Page 1

OPERATOR’S

MANUAL

H2XXXX-XXX-X

INCLUDING: APPLICATION, LUBRICATION, INSTALLATION & SERVICE

H SERIES VALVES

RELEASED: 11-20-87

REVISED: 1-26-01

(REV.

A)

READ THIS MANUAL CAREFULL

OPERA

It

is the responsibility of the employer to place this information in the hands of the operator

TING OR SER

VICING THIS EQUIPMENT

Y BEFORE INST

ALLING,

.

. Keep for future reference.

MODEL

VALVE TYPE

2 Ć 2 Position

BODY STYLE

1 Ć 4 Way Side Ported

4 Ć 4 Way Bottom Ported

5 Ć 3 Way Side Ported

8 Ć 3 Way Bottom Ported

PORT SIZE

2 Ć 1/4" NPT

3 Ć 3/8" NPT

4 Ć 1/2" NPT

DESCRIPTION CHART

H2X X XX Ć XXX ĆX

CURRENT TYPE

AĆAC

DĆDC

N Ć No Coil

COIL VOLTAGE

000 Ć No Coil

005 Ć 5 V

012 Ć12V

024 Ć24V

120 Ć 120 V

240 Ć 240 V

ACTUATOR / RETURN

BD Ć Bleed / Bleed (page 5)

KD Ć Solenoid / Solenoid (page 8)

PA Ć Pilot / Internal Pilot (page 5)

PD Ć Pilot / Pilot (page 5)

PS Ć Pilot / Spring (page 3)

SA Ć Solenoid / Internal Pilot (page 6)

SD Ć Solenoid / Solenoid (page 7)

SS Ć Solenoid / Spring (page 4)

INGERSOLL-RAND COMPANY

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506Ć0151

&

(419) 636-4242 D F

AX (419) 633-1674

E2001 D PRINTED IN U.S.A.

Page 2

Warnings

and Cautions

APPLICATION

WARNINGS:

1. ARO

2. When any ARO valve is used in any type application, safe-

3. ARO

valves are designed for use only in industrial

(air) and / or vacuum systems applications and are NOT to be

used

for individual consumer use, application or service.

guards

must be provided to insure against bodily injury for the

operator

ate

tems and / or brake systems on power presses or similar

equipment.

uses.

and / or other persons in the immediate area.

valves are NOT to be used as a safety device or to oper

and /

or control the operation of full revolution clutch sys

ARO valves are not designed or intended for such

pneumatic

LUBRICATION

Valve components are lubricated at the time of assembly at the

factory

and

can normally be operated without air line lubrication to

an approximate life of twenty million cycles, depending on application.

junction

ing oils used are compatible with the valve seals and are of

sufficient viscosity to assure adequate lubrication. Aro recommends

and

use of compound oils containing graphite fillers, extremely low

viscosities and other non-fluidic lubricants. RECOMMENDED:

Aro

If air line cylinders or other air line devices, used in con

with ARO valves, require lubrication, be sure the

an oil lubricant

an aniline point above 200_ F

29665 air line lubricator oil is

INSTALLATION

with a viscosity of 100 - 200 SUS at 100_ F

. Aro does not recommend the

available in one quart containers.

AND SER

VICE

lubricat

the limits set forth in the specifications for a particular valve

model.

5. When a manually operated (actuated) valve is used or

installed into a system, provisions must be made to prevent

the

valve from being accidentally operated (actuated), which

may in turn cause bodily injury or otherwise cause a hazard

ous or dangerous condition

6. Damaged air pressure hoses

tions,

can cause accidental valve operation (actuation), which

may

in turn cause

-

-

-

-

ous or dangerous condition. KEEP ALL HOSES, ELECTRICAL

CLASS

7.

ARO 2-POSITION, 4-WAY VALVES:

the

is applied

be an open flow path of air from the inlet to one

outlets.

installed into the system so all air pressure can be

from valve or system before performing service or maintenance

8. ARO

ARO valve, either a double

pressure

tor has shifted the valve, air pressure applied at the inlet

port(s) will flow thru the valve to one of the two outlet

When

matically

closed center or open center type and will reveal the following

characteristics

WIRING,

OPERA

2-positions this type of ARO valve

A method to exhaust this trapped air pressure must be

to valve.

