Ingersoll-Rand 651511-X User Manual

OPERATOR’S MANUAL 651511-X

WARNING

CAUTION

F

E

G

DCBA

F

H

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST,

DISASSEMBLY & REASSEMBLY.

AUTOMATIC DISPENSING VALVE

651511-X

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

651511 EXTRUSION 651511-1 AIRLESS SPRAY

RELEASED: 11-24-76

REVISED: 10-7-13

(REV. E)

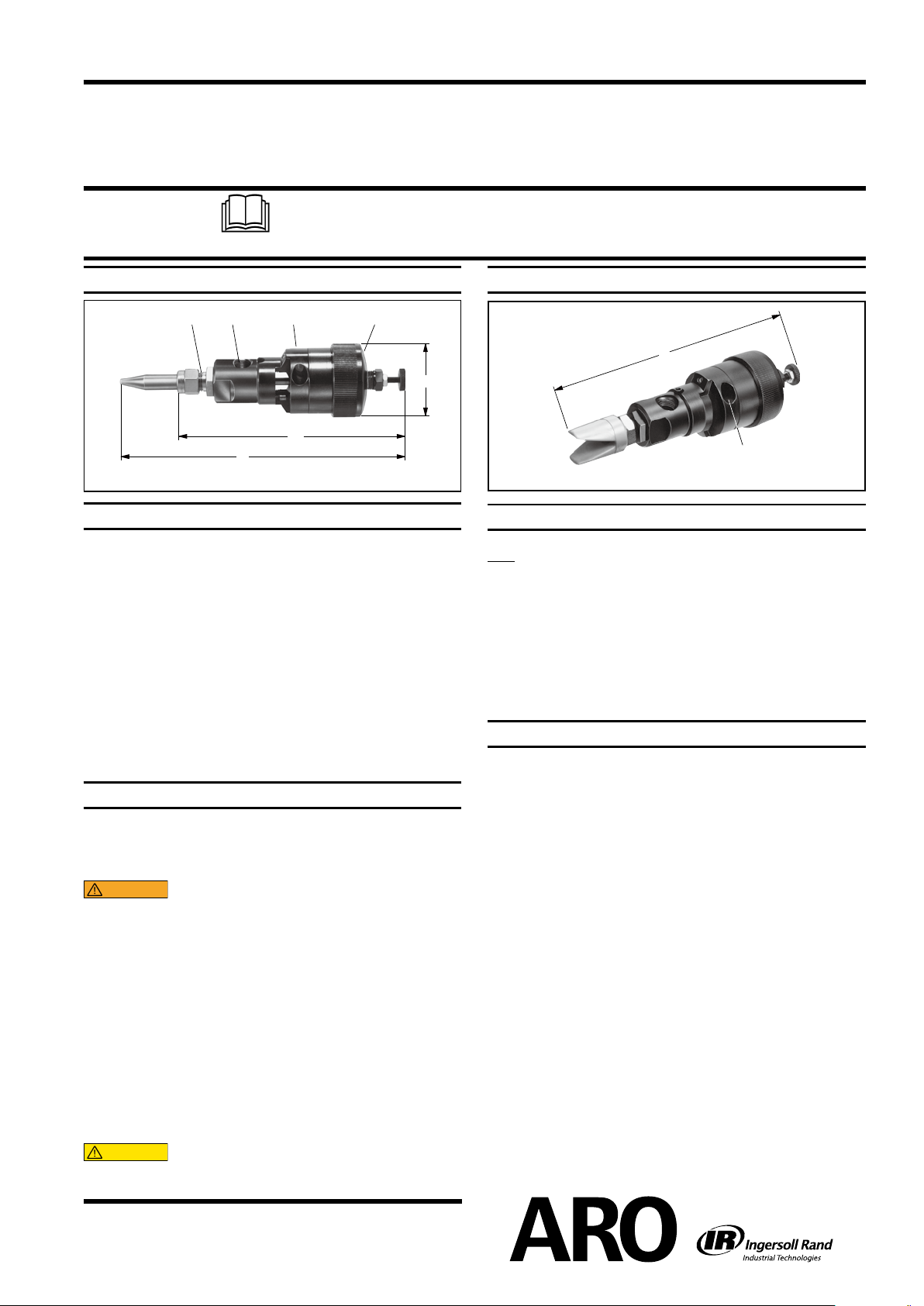

Figure 1

GENERAL DESCRIPTION

651511 Extrusion

651511-1 Airless Spray

Automatic Valve with the following features.

The ball and valve seat are made of tungsten carbide for

maximum resistance to erosion and wear.

The (3) 90565 packings are made of PTFE for maximum

wear and resistance to solvents.

This unit has a 2” diameter air cylinder. The 72842 piston

is made of Buna “N”.

It has a 1/2” mounting hole.

