M10

180

4–30–94

11–4–99

F

F

OPERATOR’S MANUAL

INCLUDING: OPERATION, INS TALLATION & MAINTENANCE

SECTION

MANUAL

Released:

Revised:

MODELS GRG15A–06G–7, GRG15A–06G–9, GRG15A–08G–7,

GRG15M–06G–7, GRG15M–06G–9, GRG15M–08G–7,

GRP15A–02P–7, GRS15A–04S–9, AND GRS15A–06S–7

1.5 H.P. ANGLE GRINDERS, POLISHERS, AND SANDERS

GRG Air Angle Grinders, GRS Air Angle Sanders and GRP Air Angle polishers are designed for smoothing, trimming or removing metal in close–quarter areas in foundries, shipyards, steel mills and in

construction applications.

ARO is not responsible for customer modification of tools for applications on which ARO was not

consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI B186.1).

• For safety, top performance, and maximum

durability of parts, operate this tool at 90 psig

(6.2 bar/620 kPa) maximum air pressure at the

inlet with 3/10” (10 mm) inside diameter air supply

hose.

• Always turn off the air supply and disconnect the

air supply hose before installing, removing or

adjusting any accessory on this tool, or before

performing any maintenance on this tool.

• Do not use damaged, frayed or deteriorated air

hoses and fittings.

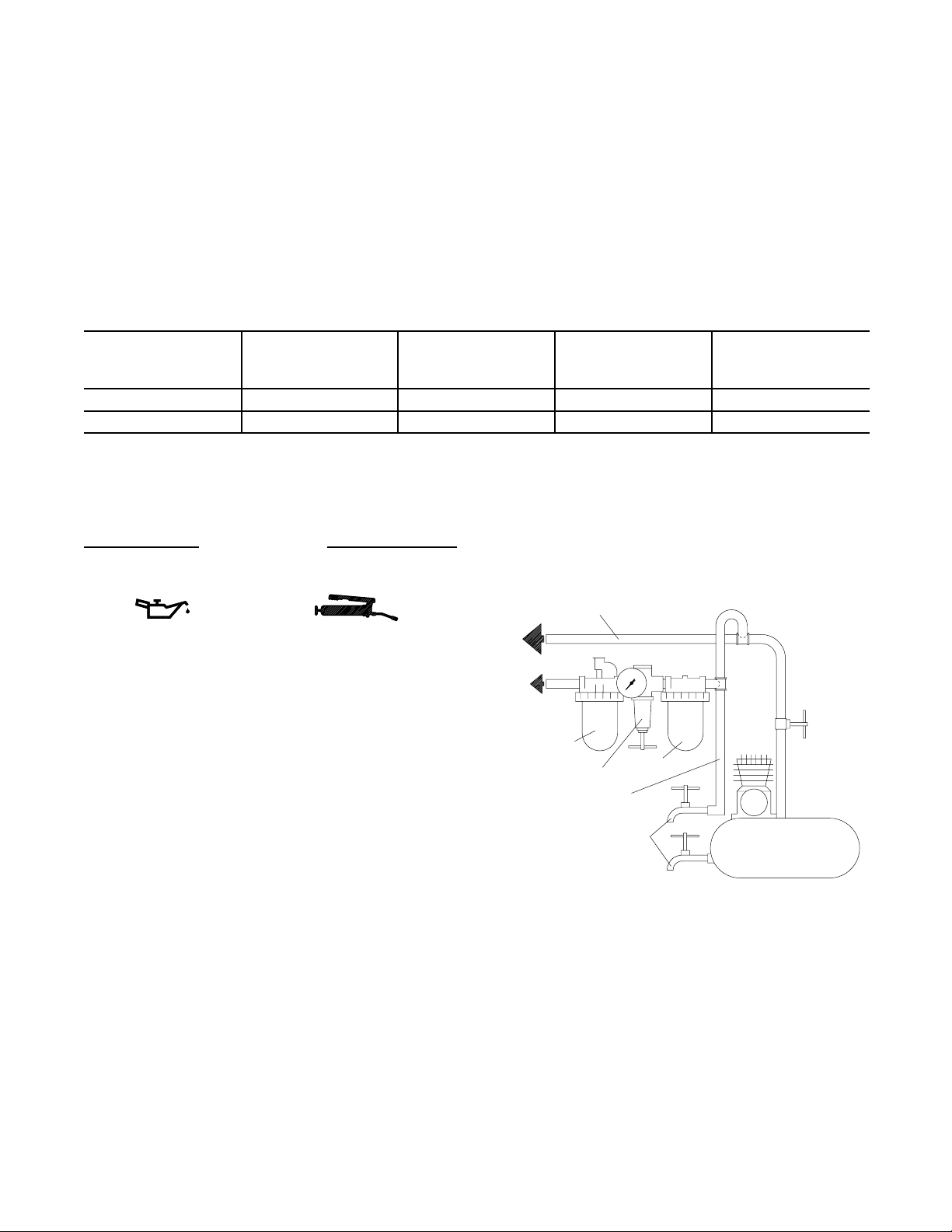

• Be sure all hoses and fittings are the correct size

and are tightly secured. See Dwg. TPD905–1 for a

typical piping arrangement.

• Always use clean, dry air at 90 psig (6.2 bar/

620 kPa) maximum air pressure. Dust, corrosive

fumes and/or excessive moisture can ruin the

motor of an air tool.

• Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged

label.

USING THE TOOL

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear hearing protection when operating

this tool.

• Keep hands, loose clothing and long hair away

from rotating end of tool.

• Anticipate and be alert for sudden changes in

motion during start up and operation of any power

tool.

• Keep body stance balanced and firm. Do not

overreach when operating this tool. High reaction

torques can occur at or below the recommended

air pressure.

• Tool accessories may continue to rotate briefly

after throttle is released.

• Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using

any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before resuming use.

• Use accessories recommended by ARO.

• Whenever the Angle Head is installed or reposi-

tioned, the Throttle Lever must be positioned so

that reaction torque will not tend to retain the

throttle in the “ON” position.

• This tool is not designed for working in explosive

atmospheres.

• This tool is not insulated against electric shock.

E

E

P

P

The use of other than genuine ARO replacement parts may result in safety hazards, decreased tool performance, and

increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest ARO Tool Products Authorized

Servicenter.

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll–Rand Distribution Center,

White House, TN at PH: (615) 672–0321, FAX: (615) 672–0801

ARO Tool Products

Ingersoll–Rand Company

1725 U.S. No. 1 North, PO Box 8000, Southern Pines, NC 28388–8000

1999 INGERSOLL–RAND COMPANY PRINTED IN U.S.A

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

M10

180

WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before resuming use.

90 psig

(6.2bar/620kPa)

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

GRINDER SPECIFIC WARNINGS

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

• Do not use this tool if actual free speed exceeds the

nameplate rpm.

• Before mounting a wheel, after any tool repair or

whenever a Grinder is issued for use, check free

speed of Grinder with a tachometer to make certain

its actual speed at 90 psig (6.2 bar/620 kPa) does not

exceed rpm stamped or printed on the nameplate.

Grinders in use on the job must be similarly

checked at least once each shift.

• Always use the recommended ARO Wheel Guard

furnished with the Grinder.

• Do not use any grinding wheel, bur or other

accessory having a maximum operating speed less

than the free speed of the Grinder in which it is

being used. Always conform to maximum rpm on

grinding wheel blotters.

• Inspect all grinding wheels for chips or cracks prior

to mounting. Do not use a wheel that is chipped or

cracked or otherwise damaged. Do not use a wheel

that has been soaked in water or any other liquid.

• Make certain grinding wheel properly fits the

arbor. Do not use reducing bushings to adapt a

wheel to any arbor unless such bushings are

supplied by and recommended by the wheel

manufacturer.

• After mounting a new wheel, hold the Grinder

under a steel workbench or inside a casting and run

it for at least 60 seconds. Make certain no one is

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

Do not carry the tool by

the hose.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pressure.

within the operating plane of the grinding wheel. If

a wheel is defective, improperly mounted or the

wrong size and speed, this is the time it will usually

fail.

• When starting with a cold wheel, apply it to the

work slowly until the wheel gradually warms up.

Make smooth contact with the work and avoid

any bumping action or excessive pressure.

• Always replace a damaged, bent or severely worn

wheel guard. Do not use a wheel guard that has

been subjected to a wheel failure.

• Make certain wheel flanges are at least 1/3 the

diameter of grinding wheel, free of nicks, burrs and

sharp edges. Always use wheel flanges furnished by

the manufacturer; never use a makeshift flange or a

plain washer. Tighten Flange Nut securely.

• Guard opening must face away from operator.

Bottom of wheel must not project beyond guard.

• Always match collet size with accessory shank size.

• Always insert tool shank no less than 10 mm in the

collet. Tighten Collet Nut securely to prevent

accessory from working out during operation of the

Grinder. Check tightness of Collet Nut before

operating the Grinder. Pay particular attention to

the fact that allowed speed of a mounted point is

lowered when the length of the shaft is increased

between end of collet and mounted point

(overhang).

WARNING

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

2

SANDER/POLISHER SPECIFIC WARNINGS

M10

180

• These Sanders and Polishers will operate at the free

speed specified on the nameplate if the air supply

line furnishes 90 psig (6.2 bar/620 kPa) air pressure

at the tool. Operation at higher air pressure will

result in excessive speed.

• Use only a sanding pad, buffing wheel or polishing

bonnet with these tools. Do not use any grinding

wheel, bur or metal removing accessory other than

accessory having a maximum operating speed less

than the free speed of the Sander or Polisher in

which it is being used.

• When using a pad on a threaded arbor, make

certain the flange nut is tightened securely. Check

the tightness of the flange nut before operating a

Sander to make certain it will not loosen during

operation.

