Page 1

I n t é g r a t i o n G

u i d e

iUP 250 & iUR 250

Ingenico – 28-32 Boulevard de Grenelle - 75015 PARIS

Tél. 33(0)1 58 01 80 00 - Fax 33 (0)1 58 01 91 35

Page 2

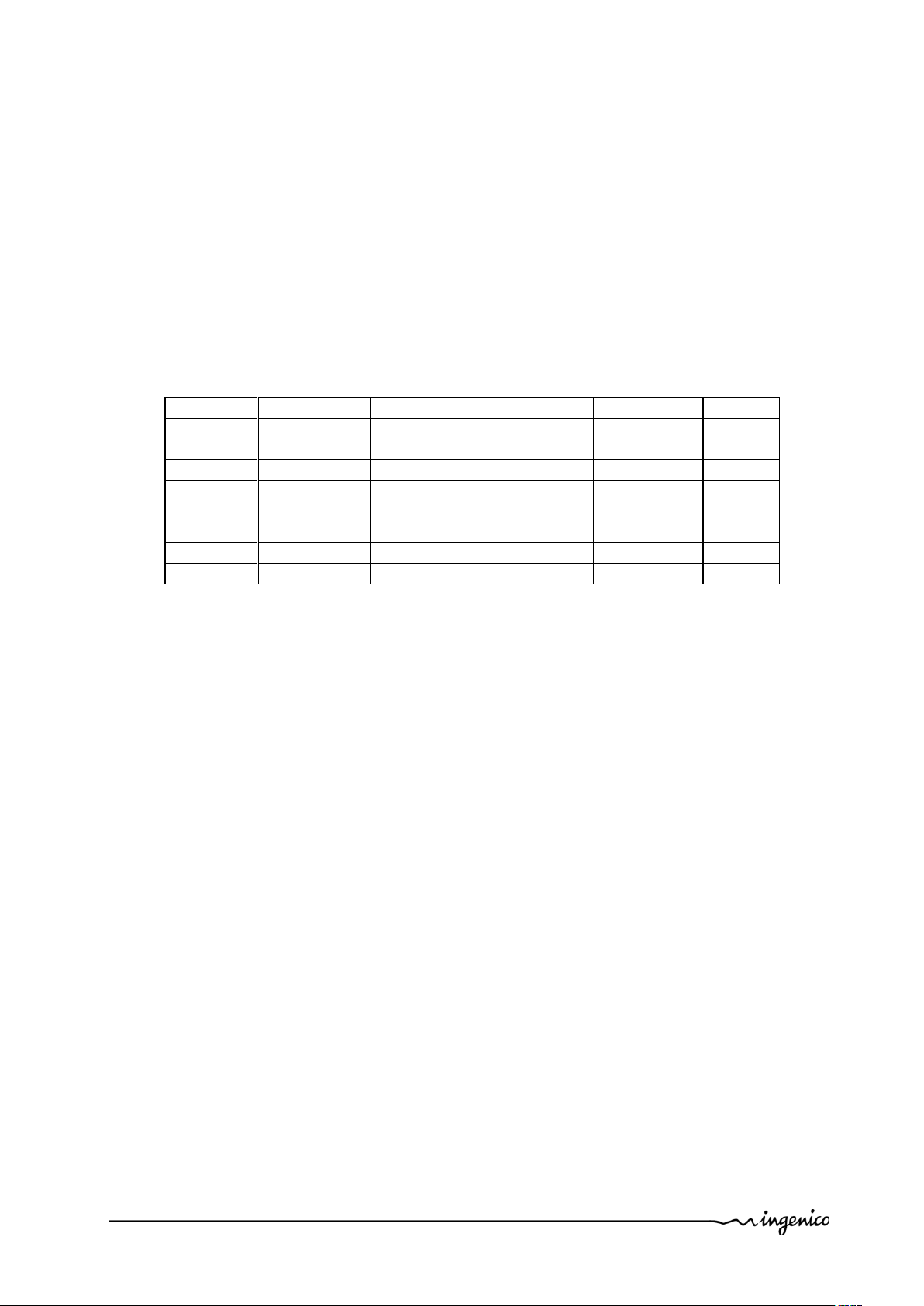

Version

Date

Nature of modifications

Author

Visa

1.0

17/11/2011

First version

D.GEORGES

2.0

01/06/2012

Official version

D.GEORGES

The scope of this document is to assist third party integrators when dealing with

Ingenico UNattended products (iUN) such as iUP250 and iUR250, both certified PCI

PTS 3.x, or others. It offers all information needed for a successful integration of

iUP250 and iUR250 products into unattended kiosk machines.

For any sales information please refer to your Ingenico contact into the region.

Updates table

Intégration Guide_iUP250&iUR250 2/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 3

Table of contents

1 GENERAL ............................................................................................................. 6

1.1 Definition of acronyms ..................................................................................... 6

1.2 iUP250 & iUR250 payment solution presentation .......................................... 7

1.2.1 Diagram of iUP250 & iUR250 connectivity and communications .................. 8

1.2.2 Examples of integration ................................................................................ 9

1.2.3 Services ...................................................................................................... 10

1.3 Description of modules .................................................................................. 11

1.3.1 iUP250 ........................................................................................................ 11

1.3.1.1 Technical Hardware characteristics ...................................................... 12

1.3.1.2 iUP250 output connectors description .................................................. 14

1.3.1.3 SAM & µSD Installation ........................................................................ 22

1.3.1.4 Buzzer ................................................................................................... 22

1.3.1.5 RGB backlight ....................................................................................... 23

1.3.1.6 Maintenance Button .............................................................................. 23

1.3.1.7 Cable Protection ................................................................................... 24

1.3.1.8 Antenna Installation .............................................................................. 25

1.3.1.9 PINPad and Reader interconnectivity ................................................... 26

1.3.2 iUR250 ........................................................................................................ 27

1.3.2.1 Technical Hardware Characteristics ..................................................... 28

1.3.2.2 iUR250 output connectors description .................................................. 29

1.3.2.3 RGB Leds ............................................................................................. 31

1.3.2.4 iUR250 Optional Lever Lock ................................................................. 31

1.4 Professional installation Requirement ......................................................... 32

2 MAIN ACCESSORIES ........................................................................................ 33

2.1.1 Generality ................................................................................................... 33

2.1.2 Optional PINPad-to-Reader USB cable ...................................................... 33

2.1.3 iUP250 Power supply ................................................................................. 33

2.1.4 Stand-by management cable ...................................................................... 33

2.1.5 Optional Pinshield ....................................................................................... 34

3 SOFTWARE ........................................................................................................ 37

3.1 iUP250 .............................................................................................................. 37

3.1.1 Software Architecture ................................................................................. 38

3.1.2 Secure management of software ................................................................ 39

3.1.3 Operating system ........................................................................................ 40

3.1.4 TELIUM MANAGER ................................................................................... 41

3.1.5 Software downloading ................................................................................ 43

3.1.6 Development station ................................................................................... 45

3.2 iUR250 ............................................................................................................. 47

Intégration Guide_iUP250&iUR250 3/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 4

3.2.1 Software architecture .................................................................................. 48

3.2.2 Software security management .................................................................. 48

3.2.3 Operating system ........................................................................................ 49

4 TERMINAL MANAGEMENT SYSTEM ............................................................... 50

4.1 Introduction ..................................................................................................... 50

4.2 Basic functions ............................................................................................... 50

4.3 Advanced functions ....................................................................................... 50

4.4 Customers savings with Ingenico TMS solution ......................................... 50

5 INSTALLATION PROCEDURE IN KIOSKS ....................................................... 51

5.1 Security requirement ...................................................................................... 51

5.2 Kiosk mechanical requirements .................................................................... 51

5.3 General installation recommendations ......................................................... 51

5.4 Kiosk suggested layouts for iUR250 IUP250 ................................................ 51

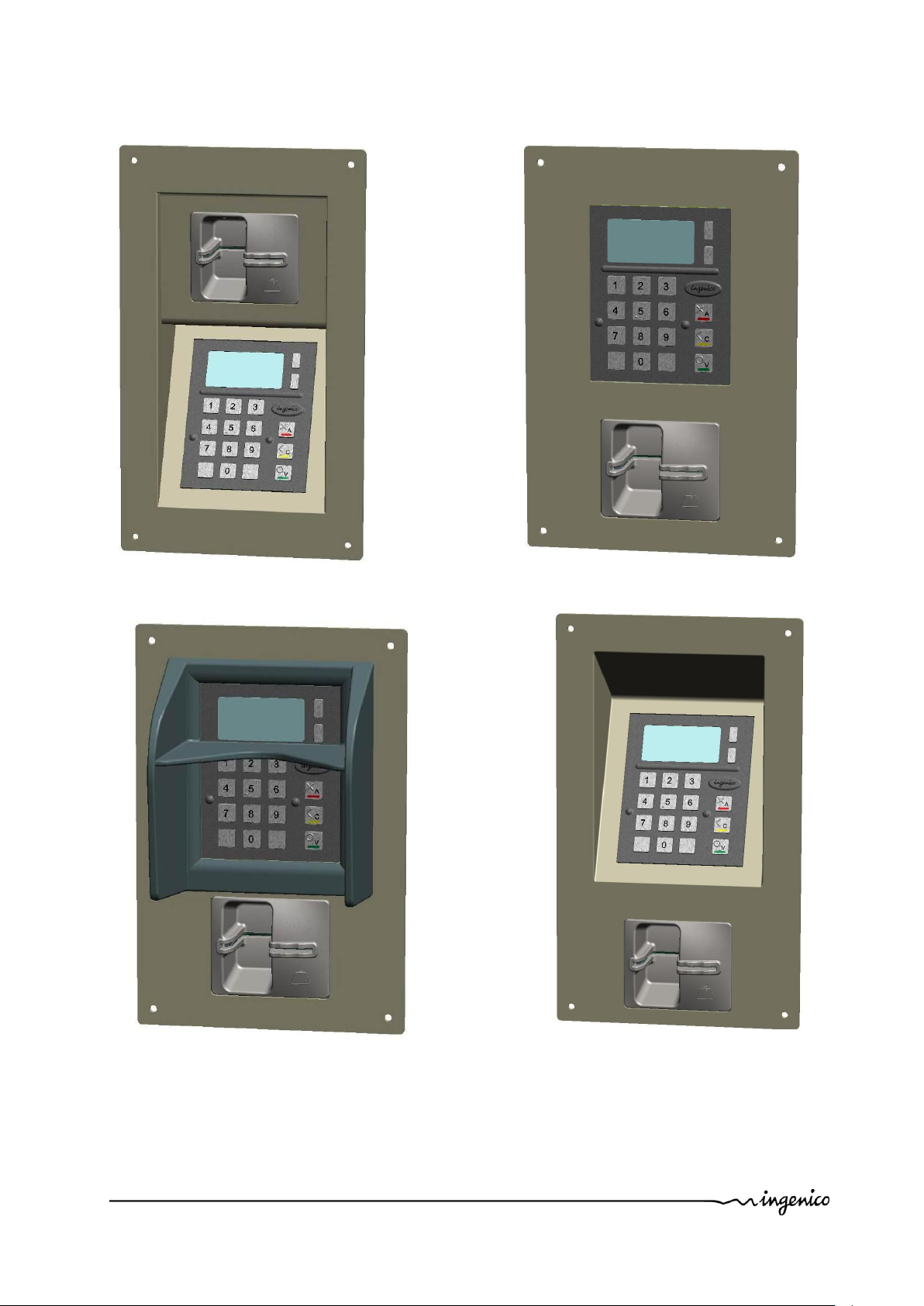

5.4.1 Vertical PINPad above the reader .............................................................. 52

5.4.2 Leaned backward PINPad above vertical reader ........................................ 53

5.4.3 Leaned forward reader above leaned backward PINPad ........................... 54

5.4.4 Optional pinshield layout considerations ..................................................... 55

5.5 Kiosk water ingress consideration ............................................................... 55

5.6 Kiosk cooling consideration .......................................................................... 55

5.7 Kiosk grounding consideration ..................................................................... 56

6 ASSEMBLY PROCEDURE FOR IUR250 CARD READER ................................ 57

6.1 Kiosk minimum volume for iUR 250 .............................................................. 57

6.2 Kiosk preparation for iUR250 installation..................................................... 58

6.3 Installing the Reader iUR250 ......................................................................... 59

6.4 Water evacuation consideration .................................................................... 60

6.5 Connecting the iUR250 to the kiosk ground ................................................ 61

7 ASSEMBLY PROCEDURE FOR IUP250 PINPAD ............................................. 62

7.1 Kiosk minimum volume for iUP250 ............................................................... 62

7.2 Kiosk preparation for iUP250 new installation ............................................. 63

Intégration Guide_iUP250&iUR250 4/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 5

7.3 Installing the iUP250 PINPad in new kiosk ................................................... 64

7.4 Kiosk preparation for iUP250 installation as replacement of i9530 product

65

7.5 Installing the iUP250 PINPad as replacement of i9530 ................................ 66

7.6 Connecting the iUP250 to the kiosk ground ................................................. 67

7.7 Installing the optional pinshield .................................................................... 68

7.7.1 Installing the standard pinshield .................................................................. 69

7.7.2 Installing the Lighting pinshield ................................................................... 70

8 INFORMATIONS ON IUC150 OR IUC180 CONTACLESS UNATTENDED

MODULES ................................................................................................................. 71

8.1.1 Kiosk mechanical requirements .................................................................. 71

9 MAINTENANCE .................................................................................................. 72

9.1 Configuration .................................................................................................. 72

9.2 Products Commisionning .............................................................................. 72

9.3 Reactivation .................................................................................................... 73

9.4 Operating life ................................................................................................... 73

10 CLEANING INSTRUCTIONS ........................................................................... 74

11 DISASSEMBLING THE PRODUCTS ACCORDING TO WEEE DIRECTIVE .. 75

11.1 iUP250 End-of–life disassembly instructions ........................................... 75

11.2 IUR250 End-of–life disassembly instructions ........................................... 77

12 STANDARDS ................................................................................................... 79

12.1 Electrical consumptions ............................................................................. 79

12.2 Temperature and humidity .......................................................................... 79

12.3 Environmental specification continued ..................................................... 80

12.4 EC standard compliance marking .............................................................. 80

12.5 IC statements ............................................................................................... 81

12.6 Environment (WEEE, Batteries and Packaging) ....................................... 83

12.7 Security of your terminal ............................................................................. 83

Intégration Guide_iUP250&iUR250 5/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 6

