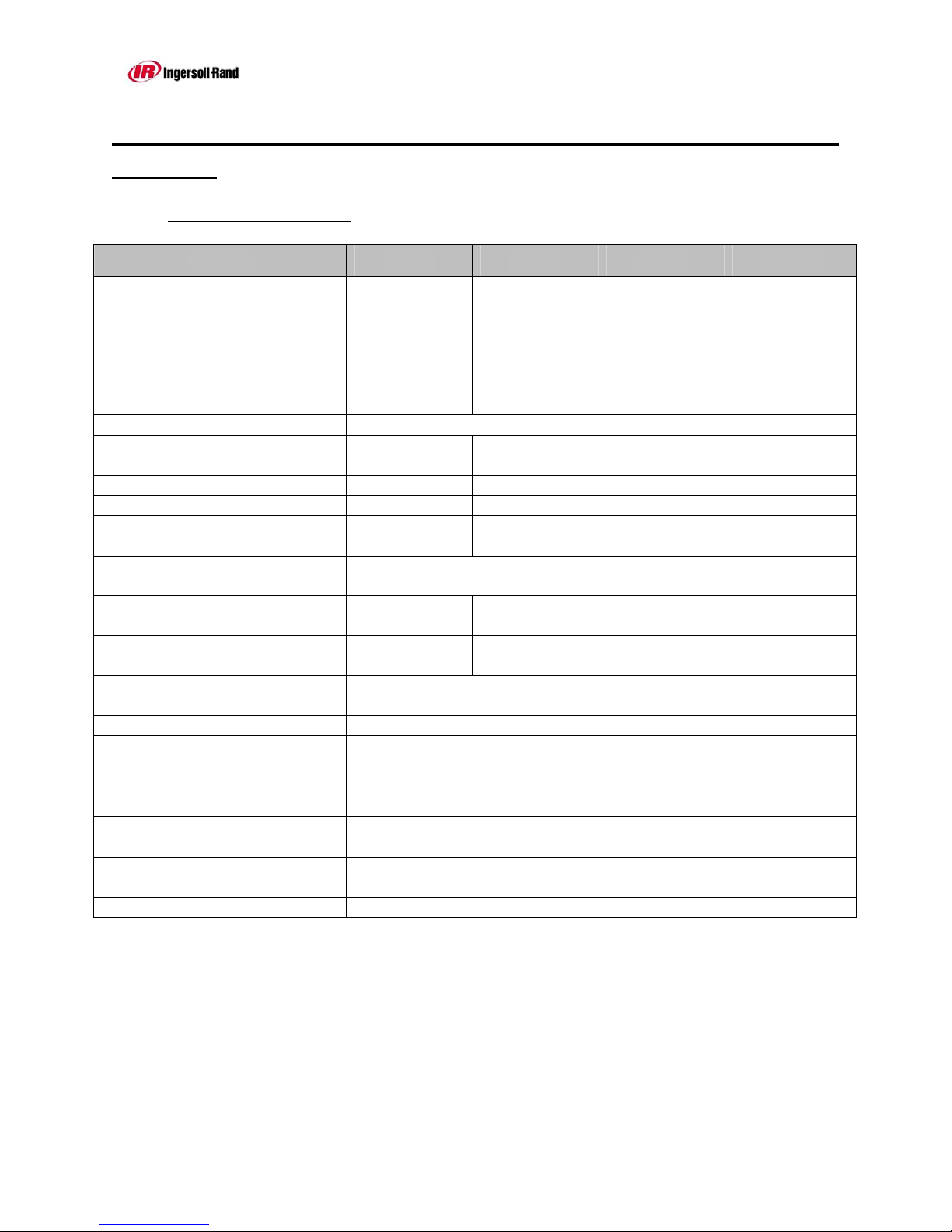

1.4.5 Technical data sheet

MODEL HC-3 HC-6 HC-7 HC-9

Flow:

(SCFM) @ 100 PSIG

100°F Drying Temperature

(m3/hr) @ 6.89Bar(g)

301

511

535

909

677

1150

37.8°C Drying Temperature

Vessel OD 12”

30.48 cm

16”

40.64 cm

18”

45.72 cm

Desiccant type IR Activated Alumina

Desiccant / Vessel 223 lbs

101 kgs

397 lbs

180 kgs

502 lbs

228 kgs

Inlet connection 2 NPT 2 NPT 3 FLG 3 FLG

Outlet connection 2 NPT 2 NPT 3 FLG 3 FLG

Afterfilter

(* Option)

AF-350

or AFH-350*

AF-550

or HAF-550*

AF-1000

or HAF-1000*

or HAF-1000*

Voltage 115/1/60 Standard

Consult Factory for other voltages

Cooling Water 9 GPM

34 LPM

Stripping Flow 6 SCFM

10 m3/hr

16 GPM

61 LPM

11 SCFM

19 m3/hr

20 GPM

76 LPM

14 SCFM

24 m3/hr

Cycle time 8 Hour NEMA Cycle –

4 Hours drying/ 4 Hours Regeneration

Outlet Dew Point Variable

DPDS Control Adjustable

High Humidity Alarm Adjustable

Pressure Switch Setpoints 10 PSI Fail to Shift 60 PSI Initiate Cooling

.7 Bar Fail to Shift 4 Bar Initiate Cooling

Cooler outlet high temperature

alarm

Low regeneration temperature

105F

40.6°C

Adjustable

alarm

Process flow Downward Regeneration / Upward Drying

836

1420

20”