a sanding pad with these tools. Never use an

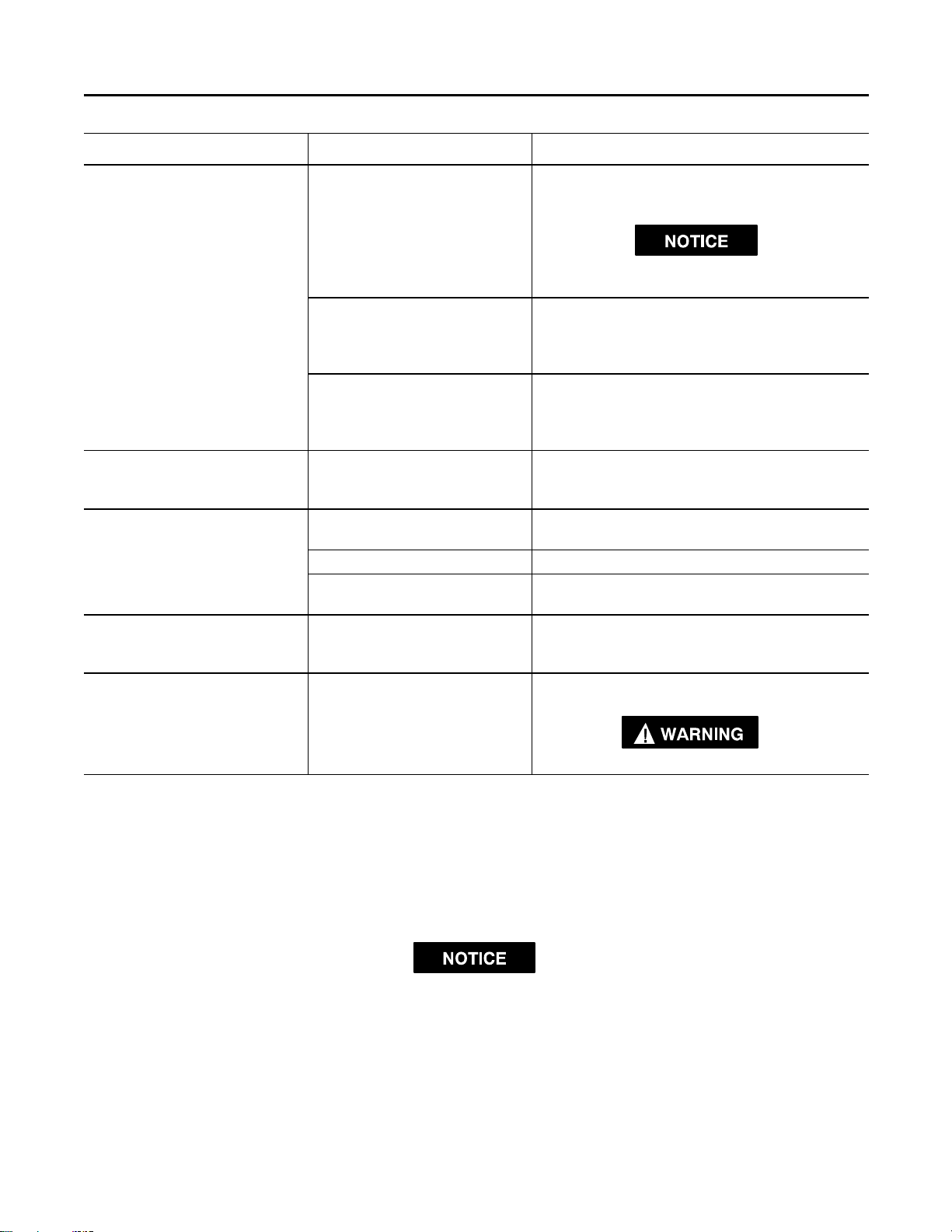

WARNING: Incorrect combinations of grinding wheel, wheel guard and tool speed could result in injury.

Correct combinations are specified below:

Guard Part Number

Wheel Type Wheel Diameter

in. (mm)

Maximum Wheel

Thickness

Maximum Speed

rpm

in. (mm)

77A–106–7 27, 28 7 (178) 1/4 (6.4) 7,500

77A–106–9 27, 28 7 (178) 1/4 (6.4) 6,000

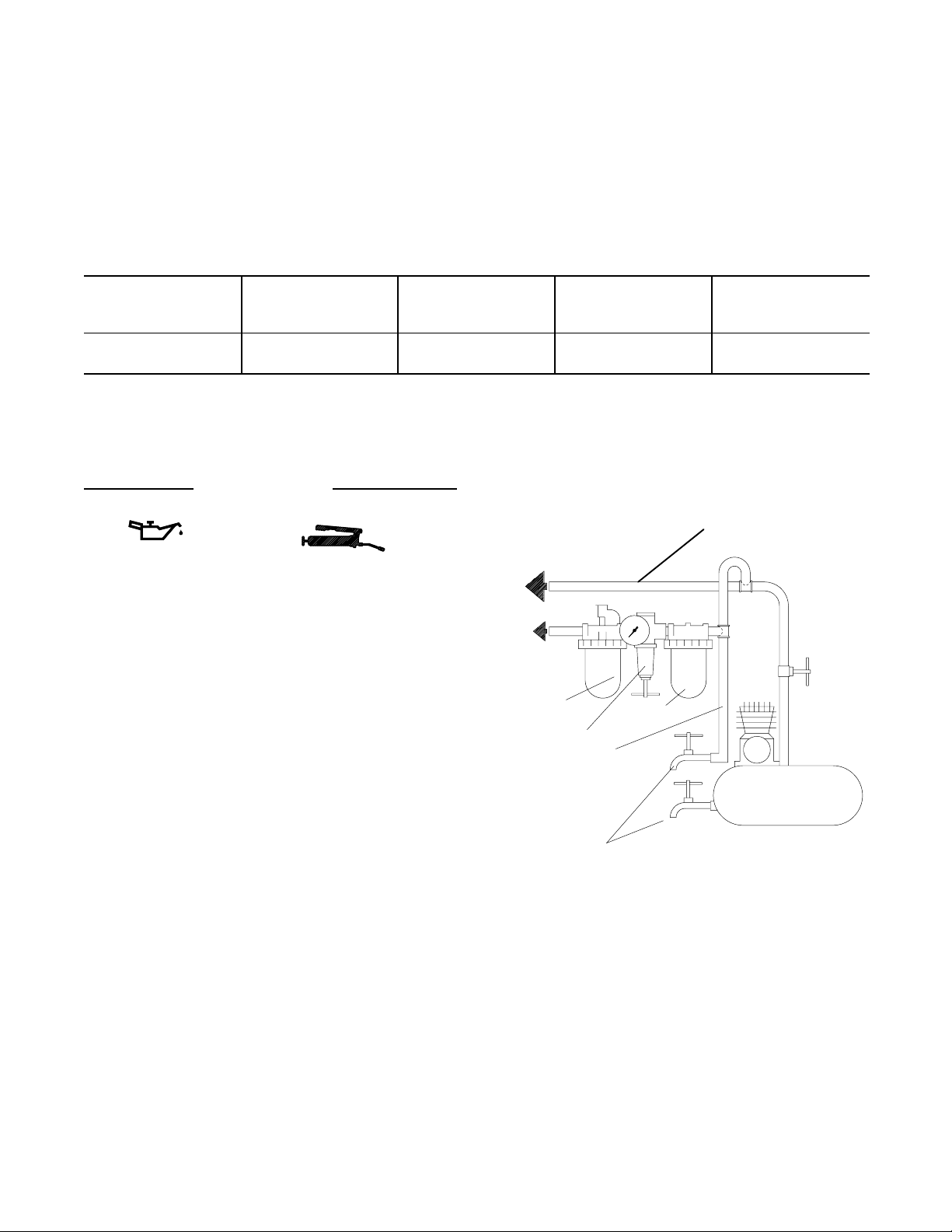

PLACING TOOL IN SERVICE

LUBRICATION

IRAX No. 50P IRAX No. 68 1LB

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – No. C18–03–FKG0–28

Before starting the tool, unless the air line lubricator is

used, detach the air hose and inject about 2.5 cc of IRAX

No. 50P Oil into the air inlet.

After each eight hours of operation, replenish the oil

supply. Remove the Oil Chamber Plug (7) from the

Throttle Handle (1) and fill the chamber.

After each forty–eight hours of operation, inject about

5 cc of IRAX No. 68 1LB Grease into each Grease

Fitting (44).

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

FILTER

COMPRESSOR

(Dwg. TPD905–1)

3

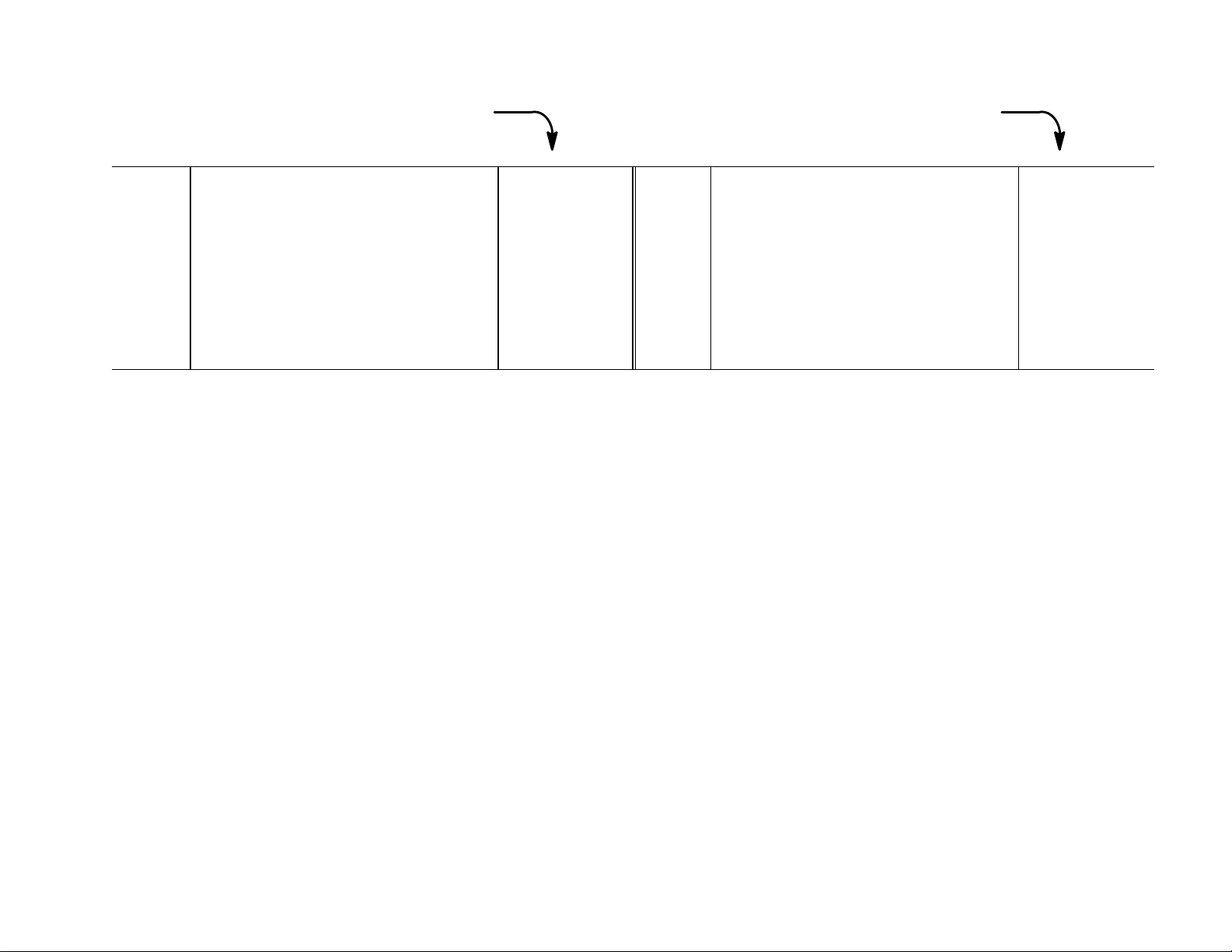

HOW TO ORDER A GRINDER

ANGLE GRINDERS with DEPRESSED CENTER WHEELS

Model Free Speed, rpm Type 27 and 28 Wheel Spindle and Guard

inches mm

GRG15A–06G–7 6,000 7 178 5/8–11, 7”

GRG15A–06G–9 6,000 9 227 5/8–11, 9”

GRG15A–08G–7 7,500 7 178 5/8–11, 7”

GRG15M–06G–7 6,000 7 178 5/8–11, 7”

GRG15M–06G–9 6,000 9 227 5/8–11, 9”

GRG15M–08G–7 7,500 7 178 5/8–11, 7”

HOW TO ORDER A SANDER OR POLISHER

ANGLE SANDERS AND POLISHER

Model Free Speed, rpm Back up Pad Spindle

inches mm

M10

180

GRP15A–02P–7 2,500 7 178 5/8–11, 7”

GRS15A–06S–7 6,000 7 178 5/8–11, 7”

GRS15A–04S–9 4,500 9 228 5/8–11, 9”

4

MANUEL DE L’OPERATEUR

COMPRENANT : EXPLOITATION, INSTALLATION & ENTRETIEN

MEULEUSES, PONCEUSES ET POLISSEUSES D’ANGLE

DES SÉRIES GRG15A–06G–7,GRG15A–06G–9,

GRG15A–08G–7GRG15M–06G–7, GRG15M–06G–9, GRG15M–08G–7,

GRP15A–02P–7, GRS15A–04S–9 ET GRS15A–06S–7 1.5 H.P.

