Ingersoll-Rand AF046X-XX, AF044X-XX User Manual

AF044X-XX

WARNING

WARNING

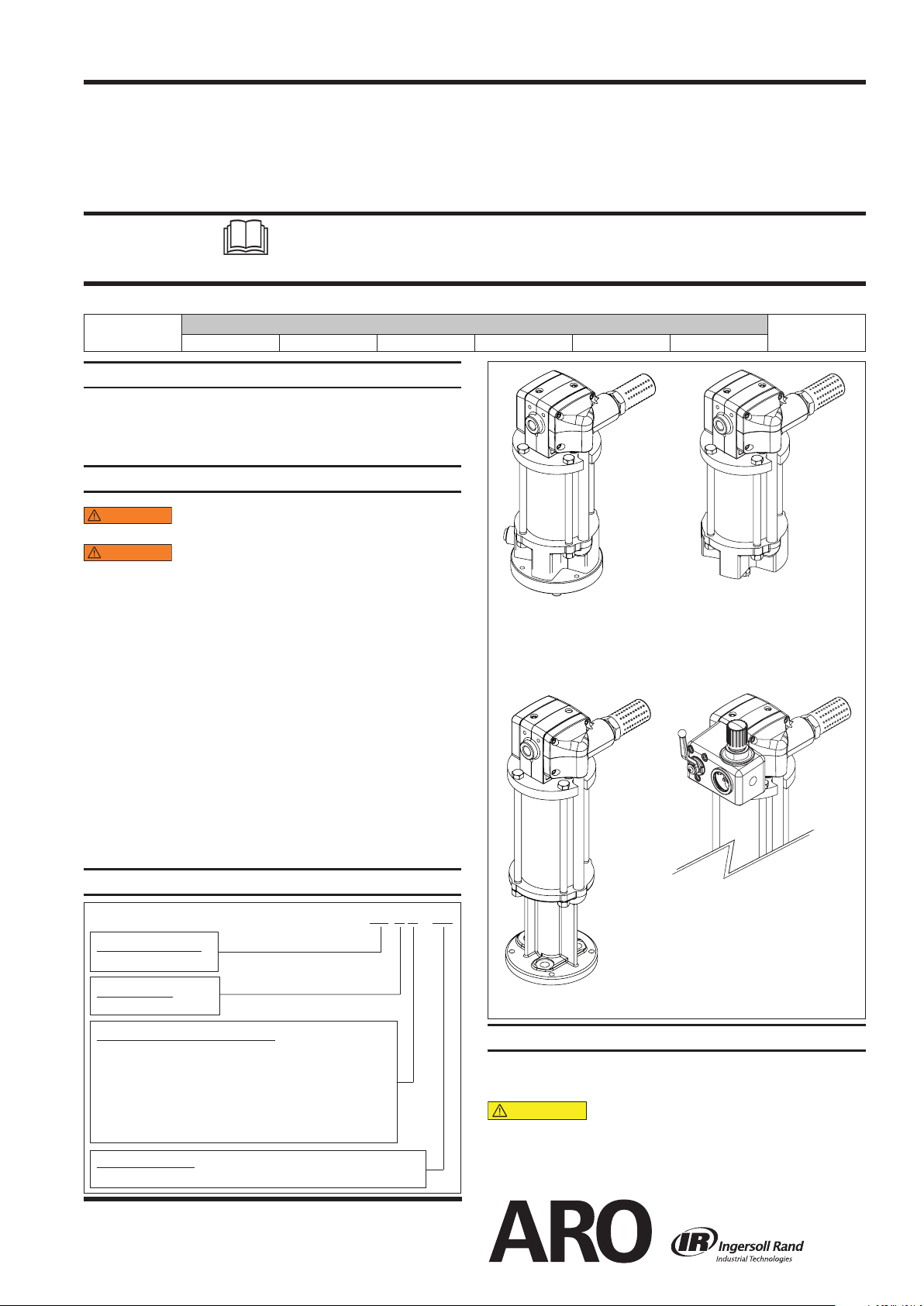

AF0441-XX

AF0442-XX

AF0443-XX

AF0444-XX

AF0445-XX

AF0460-XX

AF04XX-01

CAUTION

OPERATOR’S MANUAL AF046X-XX

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST,

DISASSEMBLY & REASSEMBLY.

