Ingersoll-Rand 8274-A, 8276-A User Manual

SECTION M40

Tool & Hoist Products

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

2200 SERIES POWER MOTORS

(44 SERIES GEARING)

MANUAL 46

Released: 4/73

Revised: 8-2-93

Form: 286-2

Models 8274-( )A and 8276-( )A

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

INDEX

MODEL IDENTIFICATION

GENERAL DESCRIPTION AND OPERATION

AIR AND LUBE REQUIREMENTS

MAINTENANCE

DISASSEMBLY AND ASSEMBLY

DIMENSIONAL DATA

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution Center, White House, TN at PH: (615) 672-0321, FAX: (615) 672-0601.

ARO Tool & Hoist Products

Ingersoll-Rand Company

1725 U.S. No. 1 North l P.O. Box 8000 0 Southern Pines, NC 28388-8000

©1993 THE ARO CORPORATION. PRINTED IN U.S.A.

......................................................................... 2

................................................................

...............................................

......................................................... 2

...................................................

.................................................................... 8

PROFESSIONALTOOLS

PAGE

1

2

3 thru 8

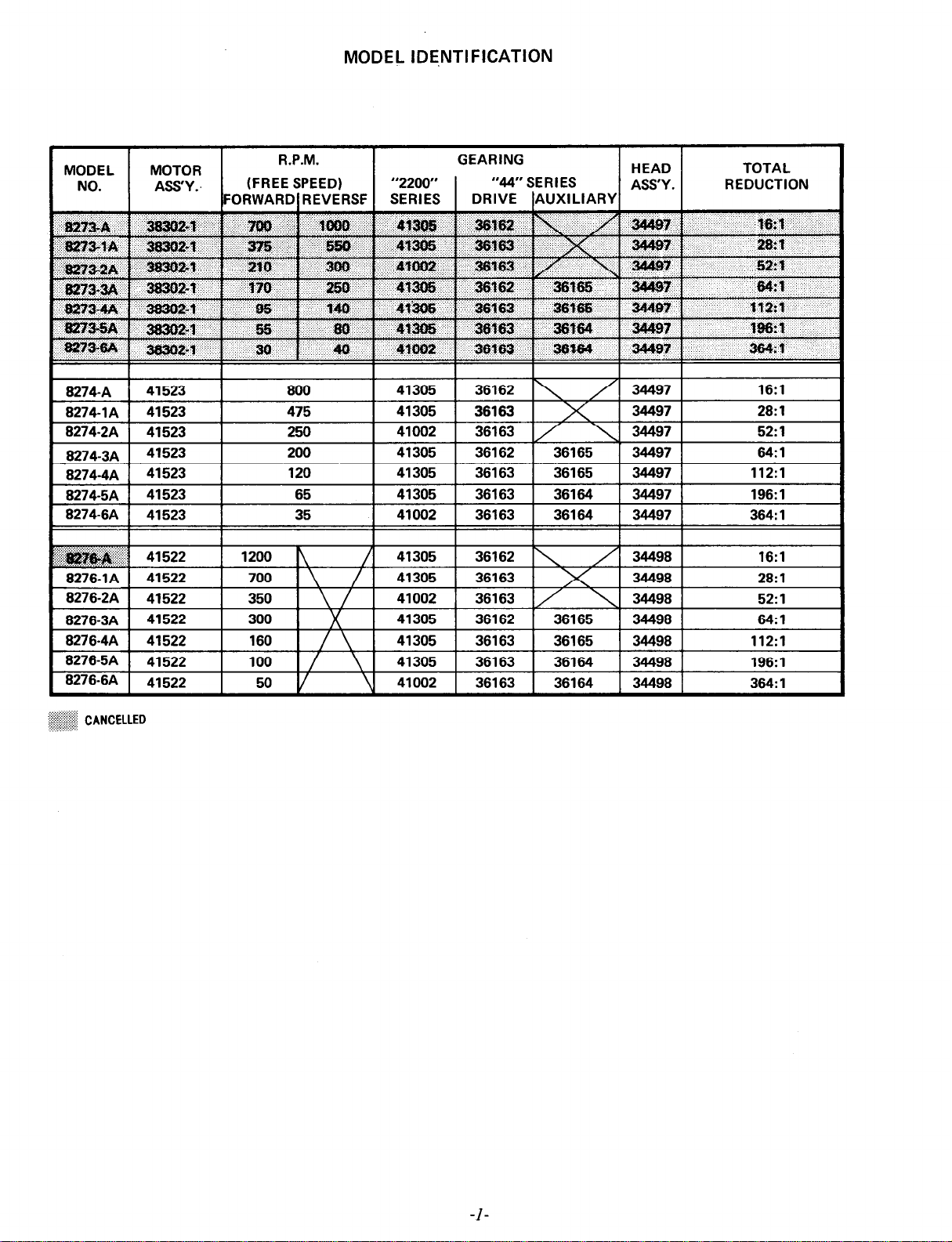

MODEL lDENTlFlCATlON

MODEL

NO.

8274-A 41523 I 800

8274-l A 41523 475

8274-2A 41523 250

8274-3A 41523 200

8274-4A 41523 120

8274-5A 41523 65

MOTOR

ASS’Y:

fORWARD(REVERSF

R.P.M. GEARING

(FREE SPEED) “2200”