NOTE

Les meuleuses, ponceuses et polisseuses d’angle des séries GRG, GRS et GRP sont destinées

au ponçage, à l’ébavurage ou à l’enlèvement du métal dans les fonderies, les chantiers navals,

les aciéries et la construction.

ARO ne peut être tenu responsable de la modification des outils pa r le cli ent pour les adapter à

des appl ica tions qui n’ont pas été approuvées par ARO.

ATTENTION

D’IMPORTANTES INFORMATIONS DE SÉCURITÉ SONT JOINTES.

LIRE CE MANUEL AVANT D’UTILISER L’OUTIL.

L’EMPLOYEUR EST TENU DE COMMUNIQUER LES INFORMATIONS

DE CE MANUEL AUX EMPLOYÉS UTILISANT CET OUTIL.

LE NON RESPECT DES AVERTISSEMENTS SUIVANTS PEUT CAUSER DES BLESSURES.

MISE EN SERVICE DE L’OUTIL

• Toujours exploiter, inspecter et entretenir cet outil

conformément au Code de sécurité des outils pneumatiques portatifs de l’American National Standards Institute (ANSI B186.1).

• Pour la sécurité, les perform ances optimales et la

durabilité maximale des pièces, cet outil doit être

connecté à une alimentation d’air comprimé de 6,2

bar (620 kPa) maximum à l’entrée , avec un flexible

de 10 mm de diamètre intérieur.

• Couper toujour s l’alimentation d’air comprimé et

débrancher le flexible d’alimentation avant d’in stal-

ler, déposer ou ajuster tout acc e ssoire sur ce t outil,

ou d’entreprendre une opération d’entretien quelconque sur l’outil.

• Ne pas utiliser des flexibles ou des raccords endom-

magés, effilochés ou détériorés.

• S’assurer que tous les flexi ble s et les raccords sont

correctement dimensionnés et bien serrés. Vo ir Plan

TPD905–1 pour un exemple type d’agencement des

tuyauteries .

• Utiliser toujours de l’air sec et propre à une pression

maximum de 6,2 bar (620 kPa). La poussi ère, les

fumées corrosives et/ou une humidité excessive peuvent endommage r le moteur d’un outil pne um a ti que .

• Ne jama is lubrifier les outil s avec des liquides infl am-

mables ou volatile s tels que le kérosène, le gasol ou le

carburant d’aviation.

• Ne retire r aucune étiquette. Remplace r toute éti-

quette endomm agée.

UTILISATION DE L’OUTIL

• Porter toujours des lunettes de protection pendant

l’utilisation et l’entretien de cet outi l.

• Porter toujours une protection ac oustique pendant

l’utilisation de cet outil.

• Tenir les mains, les vêtements flous et les cheve ux

longs, éloignés de l’extrémité rotative de l’outil.

• Prévoir, et ne pas oublier, que tout outil motor i sé est

susceptibl e d’à–coups brusques lors de sa mise en

marche et pendant son utilisation.

• Garder une position éq uilibr ée et ferme . Ne pas se

pencher trop en avant pendant l’utilisation de cet

outil. Des couples de réaction élevés peuvent se pro-

duire à, ou en dessous, de la pre ssi on d’air recommandée.

• La rotation des accessoires de l’outil peut continuer

pendant un certain temps après le relâchement de la

gâchette.

• Les outils pne umatiques pe uv ent vibrer pendant l’ex-

ploitation. Les vibrations, les mouvements répétitifs

et les positions inconfortables peuvent causer des

douleurs dans les mains et les bras. N’utiliser plus

d’outi ls en cas d’inconfort, de picotements ou de dou -

leurs. Consulter un médecin avant de recommencer à

utiliser l’ou til.

• Utiliser les accessoires recommandés par ARO.

• A chaque fois que le renvoi d’angle est installé ou

repositionné, le le vier de commande doit être posi-

tionné de manière à ce que le couple de réaction n’ait

pas te nda nc e à maintenir le le vier de comma nde en

position “MARCHE”.

• Cet outil n’est pas conçu pour fonctionner dans des

atmosphères explosives.

• Cet outil n’est pas isolé contre les chocs électriqu es.

F

NOTE

L’utilisation de rechanges autres que les pièces d’origine ARO pe ut cause r des risques d’insécurité, réduire les performances

de l ’outil et augmenter l’entretien, et peut annuler toutes les gar a nti e s.

Les réparations ne doi vent être effectuées que par des réparateur s qua lif iés autorisés. Consul tez votre Ce ntre de Servi ce ARO

Tool Products le plus proche.

Pour les informations relatives aux pièces et au service, contactez votre distributeur ARO.

ARO Tool Products

Ingersoll–Rand Company

1725 U.S. No. 1 North, PO Box 8000, Southern Pines, NC 28388–8000

1999 INGERSOLL–RAND COMPANY Imprimé aux E.U.

SIGNIFICATION DES ÉTIQUETTES D’AVERTISSEMENT

ATTENTION

LE NON RESPECT DES AVERTISSEMENTS SUIVANTS PEUT CAUSER DES BLESSURES

ATTENTION ATTENTION

Porter toujours des lunettes

de protection pendant

l’utilisation et l’entretien de

cet outil.

Porter toujours une

protection acoustique

pendant l’utilisation de cet

outil.

ATTENTION

Les outils pneumatiques

peuvent vibrer pendant

l’exploitation. Les vibrations,

les mouvements répétitifs et les

positions inconfortables

peuvent causer des douleurs

dans les mains et les bras.

N’utiliser plus d’outils en cas

d’inconfort, de picotements ou

de douleurs. Consulter un

médecin avant de recommencer

à utiliser l’outil.

ATTENTION

Garder une position équilibrée et

ferme. Ne pas se pencher trop

en avant pendant

l’utilisation de cet outil.

90 psig

(6.2bar/620kPa)

Ne pas transporter l’outil

par son flexible.

Utiliser de l’air comprimé

à une pression maximum

de 6,2 bar (620 kPa).

ATTENTION

ATTENTION

ATTENTION

Couper toujours l’alimentation

d’air comprimé et débrancher le

flexible d’alimentation avant

d’installer, déposer ou ajuster

tout accessoire sur cet outil, ou

d’entreprendre une opération

d’entretien quelconque sur l’outil.

ATTENTION

Ne pas utiliser des flexibles ou

des raccords endommagés,

effilochés ou détériorés.

AVERTISSEMENTS SPÉCIFIQUES AUX MEULEUSES

ATTENTION

LE NON RESPECT DES AVERTISSEMENTS SUIVANTS PEUT CAUSER DES BLESSURES.

• Ne pas utiliser cet outil si la vitesse à vide réelle

dépasse celle indiquée sur la plaque signalétique.

• Avant de monter une meule, après toute réparation de

l’outil ou avant de fournir une meuleuse pour

utilisation, vérifier la vitesse à vide de la meuleuse

avec un tachymètre pour s’assurer que la vitesse réelle

à 6,2 bar (620 kPa) ne dépasse pas celle poinçonnée ou

imprimée sur la plaque signalétique. Les meuleuses

sorties sur chantier doivent être vérifiées de la même

façon au moins une fois par poste.

• Utiliser toujours le protège–meule ARO fourni avec la

meuleuse.

• Ne jamais utiliser une meule, une fraise ou tout autre

accessoire ayant une vitesse de service inférieure à la

vitesse à vide de la meuleuse sur laquelle il est monté.

Respecter toujours la vitesse maximum inscrite sur les

disques en papier de la meule.

• Inspecter toutes les meules avant de les monter pour

vérifier qu’elles ne présentent pas d’éclats ou de

fissures. Ne jamais utiliser une meule écaillée, fissurée

ou ayant un endommagement quelconque. Ne jamais

utiliser une meule qui a été trempée dans l’eau ou tout

autre liquide.

• S’assurer que la meule se monte correctement sur

l’arbre. Ne pas utiliser de bagues réductrices, à moins

que ces bagues soient recommandées et fournies par le

fabricant de la meule.

• Après avoir monté une nouvelle meule, tenir la

meuleuse sous un établi en acier ou dans une pièce

coulée et la faire tourner pendant au moins 60

secondes. S’assurer que personne ne se tient dans le

plan de rotation de la meule. Toute meule défectueuse,

mal montée ou de dimension et vitesse incorrectes se

cassera généralement à ce moment là.

• Pour commencer le travail avec une meule froide,

l’appliquer lentement contre la pièce jusqu’à ce que la

meule s’échauffe progressivement. Mettre la meule en

contact avec la pièce en douceur en évitant tout choc

ou pression excessive.

• Remplacer toujours un protège–meule endommagé,

tordu ou très usé. Ne pas utiliser un protège–meule qui

a été soumis à la rupture d’une meule.

• S’assurer que les flasques de meule couvrent au moins

1/3 du diamètre de la meule, et qu’ils sont exempts

d’entailles, de bavures et d’arêtes vives. Utiliser

toujours les flasques fournis par le fabricant; ne

jamais utiliser de flasque de provenance douteuse ou

de rondelle plate. Serrer fermement l’écrou du

flasque.

• L’ouverture du protège–meule doit être orientée côté

opposé à l’opérateur. Le bas de la meule ne doit pas

dépasser le protège–meule.

• Toujours choisir une pince adaptée à la dimension de

la queue de l’accessoire.

• La queue de l’outil doit toujours être insérée dans la

pince sur au moins 10 mm. Serrer fermement l’écrou

de pince pour éviter tout desserrage de l’accessoire

pendant l’emploi de la meuleuse. Vérifier le serrage de

l’écrou de pince avant de mettre la meuleuse en

marche. Ne jamais oublier que la vitesse admissible

d’une meule sur tige doit être réduite lorsque la

longueur de la tige entre le bout de la pince et la meule

(porte–à–faux) est augmentée.

6

AVERTISSEMENTS PARTICULIERS AUX PONCEUSES/POLISSEUSES

• Ces ponceuses et polisseuses fonctionneront à la

vitesse à vide spécifiée sur la plaque signalétique

lorsque le circuit d’alimentation fournit de l’air à une

pression de 6,2 bar (620 kPa) à l’outil. L’exploitation à

une pression supérieure produira une vitesse

excessive.

• Utiliser seulement un plateau de ponçage, un disque

de polissage ou une peau de mouton de polissage avec

ces outils. Ne jamais utiliser de meule ou d’accessoire

d’ébavurage ou d’enlèvement de métal autre que le

plateau de ponçage sur ces outils. Ne jamais utiliser un

accessoire ayant une vitesse de fonctionnement

maximum inférieure à la vitesse à vide de la ponceuse

ou de la polisseuse sur laquelle il est utiliseé.

ATTENTION:Une mauvaise combinaison de roue d’affûtage, de protection de roue et de vitesse de l’outil peut provoquer un

accident corporel. Les combinaisons correctes sont spécifiées ci–dessous:

Référence de la

protection

Type de roue Diamètre de roue

mm (po.)

Epaisseru maximale

de roue

Vitesse maximale

(t/min)

mm (po.)

77A–106–7 27, 28 7 (178) 1/4 (6,4) 7.500

77A–106–9 27, 28 7 (178) 1/4 (6,4) 6.000

MISE EN SERVICE DE L’OUTIL

LUBRIFICATION

IRAX No. 50P IRAX No. 67 1LB

Utiliser toujours un lubrificateur avec ces outils. Nous

recommandons l’emploi du filtre–régulateur–lubrificateur

suivant :

For USA – N

Avant de mettre l’outil en marche, si un lubrificateur de

ligne n’est pas utilisé, débrancher le flexible d’alimentation

et verser environ 2,5 cm

raccord d’admission de l’outil.

