Ingersoll-Rand 67317-X User Manual

OPERATOR’S MANUAL

INCLUDING: SERVICE KIT, TROUBLESHOOTING, PARTS LIST, DISASSEMBLY & REASSEMBLY

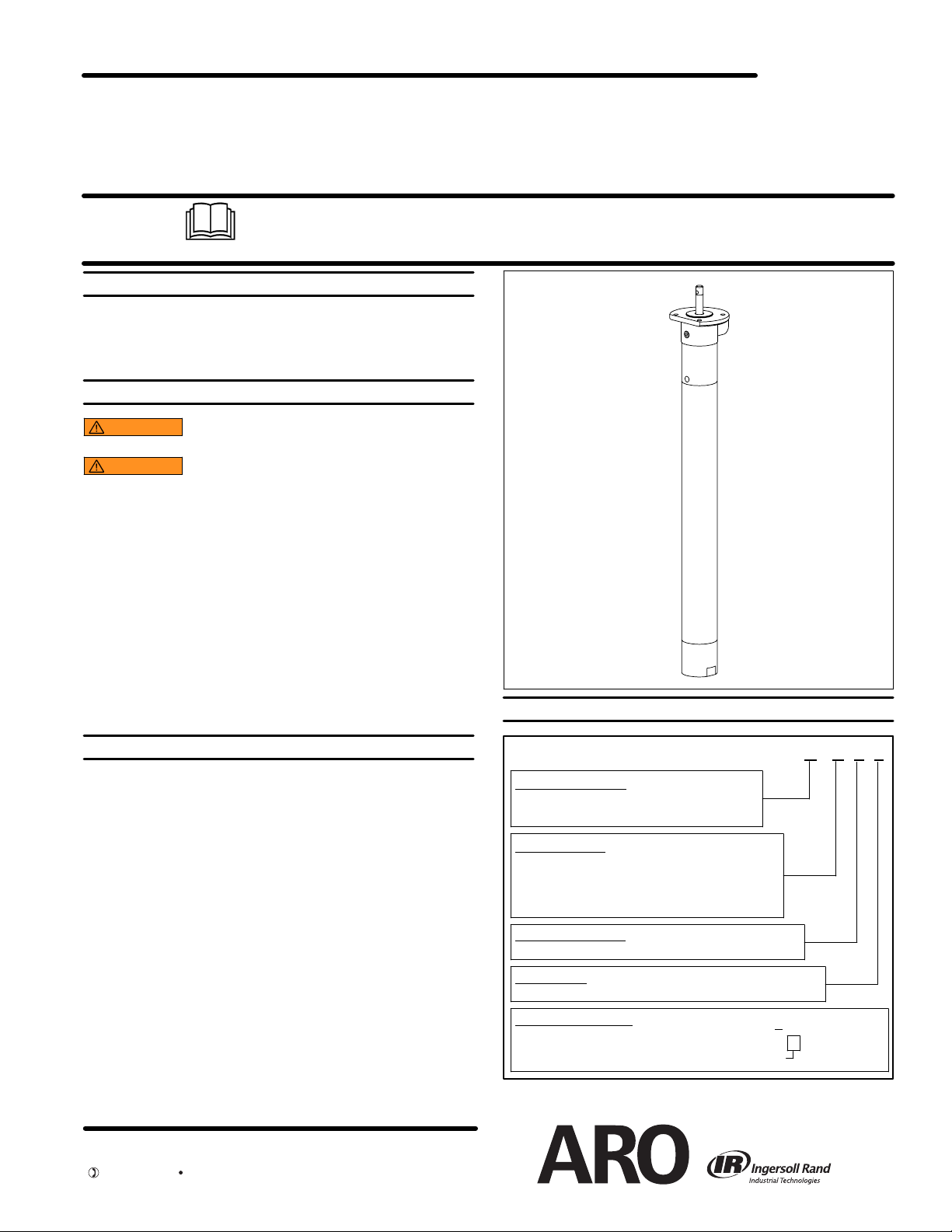

TWO-BALL STYLE LOWER PUMP ENDS

STAINLESS STEEL

ALSO COVERS 637379-X SERVICE KITS

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 637379-X31 for general repair of 6731X-X31 lower pump ends.

