Page 1

OPERATOR’S MANUAL

INCLUDING: SPECIFICATIONS, SERVICE KITS, GENERAL INFORMATION, PARTS, TROUBLESHOOTING RELEASED: 11-10-06

4.125 SQ.” MOTOR

67314-B

67314-B

REVISED: 5-17-10

(REV. 03)

65 - 2000 P.S.I. RANGE

HYDRAULIC POWER MOTOR

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Use only genuine ARO® replacement parts to assure compat-

ible pressure rating and longest service life.

637450 pump repair kit, includes the necessary soft parts for

normal service of the entire pump.

SPECIFICATIONS

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67314-B

Type . . . . . . . . . . . . . . . . . . . . Hydraulic Operated Power Motor

Motor Size . . . . . . . . . . . . . . . . . . . . . . . . . . 4.125 sq.” (26.6 sq. cm)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6” (152 mm)

Hydraulic Inlet (female) . . . . . . . . . . . . . 1/2 - 14 N.P.T.F. - 2

Hydraulic Outlet (female) . . . . . . . . . . . 3/4 - 14 N.P.S.M.

Pump Construction . . . . . . . . . . . . . . . . . Carbon Steel

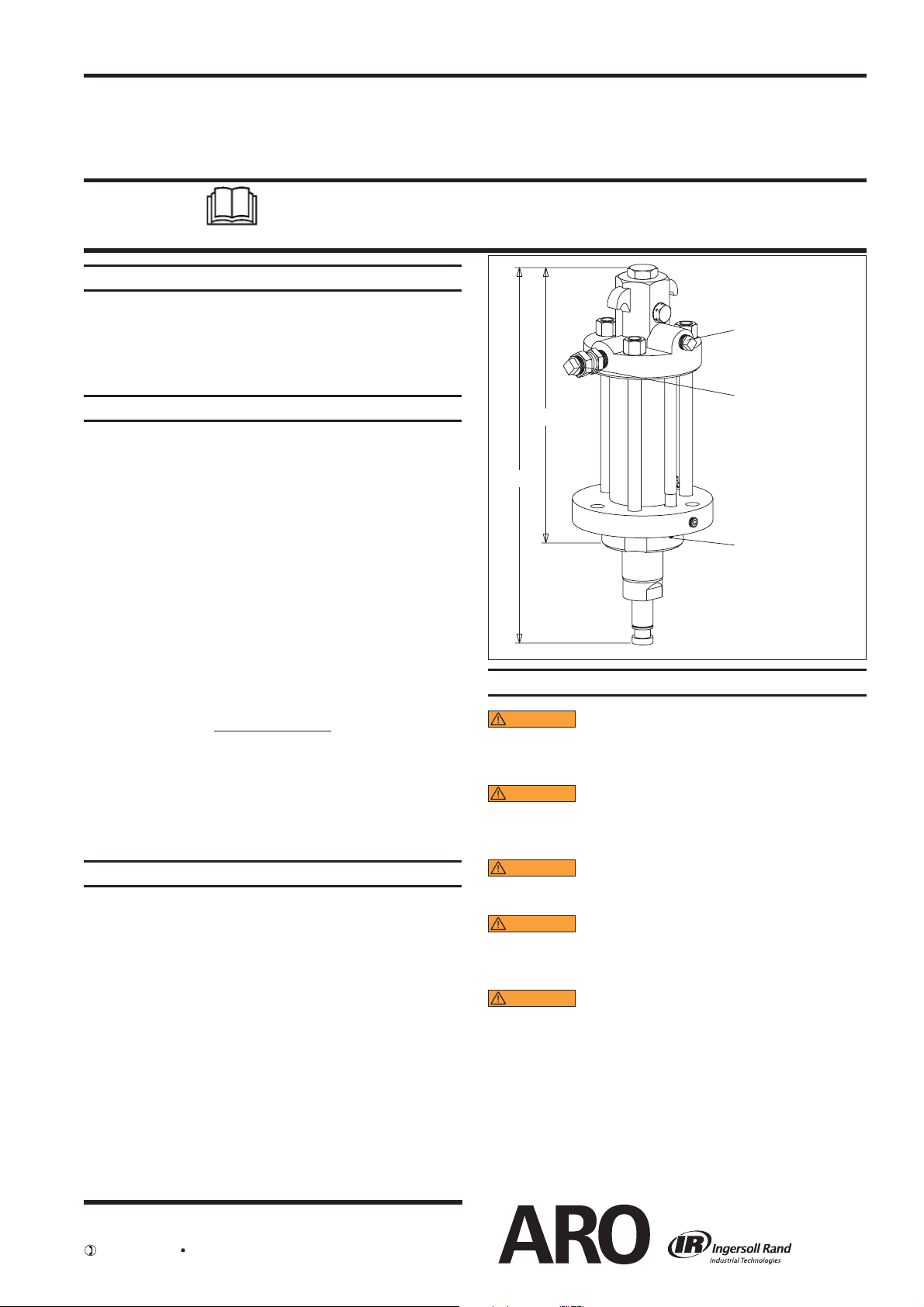

Dimension “A” . . . . . . . . . . . . . . . . . . . . . . 20-13/32” (518.2 mm)

Dimension “B” . . . . . . . . . . . . . . . . . . . . . . 15-11/16” (397.8 mm)

“C” Weep Hole . . . . . . . . . . . . . . . . . . . . . . 1/8 - 27 N.P.T.F. - 1

Motor Diameter . . . . . . . . . . . . . . . . . . . . . 8” (203.2 mm)

Maximum Temperature Limits . . . . . . 130° F (54° C)

Mounting Bracket available . . . . . . . .

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37.75 lbs (17.1 kgs)

95933

B

A

OPERATING AND SAFETY PRECAUTIONS

Hydraulic Inlet

Hydraulic Outlet

C

Figure 1

PERFORMANCE

Inlet Pressure Range . . . . . . . . 65 - 2000 p.s.i. (4.5 - 137.9 bar)

Required H-power @ 50 c.p.m. . . . . . . 3.2 @ 1200 (82.8 bar)

