Ingersoll-Rand DS15-H, DS25-H, DS50-H, DS35-H, DS75-H User Manual

...

GB

User manual

Page 1

F

ES

P

D

Manuel d’utilisation

Manual de uso

Manual do utilizador

Benutzerhandbuch

Page 7

Página 13

Página 19

Seite 25

DS15-- H --- D S 1 0 0 -- H

refrigeration dryer (60Hz)

DATE: 06.11.2002 ISSUE: 2

272716

CPN: 85616902

Index

1Introduction page2

1.1 Foreword page 2

1.2 Packaging page 2

1.3 Transport page 2

1.4 Storage page 2

1.5 Inspection page 2

2 Installation page 2

2.1 Dryer installation page 2

2.2 Electrical connection page 3

2.3 Condensate drain page 3

3 Start--- up and operation page 3

3.1 Preliminary checks page 3

3.2 Starting the dryer page 3

3.3 Stopping the dryer page 4

3.4 Operation page 4

4 Maintenance page 4

4.1 Preventive maintenance page 4

4.2 Substituting an exhausted element page 4

4.3 Disassembling t he unit page 5

4.4 Refrigerant leaks in the refrigeration circuit page 5

4.5 Refrigerant charging page 5

5Calibration page5

Safety warnings

Important:

S Keep this manual with the machine throughout its entire service life.

S Carefully read this manual before carrying out any operation on the machine.

S This m achine is designed for PROFESSIONAL USE only. Only use the ma-

chine for the purpose for which it is intended. Improper use of the machine

absolves the manufacturer from all liability.

This manual has been compiled to help the final user perform just those operations which do not require removal of the panels.

All other operations which involve the removal of covers from instruments or

electrical circuit--- breakers using special tools must only be carried out by

trained personnel due to the danger of rotating parts or live components.

Each machine is equipped with an electric disconnect device whichallows theoperator to work on the machinein absolute safety. This device must always be used

to disconnect the mains supply to avoid any risk of danger during maintenance

work (electric shocks, scalding, automatic start--- up, moving parts and remote

control).

Before servicing the dryer always make sure the compressed air circuit is depressurised.

When requesting technical assistance or ordering spare parts, always quote the

model and serial number on the identification plate mounted externally on the

unit.

IMPORTANT: data contained in this publication is to be considered as indicative

only. The manufacturer reserves the right to modify data without prior notice.

6 Spare parts list page 5

7 Troubleshooting page 6

CPN: 85616902 --- DS15-- H --- D S 1 0 0 -- H

English

1

CPN: 85616902 --- DS15-- H --- D S 1 0 0 -- H

English

2

2

All figures to which the “see Fig.” references in this text refer can be found at the

end this manual. The language translations for these figures can be found in the

Legend (A3--- sized page) inserted after all the figures.

1Introduction

1.1 Foreword

The DS- H dryers are designed to guarantee high quality compressed air and minimum maintenance.

Please carefully read this manual to obtain maximum performance from your dryer

and ensure its correct installation and start ---up in compliance with manufacturer instructions.

