Page 1

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

SOLENOID ACTUATED PUMP KITS

FOR DIAPHRAGM PUMPS

67165-X

67166-X

67277-X

RELEASED: 3-6-98

REVISED: 3-7-06

(REV. G)

SOLENOID ACTUATED PUMP KITS

67165-( ) for 3/8" and 1/2" diaphragm pumps, as follows:

66605X-X, PD03P-X-X, PD05P-X-X, PD05P-X-X-B, PD05R-X-X-B

and PM05P-X-X-A02.

67166-( ) for 1", 1-1/2" and 2" non-metallic diaphragm pumps as follows:

6661AX-X-C, 6661BX-X-C, 6661TX-X-C, 6661UX-X-C, 6662AX-X-C

and 6662BX-X-C.

67166-( ) for 1" and 1-1/2" metallic diaphragm pumps as follows:

66610X-X-C, 66611X-X-C, 66612X-X-C, 66613X-X-C, 66615X-X-C,

66616X-X-C, 66617X-X-C and 66618X-X-C.

67277-( ) for 2" and 3" metallic diaphragm pumps as follows:

PD20A-X-X, PF20A-X-X, PM20A-X-X-A02, PD30A-X-X-B and

PM30A-X-X-B02.

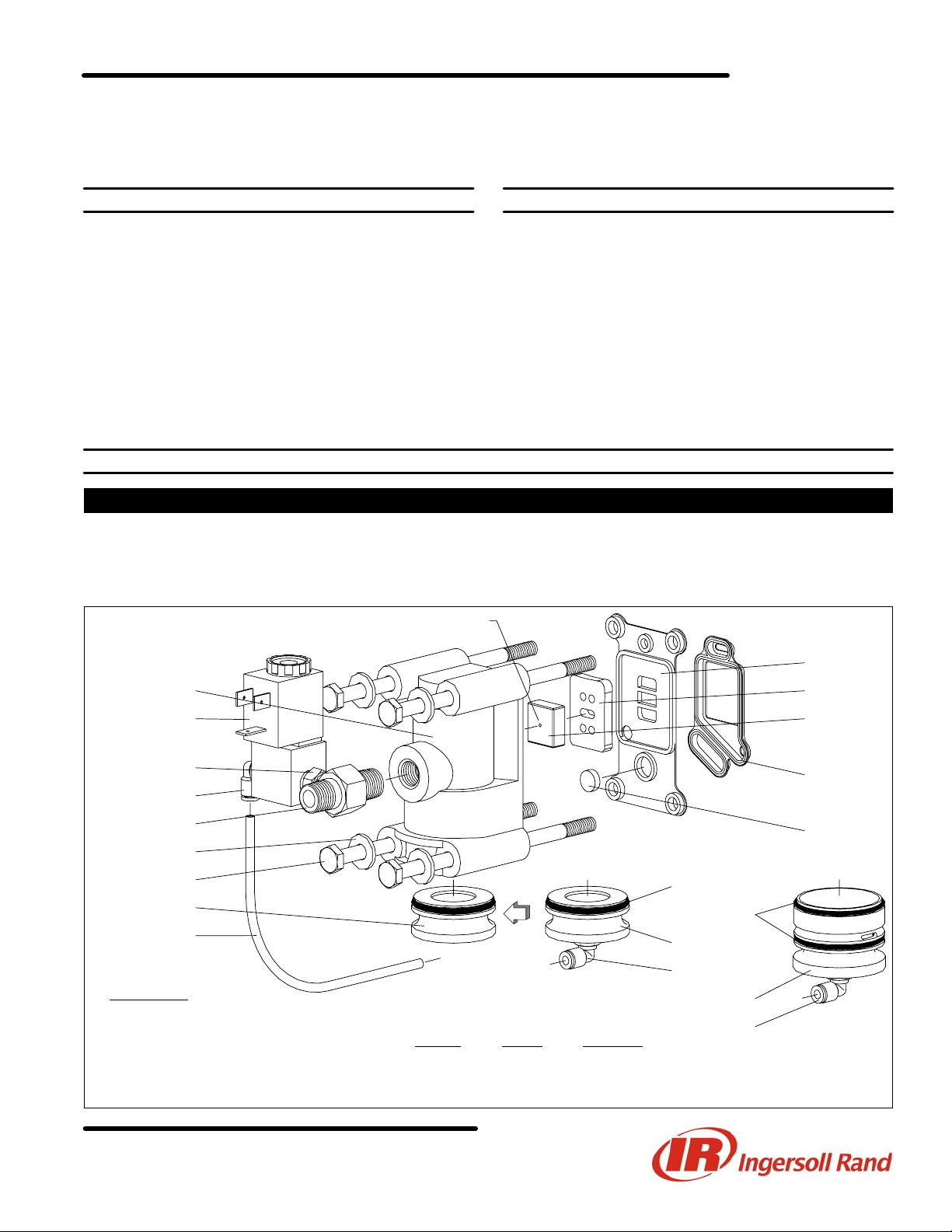

67165-( ) SOLENOID KIT INSTALLATION

3/8” AND 1/2” DIAPHRAGM PUMPS

Refer to figure 1.

1. Remove (134) bolts from the major valve and remove (135) valve

block.

2. Remove (136) plug and replace with 93909 or 96462 plug.

3. Place 94640 plug in pilot hole.

Identification dot this side.

GENERAL DESCRIPTION