3-POSITION,

the valve is not in a shifted position, the valve will auto

TING CONDITION.

to

the inlet port(s) of these valves, there will always

or manual operation is used. When the valve

move to a center position. ARO valves can be either

when the valve is in the center position:

bodily injury or otherwise cause a hazard

FITTINGS AND CONNECTIONS IN FIRST

4-W

or electrical wiring, or connec

Regardless of which of

is in, when air pressure

AY VALVES: To actuate this type of

solenoid, double remote air pilot

of the valve

removed

actua

ports.

-

-

-

-

-

WARNINGS:

1. Shut

2. Shut off and disconnect electrical supply to system before

3.

4. DO

of

f, disconnect and exhaust air pressure from system be

fore

installing or performing service to any ARO valve.

installing

Allow only persons with a thorough understanding

eration

ticular

with other components of the system to install or perform

maintenance or service to any ARO valve or other components

or performing service to any ARO valve.

of the op

and application of all ARO valves being used in a par

system and how the ARO

of the system.

NOT subject any ARO valve to any condition that exceeds

valve(s) relate to and interact

a. OPEN

-

-

-

b. CLOSED

CENTER V

the

center position, the

outlet ports are open to the exhaust port(s) of the valve.

With this type valve, in the center position, air pressure

not present at either outlet port. Do not use this type ARO

valve if exhausting the air pressure from the valve will

cause

hazardous or dangerous condition.

CENTER V

center position, all inlet, outlet and exhaust ports are

blocked.

blocked at the port(s) may cause a hazardous or dangerous

ing

trol

positive stop on the holding device.

Do not use this

condition in the application, installation and / or servic

of an ARO valve. These valves must not be used to con

load holding

ALVES:

