Ingersoll-Rand DXR Series, DXR800, DXR1000, DXR425, DXR600 Operator's Instruction Manual

DXR SERIES

REFRIGERATED AIR DRYERS

OPERATOR'S

INSTRUCTION MANUAL

DXR425

DXR600

DXR800

DXR1000

English: 1-1

Español: 2-1

Before installation or starting the dryer for the

first time, study this manual carefully to obtain

a clear knowledge of the dryer and of the

duties to be performed while operating and

maintaining the dryer.

RETAIN THIS MANUAL WITH DRYER.

This technical manual contains IMPORTANT

SAFETY DATA and should be kept with the

dryer at all times.

Bulletin 553 Revision M (2/00)

Copyright ©2000 Ingersoll-Rand Company

Printed in USA

Table of Contents

INTRODUCTION ...............................1-1

SAFETY ....................................1-1

Safety Instructions ............................1-1

Safety Labels ...............................1-1

Data Plate and Labels ..........................1-1

RECEIVING AND INSPECTION ......................1-1

INSTALLATION ...............................1-2

Ambient Air Temperature ........................1-2

Location and Clearance .........................1-2

System Arrangement ...........................1-2

Piping and Connections .........................1-2

Drains ..................................1-2

Electrical Connections ..........................1-2

Cooling Water ..............................1-2

Air-Cooled Models............................1-3

HOW IT WORKS ...............................1-3

Air Flow .................................1-3

Refrigeration System...........................1-3

INSTRUMENTATION ............................1-4

Power Signal ...............................1-4

System Operation Monitor ..........................1-4

AUTOMATIC DRAIN VALVES ......................1-7

ADV Adjustment.............................1-8

START-UP ...................................1-8

SHUTDOWN .................................1-8

MAINTENANCE ...............................1-9

General ..................................1-9

Daily Maintenance ............................1-9

Weekly Maintenance...........................1-9

Monthly Maintenance ..........................1-9

Service Due Indicator ..........................1-9

Returns to Manufacturer .........................1-9

Ambient Air Filter Replacement ....................1-10

Automatic Drain Valve Disassembly and Servicing ..........1-10

Prefilter Element Replacement .....................1-10

FIELD SERVICE GUIDE ..........................1-12

REPLACEMENT PARTS ..........................A-1

SCHEMATICS ................................A-1

INTRODUCTION

DXR Series refrigerated air dryers use mechanical re

frigeration to dry compressed air to pressure dew points

as low as 33°F-39°F. They deliver the required dew

point at specified inlet air temperature, pressure and air

flow. Any change in these operating conditions may af

fect performance. See Table 9 for rated capacity and

other dryer specifications.

To ensure continuing good performance and safe opera

tion of the dryer, everyone who installs, uses or main

tains it must read and carefully follow the instructions in

this manual.

-

-

SAFETY

DXR Series dryers are designed and built with safety as

a prime consideration; industry-accepted safety factors

have been used in the design. Each dryer is checked at

the factory for safety and operation. All necessary ad

justments are made before shipment.

Follow the maintenance schedules outlined in this manual for good performance and safe operation. Maintenance should be done only by qualified personnel with

proper tools.

Carefully read the following safety rules before proceeding with installation, operation or maintenance. The

rules are essential to ensure safe dryer operation. Failure

to follow these rules may void the warranty or result in

dryer damage or personal injury.

1. Do not install or try to repair a dryer that has been

damaged in shipment. See Receiving and Inspec

tion for instructions.

2. Compressed air and electricity have the potential to

cause personal injury or equipment damage. Before

doing any work on the dryer, be sure the electrical

supply has been locked and tagged and the internal

pressure of the dryer has been vented to the atmos

phere.

3. Do not operate the dryer at pressures or tempera

tures above the maximum conditions shown on the

data plate.

4. Always supply electrical power that complies with

the voltage shown on the data plate.

5. Do not readjust the dryer without factory authoriza

tion.

6. Work on the refrigeration system must be done

only by a competent refrigeration mechanic.

-

-

-

-

7. Use only manufacturer's genuine replacement parts.

The manufacturer bears no responsibility for haz

ards caused by the use of unauthorized parts.

-

Safety Instructions

-

-

-

Safety instructions in this manual are boldfaced for em

phasis. The signal words DANGER, WARNING and

CAUTION are used to indicate hazard seriousness lev

els as follows:

DANGER—Immediate hazard which WILL result in

severe injury or death.

WARNING—Hazard or unsafe practice which

COULD result in severe injury or death.

CAUTION—Hazard or unsafe practice which COULD

result in minor injury or in product or property damage.

-

-

Safety Labels

Dryer labels providing important safety information are

included in this manual near corresponding text. If any

of the labels is missing or damaged, contact your local

distributor, request the label by its part number and apply it to the dryer.

Data Plate and Labels

The dryer data plate and dryer labels contain critical

safety and identification information. If any label or

data plate is missing or damaged, contact your local distributor and request a replacement.

RECEIVING AND INSPECTION

Inspect the dryer closely when it is received. Record

any indication of damage on the delivery receipt, espe

cially if the dryer will not be immediately uncrated. Ob

tain the delivery person's signed agreement to recorded

damages to facilitate future insurance claims.

Since the dryer is shipped F.O.B. New Castle, Dela

ware, the manufacturer's responsibility for the shipment

ceases when the carrier signs the bill of lading.

If goods are received short or in damaged condition, no

tify the carrier and insist on a notation of the loss or

damage across the face of the freight bill. Otherwise no

claim can be enforced against the carrier.

If concealed loss or damage is discovered, notify your

carrier at once and request an inspection. This is abso

-

lutely necessary. Unless you do this the carrier will not

consider any claim for loss or damage. The carrier will

make an inspection and may grant a concealed damage

notation. If you give the carrier a clear receipt for goods

that have been damaged or lost in transit, you do so at

your own risk and expense.

-

-

-

-

-

DXR Series Dryers (Bulletin 553) 1-1

The manufacturer is willing to assist you in collecting

claims for loss or damage. Willingness does not make

the manufacturer responsible for collecting claims or re

placing material. Claim filing and processing is your re

sponsibility.

Compressed air systems commonly require filters to re

move compressor oils, particulates, condensed liquids

and other contaminants. When an oil-removal filter is

-

-

used, install the filter downstream of the DXR Series

dryer. At this location, the life of the replaceable filter

element is prolonged since some of the entrained oil is

removed by the dryer and drained through the separator.

INSTALLATION

Ambient Air Temperature

Locate the dryer indoors where the ambient air tempera

ture will be between 40°F and 100°F. Intermittent op

eration at ambient temperatures up to 120°F will not

damage the dryer but may result in a higher dew point

or dryer shutdown due to high refrigerant discharge

pressure (see Field Service Guide). Call your local dis

tributor if prolonged operation at ambient temperatures

above 100°F or below 40°F is unavoidable.