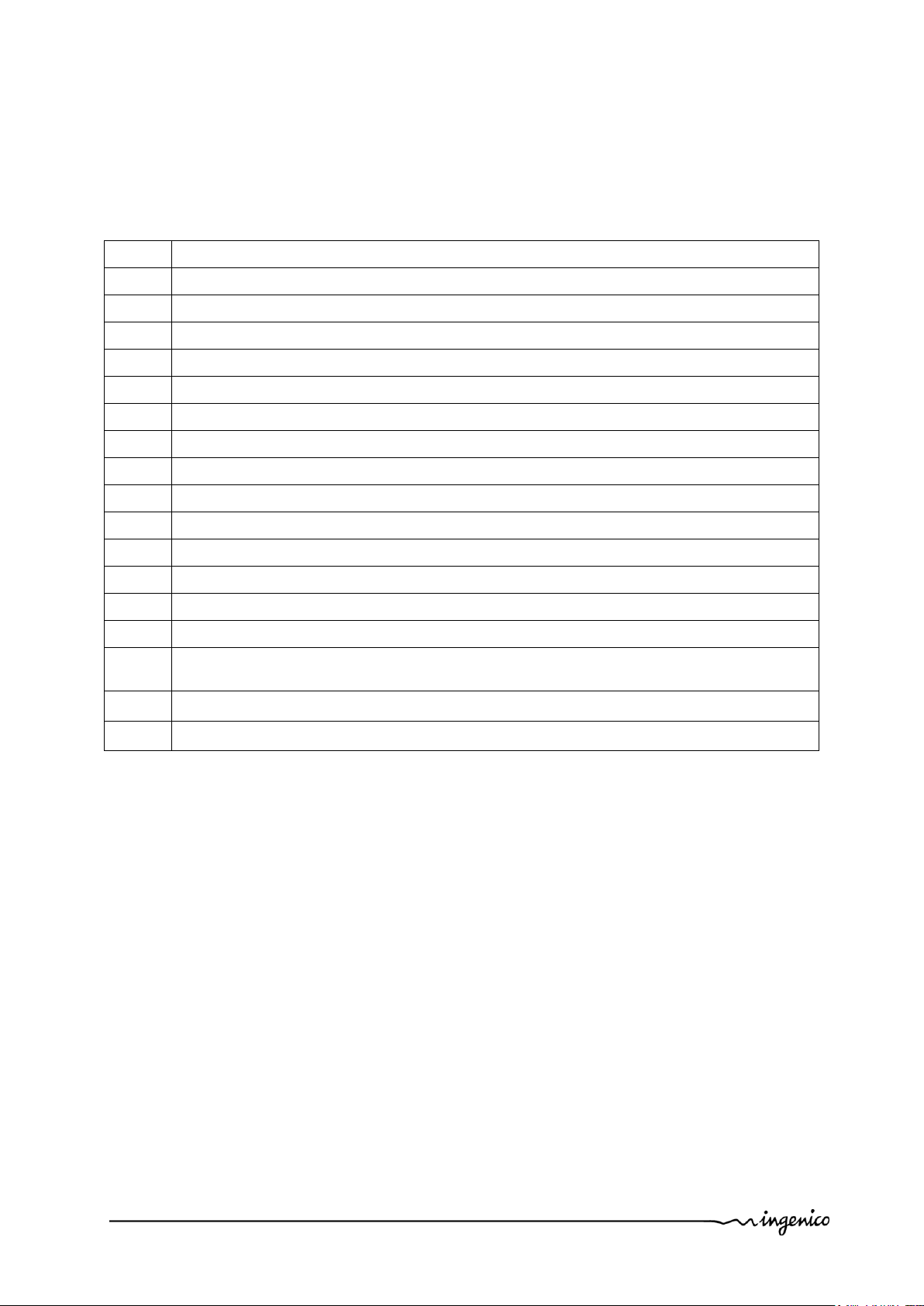

EMC

Electro Magnetic Compatibility

EMV

Europay, Mastercard, Visa

EVA

European Vending Association

GND

Ground

GPRS

General Packet Radio Service

GSM

Global System for Mobile communications

LCD

Liquid Crystal Display

LLT

Local Loading Tool

MDB

Multi Drop Bus

PCI

Payment Card Industry

PIN

Personal Identification Number

PSTN

Public Switched Telephone Network

PTS

PIN Transaction Security

RAM

Random Access Memory

RS232

Recommended Standard 232. A standard for serial binary communications

SAM

Secure Access Module – the chips storing the electronic cash register in a

stored value scheme such as Moneo, Proton or VISA Cash.

SMA

SubMiniature version A

USB

Universal Serial Bus

1 GENERAL

1.1 DEFINITION OF ACRONYMS

Intégration Guide_iUP250&iUR250 6/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 7

1.2 IUP250 & IUR250 PAYMENT SOLUTION

PRESENTATION

The iUN series is the new range of Ingenico UNattended (iUN) devices to offer

payment into any kiosk through any segments (petrol, transport, vending, parking,

etc.).

The two first modules offered for contact cards and PIN management are:

A PINPad, the iUR250,

An Hybrid Card Reader, the iUR250.

These compact devices are designed to fit everywhere, thanks to an easy

installation, respectful of EVA standard (iUP250) and IMB standard (iUR250). Usage

can be indoor or outdoor, resisting to harsh environment.

Both products, certified PCI PTS 3.x, must be installed together into an environment

that must comply with several rules described into this document to remain PCI PTS

3.X certified.

Remarks:

Additional peripherals can be added to build a complete solution such as

printer or bar code reader. Ingenico does not provide these devices so far but

they can be connected to the iUP250 (through, USB, or RS232).

Ingenico is also offering other iUN modules dedicated to contactless like

iUC150 or iUC180. The iUC150 is the preferred contactless peripheral for the

iUP250+iUR250 system.

The iUN series is the next generation of Ingenico leveraging of experience from

previous product ranges, i9500 series or CAD30 series, to renew your experience of

unattended payment.

Intégration Guide_iUP250&iUR250 7/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 8

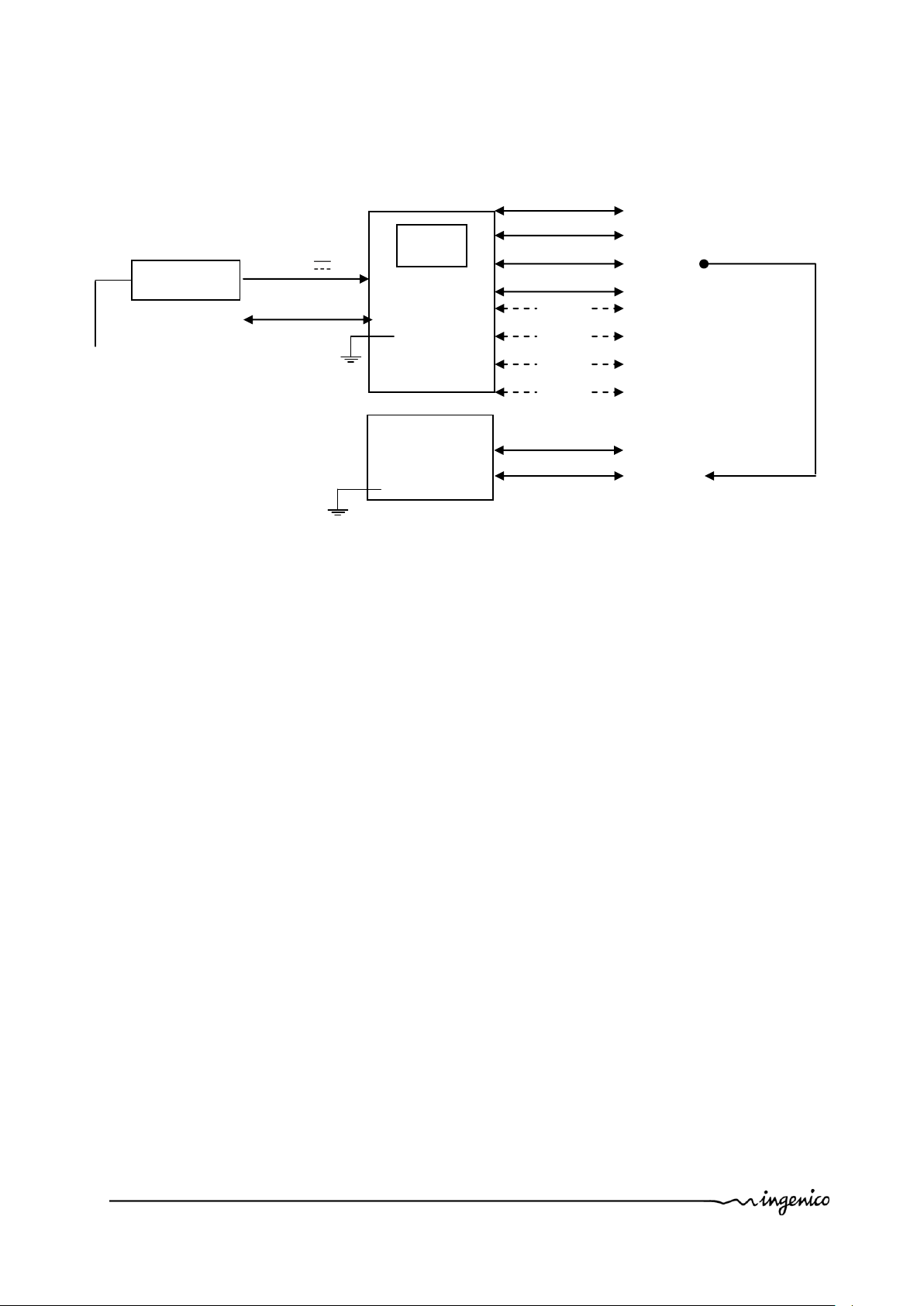

Keypad/display

iUR250

Card Reader

iUR250

Power supply

Main Power

supply

Ethernet

4 USB host

Serial port com0

GSM / GPRS

Serial port com0

USB device

MDB master

Serial port com2

(Option)

(Option)

(Option)

(Option)

Bluetooth

1USB device

12 – 30 V 3A

MDB slave

1.2.1 Diagram of iUP250 & iUR250 connectivity and

communications

Intégration Guide_iUP250&iUR250 8/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 9

1.2.2 Examples of integration

Intégration Guide_iUP250&iUR250 9/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 10

Training

Installation and exploitation

Softwares

OEMC/M²OS development ( days)

EMV Level 2 package (2 days)

Development workstation SDK

Support

Hot-line support

Technical assistance

After-Sales Service

Fixed cost repair of iUN products

Downloading server centre

User licence

Installation and commissioning

User training

Hot-line support

Technical assistance

Softwares / Licences

User licence for local loading tool, LLT

User licence for applications software

User licence for M²OS

Licence for software signature tool, SAT

Licence for "EMV Level 2 package "

Licence for TCP/IP

…

1.2.3 Services

Intégration Guide_iUP250&iUR250 10/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 11

