Ingersoll-Rand EAC180A, EAC210A, EAC240A, EAC300A Installation, Operation And Maintenance Manual

Installation, Operation,

and Maintenance

Packaged Rooftop Air Conditioners

Foundation™ Electric/Electric

15 – 25 Tons, 60Hz

Model Numbers:

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

November 2015

EAC180-300

SAFETY WARNING

RT-SVX50C-EN

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNI NG

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental

Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Important Responsible

Refrigerant Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNI NG

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

© 2015 Trane All rights reserved RT-SVX50C-EN

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

NOTICE:

Water Damage!

Non-factory penetrations through the base of this unit

are not allowed. Any penetration in the base of the unit

may affect the water tight integrity of the unit and lead

to water leaks into the conditioned space. Failure to

follow instructions could result in equipment and

property damage.

Overview of Manual

Note: One copy of this document ships inside the control

panel of each unit and is customer property. It must

be retained by the unit’s maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for air cooled systems.

By carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual.

Should equipment failure occur, contact a qualified

service organization with qualified, experienced HVAC

technicians to properly diagnose and repair this

equipment.

Introduction

Revision Summary

RT-SVX50B-EN (23 Nov 2015)

• Added 380V/60Hz Units.

• Updated Model Number Description Section

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

RT-SVX50C-EN 3

Table of Contents

Model Number Description . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . 6

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . 6

Precautionary Measures . . . . . . . . . . . . . . . . 6

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Description . . . . . . . . . . . . . . . . . . . . . . . 6

System Input Devices & Functions . . . . . . . 7

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Initiation of Operating Modes - JADE Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unit Foundation . . . . . . . . . . . . . . . . . . . . . . 16

General Unit Requirements . . . . . . . . . . . . 16

Main Unit Power . . . . . . . . . . . . . . . . . . . . . 18

Factory-Mounted Unit Options . . . . . . . . . . . 21

Unit Disconnect (FIYUDC) . . . . . . . . . . . . . . 21

Unit Economizer Control (ECA) . . . . . . . . . .29

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .30

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Central Air Conditioner . . . . . . . . . . . . . . . . .31

Pre Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Verifying Proper Air Flow (Units with Belt

Drive Indoor Fan)

Electromechanical Controls

Test Procedure

. . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . 22

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standard Economizer Start-Up . . . . . . . . . 23

LLE Controls Test Procedure . . . . . . . . . . . 23

Compressor Start-Up . . . . . . . . . . . . . . . . . 23

Heating Start-Up . . . . . . . . . . . . . . . . . . . . . 24

Final System Set Up . . . . . . . . . . . . . . . . . . 24

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fan Belt Adjustment—Belt Drive Units . . 25

Monthly Maintenance . . . . . . . . . . . . . . . . . 26

Final Process . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 28

Standard Troubleshooting . . . . . . . . . . . . . 28

Low Leak Economizer

(LLE) Troubleshooting

Resetting Cooling and Heating Lockouts . 29

. . . . . . . . . . . . . . . . . 28

4 RT-SVX50C-EN

Model Number Description

Model Number Description

EAC 180 A 3 E G A 00

123 456 7 8 9 10 11 1213

Digit 1 — Unit Type

E = Packaged Cooling, Electric Heat

Digit 2 — Efficiency

A = ASHRAE 90.1 - 2010

Digit 3 — Airflow Configuration

C = Convertible

D = Downflow Only

4

Digit 4, 5, 6 — Nominal Gross

Cooling Capacity (MBh)