Do not operate air-cooled dryers at ambient air tempera

tures below 40°F. Such operation may result in low suc

tion pressure, causing freeze-up.

Location and Clearance

Mount the dryer on a level base and bolt down if base

vibrates. If the dryer is air cooled, install it in a clean,

well-ventilated area to reduce fouling of the condenser

coils with dirt and dust. Allow 24 inches clearance on

the sides and front of the dryer for cooling airflow on

air-cooled dryers and for service access on both aircooled and water-cooled dryers.

System Arrangement

Liquid water adversely affects dryer performance. To

prevent “slugging” the dryer with liquid water, locate

the dryer downstream of an and a separator. Install

drain valves to discharge condensate that collects in

these areas.

If the airflow is relatively constant and will not cause

short term overloading of the dryer, it is recommended

that the dryer be located downstream of the receiver

tank. If the nature of the application is such that the air

demand regularly exceeds the dryer flow rating, it is

recommended that the dryer be located upstream of the

receiver.

For safety and convenience, install inlet and outlet shut

off valves and depressurization valves at the locations

indicated. These valves allow the dryer to be isolated

and depressurized for servicing. Bypass piping may be

installed around the dryer for uninterrupted airflow

when the dryer is serviced. If the compressed air opera

tion cannot tolerate undried air for short periods, install

a second dryer in the bypass line.

-

Piping and Connections

Piping must be furnished by the user unless otherwise

specified. Connections and fittings must be rated for the

maximum operating pressure given on the dryer data

plate and must be in accordance with applicable codes.

Support all piping; do not allow the weight of any pip

-

ing to stress the dryer or filters. Proper sizing of piping

-

should be determined using good engineering practice.

See Table 8 for dryer inlet and outlet connections.

Drains

Condensate must be drained from the dryer to prevent

its reentrainment. The dryers are equipped with an auto

matic drain valve. A condensate hose is coiled and secured inside the dryer cabinet for shipping. Uncoil the

hose and run it to a waste disposal collection system

that meets applicable regulations. Install the discharge

lines so that condensate can be seen as it drains.

Pipe or copper tubing

densate discharge lines. Do not use

1

-inch is recommended for con-

2

1

-inch or

4

5

16

-inch

O.D. flexible tubing unless the discharge line is shorter

than 10 feet.

Electrical Connections

Standard models are constructed according to NEMA

Type 1 electrical standard. Field wiring must comply

with local and national fire, safety and electrical codes.

Installation must be in accordance with the National

Electrical Code. Confirm that your line voltage is the

same as the voltage listed on the data plate.

Dryers are wired so that the crankcase heaters (if sup

plied) and drain valves are energized when power is

supplied, even if the power switch is turned off. See the

electrical schematics for wiring details.

Cooling Water

-

-

Water-cooled condensers are optional on some models.

The suffix W on the model number indicates watercooled. The user is responsible for piping the water to

and from the condenser. A factory-installed water regu

lating valve in the condenser inlet connection is stan

-

dard.

Required water flow rate depends on water temperature

(refer to Table 1). The valve supplied with the dryer

automatically adjusts the flow to compensate for varia

-

-

1-2 DXR Series Dryers (Bulletin 553)

tions in water temperature, water pressure and dryer air

load.

Operating the dryer with inadequate condenser cooling

water (temperatures above or pressures below those in

Table 1) will cause a rise in dew point unless the dryer

inlet airflow is reduced. The refrigerant discharge pres

sure control will shut down the refrigerant compressor if

cooling water is inadequate.

If the cooling water is dirty, install a strainer ahead of

the condenser inlet. Install shutoff valves so that the

strainer can be drained and cleaned at regular intervals.

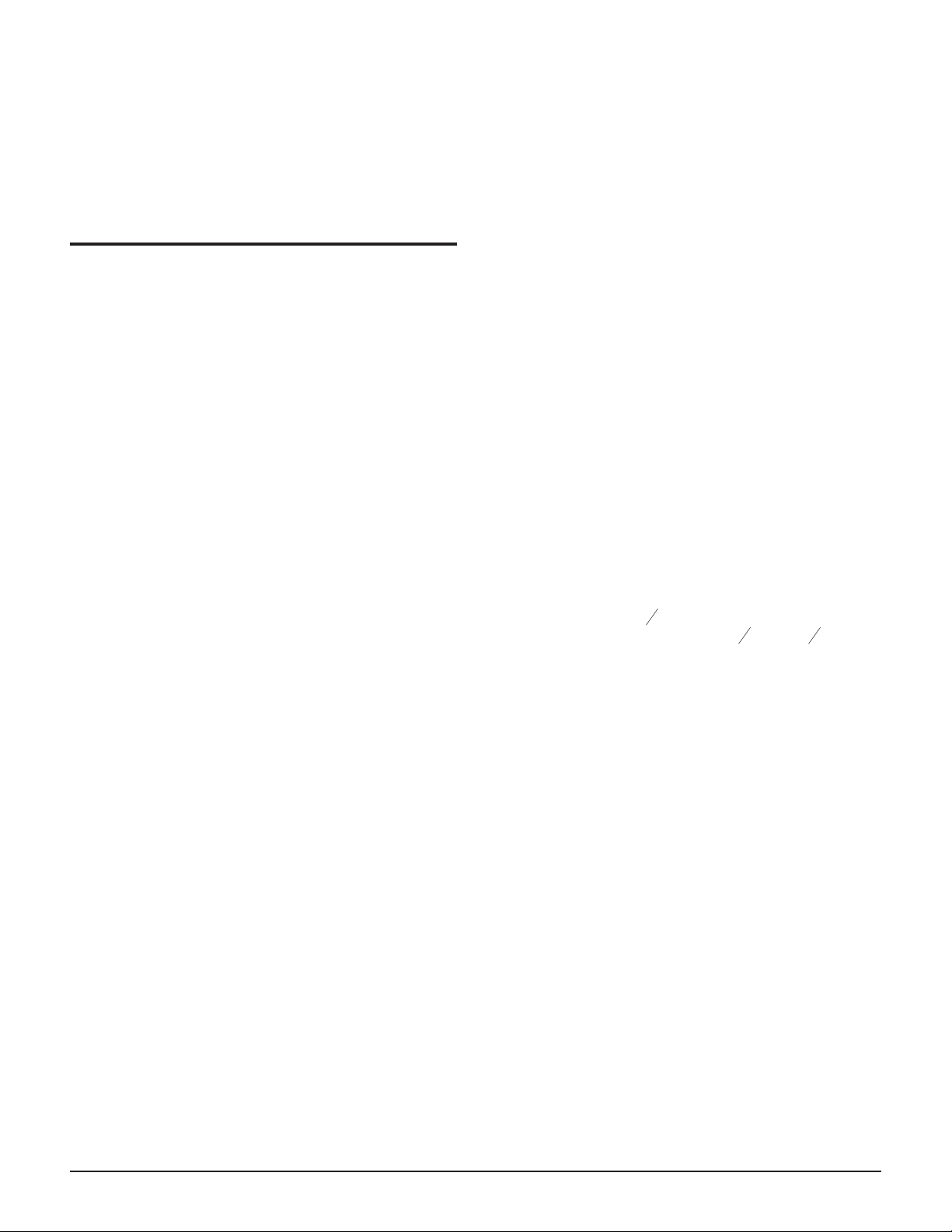

COOLING WATER REQUIREMENTS

DRYER

MODEL

DXR425-W

DXR600-W

DXR800-W

DXR1000-W

a

Minimum water pressure is 25 psig for city water and 35 psig for

tower water. Maximum water pressure is 150 psig.