RELEASED:

REVISED:

(REV. 02)

4-1/4” AIR MOTORS

AF044X-XX (4” STROKE) and AF046X-XX (6” STROKE)

Also covers 637489 service kits

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

THIS MANUAL COVERS THE FOLLOWING MODELS

MODEL

AF0441-XX AF0442-XX AF0443-XX AF0444-XX AF0445-XX AF0460-XX

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

patible pressure rating and longest service life.

637489 for general repair of all air motors.

GENERAL DESCRIPTION

DO NOT EXCEED MAXIMUM OPERATING

PRESSURE AS INDICATED ON PUMP MODEL PLATE.

REFER TO GENERAL INFORMATION SHEET

FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPORTANT INFORMATION.

This manual only covers the air motor section. It is one of

four documents which support an ARO pump. Replacement copies of these forms are available upon request.

Pump Model Operator’s Manual.

General Information for Air Operated or Hydraulically

Operated Pumps.

Lower Pump End Operator’s Manual.

Air or Hydraulic Motor Operator’s Manual.

The 4-1/4” air motor is a general purpose power unit and

is used with many 2-ball, 4-ball, and chop check pumps.

It utilizes tie rod type construction for easy breakdown

and it connects to the various lower ends via tie rods for

easy operation. Consult pump model operator’s manual

for specic instructions.

8-16-10

8-10-12

MODEL DESCRIPTION CHART

Air Motor Diameter

04 - 4 ¼”

Stroke Length

4 - 4”, 6 - 6”

Air Motor Base/Rod Combination

0 - Divorced pump base with quick coupled rod connection

1 - Divorced pump base with pinned coupled rod connection

2 - Coupled pump base with pinned coupled rod connection

3 - Coupled pump base with male threaded rod connection

4 - Coupled pump base with female threaded rod connection

5 - Coupled high pressure pump base with female threaded

rod connection (See Figure 4)

Air Motor Options

01 – Integrated On/O Valve and Regulator

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276

www.ingersollrandproducts.com

A F 04 X X – XX

© 2012 CCN 15330061

Figure 1

OPERATING AND SAFETY PRECAUTIONS

DO NOT EXCEED MAXIMUM AIR INLET PRESSURE OF

150 P.S.I. (10.3 BAR) OR 75 CYCLES PER MINUTE.

High pressure equipment – Always disconnect air supply and relieve material pressure before attempting to service.

A ground lug is located on the air motor. This ground

lug allows proper grounding of the pump.