50.8 cm

620 lbs

281 kgs

AF-1000

25 GPM

95 LPM

17 SCFM

29 m3/hr

Reference IR - 222 Rev 3

Page 16 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

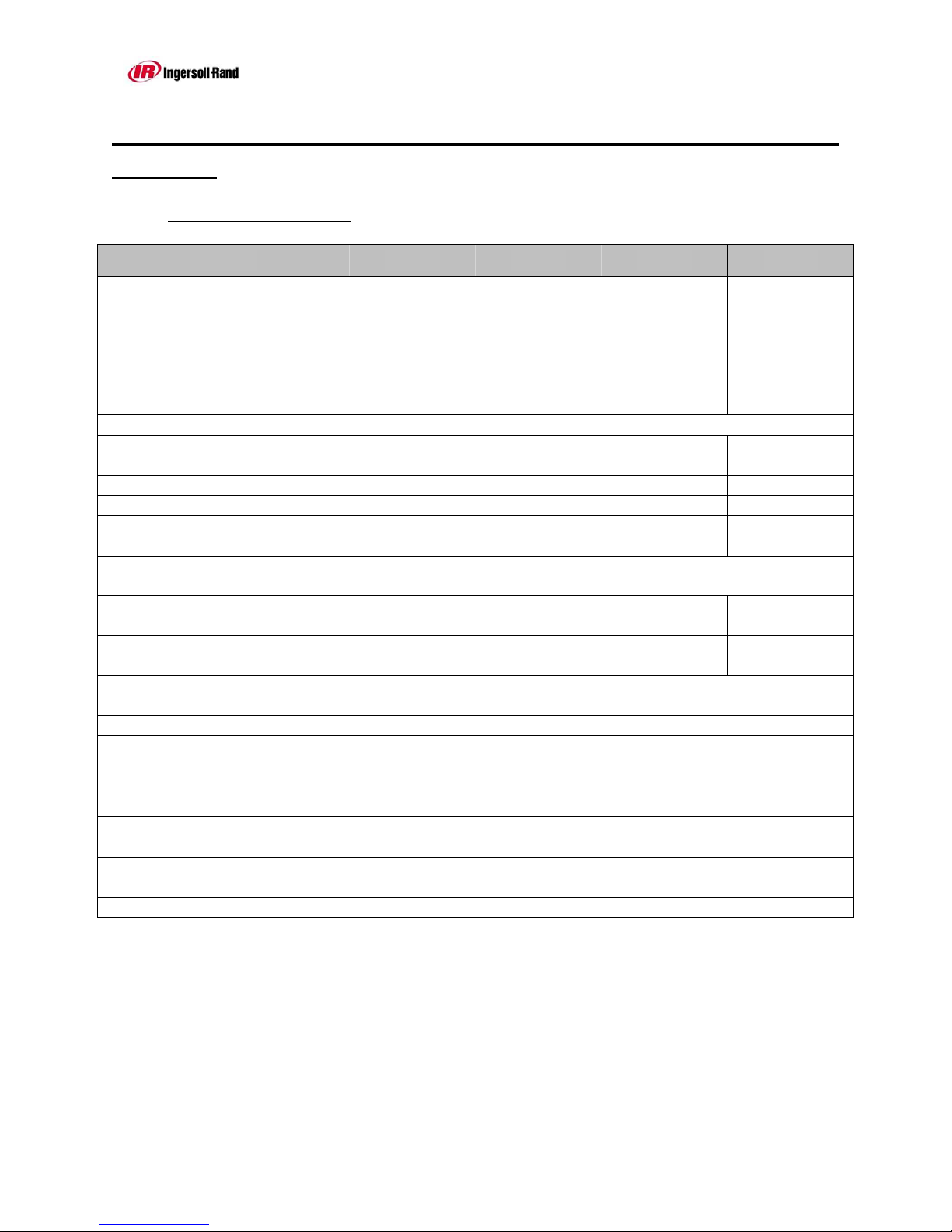

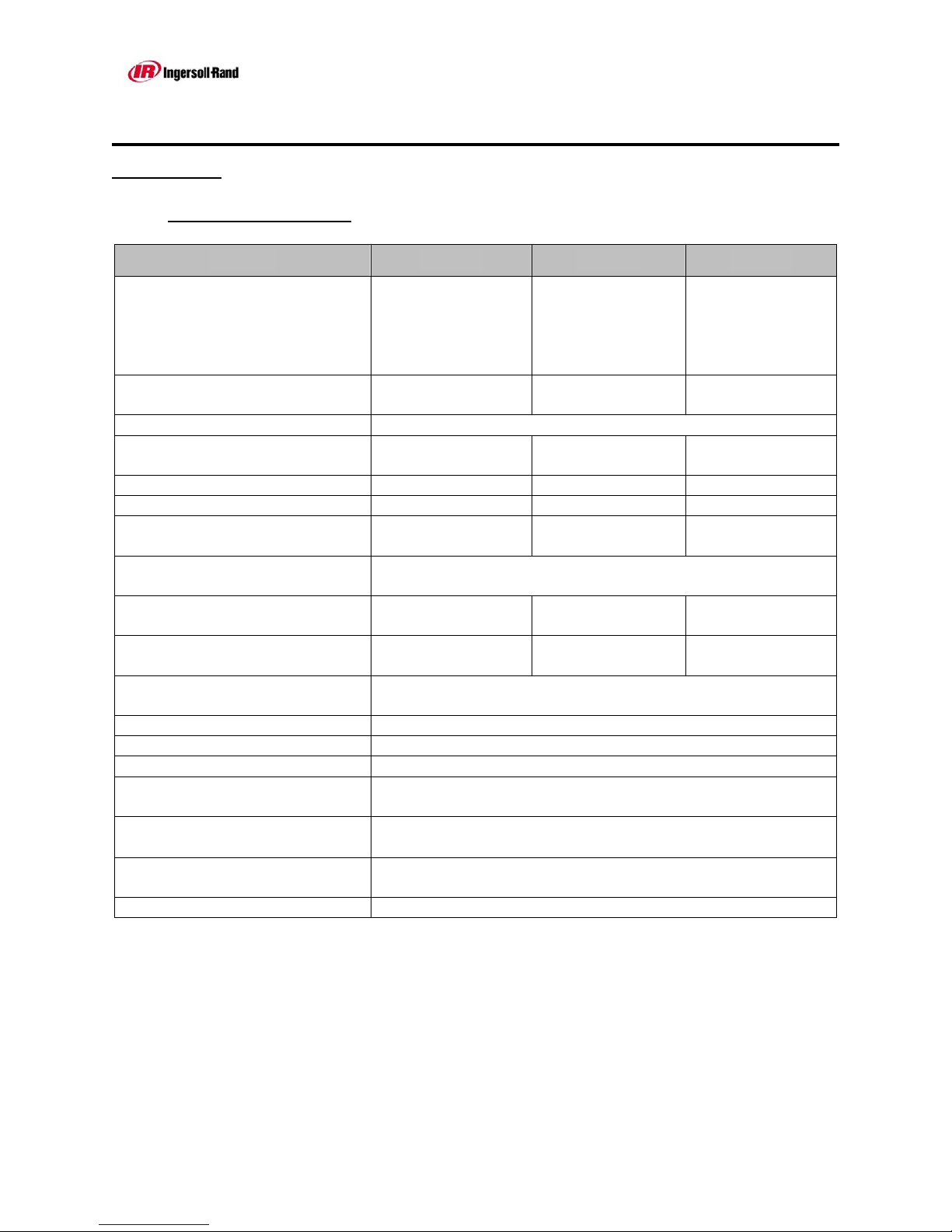

1.4.5 Technical data sheet

MODEL HC-14 HC-21 HC-30 HC-41

Flow:

(SCFM) @ 100 PSIG

100°F Drying Temperature

(m3/hr) @ 6.89Bar(g)

1204

2046

1880

3194

2708

4601

37.8°C Drying Temperature

Vessel OD 24”

60.96 cm

30”

76.2 cm

36”

91.44 cm

Desiccant type IR Activated Alumina

Desiccant / Vessel 893 lbs

405 kgs

1395 lbs

633 kgs

2009 lbs

911 kgs

Inlet connection 3 FLG 4 FLG 4 FLG 6 FLG

Outlet connection 3 FLG 4 FLG 4 FLG 6 FLG

Afterfilter

(* Option)

AF-1400

or HAF-1400*

AF-2400

or HAF-2400*

AF-3600

or HAF-3600*

or HAF-7200*

Voltage 115/1/60 Standard

Consult Factory for other voltages

Cooling Water 36 GPM

136 LPM

Stripping Flow 24 SCFM

41 m3/hr

56 GPM

212 LPM

38 SCFM

65 m3/hr

80 GPM

303 LPM

54 SCFM

92 m3/hr

Cycle time 8 Hour NEMA Cycle –

4 Hours drying/ 4 Hours Regeneration

Outlet Dew Point Variable

DPDS Control Adjustable

High Humidity Alarm Adjustable

Pressure Switch Setpoint 10 PSI Fail to Shift 60 PSI Initiate Cooling

.7 Bar Fail to Shift 4 Bar Initiate Cooling

Cooler outlet high temperature

alarm

Low regeneration temperature

105F

40.6°C

Adjustable

alarm

Process flow Downward Regeneration / Upward Drying

3686

6263

42”

106.7 cm

2735 lbs

1241 kgs

AF-7200

110 GPM

416 LPM

74 SCFM

126 m3/hr

Reference IR - 222 Rev 3

Page 17 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

1.4.5 Technical data sheet

MODEL HC-54 HC-69 HC-85 HC-103

Flow:

(SCFM) @ 100 PSIG

100°F Drying Temperature

(m3/hr) @ 6.89Bar(g)

4814

8179

6093

10352

7522

12780

37.8°C Drying Temperature

Vessel OD 48”

121.9 cm

54”

137.2 cm

60”

152.4 cm

Desiccant type IR Activated Alumina

Desiccant / Vessel 3572 lbs

1620 kgs

4521 lbs

2051 kgs

5581 lbs

2531 kgs

Inlet connection 6 FLG 6 FLG 8 FLG 8 FLG

Outlet connection 6 FLG 6 FLG 8 FLG 8 FLG

Afterfilter

(* Option)

AF-7200

or HAF-7200*

AF-7200

or HAF-7200*

AF-7200

or HAF-7200*

or HAF-10000*

Voltage 115/1/60 Standard

Consult Factory for other voltages

Cooling Water 143 GPM

541 LPM

Stripping Flow 96 SCFM

163 m3/hr

138 GPM

572 LPM

122 SCFM

207 m3/hr

172 GPM

651 LPM

150 SCFM

255 m3/hr

Cycle time 8 Hour NEMA Cycle –

4 Hours drying/ 4 Hours Regeneration

Outlet Dew Point Variable

DPDS Control Adjustable

High Humidity Alarm Adjustable

Pressure Switch Setpoint 10 PSI Fail to Shift 60 PSI Initiate Cooling

.7 Bar Fail to Shift 4 Bar Initiate Cooling

Cooler outlet high temperature

alarm

Low regeneration temperature

105F

40.6°C

Adjustable

alarm

Process flow Downward Regeneration / Upward Drying

9101

15463

66”

167.6 cm

6753 lbs

3063 kgs

AF-10000

208 GPM

787 LPM

182 SCFM

309 m3/hr

Reference IR - 222 Rev 3

Page 18 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

1.4.5 Technical data sheet

MODEL HC-122 HC-143 HC-166

Flow:

(SCFM) @ 100 PSIG

100°F Drying Temperature

(m3/hr) @ 6.89Bar(g)

10832

18404

12712

21598

37.8°C Drying Temperature

Vessel OD 72”

182.9 cm

78”

198.12 cm

Desiccant type IR Activated Alumina

Desiccant / Vessel 8037 lbs

3646 kgs

9432 lbs

4278 kgs

Inlet connection 8 FLG 8 FLG 10 FLG

Outlet connection 8 FLG 8 FLG 10 FLG

Afterfilter

(* Option)

AF-16000

or HAF-16000*

AF-16000

or HAF-16000*

or HAF-16000*

Voltage 115/1/60 Standard

Consult Factory for other voltages

Cooling Water 247 GPM

935 LPM

Stripping Flow 217 SCFM

627 m3/hr

289 GPM

1094 LPM

254 SCFM

734 m3/hr

8 Hour NEMA Cycle –

4 Hours drying/ 4 Hours Regeneration

Outlet Dew Point Variable

DPDS Control Adjustable

High Humidity Alarm Adjustable

Pressure Switch Setpoint 10 PSI Fail to Shift 60 PSI Initiate Cooling

.7 Bar Fail to Shift 4 Bar Initiate Cooling

Cooler outlet high temperature

alarm

Low regeneration temperature

105F

40.6°C

Adjustable

alarm

Process flow Downward Regeneration / Upward Drying

14742

25047

84”

213.36 cm

10939 lbs

4962 kgs

AF-16000

335 GPM

1268 LPM

295 SCFM

851 m3/hr

Reference IR - 222 Rev 3

Page 19 10/17/2013

USER MANUAL

Series HC

SECTION 1: (Continued)