devices without an additional mechanical

When this type ARO valve is

inlet port(s) is blocked and the two

ALVES: When this type valve is in the

type valve if having the air pressure

in

is

-

-

H Series Valves2OF12

Page 3

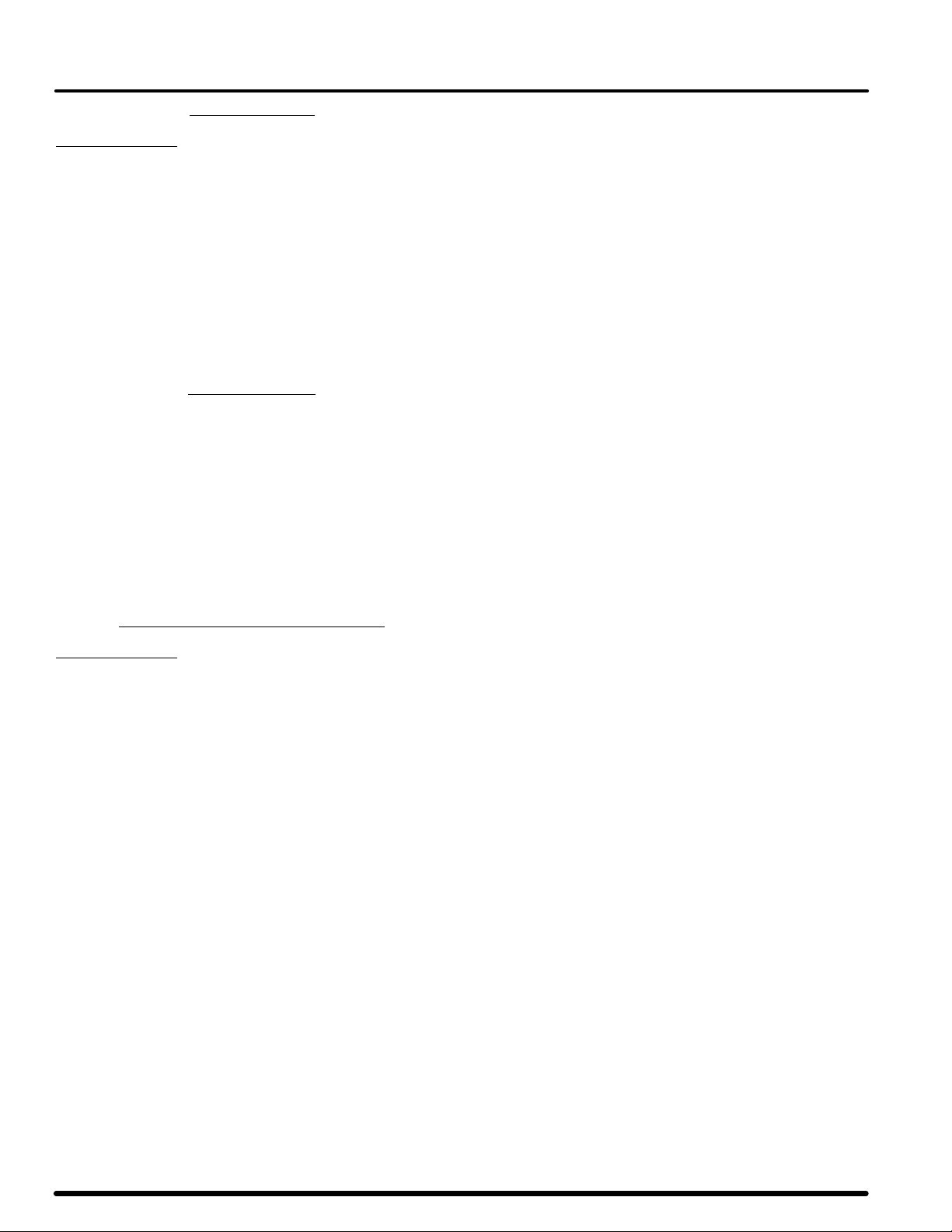

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

3-WAY PILOT, SPRING RETURN

PRESSURE RANGE: 30 - 150 p.s.i. (2.1 - 10.4 bar)

NOT SHOWN

116343 LABEL

n Y195-68-C SCREW (2)

115006 COVER Y109-428 NUT

9020 PISTON

Q Y325-9 “O” RING

1

15016 V

MODELS: H25XPS

H28XPS

118126 PIPE PLUG

ALVE ASSEMBLY

9026 “O” RING Q

Y325-25 “O” RING Q

Q Y325-10 “O” RING

Q 9019 INSERT

115021 BODY

Y325-28 “O” RING Q

30197 SPRING Q

9021 PLUNGER ASSEMBLY Q

Y195-74-C SCREW (2)

Q PARTS

n

INCLUDED IN REP

INCLUDED IN 1

AIR KIT NO. 7102.

15016 VALVE ASSEMBL

Y.

9124 GASKET Q

SUB-BASE (SEE TABLE)

“B” PIPE PLUG (SEE TABLE)

“A” PIPE PLUG (SEE TABLE)

MODEL NO. SUB-BASE PORT LOCATION PORTS (NPTF) PIPE PLUG “A” PIPE PLUG “B”

