现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Multi-Voltage Processor Power Supply

Data Sheet

1Overview

1.1 Features

• High efficiency regulator system

• Wide input voltage range from 5.5V to 60V

• Stand-by mode with low current consumption

• Suitable for standard 12V/24V and 42V PowerNets

• Step down converter as pre-regulator:

5.5V / 1.5A

• Step down slope control for lowest EME

• Switching loss minimization

• Three high current linear post-regulators with

selectable output voltages:

5V / 800mA

3.3V or 2.6V / 500mA

3.3V or 2.6V / 350mA

• Six independent voltage trackers (followers):

5V / 17mA each

• Stand-by regulator with 1mA current capability

• Three independent undervoltage detection circuits

(e.g. reset, early warning) for each linear post-regulator

• Power on reset functionality

• Tracker control and diagnosis by SPI

• All outputs protected against short-circuit

• Power-DSO-36 package

TLE 6368 / SONIC

P-DSO-36-12

Type Ordering Code Package

TLE 6368 G1 / SONIC Q67007-A9648 P-DSO-36-12

SMD = Surface Mounted Device

Data Sheet, Rev. 1.32 1 2004-10-15

TLE 6368 / SONIC

1.2 Short functional description

The

TLE 6368 G1 / SONIC is a multi voltage power supply system especially designed

for automotive applic ations usi ng a standa rd 12V / 24V batte ry as well as the new 42V

powernet. The device is intended to supply 32 bit micro-controller systems which require

different supply voltage rails such as 5V, 3.3V and 2.6V. The regulators for external

sensors are also provided.

The TLE 6368 G1 / SONIC cascades a Buck converter block with a linear regulator and

tracker block on a single chip to achieve lowest power dissipation thus being able to

power the application even at very high ambient temperatures.

The step-down converter delivers a pre-regulated voltage of 5.5V with a minimum

current capability of 1.5A.

Supplied by this step down converter three low drop linear post-regulators offer 5V, 3.3V,

or 2.6V of output voltages dependi ng on the configuration of the device with current

capabilities of 800mA, 500mA and 350mA.

In addition the inputs of six voltage trackers are connected to the 5.5V bus voltage. Their

outputs follow the main 5V linear regulator (Q_LDO1) with high accuracy and are able to

drive a current of 17mA each. The trackers can be turned on and off individually by a 16

bit serial peripheral interfac e (SPI). Throu gh t his inte rf ace als o the stat us i nform atio n of

each tracker (i.e. short circuit) can be read out.

To monitor the outp ut voltage le vels of each of the linear reg ulators three i ndependent

undervoltage detection circui ts are ava ila ble w hic h can be us ed to impl eme nt the reset

or an early warning function. The supervision of the µC can be managed by the SPItriggered window watchdog.

For energy saving reasons while the motor is turned off, the TLE 6368 G1 / SONIC offers

a stand-by mode, where the qu iescent current does n ot exceed 30µA. In this stand -by

mode just the stand-by regulator remains active.

The TLE 6368 G1 / SONIC is based on Infineon Power technology SPT which allows

bipolar , CMOS and Power DMOS circuitry to be integrated on the same monolithic

circuitry.