180 = 15 Tons

210 = 17½ Tons

240 = 20 Tons

300 = 25 Tons

Digit 7 — Major Design

Sequence

A

Digit 8 — Voltage Selection

3 = 208-230/60/3

4 = 460/60/3

W = 575/60/3

K = 380/60/3

6

Digit 9 — Unit Controls

E = Electromechanical

Digit 10 — Heating Capacity

0 = No Heat

G = 18 kW Electric Heat

N = 36 kW Electric Heat

P = 54 kW Electric Heat

R = 72 kW Electric Heat

Digit 11 — Minor Design

Sequence

J = Low Leak Economizer, Dry Bulb

w/o Barometric Relief

L = Low Leak Economizer, Reference

Enthalpy w/o Barometric Relief

N = Low Leak Economizer,

Comparative Enthalpy w/o

Barometric Relief

4

4

Digit 15 — Supply Fan/Drive

Type/Motor

0=Standard Motor

1 = Oversized Motor

7 = Multi-Speed Standard Motor

9 = Multi-Speed Oversized Motor

7

Digit 17 — Condenser Coil

Protection

0 = Standard Coil

4 = CompleteCoat™ Condenser Coil

Digit 18 — Through The Base

Provisions

0 = No Through The Base Provisions

A = Through The Base Electric

Digit 19 — Disconnect Switch

0 = No Disconnect

1 = Unit Mounted Non-Fused

Disconnect Switch

2

Digit 25 - System Monitoring

Controls

0 = No Monitoring Controls

A = Condensate Drain Pan Overflow

Switch

Digit 26

B = Economizer Fault Detection

and Diagnostics (FDD)

5

7. 10 hp oversized motor is factory

installed only.

4

Digit 12, 13 — Service Sequence

00 = None

Digit 14 — Fresh Air Selection

0=No Fresh Air

A = Manual Outside Air Damper

0-25%

B = Motorized Outside Air Damper

0-50%

C = Economizer, Dry Bulb 0-100%

without Barometric Relief

D = Economizer, Dry Bulb 0-100%

with Barometric Relief

E = Economizer, Reference Enthalpy

0-100% without Barometric

4

Relief

F = Economizer, Reference Enthalpy

0-100% with Barometric Relief

G = Economizer, Comparative

Enthalpy 0-100% without

Barometric Relief

H = Economizer, Comparative

Enthalpy 0-100% with Barometric

1, 4

Relief

4

4

1, 4

Model Number Notes

3

1. Some field set up required.

2. Must be ordered with Throughthe-Base Electrical option.

3. All Factory Installed Options are

Built-to-Order. Check order

services for estimated production

cycle.

4. Factory installed economizers

only available in downflow

1, 4

configuration.

5. Fault Detection and Diagnostics

(FDD) is available on Low Leak

Economizers only.

6. Unit will operate reliably at

400VAC.

RT-SVX50C-EN 5

General Information

Unit Inspection

As soon as the unit arrives at the job site:

• Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

• Verify that the power supply complies with the unit

nameplate specifications.

• Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

• Visually inspect the internal components for shipping

damage as soon as possible after delivery and before

it is stored. Do not walk on the sheet metal base pans.

• If concealed damage is discovered, notify the carrier’s

terminal of damage immediately by phone and by

mail. Concealed damage must be reported within 15

days.

– Request an immediate joint inspection of the

damage by the carrier and the consignee.

– Do not remove damaged material from the

receiving location.

– Take photos of the damage, if possible. The owner

must provide reasonable evidence that the damage

did not occur after delivery.

• Notify the appropriate sales representative before

installing or repairing a damaged unit.

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

• Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

• Skin Contact - Wash affected areas gently with soap

and warm water after handling.

Storage

Take precautions to prevent condensate from forming

inside the unit’s electrical compartments and motors if:

• The unit is stored before it is installed; or,

• The unit is set on the roof curb, and temporary heat is

provided in the building. Isolate all side panel service

entrances and base pan openings (e.g., conduit holes,

S/A and R/ A openings, and flue openings) from the

ambient air until the unit is ready for start-up.

Note: Do not use the unit’s heater for temporary heat

without first completing the start-up procedure

detailed under “Start Up,” p. 23.

The manufacturer will not assume any responsibility for

equipment damage resulting from condensate

accumulation on the unit’s electrical and/or mechanical

components.