Toutes les huit heures de fonctionnement, remplir la

réserve d’huile. Déposer le bouchon de la chambre d’huile

de la poignée de commande et remplir la chambre d’huile.

Toutes les quarante-huit heures de fonctionnement,

injecter environ 5 cm

chaque raccord de graissage.

o

. C18–03–FKG0–28

3

IRAX No. 50P d’huile dans le

3

IRAX No. 68 1LB de graisse dans

VERS LE

RÉSEAU D’AIR

COMPRIMÉ

VERS

L’OUTIL

PNEU-

MATIQUE

LUBRIFICATEUR

RÉGULATEUR

LIGNE SECONDAIRE AU

MOINS 2 FOIS LA DIMEN-

SION DE L’ADMISSION

D’AIR DE L’OUTIL

VIDANGER

RÉGULIÈREMENT

TUYAUTERIE PRINCIPALE

AU MOINS 3 FOIS LA DIMENSION DE L’ADMISSION D’AIR

DE L’OUTIL

FILTRE

COMPRESSEUR

(Plan TPD905–1)

7

MISE EN SERVICE DE L’OUTIL

SPÉCIFICATIONS

Modèle Vitesse à vide Meules Types 27 et 28 Arbre et protège-meule

tr/mn pouces mm

GRG15A–06G–7 6.000 7 178 5/8–11, 7”

GRG15A–06G–9 6.000 9 227 5/8–11, 9”

GRG15A–08G–7 7.500 7 178 5/8–11, 7”

GRG15M–06G–7 6.000 7 178 5/8–11, 7”

GRG15M–06G–9 6.000 9 227 5/8–11, 9”

GRG15M–08G–7 7.500 7 178 5/8–11, 7”

Modèle Vitesse à vide Plateau–support Broche

tr/mn pouces mm

GRP15A–02P–7 2.500 7 178 5/8–11, 7”

GRS15A–06S–7 6.000 7 178 5/8–11, 7”

GRS15A–04S–9 4.500 9 228 5/8–11, 9”

8

GUÍA DEL OPERARIO

MANEJO, INSTALACIÓN Y MANTENIMIENTO

LIJADORAS Y PULIDORAS, AMOLADORAS

E

ANGULARES DE LAS SERIES GRG15A–06G–7, GRG15A–06G–9,

GRG15A–08G–7,GRG15M–06G–7, GRG15M–06G–9, GRG15M–08G–7,

GRP15A–02P–7, GRS15A–04S–9 Y GRS15A–06S–7 1.5 H.P.

NOTA

Las Lijadoras y Pulidoras , Amoladoras Angulares Neumáticas de las Series GRG, GRS y GRP

están diseñadas para pulido, recorte o eliminación de metal en fundiciones, astilleros, fábricas

de acero y en la industria de construcción.

ARO no aceptará res ponsa bilidad alguna por la modificación de la s herramientas efec tuada por el

cliente para las aplicaciones que no hayan sido consultadas con ARO.

AVISO

SE ADJUNTA INFORMACIÓN IMPORTANTE DE SEGURIDAD.

LEA ESTE MANUAL ANTES DE UTILIZAR LA HERRAMIENTA.

ES RESPONSABILIDAD DE LA EMPRESA ASEGURARSE DE QUE

EL OPERARIO ESTÉ AL TANTO DE LA INFORMACIÓN QUE CONTIENE ESTE MANUAL.

EL HACER CASO OMISO DE LOS AVISOS SIG UIENTE S PODRÍA OCASIONAR LESIONES.

PARA PONER LA HERRAMIENTA EN SERVICIO

Utilice, examine y mantenga siempre esta herramien-

ta conforme al código de seguridad para herramientas

neumáticas portátiles de la American National Standards Institute (ANSI B186.1).

• Para mayor seguridad, rendimiento óptimo y larga vida

útil de las piezas, utilice esta herramienta a una presión

de aire máxima de 90 ps ig

(6,2 bar /6 20 kPa) con una mangue r a de suministro de

aire con diámetro interno de 10 mm.

• Corte siempre el suministro de aire y desconecte la man-

guera de suministro de aire antes de instalar, desmontar

o ajustar cualquier accesorio de esta herramienta, o

antes de realizar cualquier operación de mantenimiento

de la misma.

• No utilic e mangueras de aire y racores dañados, desgas-

tados o deteriorados.

• Asegúrese de que todos lo s racores y mangueras sean

del tamaño correcto y estén bien apretados. El Esq.

TPD905–1 muestra una disposición característica de las

tuberías.

• Use siempre aire limpio y sec o a una presión máxima de

90 ps ig (6,2 bar /6 2 0 kPa). El polvo, lo s gases corrosivos

y el exceso de humedad pueden estropea r el motor de

una herramienta neumática.

• No lubrique las herramientas con líquidos inflamables o

volátiles tales como queroseno, gasoil o combustible

para motores a reacción.

• No sa que ninguna etiqueta. Sustituya toda etiqueta

dañada.

UTILIZACIÓN DE LA HERRAMIENTA

• Use siempre protección ocular cuando utilice esta her-

ramienta o realice operaciones de mantenimiento en

la misma.

• Use siempre protección para los oídos cuando utilice

esta herramienta.

• Mantenga las mano s , la ropa sue lta y el cabello lar go

alejados del extremo giratorio de la herramienta.

• Anticipe y esté atento a los cambios repentinos en el

movimiento durante la puesta en marcha y utilización

de toda herramienta motorizada.

• Mantenga una pos tur a del cuerpo equilibrada y firme.

No estire demasiado los brazos al manejar la herramienta. Pueden darse elevados pares de reacción a la

presión de aire recomendada, e incluso a presiones infe -

riores.

• Los accesorios de la herramienta podrían seguir girando

brevemente después de haberse so ltado la palanca de

mando.

• Las herramientas neumáticas pueden vibrar durante el

uso. La vibración, los movimientos repetitivos o las posi-

ciones incómodas pueden dañarle los brazos y manos.

En ca s o de incomodidad, sensación de hormigueo o do-

lor, deje de usar la herramienta. Consulte con el médico

antes de volver a utilizarla.

• Utilice únicamente los accesorios ARO recomendados.

• Cuando se instale o reposicione la cabez a angular, la

palanca de mando de berá colocarse de forma que la

reacción de pa r no tienda a retener el mando en la pos i-

ción de “ON” (ACCIONAMIENTO).

• Esta herramienta no ha sido diseñada para trabajar en

ambientes explosivos.

• Esta herramienta no está aislada contra descargas

eléctri cas.

NOTA

El uso de pi ezas de recambi o que no se an las auténticas pie zas ARO puede poner en pel igro la seguridad, reducir el rendi miento de la herramienta y aumentar los cuidados de mantenimiento necesarios, así como invalidar toda garantía.

Las reparaciones sólo se de ben encom endar a per sonal debidame nte cuali ficado y autor izado. Consul te con el centro de servicio autorizado ARO Tool Products más próximo.

Pour les informations relatives aux pièces et au service, contactez votre distributeur ARO.

ARO Tool Products

Ingersoll–Rand Company

1725 U.S. No. 1 North, PO Box 8000, Southern Pines, NC 28388–8000

1999 INGERSOLL–RAND COMPANY Impreso en EE.UU.

ETIQUETAS DE AVISO

AVISO

EL HACER CASO OMISO DE LOS AVISOS SIGUIENTES PODRÍA OCASIONAR LESIONES.

ADVERTENCIA

Use siempre protección ocular

cuando utilice esta herramienta

o realice operaciones de

mantenimiento en la misma.

ADVERTENCIA

Las herramientas neumáticas

pueden vibrar durante el uso.

La vibración, los movimientos

repetitivos o las posiciones

incómodas podrían dañarle los

brazos y las manos. En caso

de incomodidad, sensación de

hormigueo o dolor, dejar de

usar la herramienta. Consultar

al médico antes de volver a utilizarla.

ADVERTENCIA

Mantener una postura del cuerpo

equilibrada y firme. No estirar demasiado los brazos al manejar la

herramienta.

90 psig

(6.2bar/620kPa)

ADVERTENCIA

Use siempre protección para

los oídos cuando utilice esta

herramienta.

ADVERTENCIA

No coger la herramienta

por la manguera para levantarla.

ADVERTENCIA

Manejar la herramienta a una

presión de aire máxima de 90

psig (6,2 bar/620 kPa).

ADVERTENCIA

Cortar siempre el suministro

de aire y desconectar la manguera de suministro de aire

antes de instalar, retirar o ajustar cualquier accesorio de esta

herramienta, o antes de realizar

cualquier operación de mantenimiento de la misma.

ADVERTENCIA

No utilizar mangueras de aire

y accesorios dañados, desgastados ni deteriorados.

AVISOS ESPECÍFICOS SOBRE LAS AMOLADORAS

AVISO

EL HACER CASO OMISO DE LOS AVISOS SIGUIENTES PODRÍA OCASIONAR LESIONES.

• No utilice esta herramienta si la velocidad en vacío

real supera la velocidad que indica la placa de

identificación.

• Antes de montar una muela, después de haberse

reparado la herramienta o cuando se proporciona

una amoladora para su uso, compruebe la velocidad

en vacío de la amoladora con un tacómetro para

asegurarse de que su velocidad real a 90 psig

(6,2 bar/620 kPa) no exceda de la velocidad

estampada o impresa en la placa de identificación.

Las amoladoras que ya están en uso también se

deben examinar como mínimo una vez en cada

turno de trabajo.

• Utilice siempre el cubremuela ARO recomendado y

suministrado con la amoladora.

• No utilice nunca una muela abrasiva, fresa u otro

accesorio cuya velocidad máxima de

funcionamiento sea inferior a la velocidad en vacío

de la amoladora en la que se va a utilizar. Observe

siempre la velocidad máxima indicada en la

arandela de sujeción de la muela.

• Inspeccione todas las muelas antes de montarlas

para comprobar que no tengan muescas ni grietas.

No utilice una muela que presente muescas, grietas

o daño alguno. No utilice una muela que haya

estado en remojo en agua o en cualquier otro

líquido.

• Asegúrese de que la muela quede bien ajustada en

el eje. No utilice casquillos reductores para adaptar

una muela al eje, salvo que éstos hayan sido

suministrados y recomendados por el fabricante de

la muela.

• Después de haber montado una muela nueva, sujete

la amoladora debajo de un banco de acero o dentro

de una pieza de fundición y hágala girar durante 60

segundos como mínimo. Asegúrese que no haya

nadie en el entorno de operación de la muela. Si la

muela es defectuosa, está mal montada o es del

tamaño y velocidad incorrectas, normalmente

fallará en este momento.

• Cuando ponga en marcha una muela en frío,

aplíquela lentamente al trabajo para que se caliente

gradualmente. Haga contacto suavemente con la

pieza a trabajar y evite los rebotes o el exceso de

presión.

• Cambie siempre un cubremuela dañado, torcido o

muy desgastado. No utilice un cubremuela que haya

estado en uso al romperse una muela.

• Asegúrese de que las bridas de la muela tengan un

diámetro de al menos 1/3 del diámetro de la muela y

que no tengan cortes, rebabas ni bordes afilados.

Utilice siempre las bridas de muela suministradas

por el fabricante; no use nunca una brida casera o

arandela normal. Apriete bien la tuerca de la brida.

