Page 1

OPERATOR’S MANUAL 651500-X

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE.

INCLUDE MANUALS: Form 772-2 Safety Precautions (pn 97999-540).

651500-X

HIGH PRESSURE SPRAY GUN

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

MAXIMUM WORKING PRESSURE 7500 P.S.I. (517.2 BAR)

SERVICE KITS

Use only genuine ARO® replacement parts to assure compat-

ible pressure rating and longest service life.

61240 for repair of spray gun.

OPERATION

The 651500-X control handle passes material at line pressure

in a continuous flow. The hose connection is a 3/8” female

pipe thread. The control handle will continue to pass material

as long as the (15) lever is squeezed enough to lift the ball

valve o the valve seat.

RELEASED: 2-12-82

REVISED: 3-23-11

(REV. D)

SERVICE INSTRUCTIONS

For adjustments of the 651500-X control handle, the following procedure will help.

To take slack out of the handle, adjust (8) set screw.

1.

a. Loosen (9) nut.

b. Adjust (8) set screw to obtain desired play or slack.

c. Tighten (9) nut.

2. Should material leak from the lever end of the gun, remove the lever and tighten (11) retainer. If this does not

stop the leak, remove the retainer and replace the (13)

packings.

3. Should you be unable to stop the ow of material from

the extrusion gun, the (16) ball is probably not seating

properly into the (3) ball seat. The ball should be removed

and inspected for dirt or nicks. Also inspect the ball seat

for dirt or nicks. If the ball or ball seat are damaged, they

should be replaced. When pressing (3) insert and ball seat

into place inside (18) body, make sure that the ball seat

is facing in the proper direction. The material outlet of

the insert must be in line with the outlet in the (18) body

after being pressed into place.

651500

651500-2

EXTRUSION GUN

(less nozzle)

651500-1

651500-3

SPRAY GUN

(less tip)