WATER

CONN.

(in NPT)

3

3

1

1

Table 1

COOLING WATER

REQUIRED

60°F 70°F 80°F 85°F 90°F

GPM GPM GPM GPM GPM

8

8

2

2

0.6 1.0 2.1 2.7 4.2

1.6 2.0 2.8 3.8 5.5

1.5 2.0 3.7 5.4 10.0

2.5 3.0 4.5 5.7 9.0

a

Air-Cooled Models

Cooling air must be drawn from a clear, well-ventilated

area to reduce dust and dirt accumulation on the condenser coils. Air temperature should not exceed 100°F.

Required air flow rates are shown in Table 2.

COOLING AIR REQUIREMENTS

MODEL

DXR425 3000

DXR600 2700

DXR800 5200

DXR1000 4800

Table 2

COOLING AIR

(cfm)

The cold, dry air is reheated by incoming warm air as it

passes back through the air-to-air heat exchanger. Using

the outgoing air to pre-cool the inlet air condenses up to

65 percent of the moisture out of the inlet air before it

reaches the chiller. Pre-cooling the inlet air reduces the

heat load on the refrigerant compressor, permitting the

use of a smaller refrigerant compressor.

Refrigeration System

The refrigeration system is designed and fabricated in

accordance with recognized commercial/industrial prac

tices. It consists of a compressor and the controls, safety

interlocks and associated equipment necessary for safe

performance.

A thermostatic expansion valve (TEV) and a hot gas by

pass valve (HGBV) are used to modulate the refrigerant

flow. The TEV adjusts the flow of liquid refrigerant to

the chiller. A temperature sensor downstream of the

chiller opens and closes the TEV in response to the tem

perature of the refrigerant leaving the chiller to maintain

the proper cooling rate under all load conditions. The

HGBV delivers hot refrigerant gas to the chiller in response to changes in refrigerant pressure. This prevents

icing in the chiller and short cycling in the refrigerant

compressor during extended periods of system operation at low load.

All refrigerant valves are adjusted at the factory; operation is fully automatic.

-

-

-

HOW IT WORKS

Air Flow

DXR Series dryers use refrigeration cooling to condense

entrained moisture out of the airstream (see Figure 2).

Warm saturated air enters the air- to-air heat exchanger

where it is cooled by outgoing cold air. The inlet air is

further cooled in the refrigeration chiller. Cooling con

denses entrained moisture. The condensate is removed

by a centrifugal separator and an automatic drain valve.

DXR Series Dryers (Bulletin 553) 1-3

-

Figure 2.

Air and refrigerant flow schematic.

INSTRUMENTATION

Power Signal

All dryers are equipped with an ON-OFF switch located

on the front panel. A white light signals when power is

on.

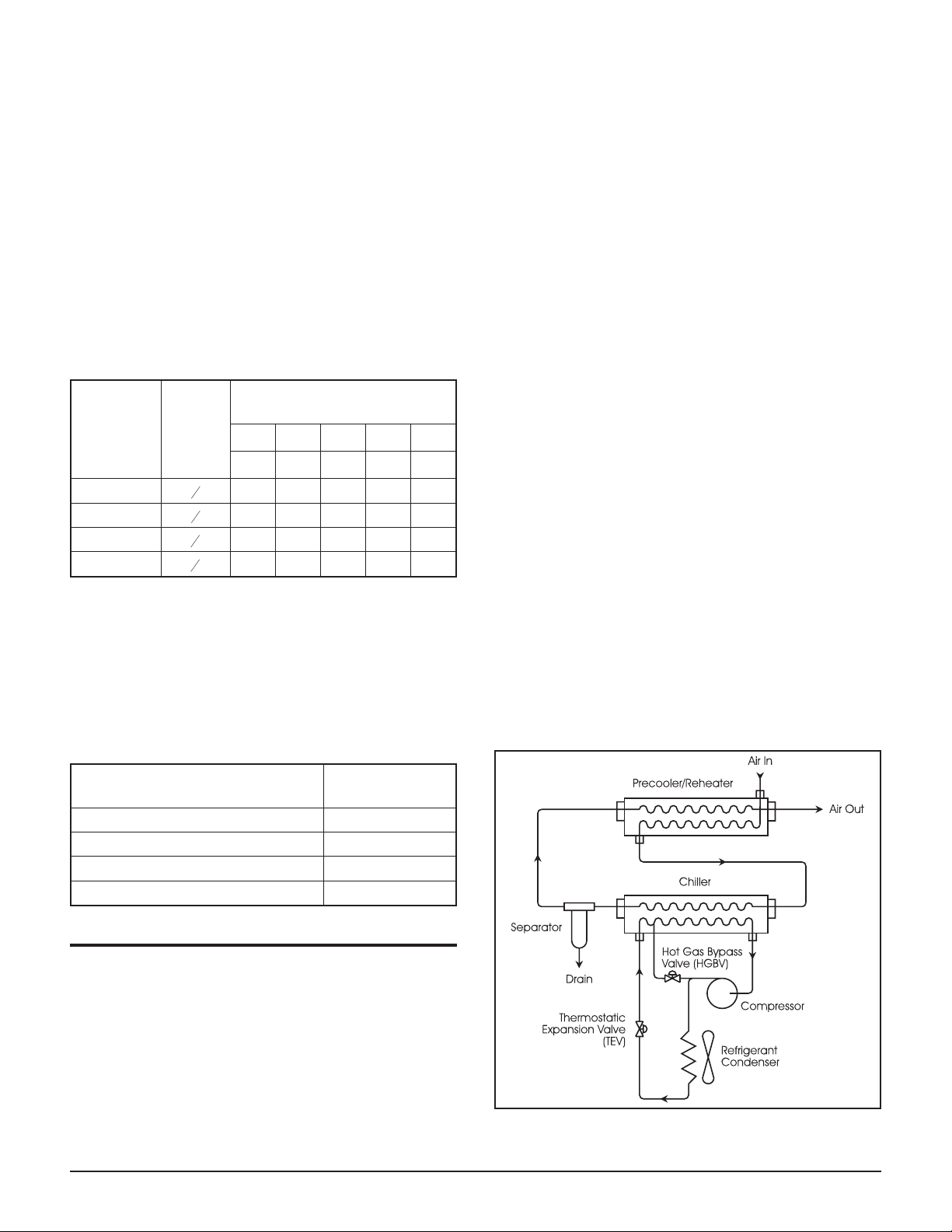

System Operation Monitor

A System Operation Monitor measures and displays

critical air and refrigerant temperatures, signals operat

ing conditions which may affect dryer performance, and

enables panel adjustment of the automatic drain valve.