(continúa)

10

AVISOS ESPECÍFICOS SOBRE LAS AMOLADORAS

• La abertura del cubremuela debe estar orientada en

sentido contrario al operario. La parte inferior de la

muela no debe sobresalir del cubremuela.

• Utilice siempre la pinza cuyo tamaño corresponda

con el tamaño del eje del accesorio.

• Introduzca siempre el eje de la herramienta en la

pinza un mínimo de 10 mm. Apriete bien la tuerca

durante el funcionamiento de la amoladora.

Compruebe el apriete de la tuerca de la pinza antes

de accionar la amoladora. Preste especial atención

al hecho de que la velocidad permitida de un

accesorio montado disminuye cuando se incrementa

la longitud del eje entre el extremo de la pinza y el

accesorio.

de la pinza para evitar que se salga el accesorio

AVISOS ESPECIFICOS DE LIJADORA/PULIDORA

• Estas Lijadoras y Pulidoras funcionarán a la

velocidad constante especificada en la placa de

identificación si la línea de suministro de aire a la

herramienta tiene una presión de 90 psig (6,2bar/

6,2 kPa). El funcionamiento a mayores presiones

resultará en exceso de velocidad.

• Use sólo lija, placa de pulir o boina de pulir con estas

herramientas. No use muela, ni accesorio escariador o

fresador, que no sea para lijar con estas heramientas.

AVISO: Combinaciones incorrectas de rueda de rectificación, protector de rueda y velocidad de herramienta

puedan resultar en lesionamientos. Las combinaciones correctas se especifican a continuación:

Número de Pieza del

Protector

Tipo de Rueda Diámetro de Rueda

mm (in.)

77A–106–7 27, 28 7 (178) 1/4 (6,4) 7.500

77A–106–9 27, 28 7 (178) 1/4 (6,4) 6.000

No use nunca un accesorio que tenga una máxima

velocidad de funcionamiento menor a la velocidad de

la Lijadora o Pulidora en la que se va a usar.

• Use sólo lija, rueda de pulir o bonete de pulir con estas

herramientas. No use muela, ni accesorio escariador o

fresador, que no sea para lijar con estas herramientas.

No use nunca un accesorio que tenga una máxima

velocidad de funcionamiento menor a la velocidad de

la Lijadora o Pulidora en la que se va a usar.

Grosor Máximo de

Rueda

Velocidad Máxima

(rpm)

mm (in.)

PARA PONER LA HERRAMIENTA EN SERVICIO

LUBRICACIÓN

IRAX N. 10P IRAX N. 67 1LB

Utilice siempre un lubricador de aire comprimido con estas

herramientas. Recomendamos el siguiente conjunto de

filtro–lubricador–regulador:

USA – N. C18–03–FKG0–28

Antes de pone la herramienta en marcha,a menos que se

haya puesto lubricante de línea de aire comprimido,

desconecte la manguera de aire e inyecte 2,5cc IRAX

N 10P de aceite en la admisión de aire.

Después de cada ocho horas de uso, reponga el suministro

de aceite. Saque el Tapón de Cámara de Aceite de la

Palanca de Estrangulador y llene la cámara.

Después de cada cuarenta y ocho horas de uso, inyecte

así como 5 cc IRAX N. 67 1LB de grasa en cada

engrasador.

TUBERÍAS PRINCIPALES 3

VECES EL TAMAÑO DE

ENTRADA DE HERRAMIENTA

AL SISTEMA

NEUMÁTICO

A LA

HERRA–

MIENTA

NEUMÁTICA

LUBRICADOR

TUBERÍA DE RAMAL

2 VECES EL TAMAÑO

DE ENTRADA DE

HERRAMIENTA

NEUMÁTICA

PURGAR

PERIÓDICAMENTE

NEUMÁTICA

REGULADOR

FILTRO

COMPRESOR

(Esq. TPD905–1)

11

PARA PONER LA HERRAMIENTA EN SERVICIO

ESPECIFICACIONES

Modelo Velocidad

Constante

rpm pulgadas mm

GRG15A–06G–7 6.000 7 178 5/8–11, 7”

GRG15A–06G–9 6.000 9 227 5/8–11, 9”

GRG15A–08G–7 7.500 7 178 5/8–11, 7”

GRG15M–06G–7 6.000 7 178 5/8–11, 7”

GRG15M–06G–9 6.000 9 227 5/8–11, 9”

GRG15M–08G–7 7.500 7 178 5/8–11, 7”

Modelo Velocidad

Constante

rpm pulgadas mm

GRP15A–02P–7 2.500 7 178 5/8–11, 7”

GRS15A–06S–7 6.000 7 178 5/8–11, 7”

GRS15A–04S–9 4.500 9 228 5/8–11, 9”

Muela Tipo 27 y 28 Eje y

Cubremuela

Placa de Reserva Eje

12

MANUAL DO OPERADOR

INCLUINDO: FUNCIONAMENTO, INSTALAÇÃO E MANUTENÇÃO

ESMERILADORAS, LIXADORAS E POLIDORAS

DE ÂNGULO PNEUMÁTICAS SÉRIES GRG15A–06G–7, GRG15A–06G–9,

GRG15A–08G–7, GRG15M–06G–7, GRG15M–06G–9, GRG15M–08G–7,

GRP15A–02P–7, GRS15A–04S–9, AND GRS15A–06S–7 1.5 H.P.

AVISO

As Esmeriladoras, Lixadoras e Polidoras de Ângulo Pneumáticas Séries GRG, GRS e GRP são concebidas para alisamento, corte de sebes ou remoção de metais em fundições, estaleiros, siderúrgias e em

aplicações de construções metálicas.

A ARO não é responsável por modi ficações, feitas pel o cliente em ferramentas, nas quais a ARO não tenha

sido consultada.

ADVERTÊNCIA

INFORMAÇÃO DE SEGURANÇA IMPORTANTE EM ANEXO.

LEIA ESTE MANUAL ANTES DE OPERAR A FERRAMENTA.

É DA RESPONSABILIDADE DO EMPREGADOR COLOCAR A INFORMAÇÃO

DESTE MANUAL NAS MÃOS DO OPERADOR.

O NÃO CUMPRIMENTO DAS SEGUINTES ADVERTÊNCIAS PODE RESULTAR EM FERIMENTOS.

COLOCANDO A FERRAMENTA EM

FUNCIONAMENTO

• Sempre opere, inspeccione e mantenha esta ferra-

menta de acordo com o Código de Segurança do

Instituto Americano de Padrões Nacionais para

Ferramentas Pneumáticas Portáteis (ANSI B186.1).

• Para segurança, máximo desempenho e máxima

durabilidade das peças, opere esta ferramenta com

uma pressão de ar máxima de 6,2 bar / 620 kPa

(90 psig) na entrada da mangue i r a de al i me ntação

de ar com diâmetro interno de 10 mm (3/8”).

• Desligue sempre a alimentação de ar e desconecte a

mangueira de alimentação de ar antes de instalar,

remover ou ajustar qualquer acessório nesta ferramenta, ou antes de executar qualquer ser viço de

manutenção nesta ferramenta.

• Não use mangueir as de ar ou adaptadores danifica -

dos, gastos ou deter iorados.

• Certifique–se de que todas as mangue ir as e adapta-

dores sejam do tama nho cor recto e estejam aperta dos com firmeza. Veja o Desenho TPD905–1 para um

arranjo típico de tubag e m .

• Use sempre ar seco e limpo com pressão máxima

de 90 psig. Pó, fumos corrosivos e/ou humidade

excessiva podem arruinar o motor de uma

ferramenta pneumática.

• Não lubrifique as ferramentas com líquidos in-

flamáveis ou voláteis tais como querosene, diesel ou

combustível de jactos.

• Não remova nenhum rótulo. Reponha qualquer

rótulo danificado.

AVISO

O uso de pe ças de substituição que não sejam genuinamente da ARO podem resultar em riscos de segurança, dimi nuição

do desempenho da ferramenta, aumento da necessidade de manutenção e pode invalidar todas as garanti as.

As reparações devem ser feitas somente por pessoal treinado autori zado. Consulte o Centro de Ser viços da ARO Tool

Products mais próximo.

Para obter informações sobre peças e assistência, contacte o seu distribuidor local ARO.

ARO Tool Products

Ingersoll–Rand Company

1725 U.S. No. 1 North, PO Box 8000, Southern Pines, NC 28388–8000

1999 INGERSOLL–RAND COMPANY Impresso nos E.U.A.

USANDO A FERRAMENTA

• Use se m pre óculos de protecção quando estiver oper -

ando ou executando serviço de manutenção nesta

ferramenta.

• Use sem pre protec ção contr a ruído ao operar esta

ferramenta.

• Mantenha as mãos, parte s do vestuário soltas e cabe-

los compr idos afastados da extremi dade em rotação.

• Antecipe e esteja alerta a mudanças repe nti nas no

movimento quando ligar e operar qualquer ferramenta motorizada.

• Mantenha a posição do corpo equilibrada e firme.

Não exagere quando operar esta ferramenta. Torques

de reac ção ele vados podem ocorrer na ou abaixo da

pressão de ar recome ndada .

• Os acessórios da ferramenta podem continuar a

impactar brevemente após a pressão te r sido ali vi a-

da.

• Ferramentas accionadas pneumáticamente podem

vibrar em uso. Vibração, movimentos repetitivos

ou posições desconfortáveis podem ser prejudiciais

às mãos e aos braços. Pare de usar a ferramenta

caso ocorra algum desconforto, sensação de formigueiro ou dor. Procure assistência médica antes de

retornar ao trabalho.

• Use acessórios recomendados pela ARO.

• Quando quer que o Cabeçote em Ångulo seja insta-

lado ou reposto, a Válvula Reguladora de Presão

deve ser posicionada de modo que um torque de

reacção não tenderá a reter o curso na posição

“LIGADA”.

• Esta Ferramenta não foi concebida para trabalhos

em atmosferas explosivas.

• Esta Ferramenta não está isolada contra choques

eléctricos.

P

IDENTIFICAÇÃO DO RÓTULO DE ADVERTÊNCIA

ADVERTÊNCIA

O NÃO CUMPRIMENTO DAS SEGUINTES ADVERTÊNCIAS PODE RESULTAR EM FERIMENTO.

ADVERTÊNCIA

Use sempre óculos de protecção

quando estiver operando ou

executando algum serviço de

manutenção nesta ferramenta.

ADVERTÊNCIA

Ferramentas accionadas

pneumáticamente podem vibrar

em uso. Vibração, movimentos

repetitivos ou posições

desconfortáveis podem ser

prejudiciais às mãos e aos

braços. Pare de usar a

ferramenta caso ocorra algum

desconforto, sensação de

formigueiro ou dor . Procure

assistência médica antes de

retornar ao trabalho.

ADVERTÊNCIA

Mantenha a posição do corpo

equilibrada e firme. Não

exagere quando operar esta

ferramenta. Torques de

reacção elevados podem

ocorrer sob a pressão de ar

recomendada.

90 psig

(6.2bar/620kPa)

ADVERTÊNCIA

Use sempre protecção contra o

ruído ao operar esta ferramenta.

ADVERTÊNCIA

Não carregue a ferramenta

segurando na mangueira.

ADVERTÊNCIA

Opere com pressão do ar Máxima

de 90–100 psig (6,2–6,9 bar).

ADVERTÊNCIA

Desligue sempre a alimentação

de ar e desconecte a mangueira

de alimentação de ar antes de

instalar, remover ou ajustar

qualquer acessório nesta

ferramenta, ou antes de executar

algum serviço de manutenção

nesta ferramenta.