H252PS 115013-1 SIDE 1/4 ––– –––

H253PS 115013-2 SIDE 3/8 ––– –––

H254PS 115009 SIDE 1/2 ––– –––

H282PS 115017-1 BOTTOM 1/4 Y227-3 Y227-4

H283PS 115017-2 BOTTOM 3/8 Y227-4 Y227-4

H Series Valves

3OF12

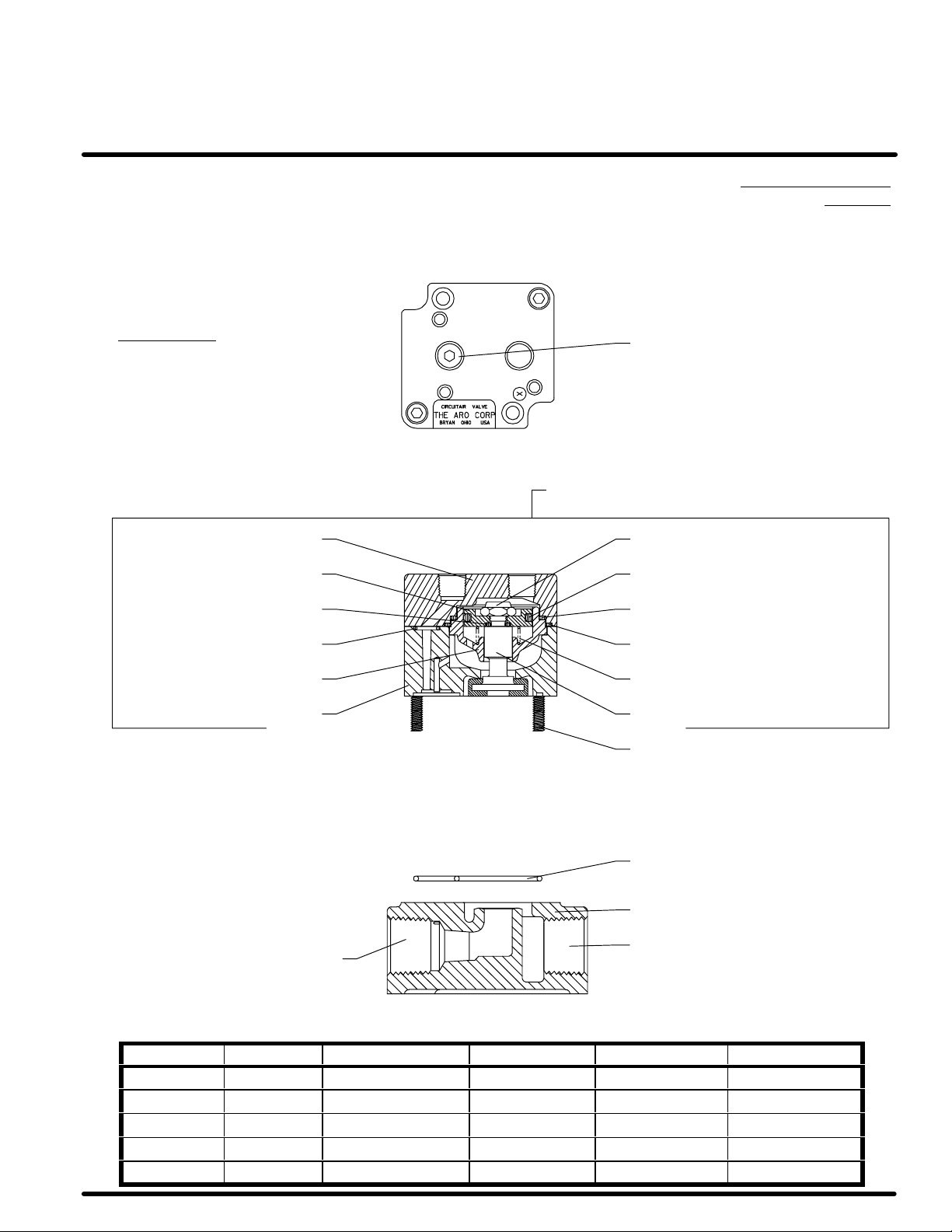

Page 4

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

3-WAY SOLENOID, SPRING RETURN

PRESSURE RANGE: 30 - 150 p.s.i. (2.1 - 10.4 bar)

MODELS: H25XSS-XXX-X

H28XSS-XXX-X

l 1

19380 NUT

l 1

16507 ARMA

TURE ASS’Y

31 = 12 VAC

33 = 120 VAC

35 = 240 VAC

37 = 5 VDC

38 = 24 VAC / 12 VDC

(DUAL RATING)

39 = 24 VDC / 48 VAC

(DUAL RATING)

116218-XX COIL

l 116506 FLANGE PLATE

l 116495 BASE PLATE

l 116499 GASKET

115006 COVER Y109-428 NUT

9020 PISTON

Q Y325-9 “O” RING

Q Y325-10 “O” RING

Q 9019 INSERT

115021 BODY

1

15016 V

Y178-3 ROLL PIN l

Y325-8 “O” RING l

118590 OVERRIDE PIN

Y195-65-C SCREW (3) l

ALVE ASSEMBLY

9026 “O” RING Q

Y325-25 “O” RING Q

Y325-28 “O” RING Q

30197 SPRING Q

9021 PLUNGER ASSEMBLY Q

Y195-74-C SCREW (2)Q 9124 GASKET

“A” PIPE PLUG (SEE TABLE)

Q PARTS

n

l P

INCLUDED IN REP

INCLUDED IN 1

ARTS INCLUDED IN REP

15016 VALVE ASSEMBL

AIR KIT NO. 7102.

