Page 1

Air Impact Wrench

Model 2100G

Product Information

EN

Product Information

ES

Especicaciones del producto

FR

Spécications du produit

04579736

Edition 3

October 2009

Save These Instructions

Page 2

4

7

5

3

2

1

9

6

10

48h

48h

PMAX

9

8h

24h

8

1

3

2

5

6

9

10

Minimum

Maximum

Power

Regulator

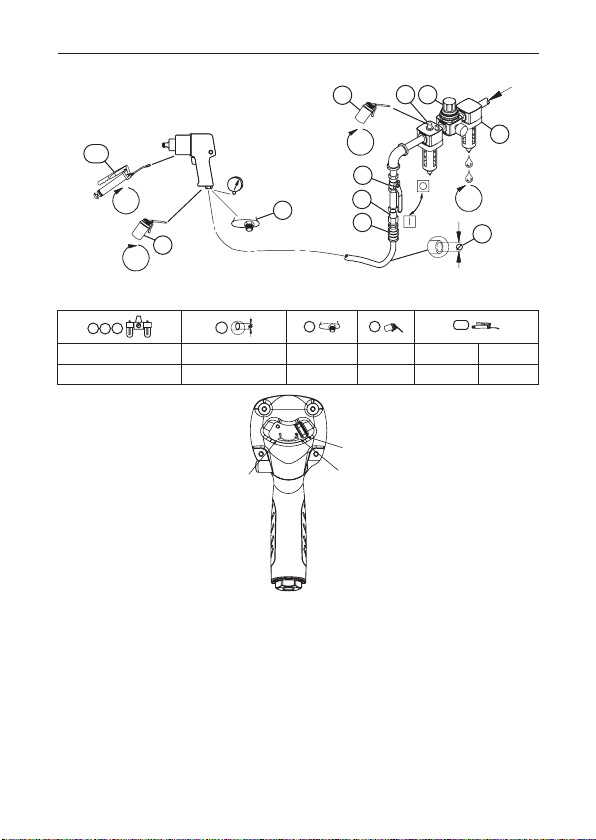

(Dwg. 45667631)

IR # - NPT inch (mm) NPT IR # IR # cm

C38121-600-V5 3/8 (10) 1/4 50 115-1lb 4

(Dwg. TP2186)

2 04579736_ed3

3

Page 3

EN

Product Safety Information

Intended Use:

These Air Impact Wrenches are designed to remove and install threaded fasteners.

For additional information refer to Air Impact Wrenches Product Safety Information

Manual Form 04580916.

Manuals can be downloaded from www.ingersollrandproducts.com.

Power Management System

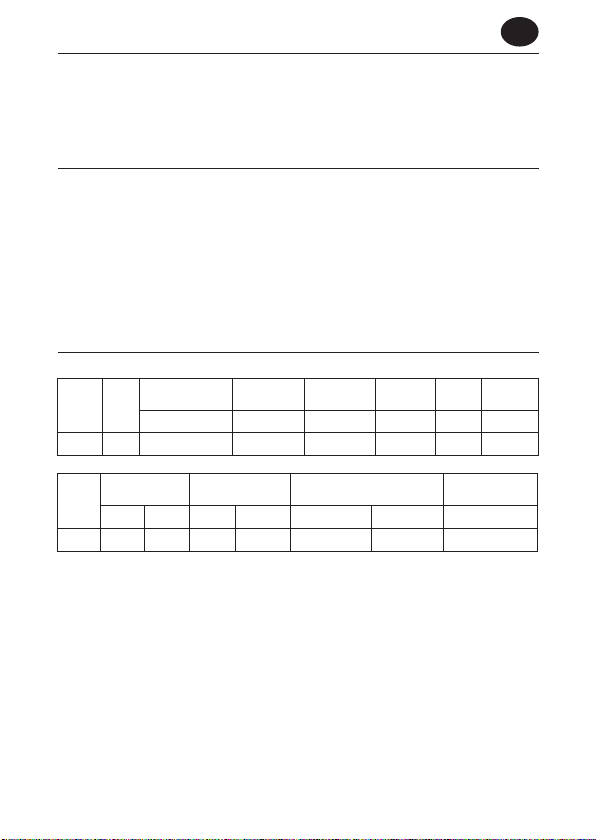

The 2100G Impact Wrench incorporates a Power Management System that allows the operator

to select two power output settings. These settings are minimum power output or maximum

power output in the clockwise direction only. The Air Wrench will always operate at maximum

power output in the counterclockwise direction, no matter what power output level is selected.