ADVERTÊNCIA

Não use mangueiras de ar ou

adaptadores danificados,

gastos ou deteriorados.

ADVERTÊNCIAS ESPECÍFICAS SOBRE A ESMERILADORA

ADVERTÊNCIA

O NÃO CUMPRIMENTO DAS SEGUINTES ADVERTÊNCIAS PODE RESULTAR EM FERIMENTO.

• Não use esta ferramenta se a velocidade livre total

exceder a rpm indicada na placa de identificação.

• Antes de montar o disco, depois de qualquer

reparação de ferramenta ou quando se pretende que

uma Esmeriladora seja colocada em funcionamento,

verifique a velocidade livre da Esmeriladora com um

tacometro para se certificar de que a sua velocidade

real a

6,2 bar/620kPa (90 psig) não exceda a rpm selada ou

impressa na placa de identificação. As Esmeriladoras

em funcionamento devem ser similarmente

verificadas pelo menos uma vez em cada turno.

• Use sempre o Protector do Disco da ARO fornecido

com a Esmeriladora.

• Não use qualquer disco de esmerilamento, broca ou

outro acessório que poss ua uma velocidade máxima

de operação menor do que a velocidade livre da

Esmeriladora que esteja a ser usada. Respeite sempre

a máxima rpm nos adaptadores de disco de

esmerilamento.

• Verifique todas os discos de esmerilamento para ver

se há lascas ou rachaduras antes da montagem. Não

use um disco que esteja lascado ou rachado ou de

alguma maneira danificado. Não use um disco que

tenha sido encharcado com água ou qualquer outro

líquido.

• Verifique se o disco de esmerilamento se encaixa na

árvore de montagem. Não use rolamentos redutores

para adaptar um disco na árvore de montagem a não

ser que tais rolamentos tenham sido fornecidos ou

recomendados pelo fabricante do disco.

• Depois de montar um novo disco, segure a

Esmeriladora sob uma bancada de aço ou dentro de

uma moldagem e coloque–a em funcionamento por 60

segundos. V erifique se não há ninguém dentro do

plano de operação. Se o disco estiver com algum

defeito, inadequadamente montado ou se for do

tamanho errado ou tiver velocidade incorrecta, este é

o momento em que ele normalmente falhará.

• Quando iniciar um trabalho com um disco frio,

ponha–o a trabalhar lentamente até que o disco

aqueça gradualmente Faça um contacto suave com o

local a ser trabalhado e evite de executar qualquer

ação de batimento ou pressão excessiva.

• Reponha um protector do disco sempre que estiver

danificado, torto ou severamente gasto. Não use um

protector do disco que tenha sido sujeito a uma falha

do disco.

(continua)

14

ADVERTÊNCIAS ESPECÍFICAS SOBRE A ESMERILADORA

• Certifique–se de que as flanges da roda sejam pelo

menos 1/3 do diâmetro do disco de esmerilamento,

livre de cortes, arestas e extremidades afiadas. Use

sempre flanges do disco fornecidas pelo fabricante.

Nunca use uma flange provisória ou uma anilha

plana. Aperte bem a Porca da Flange.

• A abertura do protector deve estar afastada do

operador. O fundo do disco não deve se extender para

fora do protector.

• Use sempre uma pinça cuja dimensão seja igual ao

encabadouro acessório.

ADVERTÊNCIA: Combinações incorrectas de disco de esmerilamento, protectordo disco e velocidade da ferramenta pode

resultar em ferimento.

As combinações correctas estaõ especificadas abaixo:

• Insira sempre o encabadouro da ferramenta com

comprimento que não seja inferior a 10 mm no colete.

Aperte a Porca do Pinça seguramente para evitar que

o acessório se desajuste durante a operação da

esmeriladora. Verifique o aperto da Porca do Pinça

antes de operar a esmeriladora. Preste particular

atenção ao facto de que a velocidade permitida de um

ponto montado é diminuída quando o comprimento do

eixo é aumentado entre a extremidade da pinça e o

ponto montado. (pendurado)

Número de Peça do

Protector

Tipo do Disco Diâmetro do Disco Espessura Máxima

do Disco

Velocidade Máxima

mm (pol.) mm (pol.) rpm

77A–106–7 27, 28 7 (178) 6,4 (1/4) 7.500

77A–106–9 27, 28 7 (178) 6,4 (1/4) 6.000

COLOCANDO A FERRAMENTA EM FUNCIONAMENTO

LUBRIFICAÇÃO

IRAX No. 50P IRAX No. 68 1LB

Use sempre um lubrificador de ar de linha com estas

ferramentas. Nós recomendamos a seguinte Unidade

Filtro–Lubrificador–Regulador:

USA– No. C18–03–FKG0–28

Antes de ligar a Ferramenta, ao menos que um

lubrificador de ar de linha seja usado, desligue a mangueira

de ar e injecte aproximadamente 2,5 cc de IRAX No. 50P

óleo na entrada de ar.

Depois de oito horas de operação, substitua o suprimento

de óleo. Remova o Bujão da Câmara de óleo do Punho

Regulador de Pressão e preencha a câmara.

Depois de quarenta e oito horas de operação, injecte

cerca de 5 cc de Massa Lubrificante IRAX No. 68 1LB no

Adaptador.

LINHAS PRINCIPAIS 3 VEZES O TAMANHO DA

PARA

SISTEMA DE AR

PARA

FERRAMENTA

PNEUMÁTICA

LUBRIFICADOR

REGULADOR

LINHA RAMIFICADA

2 VEZES O TAMANHO

DA ENTRADA DA FERRAMENTA PNEUMÁTICA

ENTRADA DA FERRAMENTA PNEUMÁTICA

FILTRO

COMPRESSOR

DRENE

REGULARMENTE

(Desenho TPD905–1)

15

COLOCANDO A FERRAMENTA EM FUNCIONAMENTO

ESPECIFICAÇÕES

Modelo Velocidade Livre Disco Tipo 27 e 28 Veio e

Resguardo

rpm pol. mm

GRG15A–06G–7 6.000 7 178 5/8–11, 7”

GRG15A–06G–9 6.000 9 227 5/8–11, 9”

GRG15A–08G–7 7.500 7 178 5/8–11, 7”

GRG15M–06G–7 6.000 7 178 5/8–11, 7”

GRG15M–06G–9 6.000 9 227 5/8–11, 9”

GRG15M–08G–7 7.500 7 178 5/8–11, 7”

Modelo Velocidade Livre Almofada Veio

rpm pol. mm

GRP15A–02P–7 2.500 7 178 5/8–11, 7”

GRS15A–06S–7 6.000 7 178 5/8–11, 7”

GRS15A–04S–9 4.500 9 228 5/8–11, 9”

16

17

MAINTENANCE SECTION

(TPA1437–3)

18

PART NUMBER FOR ORDERING

1 Throttle Handle Assembly . . . . . . . . . . . . . . . . 49843–116 23 Rear End Plate Assembly (consists of

2 Throttle Valve Assembly . . . . . . . . . . . . . . 88V60–A302 rear end plate, rotor bearing and

♦• 3 Seal (2) . . . . . . . . . . . . . . . . . . . . . . . . . C321–606 required spacers) . . . . . . . . . . . . . . . . . . . . 77H–A12

4 Inlet Bushing . . . . . . . . . . . . . . . . . . . . . . . 77H–38 ♦• 24 Rear End Plate Gasket . . . . . . . . . . . . . . . . . . . 77H–739

♦• 5 Inlet Bushing Screen . . . . . . . . . . . . . . . . . 834–61 25 Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–3

♦ 6 Throttle Valve Spring . . . . . . . . . . . . . . . . . 77H–262 26 Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–53RH

7 Oil Chamber Plug . . . . . . . . . . . . . . . . . . . R2–227 ♦•27 Vane Packet (set of 4 Vanes) . . . . . . . . . . . . . . 77H–42–4

8 Throttle Valve Seat Support Assembly . . . 77H–A303 • 28 Front End Plate . . . . . . . . . . . . . . . . . . . . . . . . 77H–11

9 Valve Seat Screw . . . . . . . . . . . . . . . . . PS3–83 29 Front Rotor Bearing . . . . . . . . . . . . . . . . . . . . . 77H–24

10 Valve Seat Lock Washer . . . . . . . . . . . . . . H54U–352 30 Cylinder Dowel . . . . . . . . . . . . . . . . . . . . . . . . 77H–98

11 Valve Seat Washer . . . . . . . . . . . . . . . . 99V–155 31 Bevel Pinion Driver

♦• 12 Valve Seat . . . . . . . . . . . . . . . . . . . . . . R4–159A for GRP15A–02P–7 . . . . . . . . . . . . 77A–8

♦ 13 Valve Support Seal (2) . . . . . . . . . . . . . SPP101–743 for all others . . . . . . . . . . . . . . . . . . 77A–7

14 Oiler Feeder Plug . . . . . . . . . . . . . . . . . 77H–75 32 Internal Gear . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–406

15 Throttle Valve Seat Support Retainer . . . . . . . 77H–518 33 Bevel Pinion Driver Bearing . . . . . . . . . . . . . . WFS182–97

16 Throttle Lever Pin . . . . . . . . . . . . . . . . . . . . . . MR–100 34 Planet Gear Shaft (2) . . . . . . . . . . . . . . . . . . . . G700–191

17 Throttle Lever Assembly . . . . . . . . . . . . . . . . . 77H–A400 35 Rotor Pinion . . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–17

18 Lever Lock Pin . . . . . . . . . . . . . . . . . . . . . R100B–120 36 Planet Gear Assembly (2) . . . . . . . . . . . . . . . . 77H–A10

19 Lever Lock Spring . . . . . . . . . . . . . . . . . . . DG120–405 37 Planet Gear Bearing (one for each gear) . . G700–654

20 Lever Lock . . . . . . . . . . . . . . . . . . . . . . . . . DG120–402 38 Thrust Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . 77A–104

21 Coupling Nut . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–282 39 Bevel Pinion Bearing Assembly . . . . . . . . . . . 77A–A510

22 Controller Assembly (Consists of 40 Matched Gear Set (Bevel Gear

Controller and Rear End Plate Assembly) and Pinion not sold separately) . . . . . . . . . . . . 77A–A552

for GRS15A–04S–9 . . . . . . . . . . . . 77H90–A524RH 41 Motor Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . 77E–208–H8

for GRS15A–06S–7, 42 Arbor Coupling . . . . . . . . . . . . . . . . . . . . . . . . 66H–304

GRG15A–06G–7,GRG15M–06G–7 + 43 Angle Arbor Housing

and GRG15M–06G–9 . . . . . . . . . . 77H120–A524RH for models ending in –EU . . . . . . . 49842–EU–147

for GRP15A–02P–7, for all other models . . . . . . . . . . . . 49842–104

GRG15A–08G–7 and

GRG15M–08G–7 . . . . . . . . . . . . . . 77H150–A524RH

PART NUMBER FOR ORDERING

MAINTENANCE SECTION

♦ Indicates Tune–up Kit part.

• To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one (pair or set) of each part indicated by a

bullet (•) for every four tools in service.

+ Whenever a new Angle Arbor Housing is installed, order the correct Nameplate (43A) and attach it to the Housing with the Nameplate Screws (43B).