“44” SERIES

DRIVE AUXILIARY

SERIES

41305 36162 34497

41305 36163 34497

41002 36163 34497

41305 36162 36165 34497

41305 36163 36165 34497 112:1

41305 36163 36164 34497 196:1

I

HEAD TOTAL

ASS’Y.

REDUCTION

16:1

28:1

52: 1

64:1

8276-4A 41522 160

8276-5A 41522 100

8276-6A

41522 50

41305 36163 36165 34498 112:1

41305 36163 36164 34498 196:1

\

41002 36163 36164 34498 364: 1

OPERATORS MANUAL

This Parts List and Service Instruction Manual is composed

of four sections:

GENERAL DESCRIPTION AND OPERATION

AIR AND LUBE REQUIREMENTS

MAINTENANCE

DISASSEMBLY AND REASSEMBLY OF TOOL

GENERAL DESCRIPTION AND OPERATION

The ARO Models 8274-(

)A and 8276-(

feature “2200” series motors with “44” series gearing.

Models 8274-(

)A are reversible rotation models with a

balanced cylinder which produces the same power in either

forward or reverse rotation. Models 8276-(

direction models.

)A Power Motors

)A are single

AIR AND LUBE REQUIREMENTS

AIR PRESSURE of 90 pounds per square inch at the air

inlet of the tool is required for maximum motor efficiency.

If necessary, an air regulator should be installed to maintain

this pressure when tool is in operation.

FILTERED AND OILED AIR will allow the tool to

operate more efficiently and yield a longer life to operating

parts and mechanisms. A line filter capable of filtering

particles larger than 50 microns should be used with a line

oiler.