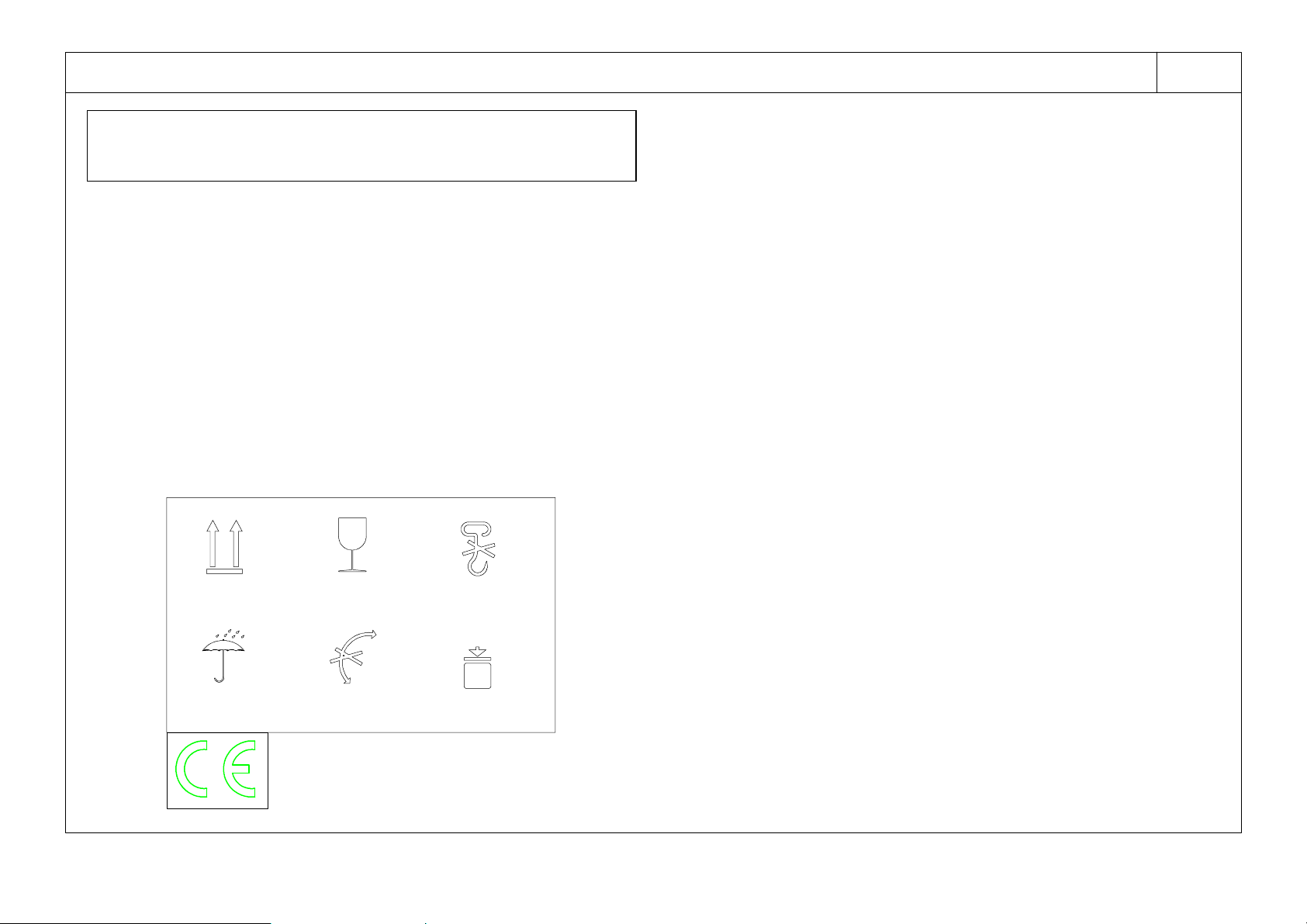

1.2 Packaging

The dryer is packaged with a strong cardboard box strapped to a wooden pallet.

Instruction symbols (UNI ISO 780) for the movement, transport and stocking of the

product are printed on two sides of the packing.

1.3 Transport

S Keep the unit in an upright position and do not leave it outdoors.

S Use a forklift truck to move the machine.

S Care should be taken to avoid damaging internal components through poor

handling during movement, installation or use.

S Unpack the machine as close as possible to the installation site.

1.4 Storage

If stored the packaged units must be kept inside, protected from humidity, direct

sunlight and rain.

Moreover, although stacking is permitted the maximum weight must not be more

than the value shown on the packaging.

1.5 Inspection

On receipt of the machine, make sure it has incurred no damage during transit.

If any damage is detected promptly contact the haulage company.

2 Installation

2.1 Dryer installation (see Fig. 1)

THIS WAY UP

KEEP DRY DO NOT ROLL STACKING

FRAGILE: HANDLE

WITH C ARE

USE NO HOOKS

Kg max

LIMITATION

a) Dryer should be installed indoors; where this is not possible it must however be

installed in a clean dry area, with a temperature within the limits 41---115˚F

( 5 --- 4 6 ˚C), and sheltered from the effects of direct weather (including direct sun-

light); do not install the dryer in rooms used for laundry operations.

b) The compressed air inlet temperature must never exceed 200˚F(93˚C). For dif-

ferent temperatures to those indicated above, consult the manufacturer.

c) For most compressed air applications we recommend following the installation

plan (see Fig. 1). This layout ensures optimum compressor, filter and dryer performance and also guarantees excellent air qua lity whilst minimising operating

costs.

d) Donotobstructthedryerairgrilles.

e) Allow sufficient gap around the unit to facilitate maintenance and ensure unim-

peded air discharge from the condenser.

f) Avoid recirculation of hot condenser air back into t he condenser air inlet.

.

g) If the system is prone to instantaneous pressure surges which exceed the dryer’s

rated capacity, mount a suitably sized receiver near the overpressure source. For

more precise information, contact the manufacturer or distributor.

h) Installing a by--- pass line with shut---off valves (supplied as option) is suggested

to permit maintenance or calibration without interrupting the compressed air

flow to the user.

Pay attention when you by--- pass the aftercooler section, as this will cause hot air

to flow through the compressed air network.

i) Correctly connect the dryer to the air inlet and outlet connections. If the com-

pressed air network is prone to vibrations, use hoses to make the connections.