19

PART NUMBER FOR ORDERING PART NUMBER FOR ORDERING

43A Nameplate 43B Nameplate Screw (4) . . . . . . . . . . . . . . BN403–302

for model GRG15A–06G–7 . . . . . . 49842–110 * Warning Label

for model GRG15A–06G–9 . . . . . . 49842–111 for Grinders ending in –EU . . . . . . EU–99

for model GRG15A–08G–7 . . . . . . 49842–112 for all other Grinders . . . . . . . . . . . WARNING–4–99

for model GRG15M–06G–7 . . . . . 49842–148 for Sanders and Polishers ending

for model GRG15M–06G–9 . . . . . 49842–149 in –EU . . . . . . . . . . . . . . . . . . . . . . EU–99

for model GRG15M–08G–7 . . . . . 49842–150 for all other Sanders and Grinders . WARNING–5–99

for model GRG15M–08G–7–EU . . 49842–150–EU

for model GRP15A–02P–7 . . . . . . 49842–107

for model GRS15A–04S–9 . . . . . . 49842–108

for model GRS15A–06S–7 . . . . . . 49842–109

* Not illustrated.

MAINTENANCE SECTION

20

PART NUMBER FOR ORDERING PART NUMBER FOR ORDERING

44 Grease Fitting (2) . . . . . . . . . . . . . . . . . . . . 130SR–188 65 Wheel Retaining Screw

45 Mounting Plate Pin . . . . . . . . . . . . . . . . . . 77A–31 (for all Type 27 and 28 Wheels) . . . . . . . . . . . 99V60–219

• 46 Upper Bearing Spring Washer . . . . . . . . . . . . . 4U–278 66 Depressed Center Wheel Flange

• 47 Upper Arbor Bearing . . . . . . . . . . . . . . . . . . . . WWA100–7 (for Type 27 and 28 Plain Hole Wheels) . . . . . 99V60–386

48 Bevel Gear Nut . . . . . . . . . . . . . . . . . . . . . . . . 77A–578 67 Depressed Center Wheel Nut

49 Bevel Gear Spacer . . . . . . . . . . . . . . . . . . . . . . 77A–25 (for Type 27 and 28 Plain Hole Wheels) . . . . . 99V85–186

50 Arbor Lower Bearing Assembly . . . . . . . . . . . 77A–A593 * Depressed Center Wheel Nut

51 Lower Arbor Spring Washer . . . . . . . . . . . . . . 77A–307 Spanner Wrench . . . . . . . . . . . . . . . . . . . . . . . . D32–26

52 Sander Arbor Retaining Plate . . . . . . . . . . . . . 77A–55 * Wheel Flange Wrench (for all GRG models) . TRAQT4–254

53 Screw Lock Washer (6) . . . . . . . . . . . . . . . . . . 88H60–67 68 Depressed Center Wheel Flange Assembly

54 Guard Screw or Retaining Plate Screw (6) . . . 77H–638 (for GRG15M–06G–7, GRG15M–06G–9

55 Sander Arbor . . . . . . . . . . . . . . . . . . . . . . . . . . 77A–204–P10 and GRG15M–08G–7 with Type 27 and

56 Sanding Pad Assembly Type 28 Plain Hole Depressed Center

with 5” Sanding Pad . . . . . . . . . . . 77A–AM825–5 Wheels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99V60–386–M

with 7” Sanding Pad (medium) . . . 77A–AM825–7 70 Dead Handle . . . . . . . . . . . . . . . . . . . . . . . . . . ERG0–A48

with 7” Sanding Pad (firm) . . . . . . 77A–BM825–7 72 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66H–301

with 9” Sanding Pad . . . . . . . . . . . 77A–AM825–9 73 Nameplate Screw (4) . . . . . . . . . . . . . . . . . . . . BN403–302

57 Pad Mounting Kit . . . . . . . . . . . . . . . . . . . 77A–826 * Bearing Clamp Assembly . . . . . . . . . . . . . . . . 77H–A952

58 Wool Bonnet (for GRP15A–02P–7) . . . . . . . . P500–850 * Controller Wrench . . . . . . . . . . . . . . . . . . . . . . 77H–950

59 Depressed Center Wheel Guard * Throttle Valve Seat Support

for 7” diameter wheels . . . . . . . . . . 77A–106–7 Retainer Pliers . . . . . . . . . . . . . . . . . . . . . . . . . 77H–154

for 9” diameter wheels . . . . . . . . . . 77A–106–9 * Coupling Nut Wrench . . . . . . . . . . . . . . . . . . . 77H–281

60 Depressed Center Wheel Arbor . . . . . . . . . . . . 77A–4–B10 * 1/2” Pipe Tap Inlet Bushing . . . . . . . . . . . . . . 88V60–38

61 Autobalancer Assembly . . . . . . . . . . . . . . . . . . 99V60–A713 * Vibra–Tite** 0.6 cc . . . . . . . . . . . . . . . . . . . 5R–VT06

* Autobalancer Wrench (7/8” single–end; * Adhesive Kit . . . . . . . . . . . . . . . . . . . . . . . . . . 77H–KVLT

open–end wrench) . . . . . . . . . . . . . . . . . . . . . . 88V60–169 Tune–up Kit includes illustrated parts:

63 Depressed Center Wheel Spacer (3 [2], 5, 6, 12, 13 [2], 24 and 27) . . . . . . . . . . 77H77A–TK3

(2 for all Type 27 Mounted Wheel) . . . . . . . . 99V–286

* Not illustrated.

• To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one (pair or set) of each part indicated by a

bullet (•) for every four tools in service.

** Registered trademark of ND Industries.

MAINTENANCE SECTION

MAINTENANCE SECTION

Always wear eye protection when operating or

performing maintenance on this tool.

Always turn off air supply and disconnect air supply

hose before installing, removing or adjusting any

accessory on this tool, or before performing any

maintenance on this tool.

LUBRICATION

Each time a GRG Grinder, GRS Sander, or GRP Polisher

is disassembled for maintenance, repair or replacement of

parts, lubricate the tool as follows:

1. Moisten all O–rings with O–ring lubricant.

2. Coat the inner surface of the Arbor Coupling (42), the

spline of the Rotor (26) and the spline of the Bevel

Pinion (31) with 3 to 4 cc of IRAX No. 68–1LB

Grease. Do not substitute any other grease.

3. After assembling the tool, remove the Oil Chamber

Plug (7) and fill the oil chamber with IRAX

No. 50P Oil. Tighten the Plug to 3–3/4 to 7–1/2 ft–lb

(5 to 10 Nm) torque. Inject 2.5 cc of the

recommended oil into the inlet before installing the

Inlet Bushing (4).

4. Inject 5 cc of IRAX No. 68–1LB Grease into both

Grease Fittings (44).

DISASSEMBLY

General Instructions

Disassembly of the Angle Head

For GRG15A or GRG15M Models:

1. Grasp the Angle Arbor Housing (43) in

leather–covered or copper–covered vise jaws, angle

head up.

2. Insert a 5” (127 mm) long 3/16” hex wrench into the

elongated slot in the end of the Dead Handle (70) and

loosen and remove the screw and the Dead Handle

from the Angle Arbor Housing (43).

3. Using the Autobalancer Wrench (Part No.

88V60–169) to hold the Depressed Center Wheel

Arbor (60) against rotation, proceed as follows:

a. Using a hex wrench, unscew and remove the

Wheel Retaining Screw (65).

b. For Type 27 and 28 Plain Hole Wheels, use the

Depressed Center Wheel Nut Spanner Wrench

(Part No. D32–26) to unscrew and remove the

Depressed Center Wheel Nut (67). Remove the

wheel.

For Type 27 and 28 Mounted Wheels, unscrew

the wheel.

c. For Type 27 and 28 Plain Hole Wheels, unscrew

and remove the Depressed Center Wheel Flange

(66 or 68).

For Type 27 and 28 Mounted Wheels, remove

any Depressed Center Wheel Spacers (63).

4. Slide the Autobalancer Assembly (61) off the Arbor.

5. Unscrew and remove the Wheel Guard Screws (54).

Remove the Screw Lock Washers (53) and the Wheel

Guard (59).

6. Lift the Depressed Center Wheel Arbor (60) from the

Angle Arbor Housing.

1. Do not disassemble the tool any further than

necessary to replace or repair damaged parts.

2. Whenever grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws to

protect the surface of the part and help prevent

distortion. This is particularly true of threaded

members and housings.

3. Do not remove any part which is a press fit in or on a

subassembly unless the removal of that part is

necessary for repairs or replacement.

4. Do not disassemble the tool unless you have a

complete set of new gaskets and O–rings for

replacement.

Do not remove the Mounting Plate Pin (45) unless

it is bent or broken. The Mounting Plate Pin is the

alignment pin for the Wheel Guard and must be

used to assure correct mounting of the Wheel

Guard. Use pliers to remove the Mounting Plate

Pin if removal is necessary and a new Pin is

available.

7. Remove the Angle Arbor Housing from the vise.

8. Lay the Angle Arbor Housing on a workbench, guard

side down. Lightly tap the angle arbor housing head

with a soft hammer to release the Upper Arbor

Bearing (47) and Upper Bearing Spring Washer (46).

21

MAINTENANCE SECTION

A thread locking compound was applied to the

threads of the Bevel Gear Nut (48) during

assembly. It may be necessary to warm the Nut

with a propane torch in order to remove it. Use

only enough heat to warm the Nut for removal.

Do not overheat.

9. Grasp the flats of the Depressed Center Wheel Arbor

in leather–covered or copper–covered vise jaws,

Arbor Bearing end up. Using a wrench, remove the

Bevel Gear Nut.

10. Remove the Bevel Gear Spacer (49) and Bevel Gear

(40).

11. Press the Arbor Lower Bearing Assembly (50) from

the Arbor. Remove the Lower Arbor Spring Washer

(51). Remove the Arbor from the vise.

For GRP15A or GRS15A Models:

1. Grasp the Angle Arbor Housing (43) in

leather–covered or copper–covered vise jaws, angle

head up.

2. Use a No. DG120–69 Sander Arbor Wrench to hold

the Arbor (55). Remove the Pad Mounting Kit

Nut (57).

3. For GRP15A Models, remove the Wool Bonnet (58).

Unscrew and remove the Sanding Pad Assembly (56).

4. For GRS15A Models, remove the Sanding Pad

Assembly.

5. Remove the Pad Mounting Kit washers (57).

6. Unscrew and remove the Retaining Plate Screws (54).

Remove the Screw Lock Washers (53) and the Sander

Arbor Retaining Plate (52).

Do not remove the Mounting Plate Pin (45) unless

it is bent or broken. The Mounting Plate Pin is the

alignment pin for the Sander Arbor Retaining

Plate. Use pliers to remove the Mounting Plate Pin

if removal is necessary and a new Pin is on hand.

7. Remove the Angle Arbor Housing from the vise.

8. Lay the Angle Arbor Housing (43) on a workbench,

guard side down. Lightly tap the Angle Arbor

Housing with a soft hammer to release the Upper

Arbor Bearing (47) and Upper Bearing Spring Washer

(46).

only enough heat to warm the Nut for removal. Do

not overheat.

9. Grasp the flats of the Sander Arbor (55) in

leather–covered or copper–covered vise jaws, arbor

bearing end up. Using a wrench, remove the Bevel

Gear Nut.

10. Remove the Bevel Gear Spacer (49) and Bevel Gear

(40).

11. Press the Arbor Lower Bearing Assembly (50) from

the Arbor. Remove the Lower Arbor Spring Washer

(51). Remove the Arbor from the vise.

Disassembly of the Throttle Lever and Inlet

1. Grasp the flats of the Throttle Handle (1) in

leather–covered or copper–covered vise jaws, air inlet

up.

2. Remove the Inlet Bushing (4), Inlet Bushing Screen

(5) and the Throttle Valve Spring (6). The Bushing

has an interference thread and is tightly fit.

