Page 1

04578092

P7529

Edition 1

January, 2002

Expert Torque Analyzers

ETA2 and ETA5

OPERATORS MANUAL

©2002 Ingersoll-Rand

P7529_Cover_eng.qxd 8/7/03 8:54 AM Page 1

Page 2

7529_eng.fm Page 1 Wednesday, November 12, 2003 8:57 AM

OPERATORS MANUAL FOR

MODEL ETA2 AND ETA5 ANALYZERS

This ETA Analyzer is used for calibration or data collection of torque tools, power and

hand operated, using external transducer(s). This Analyzer can also be used for joint

development and as a failure analysis instrument (using external transducers).

Ingersoll-Rand is not responsible for customer modification of units for applications on

which Ingersoll-Rand was not consulted.

This symbol is to alert the user and service personnel to the presence of important operating instructions that must be read and understood to prevent personal injury, electrical

shock or damage to the equipment.

IMPORTANT SAFETY INFORMATION ENCLOSED -

SAVE THESE INSTRUCTIONS.

READ AND UNDERSTAND THIS MANUAL BEFORE OPERATING THIS PRODUCT.

IT IS YOUR RESPONSIBILITY TO MAKE THIS SAFETY INFORMATION

AVAILABLE TO OTHERS THAT WILL OPERATE THIS PRODUCT.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN

ELECTRIC SHOCK, FIRE AND/OR SERIOUS PERSONAL INJURY.

04578092

Form P7529

Edition 1

January, 2002

Refer All Communications to the Nearest Ingersoll-Rand

Office or Distributor.

© Ingersoll-Rand Company 2002

Printed in U.S.A.

Page 3

7529_eng.fm Page 2 Wednesday, November 12, 2003 8:57 AM

PLACING ANALYZER IN SERVICE

• Always install, operate, inspect and

maintain this product in accordance

with all applicable standards and

regulations (local, state, country, federal, etc.).

USING THE ANALYZER

• Always wear eye protection when operating or performing maintenance on

this tool.

• Always use Personal Protective Equipment appropriate to the tool used and

material worked. This may include dust

mask or other breathing apparatus,

safety glasses, ear plugs, gloves,

apron, safety shoes, hard hat and other

equipment.

• Keep others at a safe distance from

your work area, or ensure they use

appropriate Personal Protective Equipment.

• This tool is not insulated against electric shock.

• This unit is for indoor use only.

• Store idle units. When not in use, units

should be stored in a dry, high or

locked location, out of the reach of children.

• Power tools can vibrate in use. Vibration, repetitive motions or uncomfortable positions may be harmful to your

hands and arms. Stop using any tool if

discomfort, tingling feeling or pain

occurs. Seek medical advice before

resuming use.

• Keep body stance balanced and firm.

Do not overreach when operating this

tool. Anticipate and be alert for sudden

changes in motion, reaction torques, or

forces during start up and operation.

• Ensure work pieces are secure. Use

clamps or vises to hold work piece

whenever possible.

• Never use a damaged or malfunctioning tool or accessory.

• Keep work area clean, uncluttered,

ventilated and illuminated.

• Do not remove any labels. Replace

any damaged label.

• Maintain unit with care. Keep unit clean

for better and safer performance. Follow instructions for changing accessories. Inspect unit cords periodically and

if damaged, have them repaired by an

authorized service facility.

• Do not operate this product in explosive atmospheres, such as in the presence of flammable liquids, gases or

dust.

• Do not modify this product, safety

devices, or accessories.

• Do not use this product for purposes

other than those recommended.

• Use accessories recommended by

Ingersoll-Rand for your model.

• Don’t abuse the cord. Never use the

cord to pull the plug from an outlet.

Keep cords away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

• Avoid body contact with grounded surfaces such as pipes, metal structures

or other electrical products.

• Stay alert, watch what you are doing

and use common sense when operating this product. Do not use this product while tired or under the influence of

drugs, alcohol, or medication.

• Do not use this product near water or

other liquids.

• Do not attach or place external loads

on any part of the unit.

• Replace battery with the same or equivalent type recommended by the battery

manufacturer. Observe correct polarity

when installing battery. Dispose of

used batteries according to battery

manufacturer’s instructions.

2

Page 4

7529_eng.fm Page 3 Wednesday, November 12, 2003 8:57 AM

CAUTION

• The unit should be checked periodically to ensure that the torque readings

are accurate.

• DO NOT store the unit in relative

humidity above 85%.

• Have the unit calibrated at least once a

year.

• Keep the exterior of the unit clean and

dry.

• Do not drop or abuse the unit.

• Do not allow chemicals such as ace-

tone, benzene, thinner, ketone or

trichloroethylene to come in contact

with the housings, as damage will

result.

• The instrument should not be subjected to vibration or shock.

Ingersoll-Rand Company makes no warranty or implies any warranty or liabilities due to the

misuse or damage resulting from the application of the information supplied by this manual.

Liabilities due to errors in the manual are only limited to replacement of the manual.

Ingersoll-Rand reserves the right to change information contained in this manual or the program without notice at any time.

All programs and themanual are copyrighted and rights reserved. Reproduction is prohibited

without prior permission of Ingersoll-Rand.

The use of other than genuine Ingersoll-Rand replacement parts may result in safety hazards,

decreased tool performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest IngersollRand Authorized Servicenter.

• For calibration or repair, return to:

Ingersoll-Rand

ETA Dept.

510 Hester Dr.

Whitehouse, TN 37188

Ingersoll-Rand IDC

ETA Dept.

Swan Lane, Hindley Green

Nr. Wigan

Lancashire, WN2 4EZ

U.K.

3

Page 5

7529_eng.fm Page 4 Wednesday, November 12, 2003 8:57 AM

WARNING SYMBOL IDENTIFICATION

WARNING

Always wear eye protection

when operating or performing

maintenance on this tool.

WARNING

Read this manual before

operating tool.

WARNING

Always wear hearing

protection when operating

this tool.

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

When the life of the tool has expired, it is recommended that the

tool be disassembled, degreased and the parts be separated by material

so that they can be recycled.

4

Page 6

7529_eng.fm Page 5 Wednesday, November 12, 2003 8:57 AM

Table of Contents

ETA Analyzer usage and warnings . . . . . . . . . . . . . . . . . . . . . . . . . 1

Placing Analyzer in Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warning Symbol Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How to use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Care and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Edit Transducer File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Barcode read input for characteristic names and comments. . . . . . 13

Measure Mode (Up to 200 readings stored) . . . . . . . . . . . . . . . . . . 14

Measure Mode Circle--Store Option . . . . . . . . . . . . . . . . . . . . . . . . 16

Direct Measure Mode -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . . . . . 17

To set up a Characteristic -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . . 19

Direct Characteristic Mode -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . 21

To Store Data (single characteristic) -- ETA5 ONLY. . . . . . . . . . . . . 23

To set up a Round -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To Store Data by Round -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . . . 26

To set up a Master Round -- ETA5 ONLY . . . . . . . . . . . . . . . . . . . . 27

To Store Data by Master Round. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

To Display Recorded Data on ETA2 and ETA5 . . . . . . . . . . . . . . . . 29

To View Cp and Cpk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

French Cp and Cpk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To Erase Stored Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To Erase Stored Data and Setups on ETA5. . . . . . . . . . . . . . . . . . . 32

Page No.

5

Page 7

7529_eng.fm Page 6 Wednesday, November 12, 2003 8:57 AM

Table of Contents (continued)

Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

To Print details of Setup or Analysis of Data from ETA5 . . . . . . . . . 34

Printing Data to PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To Set Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To Set Power Off and Backlight Time Delays. . . . . . . . . . . . . . . . . . 40

To Configure Printer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

To Display Software Version Number. . . . . . . . . . . . . . . . . . . . . . . . 41

To Set Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

To Clear Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

To Perform Software Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

To Communicate with a PC using PC Comms Software . . . . . . . . . 44

Printout of Readings taken in Measure Mode . . . . . . . . . . . . . . . . . 45

Printout of Setup and Readings taken by Characteristic . . . . . . . . . 46

Printout of Analysis by Characteristic . . . . . . . . . . . . . . . . . . . . . . . 47

Printout of details of all Characteristic setups . . . . . . . . . . . . . . . . . 48

Printout of Round setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Printout of Readings taken by Characteristic. . . . . . . . . . . . . . . . . . 50

Rotary and Stationary Joint Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Nominal Joint Stiffnesses - Table. . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Bolt Hole Diagram and Sectional View Diagram . . . . . . . . . . . . . . . 53

Parts List - Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

External Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Page No.