Hydraulic ow required @ 50 c.p.m. 11 g.p.m. (41.6 l.p.m.)

Maximum Thrust generated . . . . . . . . 8250 lbs

Maximum recommended cycles / minute . . . . . . . . . 50

Noise Level . . . . . . . . . . . . . . . . . . . . . . . . . N/A

GENERAL DESCRIPTION

The 4.125 square inch hydraulic motor is a general purpose

power unit and is used on many ARO industrial 2-ball, 4-ball

and chop-check pumps. It utilizes tie rod type construction

for serviceability and connects to the various lower pump

ends by tie rods.

Due to frictional losses in the system, a greater horsepower

is required to run the motor. Power supplies generating less

than shown as required in the Performance Specifications

above will work with the motor but at a reduced pressure or

cycle rate.

WARNING

UAL INCLUDED FOR ADDITIONAL OPERATING AND

SAFETY PRECAUTIONS AND OTHER IMPORTANT INFORMATION.

WARNING

equipment failure resulting in severe injury or property damage. Do not exceed the maximum material

pressure of any component in the system.

WARNING

vent over-pressurization of the system and possible

component rupture.

WARNING

cause re. The unit is rated for operation up to 130° F

(54° C). Be sure return lines are sized larger than supply lines and similarly pressure rated.

WARNING

unit components without relieving hydraulic system

pressure rst. The high pressures involved could

cause serious injury.

NOTE: If this pump was purchased separately (not part

of a system), consult your sales representative for compatible dispensing accessories which will best match the

application. All accessories must be able to withstand the

maximum pressure developed by the pump.

A replacement warning label is available upon request,

pn \ 94576.