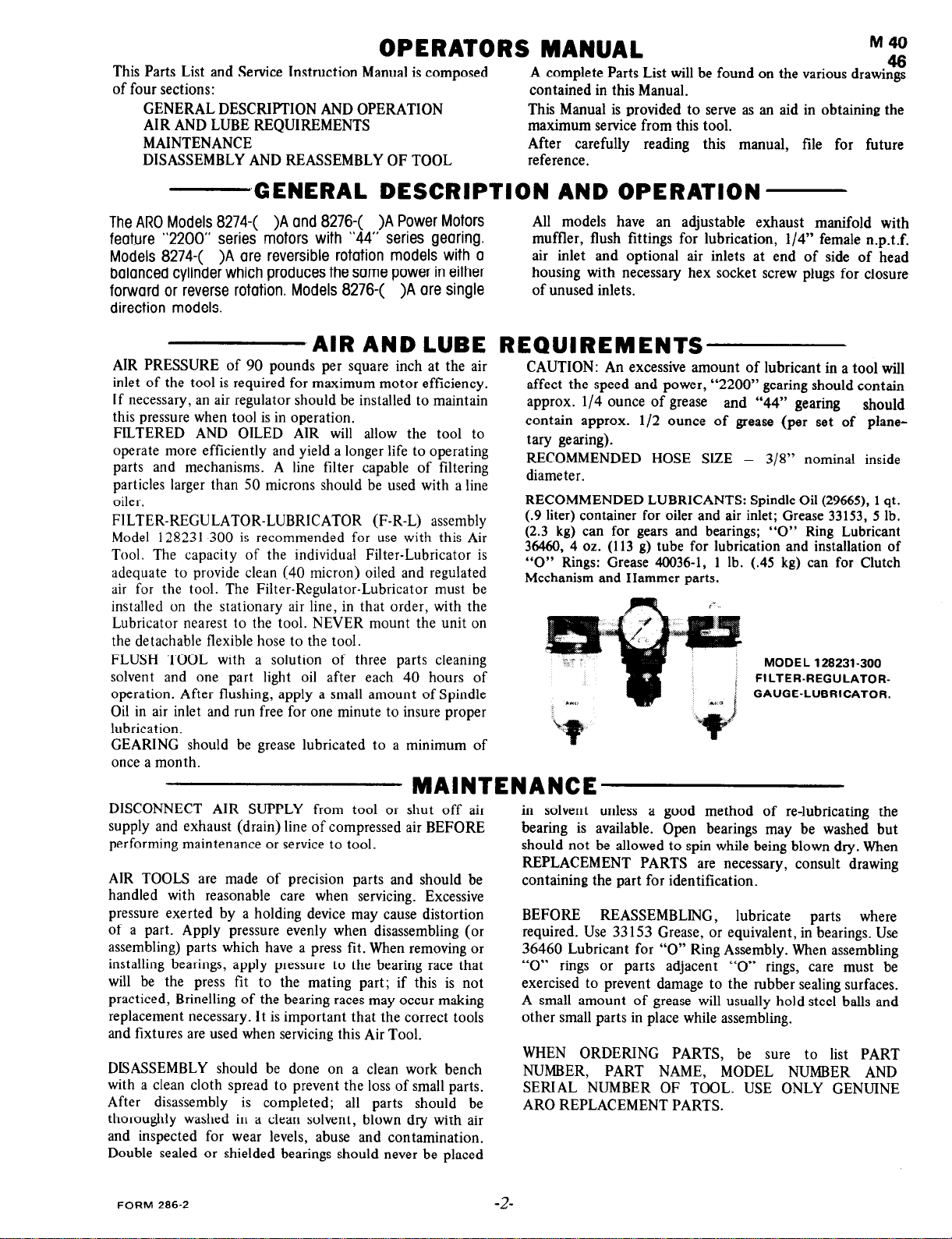

FILTER-REGULATOR-LUBRICATOR (F-R-L) assembly

Model 128231-300 is recommended for use with this Air

Tool. The capacity of the individual Filter-Lubricator is

adequate to provide clean (40 micron) oiled and regulated

air for the tool. The Filter-Regulator-Lubricator must be

installed on the stationary air line, in that order, with the

Lubricator nearest to the tool. NEVER mount the unit on

the detachable flexible hose to the tool.

FLUSH TOOL with a solution of three parts cleaning

solvent and one part light oil after each 40 hours of

operation. After flushing, apply a small amount of Spindle

Oil in air inlet and run free for one minute to insure proper

lubrication.

GEARING should be grease lubricated to a minimum of

once a month.

MAINTENANCE

DISCONNECT AIR SUPPLY from tool or shut off air

supply and exhaust (drain) line of compressed air BEFORE

performing maintenance or service to tool.

