Ingersoll-Rand 210CSA, 270G User Manual

Paint Sprayer

Models 200G, 210G, 270G and 210CSA

Product Information

EN

Product Information

ES

Especicaciones del producto

FR

Spécications du produit

47083068

Edition 1

December 2009

Save These Instructions

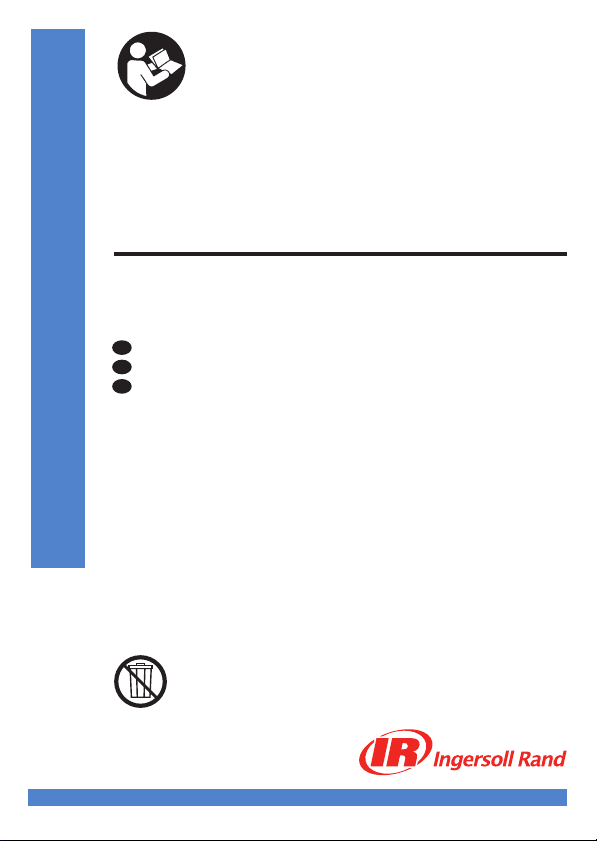

MODEL 210CSA MODEL 200G, 210G and 270G

3

1

2

1

3

2

3

7

4

2

1

48h

5

6

4

5

(Dwg. 47083233)

(Dwg. TP2051)

(Dwg. 16577629)

inch (mm) NPS (inch)

2 47083068_ed1

5/16 (8) 1/4

EN

WARNING

NOTICE

Fan Direction

Air Cap

Lock Ring

Product Safety Information

Intended Use:

Paint Sprayers are designed for paint, lacquer, stain or other nish type material.

For additional information refer to Product Safety Information Manual Form 16576563.

Manuals can be downloaded from www.ingersollrandproducts.com.

Product Specications

Model Description

Touch-Up Gravity

200G

Feed Spray Gun

Gravity Feed

210G

Spray Gun

HVLP Gravity

270G

Feed Spray Gun

Suction Feed

210CSA

Spray Gun

Operations

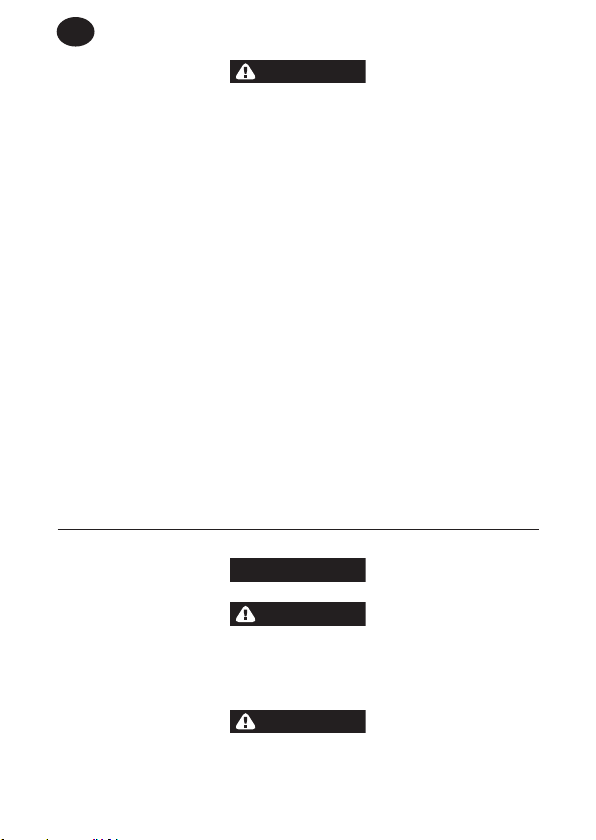

Spray Gun Handling

Do not point the spray gun at anyone or at any part of the body.