READ THE GENERAL INFORMATION MAN-

EXCESSIVE MATERIAL PRESSURE. Can cause

A pressure relief valve must be used to pre-

Excessive hydraulic oil temperature can

Never service or disassemble the unit or

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 276-4658 FAX (800) 266-7016

www.ingersollrandproducts.com

© 2010 CCN 15267008

Page 2

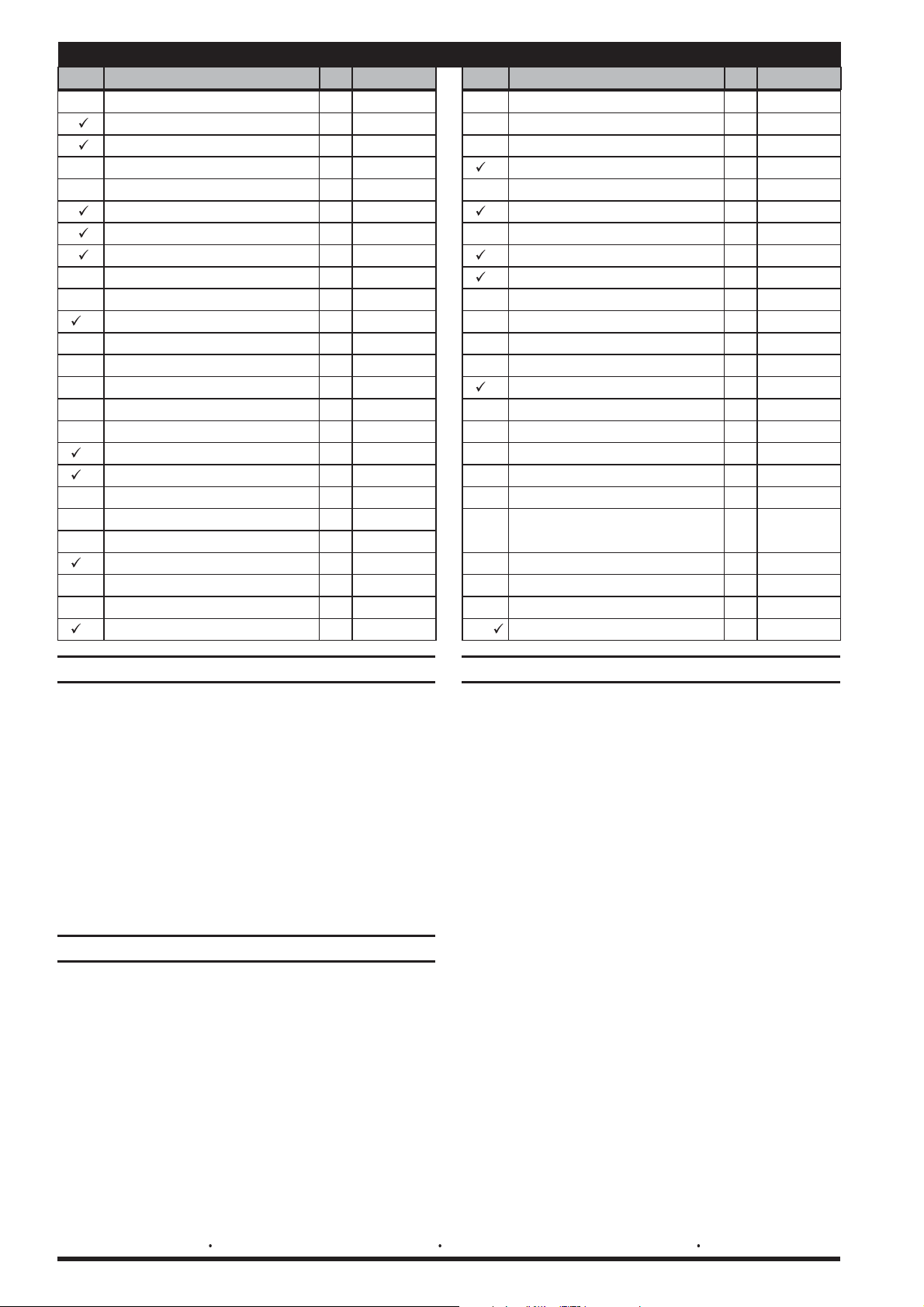

PARTS LIST / 67314-B

Item Description

2 “O” Ring

(1/4" - 28)

3 Nut

4a Spool (1) 94551

4b Sleeve (1) 94552

(0.3750” diameter)

5 Ball

7 “O” Ring

9 Cylinder Head (1) 95866

10 “O” Ring

11 Sleeve Washer (1) 94553

12 Retaining Ring (1) Y147-18

13 “O” Ring

21 “O” Ring

24 “O” Ring

(size)

(3/32” x 1-3/16” o.d.)