AIR KIT NO. 1

Y.

16572.

“B” PIPE PLUG (SEE TABLE)

NOT SHOWN

116343 LABEL

n Y195-68-C SCREW (2)

l 116346 SCREW (2)

l 118126 PIPE PLUG

MODEL NO. SUB–BASE PORT LOCATION PORTS (NPTF) PIPE PLUG “A” PIPE PLUG “B”

H252SS-XXX-X 115013-1 SIDE 1/4 ––– –––

H253SS-XXX-X 115013-2 SIDE 3/8 ––– –––

H254SS-XXX-X 115009 SIDE 1/2 ––– –––

H282SS-XXX-X 115017-1 BOTTOM 1/4 Y227-3 Y227-4

H283SS-XXX-X 115017-2 BOTTOM 3/8 Y227-4 Y227-4

SUB-BASE (SEE TABLE)

H Series Valves4OF12

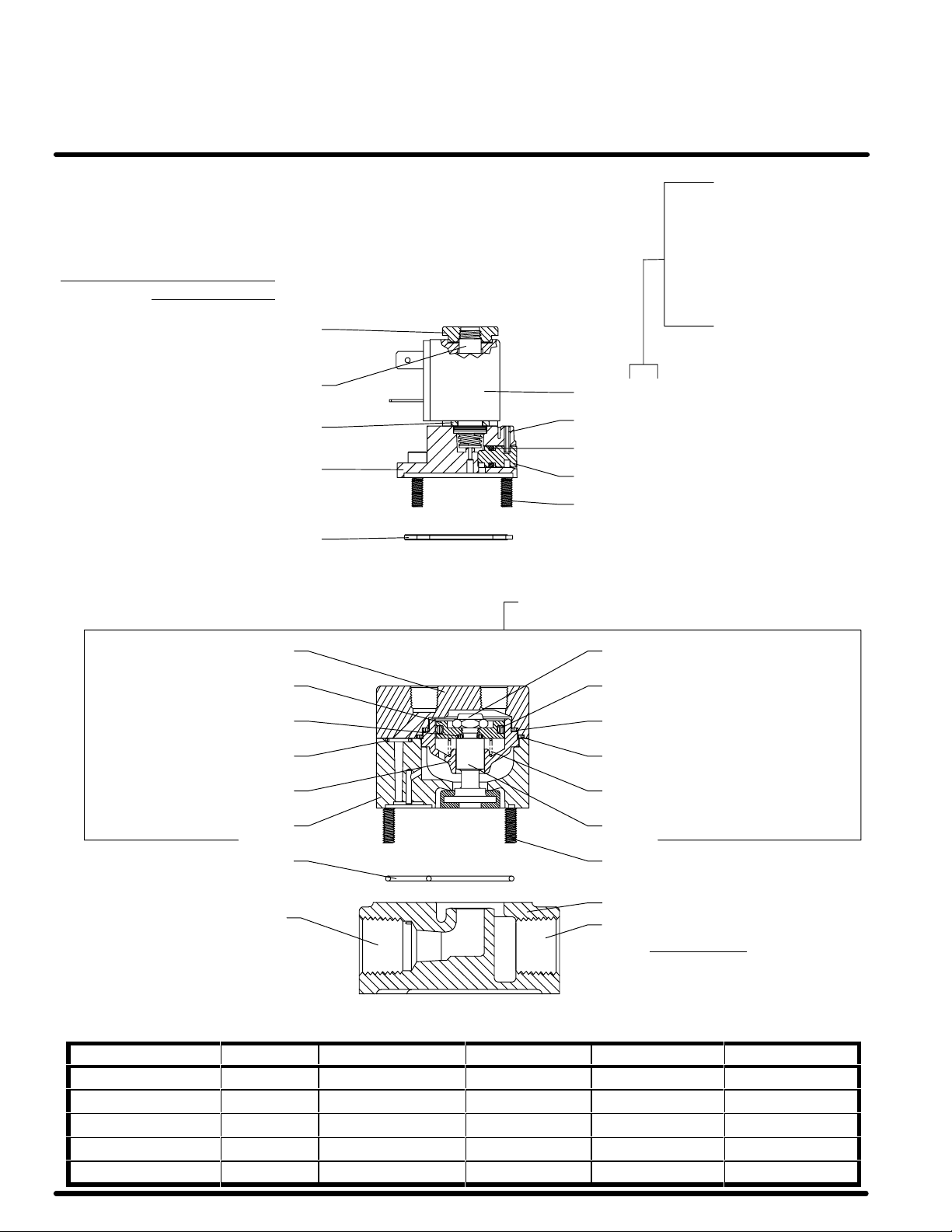

Page 5

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

4-WAY PILOT AND DOUBLE BLEED

PRESSURE RANGE: 20 - 150 p.s.i. (1.4 - 10.4 bar)

Q PARTS

n

INCLUDED IN 1

INCLUDED IN REP

15014 VALVE ASSEMBL

118126 PLUG

MODELS: H21XPA

115007 COVER Y109-428 NUT (2)

AIR KIT NO. 7103.

H24XPA

Q 9025 DISC

24130 BUTTON BLEEDER

Y.

ASSEMBLY (2)

MODELS: H21XBD

H24XBD

1

15014 V

9023 GASKET Q

9600 PILOT BLEEDER

ASSEMBLY (2)

MODELS: H21XPD

H24XPD

ALVE ASSEMBLY

Q Y325-25 “O” RING (2)

9020 PISTON (2)

Q Y325-9 “O” RING (2)

Q 9021 PLUNGER ASS'Y (2)

Q 9024 GASKET

NOT SHOWN

116154 LABEL

n Y195-68-C SCREW (2)

MODEL NO. SUB-BASE PORT LOCATION PORTS (NPTF) PIPE PLUG (2)

H212XX 115022-1 SIDE 1/4 –––

H213XX 115022-2 SIDE 3/8 –––

H214XX 115008 SIDE 1/2 –––

H242XX 115029-1 BOTTOM 1/4 Y227-3