There is also a light to indicate the need for routine

service.

The monitor consists of (refer to Figure 4):

indicating lights

•

alphanumeric display

•

• controls (push buttons) that provide access to

critical air and refrigerant temperatures

• schematic with lights that correspond to the

locations of the temperature sensors in the system

• drain valve controls

• temperature sensor probes

-

Indicating lights

The System Operation Monitor has four indicating

lights: NORMAL OPERATION, CHECK OPERAT

ING CONDITIONS, SERVICE DUE and SYSTEM

ALARM. Table 3 provides instructions for using the in

dicating lights to monitor dryer operation .

NORMAL OPERATION—The green NORMAL OP

ERATION indicator will light when the temperature in

side the evaporator (chiller) is normal.

CHECK OPERATING CONDITIONS —The red

CHECK OPERATING CONDITIONS indicator will

light when the temperature inside the evaporator is too

high.

SERVICE DUE—The yellow SERVICE DUE indica

tor will light under two conditions: as a reminder to per

form routine maintenance after 4,500 hours of dryer

service (approximately six months) and when a tem

perature sensor probe fails.

SYSTEM ALARM—The red SYSTEM ALARM indi

cator signals air system or dryer operating conditions

that may affect dew point performance or cause damage

to the dryer.

Temperature SCAN/SEEK push button

The SCAN/SEEK push button on the System Operation

Monitor provides a readout on the alphanumeric display

of the following temperatures:

-

-

-

-

-

-

-

-

• inlet air

System Operation Monitor

Figure 4.

1-4 DXR Series Dryers (Bulletin 553)

INDICATING

LIGHT

NORMAL

OPERATION

CHECK

OPERATING

CONDITIONS

SERVICE

DUE

SYSTEM

ALARM

SYSTEM OPERATION MONITOR INDICATING LIGHTS

INDICATES ACTION REQUIRED NOTES

The temperature inside the evaporator

(chiller) is normal.

The temperature inside the evaporator

(chiller) is too high.

1. 4,500 hours of dryer service

(approximately six months) has

passed; routine maintenance should

be performed.

2. A temperature sensor probe is

sensing temperature outside of normal

range or probe has failed. The probe

may sense temperatures outside of

normal range for up to two minutes

after startup or in extreme temperature

conditions. (The alphanumeric display

will read T1, T2, T3, T4 or T5

MALFUNCTION. T1 = inlet air, T2 =

refrigerant suction, T3 = refrigerant

discharge, T4 = ambient air, T5 =

evaporator.)

1. Inlet air temperature is too high.

2. Refrigerant suction temperature is

too low.

3. Ambient air temperature is too low.

4. Ambient air temperature is too high.

Table 3

This indicator should light within 30 minutes

of start-up, after the refrigeration system has

stabilized. It should remain on when the dryer

is operating.

It is normal for this light to be on when the

dryer is first turned on and remain on until

dryer has reached normal operating

temperatures (about 30 minutes).

If the CHECK OPERATING CONDITIONS

indicator turns on during normal operation,

turn the dryer off to avoid compressor

damage. Have a refrigeration mechanic

identify and correct the malfunction. If the

dryer is under warranty, call your local

distributor for authorization before servicing

1. See maintenance section in this manual for

further instructions.

2. Check sensor probe. Replace if necessary.

Determine which temperature(s) is out of

range. See Table 5 and the Field Service

Guide in this manual for possible

causes/remedies

Indicator will go off if the

CHECK OPERATING

CONDITIONS indicator

comes on or when a

temperature sensor

probe has failed.

Indicator will remain

illuminated until

problem has been

corrected.

See maintenance

section in this manual

for instructions on

resetting indicator.

Indicator will go off

when the dryer is turned

off. This will not affect

the 4,500 hour routine

maintenance indicator.

Indicator will not stop

flashing until the

problem has been

corrected.

•

refrigerant suction

•

refrigerant discharge

•

ambient air

The display can be programmed to automatically scan

each temperature for five seconds in sequence or to con

tinuously display any selected reading. The correspond

ing light on the system schematic will illuminate when

the temperature is displayed.

To scan the temperatures (normal mode): press and

hold the SCAN/SEEK button for three seconds. Each

temperature will then be displayed for five seconds in

the following sequence: inlet air, refrigerant suction, re

frigerant discharge and ambient air. To stop the scan

-

-

To display any selected temperature (seek/test

mode): press the SCAN/SEEK button once. The display

will read the same temperature until the button is

pressed again. When in seek mode, it will continue to

monitor for abnormal conditions.

-

Critical Air and Refrigerant Temperatures

Table 4 provides the normal range for each displayed

temperature when the dryers are operated in accordance

with specified conditions. If a temperature reaches the

warning set point indicated in the table, the correspond

ing light on the system schematic will flash during the

5-second display. If the temperature reaches the alarm

set point indicated in the table, the System Alarm indi

cator will flash. Refer to the Field Service Guide in this

-

mode push the TIME ADJUST button once.

DXR Series Dryers (Bulletin 553) 1-5

-

manual if any temperature readout falls outside the nor

mal range.

Inlet Air Temperature—If the inlet air temperature

falls outside the normal range, the dryer may fail to

achieve the required dew point. Check the compressor

aftercooler and adjust aftercooler operation to ensure

specified inlet air temperature to the dryer.

Refrigerant Suction Temperature—If the dryer has

been operating for more than 20 minutes and the refrig

erant suction light flashes, there may be a malfunction

in the refrigeration system. Turn the dryer off and have

a refrigeration mechanic identify and correct the mal

function. If the dryer is under warranty, call your local

distributor for authorization before servicing.

Refrigerant Discharge Temperature—This tempera

ture is used by service personnel to analyze the perform

ance of the refrigeration system.

-

able range, the dryer may fail to achieve the required

dew point or dryer shutdown may result due to high re

-

frigerant temperature.

Intermediate Air Temperature

This temperature is used by service personnel to analyze

the performance of the refrigeration system. Intermedi

ate air temperature is displayed by putting monitor in

Scan mode then pushing and holding down the TIME

-

ADJUST and CLOSED/OPEN buttons simultaneously

for three seconds. The intermediate air temperature will

be displayed for 5 seconds. The digital display will then

return to its last temperature readout.