(3/32” x 11/16” o.d.)

(3/32” x 3-7/16” o.d.)

(3/32” x 1-3/4” o.d.)

(1/16” x 2-1/4” o.d.)

(3/32” x 1-7/8” o.d.)

(Qty) Part No. Item Description

(1) Y330-120

(3) 94794

(2) Y16-112

(2) Y330-112

(2) Y330-152

(3) Y330-129

(1) Y325-34

(1) Y330-131

(size)

94549)1(gulP poT1

11669)2(gnirpS6

01669)2(gulP pirT8

96859)1(wercS notsiP41

07859)1(notsiP51

17859)1(gniR raeW61

27859)1(laeS71

62669)1(doR pirT81

72669)2(rehsaW pirT91

85549)1(gnirpS pirT02

37859)1(doR notsiP22

76859)1(rednilyC32

25 Piston Rod Adapter (1) 95875

27 Plug

28 Polypack Rod Seal (1) 95903

32 “O” Ring

34 Hydraulic Tube (1) 94563

35 Washer

36 Hex Cap Screw

37 Nut

38 Spring Follower (2) 96609

39 Pipe Plug

40 Pipe Plug

41 Screw

43 Cap Screw

44 Swivel Union

45 Retaining Ring (1) Y145-4

(1/4 - 18 N.P.T.F.)

(1/16” x 5/8” o.d.)

(49/64” i.d. x 1-1/4” o.d. x 1/16”)

(3/4” - 16 x 11”)

(3/4” - 16)

(1/2 - 14 N.P.T.)

(3/4 - 14 N.P.T.)

(1/4” - 14 x 1/2”)

(3/8” - 24 x 1-1/2”)

14 N.P.S.M. female)

Temperature Label

Included in Service Kit 637450

(3/4 - 14 N.P.T.F. - 1 male x 3/4 -

(not shown)

(Qty) Part No.

86859)1(esaB rotoM62

(1) Y227-3-L

40959)1(gnihsuB92

50959)1(repiW03

47859)1(reniateR laeS13

(2) Y330-14

41-811Y)2(gniR pu-kcaB33

(3) F15-9-C

(3) 95876

(3) 96272

(1) Y17-13-C

(1) Y17-14-C

(1) Y334-104-C

40039)1(guL dnuorG24

(6) Y157-64

(1) 75367

(1) 94574

INSTALLATION

Use only flexible tubing for inlet and outlet porting to hydraulic source to prevent wear of components.

Be sure return lines are sized larger than supply lines and

similarly pressure rated.

Inspect the system hoses frequently for wear or damage and,

if necessary, replace them immediately. Never plug hose

leaks with your nger, tape or any similar devices.

Do not use PTFE tape on the inlet and outlet port

y

fittings. Loctite® 571 pipe thread sealant or equivalent is the recommended sealant.

Tighten the inlet and outlet fittings to 50 - 70 ft lbs

y

(67.8 - 94.9 Nm).

SERVICE

NOTE: The 67314-B hydraulic motor will contain about one

pint of hydraulic uid. Drain this uid before attempting any

disassembly.

NOTE: Do not disassemble this motor except in a clean area.

Any dust or dirt contamination of this assembly will shorten

the service life of this motor and other system components.

NOTE: All power supply pumps should have a ten micron

lter on the return line and a 100 mesh lter on the inlet. Failure to maintain lters will shorten service life of this motor

and other system components.

TROUBLE SHOOTING

If the pump will not cycle or will not deliver material.

Be certain to check for non-pump problems, including

y

kinked, restrictive or plugged inlet / outlet hose or dispensing device. Depressurize the pump system and clean

out any obstructions in the inlet / outlet material lines.