ARO solenoid actuated diaphragm pump kits allow the cycle rate of the

pump to be controlled electronically. When the solenoid is energized, the

pump strokes and dispenses the fluid in one chamber. When the solenoid is de-energized, the pump strokes in the opposite direction, dispensing the fluid in the other chamber.

By providing continuous ON - OFF signals to the solenoid, the fluid

transfer rate may be increased or decreased remotely.

Some parts of the pump must be replaced with those included in these

kits to enable solenoid actuation.

4. Attach (135) valve block to (101) motor body, using (133) washers

and (134) bolts. NOTE: Torque to 15 - 20 in. lbs (1.7 - 2.3 Nm).

5. Thread CAT33P-( )-( ) valve assembly into air supply port.

6. Connect CAT33P-( )-( ) valve with 93909 plug, using 94981-XXX-X

tube.

135

~ Valve

(see table)

~ 676

~ 59756-4

~ 90351

133

. 134

136

~ 94981-XXX-X

(5" long) g

NOT SHOWN

CHW Connector

k Assemble with 2 identification dots toward (132) gasket.

. Torque to 15 - 20 in. lbs (1.7 - 2.3 Nm).

~ Supplied with 67165-( ) Kit.

Z See page 4 for coil options.

g 94981-XXX-X Bulk Tubing (100’ long).