Intermediate air temperature varies with operating con

ditions and ambient air temperature. Table 5 lists ap

-

proximate normal ranges of this temperature at various

inlet flows and dew point classes.

-

-

-

Ambient Air Temperature—If the ambient air tem

perature falls outside the acceptable range, the dryer

may fail to achieve the required dew point or dryer shutdown may result due to high refrigerant discharge pressure.

Inlet Condensing Water Temperature (Water-cooled

models) — If the cooling water falls outside the accept-

AIR AND REFRIGERANT TEMPERATURES

DIGITAL

DISPLAY

Inlet Air Inlet air piping

Refrigerant

Suction

Refrigerant

Discharge

Ambient Air

(Air-Cooled Only)

Inlet Condensing

Water

(Water-Cooled Only)

Intermediate Air

a

Normal temperature range is indicated by a 3-second red light. The red light flashes when temperatures are outside the normal range.

Dew points 50°F or higher may cause the REFRIG. SUCTION signal to flash. See the Field Service Guide if red lights flash.

TEMPERATURE

PROBE

LOCATION

Refrigerant line

upstream of

compressor

Refrigerant line

downstream of

compressor

Outside the

condenser

Inlet pipe of the

condenser

Outside surface

of chiller

discharge

piping

Inlet air temperature varies with

changes in aftercooler cooling

medium temperature and air

compressor unloading. Inlet

temperatures higher than 100°F

reduce drying capacity.

These refrigerant temperatures vary

with the refrigeration load and are

controlled by refrigeration valve

settings. These readings are used

primarily by service personnel to

analyze refrigeration system

performance.

Ambient air temperatures higher

than 100°F will reduce drying

capacity.

Cooling water temperatures in

excess of 100°F will reduce drying

capacity.

Intermediate air temperature varies

with inlet air pressure, ambient

temperature and airflow. This

reading is used primarily by service

personnel to analyze refrigeration

system performance.

Table 4

COMMENTS

NORMAL

TEMPERATURE

RANGE

40°F – 120°F >115°F >120°F

32°F – 55°F N.A. 25°F

140°F – 240°F N.A. N.A.

35°F – 120°F

35°F – 120°F

Variable;

see Table 5

a

WARNING

SET

POINT

> 115°F/

< 35°F

> 115°F/

< 35°F

N.A. N.A.

ALARM

SET

POINT

> 120°F/

< 35°F

> 120°F/

< 35°F

1-6 DXR Series Dryers (Bulletin 553)

INTERMEDIATE AIR TEMPERATURE

DRYER INLET

AIRFLOW

(% of rated

capacity)

80 - 100 35°F - 45°F 50°F - 60°F

50 - 79 45°F - 55°F 60°F - 70°F

25 - 49 55°F - 65°F 70°F - 80°F

10 - 24 65°F - 75°F 80°F - 90°F

No airflow 75°F - 100°F 90°F - 100°F

a

Based on 90°F - 100°F dryer inlet air temperature and 100°F ambient

air temperature. These ranges are approximate and may vary with

changes in inlet air pressure, ambient temperature and inlet airflow.

Table 5

APPROXIMATE NORMAL RANGE

33°F - 39°F

Dew Point

50° - 54°F

Dew Point

a

RS-232 Serial Port

The RS-232 serial communications port allows for mon

itoring of current temperature and error flags. Commu

nication is via a series of ASCII characters sent every

second. The data format is shown below. The baud rate

is 4800, 8 bits, no parity.

Message format:

DS version:

:Ixxx,Sxxx,Dxxx,Axxx,Oxxx,Nxxx,Lyy,Syy<cr><lf>

•

Where:

** Intermediate or Glycol is displayed, based on

version.

The alarm bits are preceded with either:

L = Alarm bits

•

S = Service Due indication

•

The HEX characters that follow “L” or “S” convey an

eight-bit field which indicates the source of the alarm or

service due indicator. A value of all zeros (0x00) indi

-

cates that no alarm or service due condition exists.

Version Program

-

1

-

svc = > 4500 hours operating time

DS inlet

Remote Alarm Contacts (Optional)

Dry (unpowered) contacts including one normally open

set and one normally closed set are provided to signal

remote indication if the CHECK OPERATING CON

DITIONS or SYSTEM ALARM indicators are activated. The contacts are 2½ Amps max., unfused and

120/240 VAC max.

• “:” = colon character

• “,” = comma character

• <cr> = carriage return

• <lf> = line feed

•

xxx = temperature in BCD, leading zeros are sup

pressed (replaced with spaces. Out-of-range val

ues are displayed as “---”.)

•

yy = alarm bits in ASCII HEX format

Each numerical temperature value is preceded with a

single alphabetic identifier:

•

I = Inlet air

•

S = Suction

•

D = Discharge

•

W = Water*

•

A = Ambient*

•

O = Operation

•

G = Glycol**

•

N = Intermediate**

* Water or Ambient is displayed, based on ver

sion.

AUTOMATIC DRAIN VALVES

All dryers are equipped with an electronic drain valve

that automatically discharges condensate from the dryer.

Drain valve controls are on the system operation monitor. The ADV controls allow the period of drain open-

-

-

-

ing to be set from 1 second to 10 seconds and the drain

closed (cycle) time to be set from 0.5 minutes to 10

minutes. A test push button helps to check ADV opera

tion. When the button is pushed, the drain port clicks

open with a clearly audible sound.

To set the drain closed (cycle) time:

The monitor must be in the Scan mode. Press the

CLOSED/OPEN button once. The display will show the

current setting for the ADV closed time.

Press and hold the TIME ADJUST button. Release the

button when the display reads the desired time. The se

-

lected time will be locked into memory.

To set the drain open time:

The monitor must be in the Scan mode. If monitor is not

already in the mode for adjusting drain closed time,

slowly push the CLOSED/OPEN button once. Allow a

few seconds for monitor to set up, then push the button

a second time. The display will show the current setting

for the ADV open time.

-

DXR Series Dryers (Bulletin 553) 1-7

Press and hold the TIME ADJUST button. Release the

button when the display reads the desired time. The se

lected time will be locked into memory.

-

ADV Adjustment

To minimize air losses, the ADV timer should be ad

justed to open the drain port just long enough to dis

charge accumulated condensate. Set the timer so that

only air discharges at the end of the open period. Rec

ommended initial settings are a 3-second drain opening

and a 3-minute drain closed time (cycle). The separator

or filter bowl is likely to fill with water if the drain cy

cle is too long. If liquid discharges as the port is closing,

set the timer for a shorter cycle or a longer opening.

-

-

-

-

START-UP

Follow the procedure below to start your dryer. Failure

to follow the prescribed start-up procedure will invali

date the warranty. If problems arise during start-up, call

your local distributor.