Check all seals, including track gaskets.

y

Check direction of “U” cup lips.

y

Motor is running beyond recommended temperature operating conditions.

Hydraulic oil cooling system is not working.

y

Piston seals are worn, replace seals.

y

Leakage from weep hole in retainer.

Detection of rod seal wear, when the amount this ex-

y

ceeds is 5 cc / day, replace wiper and rod seal.

Preventive maintenance issue, consult the factory for rec-

y

ommendations.

Motor stalls at fully retracted or extended position.

Insufficient pressure to motor (65 p.s.i. / 4.5 bar mini-

y

mum).

Springs need to be replaced.

y

Valve is damaged, service hydraulic motor.

y

ARO® is a registered trademark Ingersoll-Rand Company Loctite® is a registered trademark of Henkel Loctite Corporation

Page 2 of 4 67314-B (en)

Page 3

PARTS LIST / 67314-B

1

3a

)

7

8 5

) 37

35

44

40

13

12

2

4a

38

6

39

9

4b

11

10

23

)

19

24

25

45

20

3b (

21

22

32

33

34

4241

14

16

15

17

18

(

10

Figure 2

28

29

31

30

43

36

33

32

26

27

) TORQUE REQUIREMENTS (

NOTE: DO NOT OVERTIGHTEN FASTENERS.

(3a, 3b) 90 - 110 in. lbs (10.2 - 12.4 Nm).

(14) 100 - 120 ft lbs (135.6 - 162.7 Nm).

(25) 100 - 120 ft lbs (135.6 - 162.7 Nm).

(37) 44 - 56 ft lbs (59.7 - 75.9 Nm).

LUBRICATION / SEALANTS

Apply Loctite 571 pipe thread sealant or equivalent.

Apply Loctite 572 sealant to threads.

Apply Loctite 271 to the middle 7 - 9 threads.

See reassembly instruction step #5.

67314-B (en) Page 3 of 4

Page 4

DISASSEMBLY

REASSEMBLY

All threads are right hand. Refer to gure 2, page 3. These

procedures are for the installation of repair kit parts.

Disconnect power supply and relieve all system pressure

prior to servicing. Carefully remove the parts, inspect parts

for damage, nicks or excessive wear and determine if any

parts will need replacement.

1.

Remove (1) top plug and remove (2) “O” ring.

2.

Remove (8) trip plug and remove (5) ball, (38) spring follower, (6) spring and (7) “O” ring.

3.

Move piston rod to the fully retracted position and pull

(4a) spool out of (4b) sleeve through the top.

.

4

Using the ats on (18) trip rod to hold, remove and discard (3a) nut. DO NOT RE-USE. The trip rod wrench ats

are only accessible through the port holes that retain the

(8) trip plug. This will require a narrow width open-end

wrench.

NOTE: Be very careful when removing the spool from

the valve. The nish of this part is critical for proper

motor performance. Any nicks, scratches or dirt may

damage the set.

5. Remove (43) cap screws.

6. Slide (31) seal retainer, (29) bushing and (30) wiper off

(22) piston rod and (25) piston rod adapter.

7. Remove (37) tie rod nus and (35) washers.

8. Clamp (9) cylinder head and remove (26) motor base by

tapping with a soft hammer, then remove (10) “O” ring

and (28) polypack rod seal.

9. Remove (34) hydraulic tube from (9) cylinder head and

remove (32) “O” rings and (33) back-up rings.

10. Remove (22) piston rod assembly and (23) cylinder from

(9) cylinder head and remove (10) “O” ring.

11. Separate (22, 17, 21, 16, 15, 14) piston rod assembly from

(23) cylinder.

12. Remove (17) seal and (16) wear ring from (15) piston.

13. If further disassembly is required, such as removal of (22)

piston rod, (4) valve spool assembly, or (45, 20, 19, 18)

shifter assembly, see next section. (Order “O” rings separately.)

Removal of (4) sleeve and spool assembly.