Ensure appropriate air line lter is being used. Water, oil, and debris in the air may cause

damage to the workpiece.

The spray gun should be held perpendicular to the work surface and 6 to 12 inches from the

work surface. Keep the gun parallel to the work surface during the stroke to ensure even coating.

DO NOT move the gun in an arc. This will result in a build up of paint in the center of the stroke

and a light coating at each end.

Start the gun moving prior to pulling the trigger and release the trigger before stopping the gun

movement. Overlap strokes enough to get a uniform nish.

Maximum

Air Pressure

35 psig

[2.4 bar]

60 psig

[4.1 bar]

40 psig

[2.8 bar]

60 psig

[4.1 bar]

Average Air

Consumption

5 cfm

[140 l/min]

11 cfm

[300 l/min]

8 cfm

[235 l/min]

12 cfm

[340 l/min]

Tool

Weight

1.2 lbs

[0.52 kg]

2.6 lbs

[1.2 kg]

2.7 lbs

[1.3 kg]

1.5 lbs

[0.62 kg]

Cup

Capacity

4.2 oz

[125 cc]

20 oz

[600 cc]

33 oz

[1,000 cc]

33 oz

[1,000 cc]

Fluid

Nozzle Size

0.03 in

[0.8 mm]

0.05 in

[1.4 mm]

0.06 in

[1.5 mm]

0.07 in

[1.8 mm]

(Dwg. TP2049)

47083068_ed1 EN-1

(Dwg. TP2053)

EN

WARNING

NOTICE

WARNING

WARNING

Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool, or before performing any maintenance on this

tool.

The direction of the fan can be adjusted from horizontal to vertical be loosening the lock ring

and turning the air cap to the proper location. Hand tighten lock ring after adjustment.

Controls

Refer to illustration 47083233 on page 2.

1. Fluid Control

The uid control knob will adjust the atomization of the paint. Turn the knob clockwise until fully

closed. Then while turning the knob

counterclockwise, trigger short bursts of paint. This counterclockwise movement of the knob will

move the pattern from ne to coarse. Adjust the knob until the desired pattern is obtained.

2. Pattern Control

The pattern control knob adjusts the size of the fan. A wide fan will result if the knob is fully

opened by turning it counterclockwise. As the knob is turned clockwise, a smaller round pattern

will be achieved.

3. Air Control (If Applicable)

Open the air control knob fully by turning counter clockwise. Set desired air pressure using

regulator. Do not exceed maximum air pressure. If a lower air pressure is desired for some parts

of the spray job, turn the air control knob clockwise as needed.

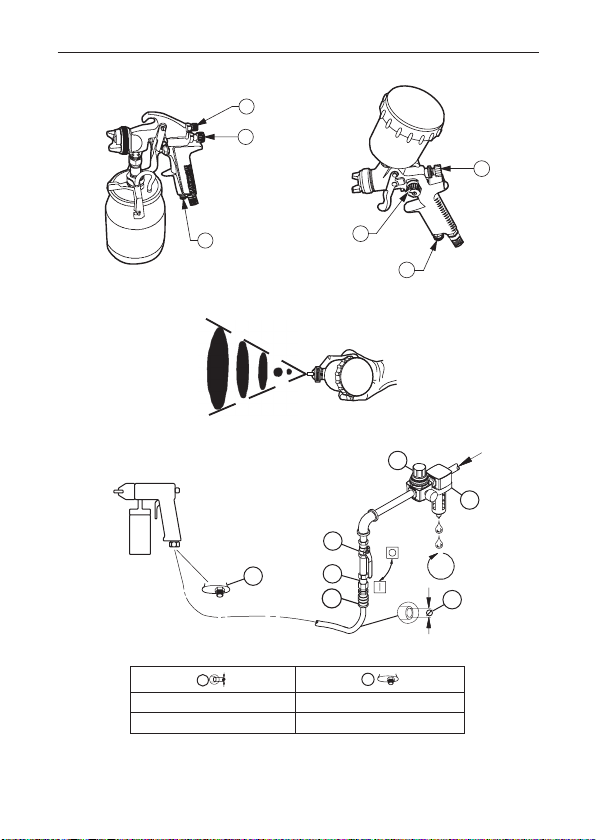

Spray Patterns

If the pattern is too coarse and the uid control knob can not adjust it properly, try adjusting the