The two power setting indicators on the rear of the housing are for reference only and DO NOT

denote a specic power output. The number 1 indicator designates minimum power output and

the number 2 setting indicator denotes maximum power output (See TPD2186 on page 2). The

power output can be further reduced in clockwise or counterclockwise by using the variable

throttle. Air supply systems which do not deliver adequate air pressure can aect power output

at all settings.

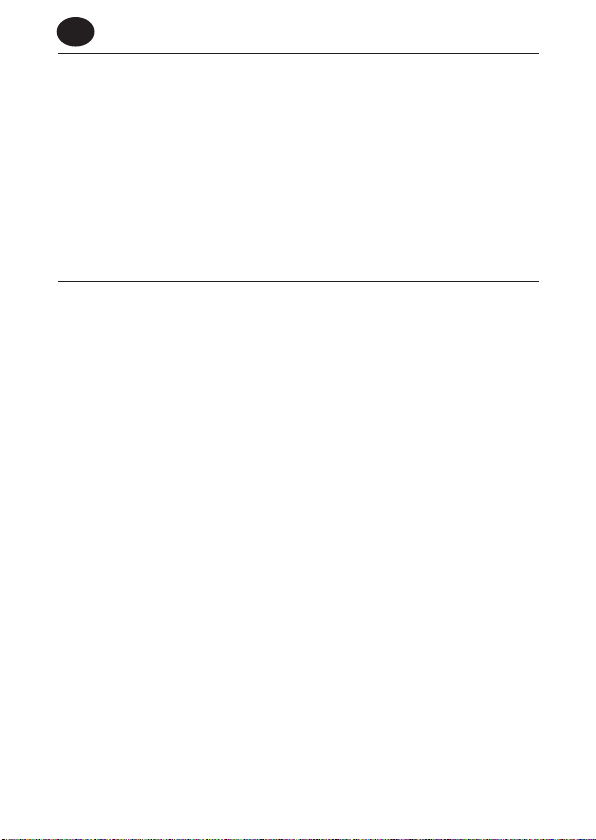

Product Specications

Recommended

Drive

Model

2100G 1/2” 25-350 (34-474) 550 (745) 9500 1200 4.3 (2) 7.4 (187)

Torque Range

Size

ft-lbs (Nm) ft-lbs (Nm) rpm BPM lbs (Kg) inch (mm)

Max. Torque

(Reverse)

Maximum

Free Speed

Blows Per

Minute

Tool

Weight

Overall

Length

Average Air

Consumption

Model

cfm l/min cfm l/min † Pressure (Lp) ‡ Power (Lw) m/s²

2100G 5 142 25 708 96.6 107.6 4.6

† KpA = 3dB measurement uncertanity

‡ KwA = 3dB measurement uncertanity

04579736_ed3 EN-1

Air Consumption

@ Load

Sound Level dB (A)

(ISO15744)

Vibration Level

(ISO8662)

Page 4

EN

Installation and Lubrication

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air lter and compressor tank daily. Install a

properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any hose

coupling without internal shut-o, to prevent hose whipping if a hose fails or coupling

disconnects. See drawing 45667631 and table on page 2. Maintenance frequency is shown in a

circular arrow and dened as h=hours, d=days, and m=months of actual use. Items identied as:

1. Air lter 6. Thread size

2. Regulator 7. Coupling

3. Lubricator 8. Safety Air Fuse

4. Emergency shut-o valve 9. Oil

5. Hose diameter 10. Grease - through tting

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled,

degreased and parts be separated by material so that they can be recycled.

The original language of this manual is English.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Oce or Distributor.