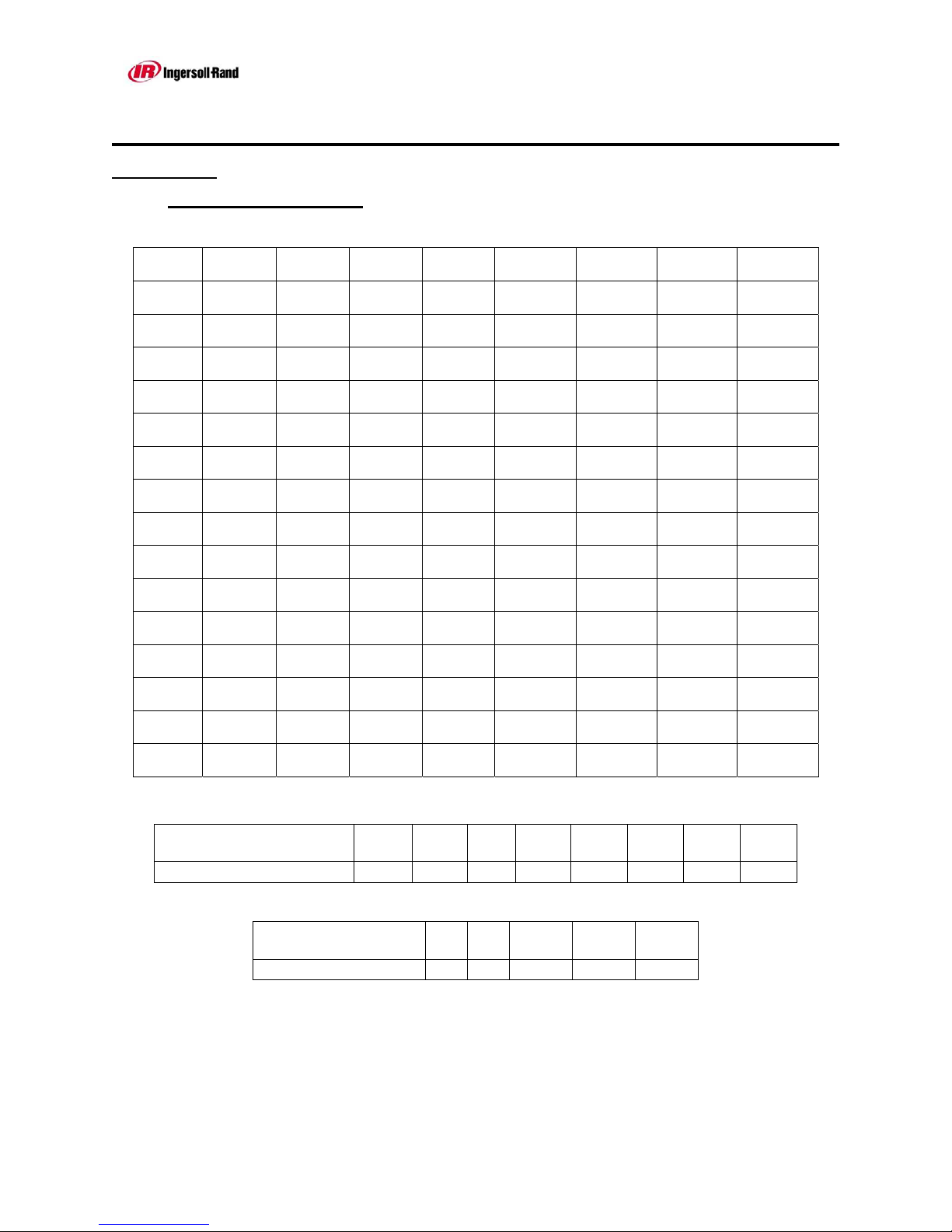

1.4.6 Dryer Flow Capacities

Model Selection Chart:

MODEL

HC-3

HC-6

HC-7

HC-9

HC-14

HC-21

HC-30

HC-41

HC- 54

HC-69

HC-85

HC-103

HC-122

HC-143

HC-166

PSI:

Bar:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

SCFM:

Nm3/h:

Minimum Inlet Pressure

Correction Factor

CORRECTION FACTOR FOR COOLING WATER TEMPERATURE

85

5.86

262

421

465

748

588

945

726

1167

1046

1682

1634

2627

2353

3783

3203

5150

4183

6725

5295

8513

6537

10510

7909

12716

9413

15134

11047

17761

12812

20598

Note: Maximum operating pressure is 150 PSIG (10.34 Bar);

higher pressures available as an option. Consult factory.

90

6.2

274

441

486

781

615

989

760

1222

1094

1759

1709

2748

2462

3958

3351

5388

4376

7035

5539

8905

6837

10992

8273

13301

9846

15830

11555

18577

13401

21545

PSIG:

Bar:

95

6.55

287

461

509

818

645

1037

796

1280

1146

1842

1790

2878

2578

4145

3509

5642

4583

7368

5801

9326

7161

11513

8664

13929

10312

16579

12102

19457

14035

22565

85

5.86

90

6.2

100

6.9

301

484

535

860

677

1088

836

1344

1204

1936

1880

3023

2708

4354

3686

5926

4814

7740

6093

9796

7522

12093

9101

14632

10832

17415

12712

20438

14743

23703

95

6.55

105

7.24

313

503

557

896

705

1133

870

1399

1253

2014

1957

3146

2819

4532

3837

6169

5011

8056

6343

10198

7830

12589

9474

15232

11276

18129

13233

21275

15347

24674

100

6.9

105

7.24

1.15 1.1 1.05 1 .96 .92 .88

110

7.58

327

526

581

934

735

1182

908

1460

1308

2103

2042

3283

2941

4728

4003

6436

5228

8405

6617

10638

8169

13134

9884

15891

11764

18913

13805

22195

16011

25741

110

7.58

115

7.93

342

550

608

978

769

1236

950

1527

1368

2199

2136

3434

3076

4945

4187

6732

5469

8793

6922

11129

8545

13738

10339

16622

12305

19783

14441

23217

16748

26926

115

7.93

Temperature

Correction Factor

To correct for a cooling water temperature other than 85F, or an operating pressure other than

100 psig, multiply dryer capacity by the correction factors listed above.