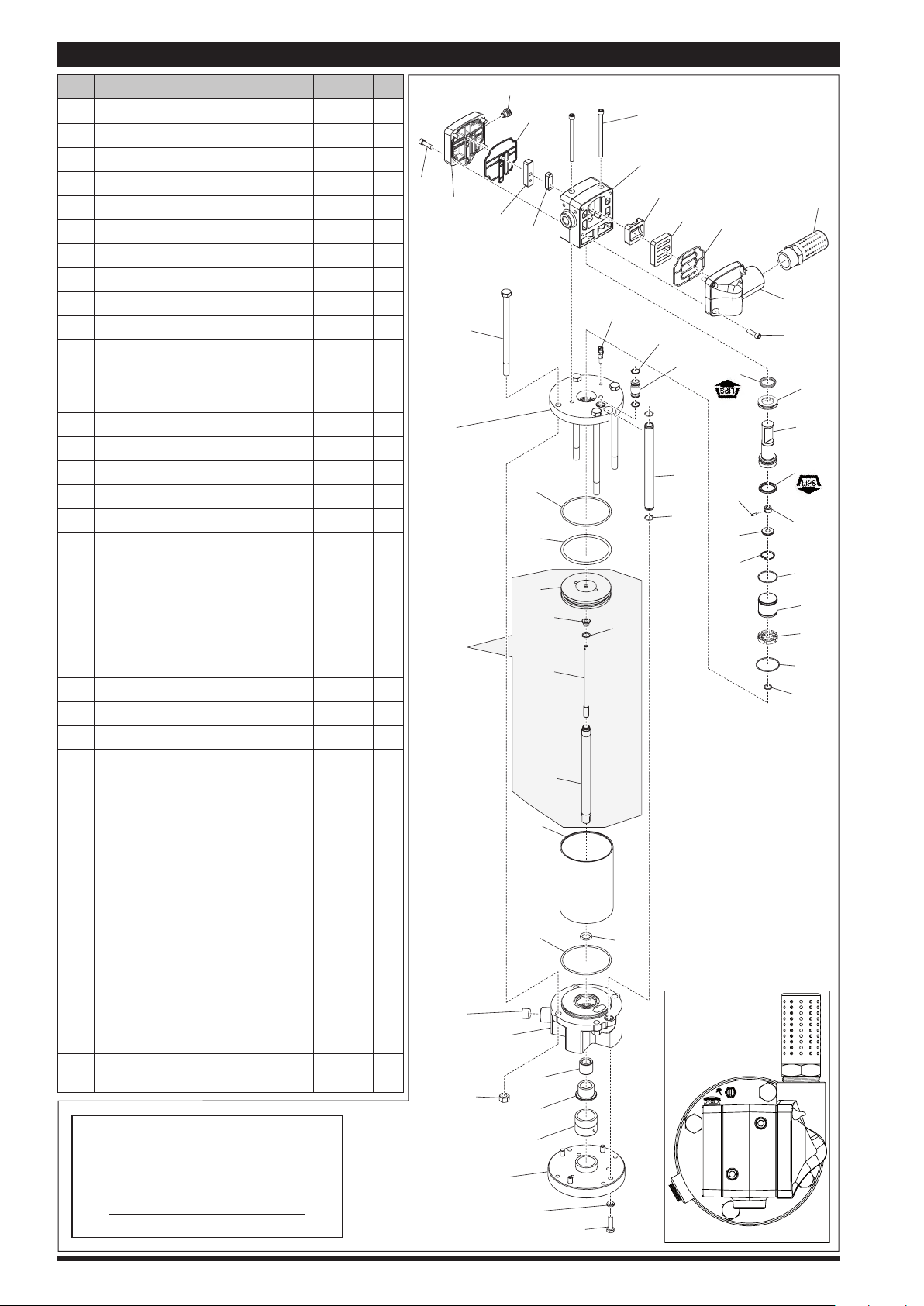

PARTS LIST / AF044X-XX & AF046X-XX

Item Description (Qty) Part No. [Mtl]

111 O-Ring

113

*115 Rod (1) [SS]

116 O-Ring

*117 Piston (1) [A]

*118 O-Ring

*119 Bushing (1) [C]

*120 Trip Rod Assembly (1) [A]

122 Head Plate (1) 96859 [A]

123 O-Ring

124 O-Ring

125 Cap (1) 96897 [D]

126 Sleeve (1) 96901 [Br]

127 Ground Lug (1) 96878 [Bz]

128 O-Ring

129 Snap Ring

130 Washer (1) 96894 [C]

131 Pin (1) 96895 [C]

132 Driver (1) 96868 [C]

133 U-Cup

134 Spool (1) 96875 [A]

135 Vent Bushing (1) 96896 [D]

136 U-Cup

137 Tube (1) 96873 [C]

138 Socket Head Screw

140 Head Manifold (1) 96854 [A]

141 Major Gasket (1) 96900 [B]

142 Valve Plate (1) 96884 [CK]

143 D-Valve (1) 96889 [D]

144 Valve Housing (1) 96864 [A]

145 Socket Head Screw

146 Pilot Insert (1) 96882 [D]

147 Pilot Valve Plate (1) 96883 [CK]

148 Pilot Gasket (1) 96899 [B]

149 Vent Plug (1) 96906 [D]

150 Pilot Cover (1) 96865 [A]

155 Muer (1) 96916 [C]

201 Muer Kit (Optional, See Fig. 5) (1) 67445-1 [C]

202

(1/8” X 4 1/4” o.d.)

(1/16” X 3/4” o.d.)

O-Ring

(3/16” X 4 1/4” o.d.)

(1/16” X 11/16” o.d.)

(3/32” X 1/2” o.d.)

(1/16” X 2” o.d.)

(1/16” X 1 11/16” o.d.)

(1.180” o.d.)

(3/16” X 1 1/2” o.d.)

(5/32” X 1 3/8” o.d.)

(5/16”-18 X 1”)

(5/16”-18 X 4 1/2”)

Regulator / Shut-O (Optional,

See Fig. 5)

Lubriplate FML-2 Grease Packet

(1/4 oz.)

