Ingersoll-Rand 67072 User Manual

OPERATOR’S MANUAL

67072 CYCLE CONTROLLER

(PNEUMATIC COUNTDOWN TYPE)

FOR 3/8”, 1/2” & 1” DIAPHRAGM PUMPS WITH 1/4” AIR INLETS

67072

CYCLE CONTROLLER RETRO-FIT KIT.

This kit includes additional parts to do a field retro-fit to standard pumps

models as follows:

3/8” -- PD03P-XXX-XXX (refer to page 3).

1/2” -- 66605X-XXX, PD05P-XXX-XXX, PD05P-XXX-XXX-B and

PD05R-XXX-XXX-B (non-metallic air motor)(refer to page 3).

1” -- 6661A

• 3/8” and 1/2” Pumps - Pilot plug and replacement “O” ring(s).

• 1” Pumps - Screws, plate, gaskets, & template for leg modification.

X-XXX-C, 6661BX-XXX-C (refer to page 3), 66610XXXX-C, 66611

(refer to page 4).

X-XXX-C, 66612X-XXX-C and 66613X-XXX-C

GENERAL DESCRIPTION

67072

RELEASED: 3-7-06

REVISED: 1-05-10

(REV. G)

The diaphragm pump Cycle Controller Assembly provides logic control

for preset dispensing. When installed on a diaphragmpump, itcan monitor the diaphragm pump pulse or cycle and allow the user to accurately

control the number of cycles the pump will produce. This will effectively

allow a preset and repeatable amount of material to be dispensed

through the pumping system.

Pumps used with this counter assembly must be retrofitted with special

parts. These special parts will allow the pump to output a pilot air signal

which is needed to trigger the counter.

The controller assembly, with 1/4” N.P.T. inlet / outlet, includes a pre-assembled countdown counter, palm operated valve, bracket, tubing and

an air regulator with air pressure gauge.

NOTE: This kit is intended to be attached directly to the pump air inlet.

Mounting it a distance from the pump couldresult in an air pressure drop

in the pilot signal to the counter and may affect the accuracy.