GENERAL DESCRIPTION

67317-X

67318-X

RELEASED: 3-6-03

REVISED:

J)

(REV.

8-1-11

WARNING

SURE AS INDICATED ON PUMP MODEL PLATE.

WARNING

FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPORTANT

INFORMATION.

DO NOT EXCEED MAXIMUM OPERATING PRES-

REFER TO GENERAL INFORMATION SHEET

• This manual only covers the lower pump section. It is one of four

documents which support an ARO pump. Replacement copies of

these forms are available upon request.

- NM2202B-X-X Pump Model Operator’s Manual.

- General Information for Air Operated or Hydraulically Operated

Pumps.

= Lower Pump End Operator’s Manual.

- Air or Hydraulic Motor Operator’s Manual.

• Thetwo-ball design provides for easy priming of the lower foot valve.

The double acting feature is standard in all ARO industrial pumps,

material is delivered to the pump discharge outlet on both the up and

down stroke.

MAINTENANCE

The air / hydraulic motor is completely separate from the lower pump

end. This helps to keep the motor from being contaminated by the material being pumped. Periodically, flush entire pump system with a lubricant that is compatible with the material being pumped.

Provide a clean work surface to protect sensitive internal moving parts

from contamination from dirt and foreign matter during disassembly and

reassembly.

Before reassembling, lubricate parts as required. When assembling “O”

rings, or parts adjacent to “O” rings, exercise care to prevent damage to

“O” rings and “O” ring groove surface.