Before you start the dryer:

1. Turn off the dryer ON/OFF switch.

2. Verify the main electrical supply voltage matches

the voltage specified on the dryer data plate.

3. Turn on the main electrical power to the dryer.

The crankcase heater is wired to be on when power

is supplied to the dryer. The crankcase heater

must be warmed up for 4 hours before starting

the dryer. This warm-up heats the compressor

oil and boils off liquid refrigerant to prevent

damage to the compressor.

During the warm-up period:

•

Do not turn the dryer switch on.

•

Compressed air may flow through the dryer dur

ing warm-up but drain valves will not be func

tional.

After the main electrical power to the dryer has

been on for 4 hours, the dryer may be started.

To start the dryer:

-

-

-

a collection tank or an environmentally-approved

disposal system.

3. Check ADV timing. See Automatic Drain Valve

section for ADV adjustment procedure.

4. Check customer-supplied circuit breakers or fuses.

Reset or replace as required.

5. Check proper connection and support of com

pressed air lines to the dryer; check bypass valving

system, if installed.

6. Ensure adequate ventilation for air-cooled dryers.

7. For water-cooled models, verify the water supply is

connected to the water regulating valve on the con

denser. Confirm that the cooling water supply

meets the required flow and temperature (see Table

1).

8. Confirm that the inlet air temperature, pressure and

airflow to the dryer meet the specified requirements

(see Tables 8 and 9).

9. After 30 minutes of operation, check the CHECK

OPERATING CONDITIONS indicator. If this indicator is lit, turn the dryer off and call your local

distributor.

10. If the CHECK OPERATING CONDITIONS indicator has turned off after 30 minutes of operation,

check the following temperatures on the System

Operation Monitor:

• Refrigerant discharge (head) temperature should

be within the range of 140°F to 220°F.

•

Refrigerant suction temperature should be within

the range of 32°F to 55°F.

If either temperature is out of range, see the Field

Service Guide for correction.

The dryer is designed to run continuously. Let the dryer

run even when the demand for compressed air is inter

rupted; the dryer will not freeze up. If the supply power has

been turned off for more than four hours, supply power to

the dryer; warm up the crankcase heater (if applicable) for

4 hours before starting the dryer to vaporize any accumu

lated liquid refrigerant from the compressor oil.

-

-

-

-

1. Turn the power switch to ON. The refrigerant com

pressor will turn on. The monitor will turn on and

the CHECK OPERATING CONDITIONS indica

tor may turn on. If the dryer does not start in this

way, call your local distributor.

2. Confirm that condensate is discharging from the

automatic drain valves and that the condensate

lines from the automatic drain valve discharge into

1-8 DXR Series Dryers (Bulletin 553)

-

SHUTDOWN

When the dryer must be shut down for maintenance or

other reasons, use the following procedures.

If electrical repairs must be made:

1. Turn off the power switch.

2. Disconnect the main power supply.

3. Lock out and tag the power supply in accordance

with OSHA requirements.

Refer to the Instrumentation section and the Field Serv

ice Guide for further information.

-

DANGER

Portions of the control circuit remain

energized when the power switch is in the OFF

position. Disconnect supply powerto the dryer

before performing maintenance on the

electrical system.

If mechanical repairs must be made, vent the internal

pressure of the dryer to atmospheric pressure.

Restart the dryer according to the start-up instructions.

MAINTENANCE

DXR Series dryers require little maintenance for satis

factory operation. Good performance can be expected if

the following routine maintenance steps are taken.

DANGER

Dismantling or working on any component of

the compressed air system under pressure

may cause equipment failure and serious

personal injury. Before dismantling any part of

the dryer or compressed air system,

completely vent the internal pressure to the

atmosphere.

General

For continued good performance of your refrigerated

dryer, all refrigeration system maintenance should be

performed by a competent refrigeration mechanic. Bef

ore corrective maintenance is done during the warranty

period, call your local distributor and proceed according

to instructions. Refer to the warranty for limits of your

coverage.

Daily Maintenance

Check the operation of the automatic drain valve at least

once during each 8-hour shift. See the Field Service

Guide for remedies to drain valve malfunctions. See the

Instrumentation section for drain valve adjustment.

Check the following readouts on the system operation

monitor.

•

high evaporator temperature

•

refrigerant suction temperature

•

refrigerant discharge temperature

•

alarm lights

-

-

Weekly Maintenance

Check prefilter (if installed) differential pressure gauge.

Replace filter element when pointer reaches red zone of

gauge (approx. 7 to 10 psid). Failure to change element

at least once a year or when the gauge reaches the red

zone will adversely affect dryer performance. See Filter

Element Replacement procedure.

Monthly Maintenance

For air-cooled condensers, inspect the condenser coils.

Remove dust, dirt or other particles with a soft brush or

with compressed air from an OSHA-approved air nozzle

that limits its discharge pressure to 30 psig. If the coils

are coated with oil, grease or other substances that re

duce the cooling efficiency, clean the coil.

Replace the ambient air filter. See Ambient Air Filter

Replacement procedure.

-

Service Due Indicator

On dryers equipped with the System Operation Monitor,

the yellow SERVICE DUE indicator will light after

4,500 hours (six months) of dryer operation. At this

time, complete the following:

• Disassemble and clean automatic drain valve.

• Disassemble and clean separator bowl.

• For air-cooled condensers, inspect the condenser

coils; clean if necessary. Lubricate fan motors

with 20 wt motor oil (if necessary).

•

For water-cooled condensers, clean customersupplied strainer.

To reset the SERVICE DUE INDICATOR:

1. Turn the power switch to the OFF position.

2. Hold down the PUSH TO TEST and

CLOSED/OPEN buttons simultaneously.

3. Turn the power switch to the ON position.

4. Wait two seconds. Release the PUSH TO TEST

and CLOSED/OPEN buttons. The indicator is now

reset.

Returns to Manufacturer

If the dryer or a component of the dryer must be re

turned to the manufacturer, first call your local distribu

tor for a return authorization number and shipping

address. Your distributor will inform you whether the

dryer or only a component must be returned. Mark the

package with the return authorization number and ship

freight prepaid as directed by your local distributor.

-

-

DXR Series Dryers (Bulletin 553) 1-9

Ambient Air Filter Replacement

For units equipped with the optional ambient air filter

(designated by the suffix F in the model number), in

spect the filter element. If necessary, replace the ele

ment by lifting it out and slipping in a replacement. See

the replacement parts lists for replacement element

model numbers.