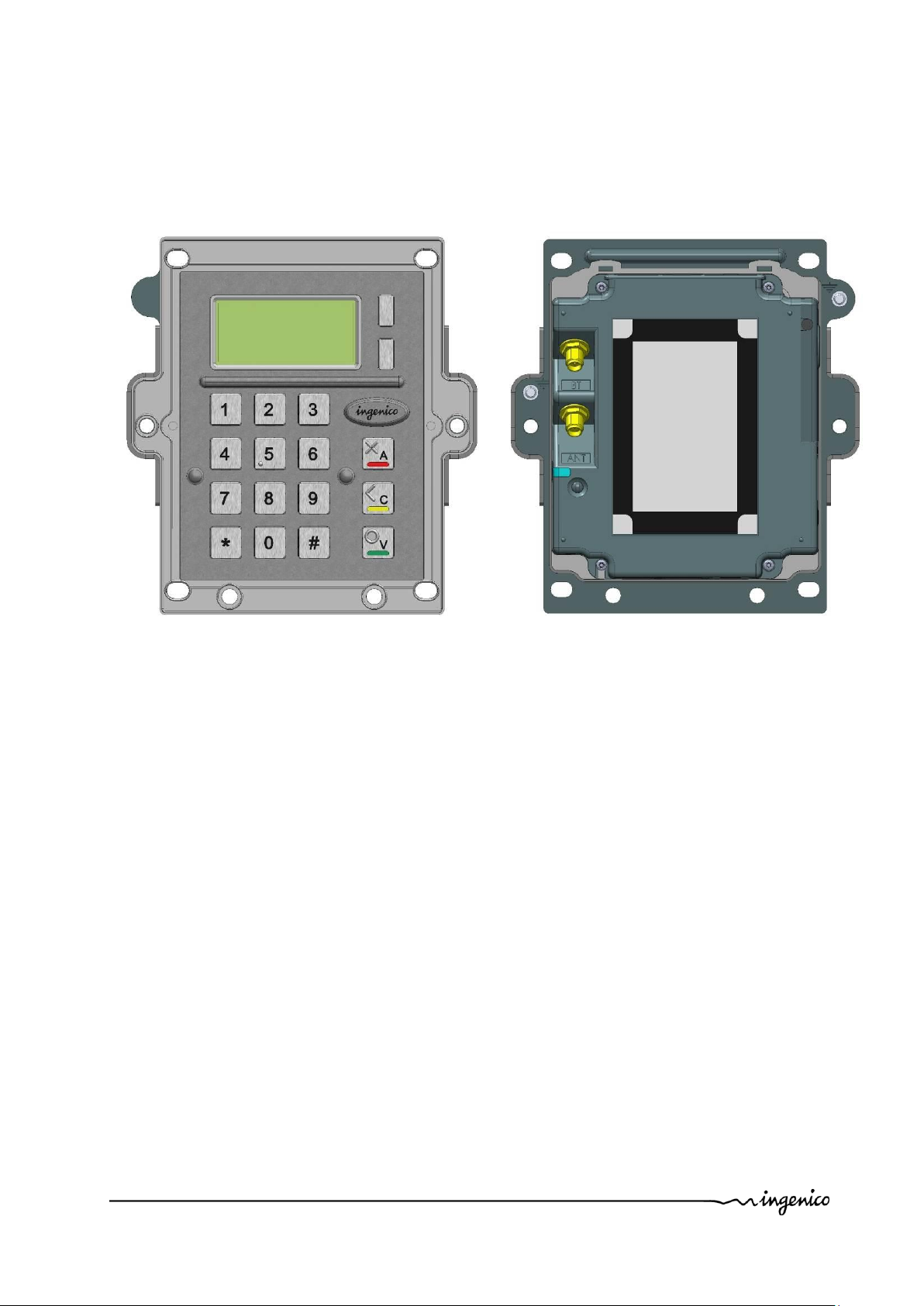

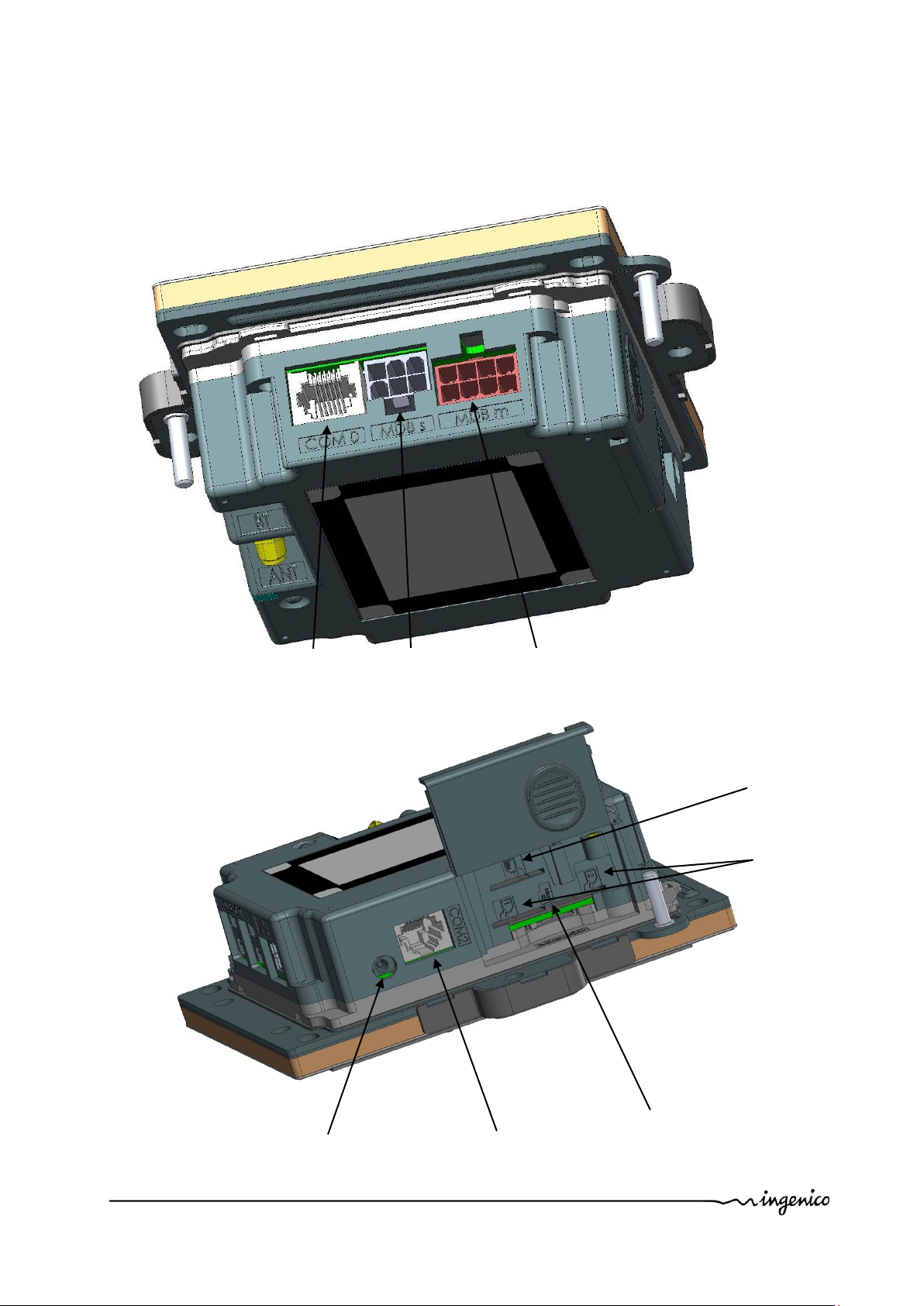

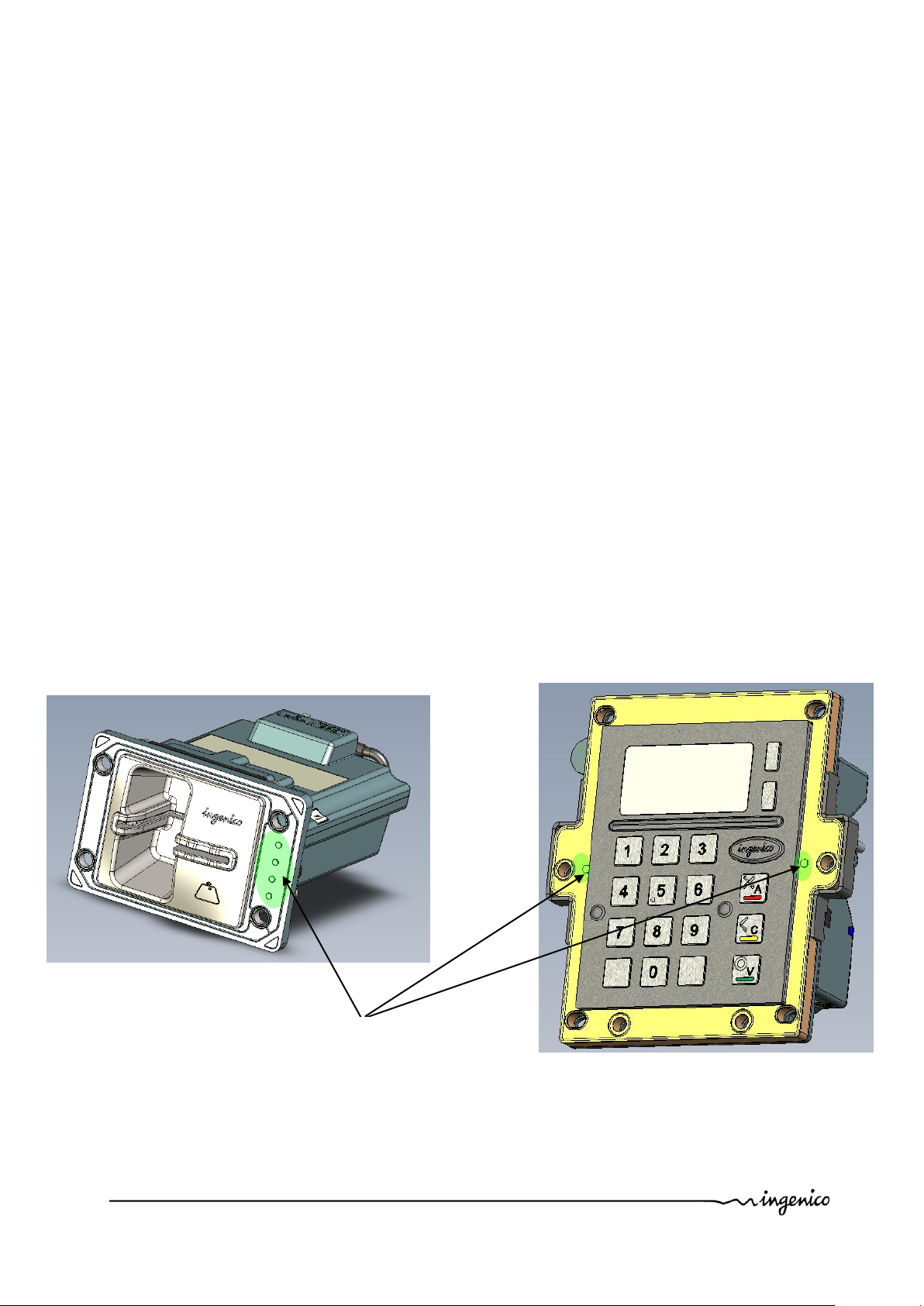

Front view

Rear view

1.3.1 iUP250

1.3 DESCRIPTION OF MODULES

Intégration Guide_iUP250&iUR250 11/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 12

Mass

700 g

Dimensions

132 x 123 x 46 mm (height x width x

depth)

Operational temperature*

-20°C,+55°C

Functional temperature*

-20°C, +65°C

Max relative humidity

85% at 55°C, non-condensing

Maximum backward

leaning

30 degrees from vertical

Power Supply

12 – 30 V max 3A

Platform

Telium2

Memory

16 Mb SDRAM and 128 Mb Flash

Functionality

Keys: 17 metallic keys

128 x 64 graphic display

RGB Backlight

Buzzer

RGB led internal status indicator

1 Maintenance Button

µSD

2 SAM

1 SIM (optional)

1 Jack for external lighting

wake-up mechanism on RS232

connectors

1.3.1.1 Technical Hardware characteristics

iUP250 technical characteristics:

Operating conditions

Intégration Guide_iUP250&iUR250 12/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 13

Link

Ethernet

GSM/GPRS (optional)

Bluetooth (optional)

4 USB host (1.2 A total max)

1 USB device

2x RS232 (1 optional)

MDB slave

MDB Master (optional)

Storage temperature

-20°C,+65°C

Max relative humidity

85% at 55°C, non-condensing

* 55°C is a maximum using temperature for user safety (IEC 60950). The product is operational up to

65°C with no tampering issue.

Storage conditions

Intégration Guide_iUP250&iUR250 13/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 14

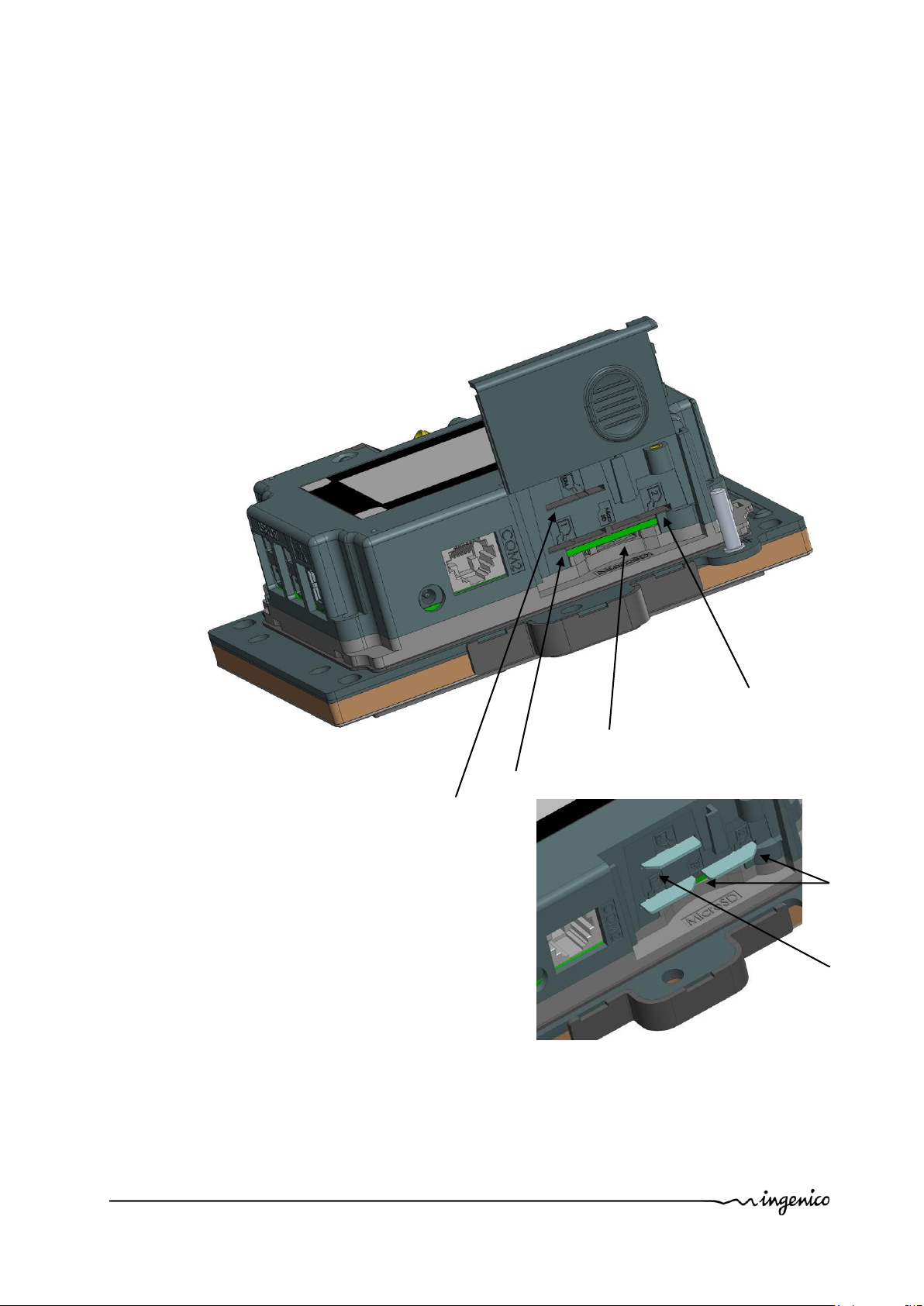

COM0 link

MDB slave

MDB master

Pinshield light output

COM2 Link

µSD

2 SAM

SIM

1.3.1.2 iUP250 output connectors description

Intégration Guide_iUP250&iUR250 14/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 15

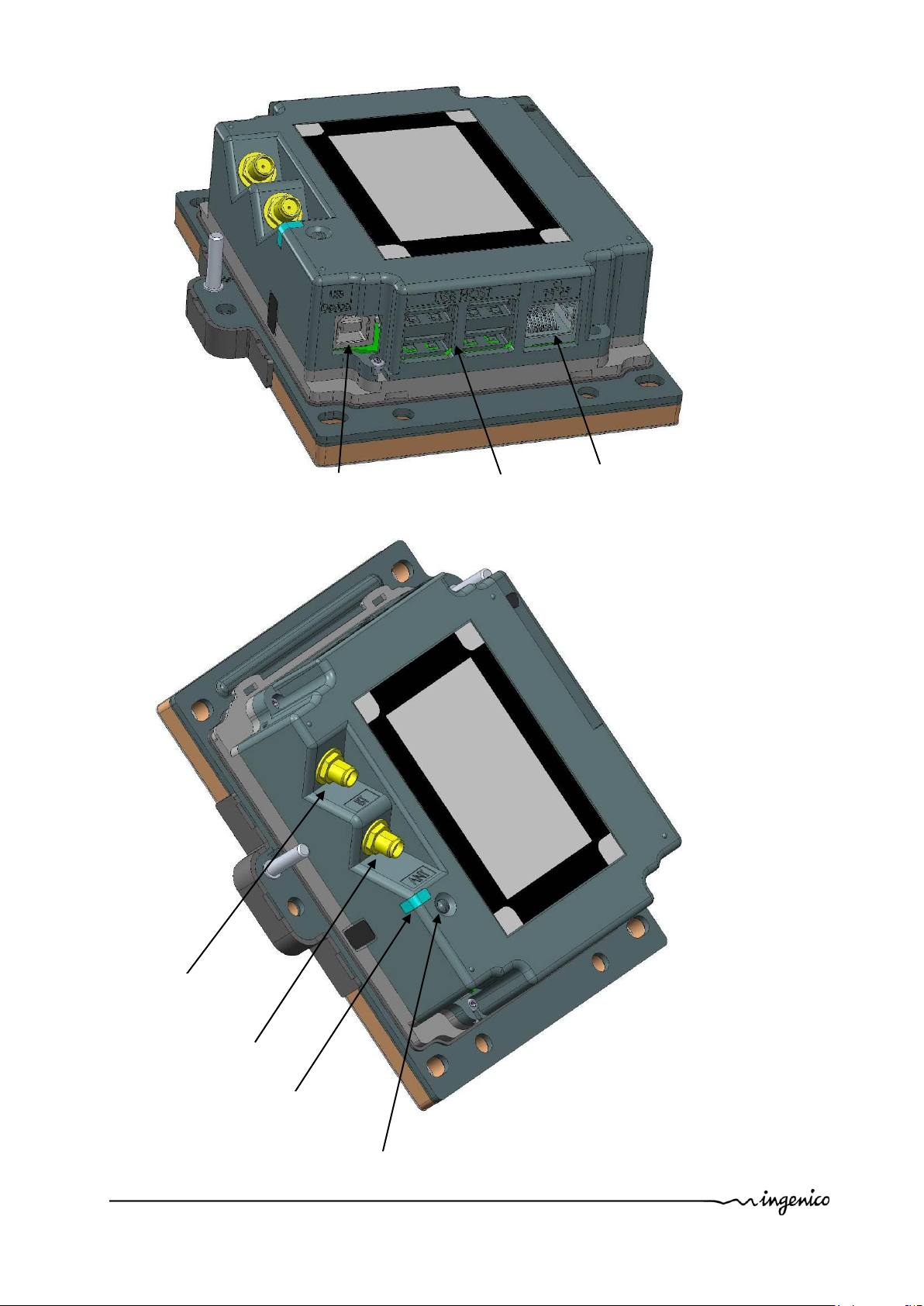

GSM Antenna

Bluetooth Antenna

LLT/Maintenance LED

LLT/Maintenance Button

USB Device

USB hosts

Ethernet

Intégration Guide_iUP250&iUR250 15/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 16

