Page 1

Form MHD56298

IMPORTANT INFORMATION:

• A copy of our “Safe Operating Practices” Manuals are always available free of charge either by downloading it from our

Technical Publications website @ www.airwinch.com or by contacting the Factory at (800) 866-5457 for North America and

(206) 624-0466 for International. The Safe Operating Practices manual must be read prior to anyone operating a

Ingersoll-Rand winch or hoist. The manual form numbers are as follows:

“Safe Operating Practices Non-Man Rider™ Winches” Manual, Form No. MHD56250

“Safe Operating Practices for Man Rider™ Winches” Manual, Form No. MHD56251

“Safe Operating Practices for Pneumatic, Hydraulic and Electric Hoists” Manual, Form No. MHD56295

• Available winch options may require additional supplements to the basic winch manual.

• For Man Rider™ winches ensure a copy of the Man Rider™ supplement is made available to the operator prior to winch

operation.

Winch Man Rider

Model: Publication No. Model: Publication No.

FA2, FA2.5,

FH2, FH2.5

FA5

FA10 MHD56252

FA2.5A MHD56236

FA2B and

HU40A

FH10MR MHD56212

Fulcrum Electric MHD56277

LS500HLP/

LS1000HLP

™ Supplements:

MHD56046

MHD56042 and

MHD56220

MHD56207

SAM0004

LS500RLP SAM0011

LS1000RLP SAM0012

LS150RLP SAM0082

LS150RLP/500/

1000

LS150RLP and

LS150PLP-PH

LS500RLP-E SAM0122

LS150RLPDP5M-F

LS150HLP SAM0222

SAM0115

SAM0120

SAM0184

• We strongly recommend that ALL maintenance on Ingersoll-Rand equipment be carried out by personnel certified by

Ingersoll-Rand, or by Ingersoll-Rand Authorized Service Centers.

• Contact the Factory if in doubt about installation, operation, inspection and maintenance instructions.

• Use only Genuine Ingersoll-Rand parts when maintaining or repairing a winch, hoist or any component of a winch or hoist.

• ANSI / ASME recommends that a winch or hoist (or any components of a winch or hoist) that has been repaired be tested

prior to being placed into service:

* Winches - ANSI / ASME B30.7 (BASE MOUNTED DRUM HOISTS) Refer to section 7.2.2 - Testing.

* Hoists - ANSI / ASME B30.16 (OVERHEAD HOISTS - UNDERHUNG) Refer to section 16.2.2 - Testing.

Form MHD56298

Edition 2

November 2004

71441844

© 2004 Ingersoll-Rand Company

Page 2

Form MHD56040

PARTS, OPERATION AND MAINTENANCE MANUAL

for

MODELS FA2 AND FA2.5

READ THIS MANUAL BEFORE USING THESE PRODUCTS. This manual

contains important safety, installation, operation and maintenance

information. Make this manual available to all persons responsible for the

installation, operation and maintenance of these products.

WARNING

Do not use thiswinch for lifting, supporting, or transporting people unless winch is

TM

approved for Man Rider

Always operate, inspect and maintainthiswinch in accordance with American Society of

Mechanical Engineers Standards Safety Code (ASME B30.7) and any other applicable

safety codes and regulations.

Form MHD56040

Edition 3

May 2006

71072060

© 2006 Ingersoll Rand Company

applications. Do not lift or support loads over people.

Page 3

Page 4

SAFETY INFORMATION

f

This manual provides important information for all personnel

involved with the safe installation, operation and proper

maintenance of this product. Even if you feel you are familiar

with this or similar equipment, you should read this manual

before operating the winch.

Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures which, if

not followed, may result in a hazard. The following signal words

are used to identify the level of potential hazard.

DANGER

WARNING

CAUTION

NOTICE

Danger is used to indicate the presence of

ahazardwhichwill cause severe injury,

death, or substantial property damage if

the warning is ignored.

Warning is used to indicate the presence

of a hazard which can cause severe injury,

death, or substantial property damage if

the warning is ignored.

Caution is used to indicate the presence o

a hazard which will or can cause injury or

property damage if the warning is

ignored.