Both air inlets are 1/8 - 27 NPTF (female).

Air operated opening and closing.

OPERATING INSTRUCTIONS

Use only genuine ARO® replacement parts to assure com-

patible pressure rating and longest service life.

HEED ALL WARNINGS.

HIGH PRESSURE DEVICE. Improper usage of this

equipment could result in serious injury. The possibility of

injection into the esh is a potential hazard. Never allow

any part of the human body to come in front of, or in direct

contact with, the material outlet. An injection injury can be

serious. If injection should occur, contact a qualied physician for immediate treatment of such injuries.

SERVICING. Before servicing or removing uid hose or

valve from a unit that has been used, be sure to disconnect

air lines and carefully bleed pressure o of the system.

PREVENT FIRES. When pumping, ushing or recirculating

volatile solvents, the area must be adequately ventilated.

Keep solvents away from heat, sparks and open ames.

Keep containers closed when not in use.

The maximum working pressure for the auto-

matic dispensing valve assembly is 5000 p.s.i. (345 bar).

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276

© 2013 CCN 81380065

Figure 2

SPECIFICATION DATA

REF.

A - Material Outlet 11/16” - 16 UN-2A

B - Material Inlet (2) 3/8 “ PTF

C - Air Inlet 1/8” NPTF (Return or "Closing")

D - Air Inlet 1/8” NPTF (Actuating)

E - Width Dia. 2-1/2" (63.5 mm)

F - Overall Length Approx. 8.937" (227 mm)

G - Body Length Approx. 7-1/2" (190 mm)

H - Mounting Hole 1/2" dia.

MAINTENANCE

With proper care, this unit will give long reliable service. To

maintain this performance, it should be “ushed thoroughly”

with solvent immediately following each application period if

equipment is to be idle for a long period of time.

If material leakage occurs between valve housing (25)

and body (19), check gasket (24).

If material leakage occurs at orice of gun, check ball and

ball seat for dirt or foreign substance. Inspect ball and

ball seat (23).

If material leakage occurs around piston rod (21) in open-

ing of air cylinder head (13) check tightness of retainer

(15) or worn packings (17).

If air leakage occurs around the air cylinder, check for

damaged or worn “O” rings. (Indicated on the drawing

(12), (11), and (4)).