Wake-up pin state

Hz (high impedance)

Stand-by authorized

Drive to “0”

Wake-up / Stand-by unauthorized

PINPad

iUP 250

Card Reader

iUR 250

USB

COM0

1 - GND

2 - Wake-up

3

4

5

COM0 & 2

1 - GND

2 - Wake-up

3

4

5

USB

Any devices design to be compliant.

HZ => Stand-by

« 0 » => Wake-up

HZ => Stand-by

« 0 » => Wake-up

HZ => Stand-by

« 0 » => Wake-up

Do not connect

DC PLUG

1.3.1.2.1 Ethernet

The IUP250 PINPad unit can be connected to Ethernet. The connector type is

shielded RJ45.

The Ethernet cable is standard and not provided.

The Ethernet cable must be shielded.

1.3.1.2.2 USB device

The IUP250 PINPad unit can be connected by type B USB.

1.3.1.2.3 USB host

The iUP250 PINPad unit can drive 4 USB accessories. The connector is standard

type A.

The power available is limited to 1.2A Max dispatched between the 4 USB.

1.3.1.2.4 Wake-up mechanism

iUP250 is design to save power thanks to a “stand-by mode”.

To wake-up iUP250, press green key or use Wake-up mechanism.

Pin 2 of COM0 link & COM2 link drive the wake-up mechanism.

The Wake-up pin is drive to “0” by the one asking the wake-up.

It could be driven by iUR250, iUP250 or any devices designed to be compliant (Host

device…).²

Intégration Guide_iUP250&iUR250 16/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 17

Pin N°

Function

1

GND

2

Wake-up

3

RXD

4

TXD

5

CTS

6

RTS

Pin N°

Function

1

GND

2

Wake-up

3

RXD

4

TXD

5

CTS

6

RTS

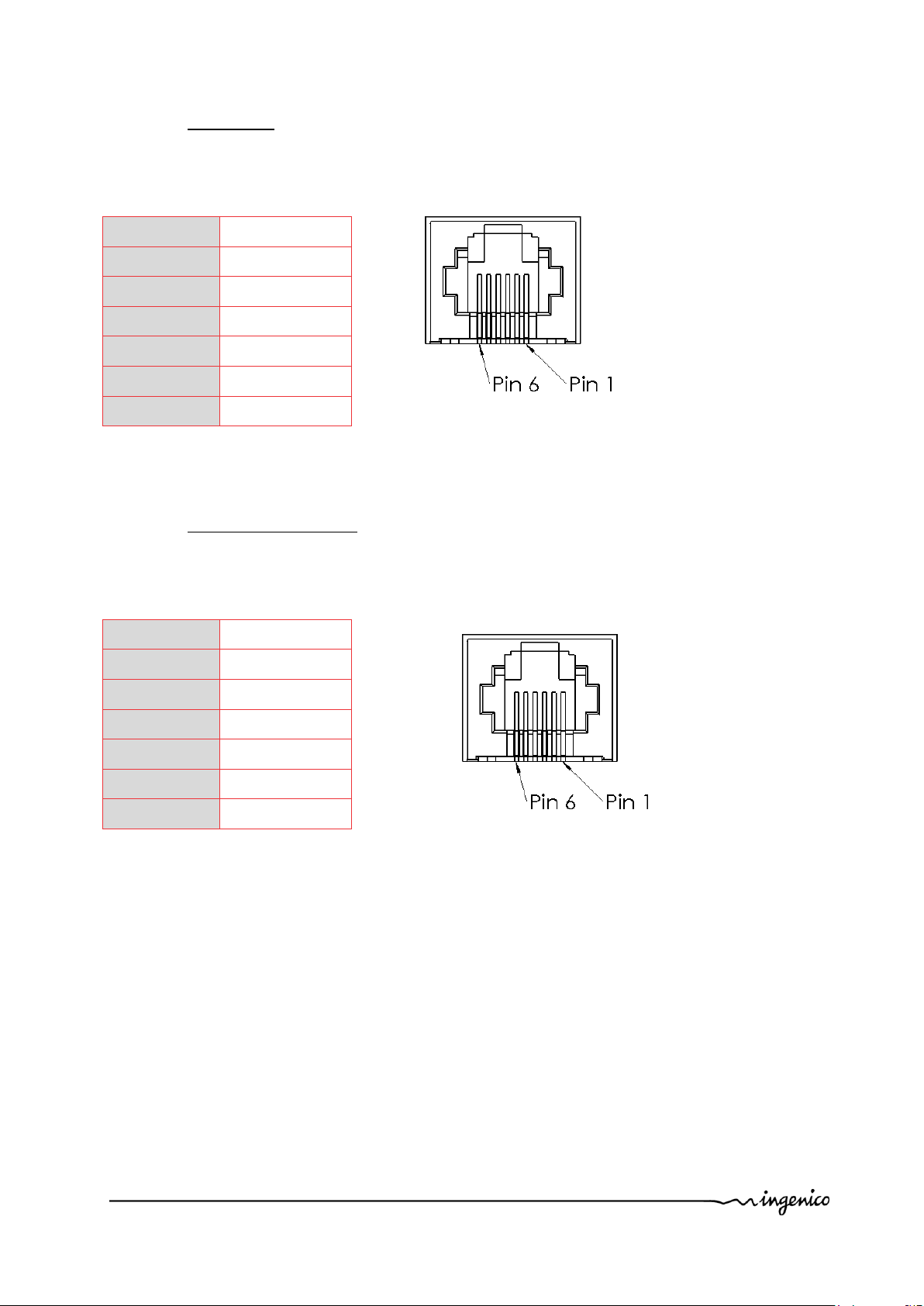

1.3.1.2.5 COM0 link

The iUP250 PINPad unit can be connected to serial port COM0. The connector type

is RJ11.

1.3.1.2.6 COM2 link (optional)

The iUP250 PINPad unit can be connected to serial port COM2 if the option is

available. The connector type is RJ11.

Intégration Guide_iUP250&iUR250 17/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 18

Pin N°

Function

1

Vin

2

GND

3

NC

4

MDBS_RXD

5

MDBS_TXD

6

MDBS_COMMUN

Pin N°

Function

1

NC

2

NC

3

NC

4

NC

5

MDBM_RXD

6

ISO_GND

7

MDBM_TXD

8

ISO_GND

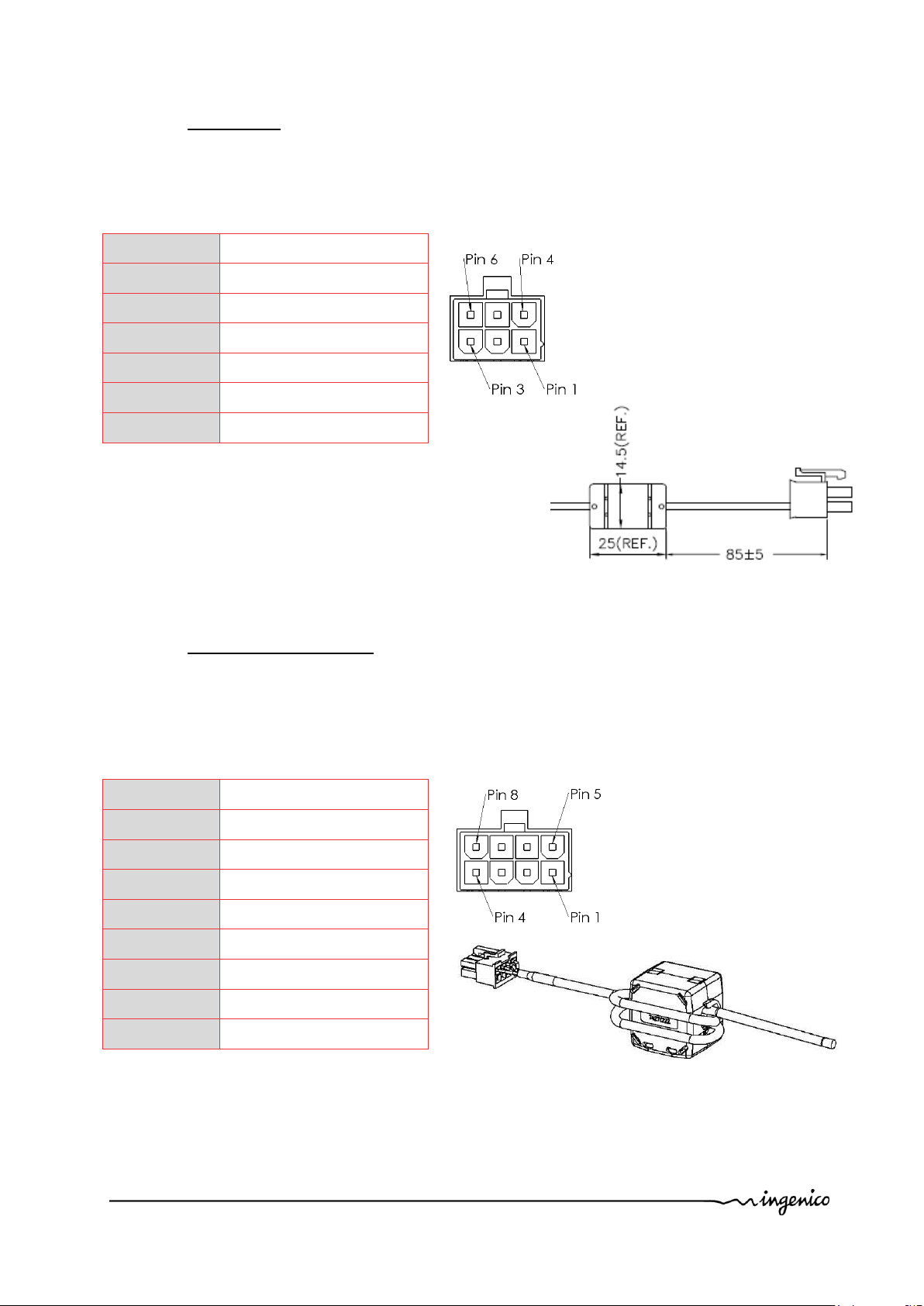

1.3.1.2.7 MDB Slave

iUP250 PINPad unit can be connected by MDB slave. The connector type is

MDB 6 pins (Mini – Fit series 87827 (MOLEX)). iUP250 is powered on the MDB

connectors by power supply 12 to 30V DC (30V is a maximum).

A ferrite B & F ELECTRONICS CO.,

LTD. ref MD-05-265C or equivalent must be

added on the power cable.

1.3.1.2.8 MDB master (optional)

The iUP250 PINPad unit can be connected by MDB master if option available.

The connector type is MDB master 8 pins (Mini – Fit series 87827 (MOLEX)).

iUP250 does not support EXE power supply. A ferrite Würth ref 74271222 or

equivalent must be added with two turns on the cable.

Intégration Guide_iUP250&iUR250 18/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 19

Pin N°

Function

1

5V

2

HZ

Light off

“0”

Light on

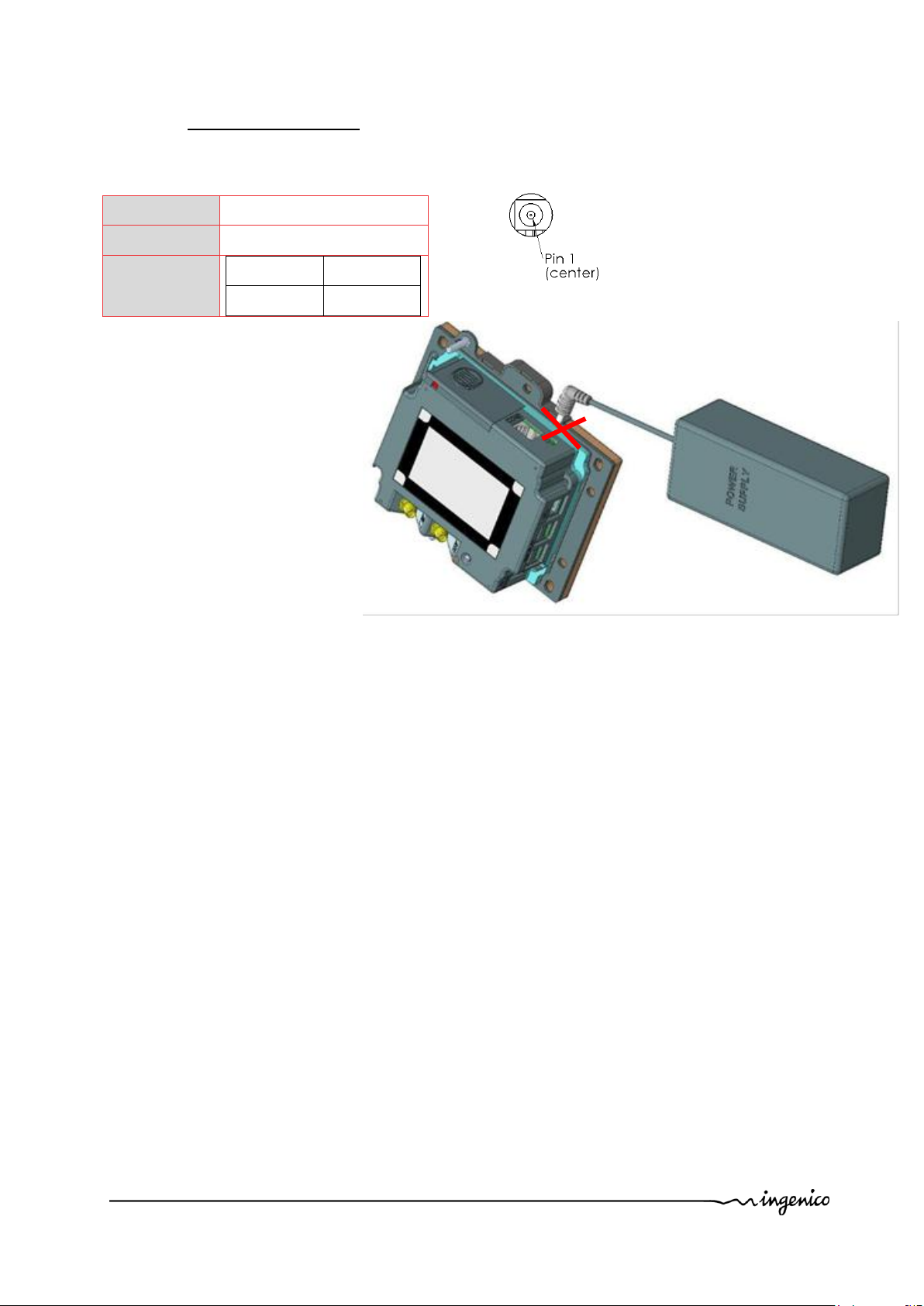

1.3.1.2.9 Pinshield light output

This connector is used to plug the pinshield with optional lighting.