-

-

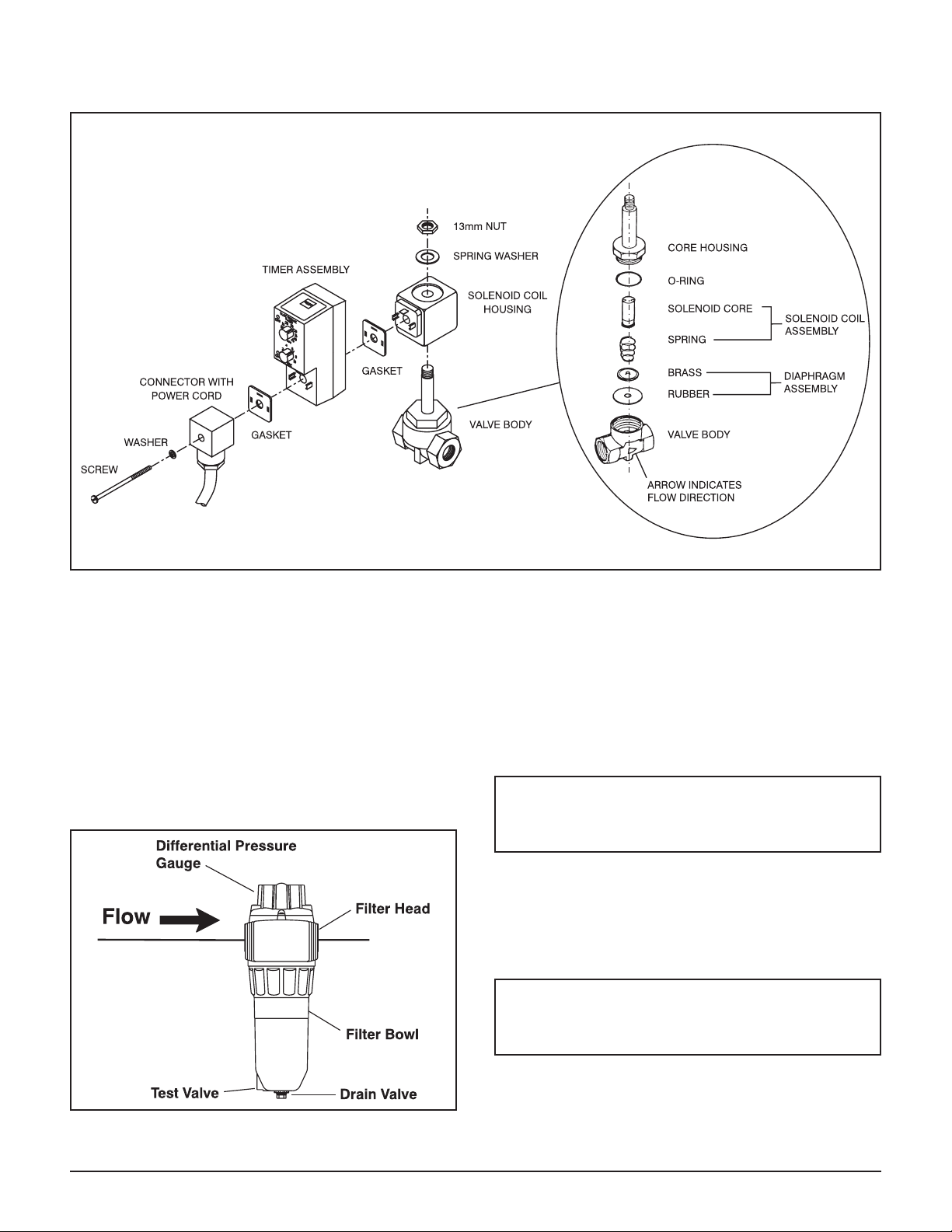

Automatic Drain Valve Disassembly and

Servicing

All DXR Series dryers have a timer-controlled auto

matic drain valve.The valve body is mounted on the

frame bottom; a hose connects the valve body to the

separator.

CAUTION

Do not disassemble drain valve timer or

attempt to repair electrical parts. Replace

timer if defective.

The drain valves discharge condensate through a

full-port drain opening.

The valve body may need to be cleaned under conditions of gross particulate contamination. To disassemble

the drain valve body for cleaning or other maintenance

(see Figure 6):

1. Turn power switch off.

2. Disconnect main power supply to dryer.

3. Lock out and tag power supply in accordance with

OSHA requirements.

-

Once the drain valve is disassembled, the following

maintenance can be performed.

1. Inspect diaphragm; clean or replace as required.

2. Remove debris from valve body.

3. Wipe solenoid core components with a clean cloth

or blow out debris with compressed air from an

OSHA-approved air nozzle that limits its discharge

pressure to 30 psig.

4. Check that small port in diaphragm assembly is

clear and solenoid coil moves freely in housing. Vi

ton diaphragm seals are compatible with commonly

used synthetic lubricants.

5. If timer is attached to valve body, check electrical

continuity across timer assembly.

To reassemble the drain valve, reverse the sequence of

the preceding steps. After the drain valve is reassem

bled, connect the main power supply to the dryer. When

the dryer is returned to service, check the drain valve for

air or condensate leaks; tighten connections as required

to correct leaks. Check the drain cycle; adjust the timer

according to the procedure in the Automatic Drain

Valve Adjustment section.

-

Prefilter Element Replacement

On models equipped with the cold coalescing option (C

option), the filter element must be replaced at least once

a year or when the differential pressure gauge on top of

the filter is in the red zone.

To replacing the coalescing prefilter element:

-

WARNING

If power supply is not disconnected before

disassembly, serious personal injury and

valve damage may result.

4. Remove hoses that connect the drain valve to the

separator.

5. Remove screw and washer from front of the drain

valve.

6. Remove the power supply connector and gasket

(with timer assembly if attached) from the solenoid

coil housing. Do not damage or lose the gasket.

7. Remove 13mm nut and spring washer from top of

solenoid coil housing.

8. Lift solenoid coil housing off solenoid core in valve

body.

9. Unscrew solenoid core from valve body.

1-10 DXR Series Dryers (Bulletin 553)

Vent internal pressure to atmospheric

pressure before performing anymaintenance.

1. Vent the internal pressure to the atmosphere. Refer

to the shutdown instructions on page 8.

2. Disconnect drain lines at manual and automatic

drain valves (if installed).

A “hissing” sound while the bowl is being

removed indicates the filter has not been

properly depressurized. DO NOT continue to

remove the bowl until the filter has been

completely vented to atmospheric pressure.

Filter bowls may be heavy. Caution should be

taken when removing the bowl.

DANGER

DANGER

CAUTION

Automatic Drain Valve Components

Figure 6

3. Remove the bottom bowl by unscrewing it from the

head. A strap wrench may be needed.

4. Remove the element from the filter head with a

brisk downward pull, or by working the element

back and forth until it snaps free. Discard the ele

ment in accordance with applicable regulations.

Used elements typically hold contaminants, such as

compressor lubricants and particulate matter.

Note: The element may be unsnapped by DPin

normal operation. This will not affect filtration,

as the O-ring on the element maintains a positive

seal.