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET -BRYAN, OHIO 43506

(800) 495-0276 y FAX (800) 892-6276

www.ingersollrandproducts.com

© 2011 CCN 99711202

Page 2

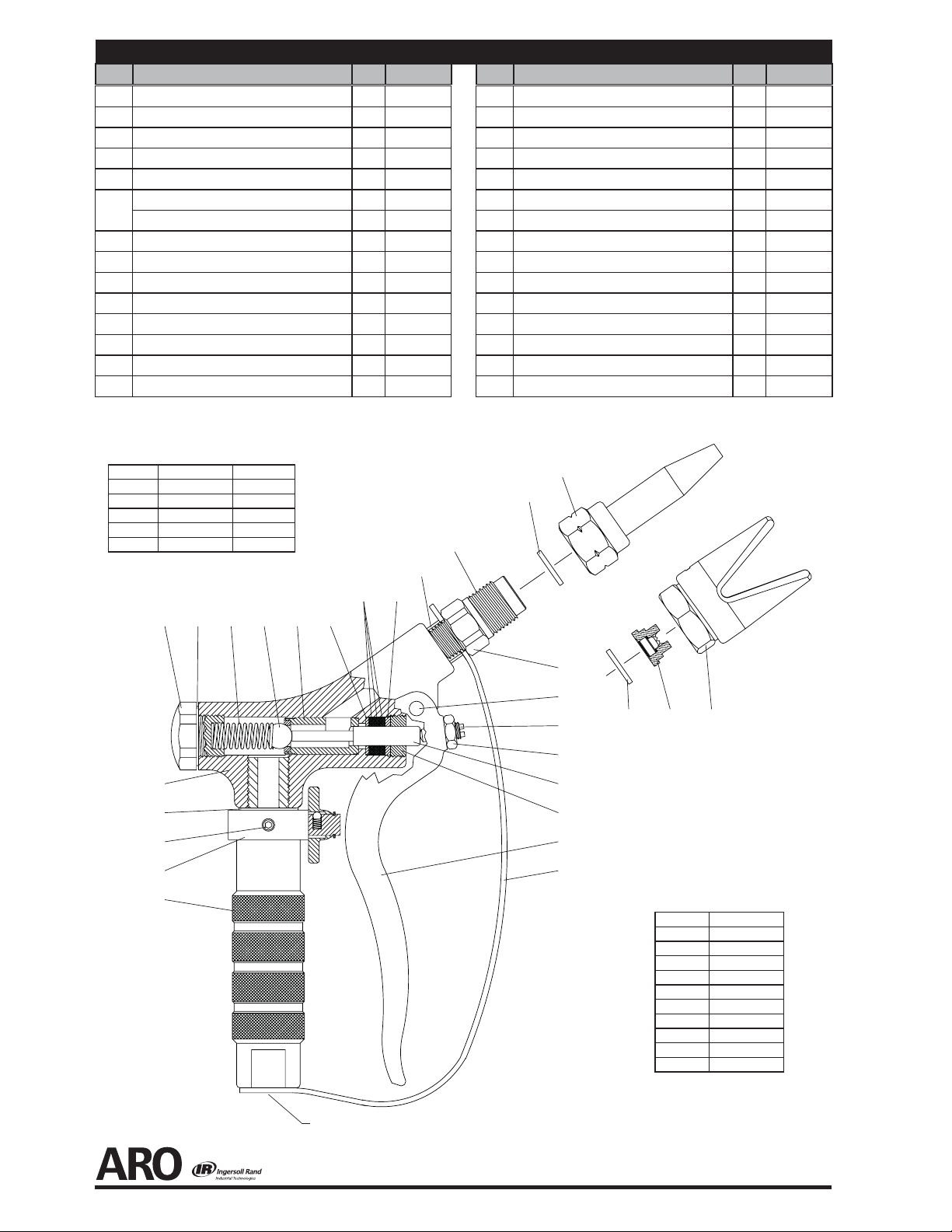

PARTS LIST / 651500-X CONTROL HANDLE

16 31414

171 2

12

4

25

24

26 5

8

9

10

11

15

21

3/8 - 18 N.P.T.F. - 1

18

19

22

23

20

6

7

13

11/16” - 16

Item Description

1 Cap (1) 90395

2 Gasket (1) F21-23

9

3 Valve and Ball Seat Insert Assembly (1) 65732

9

4 Sleeve (1) 90332

5 Cap and Guard Assembly

Adapter

6

7 Pin (1) 2487

8 Set Screw (1) 2484

9 Nut

10 Piston Assembly (1) 65896

9

11 Retainer (1) 76886

12 Washer (1) F174-9

13 Packing (3) F26-35

9

14 Washer (1) F15-64

Typical spray tips available for mod-

els 651500-1 and 651500-3.

Tip No. Ori ce Diameter Pattern Width

TC-1850 0.018” 10”

TC-2140 0.021” 8.5”

TC-2150 0.021” 11.5”

TC-2640 0.026” 9”

TC-2650 0.026” 12”

(size)

(651500 and 651500-1 only)

(651500-2 only)

(1/4” - 28)

17

(651500-1 only)

16

(Qty) Part No. Item Description

(1) 66504

(1) 76751

(1) 32854

(1) Y11-104-C

12

13

11/16” - 16

(size)

(Qty) Part No.

15 Lever (1) 2661

16 Ball (1) 90399

9

17 Spring (1) 76948

9

18 Body and Bushing Assembly (1) 65752

19 Gasket (1) F21-23

9

20 Handle (1) 4880

21 Trigger Guard (1) 90371

22 Set Screw

(#10 - 32 x 3/16”) (included with item 23)

(3) Y23-101

23 Knob Assembly (1) 66534

Extrusion Nozzle & Retaining Nut Ass’y (1) 66541-XX

24

c

25 Washer (1) 75815

c

26 Spray Tip (1) TC-XXXX

c

27 Washer (1) 91181

c

Items included in Service Kit 61240

9

24

25

272726

18

10

19

22

11

15

23

21

20

Not included. Must be ordered separately.

c

Apply Loctite® 242® to threads.

d

Lubricate with Shell AW 32 Oil or equivalent.

3/8 - 18 N.P.T.F. - 1

Page 2 of 2 651500-X (en)

e

y ARO® is a registered trademark of Ingersoll-Rand Company y

y Loctite® and 242® are registered trademarks of Henkel Loctite Corporation y

Typical extrusion tips

available for models

651500 and 651500-2.

Tip No. Ori ce Diameter

66541-03 0.031”

66541-04 0.046”

66541-06 0.063”

66541-09 0.093”

66541-12 0.125”

66541-15 0.156”

66541-17 0.172”

66541-18 0.187”

66541-25 0.250”

66541-37 0.375”

PN 97999-21

Loading...

Loading...