WARNING:

This DC Jack is only an

output power supply for the

Lighting pinshield.

Plugin a DC power could

damage the iUP250.

Intégration Guide_iUP250&iUR250 19/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 20

Antenna

type

manufacturer

model

gain

impedance

Minimum

cable

length

Ingenico

Reference

bipolar

EAD

FBTS35024-

SM-ST

0dBi

50ohm

0

192023282

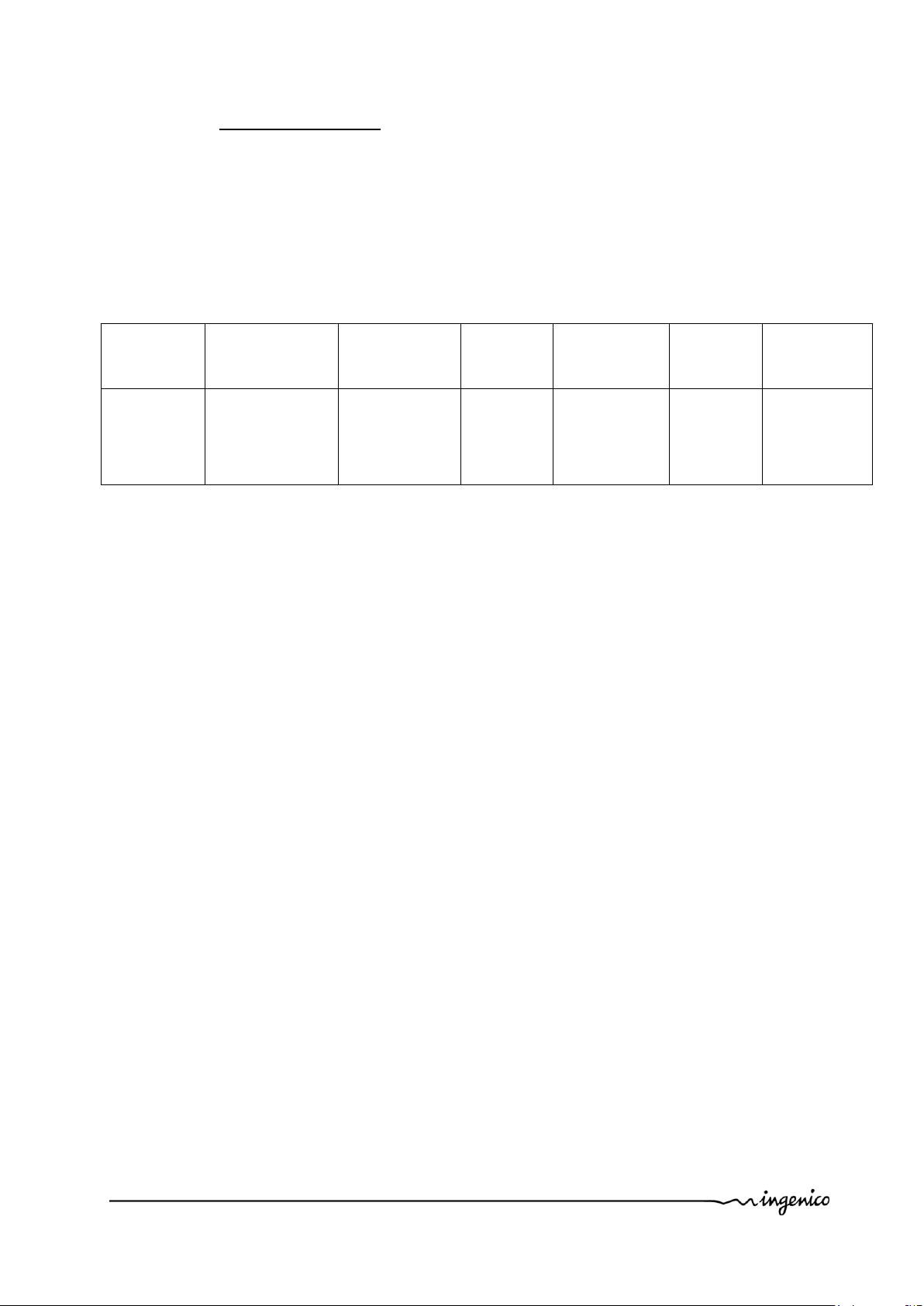

1.3.1.2.10 Bluetooth (optional)

When the iUP250 is ordered with Bluetooth option, it must be connected to an

external Bluetooth antenna.

Ingenico can provide an antenna, or a standard one can be used. This standard

Antenna must have an impedance of 50 Ohm and a maximum gain of 0 dBi.

Ingenico recommended antennas:

Intégration Guide_iUP250&iUR250 20/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 21

Antenna

type

manufacturer

model

gain

impedance

Minimum

cable

length

Ingenico

Reference

bipolar

AMPHENOL

90-00234

1.7dBi

50ohm

0

179900131

bipolar

HIRSHMANN

MCA 18 90

MP

2.1dBi

50ohm

2.5m

189968573

bipolar

Giga concept

GC300M-

011-2500

2.2dBi

50ohm

2.5m

189963487

GPRS (optional)

When the PINPad unit is provided with GPRS functionality (configuration upon

request), the external antenna is not provided with the unit.

Ingenico can provide an antenna, or a standard one can be used. This standard

Antenna must have an impedance of 50 Ohm and a maximum gain of 3.5 dBi.

The SIM used for GSM functionality must be assigned to SIM slot.

Ingenico recommended antennas:

Intégration Guide_iUP250&iUR250 21/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 22

µSD card slot

SAM slot 2

SIM slot

SAM slot 1

Cut angle

orientation

(SAMs)

Cut angle

orientation

(SIM)

1.3.1.3 SAM & µSD Installation

1. Disconnect the iUP250 from the main power supply.

2. Open the SAM door by removing the screw.

3. Insert the SAM cards in SAM slot 1 and /or slot 2

4. Insert µSD card in µSD slot

5. Insert SIM card in SIM slot.

6. Slide the SAM door and screw.

For SAM/SIM cards, take care of cards

orientation and do not push in excess the cards.

After insertion, the cards position is 4 mm

out of the products as shown on picture.

1.3.1.4 Buzzer

The buzzer is controlled by application. The frequency depends of software.

Intégration Guide_iUP250&iUR250 22/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 23

1.3.1.5 RGB backlight

The iUP250 has a RGB backlight controlled by applications.

Red backlight is used to indicate the following priority information:

· Red backlight on steady: product has been tampered (Key erased, irruption).

· Red backlight flashing slowly: product is disabled (Keys erased, no irruption).

· Red backlight flashing quickly: product is out of order (Commissioning

needed).

1.3.1.6 Maintenance Button

The iUP250 has a maintenance button on the back.

- To enter LLT mode, press the button at power up or at restart, until the red led

lights on.

- To enter Maintenance mode, press the button at power up or at restart, until the

red led starts blinking.

- To restart the product, press the button until the blue led lights on.

Intégration Guide_iUP250&iUR250 23/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 24

Cable sealing sleeve clipped on back cover

1.3.1.7 Cable Protection

A cable sealing sleeve is provided with iUP250 to protect the top of product against

water runoff.

Connect the cables, and snap in the part on the rear cover to cover the cables.

This sleeve also holds the antenna tool for GPRS and BT options.

Intégration Guide_iUP250&iUR250 24/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 25

1.3.1.8 Antenna Installation

A tool is provided to help screwing the external antenna.

1. Remove the antenna tool from the cable sleeve.

2. Insert the SMA antenna cable through the slot of the antenna tool.

3. Slide the antenna tool over the SMA Cable connector.

4. Screw the cable.

Intégration Guide_iUP250&iUR250 25/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 26

1.3.1.9 PINPad and Reader interconnectivity

Connection between the iUP250 and iUR250 is done through USB.

Plug the USB cable on iUP250 and iUR250 with a standard USB cable (not provided)

or with low profile Ingenico USB cable (spare part reference 29129367)

Warning :

iUP250 & iUR250 have to be grounded to respect IEC 60950.

The grounding connections must respect the following scheme.

Intégration Guide_iUP250&iUR250 26/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 27

Front view

Rear view

1.3.2 iUR250

Intégration Guide_iUP250&iUR250 27/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 28

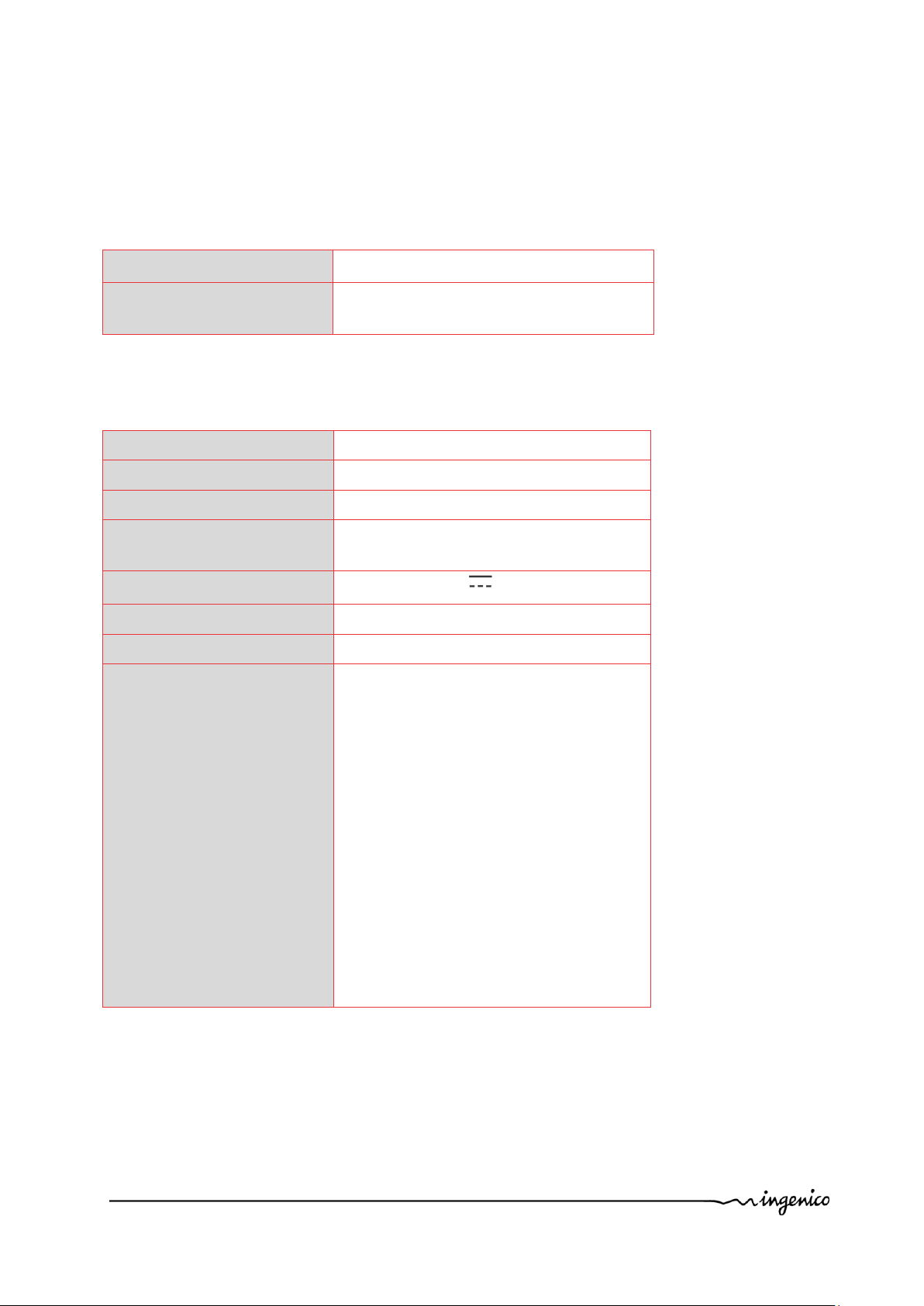

Mass

700g without cable

Dimensions

148 x 108 x 73 mm (depth x width x

height)

Functional temperature

-20°C,+65°C

Max relative humidity

85% at 55°C, non-condensing

Fixing Tilt

iUR250 must be horizontally fixed or

can be leaned up to 45° to evacuate

water

Power Supply

USB 5V 500 mA

Platform

Telium2

Card interface

EMV level 1 and ISO 7816 (read &

write) T=0, T=1 and synchronous

cards

Magnetic stripe: ISO 1 /2 /3 (read

only)

Functionality

Buzzer

RGB led indicator

Level lock (optional)

Link

USB device

RS232 connection only for wake-up

mechanism

Storage temperature

-20°C,+65°C

Max relative humidity

85% at 55°C, non-condensing

1.3.2.1 Technical Hardware Characteristics

iUR250 technical characteristics:

Operating conditions

Storage conditions

Intégration Guide_iUP250&iUR250 28/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 29

Wake-up

USB Device

1.3.2.2 iUR250 output connectors description

Intégration Guide_iUP250&iUR250 29/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 30

Wake-up pin state

Hz (high impedance)

Stand-by authorized

Drive to “0”

Wake-up / Stand-by unauthorized

PINPad

iUP 250

Card Reader

iUR 250

USB

COM0

1 - GND

2 - Wake-up

3

4

5

COM0 & 2

1 - GND

2 - Wake-up

3

4

5

USB

Any devices design to be compliant.