If the mains is subject to high levels of pulsation, ensure that the connection is

equipped with pulsation dampers.

j) Do not connect condensate drains common to other pressurised drain lines in a

closed circuit. Make sure the outflow from the condensate drains is unimpeded.

Connect the condensate piping in such a way to ensure that sound levels are kept

to a minimum during drainage.

Ensure that all condensate is disposed of in a responsible manner, in accordance

with local norms concerning environmental protection.

k) The ambient air around the dryer and compressor must not contain solid or gas-

eous contaminants. All compressed and condensed gases can generate acids or

chemical products which may damage the compressor or components inside the

dryer.

Take particular care with sulphur, ammonia, chlorine and installations in marine

environments. For further advice or assistance consult the manufacturer.

2.2 Electrical connection (see Fig. 5 / Fig. 10)

The dryer is supplied with a 3 x AWG16 power cable complete with plug.

2.3 Condensate drain

The dryer is supplied either with a float drain (see Fig. 9), a timed drain or an electronic level sensing drain.

Fortimed and electronic drains:refer to separate manual supplied with the dryer for

specific details concerning the condensate drain.

3 Start---up and operation

3.1 Preliminary checks

Beforestartingupthedryer,makesurethat:

a) the air inlet valves are closed and there is no air flow through the dryer.

b) The mains power supply is commensurate with the dryer voltage.

c) The dryer is installed in compliance with the installation instructions given in

Chapter 2.

3.2 Starting the dryer

a) Use the switch to start the dryer.

b) Always start up the dryer before activating the air compressor.

c) Waitabout 5 minutes until the dryer is running at the correct operatingtempera-

tures and pressures.

d) Slowly open the air inlet valve to pressurise the dryer.

e) Slowly open the air outlet valve. The dryer is now operating (drying).

f) Always leave the dryer running while the air compressor is operating.

g)

After stopping the dryer wait at least 3 minutes before starting it again

Install an overcurrent and earth leakage circuit breaker upstream from the

plant (IDn = 0.03A) with a 0.12 inch (3 mm) gap between contacts when open (refer

also to local laws).

CPN: 85616902 --- DS15-- H --- D S 1 0 0 -- H

3.3 Stopping the dryer

a) Use the switch to stop the dryer.

English

3

CPN: 85616902 --- DS15-- H --- D S 1 0 0 -- H

y

WEEKL

Y

CONDENATEDRAI

N

MONTHLY

Mak

t

h

d

t

200F(93C)

EVERY4MONTH

S

specification

s

English

4

4

b) Stop the dryer 2 minutes after shutting down the air compressor or interrupting

the air flow to the dryer.

Avoidallowingcompressedairtoenterthedr

er when the dryer is

switchedofforwhenitisinanalarmsituationwhichstopstherefrigeration

compressor.

3.4 Operation

S The dryer operates automatically. It is factory set for a dew point of 50˚F(10˚C)

and therefore requires no further calibration.

S Do not exceed the machine’s design limits, by---pass excess air flow and check the

unit model and/or installation.

S For maximum performance from your dryer, follow the maintenance schedule de-

scribed i n Chapter 4.

S The sound pressure level recorded for these dryers 40 inch (at 1 metre) from the

machine in free fieldconditionsis less then50 dB(A) (models DS15-- H), 55dB(A)

(models DS25-- H --- D S 1 0 0 -- H)

Fig. 6 shows the Dryer’s refrigeration and air circuits.

N.B.: In the event of aftercooler fan malfunction leading to an increase in the tem-

perature within the filter, to above 149˚F(65˚C), check the integrity of the filter’s

element and drain and substitute these components if necessary.