Example: To size for an inlet flow of 2208 m^3/hr @ 6.2 Bar, using 32C cooling water:

Multiply 2208 * (1.1) * (1.2) = 2914 Use Model HC-21

Reference IR - 222 Rev 3

Page 20 10/17/2013

°F

ºC 7524

.85 .9 1.0 1.2

80

27

85

29

90

32

USER MANUAL

Series HC

SECTION 1: (Continued)

1.4.7 Transport

After the adsorption dryer has been delivered, it must be checked for damage that

may have occurred during transport. The Transport Company must be informed to

register any damage. Shipping damage is not covered by any warranty.

1.4.8 Storage

If the adsorption dryer is to be stored for a prolonged period of time, it should be

stored in a dry place, preferably indoors; protected from the elements including

freezing or extremely warm temperatures.

1.4.9 Use of a pre and afterfilter

Use of a prefilter is not necessary with a heat-of-compression dryer. An afterfilter

should be provided to prevent desiccant dust from migrating downstream.

Reference IR - 222 Rev 3

Page 21 10/17/2013

USER MANUAL

Series HC

Prior to installation and start-up of this dryer,

please read and implement this section.

SECTION 2

INSTALLATION

Reference IR - 222 Rev 3

Page 22 10/17/2013

USER MANUAL

Series HC

SECTION 2:

INSTALLATION

2.1 SET-UP AND INSTALLATION

Once at the installation location, the adsorption dryers of the series HC-3 – HC-239,

which are supplied with a base frame, must be positioned so that all sides are easily

accessible. Should vibrations occur on the installation location, the adsorption dryer

is to be placed onto vibration dampeners.

Since the adsorption dryer has already been completely wired at our factory, the

customer only has to connect the power supply cable to the terminal strip according

to the supplied wiring diagrams.

Advice

Should you still have questions regarding installation, you can request

installation blueprints separately from IInnggeerrssoollll--RRaanndd Davidson NC.

Warning!

Use the appropriate, load-rated lifting equipment

and observe safe lifting procedures during all

operations of installation.

The equipment should be unloaded as close as

possible to the installation site to minimize any

chances of equipment damage.

Reference IR - 222 Rev 3

Page 23 10/17/2013

USER MANUAL

Series HC

SECTION 2: (Continued)

2.1.1 Mechanical installation

The equipment should be located in an area as practically possible with

adequate clearances for service. An overhead clearance of not less than three

feet above each adsorber tower is required for loading of the desiccant. Access

clearance of three feet in front of the control panel should be provided. Insulate

the pipe between the compressor and dryer to minimize heat loss. Remove all

protective shipping crates, flange covers, etc.

Utilizing the mounting holes provided on the skid, anchor the IInnggeerrssoollll--RRaanndd type

HC Dryer to a solid, level foundation designed to support the dryer.

Do not hydrostatically test the pressure vessels. All HC dryers’ pressure vessels

are hydrostatically tested at 1.3 times the design pressure after fabrication and

before assembly.

Desiccant is shipped loose (HC-41 and above) and must be installed. Refer to

Section 4.2 for installation of desiccant.

If the equipment is installed in a high traffic area, protective barriers may be

required to prevent possible damage of equipment and to prevent contact with

hot surfaces.

Because of vibration during shipping, some tube fittings may have loosened;

therefore, inspect all connections and tighten if required. Also, flange

connections may have loosened; therefore tighten all flange bolts.

Ensure that the inlet and outlet connections to and from the IInnggeerrssoollll--RRaanndd type

HC Dryer are made using the correct rated fittings and piping to meet the design

conditions.

System isolation and by-pass valves should be installed. If not supplied as part

of the equipment package by IInnggeerrssoollll--RRaanndd, they should be supplied and installed

by others. It must be verified that these exist, so that future servicing of the Dryer

System may take place.

Full flow relief valves to protect the system from over-pressure must be provided

by others in accordance with local regulations.

The purge exhaust connection on the HC larger dryers may be connected to a

vent header. To ensure satisfactory regeneration of the desiccant chambers is

achieved, the purge exhaust piping should be sized as follows to prevent "back

pressure" build up.

Installed length of exhaust pipe Pipe size required

Up to 10 ft (3.048 m) Same size as the dryer exhaust

Up to 25 ft (7.62 m) One size larger than dryer exhaust

Up to 50 ft (15.24 m) Two sizes larger than dryer exhaust

Up to 100 ft (30.48 m) Three sizes larger than dryer exhaust

Reference IR - 222 Rev 3

Page 24 10/17/2013

USER MANUAL

Series HC

SECTION 2: (Continued)

2.1.2 Preventative Maintenance Prior to Start-up

2.1.2.1 All air dryers are test ed at the factory for leak-tight joints and tightness of bolts;

however, during shipment, some bolts may vibrate loose. We have no control

over the handling our compressed air systems receive after leaving our factory.

To prevent costly problems at start-up and operation, all bolts should be

checked for tightness prior to system pressurization. This will assure gasket life

as well as prevent possible gasket blowout. Gasket joints should be bubble

tested after four or five complete cycles of the dryer, to ensure gaskets are

sealed. Any loose joints will need to be re-tightened and re-tested for leaks.