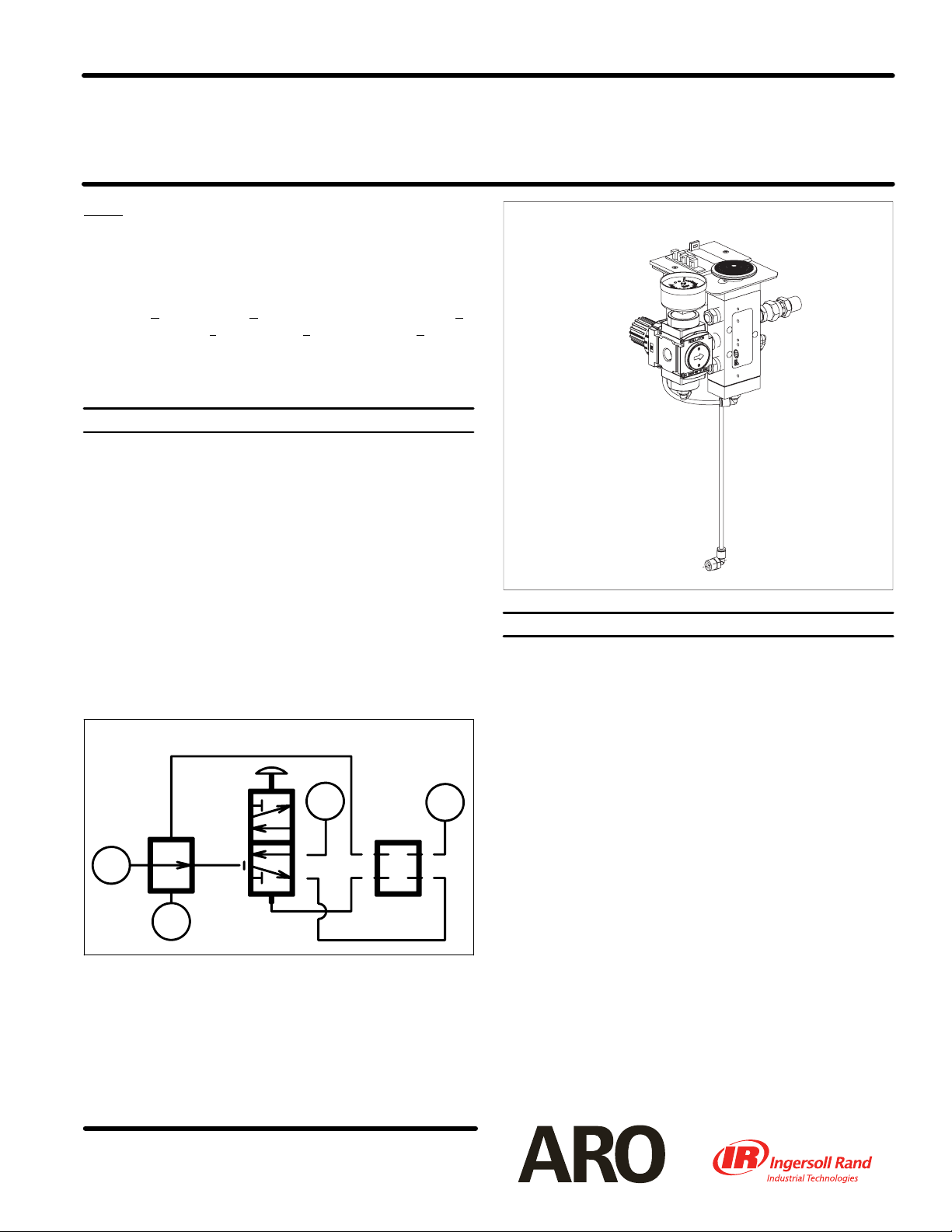

Figure 1

REGULATOR

R37121- 100

AIR

INLET

SCHEMATIC VIEW

PAL M

VALV E

E212HP

-5

-3

GAUGE

4

2

AIR

OUTLET

COUNTER

59802

P

A

PUMP

SIGNAL

Z

Y

67020

CYCLE CONTROLLER

SEE ADDITIONAL PARTS

ON FOLLOWING PAGES

OPERATION

To determinethe number of cycles neededto get the desired output, use

the following formula: Divide the amount of material desired by the displacement per cycle to get the counter settingthat is needed (refer to the

pump manual).

NOTE: For best results, operate the pump at 30 - 90 p.s.i. (2.1 - 6.2

bar). Fluctuations in the air pressure can affect the displacement per

cycle. Once the desired displacement is achieved,keep the air pressure

as constant as possible.

BASIC OPERATION

1. Connect air to pump.

2. Set cycle count: Hold the reset button down while entering a new

number of cycles on the counter.

3. Press the palm button to start the cycle.

4. The pump will automatically shut off and reset to the count originally

set.