EN-2 04579736_ed3

Page 5

ES

Información de Seguridad Sobre el P roducto

Uso Indicado:

Los aprietatuercas neumáticos de percusión están diseñados para extraer e instalar

adores roscados.

Para más información, consulte el Manual de información de seguridad de producto

04580916 Aprietatuercas neumático de percusión.

Los manuales pueden descargarse en www.ingersollrandproducts.com.

Sistema de Gestión de Potencia

Las llaves de impacto 2100G tienen incorporado un sistema de control de potencia que permite

al operario seleccionar entre 2 ajustes de potencia. Estos ajustes van mínima hasta potencia o

máxima en el sentido de giro a derechas solamente. La llave neumática siempre funcionará con

la máxima potencia en el sentido inverso, cualquiera que sea el nivel de potencia seleccionado.

Los 2 indicadores situados en la parte posterior de la carcasa sirven solamente de referencia; NO

indican una potencia especíca. El indicador de potencia más no. 1 mínima, y el indicador no. 2

representa la máxima potencia (Ver TPD2186 en la página 2). La potencia puede reducirse aun

más con accionamiento a derechas o a izquierdas mediante el gatillo de mando. Los sistemas de

aire comprimido que no suministren aire a la presión apropiada pueden afectar la potencia en

todos los ajustes.

Especicaciones del Producto

Tamaño de

Modelo

Accionamiento

2100G 1/2” 25-350 (34-474) 550 (745) 9500 1200 4.3 (2)

Intervalo de par

Recomendado

ft-lbs (Nm) ft-lbs (Nm) rpm BPM lbs (Kg)

(Retroceso)

Par Máx.

Velocidad

Libre

Máxima

Percusiones

por Minuto

Peso de la

Herramienta

Longitud

General

Modelo

inch (mm) cfm l/min cfm l/min † Presión (Lp) ‡ Potencia (Lw) m/s²

2100G 7.4 (187) 5 142 25 708 96.6 107.6 4.6

† KpA = 3dB de error

‡ KwA = 3dB de error

04579736_ed3 ES-1

Consumo

Medio

de Aire

Consumo

Medio

Según Carga

Nivel Sonoro dB (A)

(ISO15744)

Nivel de

Vibración

(ISO8662)

Page 6

ES

Instalación y Lubricación

Diseñe la línea de suministro de aire para asegurar la máxima presión de funcionamiento (PMAX)

en la entrada de la herramienta. Vacíe el condensado de las válvulas en los puntos inferiores de

la tubería, ltro de aire y depósito del compresor de forma diaria. Instale una contracorriente de

manguera de fusil de aire de seguridad de tamaño adecuado y utilice un dispositivo

antilatigazos en cualquier acoplamiento de manguera sin apagador interno para evitar que

las mangueras den latigazos en caso de que una manguera falle o de que el acoplamiento se

desconecte. Consulte la dibujo 45667631 y la tabla en la página 2. La frecuencia de

mantenimiento se muestra en forma de echa circular y se dene como h=horas, d=días y

m=meses de uso real de. Los elementos se identican como:

1. Filtro de aire 6. Tamaño de la rosca

2. Regulador 7. Acoplamiento

3. ubricador 8. Fusil de aire de seguridad

4. Válvula de corte de emergencia 9. Aceite

5. Diámetro de la manguera 10. Grasa - durante el montaje

Piezas y Mantenimiento

Una vez vencida la vida útil de herramienta, se recomienda desarmar la herramienta,

desengrasarla y separar las piezas de acuerdo con el material del que están fabricadas para

reciclarlas.

El idioma original de este manual es el inglés.

Las labores de reparación y mantenimiento de las herramientas sólo puede ser realizadas por un

Centro de Servicio Autorizado.

Toda comunicación se deberá dirigir a la ocina o al distribuidor Ingersoll Rand más próximo.

ES-2 04579736_ed3

Page 7

FR

Informations de Sécurité du Produit

Utilisation Prévue:

Ces clés pneumatiques à chocs sont conçues pour le vissage/dévissage de dispositifs de

xation letés.