6

Page 8

7529_eng.fm Page 7 Wednesday, November 12, 2003 8:57 AM

How to use this Manual

This manual is split into sections describing the steps to be taken to configure the

ETA for use in measuring and recording torque values.

There are a number of other parameters which are set from the Software Reset Menu, some of

which are detailed elsewhere in this manual.

Pressing after making a selection will take the user on to the next screen.

Pressing will give the user the option to exit to the Misc menu or continue to edit by

Enter

MENU

pressing .

Screens can be skipped using the and keys.

The following method is adopted throughout this manual.

Keys to be pressed will be shown as the key legend in large type: Example

Any special instructions or point to note will be shown as:

Enter

Enter

INSTRUCTION

TO BE

FOLLOWED

Refer to the table of contents to find action to be performed.

Follow instructions for key presses required to carry out required action.

Note: It is possible to change the default primary character on dual function

keys. ie: when text is entered into various fields, it is possible to set

the ETA to default to either the numerals or text as the primary character (the alternate character is selected by pressing the shift key

before typing). To set this:

From main menu:

Press then press (Misc)

6

Press then press (Software Reset)

6

Press the 7 times to access the ‘Shift key’ menu

Select between options 1 ‘Characters’ or 2 ‘Numbers’ using:

MENU

Press Screen will prompt “End of setup”

MENU MENU

Press to return to main menu

7

Page 9

7529_eng.fm Page 8 Wednesday, November 12, 2003 8:57 AM

The following items, except those listed as optional, are included with the ETA unit:

1 x ETA Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ETA

1 x Camera (Neck) Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ETA-STRAP

1 x 9 way D type to 9 way D type PC cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ETA-PC99

1 x 9 way D type to 25 way D type Printer cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . ETA-P925

1 x 25 way D type to 25 way D type Port Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . ETA-PS25

1 x Fastcharge Charging Unit (Max. current 1 A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ETA-BC

1 x Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7464

1 x Warranty Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50807

1 x Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ETA-CASE

1 x Certificate of Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89937759

Packing List

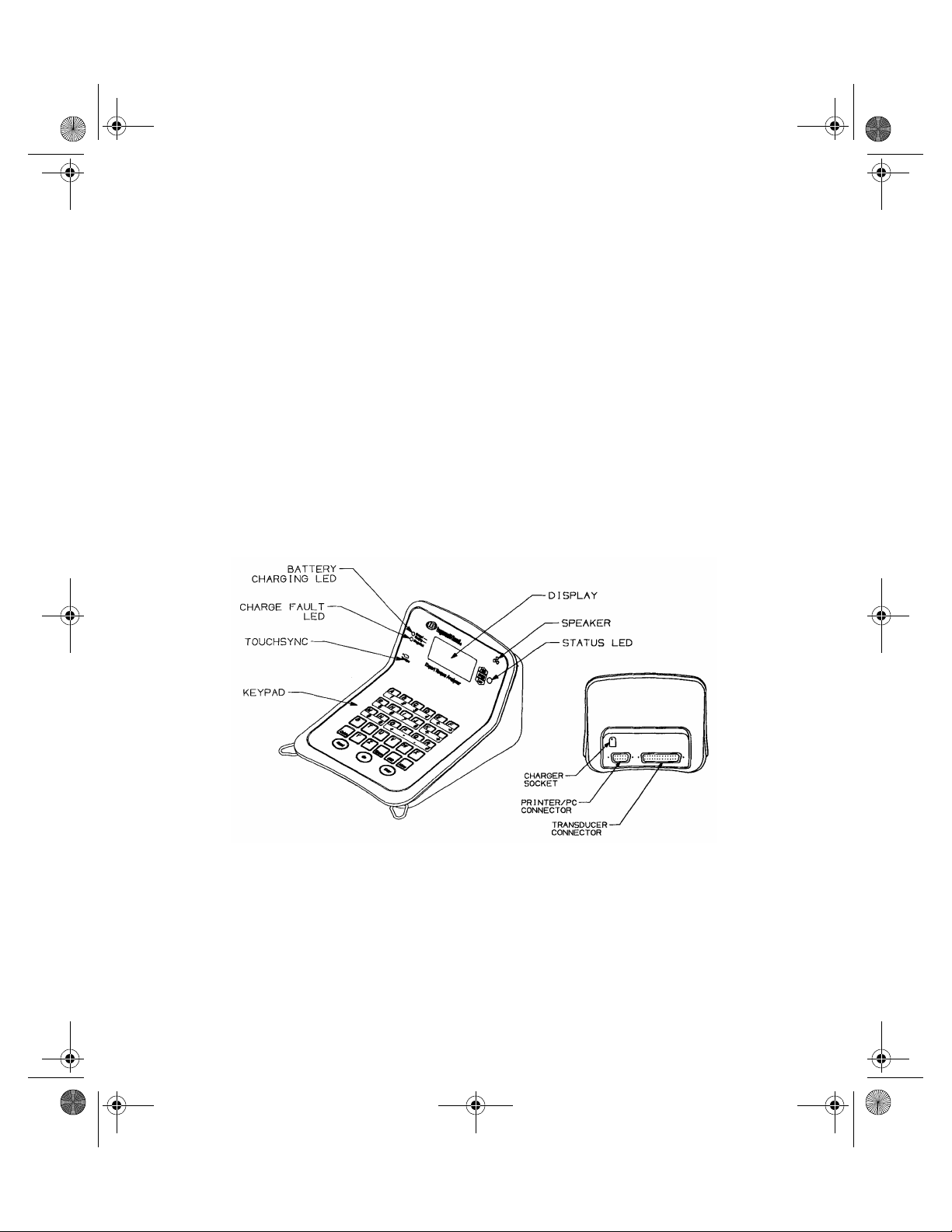

(Dwg. TPA1821)

8

Page 10

7529_eng.fm Page 9 Wednesday, November 12, 2003 8:57 AM

Care and Storage

When not in use the unit should be returned

to the supplied carry case.

This unit is designed for indoor use only

Operating temperature range

5-40 degrees C

Storage temperature range

0-50 degrees C

Battery Charging

The batteries in the ETA unit are shipped

fully charged.

In continuous use with a transducer connected, the batteries have a life of at least 8

hours.

With the unit switched off from a 10% charge

state, the batteries will fully discharge in 2550 days. To prevent the loss of all setup

data, the unit has additional battery backup

for the internal memory.

Automatic Power Off

To conserve battery life in use, the unit will

switch off automatically after a predefined

period. Pressing the on key will restore the

unit to the last display prior to powering off.

The membrane keypad may be wiped clean

with a soft damp cloth. The unit is not waterproofed and spillages should be avoided.

THIS UNIT CONTAINS NO USER SERVICEABLE PARTS. ONLY QUALIFIED

SERVICE PERSONNEL SHOULD

REPLACE OR FIT PARTS.

Fast Charge

The ETA’s should only be recharged with the

supplied ETA-BC (Model MPP3OUS12) Battery Charger. ETA’s, are supplied with internal NiMH (Nickel Metal Hydride) batteries.

These are environmentally friendly batteries

presenting no problems for safe disposal

and are capable of sustaining a rapid

recharge. From fully discharged, the unit will

require a charging period of approximately

2.5 hours.

To charge the batteries following a period of

use, connect the supplied charger to the

charging socket on the back of the unit and

plug the charger into a suitable supply. The

green LED will come on to indicate the

machine is charging and will start to flash

when the unit is fully charged. If the red LED

comes on, this means there is a problem

and usually indicates a faulty battery.

The Fast Charge method gives an increase

in the effective life of the charged batteries.

9

Page 11

7529_eng.fm Page 10 Wednesday, November 12, 2003 8:57 AM

Edit Transducer File

Failure to input proper information may result in inaccurate readings.

The following instructions for “Edit Transducer File” must be followed

before any reading or measurements can be taken.

This section may be skipped if you are using an Ingersoll-Rand TSD,

TRD or Crane UTA Series Transducer.

There are 5 types of transducers and inputs

which the ETA will accept.

1. High Output (H/O). These transducers

have an internal amplifier and give an

output signal level of 1-2 Volts.

