Ingersoll-Rand 651533-X Operator's Manual

OPERAT

MANUAL

DEL OPERARIO

OR’S MANUAL

MANUEL DE L’UTILISATEUR

INCLUDING: OPERA

INCLUYE: FUNCIONAMIENT

COMPREND: FONCTIONNEMENT

INCLUDE FORM 772Ć2 (97999Ć540)

INCLUYE FORMULARIO 772Ć2

COMPREND FORM 772Ć2

PISTOLA PUL

TION, INST

ALLA

O, INST

TION & MAINTENANCE

ALACIÓN & MANTENIMIENT

, INST

ALLA

AIRLESS P

VERIZADORA SIN AIRE P

PIST

OLET À PEINDRE SANS AIR (SANS BUSE DE PUL

TION & ENTRETIEN

651533 & 651533-1

AINT SPRA

ARA PINTURA (SIN BOQUILLA PULVERIZADORA)

RELEASED

REVISED / REVISADO / REVISE:

(REV

O

/ LIBERADO / DECHARGE:

. C)

Y GUN (WITHOUT SPRAY TIP)

VÉRISATION)

651533-X

9-16-80

7-14-00

READ THIS MANUAL CAREFULL

OPERA

It

is the responsibility of the employer to place this information in the hands of the operator

SER

VICE KITS

TING OR SER

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 637103 for repair of spray gun.

OPERATING

STATIC

SPARK

WARNING

in severe injuryor death. Ground pump and pumping system.

AND SAFETY PRECAUTIONS

HAZARDOUS

PRESSURE

STATIC SPARK. Can cause explosion resulting

INJECTION

HAZARD

• The pumping system and object being sprayed must be

grounded whenit ispumping, flushing, recirculatingor sprayĆ

ing flammable materials such as paints, solvents, lacquers,

etc. or used in a location where surrounding atmosphere is

conducive to spontaneous combustion. Ground the dispensĆ

ing valveor device,containers, hoses andany objectto which

material is being pumped.

• Use hoses incorporating a static wire.

• Use proper ventilation.

• Keep inflammables away from heat, open flames and sparks.

• Keep containers closed when not in use.

WARNING

injury orproperty damage. Do not service or clean while presĆ

surized.

WARNING

flesh can cause severe injury or death. If an injection occurs

immediately contact a doctor.

HAZARDOUS PRESSURE. Can result in serious

INJECTION HAZARD. Any material injected into

• Do not grab front end of dispensing device.

• Do not aim dispensing device at anyone or any part of the

body.

NOTICE Liquid pressureat the outletofgun may bemany

times the air inlet gauge pressure of air operated pumps.

Y BEFORE INST

VICING THIS EQUIPMENT

. Keep for future reference.

Safety precautions should be taken while operating or servicing

high pressure equipment.

ALLING,

.

• CHECK hoses for weak or worn condition before each use,

and tighten all fluid connections securely.

• DO NOT alter equipment in any manner whatsoever.

• DO NOT exceed the maximum working pressure of any comĆ

ponent in the system (including but not limited tospray guns,

hose, hose connections, heaters and pumps).

• DISCONNECT pump power source and RELIEVE allpressure

from system when not in use.

• When gun is not in use, always set safety lock in closed posiĆ

tion.

INGERSOLLĆRAND COMPANY shall not be liable for any conseĆ

quential damages as a result of misuse, misapplication, abuse,

etc. of this equipment.

MAXIMUM WORKING PRESSURE 5000 P.S.I. (345 BAR)

INGERSOLL-RAND COMPANY

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506Ć0151

&

(419) 636-4242 D F

AX (419) 633-1674

E2000 D PRINTED IN U.S.A.

MAINTENANCE

DISASSEMBLY

With proper care, this unitwill give long reliable service.To maintainthis

performance it shouldbe flushed out with solvent immediately following

each spray period.

CAUTION Always disconnect pump power source and reĆ

lease all pressure before disassembly or removal of any part.

FOR CLEANING: Use solvent with highest possible flash point,

that is compatible to material being used.