Precautionary Measures

WARNI NG

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or repair will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. You MUST wear all necessary Personal

Protective Equipment (PPE) including gloves, eye

protection, a NIOSH approved dust/mist respirator, long

sleeves and pants when working with products

containing fiberglass wool. Exposition to glass wool

fibers without all necessary PPE equipment could result

in cancer, respiratory, skin or eye irritation, which could

result in death or serious injury.

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing: rinse

washer thoroughly.

• Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and compressor oil, and run

tested for proper control operation.

Direct-drive, vertical discharge condenser fans are

provided with built-in thermal overload protection.

The stages of capacity control for these units are achieved

by starting the Economizer Control Actuator (ECA).

Economizer Control Actuator

Electromechanical Control

The ECA monitors the mixed air temperature, return air

temperature, minimum position setpoint (local or

remote), power exhaust setpoint, CO

ambient dry bulb/ enthalpy sensor or comparative

humidity (return air humidity against ambient humidity)

sensors, if selected, to control dampers to an accuracy of

±5 percent of stroke. The actuator is spring returned to the

closed position any time that power is lost to the unit. It is

capable of delivering up to 25 in·lb of torque and is

powered by 24 Vac.

setpoint, CO2, and

2

6 RT-SVX50C-EN

General Information

JADE Economizer Control (For Low Leak

Economizer (LLE) Only)

The JADE controller is a standalone economizer controller

that provides outdoor air dry-bulb economizer control

standard. With optional Sylk Bus sensors, the controller

can provide comparative or reference enthalpy control.

Dampers are controlled to an accuracy of ±3.2 percent of

stroke. The actuator is spring returned to the closed

position any time that power is lost to the actuator. It is

capable of delivering up to 88 in·lb of torque and is

powered by 24 Vac.

System Input Devices &

Functions

The unit must have a thermostat input in order to operate.

The descriptions of the following basic input devices used

within the unit are to acquaint the operator with their

function as they interface with the various features.

Refer to the unit’s electrical schematic for the specific

device connections. The following controls are available

from the factory for field installation.

Drain Pan Condensate Overflow Switch

(Optional)

This input incorporates the Condensate Overflow Switch

(COF) mounted on the drain pan. When the condensate

level reaches the trip point, the COF relay energizes and

opens the 24VAC control circuit, disabling the unit. A delay

timer prevents the unit from staring for 3 minutes.

Phase Monitor

The Phase Monitor is a three-phase line monitor module

that protects against phase loss, phase reversal and phase

unbalance. It is intended to protect compressors from

reverse rotation. It has an operating input voltage range of

190–600 Vac, and LED indicators for ON and FAULT. There

are no field adjustments and the module will automatically

reset from a fault condition.

Discharge Line Thermostat Control

The high pressure controls and discharge line thermostats

are wired in series between the thermostat signal and the

compressor contactors. If the high pressure control switch

or the discharge line thermostat open, the 24VAC signal

from the thermostat is interrupted and the compressor is

disabled. There is no automatic lockout.

Power Exhaust Control (Optional)

To configure the LLE controller, set EXH1 SET (or EXH1 L

& EXH1 H with two-speed fan) in the SETPOINTS menu. 2speed fan mode requires AUX2 I set as W.

Evaporator Frost Control (Optional)

This input incorporates the Frostat™ control (FOS)

mounted in the indoor coil and can be activated by closing

a field supplied contact installed in parallel with the FOS.

If this circuit is open before the compressor is started, the

compressor will not be allowed to operate. Anytime this

circuit is opened for 5 continuous seconds during

compressor operation, the compressor for that circuit is

immediately turned “Off”. The compressor will not be

allowed to restart for a minimum of 3 minutes should the

FOS close.

Sensors

High Temperature Sensor (BAYFRST003*)

This sensor connects to the Emergency Stop Input on the

LTB and provides high limit “shutdown” of the unit. The

sensor is used to detect high temperatures due to fire in

the air conditioning or ventilation ducts. The sensor is

designed to mount directly to the sheet metal duct. Each kit

contains two sensors. The return air duct sensor

(X1310004001) is set to open at 135°F.