2. Industry Standard (IS). These trans-

ducers have no internal amplifier. The

exact span or rated torque will be

marked on the transducer nameplate.

The sensitivity of these transducers is 2

mV/V., they are fitted with a 350 Ohm

bridge.

3. Serial. These are digital type transducers and produce an RS232 signal.

4. Keypad (KPD). This is an optional keypad which connects to the ETA.

5. Keyboard (KEY). Keyboard on ETA.

Use of any of the above 5 types of inputs

requires that settings are made in the transducer file before any measurements can

take place. The procedure for entering settings follows.

For ETA5:

At main menu, press (Configure) then

press (Edit Tx)

Screen will show

2

1

Transducer

B (Current set-up)

Complete set-up

The ‘B’ indicates that this is the ‘B’ file in

memory. It is the first of 8 memories (labelled

B to I) reserved for the saving of transducer

set-ups. Your most used transducer setting

should be stored in this memory.

The remaining memories (C to I) may be

accessed by pressing .

Press

Select input type H/O, I/S, SER, KPD or

KEY using ; press .

Enter

Enter

For ETA2:

At main menu, press (Edit Tx)

1

Depending on type of type selected above,

continue set-up by following the appropriate

section.

10

Page 12

7529_eng.fm Page 11 Wednesday, November 12, 2003 8:57 AM

If you have chosen I/S

Select units of measure - inlb, ftlb etc. using press

Type in transducer span- press

Type in mV/V press

Type in Bridge resistance press

Type in Pulses Per Rev (only for angle type) press

Type in Serial Number press

To set-up another transducer press

Enter

Enter

Enter

Enter

Enter

Enter

MENU

Select another memory (B to I) using the keys and press

To return to the main menu, press

MENU

If you have chosen SER

Select location of decimal point using press

Enter

1

Enter

Select Baud Rate, Data Bits, Stop Bits and Parity in the same manner

To set-up another transducer press

MENU

1

Select another memory (B to I) using the keys and press

To return to main menu press

MENU

11

Enter

Page 13

7529_eng.fm Page 12 Wednesday, November 12, 2003 8:57 AM

If you have selected H/O

Select units of measure- inlb, ftlb, etc. using

Note: High Output devices usually produce an output voltage of approximately 1-2 Volts. This

analogue voltage signal will not be exact and may not be linear. If you are using a device that

has a nominal 1Volt output, we suggest that you multiply the span of your transducer by 2.5 to

determine the new span setting.

Type in your new span; press

Type in Serial Number; press

Screen will indicate ‘End of Set-up’; press to return to main menu

Enter

Enter

MENU

Connect your high output device and select measure mode

(refer to instruction sheet for measure mode only)

Use an independent measuring device to apply a torque to the transducer and check the reading on the independent unit against the reading shown on the ETA. It will be necessary to return

to the ‘Edit Tx’ menu option and adjust the span setting until the two readings agree. You may

have to repeat the above procedure several times until your high output transducer is correctly

calibrated.

If you have selected KPD

Select location of decimal point using then press

Select Parity- Odd, Even or Disabled using then press

To set-up another transducer press

MENU

1

Select another memory (B to I) using the keys and press

Enter

Enter

Enter

To return to main menu press

MENU

12

Page 14

7529_eng.fm Page 13 Wednesday, November 12, 2003 8:57 AM

If you have selected KEY

Select location of decimal point using then press

To set-up another transducer press

MENU

1

Select another memory (B to I) using the keys and press

To return to main menu press

MENU

Enter

Enter

Barcode read input for characteristic

names and comments

It is possible to scan a barcode name in ETA5 at certain prompt lines. The input of a barcode is

allowed at the characteristic name prompt in store characteristic, direct characteristic and edit

characteristic modes. In addition it is also possible to scan a barcode in the comment field in

store characteristic only. Edit characteristic and normal store behave in a slightly different manner to direct characteristic. The ETA5 will accept most barcode reading formats, but not all.

General Operational Method for Scanning Bar Code Data

Connect the Bar Code Reader ETA-BAR to the Printer/PC connector at the rear of the ETA5.

Barcode readings can generally be taken at the prompt to input data (Characteristic name or a

comment) when the flashing cursor is on the screen. This can be on a blank line or following a

line of data (an existing characteristic or a comment). When the cursor is flashing, scan the

code with a barcode reader and observe the screen. If the flashing cursor disappears, the code

has been captured - wait a few seconds for the data to appear in the display. If the flashing cursor remains, re-scan the code until it is accepted.

When the data is displayed, press to continue. From this point, follow the instructions

Enter

as for normal data input.

When entering data via the Bar Code Reader into a comment field, make sure you have

reserved enough characters in the comment field to accept the code. If the number of characters scanned in exceeds the number reserved, the ETA5 will beep and refuse to accept the

data. Refer to the instructions on Configuration for more details.

13

Page 15

7529_eng.fm Page 14 Wednesday, November 12, 2003 8:57 AM

Measure Mode (Up to 200 readings stored)

To start, press

MENU

Press

Press (measure)

2

Plug in transducer; press

On

Enter

select proper transducer using

then press

Enter

If using I/S or H/O type transducers

continue with instructions.

If using SER, KPD or KEY, you are now

ready to take measurements.

Select units of measure using ; press

Select Peak, Track, Impulse or ‘Click Dip’ using ; press

Use Peak for direct drive tools, Track for diagnostics, Impulse for pulse tools, and ‘Click Dip’ for

click wrenches.

Select measurement direction using (Right is clockwise. Left is anti-clockwise);

Enter

Enter

press

Select ‘Cycle end Time’ using ; press (normal is 0.5 sec.)

Select frequency response using ; press

Type in Max torque value; press

Type in Min torque value; press

Enter

Enter

Enter

Enter

Enter

14

Page 16

7529_eng.fm Page 15 Wednesday, November 12, 2003 8:57 AM

Type in threshold value; press

Enter

Note: When selecting a threshold torque value the ETA will ignore any

torque that is below this value. You cannot take another reading until

the applied torque falls below this value.

Type in amount of Dip; press

Select Second Parameter using ; press

Enter

Enter

If the setup and transducer has not been changed since the ETA was last used you are now

ready to take torque measurements.

Pressing after taking a series of readings will result in statistical information being dis-

#

played (Range, mean and standard deviation) for the stored readings.

To return to measure mode, press

If you have selected ‘Click Dip’ type in the amount of ‘Dip’ to be sensed; press

#

Enter

Note: 5% of torque for 0 to 100 Nm and 10% of torque for over 100 Nm

generally provide excellent results.

You are now ready to take torque measurements. When finished press

MENU

Note: When taking readings you can change the set-up parameters by

pressing the up arrow

Changing any of the set parameters will result in the ETA prompting to erase all data.

To erase stored readings, press

To return to setup screens, press

Enter

MENU

Example: You have been measuring in a right hand direction and you want to

switch to left hand.

Press the up arrow twice, change from right hand to left hand. Screen will prompt to erase

all data.

Press to erase all stored readings and return to the measure screen.

Enter

15

Page 17

7529_eng.fm Page 16 Wednesday, November 12, 2003 8:57 AM

Printing of stored readings from measure mode

Pressing from the measure mode will result in all stored readings being printed to an

attached printer or computer.

P

Note: Transducer needs to be connected to ETA.

Measure Mode Circle-Store Option

Circle-Store is a function to increase the number of stored readings to extend beyond the normal maximum of 200 readings possible in measure mode. With the circle-store option selected,

readings will be accepted beyond the 200 limit but the first readings taken will be lost. Effectively

the last 200 readings taken will be stored but the user is not limited to taking only 200 readings.

To select this option:

From main menu

Press then press (Misc’)

Press then press (Software Reset)

Press the 6 times to access the Circle-store menu

Select option 2 ‘Circle-store On’ using ; press

Press Screen will prompt: “End of setup”

Press to return to main menu

MENU

MENU MENU

6

6

Enter

16

Page 18

7529_eng.fm Page 17 Wednesday, November 12, 2003 8:57 AM

Direct Measure Mode - ETA5 ONLY

(Ingersoll-Rand TRD, TSD or

Crane UTA Type Transducers)

Direct measure mode allows an operator to connect different transducers which may have different spans and an angle output, and can switch between them using an external T switch. This is

a display only function and readings are not stored or printed out.