HZ => Stand-by

« 0 » => Wake-up

HZ => Stand-by

« 0 » => Wake-up

HZ => Stand-by

« 0 » => Wake-up

1.3.2.2.1 USB device

iUR250 reader unit can be connected by type A USB.

1.3.2.2.2 Wake-up mechanism

iUR250 is design to save power thanks to a “stand-by mode”.

To wake-up iUR250, insert a card or use Wake-up mechanism.

Pin 2 of COM0 link drive the wake-up mechanism.

The Wake-up pin is drive to “0” by the one asking the wake-up.

It could be driven by iUR250, iUP250 or any devices designed to be compliant (Host

device…).

Intégration Guide_iUP250&iUR250 30/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 31

Pin N°

Function

1

GND

2

Wake-up

3

RXD (Not for customer use)

4

TXD (Not for customer use)

5

CTS (Not for customer use)

6

RTS (Not for customer use)

1.3.2.2.3 COM0 link

The IUR250 serial port COM0 is only available for debug feature and to manage

wake-up mechanism. The connector type is RJ11.

1.3.2.3 RGB Leds

The iUR250 contains RGB leds controlled by applications.

Red led is used to indicate the following priority information:

· Red led on steady: product has been tampered (Key erased, irruption).

· Red led flashing slowly: product is disabled (Keys erased, no irruption).

· Red led flashing quickly: product is out of order (Commissioning needed).

1.3.2.4 iUR250 Optional Lever Lock

The Lever lock is controlled by application.

It may be used to forbid the withdrawal of the card during chip access.

Intégration Guide_iUP250&iUR250 31/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 32

1.4 PROFESSIONAL INSTALLATION REQUIREMENT

Ingenico only sells its products, to qualified partners and integrators. They are in

charge of professionally resell, integrate, and install these products inside complete

solution for end customers.

These end customers solution can be:

Petrol station.

Ticketing kiosk (Airline tickets, cinema, transport, etc.)

Vending machine operator

Parking kiosk (On / off street)

Other

Thus, the general public cannot purchase Ingenico hardware or software.

Partners, resellers, and Integrators must have qualified electronics engineers to be

able to install or integrate our products. Furthermore, they must follow a specific

technical training conducted by Ingenico technical experts.

In addition installation must follow Ingenico recommendations, as describe in this

document, in order to respect:

Local regulations for Electrical Safety and Radio emission levels

Ferrite beam installation

Our field support & maintenance engineers are available for follow up and

commissioning of installation.

Intégration Guide_iUP250&iUR250 32/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 33

2 MAIN ACCESSORIES

2.1.1 Generality

For a complete description of Ingenico Accessories, please refer to iUN accessories

catalog.

2.1.2 Optional PINPad-to-Reader USB cable

The interconnection between the iUR250 and iUP250 is done with a standard USB

cable.

An optional USB cable with short right-angle overmolded connectors can be

purchased as an accessory. This cable is designed to optimize the required volume

for iUR250 & iUP250 installation in the kiosk.

2.1.3 iUP250 Power supply

Ingenico power supply can be ordered under reference 192017549 (only for 0 to

40°C use)

Input: Main voltage supply ranging from 100V to 240V

Maximum current of 3A

Working frequency range between 47Hz and 63Hz

Output: Regulated DC voltage 12V

2.1.4 Stand-by management cable

Under definition, specification available on demand.

Intégration Guide_iUP250&iUR250 33/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 34

2.1.5 Optional Pinshield

Designed specifically for the iUP250, optional privacy shield is compliant with

EPC343-08.

There are 2 optional privacy shields: standard (no light) and lighting.

Standard pinshield

Front view Rear view

Intégration Guide_iUP250&iUR250 34/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 35

Lighting pinshield

Intégration Guide_iUP250&iUR250 35/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 36

Dimensions of the pinshield

Global dimensions

3D design on demand

Intégration Guide_iUP250&iUR250 36/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 37

3 SOFTWARE

3.1 IUP250

The system unit, equipped with Telium2® technology, is designed with a

structure supporting several applications without any mutual interference.

The operating system is a multi-task, real time, preemptive system.

The inputs and outputs are managed by interrupts.

This provides for simultaneous processing of peripherals, thus increasing

system unit performance.

It is downloadable to FLASH memory.

Intégration Guide_iUP250&iUR250 37/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 38

Telium manager

System

Applications

Resident

loading

Bootstrap

Power up

Operating system

Local loading

SAM

Key

pad

Display

µSD

Me

mory

Application manager

Downloading

Remote

diagnostics

Local

diagno

Appli 2

CB Appli

Appli 3

Appli n

USB

UCMC

UCM component

Transaction

Flow

Management

USB slave/

PSU 5V

3.1.1 Software Architecture

Intégration Guide_iUP250&iUR250 38/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 39

The software architecture is divided into four levels:

System

Multi-application manager

Universal Controller Module Component (UCMC)

Independent applications

The system manages access to all the terminal’s peripherals. Access is achieved

through standard C primitives for all the input/output peripherals (keypad…) and

through specific primitives for the other peripherals (smart cards and magnetic stripe

cards). Further, the system takes charge of memory management. It allocates

memory space to the software applications and access control.

The multi-application manager is the entity, which calls the various applications

downloaded in the terminal in response to the various events that occur in the

terminal.

The UCMC component interfaces between the applications and the peripherals

(PINPad, Reader, Printer…). This makes the applications independent of the

peripherals.

It can also manage the « transaction flow ».

The applications are modeled around the demands made by the multi-application

manager. Each request or input point represents a processing operation to be

performed. Each application manages the execution of these processing operations

according to its specifications. This standardization based on input points simplifies

the implementation of the applications on terminals. The terminal provides natural

access to the modularity concepts and improves the maintainability and quality of the

applications.

3.1.2 Secure management of software

The terminal is designed to execute authentic software only and to do this in a ranked

context.

The terminal performs the following checks:

1. During a software download, the terminal checks :

Its authenticity, by checking its signature with the RSA algorithm with a

2048 bit key.

2. Before running a software, the terminal checks :

Its presence by looking for the software’s identity.

Its integrity by checking checksums and CRCs.

Intégration Guide_iUP250&iUR250 39/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 40

3.1.3 Operating system

Bootstrap

Bootstrap is resident.

The bootstrap very briefly takes control of the terminal after each power up to perform

the initialization and the self-test. Then, it automatically runs the operating system,

which in turn starts the applications manager.

Thus, the Bootstrap provides the following functionalities:

Memory and checksum self-test

Local download of the operating system if absent

Operating system authenticity check and start-up.

Operating system characteristics

The operating system is downloaded (locally or remotely) into the memory. It is

upgradeable. After a few fractions of a second following a power-up, the operating

system takes control. It checks the presence, integrity and authenticity of the system

components and application software present in the terminal.

The maintenance sub-system takes control in the following cases:

if no authentic application is present,

or, if a manual action is made by the operator during power up,

or, if it is activated by an application.

The maintenance sub-system ensures, among other things, the downloading of the

application software.

The operating system ensures the start of the multi-task core and then runs the

applications by making a set of services available to them:

Multi-task management: Availability of a pre-emptive real-time environment,

based on interruptions, events and mailboxes. This management enables

simultaneous processing, which improves the terminal’s performance.

Input/Output management: This is carried out under interruptions, generally in

buffered mode. Thus, the application developer enters a “conventional” C

context.

System alarm management: Certain incidents (e.g. swipe card reading error)

detected by the operating system are recorded. They can be used later by the

maintenance sub-system during remote or local diagnostics.

Application alarm management: A number of incidents detected by the

applications can be saved by the operating system at their request. This

recording is used later as in the case of system alarms.

Application isolation management: The operating system provides the

mechanisms described in the section on software isolation and memory

protection.

Inter-application isolation is managed by the Memory Management Unit

(MMU).

Application download management : The operating system offers the

downloading services described in the « Software download » section.

Intégration Guide_iUP250&iUR250 40/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 41

3.1.4 TELIUM MANAGER

The main functions offered by the manager are the following:

Application management

Terminal initialization

Terminal maintenance

Card Recognition and routing to the applications

When the EMV DC module is present, it selects the applications:

EMV applications (EMV level 2 compliant)

Non-EMV applications

In France, it is compatible with the following environments

Health system

French banking system

"Private applications"

Terminal initialization

Required operating conditions

To operate, the system unit has to be equipped with its system, the application

manager, the UCMC and at least one application.

If no application is initialized, the application manager displays a message requesting

initialization for an application (in maintenance mode).

If at least one application is initialized, the terminal is operational. The application

manager then waits for an event to poll the applications loaded in the terminal.

Initialisation of common parameters (in maintenance mode)

The application manager is used to initialize the common parameters:

Date, time, message display language, IP network configuration data, local loading or

remote diagnostics.

System unit maintenance (in maintenance mode)

The system unit has maintenance functions.

Properties

Local downloading

Diagnostics

Properties

The properties function is used to obtain the following information:

List of applications loaded in terminal, version number, checksum, etc. The

application manager gives this information for itself and for the operating

system.

Application call time: remote collection, loading, etc.

Total number of transactions in each application file contained in system unit.

Intégration Guide_iUP250&iUR250 41/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 42

Download

The downloading function uses the information supplied on initialization of the

application manager.

The program update function is used to update the system unit by:

Using a special local loading tool connected to the terminal,

Using a remote loading tool,

Using a USB key. The iUP250 must be in maintenance mode with a USB key

containing the software to load plugged in. Then, launch the download by

using the manager menu

Diagnostics

The diagnostics function is used for:

Local diagnostics (in maintenance mode)

The operator can request the incidents or alarms stored in the terminal.

The storage function implements two sets of elements:

o Incident counters: Used for « repetitive » incidents, for which only the

number of occurrences is significant. For example, number of incorrect

swipe reads.

o Events: Exceptional in nature. The information content depends on the

type of incident. Generally, this comprises the date, time and

information relative to the incident itself. The events are stored in a

rotating file where the most recent events are kept.

Remote diagnostics

This function is used by the operator to trigger a call to a server to dump the

information stored in the terminal. The server thus enriches a database by

which it can efficiently monitor a terminal population, or propose services such

as preventive maintenance, operating statistics, etc.

Diagnostics by USB key

Diagnostic files are copied to a USB key if present at start-up.

Intégration Guide_iUP250&iUR250 42/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 43

3.1.5 Software downloading

Downloading

The software can be downloaded:

Locally via the serial link (COM or USB).

Remotely, via the switched telephone network (PSTN) using an external

modem, Ethernet, GPRS, TCP/IP network.

By a USB key. The iUP250 must be in maintenance mode with a USB key

containing the software to load plugged in. Then, launch the download by

using the manager menu.

The techniques used:

Data compression,

Authenticity checking,

Memory allocation management,

TCP/IP,

best optimize the software downloading operations.

These features provide faster downloading time, enhanced security, an ease in

upgrading, and a larger number of software installed on the system unit.

Local Loading Tool (LLT)

The LLT is used for local software download.

The LLT is formed by:

A PC running with Windows Seven, Vista Pro, XP, 2003 Server, 2000

Professional SP2

A INGENICO loading software,

A PC-terminal connecting cable

Local loading is performed:

From a PC equipped with the Local Loading Tool (LLT) on the COM serial or

slave USB link

By automatic switching to the local loader of the operating system.

Two connections are possible:

By COM link: Speed 115200 bits/s

By slave USB link: Speed 8 Mbits/s approx.

Selection of the software to be loaded is guided on the PC screen by an Explorer

type Windows system (Windows loader).

Loading time for a 1Mo application is 4s by USB port.

Intégration Guide_iUP250&iUR250 43/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 44

Loading by USB key

With the USB key loading method, the software is loaded locally with no need for a

PC type tool.

The loading time is identical to that of the USB.

Terminal Management Server (TMS)

For a complete description of the TMS possibilities, refer to the "TMS" section.

Loading and management of memory space in system unit

Before a (down)load, the system ensures that the necessary memory space is

available.

The software (possibly compressed) are downloaded to flash.

If software is deleted, the system frees the space. If software is upgraded, the system

loads the new software, checks it, and deletes the old version.

The entire memory area is used and is usable. No area is reserved for upgrades.

On start-up of the terminal (power up or reset), the applications are decompressed and the code is

copied to RAM.

Improved software downloading

Includes the following characteristics:

Softwares are loaded by FTP TCP/IP and PPP for optimized loading.

Downloading performance in V32bis is around 14, 4 kbps on the original files.

Once the connection is set up with the V32bis modem, a 120 Kbytes

application is downloaded in around 1 minute.

Automatic dialling and access to downloading server by switched telephone

network (STN) - with an external modem - using a public PAD or private PAD

access.

Downloading can be performed in IP mode via Ethernet via a secure channel

(SSL).

Data is compressed in accordance with an algorithm derived from the Lempel-

Ziv method ensuring compression rates of the order of 40 %.

For downloading, only the improved application will be downloaded.

This management function is handled by the system unit itself and not by the

remote server, providing enhanced functional security in a multiple source

loading context.

Recovery management in the event of loss of communication. This service

resumes the downloading which has been interrupted at the exact location

where the interruption took place, so that only the missing portion is

downloaded when the communication is recovered.

The downloaded software is run in a secure context by authenticity check.

Intégration Guide_iUP250&iUR250 44/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 45

Downloading Starting

The downloading can be requested:

Using the application manager on maintainer request. This is the case, in

particular, where a program upgrade is concerned or when a new software is

added in the terminal memory. In this case, the procedure is simplified to the

utmost.

The user triggers the call from the application manager by choosing the upgrade

function in the menus and using the dialogue keys. Connection to the server takes

place automatically.

For an upgrade, the user has nothing to enter.

To request a new software, the user is guided on the screen in making his choice.

The identity of the business is not requested. The identity stored in the system unit is

automatically transmitted to the server.

Using the application software on request by the center or merchant (Example:

in France, by « envelopes").

In this case, downloading takes place entirely automatically. The downloading

ticket informs the merchant.

Local loading procedure on iUP250:

Trigger the LLT software on the PC.

Switch off the iUP250.

Connect the PC to the COM or slave USB connector of the iUP250

Press the rear button.

Switch on the iUP250.

When the led near the button becomes fix red, release the button. “LLT” text is

now displayed on screen.

Trigger the LLT and follow the instructions given in the « LLT User’s guide v4

» to load the software.

The parameter definition files must be placed in the "HOST" directory.