1. ShutĆoff air pressure to pump and relieve liquid pressure in system

through manual relief valve at outlet filter on those models

equipped, or trigger gun making sure pressure is relieved. Never

attempt to force paint backward from gun through hose to pump

and paint container.

2. Place gun safety lock in closed position and remove spray tip from

gun. Place tip in small container of solvent for soaking and final

cleaning. Use soft bristle brush to remove any paint collection on

tip. If tip orifice isclogged, remove obstruction byusing air blow gun

applied to outlet of orifice at front of tip and blowing back through

rear of tip, if obstruction will not blow out, use cleaning wire, toothĆ

pick or brush bristle to dislodge. NEVER ATTEMPT TO CLEAN

TIP WHILE IT IS ATTACHED TO SPRAY GUN.

3. Remove gunfrom hose and cleanexterior with suitable solventand

brush. Allow gun to soak in solvent for a short time if necessary to

soften accumulation. After cleaning, wipe exterior of gun with dry

cloth. (NOTE: Interior of gun has not yet been cleaned).

4. Remove pump from paint container and place pump inlet into conĆ

tainer of suitable clean solvent.

5. Direct open end of hose into paint container and start pump by apĆ

plying only sufficient air pressure to cycle pump slowly and to force

paint frompump and hose into groundedpaint container.When solĆ

vent begins to flow from hose, switch hose to grounded solvent conĆ

tainer, increase air pressure to pump allowing solvent to circulate

through pump, hose and back to container for approximately one

minute or until examination indicates hose and system are clean.

6. Whenever 60530 inline swivel filter is being used, remove from

hose and gun, disassemble and clean.

7. ShutĆoff air pressure to pump and assemble gun to end of hose.

8. Direct end gun (without tip) into top of grounded (bonding recomĆ

mended) solvent container and release safety lock on gun so trigĆ

ger can be retracted.

9. Start pump with gun trigger retracted, increase air pressure until

sufficient pressureisobtained to cause pump tocycleapproximateĆ

ly 25 cycles per minute. Purge gun approximately oneminute while

intermittently operating trigger. Adjust packing gland if necessary to

prevent leakage.

10. ShutĆoff air pressure to pump and pull gun trigger to relieve presĆ

sure in system while gun is still directed into grounded solvent conĆ

tainer.

11. Place safety lock on gun inclosedpositionandreassemblecleaned

spray tip to gun, wipe all exterior surfaces clean.

12. Disconnect pump from power source.

SERVICE

1. Disconnect air line from pump and relieve material line pressure by

pulling (22) trigger.

2. Disconnect material line from gun.

3. Unscrew the (1) capand guard assemblyand remove the (2)washĆ

er and spray tip.

4. Loosen the (13) collet nut.

5. Loosen the (19) set screw. Disconnect and remove the (21) inlet

tube brazing assembly by loosening the tube nut and rotating the

tube assembly 90_ to either side of the (20) handle.

6. Unscrew the (9) spray gun body and adapter assembly from the

(20) handle.

7. Remove the (3) screw, (8) washer and (12) retaining screw from (9)

spray gun body and adapter assembly.

8. Remove the (7) ball and stem assembly and the (10) packing and

(11) flat packing fromthe (9) spraygun body and adapter assembly.

For normalcleaning orservice, parts(14), (15),(16), (17), (18), (22),

(23), (24), (25), (26), (27) and (28) need not be removed.

REASSEMBLY

1. Insert the (7) ball and stem assembly into the (9) spray gun body

and adapter assembly.

2. Carefully slip the two (10) packings and two (11) flat packings inthe

order shown in the diagram over the wire of the (7) ball and stem

assembly.

3. Slide the (12) retaining screw onto the (7) ball and stem assembly

and push the packings into the (9) spray gun body and adapter asĆ

sembly. Tighten (12) retaining screw hand tight.

4. Install the (8) washer on the (3) screw and screw the assembly into

(9) spraygun body and adapter assembly hand tight. Then back off

screw 3/4 turn.

5. Push the (7)ball and stem assembly forwarduntilitseatson the ball

seat of the (3) screw and tighten (12) retaining screw.