AIR TOOLS are made of precision parts and should be

handled with reasonable care when servicing. Excessive

pressure exerted by a holding device may cause distortion

of a part. Apply pressure evenly when disassembling (or

assembling) parts which have a press fit. When removing or

installing bearings, apply pressure to the bearing race that

will be the press fit to the mating part; if this is not

practiced, Brinelling of the bearing races may occur making

replacement necessary. It is important that the correct tools

and fixtures are used when servicing this Air Tool.

DISASSEMBLY should be done on a clean work bench

with a clean cloth spread to prevent the loss of small parts.

After disassembly is completed; all parts should be

thoroughly washed in a clean solvent, blown dry with air

and inspected for wear levels, abuse and contamination.

Double sealed or shielded bearings should never be placed

M

40

A complete Parts List will be found on the various drawings

contained in this Manual.

This Manual is provided to serve as an aid in obtaining the

maximum service from this tool.

After carefully reading this manual, file for future

reference.

All models have an adjustable exhaust manifold with

muffler, flush fittings for lubrication, l/4” female n.p.t.f.

air inlet and optional air inlets at end of side of head

housing with necessary hex socket screw plugs for closure

of unused inlets.

CAUTION: An excessive amount of lubricant in a tool will

affect the speed and power, “2200” gearing should contain

approx. l/4 ounce of grease

contain approx. l/2 ounce of grease (per set of plane-

tary gearing).

RECOMMENDED HOSE SIZE - 3/8” nominal inside

diameter.

RECOMMENDED LUBRICANTS: Spindle Oil (29665), 1 qt.

(.9 liter) container for oiler and air inlet; Grease 33153, 5 lb.

(2.3 kg) can for gears and bearings; “O” Ring Lubricant

36460, 4 oz. (113 g) tube for lubrication and installation of

“0” Rings: Grease 40036-1, 1 lb. (.45 kg) can for Clutch

Mechanism and Hammer parts.

in solvent unless a good method of re-lubricating the

bearing is available. Open bearings may be washed but

should not be allowed to spin while being blown dry. When

REPLACEMENT PARTS are necessary, consult drawing

containing the part for identification.

BEFORE REASSEMBLING, lubricate parts where

required. Use 33 153 Grease, or equivalent, in bearings. Use

36460 Lubricant for “0” Ring Assembly. When assembling

“0” rings or parts adjacent “0” rings, care must be

exercised to prevent damage to the rubber sealing surfaces.

A small amount of grease will usually hold steel balls and

other small parts in place while assembling.

WHEN ORDERING PARTS, be sure to list PART

NUMBER, PART NAME, MODEL NUMBER AND

SERIAL NUMBER OF TOOL. USE ONLY GENUINE

ARO REPLACEMENT PARTS.

and “44” gearing

MODEL 128231-300

FILTER-REGULATOR-

GAUGE-LUBRICATOR.