air pressure or thin the paint to achieve

desired pattern.

The spray pattern varies from round to at with patterns in between (Refer to illustration TP2051

on Page 2).

Routine Maintenance

Dispose of hazardous uid according to all local, state, and national guidelines.

Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool, or before performing any maintenance on this

tool.

Clean spray gun and canisters immediately after use. Paint or other uids can dry quickly and can

easily plug internal passageways and render the spray gun useless.

Do not use Methylene chloride (Dichloromethane) or any halogenated hydrocarbon

solvents with this spray gun.

EN-2 47083068_ed1

EN

NOTICE

NOTICE

Remove and empty the canister. Rinse canister with a solvent recommended for the paint being

used.

Fill canister with solvent and attach to spray gun. Spray solvent into an approved container, while

shaking the gun vigorously. Continue until all traces of paint have been eliminated from spray.

Also wipe the exterior of the gun with a rag soaked with the solvent.

Remove the air cap and soak in solvent. Use a toothpick or plastic brush, to clean air passages.

Using metal objects can damage the precision air passages. DO NOT soak spray gun in

solvent. This can damage non-metallic

components.

After cleaning, lubricate lightly with NON-SILICONE OIL. Silicone oil can cause oil spots to

occur in the paint.

Installation and Lubrication

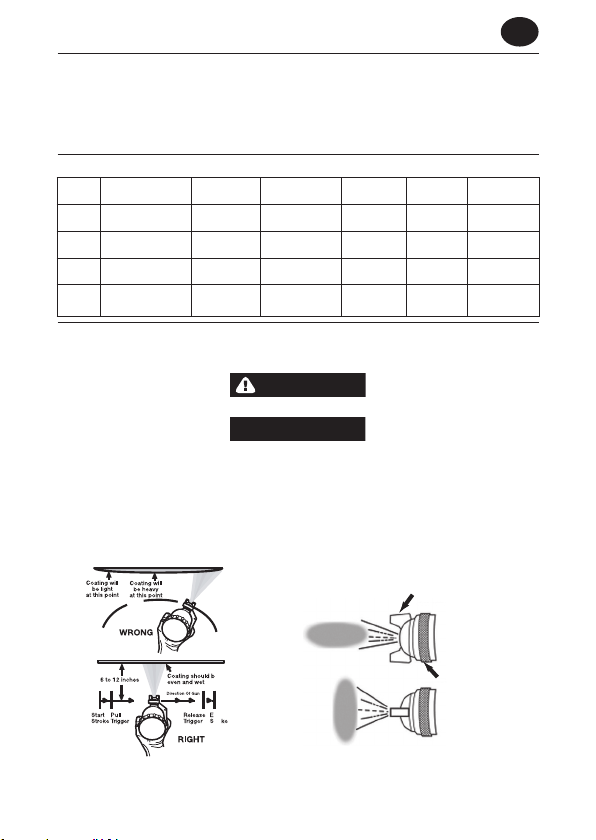

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air lter and compressor tank daily. Install a

properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any hose

coupling without internal shut-o, to prevent hose whipping if a hose fails or coupling disconnects. See drawing 16577629 and table on page 2. Maintenance frequency is shown in circular

arrow and dened as h=hours, d=days, and m=months of actual use.. Items identied as:

1. Air lter 5. Thread size

2. Regulator 6. Coupling

3. Emergency shut-o valve 7. Safety Air Fuse

4. Hose diameter

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled, degreased and parts be separated by material so that they can be recycled.

The original language of this manual is English.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Oce or Distributor.

47083068_ed1 EN-3

Loading...

Loading...