6. Screw the (9) spray gun body and adapter assembly into the (20)

handle. Be sure the wire of the (7) ball and stem assembly enters

the hole in the (13) collet nut. Back off the (9) spray gun body and

adapter assembly until material inlet faces down. Tighten (19) set

screw.

7. Being sure the ball is still seated in the ball seat, retighten the (13)

collet nut.

8. Tighten the (3) screw.

9. Replace the (21) inlet tube brazing assembly into the (20) handle

and (9) spray gun body and adapter assembly.

10. Check safety operation byrotating the (25) knob tothesafeposition

and pull the (22) trigger. If movement of the (7) ball and stem asĆ

sembly is noted, adjust the gun as follows. With the safety off and

the ball seated on the ball seat, hold the trigger and loosen the (13)

collet nut. Pull the trigger back slightly and retighten the (13) collet

nut. Recheck safety operation and readjust if necessary.

11. Insert the spray tip and (2) washer in the (1) capand guard assemĆ

bly and screw cap on (9) spray gun body and adapter assembly.

If material leakage occurs around the (12) retaining screw, the (10)

packing and the (11) flat packing have perhaps become worn. Tighten

the (12) retaining screw and if this doesn't stop the leakage replace the

packing.

If material leakage occurs at the spray tip of the gun, check for dirt or

foreign matter which may prevent the (7) ball and stem assembly from

seating properly.