MODEL VALVE VOLTAGE

67165-1 CAT33P-024-D 24 VDC

67165-2 CAT33P-120-A 120 VAC

67165-3 CAT33P-000-N No Coil Z

132

141 k

140

96214-2 ~

94640 ~

Y325-125 ~

~ Y325-29

93909 ~

59756-4 ~

~ 96462

~ 59756-4

Figure 1

INGERSOLL RAND COMPANY LTD

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506-0151

& (800) 276-4658 D FAX (800) 266-7016

E2006 CCN 99711780

Page 2

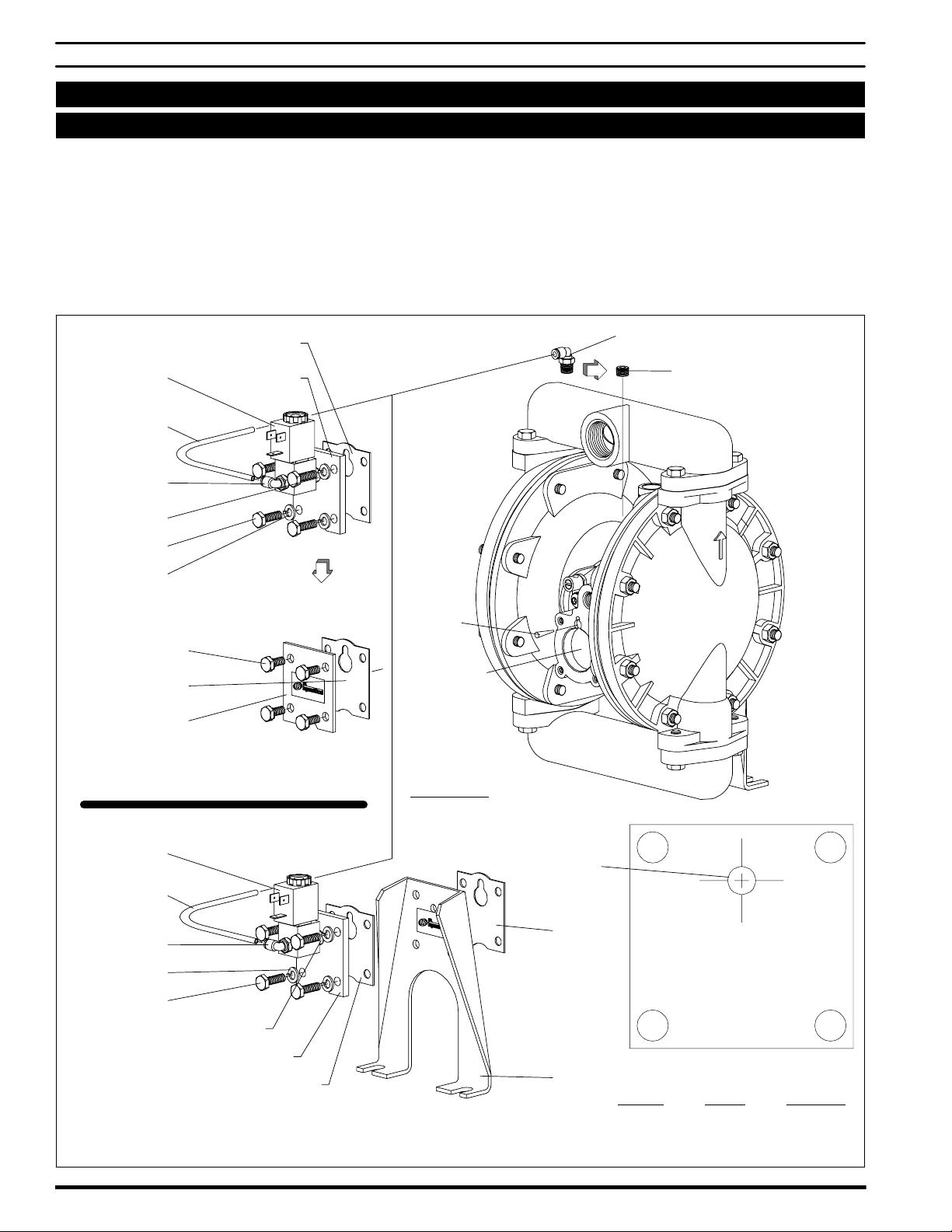

67166-( ) SOLENOID KIT INSTALLATION

1”, 1-1/2” AND 2” NON-METALLIC DIAPHRAGM PUMPS

1” AND 1-1/2” METALLIC DIAPHRAGM PUMPS

Refer to figure 2.

1. Remove (105) bolts from air inlet end of (101) motor body and remove (107) leg / plate and (108) gasket.

2. Place 94641 taper plug in pilot hole of (101) motor body.

3. Replace (128) pipe plug on (101) motor body with 59756-4 fitting.

For 1" Metallic models only:

4. Drill a 1/4" (0.250) hole in (107) leg, using the template below.

5. Attach (108) gasket, modified (107) leg, 92878 gasket and CAT33P-(

)-( ) valve to (101) motor body, using Y6-44-C bolts and Y14-416-T

washers. NOTE: Torque to 40 - 50 in. lbs (4.5 - 5.6 Nm).

6. Connect CAT33P-( )-( ) valve with 59756-4 fitting, using

94981-XXX-X tube.

For all others:

4. Attach (108) gasket and CAT33P-( )-( ) valve to (101) motor body,

using Y6-44-C bolts and Y14-416-T washers. NOTE: Torque to 40 50 in. lbs (4.5 - 5.6 Nm).

5. Connect CAT33P-( )-( ) valve with 59756-4 fitting, using

94981-XXX-X tube.

108

~ Valve

(see table below)

~ 94981-XXX-X

(6-1/16" long) g

~ 59756-4

~ 676

~ . Y6-44-C (4)

~ Y14-416-T (4)

~ 93911

105

108

107

1", 1-1/2" and 2" Non-Metallic and 1-1/2"

Metallic models (above heavy line)

1" Metallic models (below heavy line)

~ 94641

NOT SHOWN

CHW Connector

59756-4 ~

(Located on bottom of 1-1/2"

128

and 2" motor bodies.)

TOP

~ Valve

(see table below)

~ 94981-XXX-X

(6-1/16" long) g

~ 59756-4

~ Y14-416-T (4)

~ . Y6-44-C (4)

~ 676

. Torque to 40 - 50 in. lbs (4.5 - 5.6 Nm).

~ Supplied with 67166-( ) Kit.