3. Drive out the Throttle Lever Pin (16) to release the

Throttle Lever Assembly (17).

4. Remove the Throttle Handle from the vise.

5. Using a soft hammer, tap the arbor end of the housing

to release the Throttle Valve Assembly (2), or using

snap ring pliers, pull the Assembly from the Throttle

Handle. Remove the two Seals (3).

Disassembly of the Motor and Throttle

1. Grasp the Angle Arbor Housing (43) horizontally in

leather–covered or copper–covered vise jaws.

2. Using No. 77H–281 Coupling Nut Wrench, remove

the Coupling Nut (21).

3. Grasp the Throttle Handle (1) and pull the Handle

from the Arbor Housing.

4. Grasp the splined end of the Rotor (26) and pull the

motor from the Throttle Handle.

5. Remove the Cylinder Dowel (30).

6. Grasp the splined end of the Rotor in leather–covered

or copper–covered vise jaws.

7. Remove the Front End Plate (28) and Front Rotor

Bearing (29) from the Rotor.

8. If the Front Rotor Bearing needs to be replaced, press

it from the Front End Plate.

9. Lift off the Cylinder (25).

10. Remove the Vanes (27).

A thread locking compound was applied to the

threads of the Bevel Gear Nut (48) during

assembly. It may be necessary to warm the Nut

with a propane torch in order to remove it. Use

22

MAINTENANCE SECTION

A thread locking compound was applied to the

threads of the Rotor during assembly to prevent

the Controller Assembly (22) from loosening

during operation. Before attempting to unscrew

the assembly from the Rotor, apply moderate heat

from a propane torch to the middle of the rotor

body to soften the compound. Do not overheat the

Rotor. Heat it only long enough to allow the

Controller Assembly to be unscrewed without

using excessive force.

Use only the special Controller Wrench for

removing the Controller Assembly. Do not attempt

to disassemble the Controller. It is available only

as a unit and is guaranteed for the life of the

Grinder if it is not abused.

11. Using the No. 77H–950 Controller Wrench, unscrew

and remove the Controller Assembly (22).

4. Check the Planet Gears (36) and Planet Gear Bearings

(37) for wear. If they need to be replaced, proceed as

follows:

Always remove the Planet Gear Shafts (34) in

the direction shown on the drawing.

a. Using a pin punch and soft hammer, remove the

Planet Gear Shaft.

b. Remove the Planet Gear Assembly.

c. Remove the Planet Gear Bearing from inside

the Planet Gear.

d. Remove the Rotor Pinion (35).

Always replace both Planet Gears even if only

one Planet Gear shows wear.

e. Remove the second Planet Gear as previously

instructed.

5. Unscrew and remove the Pinion (40).

The Rear End Plate, Spacer and Bearing are a

matched set. Do not mix the components with

those of another set. The Rear Rotor Bearing is

always damaged during the removal process, and a

complete new Rear End Plate Assembly must be

installed.

12. If the Rear End Plate Assembly (23) consisting of the

Rear End Plate, Spacer and Bearing needs to be

replaced, press it from the Controller.

13. Remove the Rear End Plate Gasket (24).

14. Using No. 77H–154 Retainer Pliers, remove the

Throttle Valve Seat Support Retainer (15).

15. Grasp the Throttle Handle horizontally in

leather–covered or copper–covered vise jaws. Using

a brass rod 8” (204 mm) long inserted into the air

inlet end of the handle, lightly tap the brass rod with a

soft hammer to release the Throttle Valve Seat

Support Assembly (8).

16. Remove the Valve Seat Screw (9), Valve Seat Lock

Washer (10), Valve Seat Washer (11), Valve Seat (12)

and Valve Support Seals (13).

17. Check the Oiler Feeder Plug (14). Replace if

necessary.

Disassembly of the Bevel Pinion Driver

For GRP15A–02P–7 Models:

1. Lightly tap the Angle Arbor Housing (43) to release

the Bevel Pinion Driver (31).

2. Remove the Internal Gear (32).

3. Remove the Bevel Pinion Driver Bearing (33). This

is a light press fit.

If the Pinion is worn or broken, replace both the

Pinion and Bevel Gear as they are a matched set

and cannot be matched with other Bevel Gears.

6. Press the Bevel Pinion Bearing (39) from the Bevel

Pinion Driver.

7. Remove the Thrust Spacer (38).

For GRG15A, GRG15M or GRS15A Models:

1. Lightly tap the Angle Arbor Housing (43) to remove

the Motor Spacer (41), Arbor Coupling (42), Thrust

Spacer (38), Bevel Pinion Bearing Assembly (39),

and the Bevel Pinion Driver (31).

2. Unscrew and remove the Bevel Pinion (40).

If the Pinion is worn or broken, replace both the

Pinion and the Bevel Gear as they are a matched

set and cannot be matched with other Bevel Gears.

3. Press the Bevel Pinion Bearing (39) from the Bevel

Pinion Driver.

ASSEMBLY

General Instructions

1. Always press on the inner ring of a ball–type bearing

hen installing the bearing on a shaft.

2. Always press on the outer ring of a ball–type bearing

when pressing the bearing into a bearing recess.

3. Whenever grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws.

Take extra care with threaded parts and housings.

23

MAINTENANCE SECTION

4. Always clean every part and wipe every part with a

thin film of oil before installation.

5. Apply a film of o–ring lubricant to all O–rings before

final assembly.

Assembly of the Motor and Throttle

10. Clean the threads of the Controller Assembly (22) and

apply two or three drops of a thread locking

compound to the threads. Thread the Controller onto

the Rotor.

1. Assemble the Throttle Valve Seat Support Assembly

(8). Secure the Valve Seat (12), the Valve Seat

Washer (11), and the Valve Seat Lock Washer (10)

with the Valve Seat Screw (9). Tighten the Valve Seat

Screw between 0.75 to 2.25 ft–lb (1 to 3 Nm) torque.

Apply o–ring lubricant to the Valve Support Seals

(13) before installing them on the Throttle Valve Seat

Support.

2. Insert the Assembly into the large diameter of the

handle, Valve Seat Screw end first.

3. Using No. 49843–146 Retainer Pliers, install the

Throttle Valve Seat Support Retainer (15).

4. Press the Front Rotor Bearing (29), with Front End

Plate (28), onto the rotor shaft.

5. Grasp the splined end of the Rotor (26) in

leather–covered or copper–covered vise jaws.

6. Place the Cylinder (25) over the Rotor, aligning the

dowel hole in the Cylinder with the dowel hole in the

Front End Plate.

7. Apply a film of the recommended oil to each Vane

(27) and insert a Vane, straight edge out, into each

vane slot in the Rotor. If new Vanes are required,

replace the entire set.

8. Check the large inside diameter of the Rear End Plate

Assembly (23) for wear. If the large inside diameter

of the Rear End Plate is worn to 1.516” (38.506 mm)

or larger, install a new Rear End Plate Assembly.

If the Controller Assembly must be replaced, it is

furnished with a new Rear End Plate Assembly.

Use only the End Plate Assembly furnished with

the Controller Assembly. If the Controller is good

but the Rear End Plate Assembly needs

replacement, only install a new Rear End Plate

Assembly. Do not use or interchange old parts

with new Rear End Plate Assembly components.

The End Plate, Spacer and Bearing are a matched

set. Do not mix components with those of another

set. The Rear Rotor Bearing is always damaged

during removal and a new Rear End Plate

Assembly must be installed.

9. Press the Rear End Plate Assembly onto the shaft of

the controller body making certain the marked end of

the Bearing faces toward the Controller or rear of the

Grinder. Also make certain that the beveled end of

the Spacer faces the Cylinder or front of the Grinder.

Before tightening the Controller, be certain that

the dowel holes in the Cylinder and End Plate are

aligned. Use the 77H–950 Controller Wrench to

tighten the Controller between 7.5 and 8.0 ft–lb

(10.1 and 10.8 Nm) torque. Do not exceed 8 ft–lb

(10.8 Nm) torque because it could damage the

Controller. Allow the thread locking compound to

cure for six hours before putting the Grinder back

in service.

Always check the free speed of the Grinder after it

has been reassembled and before it is put back into

service. Never use a Grinder with a free speed that

exceeds the maximum speed listed on the

Nameplate.

11. Remove the Rotor from the vise.

12. Insert the Cylinder Dowel (30) so it is flush with the

face of the Front End Plate and protrudes from the

back of the Rear End Plate Assembly.

13. Install a new End Plate Gasket (24) into the Throttle

Handle (1).

14. Install the assembled motor into the Throttle Handle

(1), making sure the Cylinder Dowel (30) aligns with

the pin hole inside the Throttle Handle.

Assembly of the Bevel Pinion Driver

1. For GRP15A Models:

a. Install the Planet Gear Bearings (37) into the

Planet Gears (36).

b. Install an assembled Planet Gear into one of the

slots in the gear head. Make sure the shaft hole

aligns in both the Planet Gear and the gear head.

c. Press the Planet Gear Shaft (34) into the hole

opposite the tapered shaft hole in the gear head

until it is flush with the face of the gear head.

d. Install the Rotor Pinion (35), making sure the teeth

of the Planet Gear and Rotor Pinion mesh. Install

the other assembled Planet Gear into the

remaining slot of the gearhead. Make sure the

teeth of the Planet Gear and the Rotor Pinion mesh

and the shaft hole aligns in both the Planet Gear

and gear head.

e. Press the other Planet Gear Shaft (34) into the hole

opposite the tapered shaft hole in the gear head

until it is flush with the face of the gear head.

Lubricate the Gearing liberally with IRAX

No. 68–1LB Grease.

24

MAINTENANCE SECTION

f. Press the Bevel Pinion Driver Bearing (33) onto

the gear head end of the Bevel Pinion Driver (31).

g. Install the Internal Gear (32) over the gear head

end of the Bevel Pinion Driver, making sure the

splines of the Internal Gear mesh with the Planet

Gear teeth.

h. Install the Thrust Spacer (38) over the threaded

end of the Bevel Pinion Driver.

i. Press the Bevel Pinion Bearing (39) onto the

Bevel Pinion Driver.

If the Pinion (40) needs to be replaced, replace

both the Pinion and Bevel Gear. They are a

matched set and cannot be matched with other

Bevel Gears.

j. Check the Pinion for worn or broken teeth.

k. Screw the Pinion onto the threaded Bevel Pinion

Driver and tighten to 14 to 19 ft–lb (19 to 26 Nm)

torque.

For GRG15A, GRG15M or GRS15A Models:

a. Press the Bevel Pinion Bearing (39) over the

threaded end and onto the Bevel Pinion

Driver (31).

Make sure the Throttle Lever Assembly (17)

mounting boss on the Throttle Handle (1) aligns

with the closed, upper portion of the Angle Arbor

Housing.

For GRP15A–02P–7 Models, make sure the spline

on the Rotor (26) properly engages the spline in the

Rotor Pinion (35).

5. Slide the assembled Throttle Handle into the Angle

Arbor Housing.

6. Clean the Coupling Nut (21) threads and carefully

apply a uniform coat of Vibra–Tite** VC3 No. 205

to at least the first three threads. Allow the

Vibra–Tite to cure for ten to twenty minutes before

assembly.

Do not exceed 52.5 ft–lb (71.2 Nm) torque. The

motor may be damaged if this torque is exceeded.

7. Using the No. 49843–147 Coupling Nut Wrench,

install the Coupling Nut and tighten it between 48 to

52.5 ft–lb (64 to 71 Nm) torque.

Assembly of the Throttle Lever and Inlet

If the Pinion (40) needs to be replaced, replace

both the Pinion and the Bevel Gear. They are a