H243XX 115029-2 BOTTOM 3/8 Y227-4

9026 “O” RING (2) Q

Y325-28 “O” RING (2) Q

9019 INSERT (2) Q

115015 BODY

Y195-74-C SCREW (3)

SUB-BASE (SEE TABLE)

H Series Valves

5OF12

Page 6

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

4-WAY SOLENOID, INTERNAL PILOT RETURN

PRESSURE RANGE: 25 - 135 p.s.i. (1.7 - 9.3 bar)

MODELS: H21XSA-XXX-X

H24XSA-XXX-X

l 1

19380 NUT

l 1

16507 ARMA

TURE ASS’Y

31 = 12 VAC

33 = 120 VAC

35 = 240 VAC

37 = 5 VDC

38 = 24 VAC / 12 VDC

(DUAL RATING)

39 = 24 VDC / 48 VAC

(DUAL RATING)

116218-XX COIL

l 116506 FLANGE PLATE

l 116495 BASE PLATE

l 116499 GASKET

115007 COVER Y109-428 NUT (2)

Q Y325-25 “O” RING (2)

9020 PISTON (2)

Q Y325-9 “O” RING (2)

Q 9021 PLUNGER ASS'Y (2)

Q 9024 GASKET

Q 9025 DISC

Y178-3 ROLL PIN l

Y325-8 “O” RING l

118590 OVERRIDE PIN

Y195-65-C SCREW (4) l

1

15014 V

9023 GASKET Q

ALVE ASSEMBLY

9026 “O” RING (2) Q

Y325-28 “O” RING (2) Q

9019 INSERT (2) Q

115015 BODY

Y195-74-C SCREW (3)

SUB-BASE (SEE TABLE)

Q PARTS

n

l P

INCLUDED IN REP

INCLUDED IN 1

ARTS INCLUDED IN REP

H212SA-XXX-X 115022-1 SIDE 1/4 –––

H213SA-XXX-X 115022-2 SIDE 3/8 –––

H214SA-XXX-X 115008 SIDE 1/2 –––

H242SA-XXX-X 115029-1 BOTTOM 1/4 Y227-3

H243SA-XXX-X 115029-2 BOTTOM 3/8 Y227-4

NOT SHOWN

116154 LABEL

AIR KIT NO. 7103.