To start, press

ON

press

press (Direct)

press (Direct Measure)

press (Setup)

select units of measure using ; press

select peak, track, Impulse or ‘Click Dip’ using ; press

MENU

4

1

1

Enter

Enter

select measurement direction using (Right is clockwise. Left is anti-clockwise);

press

select ‘Cycle end Time’ using ; press

select frequency response using ; press

type in the Threshold Percent (mx 50.0; mn 0.0), and press

type in amount of Click (mx 100.0 Nm; mn 0.0 Nm), and press

Enter

Enter

Enter

Enter

Enter

select ‘Second Parameter’ using ; press

Screen shows “End of Setup”, press to exit

MENU MENU

press to return to main menu

MENU

17

Enter

Page 19

7529_eng.fm Page 18 Wednesday, November 12, 2003 8:57 AM

The READ option allows you to read the torque from a connected transducer.

From the main menu, press (Direct)

press (Direct Measure)

press (Read)

If no transducer is connected, display will prompt: “Insert Tx” (transducer)

connect transducer and press

Screen will show the span of the connected transducer and the torque measured in units

selected at setup. The display will show the last reading taken until the next torque input

exceeds the threshold level set.

Note: If password protection has been set on Direct measure, then exit is by

password only. A correct password returns you to the setup read submenu. Entering three incorrect passwords will force the user back

into read mode. See password protection later in this book.

4

1

2

Enter

18

Page 20

7529_eng.fm Page 19 Wednesday, November 12, 2003 8:57 AM

To set up a Characteristic - ETA5 ONLY

To set up a job

To start, press

press

ON

MENU

plug in transducer

press (Configure)

press (Edit Char)

Type in Job Name ______________________ , press

1

1

Enter

Alternatively, when the cursor is flashing, you may connect a Bar Code Reader to the Printer/PC

connector on the back of the ETA5 and scan the information from a barcode. Scan across the

label (from left or right) and watch the display. If the flashing cursor disappears, the reading has

been captured; wait a few seconds for the reading to be displayed. If not, re-scan until the data

is accepted.

When the information is displayed on the screen, press

Type in number of samples __________________ , press

Type in number of subgroups ________________ , press

Select transducer ID using , press

Enter

Enter

Enter

Enter

Select units of measure using , press

Enter

Select ‘Peak’, ‘Impulse’, or ‘Click’ using ; then press

Select measurement direction using ; then press

Select cycle end time using ; then press

19

Enter

Enter

Enter

Page 21

7529_eng.fm Page 20 Wednesday, November 12, 2003 8:57 AM

Select Frequency Response using ; then press

Enter

Note: No prompt will appear for frequency response if this value is set as a

default during a software reset.

Type in maximum torque specification __________ , then press

Type in minimum torque specification ___________ , then press

Type in threshold torque value ________________ , then press

Select ‘Second Parameter’ using , press

Enter

Enter

Enter

Enter

If you have selected ‘Click Dip’, type in amount of ‘Dip’ to be sensed, press

Note: 5% of torque value for 0 to 100 Nm and 10% of torque value for over

100 Nm generally provide excellent results.

Type in number of characters to reserve for subgroup comment, then press

To return to main menu, press

MENU MENU

Note: Repeat above steps for each additional job or characteristic. If you

wish to establish a route or ‘ROUND’, enter all of your characteristics

or jobs now.

Enter

Enter

20

Page 22

7529_eng.fm Page 21 Wednesday, November 12, 2003 8:57 AM

Direct Characteristic Mode - ETA5 ONLY

Direct characteristic mode is a quick entry method of using a pre-set characteristic and can be

used directly or stored for setting up torque measuring equipment. The characteristics used are

taken from the edit characteristic function in ETA5.

At main menu, press (Direct)

press (Direct Char)

select storage option by pressing (Do not store), or (Store)

type in the characteristic name and press . Use the and keys to scroll

through the available characteristics and press

4

2

1 2

Enter

Enter

Alternatively, when the cursor is flashing, you may connect a Bar Code Reader to the Printer/PC

connector on the back of the ETA5 and scan the information from a barcode. Scan across the

label (from left or right) and watch the display. If the flashing cursor disappears, the reading has

been captured; wait a few seconds for the reading to be displayed. If not, re-scan until the data

is accepted. If a further reading needs to be taken, press to clear the data and allow a

Reset

further scan to be taken or data to be keyed in.

When the information is displayed on the screen, press

Display now shows the status of the characteristic. Press

Enter

Enter

Display now prompts “Insert TX” (transducer)

Connect the transducer to the ETA5 and press

Enter

Torque measurement can now be taken and will be overwritten or stored depending on the

selection made previously. At the end of the subgroup of readings, the display will return to characteristic name entry line and the LEDs on the ETA5 will flash to show the subgroup status:

RED LED = One or more readings out of the specified range

GREEN LED = All readings within the specified range

21

Page 23

7529_eng.fm Page 22 Wednesday, November 12, 2003 8:57 AM

Press to accept the subgroup and prepare to accept readings for the next subgroup.

Enter

When all the subgroups are full, the display will return to characteristic name entry line

(pressing will also do this).

Enter

Note: If password protection has been set on Direct measure, then exit is by

password only. A correct password returns you the Store/Not store

sub-menu. Entering three incorrrect passwords will keep the user at

the current display. See password protection later in this book.

If Store mode has been used, results can be printed or analyzed using the appropriate ETA

Functions.

22

Page 24

7529_eng.fm Page 23 Wednesday, November 12, 2003 8:57 AM

To Store Data (single characteristic) - ETA5 ONLY

At main menu, press (Store)

press (Single Characteristic)

press

3

1

Enter

A job name will appear on screen. If more than one job has been set up in the ETA5, you can

scroll through the jobs in sequence using

You can also find your job by typing in the name after you press , then pressing

Alternatively, after pressing , when the cursor is flashing, you may connect a Bar Code

1

1

Enter

Reader to the Printer/PC connector on the back of the ETA5 and scan the information from a

barcode. Scan across the label (from left or right) and watch the display. If the flashing cursor

disappears, the reading has been captured; wait a few seconds for the reading to be displayed.

If not, re-scan until the data is accepted.

If a further reading needs to be taken, press to clear the data and allow a further scan

Reset

to be taken or data to be keyed in.

When correct job appears on screen, press

Enter

If you are using an Ingersoll-Rand TRD, TSD or Crane UTA type transducer and it is already

plugged in, you are now ready to take readings. The screen will show transducer size and Sub 1

Sam 1

If you are using any other type of transducer or it is not yet plugged in, you will be prompted to

insert transducer and select transducer type required.

Plug in correct transducer and press

Enter

When you have taken all readings, the screen will show that all torque collection is complete.

To return to the main menu, press

MENU MENU

Note: When each reading is taken you will get an audible/visual signal.

23

Page 25

7529_eng.fm Page 24 Wednesday, November 12, 2003 8:57 AM

1 beep/Amber LED = Torque value or Angle/Pulse count is low (if used)

2 beeps/Green LED = Torque value or Angle/Pulse count is OK (if used)

3 beeps/Red LED = Torque value or Angle/Pulse count is high (if used)

The final reading of a subgroup will be indicated by an extended beep.

If you make a mistake when taking a reading it can be erased by pressing .

If you continue to press you can erase all readings within the current subgroup. It is not

possible to erase readings taken in a previous subgroup.

No readings will be stored if the torque value is below the threshold value previously set.

If the characteristic has been configured with Subgroup comment size set to a value other than

0, then pressing will allow a subgroup comment to be entered.

Alternatively, when the cursor is flashing, you may connect a Bar Code Reader to the Printer/PC

connector on the back of the ETA5 and scan the information from a barcode. Scan across the

label (from left or right), and watch the display. If the flashing cursor disappears, the reading has

been captured; wait a few seconds for the reading to be displayed. If not, re-scan until the data

is accepted. If a further reading needs to be taken, press to clear the data and allow a

further scan to be taken or data to be keyed in.

When the information is displayed on the screen, press

Pressing gives analysis of last completed subgroup. (Press again to continue.)

Z

Note: If the bar code data exceeds the number of characters reserved for

# #

Reset

Reset

the comment, the ETA5 will beep and show an error message. The

data will not be accepted.

Enter

Reset

Pressing gives analysis of current subgroup, up to current reading. (Press again to

continue.)

. .