The supply air duct sensor (X1310004002) is set to open at

240°F. The control can be reset after the temperature has

been lowered approximately 25°F below the cutout

setpoint.

Thermostat (TCONT802AS32DA)

This thermostat is a multi-stage 3 heat/2 cool, autochangeover digital display thermostat. It is a

programmable thermostat, and a 7-day programmable

stat with night setback shall be available. In addition, it is

wall mounted.

Thermostat (TCONT402AN32DA)

This thermostat is a multi-stage 3 heat/2 cool, auto

changeover digital display thermostat. It is a nonprogrammable, wall-mounted thermostat, and it can be

used for economizer operation.

CO2 Sensor

This optional sensor can be added for Demand Control

Ventilation (DCV) functionality.

On units with a low leak economizer, configure the JADE

controller by setting the following parameters:

The power exhaust fan is started whenever the position of

the economizer dampers meets or exceed the power

exhaust setpoint when the indoor fan is on.

The setpoint panel is located in the return air section and

is factory set at 25% (50% for LLE).

RT-SVX50C-EN 7

SETPOINTS Menu:

DCV SET = desired CO2 ppm to start DCV

VENTMAX = desired maximum position w/DCV &

occupied status (2-speed applications require LO & HI

settings)

General Information

VENTMIN = desired minimum position w/DCV & occupied

status (2-speed applications require LO & HI settings)

ADVANCED SETUP Menu:

CO2 ZERO = set to detector's start level

CO2 SPAN = detector's max level minus start level

Attach the sensor to the CO

customer connections).

Note: When using any 0-10 Vdc CO

you will need to set CO2 ZERO to 400 ppm and the

CO2 SPAN to 1600 ppm in the ADVANCED SETUP

menu.

and "R" terminals (at

2

sensor with the JADE

2

Occupancy Sensor

A customer-supplied occupancy sensor can also be added

to provide damper control based on occupied/unoccupied

conditions.

Low Leak Economizer Units

To configure the JADE controller, set:

SYSTEM SETUP menu: OCC = INPUT

Attach the occupancy sensor to the OCC SENSOR wire and

"R" terminal (at customer connections). The occupancy

sensor must utilize a normally open contact for proper

operation.

If an occupancy sensor is not used, another option to

controlling occupied and unoccupied status is to use the

'G' input (fan is running). Connect the G input to the OCC

SENSOR wire (at customer connections). The controller

will then operate in the occupied mode every time the

indoor fan is running.

Initiation of Operating Modes JADE Controller

The JADE controller is able to initiate the following modes:

Compressor, Economizer, Fans, Heating System, and

Cooling System.

The Compressor mode is initiated by either the OAT going

above the DRYBLB SET setting or by the thermostat

initiating a call to cool when the damper is at 100% open.

The Economizer mode is controlled by the MAT getting

above the MAT SET setting while the OAT is below the

DRYBLB SET setting. While the fans are not controlled by

the controller, the Fan mode is dependent on what state

the system is in (OCC or Y1 states will cause the damper to

go to a LOW fan speed damper setting, while Y2 or W

states will cause the controller to open the damper to the

HIGH fan speed damper setting). The Heating System

mode requires an input to the AUX2-1 terminal from the

thermostat, and the Cooling System mode requires an

input to the Y2 IN and/or the Y1 IN terminals from the

thermostat.