15014 VALVE ASSEMBL

AIR KIT NO. 1

Y.

16572.

n Y195-68-C SCREW (2)

Q Y325-10 “O” RING

l 116346 SCREW (2)

l 118126 PIPE PLUG

MODEL NO. SUB-BASE PORT LOCATION PORTS (NPTF) PIPE PLUG (2)

H Series Valves6OF12

Page 7

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

4-WAY DOUBLE SOLENOID

PRESSURE RANGE: 25 - 135 p.s.i. (1.7 - 9.3 bar)

l 119380 NUT (2)

l 116507 ARMATURE ASS'Y (2)

l 116506 FLANGE PLATE (2)

l Y178-3 ROLL PIN (2)

118590 OVERRIDE PIN (2)

l 116501-2 BASE PLATE

l 116505 GASKET

Q 9025 DISC

116218-XX COIL (2)

Y325-8 “O” RING (2) l

Y195-65-C SCREW (4) l

1

15014 V

9023 GASKET Q

MODELS: H21XSD-XXX-X

H24XSD-XXX-X

31 = 12 VAC

33 = 120 VAC

35 = 240 VAC

37 = 5 VDC

38 = 24 VAC / 12 VDC

(DUAL RATING)

39 = 24 VDC / 48 VAC

(DUAL RATING)

ALVE ASSEMBLY

115007 COVER Y109-428 NUT (2)

Q Y325-25 “O” RING (2)

9020 PISTON (2)

Q Y325-9 “O” RING (2)

Q 9021 PLUNGER ASS'Y (2)

Q 9024 GASKET

Q PARTS

n

l P

INCLUDED IN REP

INCLUDED IN 1

ARTS INCLUDED IN REP

15014 VALVE ASSEMBL

MODEL NO. SUB-BASE PORT LOCATION PORTS (NPTF) PIPE PLUG (2)

H212SD-XXX-X 115022-1 SIDE 1/4 –––

H213SD-XXX-X 115022-2 SIDE 3/8 –––

H214SD-XXX-X 115008 SIDE 1/2 –––

H242SD-XXX-X 115029-1 BOTTOM 1/4 Y227-3

H243SD-XXX-X 115029-2 BOTTOM 3/8 Y227-4

AIR KIT NO. 7103.

Y.

AIR KIT NO. 1

16574.

9026 “O” RING (2) Q

Y325-28 “O” RING (2) Q

9019 INSERT (2) Q

115015 BODY

Y195-74-C SCREW (3)

SUB-BASE (SEE TABLE)

NOT SHOWN

116154 LABEL

n Y195-68-C SCREW (2)

l 116346 SCREW (4)

l 118126 PIPE PLUG

H Series Valves

7OF12

Page 8

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

4-WAY DOUBLE SOLENOID

PRESSURE RANGE: 25 - 135 p.s.i. (1.7 - 9.3 bar)

MODELS: H21XKD-XXX-X

H24XKD-XXX-X

119380 NUT (2)

116507 ARMATURE ASS'Y (2)

116506 FLANGE PLATE (2)

31 = 12 VAC

33 = 120 VAC

35 = 240 VAC

37 = 5 VDC

38 = 24 VAC / 12 VDC

(DUAL RATING)

39 = 24 VDC / 48 VAC

(DUAL RATING)

Y178-3 ROLL PIN (2)

118590 OVERRIDE PIN (2)

116501-1 BASE PLATE

116505 GASKET

115007 COVER Y109-428 NUT (2)

Q Y325-25 “O” RING (2)

9020 PISTON (2)

Q Y325-9 “O” RING (2)

Q 9021 PLUNGER ASS'Y (2)

Q 9024 GASKET

Q 9025 DISC

116218-XX COIL (2)

Y325-8 “O” RING (2)

Y195-65-C SCREW (4)

1

15014 V

9023 GASKET Q

ALVE ASSEMBLY

9026 “O” RING (2) Q

Y325-28 “O” RING (2) Q

9019 INSERT (2) Q

115015 BODY

Y195-74-C SCREW (3)

