Ingersoll-Rand 650937-XX3 User Manual

OPERATOR’S MANUAL 650937--X

SPECIFICATIONS, SERVICE KITS, GENERAL INFORMATION, TROUBLESHOOTING

INCLUDE MANUALS: 6694X--X LOWER PUMP END (PN 97999--012) &

FORM 3638--2 GENERAL INFORMATION MANUAL (PN 97999--353)

2.062 SQ.” HYDRAULIC MOTOR

0.4:1 RATIO

6” STROKE

TWO--BALL PUMP SERIES

400 SERIES STAINLESS STEEL

650937--X

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

R E L E A S E D : 8 -- 3 0 -- 9 6

REVISED: 6--4--10

02 )

(REV.

SERVICE KITS

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 637164 for repair of Hydraulic Motor section.

Service Note: The Hydraulic Motor Service/Parts Manual is not

shipped with the pump but it is included with each Service Kit. If this

Service/Parts Information is needed, request the Hydraulic Motor

Operator’s Manual from ARO. (Manual 61588--100,

PN 97999--063).

• 637211- XX3 for repair of Lower Pump section.

Refer to the chart on page 2 for description of --XXX options.

SPECIFICATIONS

Model Series (Refer to option chart) 650937--XX3..

Type Hydraulically Operated, Two--Ball....................

Ratio 0.4:1....................

Hydraulic Motor 61588--100............

Motor Repair Kit 637164..........

Motor Size 2.062 sq.’’ (13.3 sq. cm)..............

Stroke 6’’..................

Hydraulic Inlet 3/8’’ -- 18 NPTF--1(f)...........

Hydraulic Return 1/2” -- 14 NPTF--1(f).........

Lower Pump End Series 66941--XX3.....

Lower Pump Repair Kit 637211--XX3.....

Material Inlet 2” NPTF--1 (m).............

Material Outlet 1--1/4’’ NPTF--1(f)...........

PERFORMANCE

Hydraulic Inlet Pressure Range 50 -- 1200 PSI (3.4 -- 83 bar)

Fluid Pressure Range 20 -- 515 PSI (1.4 -- 35.5 bar).......

Max. Rec’d Cycles / Minute 50...

Displacement In

Volume / Cycle 33 oz. (979 ml).............

Cycles Per Gallon 3.86..........

Flow @ 50 Cycles / Minute 12.9 GPM (49.0 lpm)....

Noise Level N/A...............

3

Per Cycle 59.79...

PUMP DATA

MODEL 650937- XX3

Hydraulic Inlet

3/8--18 NPTF--1(f)

(Not Shown)

Hydraulic Motor

61588--100

(See Manual 61588 --100)

45- 9/16

(1157 mm)

29- 17/32

(750 mm)

14- 25/32

(375 mm)

FIGURE 1

Accessory Available: 61938--1 Wall Bracket and 65139 Floor Mounting Flange.

IMPORTANT

This is one of the four documents which support the pump.

Replacement copies of these forms are available upon request.

= 650937--X MODEL OPERATOR’S MANUAL

- GENERAL INFORMATION -- INDUSTRIAL PISTON PUMPS

- 6694X--X LOWER PUMP END OPERATOR’S MANUAL

- 61588--100 HYDRAULIC MOTOR OPERATOR’S MANUAL

Spacer Section

CAP SCREW Y5--107--C (3)

WASHER Y14--625--C (3)

MOUNTING PLATE 93353--1

CONNECTOR (See Figure 2)

SPACER ROD 93347--1 (3)

CAP SCREW 79186 (3)

Material Outlet

1-- 1/4’’ NPTF--1(f)

146_ FROM HYDRAULIC INLET

Lower Pump

66941-- XX3

(See Manual 6694X -- X)

Material Inlet

2’’ NPTF--1(male)

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 99711517

650937--X

PACKING MATERIAL

PUMP OPTION DESCRIPTION CHART

PACKING MATERIAL (PACKINGS ARE UPPER AND LOWER UNLESS NOTED)

X3

PLUNGER TYPE

SPRING ARRANGEMENT

C UHMW--PE P UHMW--PE/PTFE STAG’D (UPPER)

K CARBON GRAPHITE FILLED PTFE UHMW--PE (LOWER)

L MINERAL FILLED PTFE R PTFE/UHMW--PE STAG’D (UPPER)

SPRING ARRANGEMENT

3

NO SPRING

6 WAVE SPRING

PTFE (LOWER)

PLUNGER TYPE

3

HD SS W/HD CHROME PLATING

GENERAL DESCRIPTION

WARNING

mum operating pressure of 515 psi (35.5 bar) at 1200 psi (83

bar) inlet hydraulic pressure.

INLET PRESSURE TO PUMP MOTOR

Pump ratio is an expression of the relationship between the pump motor area and the

lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure is supplied

to the motorofa5:1ratiopump it will develop a maximum of 750 p.s.i. (52bar)fluidpressure (at no flow) -- as the fluid control is opened, the flow rate will increase as the motor

cycle rate increases to keep up with the demand.

WARNING

safety precautions and important information.

HAZARDOUS PRESSURE. Do not exceed maxi-

PUMP RATIO X MAXIMUM PUMP

= FLUID PRESSURE

Refer to general information sheet for additional

• The Two--Ball pumps are primarily designed for the pumping of me-

dium viscosity fluids compatible with 400 series stainless steel. The

lower pump is designed for easy priming and the double acting feature is standard in all ARO industrial pumps. Material is delivered to

the pump discharge outlet on both the up and down stroke.

• The motor is connected to the lower pump end by a spacer section.