Notice is used to notify people of

installation, operation, or maintenance

information which is important but not

hazard-related.

Safety Summary

WARNING

• Do not use this winch for lifting, supporting, or transporting

people unless winch is approved for Man Rider

applications. Do not lift or support loads over people.

• The supporting structures and load-attaching devices used in

conjunction with this winch must provide an adequate safety

factor to handle the rated load, plus the weight of the winch

and attached equipment. This is the customer’s responsibility.

If in doubt, consult a registered structural engineer.

TM

The Occupational Safety and Health Act of 1970 generally places

the burden of compliance with the user, not the manufacturer.

Many OSHA requirements are not concerned or connected with

the manufactured product but are, rather, associated with the final

installation. It is the owner’s and user’s responsibility to

determine the suitability of a product for any particular use. It is

recommended that all applicable industry, trade association,

federal, state and local regulations be checked. Read all operating

instructions and warnings before operation.

Rigging: It is the responsibility of the operator to exercise

caution, use common sense and be familiar with proper rigging

techniques. Refer to ASME B30.9 for rigging information,

American Society of Mechanical Engineers, Three Park Avenue,

New York, NY 10015.

This manual has been produced by Ingersoll Rand to provide

dealers, mechanics, operators and company personnel with

information required to install, operate, maintain and repair the

products described herein.

It is extremely important that mechanics and operators be familiar

with servicing procedures of these products, or like or similar

products, and are physically capable of conducting the

procedures. These personnel shall have a general working

knowledge that includes:

1. Proper and safe use and application of mechanics common

hand tools as well as special Ingersoll Rand or

recommended tools.

2. Safety procedures, precautions and work habits established

by accepted industry standards.

Ingersoll Rand cannot know of, or provide all the procedures by

which product operations or repairs may be conducted and the

hazards and/or results of each method. If operation or

maintenance procedures not specifically recommended by the

manufacturer are conducted, it must be ensured that product

safety is not endangered by the actions taken. If unsure of an

operation or maintenance procedure or step, personnel should

place the product in a safe condition and contact supervisors and/

or the factory for technical assistance.

Ingersoll Rand winches are manufactured in accordance with the

latest ASME B30.7 standards.

The National Safety Council, Accident Prevention Manual for

Industrial Operations, Eighth Edition and other recognized safety

sources make a common point: Employees who work near

suspended loads or assist in hooking on or arranging a load

should be instructed to keep out from under the load. From a

safety standpoint, one factor is paramount: conduct all lifting or

pulling operations in such a manner that if there were an

equipment failure, no personnel would be injured. This means

keep out from under a raised load and keep out of the intended

path of any load.

3

Page 5

SAFE OPERATING INSTRUCTIONS

The following warnings and operating instructions have been

adapted in part from American Society of Mechanical Engineers

(Safety) Standard ASME B30.7 and are intended to avoid unsafe

operating practices which might lead to injury or property

damage.

Ingersoll Rand recognizes that most companies who use winches

have a safety program in force at their facility. In the event that

some conflict exists between a rule set forth in this publication

and a similar rule already set by an individual company, the more

stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator

aware of dangerous practices to avoid and are not necessarily

limited to the following list. Refer to specific sections in the

manual for additional safety information.

1. Only allow personnel trained in safety and operation of this

product to operate and maintain this winch.

2. Only operate a winch if you are physically fit to do so.

3. When a “DO NOT OPERATE” sign is placed on winch, or

controls, do not operate winch until sign has been removed

by designated personnel.

4. Before each shift, check winch for wear and damage. Never

use a winch that inspection indicates is worn or damaged.

WARNING LABEL

5. Never lift a load greater than rated capacity of the winch.

Refer to labels attached to winch or to “SPECIFICATIONS”

section.

6. Keep hands, clothing, etc., clear of moving parts.

7. Never place your hand in the throat area of a hook or near

wire rope spooling onto or off of winch drum.

8. Always rig loads properly and carefully.

9. Be certain the load is properly seated in saddle of hook. Do

not support load on tip of hook.

10. Do not “side pull” or “yard”.

11. Always ensure that you, and all other people, are clear of the

path of the load. Do not lift a load over people.