TORQUE REQUIREMENTS

(2) Y325-242 [B]

Y325-16

(4)

(1) Y325-344 [B]

(1) [B]

(1) Y325-109 [B]

(1) Y325-32 [B]

(1) 96917 [B]

(1) Y147-7 [C]

(1) 96908 [B]

(1) 96907 [B]

(8) Y99-52 [C]

(2) Y99-516 [C]

(1) 67442

(2) 94276

[B]

NOTE: DO NOT OVERTIGHTEN FASTENERS.

Tighten (109 & 121) to 10-15 ft-lbs (13.6-20.3 Nm)

Tighten (138 & 145) to 50-60 in-lbs (5.6-6.8 Nm)

LUBRICATION / SEALANTS

NOTE: Lubricate with Grease (ARO p/n 94276).

138

122

*203

Not User

Serviceable

110

Figure 2

150

121

109

147

�

101

106

149

148

146

111

�

116

�

117

112

111

�

103

104

105

107

�

119

120

115

�

108

127

118

102

�

145

144

�

143

113

142

�

�

137

114

113

�

TORQUE SEQUENCE

2

141

�

136

131

130

129

4

�

155

140

138

135

134

133

�

132

128

�

126

125

�

124

123

�

3

1

Page 2 of 8 AF044X-XX & AF046X-XX (en)