This allows for lubrication of the upper packing gland and prevents

motor contamination becauseof normal wear and eventual leakage

through the material packing gland. Be sure the solvent cup is adequately filled with lubricant to protect the upper packings and insure

longest service life.

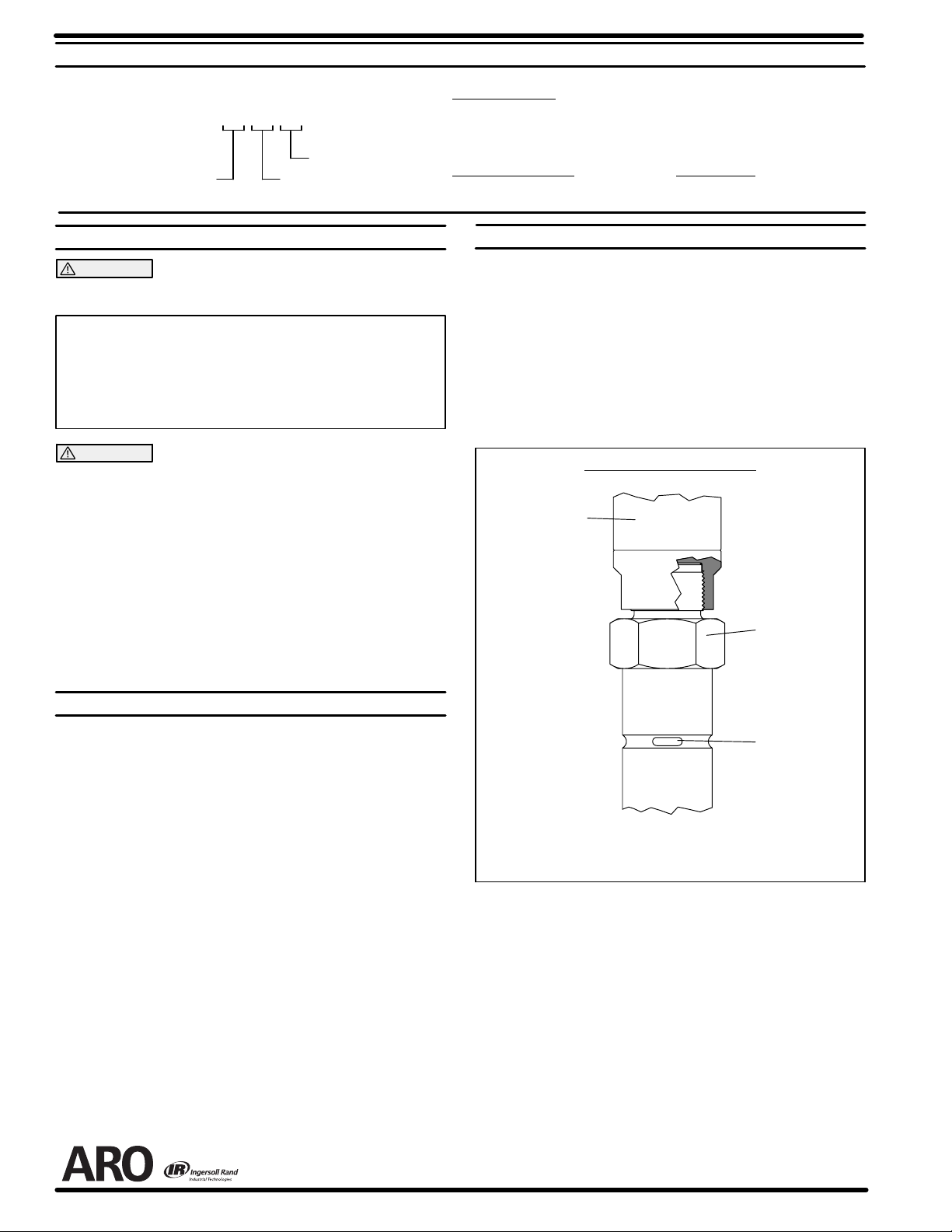

PUMP CONNECTION -- UPPER / LOWER

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Remove the top three screws and washers from the three spacer

rods (see figure 1).

3. Pull the hydraulic motor from the lower pump end until motor piston

rod is in the ‘‘down” position and lower pump end rod is in ‘‘up” position.

4. Remove the three spacer rods by unscrewing the bottom three cap

screws.

5. Remove the cotterpinand unscrew the lower pumpend rod from the

adapter (see figure 2).

PUMP CONNECTOR DETAIL

Pump Motor

Piston Rod

Adapter

93350--1

TROUBLE SHOOTING

Pump problems can occur in either the Hydraulic Motor Section or the

Lower Pump End Section, use these basic guidelines to help determine

which section is affected.

If the pump will not cycle.

• Be certain to first check for non--pump problems including kinked,

restrictiveor plugged inlet/outlet hose or dispensing device.Depressurize the pump system and clean out any obstructions in the inlet/

outlet material lines.

• Refer to the motor manual for trouble shooting if the pump does not

cycle and/or hydraulic fluid leaks from the hydraulic motor.

If the pump cycles but does not deliver material.

• Refer to the lower pump end manual for further trouble shooting.

Cotter Pin

Y15--46--S

FIGURE 2

REASSEMBLY

1. Align the pump motor with the lower pump end.

2. Screw the adapter onto the motor piston rod.

3. Screw the lower pumprodintothe adapter and secure with the cotter

pin. NOTE: Bend the ends of the pin into the groove of adapter.

4. Reinstall thespacer rods to the lower pump end, securing withthree

cap screws.

5. Bring the motor and lower pump together and retain with the three

screws and washers.

PN 97999- 550

650937- X

Loading...

Loading...