12. Never use the winch for lifting or lowering people, and never

allow anyone to stand on a suspended load.

13. Ease slack out of wire rope when starting a lift or pull. Do

not jerk the load.

14. Do not swing a suspended load.

15. Do not leave a suspended load unattended.

16. Never operate a winch with twisted, kinked or damaged wire

rope.

17. Pay attention to the load at all times when operating the

winch.

18. Never use the winch wire rope as a sling.

19. After use, or when in a non-operational mode, winch should

be secured against unauthorized and unwarranted use.

Each unit is shipped from the factory with warning label shown.

If the label is not attached to your unit, order a new label and

install it. Refer to the parts list for part number. Label is shown

smaller than actual size.

(Dwg. 71060529)

4

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

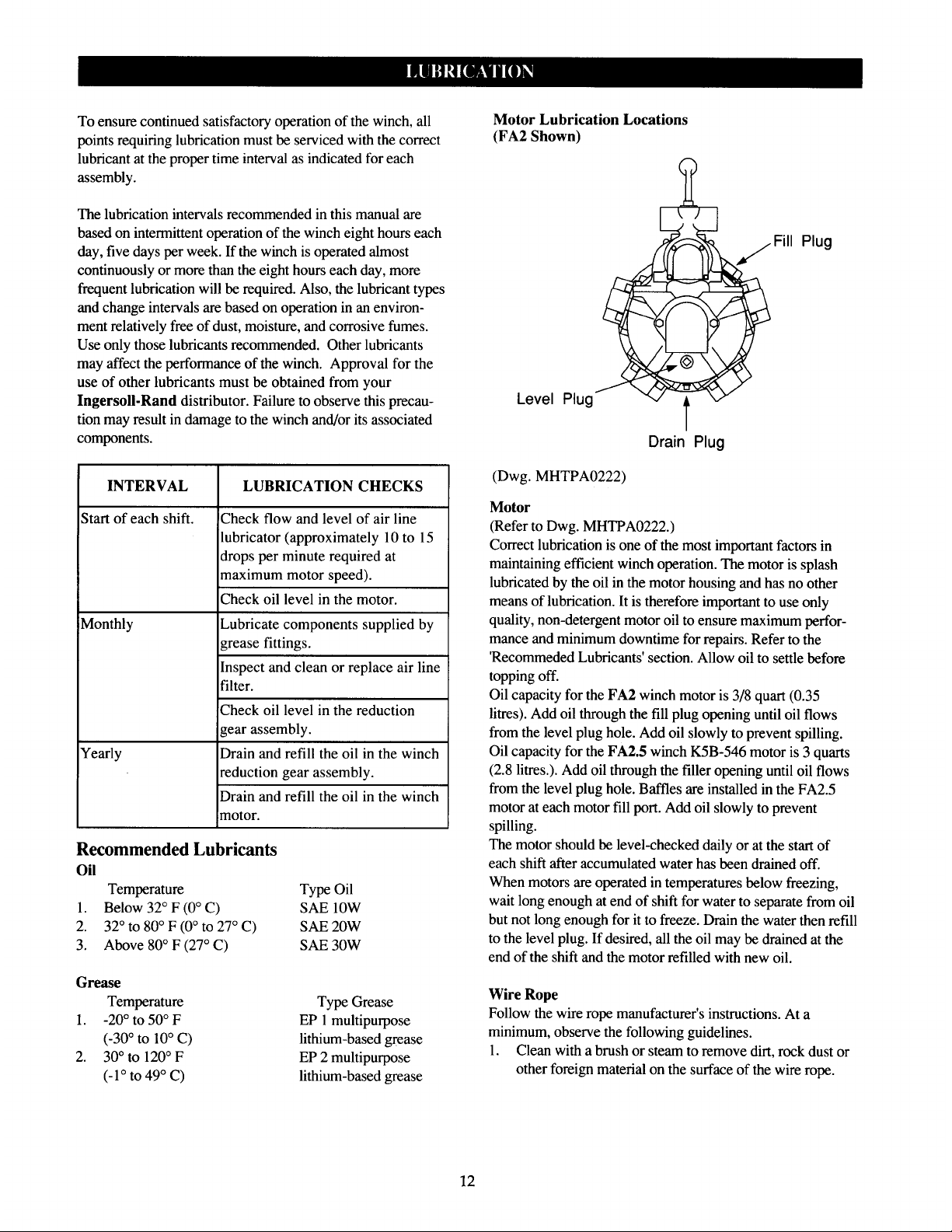

Page 12