3.1.6 Development station

Introduction

With this development station, it is possible to develop application software for the

entire range of iUN products.

The software is written in high level C language in a multi-application environment.

Ingenico provides the complete set of software and the equipment required for

development. This also includes the documentations. Training sessions can also be

proposed.

Intégration Guide_iUP250&iUR250 45/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 46

Required Configuration

The development station executes on a Pentium PC running under Windows

2000/XP/Vista/Seven.

Development tools for ARM such as a cross-compiler are required. These comprise:

A C compiler (GNU), an assembler and a link editor for ARM and Thumb,

A development environment,

A remote debugger.

Supply

The SDK 30 development station comprises:

The user license for the M²OS software which includes:

o The operating system,

o The application manager,

o The libraries

o The associated documentation in PDF format

The user license for the Software Authentication Tool (SAT) software,

The user license for the Local Loading Tool (LLT),

The card reader and the RSA cards used to sign the applications.

SDK + Add On Unattended

For iUP250 + iUR250: minimum configuration SDK 9.2 and Add-On

Unattended 3.1 are required

Associated services

Training

Development of applications on iUN

Duration: 1 day

Location: R&D center.

Pre-requisites for training:

A good understanding of the C language is required. Familiarity with firmware can

be useful.

Technical support

Duration: 6 months after the training

This includes the hot line, and updates to the documentations and softwares

during this period.

Software package

A set of software packages, used to simplify development of applications (EMV

level 2, contactless…) is available.

Intégration Guide_iUP250&iUR250 46/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 47

3.2 IUR250

The reader has a software architecture enabling execution of schemes (an

authentic program which handles secret data and manages PIN code entry)

without interfering with the operating system program.

By the preemptive and multitask features of the real time system and the

interrupt method for input / output handling, simultaneous management of

all the peripherals is ensured, enhancing PINPad performance.

Data can be loaded in the internal flash memory of the processor.

Intégration Guide_iUP250&iUR250 47/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 48

SCHEMAS

R

A

M

Start up

BOOT

Bootstrap

Reside

nt loader

ROM

SYSTEM

Operating system

buzzer

backlight

CAM

ISO1-2 - 3

Memory

Crypto

Secure

management

Other

FLASH

Local

Loader

Maintenance

System

Host

Protocol

3.2.1 Software architecture

The system manages access to all the reader’s peripherals. Access is completed via special

primitives for the peripherals (memory card, magnetic stripe…)

Further, the system takes charge of memory management. It allocates memory

space to the software applications and controls access.

3.2.2 Software security management

iUR250 is designed so that only authenticated software can be run in a ranked

context.

iUR250 checks the authenticity of the software by checking its signature with the

RSA algorithm with 2048 bits key size.

Intégration Guide_iUP250&iUR250 48/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 49

3.2.3 Operating system

Bootstrap

Bootstrap is resident.

The bootstrap very briefly takes control of the terminal following each powering up to

perform the initialization and the self-test. Then, it automatically runs the OS, which in

turn starts the applications manager.

Thus, the bootstrap provides the following functionalities:

Local download if the OS is absent;

OS authenticity check and start-up.

Operating system (OS) characteristics

The OS is downloaded (locally or remotely) into the memory. It is upgradeable. After

a few fractions of a second following powering up, it takes control. It checks the

presence, integrity and authenticity of the system components and application

present in the terminal.

The maintenance subsystem takes control in the following cases:

if a manual action by the operator is made when powering up;

Or if it is activated by application.

The maintenance subsystem ensures, among other things, the downloading of the

applications.

The OS ensures the start of the multitask core and then runs of the application by

making a set of services available to them:

Multi-task management: Availability of a pre-emptive real-time environment,

based on interruptions, events and mail boxes. This management enables

simultaneous processing, which improves the terminal's performance.

Input/output management: This is carried out under interruptions, generally in

buffered mode. Thus, the applications developer enters a "conventional" C

context.

System alarms management: Certain incidents detected by the OS are

recorded. They can be used later by the maintenance subsystem during

remote or local diagnostics.

Tamper proof Application / System management: the operating system offers

the devices described in the data security section.

Intégration Guide_iUP250&iUR250 49/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 50

4 TERMINAL MANAGEMENT SYSTEM

4.1 INTRODUCTION

Ingenico developed its own Terminal Estate Management System called

IngEstate. It is a link between an organisation with an estate of payment

terminals and their merchants. It allows users to remotely manage payment

terminals, modify their software content and interact with merchants.

4.2 BASIC FUNCTIONS

The basic functions are:

be able to locally download software on a terminal using a direct cable link

(usually RS232);

be able to remotely download software on a particular terminal using modems

and IP connections;

be able to remotely download applications and configuration updates to a

large estate of terminals;

be able to upload terminal configurations and check software status;

Be able to inform merchants when terminals are out of use during

maintenance periods.

4.3 ADVANCED FUNCTIONS

The advanced functions are extremely various, with new ones being requested

frequently:

draw statistics and reports about terminal configurations;

optimise automatic call scheduling/download balancing for large estates of

terminals;

be able to display written messages on the terminal, using the display or the

printer;

be able to easily configure a complete terminal (i.e. several applications) and

to download it in one operation;

be able to analyse the status of terminal software and do only delta downloads

(i.e. only the parts that are damaged or need updates);

be able to download to either a Peripheral or a terminal when connected;

Customise the system easily;

Integrate with systems such as SAP easily;

… and many others.

4.4 CUSTOMERS SAVINGS WITH INGENICO TMS

SOLUTION

The most obvious cost saving is not having to send a technician to service the

terminal at the merchant location. Many other costs savings are derived from the

ability to have a “clean” estate; better diagnostics and remote software repairs mean

less shipping of replacement terminals, less downtime, less mail and phone

communication costs, more efficient update campaigns, etc.

Intégration Guide_iUP250&iUR250 50/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 51

5 INSTALLATION PROCEDURE IN KIOSKS

Note: It is required to use ESD-protective clothing while handling these devices.

5.1 SECURITY REQUIREMENT

The integration must be done to be compliant with PCI requirement.

Payment Card Industry – PIN Transaction Security (PTS) - Modular Derived Test

Requirements Version 3.1 October 2011

Positioning of IUP250 on the unattended device must be in such way as to make

keypad spying difficult (according to PCI PTS - Modular Derived Test Requirements

Version 3.1 October 2011).

If the unattended device doesn’t provide such protection, an Ingenico privacy shield

option can be provided.

iUP250 and iUR250 must be mounted on the unattended machine as indicated in the

installation guide to activate removal detector.

CAUTION

NEVER ask the customer to divulge their PIN Code. Customers should be advised to

ensure that they are not being overlooked when entering their PIN Code.

5.2 KIOSK MECHANICAL REQUIREMENTS

The kiosk panel can be metallic or plastic.

The kiosk panel can be coated with painting but grounding of iUN modules must be

insured.

The kiosk panel thickness must be between 2 mm and 5 mm.

5.3 GENERAL INSTALLATION RECOMMENDATIONS

Installation requirements:

Ensure that you have enough free space for installation, operational and

maintenance needs.

Be aware of the safety regulations.

Carefully consider the general and local payment security requirements and

any impact they may have on the kiosk

Carefully consider the ergonomic aspects and also the local acts or

recommendations concerning disabled and visually impaired people.

See environmental specification and especially in case of very cold or humid

weather, take steps to ensure that the internal temperature is at least -20 °C.

5.4 KIOSK SUGGESTED LAYOUTS FOR IUR250 IUP250

In order to save space, keep good ergonomics and relative protection from

environment, we recommend the following configurations.

Intégration Guide_iUP250&iUR250 51/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 52

23 mm

5.4.1 Vertical PINPad above the reader

This is the most common layout and simplest installation.

Minimum distance between reader and PINPad is 23 mm.

Intégration Guide_iUP250&iUR250 52/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 53

5.4.2 Leaned backward PINPad above vertical reader

This installation provides a good ergonomic integration.

Maximum leaning of the keypad is 30 degrees.

Minimum distance between reader and PINPad is 25mm for cable access.

Intégration Guide_iUP250&iUR250 53/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 54

5.4.3 Leaned forward reader above leaned backward PINPad

The reader must be Horizontal or 45° max leaned in order to evacuate liquids by the

front.

Maximum backward leaning of the keypad is 30 degrees.

Intégration Guide_iUP250&iUR250 54/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 55

5.4.4 Optional pinshield layout considerations

An optional pinshield can be installed. It is mandatory that the PINPad is installed

vertical directly on the front face of kiosk (not in recess).

5.5 KIOSK WATER INGRESS CONSIDERATION

Components inside the kiosk should take care of water ingress and water collection

to avoid pouring water on the product below.

5.6 KIOSK COOLING CONSIDERATION

In case of forced cooling, air intake from the card reader opening is forbidden as it

will fill the reader with dust. A large air intake must be provided in the kiosk.

It is also recommended to have the kiosk in overpressure to avoid dust.

Intégration Guide_iUP250&iUR250 55/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 56

Connect to Ground

5.7 KIOSK GROUNDING CONSIDERATION

All parts of the kiosk should be connected to the ground using ground cables.

Intégration Guide_iUP250&iUR250 56/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 57

6 ASSEMBLY PROCEDURE FOR IUR250 CARD READER

6.1 KIOSK MINIMUM VOLUME FOR IUR 250

The iUR250 requires a minimum volume inside the kiosk. It is detailed in the drawing

below.

3D design on demand.

The minimum volume is 108 mm width x 73 mm height x 146 mm deep.

Picture of iUR250 minimum volume

Intégration Guide_iUP250&iUR250 57/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 58

iUR250

footprint area

iUR250

Anti-removal

switches area

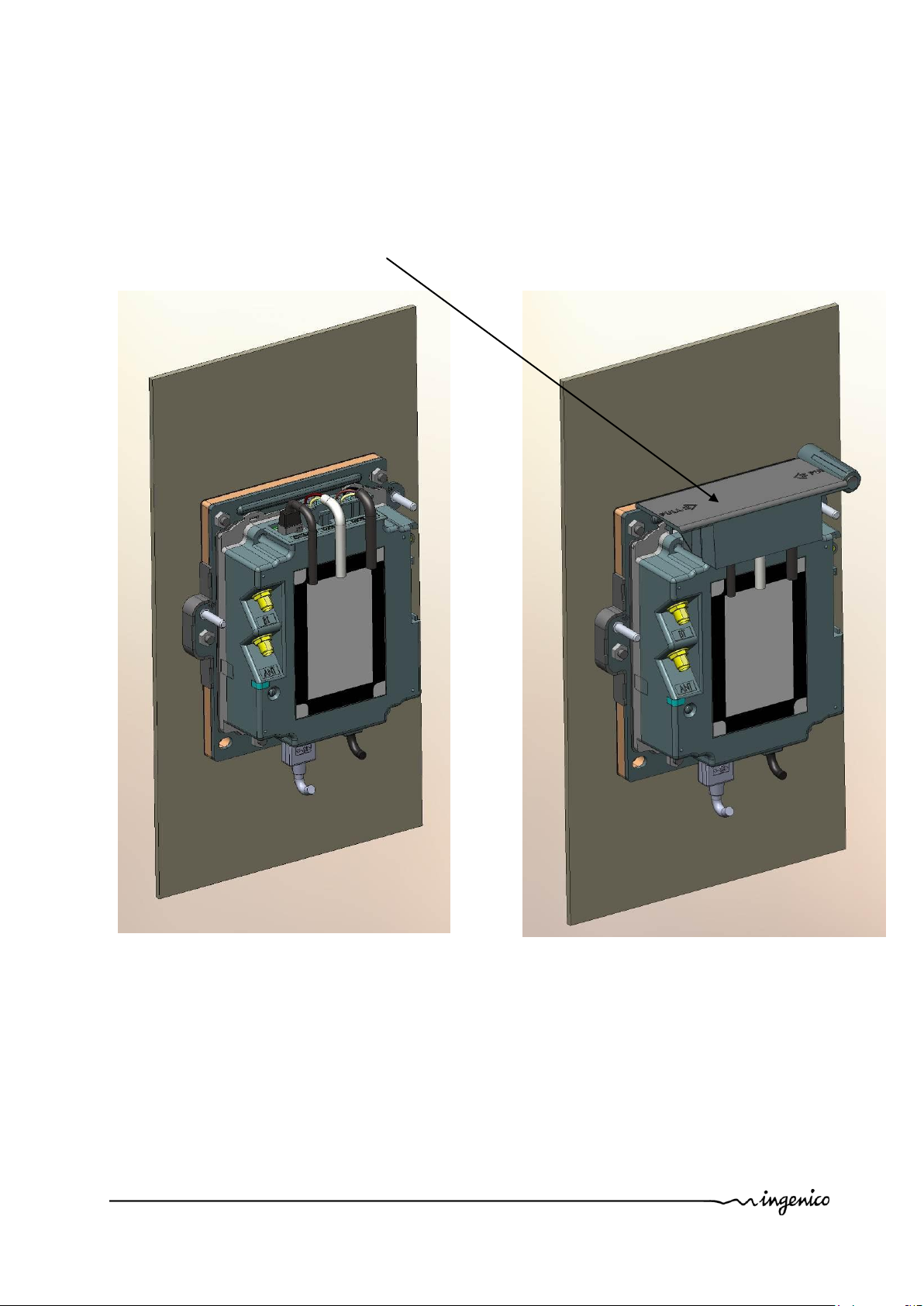

6.2 KIOSK PREPARATION FOR IUR250 INSTALLATION

The iUR250 requires a cut out in the kiosk (dimensions in millimetres detailed in

the diagram below).

CAUTION:

The equivalent iUR250 hatched footprint surface on the kiosk must be flat and

clear of any holes and burrs.

Special attention is required for the area of anti-removal switches.

Fixing must be done by 4 M4 to M6 x12mm welded studs.

Cut-out drawing for iUR250.

3D design on demand.

Intégration Guide_iUP250&iUR250 58/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 59

6.3 INSTALLING THE READER IUR250

iUR fixing requires M4-M6 hexagonal nuts.

Put the iUR over the studs.

Screw the 4 nuts with a 1.0-1.3 N.m torque.

It is recommended to use threadlocker fluid to prevent unscrewing with vibrations.

Picture showing the installation of the iUR250

Intégration Guide_iUP250&iUR250 59/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 60

Evacuation pipe

6.4 WATER EVACUATION CONSIDERATION

It is recommended to plug a flexible tube to the water evacuation pipe of the iUR250

to avoid water ingress inside the kiosk. The pipe is provided with the product and

has to be sticked to the evacuation hole.

Picture showing evacuation pipe

Intégration Guide_iUP250&iUR250 60/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 61

Grounding screw

Grounding hole

6.5 CONNECTING THE IUR250 TO THE KIOSK GROUND

The iUR250 should be connected to the ground of kiosk chassis using a copper braid

fastened with the provided grounding screw and washer.