24

Page 26

7529_eng.fm Page 25 Wednesday, November 12, 2003 8:57 AM

To set up a Round - ETA5 ONLY

To set a sequence of jobs to be performed in a set order, the method detailed below should be

used.

Note: In order to set up a Round, there must be at least 2 Characteristics set

up in the ETA5.

At main menu, press (Configure)

press (Round)

press

Type in the name of your round and press

1

4

Enter

Enter

Type in the number of characteristics (jobs) that are to be included in the round and

press

Enter

Select Vertical, Horizontal or Vert+Prompt sampling using and press

Note: If you choose Vertical sampling, the ETA5 will automatically switch

between jobs at the end of each subgroup. If you select Horizontal

sampling, the switch will be made after each individual reading.

Vert+Prompt will ask you to insert a transducer at the start of each

subgroup.

Screen will show “Characteristic No 1 of ?“

Select which job you want to be the first job using and press

Enter

Screen will show “Characteristic No 2 of ?”

Select which job you want to be the second job using and press

Enter

Enter

Continue selecting jobs in this way until all jobs to be included have been selected.

Screen will now show “End of Set-up”

To return to the main menu, press

MENU MENU

25

Page 27

7529_eng.fm Page 26 Wednesday, November 12, 2003 8:57 AM

To Store Data by Round - ETA5 ONLY

At main menu, press (Store)

Press (Round)

3

2

Screen will show “Select Round No”

Select round number using and press

Enter

The maximum number of rounds that can be stored is 25.

If you are using an Ingersoll-Rand TRD, TSD or Crane UTA type transducer and it is already

plugged in, you are now ready to take readings. The job that appears on screen will be the job

that you selected to be first when you set up the round.

If you are using any other type of transducer or it is not yet plugged in, you will be prompted to

insert transducer and select transducer to be used. Plug in the transducer and press

Enter

When a complete subgroup of readings has been taken for all jobs in the round, screen will

show “Next Round Cycle “. To continue taking readings, press (this message will be

repeated at the end of each complete subgroup Sub1, Sub2, etc.)

When you have finished taking all readings, pressing will result in a message that the

round is complete. Press .

To return to the main menu, press

MENU

MENU MENU

Note: You can erase the last reading taken by pressing .

Reset

If you have selected Horizontal sampling and the ETA5 has

already switched to the next job, it will switch back when you

press .

Reset

It is not possible to erase any readings other than the last one

taken in Horizontal sampling mode.

26

Page 28

7529_eng.fm Page 27 Wednesday, November 12, 2003 8:57 AM

If the characteristic has been configured with Subgroup comment size set to a value other

than 0:

Pressing will allow a subgroup comment to be entered.

Pressing gives analysis of last completed subgroup. (Press again to continue.)

Pressing gives analysis up to current subgroup. (Press again to continue.)

Z

# #

. .

To set up a Master Round - ETA5 ONLY

To set a sequence of Rounds to be performed in a set order, the method detailed below should

be used.

Note: In order to set up Master Round, there must be at least 2 rounds set

up in ETA5.

At main menu, press (Configure)

press (Edit Master Round)

press

Type in the number of “rounds” to be included and press

1

5

Enter

Enter

Select first “round” to be included using and press

Continue selecting rounds to be included using and press

Note: When all rounds have been selected, screen will show “End of

Set-up”

To return to the main menu, press

MENU MENU

Enter

27

Enter

Page 29

7529_eng.fm Page 28 Wednesday, November 12, 2003 8:57 AM

To Store Data by Master Round

At main menu, press (Store)

Press (Master Round)

If you are using an Ingersoll-Rand TRD, TSD or Crane UTA type transducer and it is already

plugged in, you are now ready to take readings. The job that appears on screen will be the job

that you selected to be first when you set up the master round.

If you are using any other type of transducer or it is not yet plugged in, you will be prompted to

insert transducer and select transducer to be used. Plug in transducer and press

To return to the main menu, press

Note: You can erase the last reading taken by pressing . If you have

If the characteristic has been configured with Subgroup comment size set to a value other

than 0:

Pressing will allow a subgroup comment to be entered.

Z

3

3

Enter

MENU MENU

Reset

selected Horizontal sampling and the ETA5 has already switched to

the next job, it will switch back when you press .

It is not possible to erase any readings other than the last one taken

in Horizontal sampling mode.

Reset

Pressing gives analysis of last completed subgroup. (Press again to

continue.)

Pressing gives analysis up to current subgroup. (Press again to continue.)

# #

. .

28

Page 30

7529_eng.fm Page 29 Wednesday, November 12, 2003 8:57 AM

To Display Recorded Data on ETA2

From main menu, press (Display/Analyze)

Screen will show job name and Specs; press

Screen will now show x-bar, R, and sigma for total readings

From any Subgroup display, press

Screen will show the Date and Time the readings for that subgroup were taken.

Press , screen will show subgroup comment.

Press again to see the individual readings displayed in groups of four readings per screen.

9

To Display Recorded Data on ETA5

From main menu, press (Display/Analyze)

Press to display the last recorded Characteristic

Select the job that you want to see using and press

Enter

9

Enter

Screen will show job name and Specs; press

Screen will now show x-bar, R, and sigma for Sub1; press

Screen will now show same information for Sub2

You can use to go back and forth between subgroups as required

From any Subgroup display, press

Screen will show the Date and Time the readings for that subgroup were taken.

Press , screen will show subgroup comment.

29

Page 31

7529_eng.fm Page 30 Wednesday, November 12, 2003 8:57 AM

Press again to see the individual readings displayed in groups of four readings per screen.

Note: By using the four arrow keys it is possible to move back and forth

through all of the subgroups and individual readings.

To view another job, press and repeat above procedure.

MENU

To View Cp and Cpk

At the job name/spec screen press , screen will show the Cp and Cpk and the number of

samples used in the calculations.

Press , screen will now show x-bar, R and sigma based on all of the data (all subgroups

calculated together).

The number of samples that were NOK will also be displayed expressed as a percentage.

Press , screen will show the highest and lowest torque recorded and the number of

readings that were above the maximum torque value and minimum torque value.

To return to the main menu, press

For more information on Cp, Cpk and CAM, refer to the glossary.

MENU

30

Page 32

7529_eng.fm Page 31 Wednesday, November 12, 2003 8:57 AM

French Cp and Cpk

It is possible to view the French Cpk/CAM calculations as an alternative to the standard Cp

and Cpk.

Readings must be a minimum of 30 samples.

To set this function:

From main menu

Press then press (Misc’)

Press then press (Software reset)

Press 5 times to access the Cpk Calculation screen

Use the and arrow keys to access option 2 ‘French Cpk/CAM’ and press

MENU

Press to confirm, screen will prompt “End of setup”

MENU

Press to accept and exit, or to edit

MENU

Press to return to main menu

Returning to Normal Cpk calculations is done as above, selecting option 1 ‘Normal

Cpk/no CAM’

For more information on Cp, Cpk and CAM, please refer to the glossary.

6

6

To Erase Stored Data

To Erase Readings Stored in Measure Mode:

Enter

From the main menu, press

ETA will erase all readings taken in measure mode.

Y

31

Page 33

7529_eng.fm Page 32 Wednesday, November 12, 2003 8:57 AM

To Erase Stored Data and Setups on ETA5

To Erase Characteristic Setup:

At main menu, press (Configure)

press (Erase)

press (Char’ Set-up)

Select Characteristic name by pressing and select Characteristic required

1

3

1

Enter

by pressing

Press , screen will display the Characteristic number and prompt “Erase Set-up Data”

Press to erase the characteristic data or to return to Erase menu

If was pressed, display shows “Erased OK”

Press to erase more data or press to return to main menu

Enter

Enter Reset

Enter

MENU MENU MENU

To Erase Characteristic Data:

At main menu, press (Configure)

press (Erase)

press (Char’ Data)

1

3

2

Select Characteristic name by pressing and select Characteristic required by

Enter

pressing

Press , screen will display the Characteristic number and prompt “Erase data

Enter

only”

Press to erase the characteristic data or to return to Erase menu

If was pressed, display shows “Erased OK”

Press to erase more data or press to return to main menu

Enter Reset

Enter

MENU MENU MENU

32

Page 34

7529_eng.fm Page 33 Wednesday, November 12, 2003 8:57 AM

To Erase Round Data:

At main menu, press (Configure)

press (Erase)

press (Round Data)

1

3

3

Select required round by pressing , press

To erase data by round, press

To exit without erasing round data, press

To return to main menu, press

Enter

MENU

MENU MENU MENU

To Erase Round Setup Information:

At main menu, press (Configure)

Then press (Edit Round)

1

4

Select required round by pressing , press

Display shows “Round Label”, press

Reset

Enter

Enter

Round label is cleared from display. Press

Enter

Display will prompt “Erase Rnd Set-up”

To erase round setup, press ; display will then show “ROUND ERASED”

Or, press to return to Configure Menu

Reset

To return to main menu, press

Enter

MENU

33

Page 35

7529_eng.fm Page 34 Wednesday, November 12, 2003 8:57 AM

To print readings taken in measure mode:

Connect ETA to printer or computer and switch the device ON

On ETA:

Printing

Press

Press

Press then press (Print)

Press then press (Print Measure)

On

MENU

5

8

ETA will print details of stored readings taken in measure mode (with date/time stamp)

A sample printout can be found on page 45.