SUB-BASE (SEE TABLE)

NOT SHOWN

116154 LABEL

n Y195-68-C SCREW (2)

116346 SCREW (4)

118126 PIPE PLUG

MODEL NO. SUB-BASE PORT LOCATION PORTS (NPTF) PIPE PLUG (2)

H212KD-XXX-X 115022-1 SIDE 1/4 –––

H213KD-XXX-X 115022-2 SIDE 3/8 –––

H214KD-XXX-X 115008 SIDE 1/2 –––

H242KD-XXX-X 115029-1 BOTTOM 1/4 Y227-3

H243KD-XXX-X 115029-2 BOTTOM 3/8 Y227-4

Q PARTS

n

INCLUDED IN 1

INCLUDED IN REP

15014 VALVE ASSEMBL

AIR KIT NO. 7103.

Y.

H Series Valves8OF12

Page 9

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

3-WAY MANIFOLD ASSEMBLY

1A THRU 1E

23 4 5

“O” RING TO BLOCK OUTLET IN BASE

OF VALVE, NO PORT IN MANIFOLD.

6 “O” RING FOR SEALING BETWEEN

VALVE AND MANIFOLD PORTS.

NOTE: OUTLET ON VALVE MUST BE USED.

NO OUTLET PORT IN MANIFOLD.

ASSEMBLY

9104-2 9104-3 9104-4 9104-5 9104-6

SYMBOL NO.

1A

1B

1C

1D

1E

2

3 “O” RING Y325-18 6 8 10 12 14

4 MANIFOLD BLOCK 9127 2 3 4 5 6

5

6 “O” RING Y325-18 6 9 12 15 18

DESCRIPTION PART NO. QUANTITY

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

END BLOCK

INLET BLOCK

SCREW (NOT SHOWN)

LOCK W

ASHER (NOT SHOWN)

Y 9129-2 2

Y 9129-3 2

Y 9129-4 2

Y 9129-5 2

Y 9129-6 2

9130 1 1 1 1 1

9128 1 1 1 1 1

Y154-57 4 6 8 10 12

Y14-10-C 4 6 8 10 12

NUMBER

INLET

1/2 - 14 N.P.T.

OUTLET

1/2 - 14 N.P.T.

H Series Valves

9OF12

Page 10

PARTS LIST

SERIES H POPPET VALVES

SUB-BASE MOUNTED

(1/4, 3/8 AND 1/2 N.P.T.F. PIPE PORTS)

4-WAY MANIFOLD ASSEMBLY

1342

5A THRU 5E

INLET 1/2 - 14 N.P.T.

6

OUTLET 1/2 - 14 N.P.T.

9007-2 9007-3 9007-4 9007-5 9007-6 9008-2 9008-3 9008-4 9008-5 9008-6

SYMBOL NO.

1

2 “O” RING Y325-18 6 8 10 12 14 6 8 10 12 14

3 MANIFOLD BLOCK 9027 2 3 4 5 6 2 3 4 5 6

4

5A

5B

5C

5D

5E

6

7 “O” RING Y325-18 8 12 16 20 24 8 12 16 20 24

DESCRIPTION PART NO. QUANTITY

INLET BLOCK

END BLOCK

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

TIE ROD ASSEMBL

REDUCING BUSHING

SCREW (NOT SHOWN)

LOCK WASHER (NOT SHOWN) Y14-416-C 4 6 8 10 12 4 6 8 10 12

9028 1 1 1 1 1 1 1 1 1 1

9030 1 1 1 1 1 1 1 1 1 1

Y 9129-2 2 2

Y 9129-3 2 2

Y 9129-4 2 2

Y 9129-5 2 2

Y 9129-6 2 2

Y45-103-C 4 6 8 10 12

Y99-43 4 6 8 10 12 4 6 8 10 12

7 “O” RING FOR SEALING BETWEEN

VALVE AND MANIFOLD PORTS.

ASSEMBLY

NUMBER

H Series Valves10OF12

Page 11

H Series Valves

11 OF 12

Page 12

PN 119999Ć37

H Series Valves12OF12

Loading...

Loading...