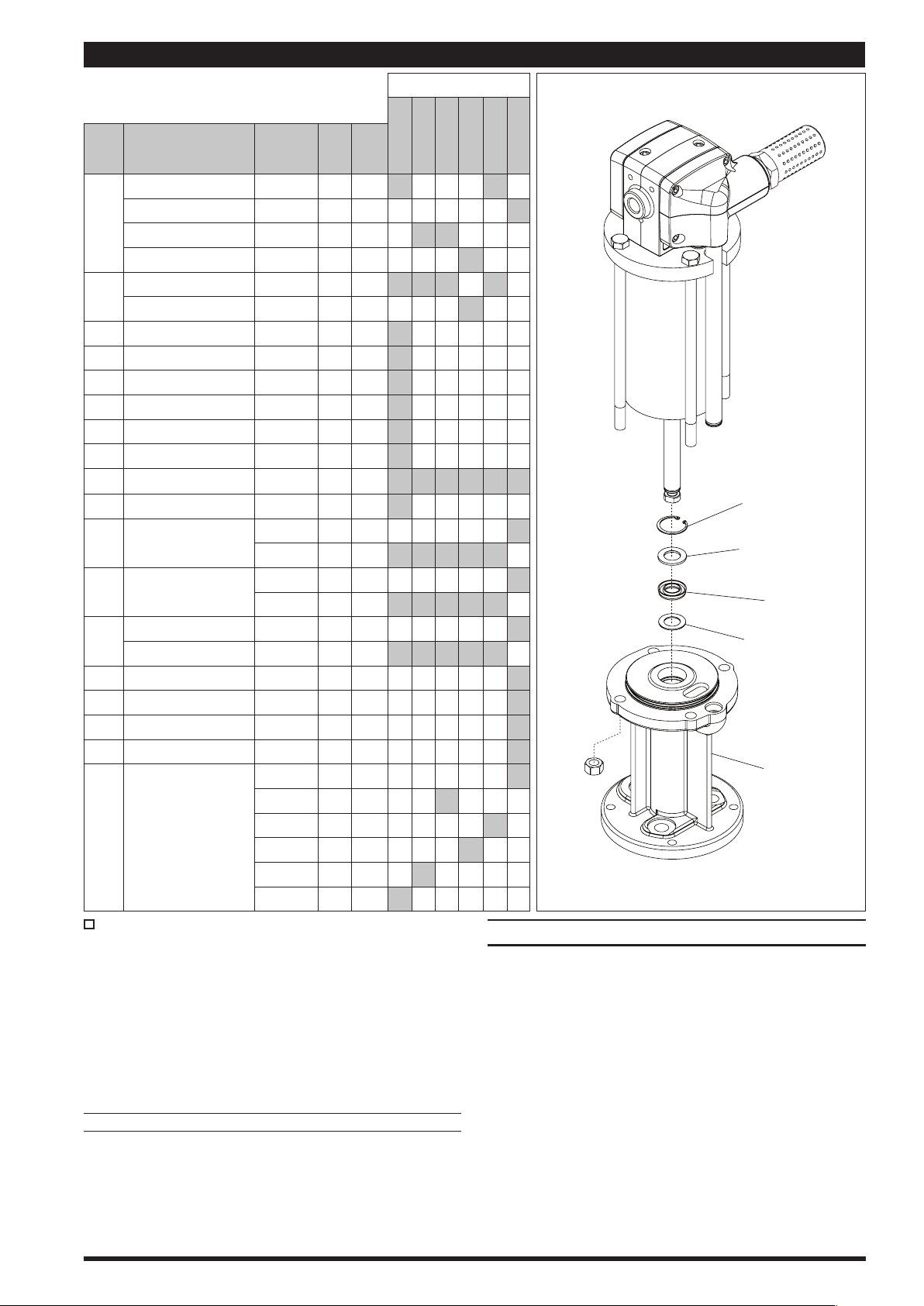

PARTS LIST / AF044X-XX & AF046X-XX

101

151

152

153

154

�

AIR MOTOR MODEL NO.

Item Description

Base & Bearing

Base & Bearing 65023 (1) [A]

101

Base & Bearing

Base

O-Ring

102

O-Ring

Bushing 93310 (1) [D]

103

Retainer 93311 (1) [SS]

104

Guide 93312 (1) [SS]

105

Plate 93958 (1) [A]

106

107 Lock Washer Y14-616-C (4) [C]

Screw

108

Nut

109

Plug

110

Cylinder

112

Tube

114

Bolt

121

Bolt

Washer 90103 (1) [A]

151

U-Cup

152

Washer 73986 (1) [Br]

153

Snap Ring

154

Piston Assembly

(includes items 115, 117, 118,

*203

119, & 120)

Indicates where parts are used.

Items included in Service Kit (637489).

(size)

(Stub)

(Stub)

(Stub)

(1/8” x 1” O.D.)

(1/8” x 1 5/8” O.D.)

(1/2” - 20)

(1/2-14 N.P.T. X 9/16”)

(1/2” - 20 x 10 1/4”)

(1/2” - 20 x 8 1/4”)

(1/4” X 1 1/4” O.D.)

(1.456” O.D.)

Part No. (Qty) [Mtl]

** 65020 (1) [A]

65775 (1) [A]

90074 (1) [A]

[B]

Y325-210

Y325-220 (1) [B]

Y6-66-C

Y11-8-C (4) [C]

93897-1 (1) [PP]

96936 (1) [Ef]

96935 (1) [Ef]

96874-1 (1) [C]

96874-2 (1) [C]

94046-1 (4) [C]

94046-2 (4) [C]

Y186-16 (1) [B]

Y147-131 (1) [C]

67489 (1) --

67490 (1) --

67491 (1) --

67492 (1) --

67493 (1) --

67494 (1) --

(1)

(4)

[C]

AF0441-XX

AF0442-XX

AF0443-XX

NOTE: Base styles and lower packings may vary from that

shown on the cover. Refer to model number in the chart

above.

For simplication of ordering and stocking, the Universal Service Kit contains service parts that can be used for every size

of air motor. When repairing the motor, use only the parts that

are needed for that specic motor. Extra service parts from the

kit will remain after repair of the air motor.

[A] = Aluminum [D] = Acetal

[B] = Buna Nitrile [PP] = Polypropylene

[Br] = Brass [SS] = Stainless Steel

[Bz] = Bronze [Ef] = Epoxy - Fiberglass Filament Reinforced

[C] = Carbon Steel

[CK] = Ceramic

MATERIAL CODE

AF0444-XX

AF0445-XX

AF0460-XX

DISASSEMBLY OF AIR MOTOR

NOTE: All threads are right hand.

Force the piston assembly up by pushing the (115) rod

1.

toward the top of the air motor.

Remove the (155) muffler/(201) muffler assembly for

2.

ease of disassembly.

Remove four (138) socket head screws from the (140)

3.

head manifold. Remove the (140) head manifold by

pulling up and outward to remove from tubes (114) and

(137).

Remove (141) major gasket from the (140) head mani-

4.

fold.

Remove tubes (114) and (137) by pulling upward.

5.

Remove the four (113) O-rings from both tubes (114) and

6.

(137).

Figure 3

(continued on page 4)

AF044X-XX & AF046X-XX (en) Page 3 of 8

Loading...

Loading...