To return to main menu, press

MENU

To print details of Setup or Analysis of Data from ETA5

To print settings and readings taken by characteristic:

Connect ETA5 to printer or computer and switch the device ON

Ensure ETA5 is configured to printer by referring to “Configure Printer Port” section

On ETA5:

Press

Press

Press , then press (Print)

Press (Print Char’)

On

MENU

5

1

34

Page 36

7529_eng.fm Page 35 Wednesday, November 12, 2003 8:57 AM

Select Characteristic name by pressing and select Characteristic required by

Enter

pressing

To start printing, press

Enter

ETA5 will print details of setup and stored reading by characteristic name.

To print settings and data analysis of readings taken by characteristic:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press (Print/Analyze Char’)

On

MENU

5

2

Select Characteristic name by pressing and select Characteristic required by

Enter

pressing

To start printing, press

Enter

ETA5 will print details of setup and analysis of stored reading by characteristic name.

To print details of readings by round:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

On

MENU

35

Page 37

7529_eng.fm Page 36 Wednesday, November 12, 2003 8:57 AM

Press , then press (Print)

Press , then press (Print Round)

5

3

Select round by using

To start printing, press

Enter

ETA5 will print details of setup and stored reading by round name.

To print details of setup and analysis of readings by round:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press , then press (Print/Analyze Round)

On

MENU

5

4

Select round by using

To start printing, press

Enter

ETA5 will print details of setup and analysis of stored reading by round name.

To print details of all characteristic setups:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

On

MENU

36

Page 38

7529_eng.fm Page 37 Wednesday, November 12, 2003 8:57 AM

Press , then press (Print)

Press , then press (Print All Char¡¦s Setup)

5

5

ETA5 will print details of all characteristic setups which are stored.

To print details of a particular round setup:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press , then press (Print Round Setup)

On

MENU

5

6

Select round by using

To start printing, press

Enter

ETA5 will print details of all round setups which are stored.

To print readings taken by characteristic:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press , then press (Print Char’ Readings)

Select Characteristic name by pressing and select Characteristic required by

On

MENU

5

7

Enter

pressing

37

Page 39

7529_eng.fm Page 38 Wednesday, November 12, 2003 8:57 AM

To start printing, press

Enter

ETA5 will print details of readings taken by characteristic.

To print readings taken in measure mode:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press , then press (Print Measure)

On

MENU

5

8

ETA5 will print details of stored readings taken in measure mode (with date/time stamp)

A sample printout can be found on page 45.

To return to main menu, press

MENU

To print setup and readings for all used characteristics containing readings:

Connect ETA5 to printer or computer and switch the device ON

On ETA5:

Press

Press

Press , then press (Print)

Press , then press (Print All Used Chars’)

On

MENU

5

9

ETA5 will print details of stored characteristic setups containing readings.

A sample printout can be found on page 46.

To return to main menu, press

MENU

38

Page 40

7529_eng.fm Page 39 Wednesday, November 12, 2003 8:57 AM

Printing Data to PC

Most data that can be sent to a printer may also be sent to a PC. Follow the same instructions

for printing. Connect the cable to the PC using Com 1. Use Hyper Terminal (found under Accessories) or other communication programs.

Note: Be sure communication protocols are set the same on the PC

and ETA.

To Set Date and Time

From main menu:

Press then press (Misc)

Press (Set Date/Time)

Select date format using

Enter date and time and press

To return to main menu, press

1

6

Enter

MENU MENU

39

Page 41

7529_eng.fm Page 40 Wednesday, November 12, 2003 8:57 AM

To Set Power Off and Backlight Time Delays

From main menu:

Press then press (Misc)

Press (Select Power Off/Backlight Time Delays)

2

6

Select Power Off time delay using Press

Select Backlight Delay using Press

To return to main menu press

MENU MENU

Enter

To Configure Printer Port

From main menu:

Press then press (Misc)

Press then press (Printer port)

Select Baud Rate using then press

Select number of data bits using then press

6

3

Enter

Enter

Enter

Select number of Stop Bits using then press

Select Parity using then press

To return to main menu press

MENU MENU

Enter

40

Enter

Page 42

7529_eng.fm Page 41 Wednesday, November 12, 2003 8:57 AM

To Display Software Version Number

From main menu:

Press then press (Misc)

Press then press (Version #)

To return to main menu, press

6

4

MENU MENU

To Set Password Protection

From main menu:

Press then press (Misc)

Press then press (Password)

Screen will prompt “Enter new Password”

Type in the password (4 characters) and press

Screen will prompt “confirm password”

Press to accept or to reject

Select desired option using

Options for protection are:

Enter Reset

1- Power up

2- Configure

3- Direct Measure

4- Direct Characteristic

5- Software Reset

6- Date and Time

6

5

Enter

Press to protect your selected option or to exit

#

Note: When an option is password protected, ‘ ’ appears in the top right

of the display window.

Pressing will remove the protection.

#

MENU

41

#

Page 43

7529_eng.fm Page 42 Wednesday, November 12, 2003 8:57 AM

MENU

Press to exit

Display now reads “End of setup”

To return to main menu press or press to edit password protection

MENU

The remaining options can be password protected in the same manner.

To Clear Password Protection

From main menu:

Press then press (Misc)

Press then press (Password)

Screen will prompt “Password” - - - - enter the existing password (4 characters) and

press

Enter

Screen will prompt “Confirm Password” and display the existing password

Press to confirm or press to clear the password protection

Enter Reset

Screen will prompt “Enter new Password”

Press to clear the password (keying in 4 characters before pressing

Enter Enter

will result in a new password being created)

6

5

Screen will say “Confirm password”

Press to confirm and password is cleared

Enter

Notes on Password Protection:

Be aware of the implications of password protection. Always keep a note of the chosen

password somewhere safe. As there is no function to enable an existing password to be

removed without it first being entered, it may be advisable for the person who is ultimately

responsible for the ETA to initially set a password and issue it only to personnel who need the

information. This will prevent an unknown password being entered, accidentally or deliberately,

without anyone else’s knowledge. If an unknown password is encountered, please contact

Ingersoll-Rand for advice.

42

Page 44

7529_eng.fm Page 43 Wednesday, November 12, 2003 8:57 AM

To Perform Software Reset

CAUTION: Use of this function will result in the loss of all stored data. Following this

procedure will return the ETA to its factory default state. This feature should

only be used when it is desired to clear all settings from the ETA.

From main menu:

Press then press (Misc)

Press then press (S/W Reset)

6

6

Press the key 8 times to access the Software Reset screen

Screen will display “Erase all data and set mode?”

To carry out S/W reset, press

To exit without performing S/W reset, press

Enter

MENU

Screen will display “ERASING ALL CHARACTERISTICS ROUNDS AND MASTER ROUNDS”

- wait a moment for display to change

Select Subgroup mode using and press screen will display “End of setup”

To return to main menu, press

MENU MENU

Enter

There are a number of other parameters which are set from the Software Reset Menu, some of

which are detailed elsewhere in this manual.

Pressing after making a selection will take the user on to the next screen.

Pressing will give the user the option to exit to the Misc menu by pressing or

Enter

MENU MENU

continuing to edit by pressing .

Screens can be skipped using the and keys.

43

Page 45

7529_eng.fm Page 44 Wednesday, November 12, 2003 8:57 AM

Settings in the order they appear when the Software Reset Menu is accessed.

