Ingersoll-Rand 7015-11V-A User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

Tool & Hoist Products

“0” SERIES DIE GRINDER

18,000 R.P.M.

Model 7015-11V-A

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

Released: 2-14-91

Revised: 9-27-93

Form:

3754-2

OPERATING AND SAFETY PRECAUTIONS

To aid the operator’s understanding of proper and safe use of

grinders, the publications, “Use, Care and Protection of Abrasive

Wheels”, A.N.S.I. 87.1 and “Safety Code for Portable Air Tools”,

A.N.S.I. B186.1, can be purchased from:

American National Standards Institute, Inc.

1430 Broadway

New York, New York 10016

CAUTION,

l

l

l

l

l

l

l

l

l

WARNING: Repeated prolonged operator exposure to vibrations

which may be generated in the use of certain hand-held tools

may produce Raynaud’s phenomenon, commonly referred to as

Whitefinger disease. The phenomenon produces numbness and

burning sensations in the hand and may cause circulation and

nerve damage as well as tissue necrosis. Repetitive users of

hand-held tools who experience vibrations should closely moni-

tor duration of use and their physical condition.

.

Keep hands and clothing away from rotating end of tool.

Wear suitable eye protection while operating tool.

Use tool only for purposes for which it was intended.

Disconnect air supply from tool before removing/installing

mounted wheel or performing other maintenance procedures.

Never exceed rated r.p.m. of tool.

Use only mounted wheels of the A, B and W shapes.

Use only medium and high strength mounted wheels.

Do not use excessive work pressure.

Allow only people who have received training in “proper grinder operation” to operate grinder.

MOUNTING INSTRUCTIONS

Be sure collet is in good condition and property secured to

grinder spindle.

Insert shaft of mounted wheel to the full depth of gripping jaws

of collet. At least one-half of shaft length shall be inserted into

collet jaws.

Be sure mounted wheel is compatible with the speed of the

grinder.

Use type 16, 17, 18, 18R and 19 cone and plug wheels only

with optional cone wheel adapter 37292-( ).

CAPACITIES (MAXIMUM)

l

Carbide Bur

l

Mounted Stone

3/4”

1-1/2”

AIR SUPPLY REQUIREMENTS

For maximum operating efficiency, the following air supply specifi-

cations should be maintained to this air tool:

l

AIR PRESSURE - 90 PSIG (6 bar)

l

AIR FILTRATION - 50 micron

l

LUBRICATED AIR SUPPLY

l

HOSE SIZE - 5/16” (8 mm) I.D.

An ARO® model 128231-800 air line FILTER/REGULATOR/LUBRICATOR (F.R.L.) is recommended to maintain the above air

supply specifications.

ROUTINE LUBRICATION REQUIREMENTS

Lack of or an excessive amount of lubrication will affect the performance and life of this tool. Use only recommended lubricants at

below time intervals:

EVERY 8 HOURS OF TOOL OPERATION -Fill lubricator reser-

voir of recommended F.R.L. with spindle oil (29665). If an in line or

air line lubricator is not used, apply several drops of spindle oil

(29665) in air inlet.

EVERY 40 HOURS OF TOOL OPERATION - Flush tool with a

solution of three (3) parts cleaning solvent to one (1) part spindle

oil (or use Kerosene).

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution Center, White House, TN at PH: (615) 672-0321, FAX: (615) 672-0601.

ARO Tool & Hoist Products

Ingersoll-Rand Company

1725 U.S. No. 1 North l P.O. Box 8000 l Southern Pines.

©1993 THE ARO CORPORATlON PRINTED IN U.S.A.

NC 28388-8000

After disassembly is complete, all parts, except sealed or shielded

bearings, should be washed with solvent. To relubricate parts, or

for routine lubrication, use the following recommended lubricants:

“0” Rings & Lip Seals

RECOMMENDED LUBRICANTS

Where Used

Air Motor

Gears and Bearings

ARO Part #

29665

36460

33153

.