Picture showing the grounding ground hole and screw of the iUR250

Intégration Guide_iUP250&iUR250 61/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 62

7 ASSEMBLY PROCEDURE FOR IUP250 PINPAD

7.1 KIOSK MINIMUM VOLUME FOR IUP250

The iUP250 requires minimum volume in the kiosk.

It includes cables and pinshield mounting.

3D design on demand.

The minimum volume is 123mm width x 154 mm height x 52 mm depth

Picture showing the minimum volume for the iUR250

Intégration Guide_iUP250&iUR250 62/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 63

7.2 KIOSK PREPARATION FOR IUP250 NEW

INSTALLATION

iUP250 uses EVA mounting standard with additional fixing studs. It requires a cut out

in the kiosk to the dimensions detailed in the diagram below (all dimensions are in

millimeters).

The drawing below shows the footprint of iUP250 product.

CAUTION:

It is important that the iUP250 footprint surface on the kiosk must be flat and cleared

of any holes and burrs.

Special attention is required for anti-removal switches area.

3D step files are also available upon request.

Fixing must be done by 6 M4x16mm welded studs.

Drawing of the cut-out for the iUP250 3D design on demand.

Intégration Guide_iUP250&iUR250 63/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 64

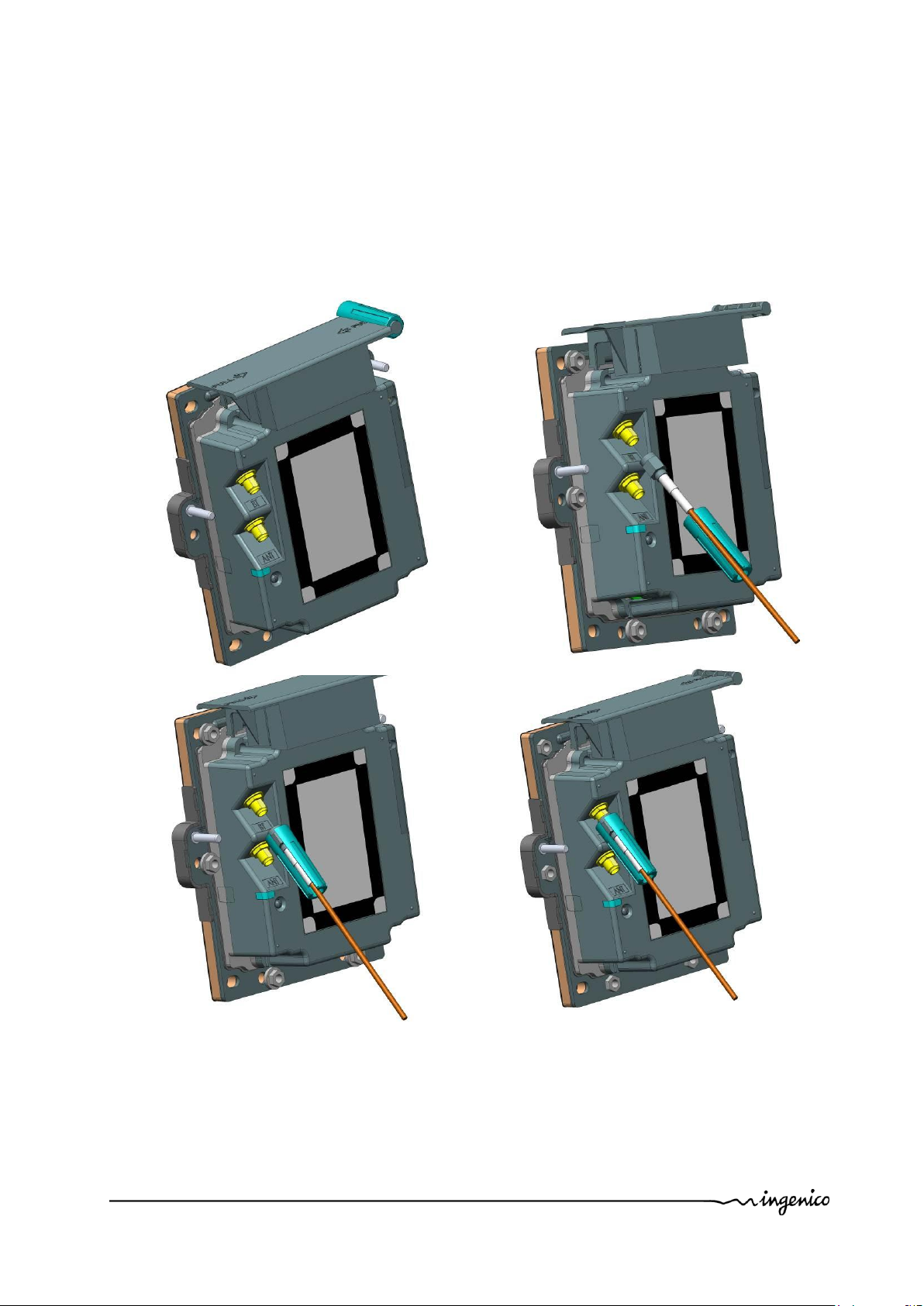

7.3 INSTALLING THE IUP250 PINPAD IN NEW KIOSK

iUR requires standards hexagonal nuts for integration into a kiosk.

Screw the 6 nuts with a 1.0 N.m torque.

It is recommended to use threadlocker fluid to prevent unscrewing with vibrations.

Picture showing a new installation of the iUP250

Intégration Guide_iUP250&iUR250 64/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 65

7.4 KIOSK PREPARATION FOR IUP250 INSTALLATION

AS REPLACEMENT OF I9530 PRODUCT

The installation of iUP250 as replacement of i9530 product requires an adapting

sheet metal part. This part is not provided by Ingenico.

It is required by security regulation that this part must be permanently mounted on

the kiosk (i.e by soldering) and cannot be removed from the kiosk.

Drawing showing the adapter part of the iUP250 in existing i9530 installation

Intégration Guide_iUP250&iUR250 65/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 66

7.5 INSTALLING THE IUP250 PINPAD AS REPLACEMENT

OF I9530

iUP250 can be installed as follow.

Existing studs on the kiosk for i9530 product are used to guide the adapter part.

Adaptator part must be permanently fixed to the kiosk.

We recommend to weld or strongly glued it.

Standard nuts cannot be used on these studs as they will interfere with the iUR250

PINPad and may create a security issue.

Top studs need to be cut to 11 mm to avoid interference with the cable sleeve.

Picture showing the installation of the iUP250 in existing i9530 kiosk

Intégration Guide_iUP250&iUR250 66/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 67

Ground studs to connect copper braid to ground.

7.6 CONNECTING THE IUP250 TO THE KIOSK GROUND

To insure good connexion of iUP250 to the kiosk ground, it is recommended to install

one copper braid connecting the 2 grounding studs and connect this braid to the

chassis.

Picture showing the grounding of the iUP250

Intégration Guide_iUP250&iUR250 67/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 68

7.7 INSTALLING THE OPTIONAL PINSHIELD

The installation of the standard or light pinshield requires 6 additional holes diameter

5 mm in the kiosk.

A diameter 10 additional hole is required for the Lighting pinshield to pass the cable

through the kiosk.

Picture showing the cut-out and holes for the iUP250 pinshield

Intégration Guide_iUP250&iUR250 68/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 69

Kiosk panel thickness

Wedge to use

2 mm

Wedge thickness 2.5

3 mm

Wedge thickness 3.5

4 mm

Wedge thickness 4.5

5 mm

Wedge thickness 5.5

Wedge

7.7.1 Installing the standard pinshield

The standard pinshield is mounted on the kiosk using 6 screws M4 x 10.

4 wedges are provided to fill the gap between the keypad and the pinshield according

to the kiosk panel thickness. One has to be selected as follow:

Picture showing installation of the iUP250 standard pinshield.

Intégration Guide_iUP250&iUR250 69/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 70

Kiosk panel thickness

Wedge to use

2 mm

Wedge thickness 2.5

3 mm

Wedge thickness 3.5

4 mm

Wedge thickness 4.5

5 mm

Wedge thickness 5.5

Wedge

Light module with cable

7.7.2 Installing the Lighting pinshield

The Lighting pinshield will light the keypad thanks to 4 LEDs. It is connected to the

iUP250 by a cable plugged on the right side. The pinshield is installed on the kiosk

using 6 screws M4 x 10.

4 wedges are provided to fill the gap between the keypad and the pinshield according

to the kiosk panel thickness. One has to be selected as follow:

Picture showing installation of the iUP250 lighting pinshield.

Intégration Guide_iUP250&iUR250 70/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 71

8 INFORMATIONS ON IUC150 OR IUC180 CONTACLESS

UNATTENDED MODULES

The iUC150 and iUC180 are Contactless solutions for unattended payment

applications (indoor and outdoor).

They can be installed and connected to iUP250 and iUR250 products.

See iUC Integration Guide for further information.

8.1.1 Kiosk mechanical requirements

The kiosk panel can be metallic or plastic.

The kiosk panel can be coated with painting but grounding of the IUC must be

insured. For the grounding connection both studs must be connected to get the best

ESD performance.

The kiosk panel thickness must be between 2 mm and 5 mm.

The iUC150 or iUC180 use EVA (European vending association) mounting standard.

Intégration Guide_iUP250&iUR250 71/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 72

Anti-removal area

9 MAINTENANCE

9.1 CONFIGURATION

The iUP250 & iUR250 supplied to you has operational configuration loaded.

In factory, softwares are loaded in the iUP250 & iUR250, as well as parameter

definition files.

The parameter definition file of the UCMC component is used, in particular, to

determine the type of printer used (local/host) and the position of the host (COMx).

To change configuration, you must load a new parameter definition file (supplied by

Ingenico).

This operation can be performed using the LLT or a USB key (see § Loading by USB

key)

For more information concerning configuration, contact Ingenico Technical Support.

9.2 PRODUCTS COMMISIONNING

Please refer to ICO/ETU/11/1849/YM : Commissioning User's Guide.

To be able to perform the commissioning procedure the anti-removal must be

correctly mounted see chapter 6.2 for iUR250 and 7.2 for iUP250.

Intégration Guide_iUP250&iUR250 72/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 73

9.3 REACTIVATION

iUR250 can be opened for maintenance (cleaning operation, extraction of jammed

object for example).

The reactivation process can be achieved with a tool terminal and two smart cards

with pin codes. (For more information, contact commercial department of Ingenico)

On the iUR250 if reactivation process fails, check that the application has been recharged and re-attempt.

If the red LED is lit, it may be a case of permanent tamper detection. Check in this

case that the product is correctly assembled and re-attempt.

If the problem persists, it may be a hardware problem (broken switch...). In this case,

a shipment repair is needed.

9.4 OPERATING LIFE

Minimum operating life of 5 years.

Keyboard

o 1.000.000 key strokes

o Keys markings ensure resistance to wear

Reader

o 500.000 card insertions

Intégration Guide_iUP250&iUR250 73/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 74

10 CLEANING INSTRUCTIONS

The external front face of the PINPad and iUN reader should be carefully cleaned in

a regular basis.

The goal is to keep the display and the keyboard free of dirt and solvents.

First of all, unplug all the wires from the terminal during this operation.

Good rules for proper cleaning of the terminal are:

Use a soft cloth that is very slightly soaked with soapy water to clean the

outside of the terminal.

Do not clean the electrical connections.

Do not use in any case, solvents, detergents or abrasive products:

Those materials might damage the plastic or electrical contacts.

Avoid also the use of pressurized liquids.

Avoid exposing the terminal to the direct rays of the sun.

Do not put anything into the slot of the smart card reader

It is recommended to clean regularly the hybrid reader smart connector with dry

cleaning cards.

Intégration Guide_iUP250&iUR250 74/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 75

Product Name

Nom du produit

Product description

Description du produit

Product mass (g)

Masse du produit (g)

IUP250

Unattended payment PINPad

700g

Components and materials

Composants et matériaux

Quantity included in

product(s)

Quantité contenue

dans le(s) produit(s)

Capacitors containing Polychlorinated biphenyls (PCB)

Condensateurs contenant du polychlorobiphényle (PCB)

0

Components containing Mercury, such as switches or backlighting lamps

Composants contenant du mercure, tels que les interrupteurs ou les lampes à rétroéclairage

0

Batteries

Piles et accumulateurs

1

Printed circuit boards greater than 10 cm²

Cartes de circuits imprimés de plus de 10 cm²

3max (2 + 1)

Toner cartridges

Cartouches de toner

0

Plastic containing brominated flame retardants

Matières plastiques contenant des retardateurs de flamme bromés

0

Asbestos waste and components which contain asbestos

Déchets d'amiante et composants contenant de l'amiante

0

Cathode ray tubes

Tubes cathodiques

0

Chlorofluorocarbons (CFC), Hydrochlorofluorocarbons (HCFC) or Hydrofluorocarbons

(HFC), Hydrocarbons (HC)

Chlorofluorocarbones (CFC), hydrochlorofluorocarbone (HCFC) ou hydrofluorocarbone (HFC),

hydrocarbures (HC)

0

ICO-ETU-11-1858-CL-V1

11 DISASSEMBLING THE PRODUCTS ACCORDING TO

WEEE DIRECTIVE

11.1 IUP250 END-OF–LIFE DISASSEMBLY INSTRUCTIONS

This document is intended for treatment and recycling facilities. It provides the basic

instructions for the disassembly of Ingenico products to remove components and materials

requiring selective treatment, as defined by EU directive 2002/96/EC, Waste Electrical and

Electronic Equipment (WEEE).

Ce document est destiné aux installations de traitement et de recyclage. Il fournit les instructions de base pour le

démontage de produits Ingenico afin de retirer les composants et matériaux nécessitant un traitement sélectif, tel

que défini par la directive européenne 2002/96/CE, sur les Déchets d’Equipements Electriques et Electroniques

(DEEE).

1. MODELS AND DESCRIPTIONS

MODÈLES ET DESCRIPTIONS

Products covered by this disassembly instructions.

Produits concernés par ces instructions de démontage.

2. COMPONENTS AND MATERIALS REQUIRING SELECTIVE TREATMENT

COMPOSANTS ET MATERIAUX NÉCESSITANT UN TRAITEMENT SÉLECTIF

The following components and materials, if present in the Ingenico product(s), have to be

removed and selectively treated.

Les composants et matériaux suivants, si présents dans le(s) produit(s) Ingenico, doivent être retirés et faire

l’objet d’un traitement sélectif.

Intégration Guide_iUP250&iUR250 75/83 Copyright © 2012 Ingenico

900009151 R11 000 01/1223 All rights reserved

Page 76

Gas discharge lamps

Lampes à décharge

0

Liquid crystal displays (LCD) of a surface greater than 100 cm² and all those back-lighted with

gas discharge lamps