Figure 1

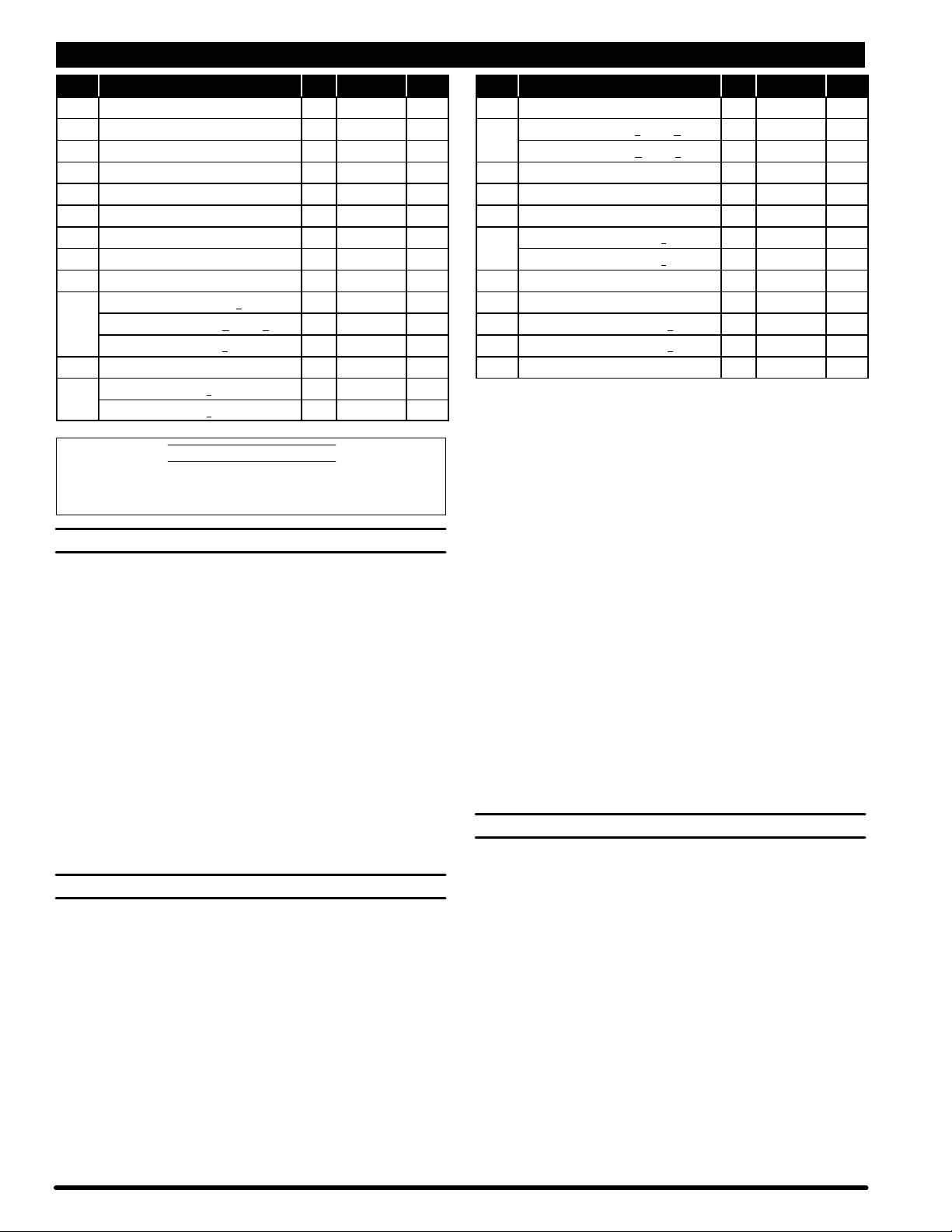

LOWER PUMP END DESCRIPTION CHART

6731 X -X 3 1

Container Suitability

7 - 55 Gallon

8 - Universal (stub)

Packing Material

7 - PTFE (upper and lower)

B - UHMW-PE (upper) / PTFE (lower)

C - UHMW-PE (upper and lower)

J - Polyurethane (upper) / UHMW-PE (lower)

Spring Arrangement

3-NoSpring

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 15211485

Plunger Type

1 - Standard (300 series stainless steel)

SERVICE KIT SELECTION

EXAMPLE: Lower Pump End # 67317-C31

Service Kit # 637379-C31

6731X - X 31

637379 - X 31

Packing

PARTS LIST

Item Description (size) Qty Part No. [Mtl] Item Description (size) Qty Part No. [Mtl]

n 1 “O” Ring (1/8” x 11/16” o.d.) (1) Y327-205 [V]

2 Pipe Plug (1/8 - 27 N.P.T.F. x 0.27”) (1) Y17-50 [C]

3 Outlet Body (1) 95705 [SS]

4 Ground Screw (#10 - 32 x 1/4”) (1) 93005 [C]

6 Inner Tube (1) 95712 [SS]

7 Rod (1) 96063 [C]

8 Dowel Pin (3/16” o.d. x 7/8”) (1) 95803 [C]

9 Retainer (1) 95804 [SH]

10 Washer (2) 95234-1 [PPS]

n 11 Rod Seal models 6731X-731 (1) 95574-2 [T]

models 6731X-B31 and -C31 (1) 95574-1 [UH]

models 6731X-J31 (1) 95235 [U]

12 Retaining Ring (0.575” i.d.) (1) 95711 [SH]

13 Rod models 67317-X (18.000” long) (1) 95710 [SS]

models 67318-X (5.500” long) (1) 95713 [SS]

14 Cup Follower (1) 90601 [SS]

n 15 Cup models 6731X-731 and -B31 (1) 73919 [T]

models 6731X-C31 and -J31 (1) 92867-1 [UH]

16 Washer (1) 90610 [SS]

17 Ball (1.000” dia.) (1) 90948 [SS]

18 Inner Check Seat (1) 96144 [SS]

19 Suction Tube models 67317-X (1) 95706 [SS]

models 67318-X (1) 95714 [SS]

21 Ball (1.1875” dia.) (1) 90949 [SS]

22 Dowel Pin (0.25” o.d. x 1.828”) (1) 90620 [SS]

23 Foot Valve Seat (models 67317-X only) (1) 95977 [SS]

24 Foot Valve Seat (models 67318-X only) (1) 96015 [SS]

n Items included in Service Kit 637379-X31

MATERIAL CODE

[C] = Carbon Steel [T] = PTFE

[PPS] = Polyphenylene Sulfide [U] = Polyurethane

[SH] = Hardened Stainless Steel [UH] = UHMW-PE

[SS] = Stainless Steel [V] = VitonR

LOWER PUMP DISASSEMBLY

NOTE: All threads are right hand.