INGERSOLL RAND COMPANY LTD

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506-0151

(800) 276-4658 D FAX (800) 266-7016

E2010 CCN 99713075

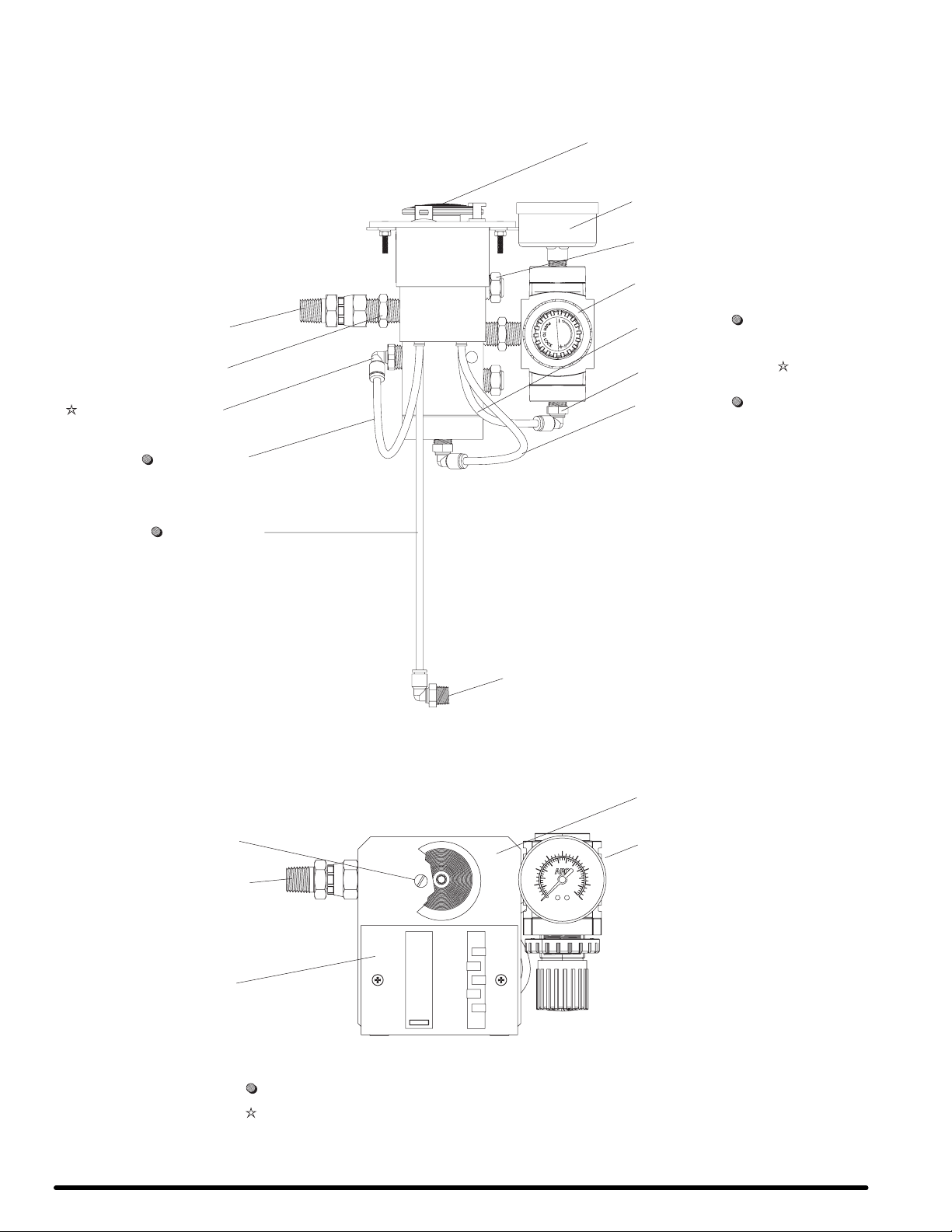

67072 CONTROLLER ASSEMBLY

E212HP Palm Valve Assembly

29850 Gauge

20311-2 Breather Vent (2)

R37121-100 (104467) Regulator

75364 Swivel Union

1950 Nipple (2)

59756-154 90° Elbow

94981-X Tube

(5/32" o.d. x 6" long)

94981-X Tube

(5/32" o.d. x 10" long)

94981-X Tube

(5/32" o.d. x 4" long)

59756-4 90 Elbow (3)

94981-X Tube

(5/32" o.d. x 6" long)

1/8 - 27 N.P.T. − Air Signal (from the pump pilot)

Y8-104-C Screw (2)

1/4 - 18 N.P.T.F. -1 − Outlet

(air supply to pump)

59802 Counter

Figure 2

93950 Bracket

1/4 - 18 P.T.F. Short

Air Inlet

maximum)

(supply

Available in bulk quantities only (5/32" o.d. x 100’ long) − pn 94981-XXX-X.

Available in bulk quantities only (10).

air 120 p.s.i.

67072Page2of4

Loading...

Loading...