Z See page 4 for coil options.

g 94981-XXX-X Bulk Tubing (100’ long).

~ 93911

~ 92878

Figure 2

1/4" Dia.

108

TEMPLATE

107

MODEL VALVE VOLTAGE

67166-1 CAT33P-024-D 24 VDC

67166-2 CAT33P-120-A 120 VAC

67166-3 CAT33P-000-N No Coil Z

67165-XPage 2 of 4

Page 3

67277-( ) SOLENOID KIT INSTALLATION

2” & 3” METALLIC DIAPHRAGM PUMPS

Refer to figure 3.

1. Remove (134) screws and (133) washers, and remove (135) valve

block and components from (101) center body.

. Torque to 40 - 50 in. lbs (4.5 - 5.6 Nm).

Z See page 4 for coil options.

~ Included in 67277-( ) Kit.

101

~ 29670 Ball

133

2. Attach 67277-( ) solenoid kit assembly to (101) center body, using

(134) screws and (133) washers. NOTE: Torque screws to 40 - 50 in.

lbs (4.5 - 5.6 Nm).

67277-( )

67277-( ) PARTS LIST

114104 O" Ring (1.5 mm x 14.5 mm o.d.)

Y325-126 O" Ring (2) (3/32" x 1-9/16" o.d.)

92011 Piston

Y186-51 U" Cup (3/16" x 1-3/8" o.d.)

94032-1 Valve Block

. 134

135

43

Figure 3

119380 Coil Nut

116218-( ) Coil (see table)

114102 Valve System

114103 O" Ring (1.5 mm x 5.5 mm o.d.)

Y147-16-C Retaining Ring (1.804" o.d.)

94728 Solenoid Plug

92005 Spool

92876 Spacer (4)

Y325-214 O" Ring (5) (1/8" x 1-1/4" o.d.)

NOT SHOWN

CHW Connector

Y16-203 Ball (2) (3/32" dia, press flush w/94032-1)

96728647 Cap Screw (2) (M3 - .5 x 18)

MODEL VOLTAGE COIL

67277-1 24 VDC 116218-39

67277-2 120 VAC 116218-33

67277-3 No Coil Z

Y325-126 O" Ring (6) (3/32" x 1-9/16" o.d.)

92877 Washer (5)

94027 Spacer

94034 Inlet Plug

Figure 4

Page 3 of 467165-X

Page 4

DISPLACEMENT PER CYCLE

Specific Gravity = 1.000

Models Gallons Ounces in.# cc Liters Grams Kg

3/8" Non-Metallic − PD03P-X-X 0.022 2.815 5.082 83 0.083 83 0.083

1/2" Non-Metallic Duck Bill − 66605X-0XX 0.032 4.095 7.392 121 0.121 121 0.121

1/2" − PD05P-X-X-B, PD05R-X-X-B 0.039 4.991 9.009 148 0.148 148 0.148

1/2" − 66605X-X, PD05P-X-X, PM05P-X-X-A02 0.040 5.119 9.240 151 0.151 151 0.151

1" Non-Metallic − 6661AX-X-C, 6661BX-X-C 0.170 21.756 39.270 643 0.643 643 0.643

1" Metallic − 66610X-X-C, 66611X-X-C, 66612X-X-C,

66613X-X-C

1-1/2" Non-Metallic − 6661TX-X-C, 6661UX-X-C 0.670 85.743 154.770 2536 2.536 2534 2.534

1-1/2" Metallic − 66615X-X-C, 66616X-X-C, 66617X-

X-C, 66618X-X-C

2" Non-Metallic − 6662AX-X-C, 6662BX-X-C 0.720 92.141 166.320 2725 2.725 2723 2.723

2" Metallic − PD20A-X-X, PF20A-X-X, PM20A-X-X-A02 1.400 179.164 323.400 5299 5.299 5296 5.296

3" Metallic − PD30A-X-X-B, PM30A-X-X-B02 2.800 358.327 646.800 10,598 10.598 10,591 10.591

2 strokes per complete cycle - 1" metallic will displace 0.080 gallons per stroke.

0.160 20.476 36.960 606 0.606 605 0.605

0.640 81.903 147.840 2422 2.422 2421 2.421

COIL OPTIONS

Coil Number 50 / 60 Hz DC

116218-31 12

116218-33 120

116218-35 240

116218-37 5

116218-38 24 12

116218-39 48 24

PN 97999-760

67165-XPage 4 of 4

Loading...

Loading...