Cm max samples - type in the required figure

Cm min samples - type in the required figure

Language - select using

Autoprint mode - select using

Capability label - select using

Cpk Calculation - select using

Circle-store (On/Off) - select using

Shift key mode - select using

To Communicate with a PC

using PC Comms Software

Connect ETA5 to PC via cable provided

On PC, start PC Comms

On ETA5:

Press

Press

Press , then press

You can now setup and view all information/data via the PC

Note: This optional PC software is used primarily to write and store

On

MENU

8

characteristics and rounds on the PC. The format of the data

stored on the PC is of little use to the computer operator without

further processing.

44

Page 46

7529_eng.fm Page 45 Wednesday, November 12, 2003 8:57 AM

Example Printout of Readings taken in Measure Mode

MEASURE-Peak Capability Results Torque

----------------------------------- ---------------------------

No of Samples 200 Based on last 15. samples

Transducer C I/S 75.00 Nm /x 6.96 Nm

Serial Number: 99999 Range 8.30 Nm

Measurement Dir Right Sigma 2.210

Max Torque Value 20.00 Nm Cp 0.754

Min Torque Value 10.00 Nm Cpk - 0.458

Thrshld Torq Val 2.00 Nm Max found 12.65 Nm

Freq response 1676 Hz Min found 4.35 Nm

Cycle end time 0.1 Sec Readings above max 0.

Date Time Torque

1 07/01/95 12:38:32 7.21 LO

2 07/01/95 12:38:35 4.87 LO

3 07/01/95 12:38:38 6.65 LO

4 07/01/95 12:38:40 6.56 LO

5 07/01/95 12:38:42 7.45 LO

6 07/01/95 12:38:45 5.76 LO

7 07/01/95 12:38:47 7.07 LO

8 07/01/95 12:38:49 12.65

9 07/01/95 12:38:52 9.37 LO

10 07/01/95 12:38:54 5.29 LO

11 07/01/95 12:38:56 6.09 LO

12 07/01/95 12:38:59 4.35 LO

13 07/01/95 12:39:01 5.90 LO

14 07/01/95 12:39:04 5.25 LO

15 07/01/95 12:39:06 10.03

Readings below min 13.

Percentage not OK 86.66 %

45

Page 47

7529_eng.fm Page 46 Wednesday, November 12, 2003 8:57 AM

Printout of Setup and Readings taken by Characteristic

Ingersoll-Rand ETA5 08/01/01 11:59:44

Characteristic WHEELNUT Capability Results Torque

----------------------------------- ---------------------------

No of Samples 4 Based on last 8. samples

No of Sub-groups 2

Transducer A TRD 75.00 Nm /x 13.93 Nm

Serial Number: 99999 Range 17.21 Nm

Measurement Dir Right Sigma 5.936

Max Torque Value 14.00 Nm Cp 0.224

Min Torque Value 6.00 Nm Cpk 0.003

Thrshld Torq Val 2.00 Nm Max found 22.17 Nm

Freq response 1676 Hz Min found 4.96 Nm

Cycle end time 0.1 Sec Readings above max 4.

Readings below min 1.

Percentage not OK 62.50 %

Sg-sp Date Time Torque

1 1 08/01/01 11:31:16 4.96 LO

12 12.28

13 9.79

14 8.81

/x 8.96

Range 7.32

Sigma 3.040

2 1 08/01/01 11:31:46 15.70 HI

22 18.93 HI

23 21.17 HI

24 18.84 HI

/x 18.91

Range 6.47

Sigma 2.641

46

Page 48

7529_eng.fm Page 47 Wednesday, November 12, 2003 8:57 AM

Printout of Analysis by Characteristic

Ingersoll-Rand ETA5 08/01/01 11:45:36

Characteristic WHEELNUT Capability Results Torque

----------------------------------- ---------------------------

No of Samples 4 Based on last 8. samples

No of Sub-groups 2

Transducer A TRD 75.00 Nm /x 13.93 Nm

Serial Number: 99999 Range 17.21 Nm

Measurement Dir Right Sigma 5.936

Max Torque Value 14.00 Nm Cp 0.224

Min Torque Value 6.00 Nm Cpk 0.003

Thrshld Torq Val 2.00 Nm Max found 22.17 Nm

Freq response 1676 Hz Min found 4.96 Nm

Cycle end time 0.1 Sec Readings above max 4.

Readings below min 1.

Percentage not OK 62.50 %

Sg-sp Date Time Torque

1 08/01/01 11:31:16 /x 8.96

Range 7.32

Sigma 3.040

2 08/01/01 11:31:46 /x 18.91

Range 6.47

Sigma 2.641

47

Page 49

7529_eng.fm Page 48 Wednesday, November 12, 2003 8:57 AM

Printout of details of all Characteristic setups

Ingersoll-Rand ETA5 08/02/01 14:36:22

----------------------------------- ---------------------------

Name smpl sgrp transducer direc max min thr units

WHEELNUTS 16 3 A TRD 11.29 Nm Right 8. 6. 2. Nm

EX MANIFOLD 6 3 A TRD 11.29 Nm Right 10. 6. 3. Nm

DOORLOCK 3 3 A TRD 11.29 Nm Right 9. 7. 3. Nm

48

Page 50

7529_eng.fm Page 49 Wednesday, November 12, 2003 8:57 AM

Printout of Round setup

Ingersoll-Rand ETA5 08/02/01 14:51:26

----------------------------------- ---------------------------

Round 1

Round Label CAVALIER Complete Setup

Sampling Vertical

No of charact s 3

Characteristic 1 DOORLOCK Complete Setup

Characteristic 2 WHEELNUTS All Data Stored

Characteristic 3 EX MANIFOLD Complete Setup

49

Page 51

7529_eng.fm Page 50 Wednesday, November 12, 2003 8:57 AM

Printout of Readings taken by Characteristic

5.90

6.28

7.39

2.90

2.87

3.46

3.62

3.19

3.23

3.07

3.78

4.03

4.01

2.93

3.07

2.70

4.51

3.63

4.99

4.06

4.25

7.53

6.10

2.90

4.71

5.64

5.62

7.78

5.19

5.72

9.74

5.16

8.22

6.27

5.42

5.38

6.22

5.84

7.70

7.01

4.98

5.71

5.52

7.40

5.98

5.11

8.33

5.93

10.0

9.0

10.0

5.0

4.0

5.0

5.0

6.0

3.0

5.0

4.0

5.0

6.0

4.0

3.0

3.0

4.0

4.0

4.0

2.0

4.0

4.0

4.0

3.0

3.0

4.0

3.0

3.0

2.0

4.0

5.0

5.0

1.0

4.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

4.0

50

Page 52

7529_eng.fm Page 51 Wednesday, November 12, 2003 8:57 AM

Rotary and Stationary Joint Kits

Introduction

The joint kits are designed as a convenient, repeatable, variable stiffness joint for assessing the

performance of torque tools. They can be used with the Ingersoll-Rand stationary (static) or

rotary transducers.

Each kit may be assembled in different ways to vary the stiffness of the joint. Reference Table 1,

to select from the available options. Care should be taken to ensure that the maximum torque

for the joint is not exceeded. Please note that the joint kit is not designed to provide an exact

joint stiffness and that the rates shown in Table 1 are given as rough guide only.

Joint Assessment

The first task is to choose the stiffness of the joint that the tool will be used to assemble. This is

best done with a torque wrench on an actual production part. If available an angle measurement

protractor may be used, but this is not essential. Tighten the fastener until it is snug, note the

torque Ts in Nm (or lbft). Tighten to the required target torque Tf Nm (or lbft), and note the angle

of rotation E in degrees. The required joint stiffness may now be calculated. The resulting units

are degrees per Nm (or degrees per lbft).

E / (Tf-Ts) Ts = Snug Torque

Tf = Target Torque

E = Angle

It should be noted that for packaging convenience Joint Kits will be delivered assembled with full

stacks of belleville washers. The spacers will be bagged separately. The Joint Kits DO NOT

represent a usable joint without adjustment to the required stiffness. A Pictorial guide to the

description of components is shown in Figure 2. Table 2 shows the parts available for each

model.

Joint Assembly

Having selected the required joint stiffness from Table 1, count out the number of Belleville

washers required for the first and second stacks. Grease each washer and assemble the first

stack around the bolt, such that the internal diameter rests against the shoulder of the bolt.