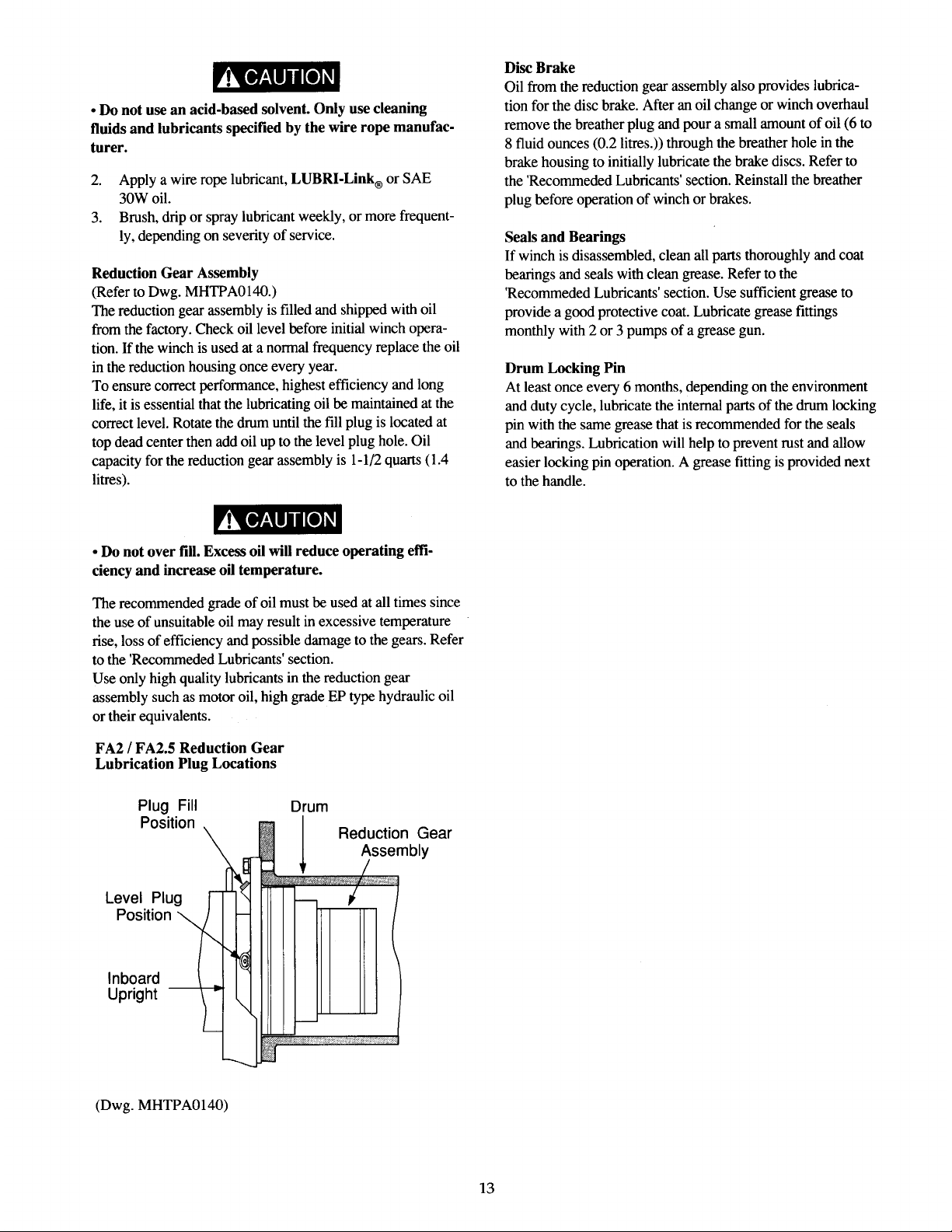

Page 13

Page 14

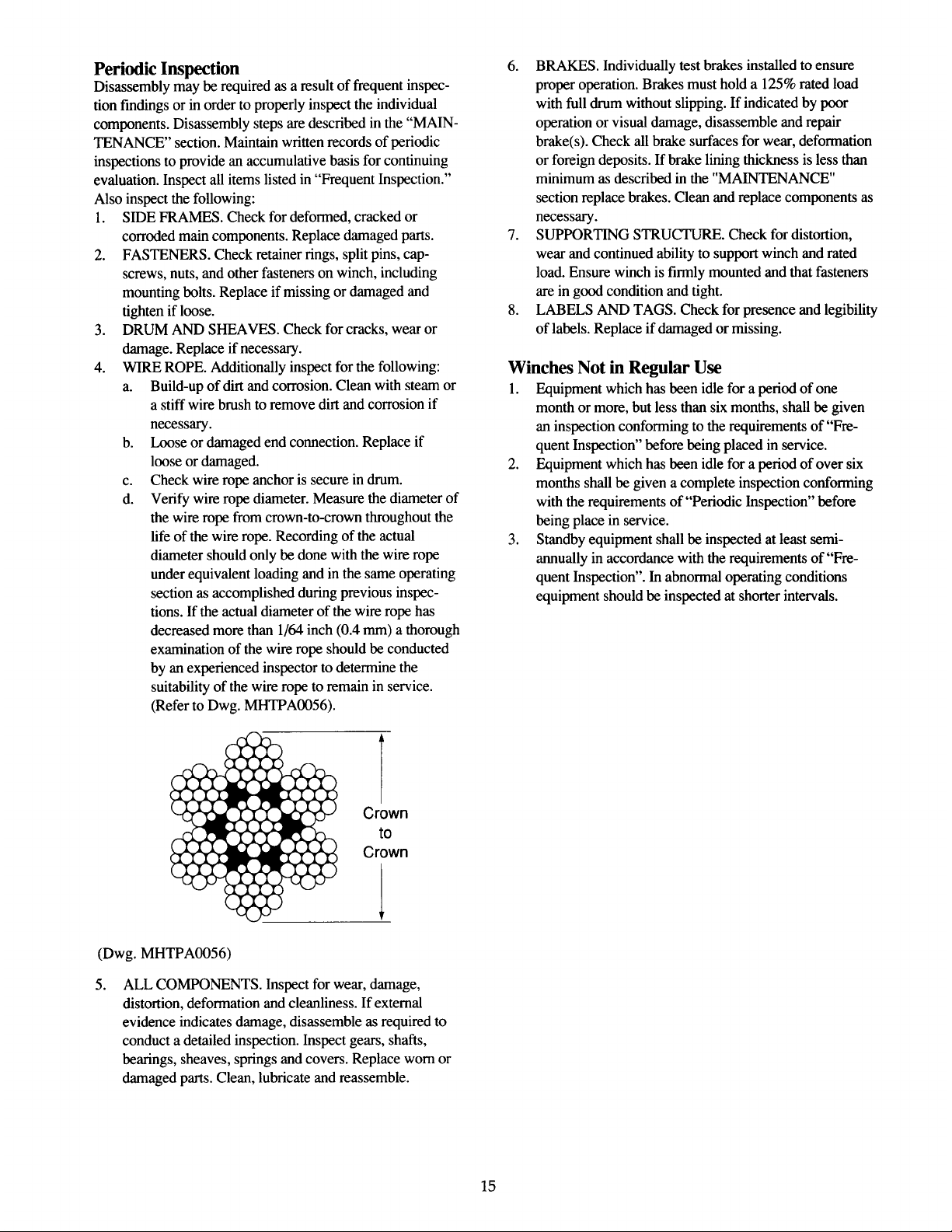

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

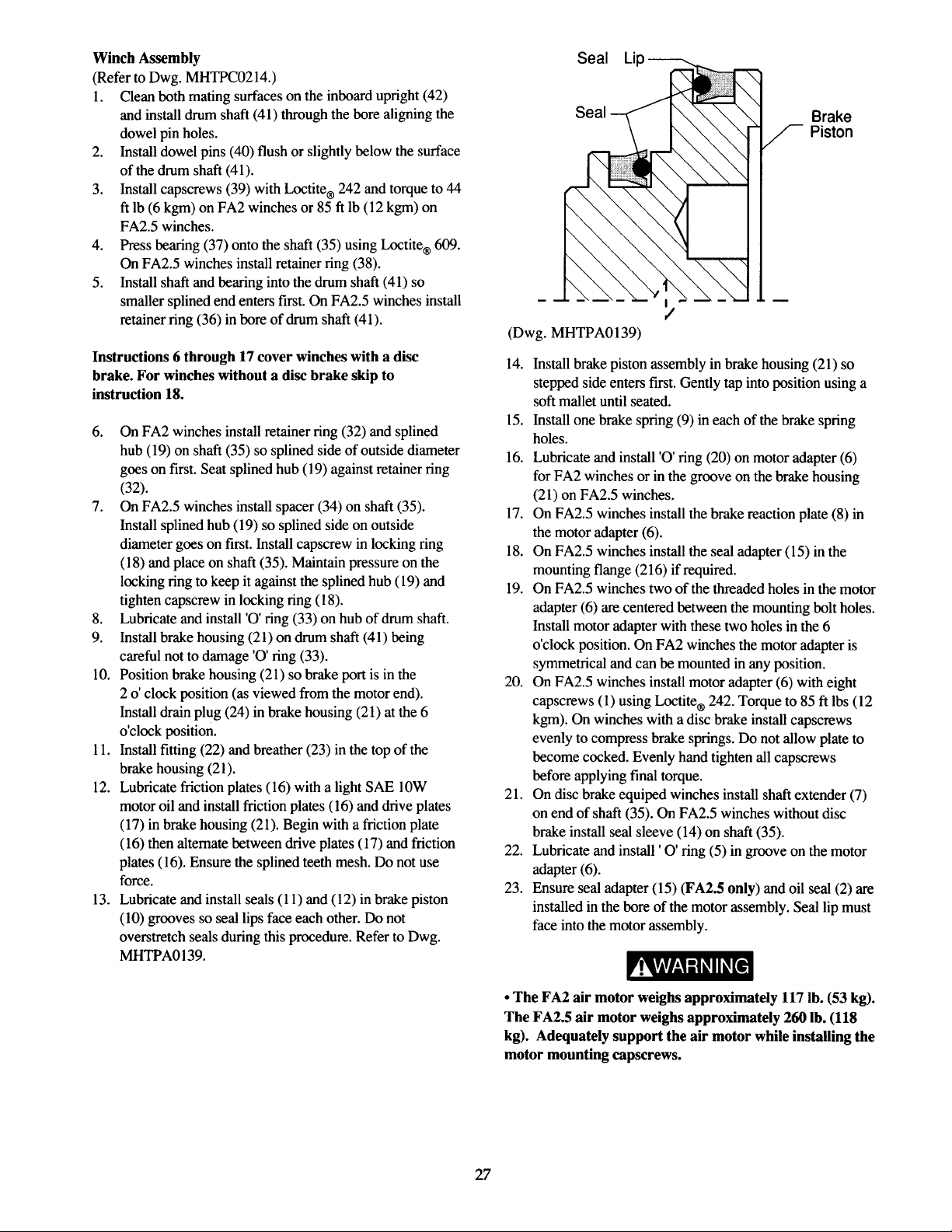

Apply Loctite 262 on threads of capscrews (60) FA2, and (75)

q

FA2.5, and install, tor

ue to 33 ft lbs(44.7 Nm).

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

PARTS ORDERING INFORMATION

Use of other than Ingersoll Rand replacement parts may

adversely affect the safe operation and performance of this

product.

For your convenience and future reference it is recommended that

the following information be recorded.

Model Number _______________________________________

Serial Number ________________________________________

Date Purchased _______________________________________

When ordering replacement parts, please specify the following:

1. Complete model number and serial number as it appears on

the nameplate.