Description

1 qt. Spindle Oil

4 oz. Stringy Lubricant

5 lb. “EP” - NLGI #1 Grease

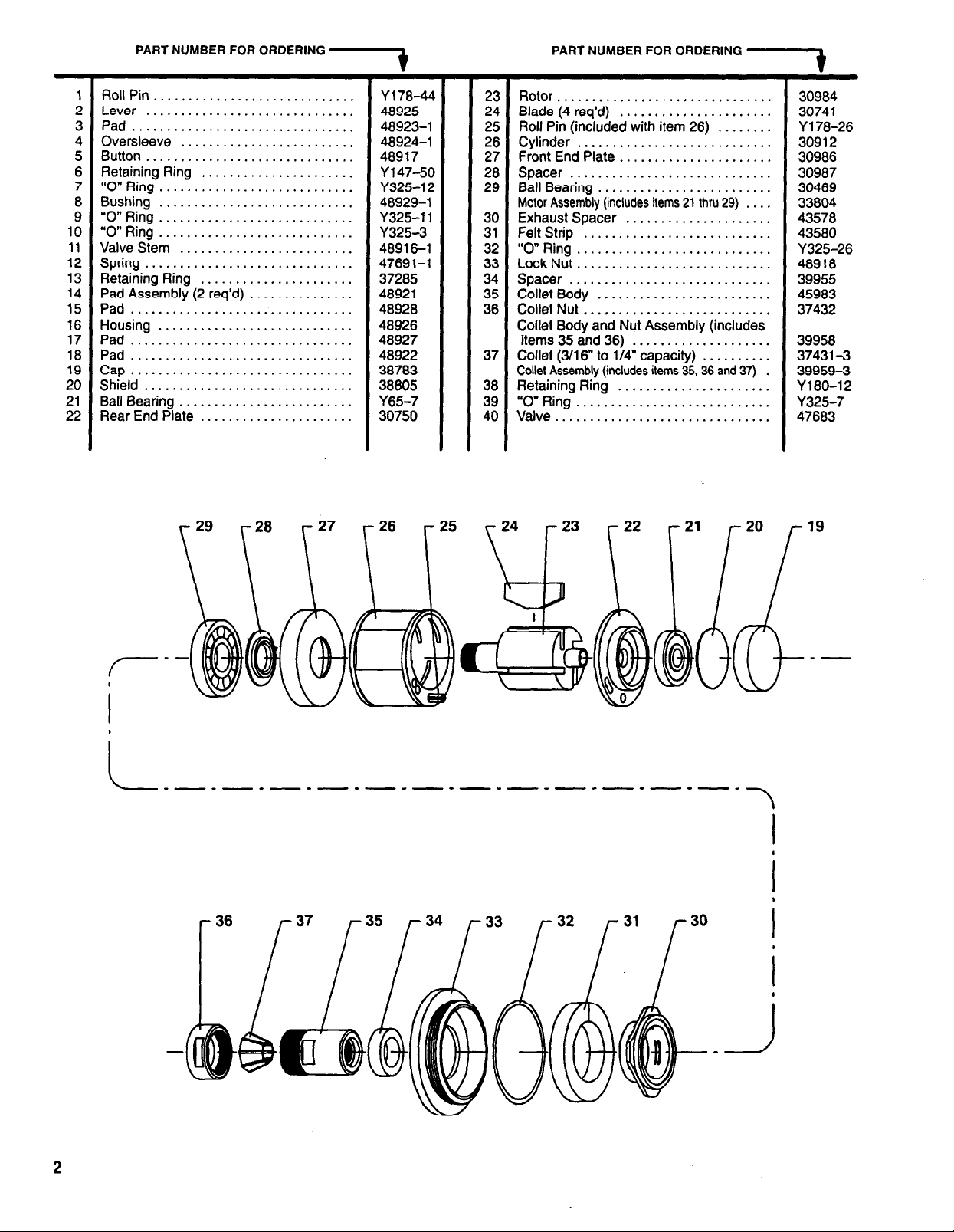

PART NUMBER FOR ORDERING

1

Roll Pin .............................

2

Lever

3

4

5

6

7

..............................

Pad.. ..............................

Oversleeve .........................

Button ..............................

Retaining Ring ......................

“0” Ring ............................

Bushing ............................

9

“0” Ring.. ..........................

10

“0” Ring.. ..........................

11

Valve Stem .........................

12

Spring ..............................

13

Retaining Ring ......................

14

Pad Assembly (2 req’d) ...............

Pad.. ..............................

15

Housing ............................

16

17

Pad.. ..............................

18

Pad.. ..............................

Cap ................................

20

Shield ..............................

21

Ball Bearing .........................

22

Rear End Plate ......................

t

Y178-44

48925

46923-1

48924-1

48917

Y147-50

Y325-12

48929-1

Y325-11

Y325-3

48916-1

47691-1

37285

48921

48928

48926

48927

48922

38783

38805

Y65-7

30750

I -

PART NUMBER FOR ORDERING

Rotor ...............................

23

24

Blade (4 req’d) ......................

Roll Pin (included with item 26) ........

25

Cylinder ............................

28

27

Front End Plate ......................

Spacer .............................

28

Ball Bearing .........................

Motor Assembly (includes items 21 thru 29) ....

Exhaust Spacer .....................

30

31

Felt Strip ...........................

32

“0” Ring.. ..........................

Lock Nut ............................

34

Spacer .............................

35

Collet Body .........................

Collet Nut ...........................

36

Collet Body and Nut Assembly (includes

items 35 and 36) ....................

37

Collet (3/16” to 1/4” capacity) ..........

Collet Assembly (includes items 35, 36 and 37) .

38

Retaining Ring ......................

39

“0” Ring.. ..........................

40

Valve ...............................

t

30984

30741

Y178-26

30912

30966

30987

30469

33804

43578

43580

Y325-26

48918

39955

45983

37432

39958

37431-3

39959-3

Y180-12

Y325-7

47683

21 20

3

19

--

Loading...

Loading...