4 Maintenance

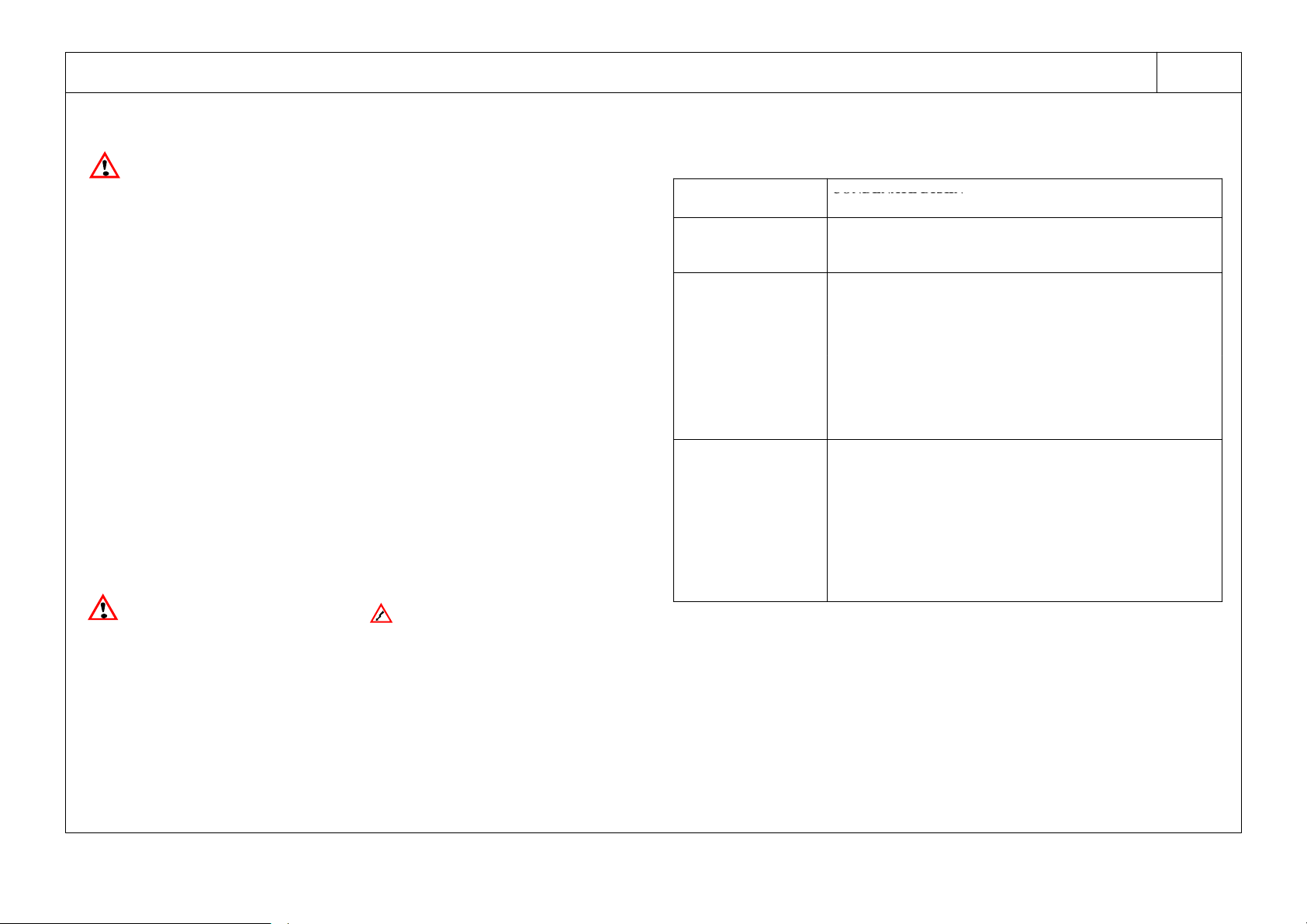

4.1 Preventive maintenance

For optimum performance from your dryer follow the periodic maintenance schedule described below.

CONDENATE DRAIN

Verify that the condensate drain is draining correctly.

COMPRESSOR

˚

˚

YEARLY

esure

when running. If this is not the case consult Chapter 7.

REFRIGERANT CONDENSER AND AFTERCOOLER

Remove any dust from the condenser/aftercooler fins.

COMPRESSOR

Make sure compressor power consumptioncomplieswith data plate

AFTERCOOLER FAN MOTOR

S

Check that the fan rotates freely without any abnormal noise.

S

Make sure fan power consumption complies with the specifications on the fan’s data plate.

AFTERCOOLER

If necessary (coil blocked) remove the fan and clean the coil in the

opposite direction to the air flow using a high pressure water jet (this

operation must be performed by a technician to avoid damage).

FILTER ELEMENT

Replace the filter element (see para. 4.2)

CONDENSATE DRAIN

Completely disassemble the drain and clean all its components (see

Fig. 9 or separate manual, according to installed drain type).

e compressorhea

.

emperatureisbelow

Before accessing live electrical parts , disconnect the power supply to the

dryer using disconnect switch QS or disconnect the cable connections.

SAFETY DEVICES

SK overload protector

HP high pressure switch (installed on models DS50-- H --- D S 1 0 0 -- H)

COMPRESSOR TYPE

HERMETIC, PISTON (single phase)

N.B.: Always use original spares supplied by the manufacturer.

Failure to do so renders the manufacturer not liable for incorrect unit operation.

4.2 Substituting an exhausted element (Fig. 9)

N.B.: Don’t touch the element sock with your bare hands; use gloves.

a) Shut off or by---pass air supply to dryer.

b) Depressurise filter usingmanual or automatic drainvalve (18). Leave valveopen.

c) Unscrew (anticlockwise) filter body from head.

d) Unscrew and remove element (17).

e) Clean inside of filter if necessary.

Loading...

Loading...