8 RT-SVX50C-EN

Dimensional Data

5' 8"

5' 0"

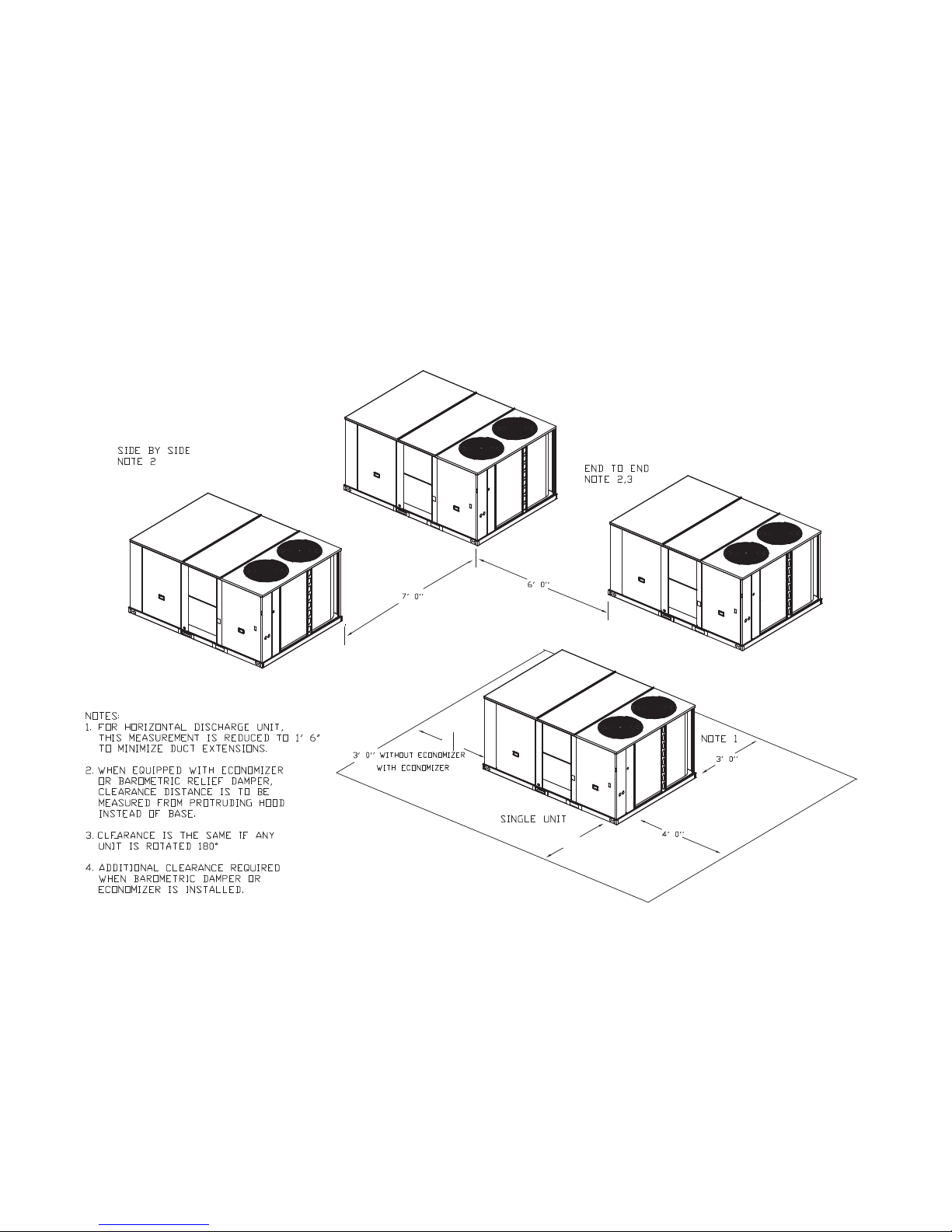

Figure 1, p. 12 illustrates the minimum operating and

service clearances for either a single or multiple unit

installation. These clearances are the minimum distances

necessary to assure adequate serviceability, cataloged

unit capacity, and peak operating efficiency.

Providing less than the recommended clearances may

result in condenser coil starvation, “short-circuiting” of

exhaust and economizer airflows, or recirculation of hot

condenser air.