2. Part number(s) and part description as shown in this manual.

3. Quantity required.

The nameplate is located on the winch outboard upright.

NOTICE

• Continuing improvement and advancement of design may

cause changes to this equipment which are not included in this

manual. Manuals are periodically revised to incorporate

changes. Always check the manual edition number on the

front cover for the latest issue.

• Sections of this manual may not apply to your winch.

• The use of other than genuine Ingersoll Rand replacement

parts may result in safety hazards, decreased performance

and increased maintenance and invalidate all warranties.

Return Goods Policy

Ingersoll Rand will not accept any returned goods for warranty

or service work unless prior arrangements have been made and

written authorization has been provided from the location where

the goods were purchased.

Winches which have been modified without Ingersoll Rand

approval, mishandled or overloaded will not be repaired or

replaced under warranty. A printed copy of the warranty which

applies to this winch is provided inside the back cover of this

manual.

Disposal

When the life of the unit has expired, it is recommended that it be

disassembled, degreased and parts separated as to materials so

that they may be recycled.

For additional information contact:

Ingersoll Rand

2724 Sixth Avenue South

Seattle, WA 98134 USA

Phone: (206) 624-0466

Fax: (206) 624-6265

or

Ingersoll Rand

Douai Operations

529, Avenue Roger Salengro

59450 Sin Le Noble, France

Phone: (33) 3-27-93-08-08

Fax: (33) 3-27-93-08-00

58

Page 60

WARRANTY

LIMITED WARRANTY

Ingersoll Rand Company (I-R) warrants to the original user its

Hoists and Winches (Products) to be free of defects in material

and workmanship for a period of one year from the date of

purchase. I-R will repair, without cost, any Product found to be

defective, including parts and labor charges, or at its option, will

replace such Products or refund the purchase price less a

reasonable allowance for depreciation, in exchange for the

Product. Repairs or replacements are warranted for the remainder

of the original warranty period.

If any Product proves defective within its original one year

warranty period, it should be returned to any Authorized Hoist

and Winch Service Distributor, transportation prepaid with proof

of purchase or warranty card.

This warranty does not apply to Products which I-R has

determined to have been misused or abused, improperly

maintained by the user, or where the malfunction or defect can be

attributed to the use of non-genuine I-R parts.

IMPORTANT NOTICE

It is our policy to promote safe delivery of all orders.

This shipment has been thoroughly checked, packed and

inspected before leaving our plant and receipt for it in good

condition has been received from the carrier. Any loss or damage

which occurs to this shipment while enroute is not due to any

action or conduct of the manufacturer.

Visible Loss or Damage

If any of the goods called for on the bill of lading or express

receipt are damaged or the quantity is short, do not accept them

until the freight or express agent makes an appropriate notation on

your freight bill or express receipt.

I-R makes no other warranty, and all implied warranties

including any warranty of merchantability or fitness for a

particular purpose are limited to the duration of the

expressed warranty period as set forth above. I-R’s maximum

liability is limited to the purchase price of the Product and in

no event shall I-R be liable for any consequential, indirect,

incidental, or special damages of any nature rising from the

sale or use of the Product, whether based on contract, tort, or

otherwise.

Note: Some states do not allow limitations on incidental or

consequential damages or how long an implied warranty lasts so

that the above limitations may not apply to you.

This warranty gives you specific legal rights and you may also

have other rights which may vary from state to state.

Damage Claims

You must file claims for damage with the carrier. It is the

transportation company’s responsibility to reimburse you for

repair or replacement of goods damaged in shipment. Claims for

loss or damage in shipment must not be deducted from the

Ingersoll

invoice be withheld awaiting adjustment of such claims as the

carrier guarantees safe delivery.

You may return products damaged in shipment to us for repair,

which services will be for your account and form your basis for

claim against the carrier.

Rand invoice, nor should payment of Ingersoll Rand

Concealed Loss or Damage

When a shipment has been delivered to you in apparent good

condition, but upon opening the crate or container, loss or damage

has taken place while in transit, notify the carrier’s agent

immediately.

59

Page 61

www.winchandhoistsolutions.com

Loading...

Loading...