14. Remove (12) retaining ring and (11) sleeve washer from

(9) cylinder head. Push the (4b) sleeve carefully down

through the (9) cylinder head using a soft faced tool.

NOTE: The finish of the upper face of the sleeve is

critical for intended operation. Any nicks or scratches

may damage the entire (4) set.

Removal of (22) piston rod.

15. Place the (22, 21, 17, 16, 15, 14) piston rod assembly in

a vertical position with the (25) piston rod adapter in a

heavy vise.

NOTE: Never clamp on the (22) piston rod.

16. Grip the ats on the (14) piston screw and unthread.

17. Remove (21) “O” ring from (22) piston rod.

18. Remove the (18, 19, 20, 45) trip rod assembly.

19. Using the ats on the (18) rod, remove and discard the

two (3b) nuts. DO NOT RE-USE.

Thoroughly clean and lubricate all seals. Replace all soft

parts with new ones included in the repair kit.

1.

Install (28) rod seal and (10) “O” ring into (26) motor base.

2.

Install (30) wiper into (31) seal retainer and slip in (29)

bushing.

3.

Slide (25, 22) piston rod assembly into (26) motor base

and retainer assembly from step #2 above.

4.

Insert (21) “O” ring onto (22) piston rod and place (15)

piston on it.

5.

Assemble (45) retaining ring, (19) trip washer, (20) trip

spring and (19) trip washer to (18) trip rod, securing with

one (3b) nut. NOTE: Orient the two (3b) nuts such that

the anges are facing each other. NOTE: (3b) nut to be

hand tight. While holding (18) trip rod on ats, assemble

(3b) nut to (18) trip rod and tighten to 90 - 110 in. lbs

(10.2 - 12.4 Nm).

6.

Place (18, 19, 20, 45, 3b) shifter assembly into (22) piston

rod and thread (14) piston screw into (22) piston rod.

7.

Torque (14) piston screw to 100 - 120 ft lbs (135.6 - 162.7

Nm) with (25) piston rod adapter in a heavy vise.

8.

Put (17) seal and (16) wear ring on (15) piston.

9.

Push (22) piston rod to fully extended position and place

(23) cylinder over the piston assembly.

10.

Seat the (23) cylinder onto the motor base. NOTE: Petroleum jelly is recommended for ease of assembly on all “O”

rings and inside the cylinder.

11.

Replace the three (13) “O” rings on (4b) valve sleeve.

12.

Push (4b) valve sleeve / spool set straight into (9) cylinder head.

13.

Place (11) sleeve washer behind (4b) valve sleeve and

retain this with (12) retaining ring.

14.

Put two (33) back-up rings and two (32) “O” rings onto

(34) hydraulic tube with back-up rings on the hydraulic

tube rst.

15.

Push tube assembly (34, 33, 32) into (26) motor base.

16.

Place (10) “O” ring on (9) cylinder head, lower (9) cylinder

head onto the (23) cylinder and (34) hydraulic tube with

the (18) trip rod through the center of the valve.

17.

Feed (36) bolts through (26) motor base and apply (35)

washers and (37) nuts to the bolts. Tighten fasteners alternately and apply 44 - 56 ft lbs (59.7 - 75.9 Nm). NOTE:

Must alternately rundown fasteners to prevent cutting

the (10) “O” rings.

18.

Assemble (31) seal retainer, retaining with six (43) cap

screws.

19.

Move piston to the retracted position.

20.

Pull (18) trip rod through the head and place the (4a)

spool on the trip rod. Using the (3a) nut and the trip rod

flats, tighten the (3a) nut to 90 - 110 in. lbs (10.2 - 12.4

Nm).

21.

Carefully push the spool / trip rod into the sleeve, creating the (4) valve.

22.

Place (2) “O” ring on (1) top plug and tighten in (9) cylinder head.

23.

Place (7) “O” ring on (8) trip plug. Place (5) ball in (9) cylinder head and (6) spring and (38) spring follower in (8)

trip plug.

24.

Thread the (8) trip plug into the (9) cylinder head.

PN 97999-1220

Page 4 of 4 67314-B (en)

Loading...

Loading...