Following is a comprehensive procedure for tightening all pressurized gasketed

joints. If the dryer includes manual butterfly valves, valves must be totally

closed before re-torquing bolts.

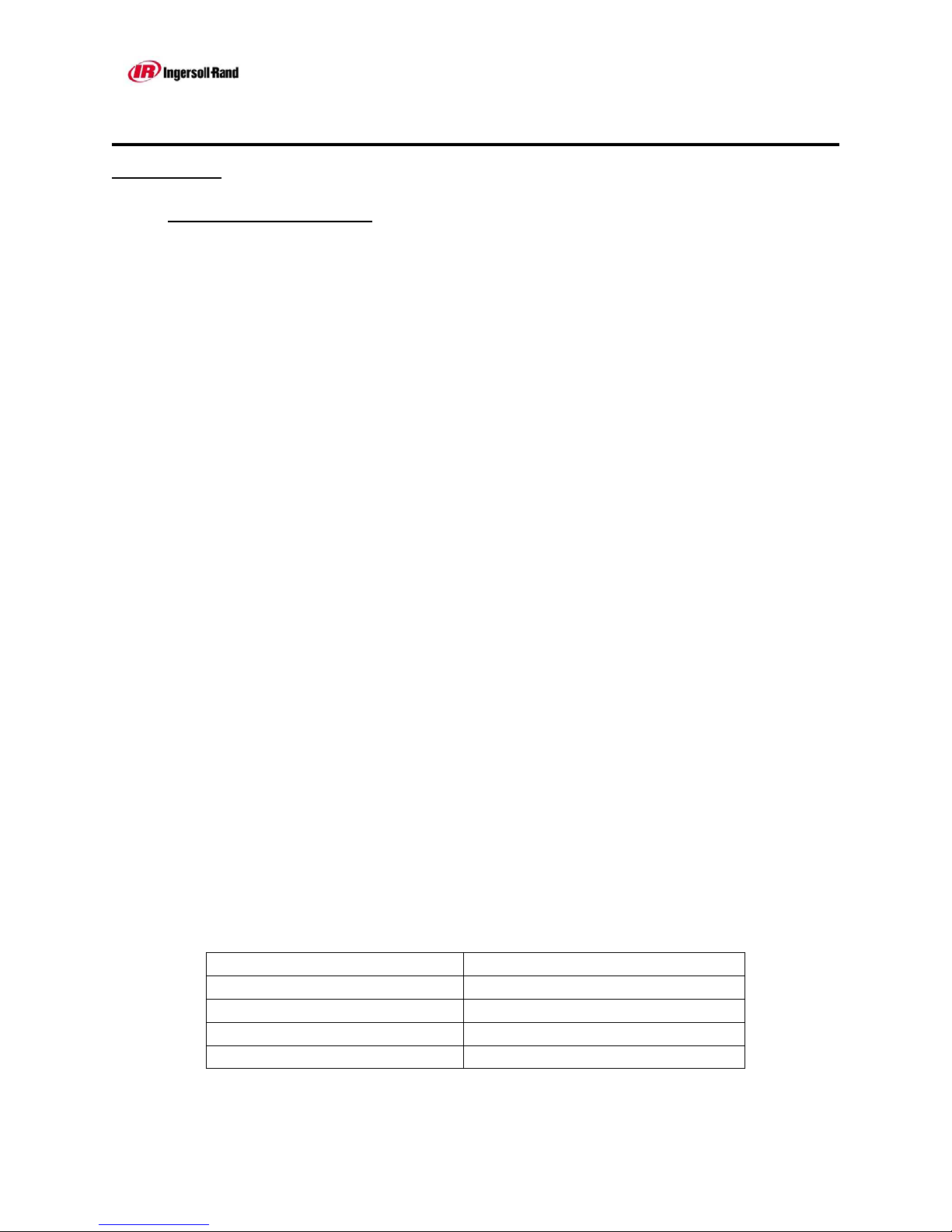

2.1.2.2 TIGHTEN BOLTS IN SEQUENTIAL ORDER (i.e. 0 - 180, 90 - 270, 45 -

225, and 135 - 315) until final torque is reached.

2.1.2.3 Use ROTATIONAL TIGHTENING until all bolts are stable at final torque level.

(Two complete times around is usually required.)

Reference IR - 222 Rev 3

Page 25 10/17/2013

USER MANUAL

Series HC

SECTION 2: (Continued)

FLANGE BOLT

TORQUE PROCEDURE

8 BOLTS

SEQUENTIAL ORDER ROTATIONAL ORDER

1-2 1

3-4 5

5-6 3

7-8 7

2

6

4

8

FLANGE BOLT TIGHTENING TORQUES

150# FLANGE RATING

RECOMMENDED

TORQUE / BOLT

(FT. LBS.)

MINIMUM TORQUE

(FT. LBS.)

MAXIMUM TORQUE

(FT. LBS.)

SIZE

BOLT

QTY.