PAGE2OF8

651533ĆX

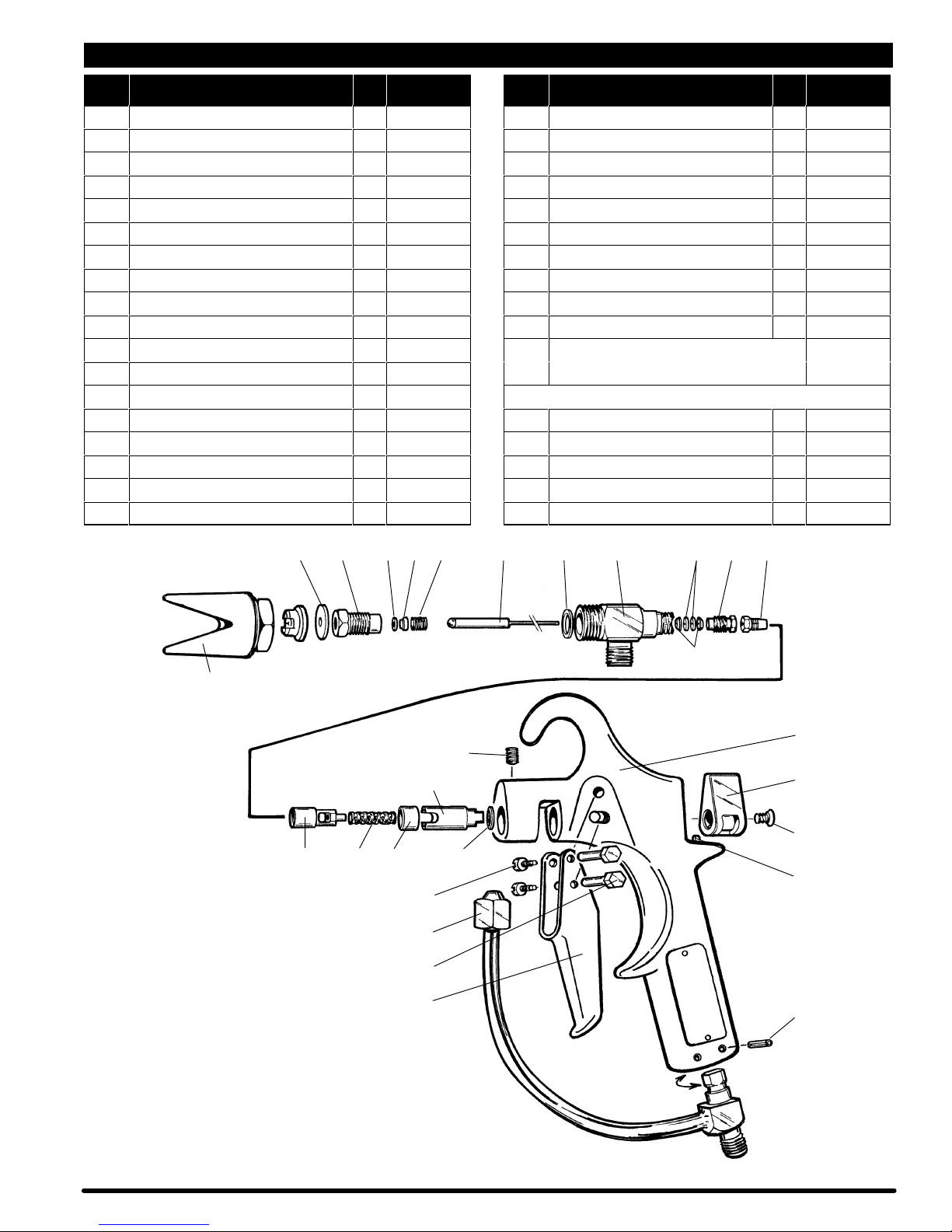

PARTS LIST / 651533-X AIRLESS GUN

ITEM DESCRIPTION (Size in inches)

QTY

PART NO. ITEM DESCRIPTION (Size in inches)

1 Cap & Guard Assembly (1) 66504

n 2 Washer (1) 91181

3 Screw (1) 92426

4 Gasket (1) 92425

5 Ball Seat (1) 92424

6 Screw (1) 92427

n 7 Ball & Stem Assembly (1) 66597Ć1

n 8 Washer (1) 91180

9 Spray Gun Body & Adapter Asm (1) 66178

n 10 Packing (2) 91471

n 11 Flat Packing (2) 91472

n 12 Retaining Screw (1) 91473

n 13 Collet Nut (1) 91474

14 Collet Adapter (1) 91475

15 Spring (1) 92746

16 Sleeve (1) 91481

17 Safety Pin (1) 92432

18 Washer (1) 92434

QTY

PART NO.

19 Set Screw (1/4" Ć 20 x 3/8" long) (1) Y29Ć44

20 Handle (1) 92430

21 Inlet Tube Brazing Assembly (1) 66596

22 Trigger (1) 92429

23 Screw (2) 90962

24 Screw Retainer (2) 92433

25 Knob (1) 92431

26 Screw (#10 Ć 24 x 1/2" long) (1) Y61Ć107ĆC

27 Roll Pin (1/8" o.d. x 3/8" long) (1) Y178Ć35

28 Roll Pin (1/8" o.d. x 3/4" long) (2) Y178Ć41

n Parts in Service Kit / Componentes en el juego

de servicio / Pièces de la trousse d'entretien

Items not shown / Artículos que no se muestran / Composants non illustrés

637103

Allen Wrench (1/8") (1) Y106Ć3

Wrench (1) 99231

Packing (Extra / Supplément) (2) 91471

Flat Packing (Extra / Supplément) (2) 91472

Spray Tip (not included / no incluidos / non compris)

TCXXXX

23~ 456z 7891011 12 13 ~

1 (651533 only)

(solamente 651533)

(651533 seulement)

14 15 16

= Apply Loctite 271 to threads.

Aplique Loctite 271 a las roscas.

Appliquer du Loctite 271 sur les filets.

~ Apply Loctite Nickel AntiĆSieze to threads.

Aplique Loctite Níquel antiadhesión a las roscas.

Appliquer du Loctite Nickel AntiĆseize sur les filets.

= 23

21

24

22

17 s

20

19

25

26 =

18

27

28

z Apply 80 Ć 90 wt gear oil to threads.

Aplique a las roscas aceite de engranajes 80 Ć 90 wt.

Appliquer de l'huile d'engrenages 80 Ć 90 SAE aux filetages.

s Coat with Shell Darina EP 2 grease.

Cubra con grasa Shell Darina EP 2.

Enduire de graisse Shell Darina EP 2.

651533ĆX PAGE3OF8

Loading...

Loading...