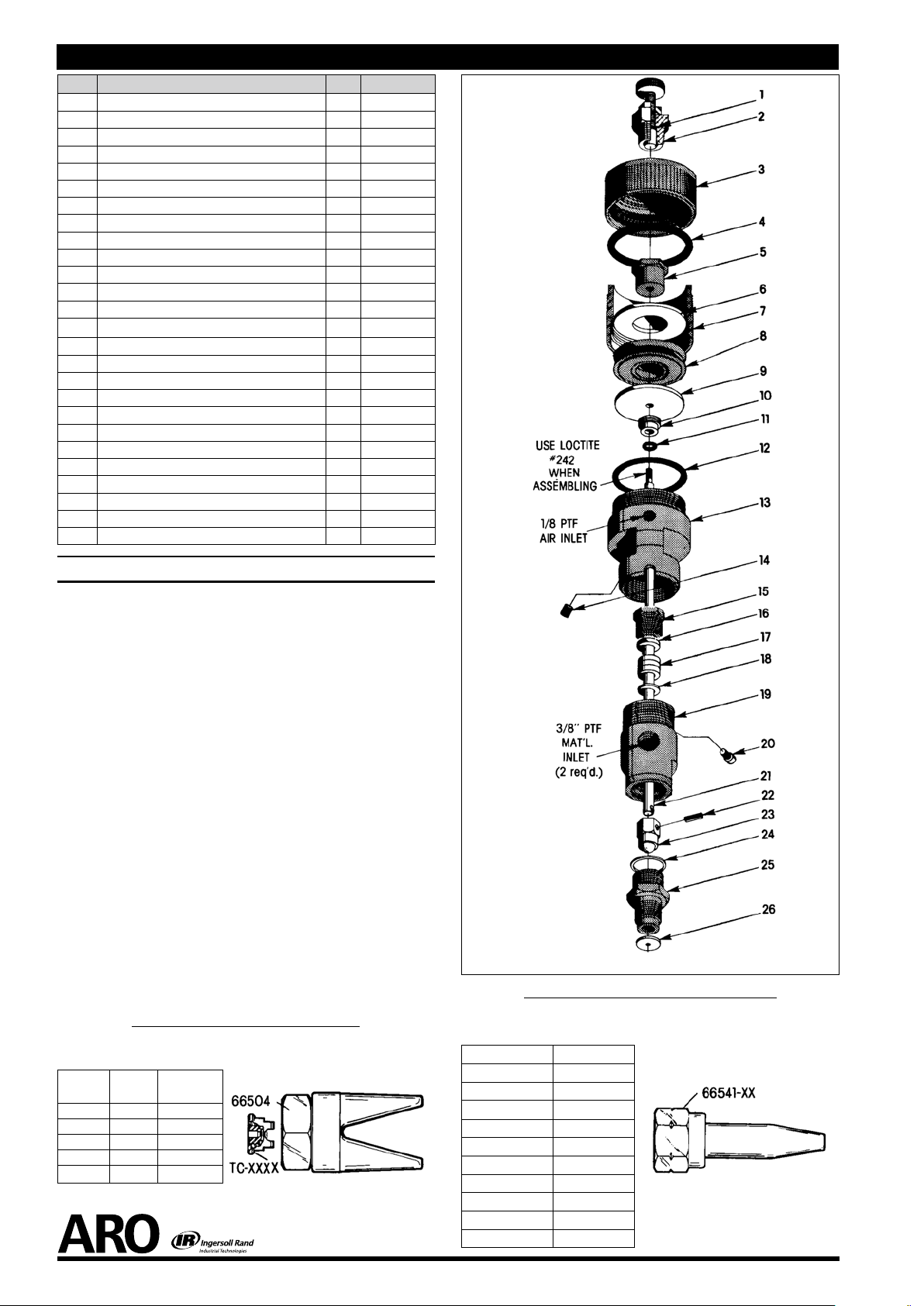

PARTS LIST / 651511-X

Item Description

1 “O” Ring

2 Adjusting Screw

3 Cap (1) 90995

4 “O” Ring

5 Piston Retainer (1) 90555

6 Piston Washer (1) 90586

7 Air Cylinder (1) 90556

8 Piston (1) 72842

9 Piston Washer (1) 90559

10 Retaining Screw (1) 90562

11 “O” Ring

“O” Ring

12

13 Air Cylinder (1) 90994

14 Set Screw

15 Retainer (1) 79255

16 Washer (1) F174-9

Packing

17

18 Washer (1) F15-64

19 Spray Gun Body (1) 92332

20 Screw

21 Piston Rod (1) 90732

22 Roll Pin

23 Ball and Socket Assembly (1) 65774

24 Washer (1) 72851

25 Valve Seat Assembly (1) 65853

26 Washer (1) 75815

(size)

(1/16” x 5/16” o.d.)

(includes item 1)

(3/32” x 2-5/16” o.d.)

(1/16” x 3/8” o.d.)

(3/32” x 2-1/16” o.d.)

(1/4” - 20 x 5/16”)

(#8 - 36 x 1/4”)

(1/8” o.d. x 7/16”)

Qty Part No.

(1) Y325-8

(1) 65958

(1) Y325-138

(1) Y325-10

Y325-134

(1)

(1) Y29-43-C

90565

(3)

(1) Y191-82

(1) Y178-36

Included but not shown

93140 wrench.

DISASSEMBLY / REASSEMBLY

If it becomes necessary to disassemble this unit, proceed in

the following manner:

1.

Place gun in vise, holding at air cylinder head (13).

2.

Unscrew screw assembly (2).

3.

Unscrew cap (3).

4.

Unscrew valve housing assembly (25).

5.

The ball and socket assembly (23) will now be exposed.

By putting a wrench on the flats of the ball and socket

(23) and on the hex of the piston retainer (5), you can

unscrew the piston retainer (5).

6.

Remove piston washer (6), piston (8) and piston washer (9).

7.

Push piston rod forward (towards spray tip end of gun),

this will remove the piston rod (21), roll pin (22) and ball

and socket (23).

8.

Unscrew retaining screw (10) from air cylinder head (13)

and check “O” ring (11).

9.

Unscrew set screw (20) from spray gun body (19).

10.

Unscrew spray gun body (19) from air cylinder head (13),

this will allow you to unscrew retainer (15) from spray

gun body (19) and inspect washer (16), packings (17)

and washer (18).

11.

Reverse above procedure for assembly.

SPRAY - FOR MODEL 651511-1

Spray Tip (Must be ordered separately by customer. See tip

Extrusion Nozzle and Retaining Nut Assembly. (Not included

and must be ordered separately)

chart for desired size).

TIP NO. ORIFICE

TC-1850 0.018” 10”

TC-2140 0.021” 8.5”

TC-2150 0.021” 11.5”

TC-2640 0.026” 9”

TC-2650 0.026” 12”

PATTERN

WIDTH

Figure 4

Page 2 of 2 651511-X (en)

EXTRUSION - FOR MODEL 651511

TIP NO. ORIFICE DIA.

66541-03 0.031”

66541-04 0.046”

66541-06 0.063”

66541-09 0.093”

66541-12 0.125”

66541-15 0.156”

66541-17 0.172”

66541-18 0.187”

66541-25 0.250”

66541-37 0.375”

Figure 3

Figure 5

PN 97999-442

Loading...

Loading...