48

should

FORM 286-2

-2-

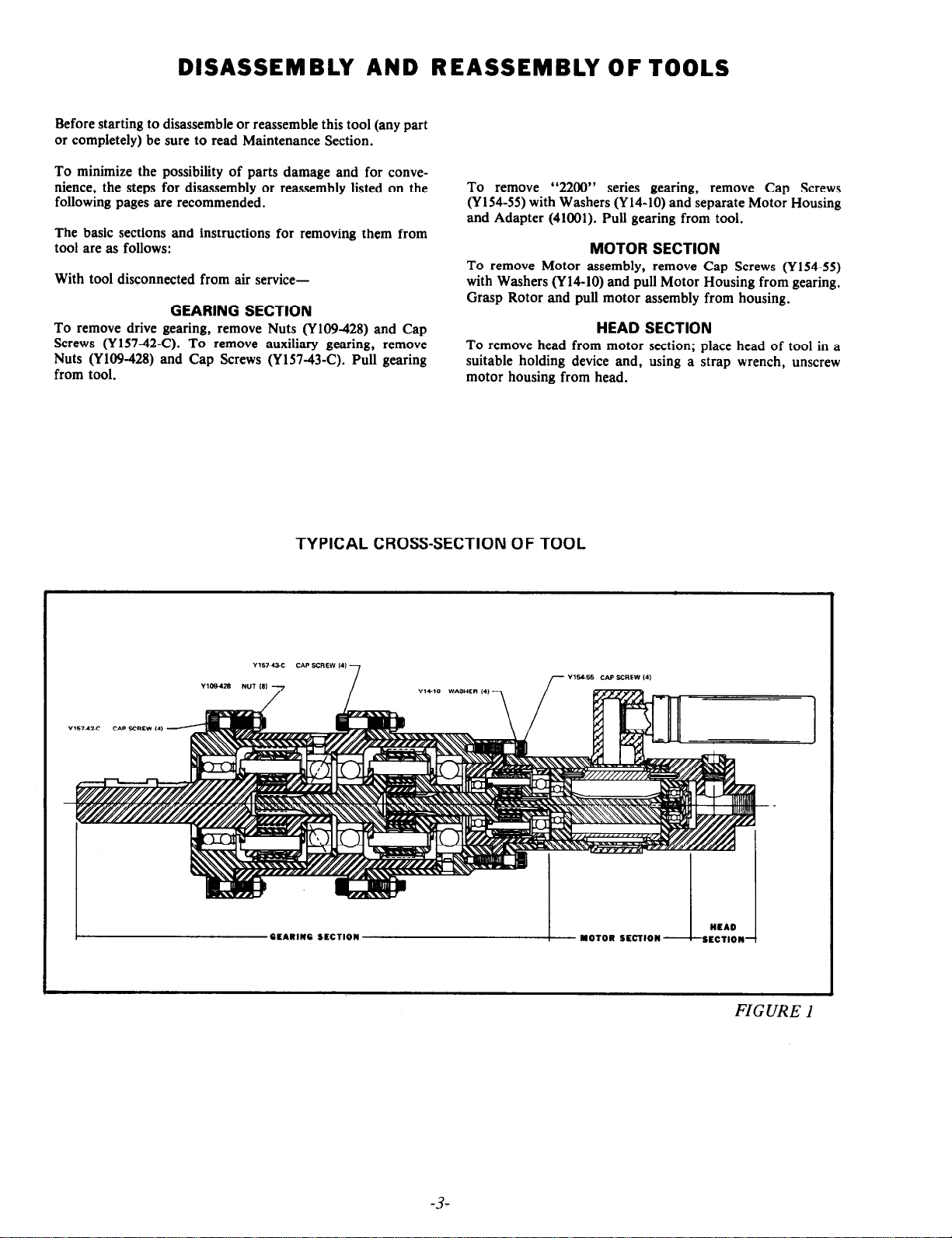

DISASSEMBLY AND REASSEMBLY OF TOOLS

Before starting to disassemble or reassemble this tool (any part

or completely) be sure to read Maintenance Section.

To minimize the possibility of parts damage and for convenience, the steps for disassembly or reassembly listed on the

following pages are recommended.

The basic sections and instructions for removing them from

tool are as follows:

With tool disconnected from air service-

GEARING SECTION

To remove drive gearing, remove Nuts (Y109-428) and Cap

Screws (Y157-42-C). To remove auxiliary gearing, remove

Nuts (Y109-428) and Cap Screws (Y157-43-C). Pull gearing

from tool.

TYPICAL CROSS-SECTION OF TOOL

To remove

(Y154-55) with Washers (Y14-10) and separate Motor Housing

and Adapter (41001). Pull gearing from tool.

To remove Motor assembly, remove Cap Screws (Y154-55)

with Washers (Y 14-10) and pull Motor Housing from gearing.

Grasp Rotor and pull motor assembly from housing.

To remove head from motor section; place head of tool in a

suitable holding device and, using a strap wrench, unscrew

motor housing from head.

“2200” series gearing, remove Cap Screws

MOTOR SECTION

HEAD SECTION

-3-

FIGURE 1

Loading...

Loading...