Figure 1. Typical installation clearance for single and multiple unit applications

RT-SVX50C-EN 9

Dimensional Data

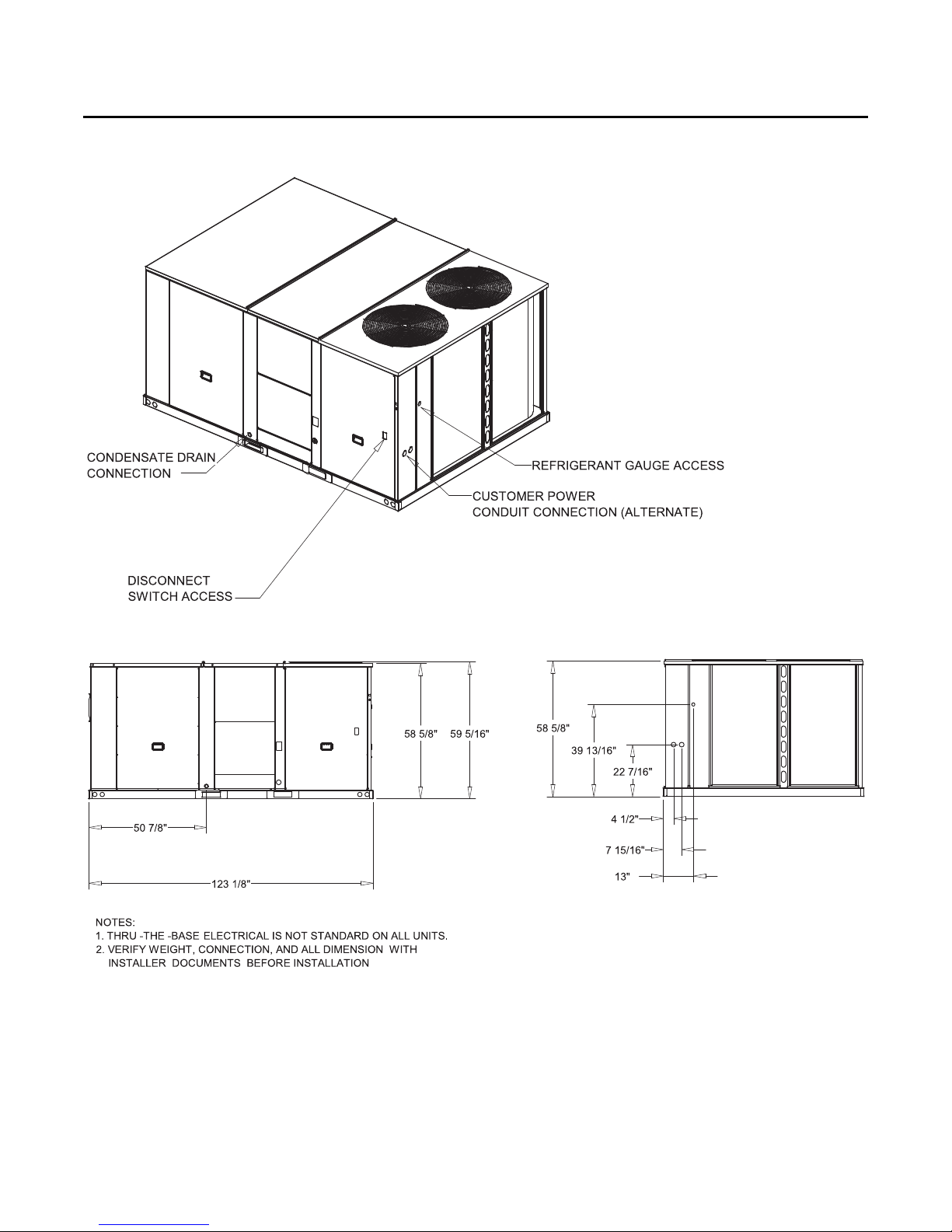

Figure 2. Cooling with optional electrical heat units — overview

Figure 3. Cooling with optional electrical units — front & side views — 15–25 tons standard efficiency

10 RT-SVX50C-EN

Loading...

Loading...