BOLT

SIZE

1" 4 ½" 16 14 64

1 ½" 4 ½" 32 28 64

2" 4 5/8" 64 56 128

3" 4 5/8" 110 96 128

4" 8 5/8" 78 68 128

6" 8 ¾" 148 129 230

8" 8 ¾" 201 175 230

10" 12 7/8" 191 166 372

12" 12 7/8" 254 221 372

Based on 1/16" gasket material.

If other than 150# flange rating, consult Ingersoll-Rand.

NOTE: We regret any inconvenience this may cause; however, we feel this preventative

procedure will save time and money in the long run. Failure to follow this procedure

may result in premature gasket failure which is not covered by warranty.

Reference IR - 222 Rev 3

Page 26 10/17/2013

USER MANUAL

Series HC

SECTION 2: (Continued)

2.1.3 Filter installation

Series HC dryers are shipped with the afterfilter loose or with the filter skid

mounted on a separate steel frame. The following installation applies to all models

that are shipped with filters loose.

2.1.3.1 Afterfilter Installation

Mount afterfilter in such a way as to allow clearance for the element

installation and removal.

The filter must be piped so that the correct flow direction indicated on the filter

is followed.

Ensure that all piping and valves are equivalent or larger in size to the dryer

inlet connection.

2.1.3.2 Filter Skid with 3-Valve Bypass Installation

Filters skid should be located as close to dryer as possible. Use the skid bolt

holes to secure the assembly.

Ensure that the skid is located such that the 3-valve bypass will bypass the

dryer and filters when in use.

Check the flow direction of each filter to ensure the after filter is connected to

the outlet pipe of the dryer.

Connect the filter skid piping and dryer skid piping using materials and

fabrication procedures that are suitable for compressed air pressure piping. All

flanges are ANSI B16.5 Class 150 Raised Face flanges.

2.1.4 Electrical installation

Connect the dryer to a correctly sized power supply. The dryer requires a

115V 60 cycle connection. A disconnect switch is not provided with the dryer

and must be supplied by end user in accordance with the recognized electrical

codes.

Ground the frame of the dryer in accordance with the recognized electrical

codes.

It is recommended that the common alarm relay, located in the dryer control

panel, be connected to the control room or operator station so that an

immediate response to the dryer alarm may be given when required.

Reference IR - 222 Rev 3

Page 27 10/17/2013

USER MANUAL

Series HC

Prior to installation and start-up of this dryer,

please read and implement this section.

SECTION 3

START-UP & OPERATION

Reference IR - 222 Rev 3

Page 28 10/17/2013

USER MANUAL

Series HC

SECTION 3:

3.1 START UP

START UP AND OPERATION

Attention!

All pipes and wire connections are to be tightened!

Furthermore, before start-up:

The pipes must be checked for the presence of scale,

abraded material from the threading, or other similar

impurities.

All shut off valves on the adsorption dryer, afterfilter

and on the bypass line should be closed.

The ambient temperature must not be less than 33°F

(0.56°C).

Breakdowns resulting from faulty installation do not fall under IInnggeerrssoollll--RRaanndd's

warranty obligation.

3.1.1 Pressurizing dryer

Prior to pressurizing the IInnggeerrssoollll--RRaanndd Series HC Dryer system, verify the

following:

- Dryer On – Off switch is in the off position.

- System outlet block valve is closed.

- Cooling water is turned on to the aftercooler.

Slightly open the inlet isolation valve slowly admitting compressed air to the

system. When full system operating pressure has been reached all connections

should be soap bubble tested for leaks. Any leaks should be repaired and

retested prior to placing the equipment in service. If some gas other than the

process air will be used for leak testing, consult Ingersoll-Rand for its

compatibility with system components before proceeding. Fully open the inlet

isolation valve.

When the system is filled with process air, is leak tight and start-up is completed,

then slowly open the system outlet valve to pressurize the downstream piping.

During the procedure, ensure that the dryer system pressure does not fall below

95% of its reading prior to opening the system outlet valve. This will protect the

equipment internal components (i.e. filter elements, desiccant) from gas

velocities above design conditions.

Reference IR - 222 Rev 3

Page 29 10/17/2013

USER MANUAL

Series HC

SECTION 3: (Continued)

3.1.1 Pressurizing dryer (Continued)

When pressurizing is complete then fully open the system outlet valve to place

the equipment in service.

Verify the system inlet pressure and temperature are at the design operating

levels.

Please note that excessive flows or rapid change in pressure may cause

damage to the air dryer skid. Every time there is no line pressure, the

dryer must be valved out and brought up to line pressure slowly.

The dryer should be carefully monitored during the first few hours of operation

to check for malfunction.

Protect the dryer from overloads. The dryer can become overloaded, if:

inlet flow is too high

temperature of the air at the discharge of the aftercooler is too high

minimum operating pressure is too low

temperature of the air at the discharge of the compressor is too low

check Specifications in Section 6 for proper operating conditions

3.2 OPERATOR INTERFACE

NOTE: Reference Section 7 (Auxiliary Manuals) for the operational instructions

specific to the operator interface purchased.

Also in Section 7 can be found the operational instructions for the

optional dew point demand system, if installed on this dryer.

Reference IR - 222 Rev 3

Page 30 10/17/2013

Loading...

Loading...