5. Clean accumulated debris from the bowl with soap

and water, and dry thoroughly.

CAUTION

Lubricate the O-ring with a petroleum-based

lubricant compatible with your application.

6. Lightly lubricate the new element O-ring before in

stalling the new element.

7. Insert new element, snapping it into place with a

firm push up into the head. The element will hang

from the head until the bowl is installed.

CAUTION

Lubricate the O-ring with a petroleum-based

lubricant compatible with your application.

8. Lightly lubricate the filter bowl O-ring.

-

Side view of coalescing filter

DXR Series Dryers (Bulletin 553) 1-11

Figure 7

CAUTION

Do not use a pipe wrench to tighten the filter

bowl to the head.

9. Reattach bowl to head and hand tighten. As the

bowl is threaded onto the head, supports in the bot

tom of the bowl ensure a proper seal between the

element and the filter head.

10. Reattach drain lines (if applicable).

11. Record the date of the element change in a record

book or on the provided

“Maintenance Reminder”

label. The maintenance

reminder label with the

updated information

should be applied over

MAINTENANCE REMINDER

Date Element Changed:

Changed By:

Next Scheduled Change:

Additional elements available from your local

Ingersoll-Rand Compressed Air System supplier

Telephone:

Fax:

the previous label each

time the element is replaced.

Restart the dryer according to the Start-up instructions

on page 8.

FIELD SERVICE GUIDE

Problems most frequently encountered with refrigerated

dryers are water downstream of the dryer and excessive

pressure drop. Most causes can be identified and remedied by following this guide.

DANGER

Closed refrigeration systems are potentially

dangerous. Work on the refrigeration system

must be done only by a competent

refrigeration mechanic.

the dryer. While the dryer is operating, the suction pres

sure/temperature may fluctuate slowly with changes in

the refrigeration load. To determine the suction pres

sure/temperature, a refrigeration mechanic should attach

a set of gauges to the unit. Gauge readings should be as

follows:

-

SUCTION PRESSURE/TEMPERATURE

REFRIGERANT

R-22 58 psig/33°F 68 psig/40°F

Do not adjust refrigerant valves without factory authori

Table 6

WITHOUT

AIRFLOW

WITH

AIRFLOW

zation. Adjustments must be made only with no airflow

into the dryer.

REFRIGERANT PRESSURE SWITCH SETTINGS

Pressure Switch Setting

Model

DXR425

DXR600

DXR800

DXR1000

Refrigerant Compressor Control

Pressure Switch Setting

Sensor Location Cut out Cut In

Compressor

Discharge

Compressor

Suction

Table 7

Fan Cycle Control

R-22

On Off

275 195

405 280

40 60

Do not release fluorocarbon refrigerants

indoors; do not discharge liquid refrigerants

into floor drains. Refrigerant vapors may

accumulate in low places. Inhalation of high

concentrations may be fatal. All refrigerants

must be recovered per EPA requirements.

Do not smoke while working on the

refrigeration system or when a refrigerant leak

is suspected. Burning materials may

decompose refrigerants, forming toxic gas or

acids that may cause serious injury and

property damage.

The refrigerant valves are adjusted at the factory with

the refrigerant system operating and no airflow through

1-12 DXR Series Dryers (Bulletin 553)

FIELD SERVICE GUIDE

PROBLEM SYMPTOM(S) POSSIBLE CAUSE REMEDY

No discharge from auto

matic drain valves.

Inlet air temperature is

outside normal range or

reaches alarm set point.

Liquid water entering

dryer.

Excessive airflow (may

also cause high pres

sure drop).

Drain valve failure or accumulation

of dirt in valve.

Dismantle drain valve; clean, repair or re

place. See Maintenance section.

Aftercooler malfunction. Check aftercooler discharge temperature.

Reduce temperature to 120°F max.; reduce

airflow if temperature is above 100°F.

Aftercooler drain valve malfunction. Dismantle aftercooler drain valve; clean, re

pair or replace.

Dryer improperly sized. Check airflow and dryer capacity (see Table

-

8). Reduce airflow or resize and replace

dryer.

1. Condenser fouled or clogged. 1. Clean condenser coils (see Mainte

nance, Monthly).

2. Fan motor stopped. 2. Repair or replace fan motor.

3. Inlet air temperature too high. 3. Check aftercooler discharge temperature.

Reduce temperature to 120°F max.; reduce

Refrigerant compressor

cut out by high

refrigerant discharge

pressure control.

4. Air in refrigeration system. 4. Have refrigeration mechanic locate and

airflow if temperature is higher than 100°F

(see Airflow section).

repair leak. Recharge. Refer to data plate for

refrigerant type and quantity.

5. Ambient air temperature too high

5. Vent compressor room to outside.

for air-cooled compressor.

6. Aftercooler coolant air blowing

6. Baffle or vent to outside air.

on air-cooled condenser.

1. Inadequate ventilation of aircooled compressor.

1. Ensure adequate ventilation of the condensing unit (see Clearance). Motor will restart automatically when compressor is

cool.

Water

downstream of

dryer.

Compressor cuts out

on internal overload.

2. Insufficient cooling water for

water-cooled compressor.

2. Ensure adequate cooling water (see Ta-

ble 1). Motor will re- start automatically

when compressor is cool.

3. Leak in refrigeration system. 3. Locate leak. Repair and recharge. Motor

will restart automatically when compressor

is cool.

4. Incorrect adjustment of refrigera

-

4. Call your local distributor.

tion control valves.

Compressor windings

read open or shorted.

Compressor burned out. Have refrigeration mechanic check and re

place.

1. Leak in refrigeration system. 1. Locate leak; repair and recharge.

2. Improper adjustment of HGBV. 2. Remove cap from HGBV and screw out

HIGH EVAP light on

or

Dew point indicator in

red zone

3. Air or noncondensables in refrig

eration system. Possible leak in

chiller.

HGBV ½-turn with an allen wrench to lower

suction temperature to the level listed in the

Refrigerant Flow section.

-

3. Locate leak; repair and recharge. If chiller

must be replaced, consult your local dis

tributor.

1. Improper adjustment of HGBV. 1. Remove cap from HGBV and screw out

HGBV ½-turn with an allen wrench to lower

suction temperature to the level listed in the

Refrigerant Flow section.

Suction temperature

higher than 65°F.

2. Inlet air temperature higher than

130°F.

2. Reduce aftercooler discharge tempera

ture to design conditions (120°F max.).

3. Excessive airflow 3. Check airflow and system capacity. Re

duce airflow or resize and replace system.

4. Leak in refrigeration system. 4. Locate leak; repair and recharge.

Refrigerant discharge

Low ambient temperature. Consult your local distributor.

temperature lower than

140°F.

-

-

-

-

-

-

-

DXR Series Dryers (Bulletin 553) 1-13

Loading...

Loading...