Pour des informations complémentaires, utilisez le formulaire 04580916 pour obtenir le

manuel d’information de sécurité du produit Clé pneumatique à chocs.

Les manuels peuvent être téléchargés à l’adresse www.ingersollrandproducts.com.

Système de Gestion de la Puissance

La 2100G sont équipées d’un système de gestion de puissance qui permet à l’opérateur de

sélectionner 2 réglages de puissance. Ces réglages vont minimum ou puissance maximum en

marche avant seulement. La clé pneumatique fonctionnera toujours à la puissance maximum en

desserrage, quel que soit le niveau de puissance sélectionné. Les 2 indicateurs de réglage de

puissance sur l’arrière du corps indiquent les niveaux, et NE DÉNOTE PAS une puissance

spécique. Le no.1 indicateur de puissance indique la puissance minimum et le no. 2 indicateur

indique la puissance maximum (Voir TPD2186 à la page 2). La puissance peut être encore plus

réduite en serrage ou desserrage à l’aide de la commande variable de mise en marche. Les

circuits d’air comprimé ne fournissant pas une pression d’air adéquate peuvent aecter la

puissance fournie à toutes les positions de réglage.

Spécications du Produit

Gamme de

Taille de la Tête

Modèle

D’entraînement

2100G 1/2” 25-350 (34-474) 550 (745) 9500 1200 4.3 (2) 7.4 (187)

Couples

Recommandée

ft-lbs (Nm) ft-lbs (Nm) rpm BPM lbs (Kg) inch (mm)

Couple

Max.

(Inversion)

Maxi

Régime

à Vide

Coups

par

Minute

Poids

de

L’outil

Longueur

Totale

Consommation

Moyenne en Air

Modèle

cfm l/min cfm l/min † Pression (Lp) ‡ Puissance (Lw) m/s²

2100G 5 142 25 708 96.6 107.6 4.6

† KpA =incertitude de mesure de 3dB

‡ KwA = incertitude de mesure de 3dB

04579736_ed3 FR-1

Consommation

D’air Avec

une Charge

Niveau Acoustique dB (A)

(ISO15744)

Niveau

Acoustique

(ISO8662)

Page 8

FR

Installation et Lubrication

Dimensionnez l’alimentation en air de façon à obtenir une pression maximale (PMAX) au niveau

de l’entrée d’air de l’outil. Drainez quotidiennement le condensat des vannes situées aux points

bas de la tuyauterie, du ltre à air et du réservoir du compresseur. Installez un raccordement à

air de sûreté dont la taille est adaptée au tuyau et placez-le en amont de celui-ci, puis utilisez

un dispositif anti-débattement sur tous les raccords pour tuyaux sans fermeture interne, an

d’empêcher les tuyaux de fouetter si l’un d’entre eux se décroche ou si le raccord se détache.

Reportez-vous à l’illustration 45667631 et au tableau de la page 2. Les intervalles d’entretien sont

indiqués à l’aide d’une èche circulaire et dénis à l’aide de lettres (h = heures, d = jours et

m =mois d’utilisation réelle). Eléments identiés en tant que:

1. Filtre à air 6. Taille du letage

2. Régulateur 7. Raccord

3. Lubricateur 8. Raccordement à air de sûreté

4. Vanne d’arrêt d’urgence 9. Huile

5. Diamètre du tuyau 10. Graisse - pour l’assemblage

Pièces Détachées et Maintenance

A la n de sa durée de vie, il est recommandé de démonter l’outil, de dégraisser les pièces et de

les séparer en fonction des matériaux de manière à ce que ces derniers puissent être recyclés.

Ce manuel a été initialement rédigé en anglais.

La réparation et la maintenance des outils ne devraient être réalisées que par un centre de

services autorisé.

Adressez toutes vos communications au Bureau Ingersoll Rand ou distributeur le plus proche.

FR-2 04579736_ed3

Page 9

Notes:

Page 10

Notes:

Page 11

Notes:

Page 12

www.ingersollrandproducts.com

© 2009 Ingersoll Rand Company

Loading...

Loading...