1. Clamp (3) outlet body horizontally in a vise. Using a strap type

wrench to hold (19) suction tube, unthread and remove (23 or 24)

foot valve seat.

2. Remove (22) dowel pin, releasing (21) ball.

3. Using a strap type wrench, unthread and remove (19) suction tube.

4. Remove (13) rod and components from (19) suction tube.

5. Using a 1-1/2” wrench, unthread and remove (18) inner check seat,

releasing (17) ball, (16) washer and (15) cup.

6. Slide (12) retaining ring, (10) washers, (11) rod seal and (9) retainer

down (13) rod, allowing removal of (8) dowel pin.

7. Remove (7) rod, (9) retainer, two (10) washers, (11) rod seal and

(12) retaining ring from (13) rod.

8. Remove (1) “O” ring from (3) outlet body.

9. DO NOT remove (6) inner tube unless damage is evident. To remove, clamp (3) outlet body in a vise and unthread (6) inner tube using a strap type wrench.

LOWER PUMP REASSEMBLY

NOTE: Refer to the illustration (figure 2, page 3) for lip seal direction.

NOTE: All threads are right hand. Thoroughly clean and lubricate all

seals and bores with Wet-Sol “Plus” upon assembly.

1. Assemble (15) cup, (16) washer and (17) ball to (14) cup follower,

securing with (18) inner check seat. NOTE: Tighten(18) inner check

seat to 60 - 70 ft lbs (81.3 - 94.9 Nm).

2. Assemble (14) cup follower and components to (13) rod. NOTE:

Tighten (14) cup follower to 60 - 70 ft lbs (81.3 - 94.9 Nm).

3. Slide (12) retaining ring, (10) washer, (11) rod seal (lips down), (10)

washer and (9) retainer onto top end of (13) rod, past the retaining

ring groove.

4. Assemble (7) rod to (13) rod, securing with (8) dowel pin.

5. Slide (9) retainer, (10) washer, (11) rod seal, (10) washer and (12)

retaining ring up, securing (8) dowel pin.

6. Clamp (3) outlet body horizontally in a vise.

7. Apply PTFE tape to 1-7/16” threads of (3) outlet body and assemble

(6) inner tube to (3) outlet body. NOTE: Tighten (6) inner tube to 120

in. lbs (13.6 Nm) minimum.

8. Assemble (1) “O” ring into (3) outlet body.

9. Assemble (7) rod and components into (6) inner tube and (3) outlet

body.

10. Assemble (21) ball to (23 or 24) foot valve seat, securing with (22)

dowel pin.

11. Apply PTFE tape to threads of (23 or 24) foot valve seat and assemble (23 or 24) foot valve seat and components to (19) suction

tube. NOTE: Tighten (23 or 24) foot valve seat to 60 - 70 ft lbs (81.3 -

94.9 Nm).

12. Apply PTFE tape to threads of (3) outlet body and assemble (19)

suctiontube to (3) outlet body.NOTE: Tighten (19) suction tube to60

- 70 ft lbs (81.3 - 94.9 Nm).

TROUBLE SHOOTING

•

No material at outlet (pump continually cycles). Check material

supply,disconnect or shut off the air supply and replenish the material, reconnect.

• Material on one stroke only (fast downstroke). The (21) lower ball

may not be seating in the (23 or 24) foot valve seat. Remove the (21)

ball from the foot valve seat, clean and inspect the ball and seat area.

If the ball or seat is damaged, replace.

• Material on one stroke only (fast upstroke). The (17) upper ball

may not be seating in the (18) inner check seat . Remove the (17) ball

from the (18) check seat, clean and inspect. If the (17) ball is damaged, replace. Check for worn or damaged packings and seals. Replace the packings and seals as necessary.

S VitonR is registered trademarks of the DuPont Company S AROR is a registered trademark of Ingersoll-Rand Company S

Page2of4 67317-X (en)

Loading...

Loading...