Invert the second stack such that the outside diameters of the last and first washers in the two

stacks touch. If only one stack is to be fitted, it should be mounted such that the external

diameter rests against the bolt shoulder. Select and fit the spacer required to complete the joint.

After greasing the bearing surface, slide the assembly into the external sleeve, fit the end collar

and secure by applying the retaining clip.

51

Page 53

7529_eng.fm Page 52 Wednesday, November 12, 2003 8:57 AM

The base plate or transducer, depending on model, should be mounted onto a rigid surface.

See Figure 1 for bolt hole pattern. Place the bolt assembly just completed into the shroud and

then onto the transducer or base plate. The last step is to apply the steel washer onto the bolt

before applying the nut.

IMPORTANT - Grease the threads and fit the nut.

The joint is now ready for use. Eventually the bolt and nut threads will wear and will need to be

replaced. IR recommends replacing worn joints with the appropriate bolt kit that matches your

joint kit model: JKS30-BKIT, JKS150-BKIT, JKS300-BKIT or JKS1000-BKIT.

- Ensure that the threads are kept clean and lubricated.

Nominal Joint Stiffnesses

Joint

Kit

Deg/Nm Deg/lbin Nm lbin

1/4” 50 6 5.65 50 3 3 17.1

3/8” 6 8 67.8 50 5 5 15.5

1/2” 3 4 135.6 100 5 5 19.5

3/4” 0.88 1.2 460 340 5 3 39.5

Rate Max Torque 1st

Stack

30 3.4 13.5 120 6 6 11.5

20 2.2 21.5 190 12 12 -

8 0.9 28.25 250 24 - -

3.5 0.4 28.25 250 - - 11.5+12.3

Deg/lbft lbft

4 5.5 120 90 9 9 -

2 2.5 100 73.75 16 - 5

1 1.3 100 73.75 - - 5+18.6+15.5

2 2.7 220 160 9 9 -

1.1 1.5 271 200 9 - 23.3

0.4 0.55 271 200 - - 3.9+23.3+19.5

0.55 0.7 830 610 10 5 -

0.35 0.5 775 570 10 - 41.3

0.11 0.15 1017 750 - - 39.2+41.3

2nd

Stack

Spacer(s)

mm

Ta ble 1

Failure to mount the base plate or transducer, depending on model,

could result in injury.

52

Page 54

7529_eng.fm Page 53 Wednesday, November 12, 2003 8:57 AM

Bolt Hole Pattern, in mm.

Figure 1.

(Dwg. TPA1919)

Figure 2.

Sectional View.

53

(Dwg. TPA1923)

Page 55

7529_eng.fm Page 54 Wednesday, November 12, 2003 8:57 AM

Parts List

Callout

Number

1 M8X55 Square Bolt JKS30-800 JKS150-120

2 M8 Nut JKS30-80 JKS150-102

3 Washers JKS30-81 JKS150-121

4 Thrust Plate JKS30-11 JKS150-11

5 Spacer (Set of 3) JKS30-10-3 JKS150-10-3

6 Belleville Washer

7 Shroud JKS30-727,

8* Base Plate JKR20-13 JKR75-13

Not

Pictured

Callout

Number

1 M8X55 Square Bolt JKS300-160 JKS1000-240

2 M8 Nut JKS300-106 JKS1000-204

3 Washers JKS300-161 JKS1000-241

4 Thrust Plate JKS300-11 JKS1000-11

5 Spacer (Set of 3) JKS300-10-3 JKS1000-10-3

6 Belleville Washer

7 Shroud JKS300-727,

8* Base Plate JKR180-13 JKR500-13

Not

Pictured

Nuts, Belleville Washers Set

Nuts, Belleville Washers Set

Description Joint Kit

(Set of 18 or 20)

Bolt Kit - Includes 1 Bolt, 2

Description Joint Kit

(Set of 18 or 20)

Bolt Kit - Includes 1 Bolt, 2

Joint Kit

JKR20 & JKS30

Part #

JKS30-904-18 JKS150-906-18

JKR20-727*

JKS30-BKIT JKS150-BKIT

JKR180 & JKS300

Part #

JKS300-908-18 JKS1000-912-20

JKR180-727*

JKS300-BKIT JKS1000-BKIT

JKR75 & JKS150

Part #

JKS150-727,

JKR75-727*

Joint Kit

JKR500 & JKS1000

Part #

JKS1000-727,

JKR500-727*

Ta ble 2

Note: Items denoted with (*) are only used with JKR20, JKR75, JKR180 and JKR500.

54

Page 56

7529_eng.fm Page 55 Wednesday, November 12, 2003 8:57 AM

Glossary of Terms

Characteristic Specification of one particular torque value to be collected. Each

Cp This is a capability index which shows the process capability potential but

CpK This is an index which indicates whether the process will produce units within

characteristic has a name of up to 14 characters. ETA5 can store up to 48

different characteristics at any one time.

takes no account of how centred the process is. This is used for capability

studies and Cp may range in value from 0 to infinity. A large value indicates

greater potential capability and a value of 1.33 or greater is desirable.

or

Max -- Min

6

(x-- M i n )

3

Cp =

(Max and Min are limit values)

the tolerance limits. If the process is centred on the nominal value then CpK

will have a value equal to Cp. For values of CpK between 0 and 1 then some

of the 6 sigma spread will fall outside tolerance limits but for values greater

then 1 these will all be within tolerance. A negative value of CpK indicates

that the process mean is outside tolerance limits. A value of 1.33 or greater is

desirable.

CpK = lesser of

(Max -- x )

3

(Max and Min are limit values)

CAM This is an alternative capability index requiring a minimum of 30 readings to

be taken. In this implementation, 5 sub-groups of 6 samples are used for

each calculation. The CAM calculation uses the following formula:

Max -- Min x Cam Factor *

6 x Average Sample Value

* CAM Factor is taken from a table

(in the case of 5 x 6 samples = 1.910)

55

Page 57

7529_eng.fm Page 56 Wednesday, November 12, 2003 8:57 AM

High Output Transducer (H/O)

Torque transducer with no coding links but internal pre-amplifier giving an

output signal level of typically 1 or 2 volts.

Horizontal Sampling

Collection of data by round, taking one reading for each characteristic in turn.

Industry Standard Transducer (I/S)

Type of transducer, with no pre-amplifier or coding links, but with the exact

rated torque, marked on the body.

Master Round A sequence of up to five rounds. It is used to allow a collection sequence,

which is part vertical, part horizontal.

Max Torque Value

Upper tolerance level of any reading. This can equal but not exceed the

torque rating of the transducer to be used.

Min Torque Value

Lower tolerance level of any reading.

No. of Sub Groups

Number used to allocate memory space in ETA, for a particular characteristic. May be set in the range of 1 to 99.

Round A sequence of characteristics to be collected either horizontally or vertically.

Each round has a name of up to 14 characters.

Sample Individual torque reading.

Standard Deviation σ

Is a measure of the variation of the samples of a statistical group. If a group

of ‘n’ values has a mean of ‘x’ then its standard deviation is given by:

56

Page 58

7529_eng.fm Page 57 Wednesday, November 12, 2003 8:57 AM

Sub-Group Grouping of samples to enable analysis, with an allowable range of 1-50.

Threshold Torque Value

Level of torque in which a signal must rise above and then fall below to be

considered a valid torque cycle. This may be set in the range of 1 to 50% of

rated span or the Min Torque Value, whichever is the lower.

Units of Measure

It is possible with ETA to read a transducer calibrated in for instance, Nm,

and convert internally to display and store in any of the other torque units.

Vertical Prompt Collection of data by round, where a full sub-group is collected for a char-

acteristic, before stepping to the next characteristic.

Vertical Plus Prompt

Identical in procedure to that of Vertical mode except that before stepping to

the next characteristic, ETA5 will prompt for the fitting of a transducer (even

though the correct one is installed) and will require the ENTR key to be

pressed. Stepping to the next characteristic, ETA5 will prompt for the fitting of

a transducer (even though the correct one is installed) and will require the

ENTR key to be pressed.

57

Page 59

7529_eng.fm Page 58 Wednesday, November 12, 2003 8:57 AM

Error Messages

Code Message Explanation

101 RANGE The selection made is not within the allowable

104 EXISTS The characteristic name entered already exists.

105 NO SPACE Insufficient memory space is available to create a