Data Sheet, Rev. 1.32 2 2004-10-15

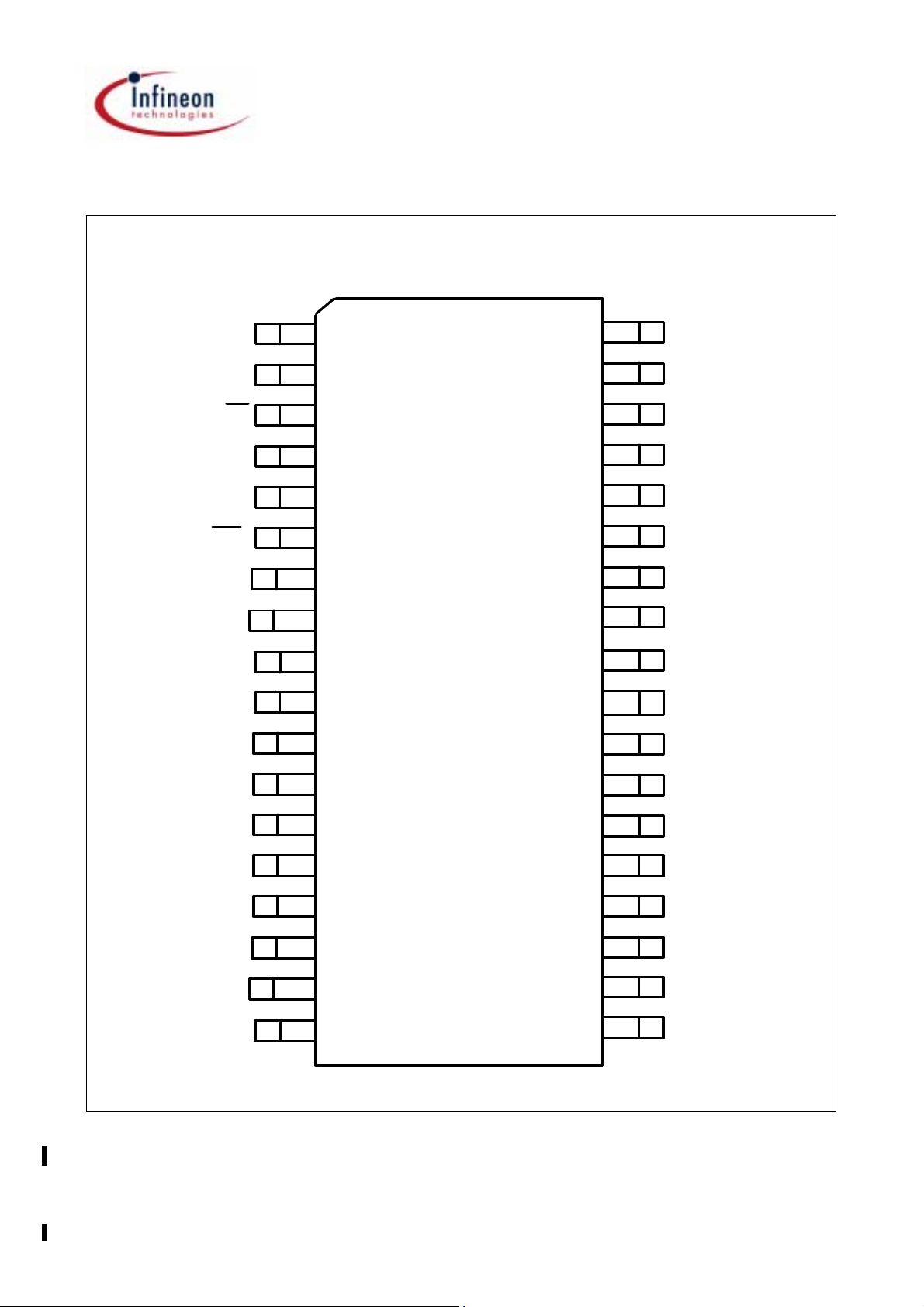

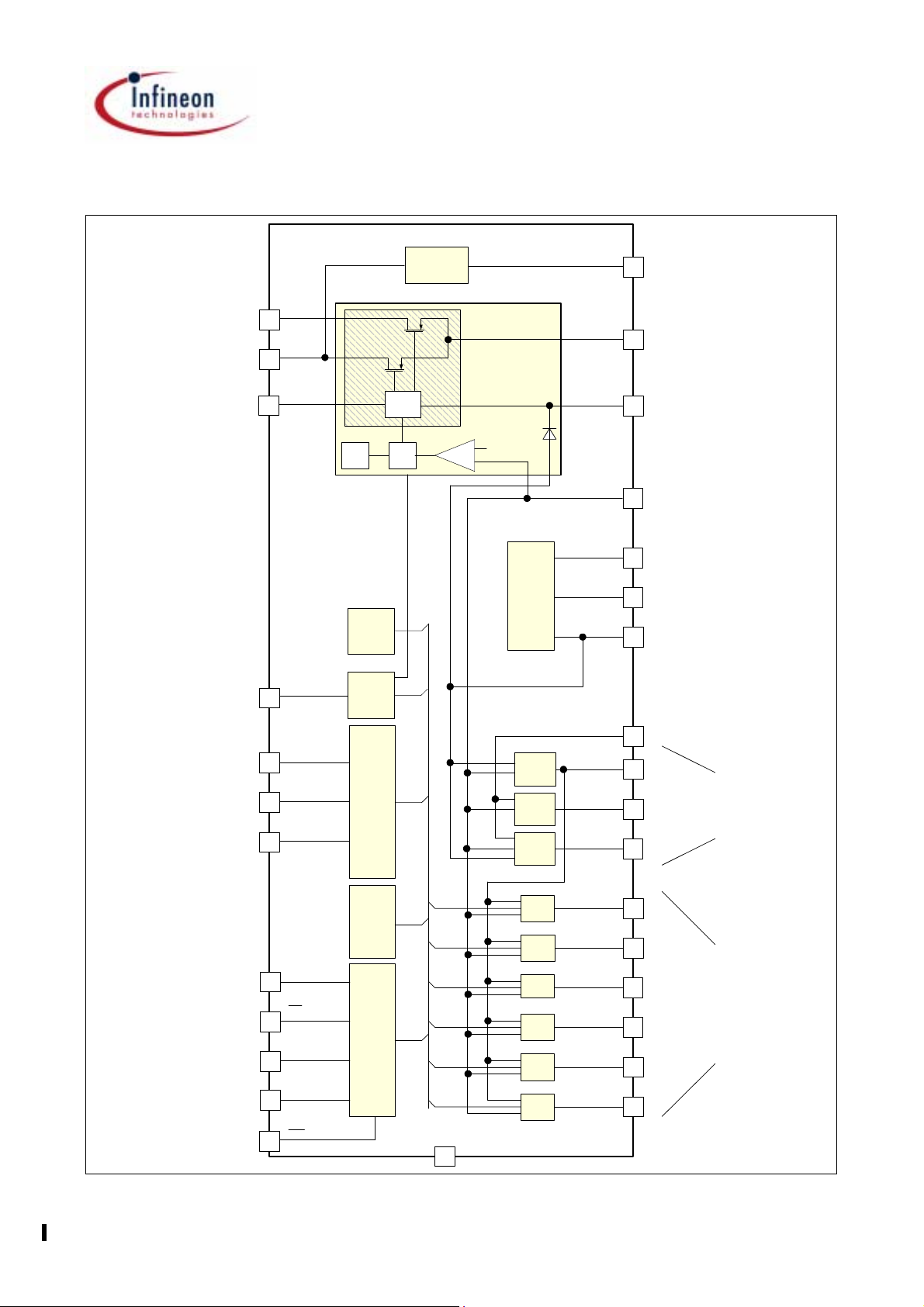

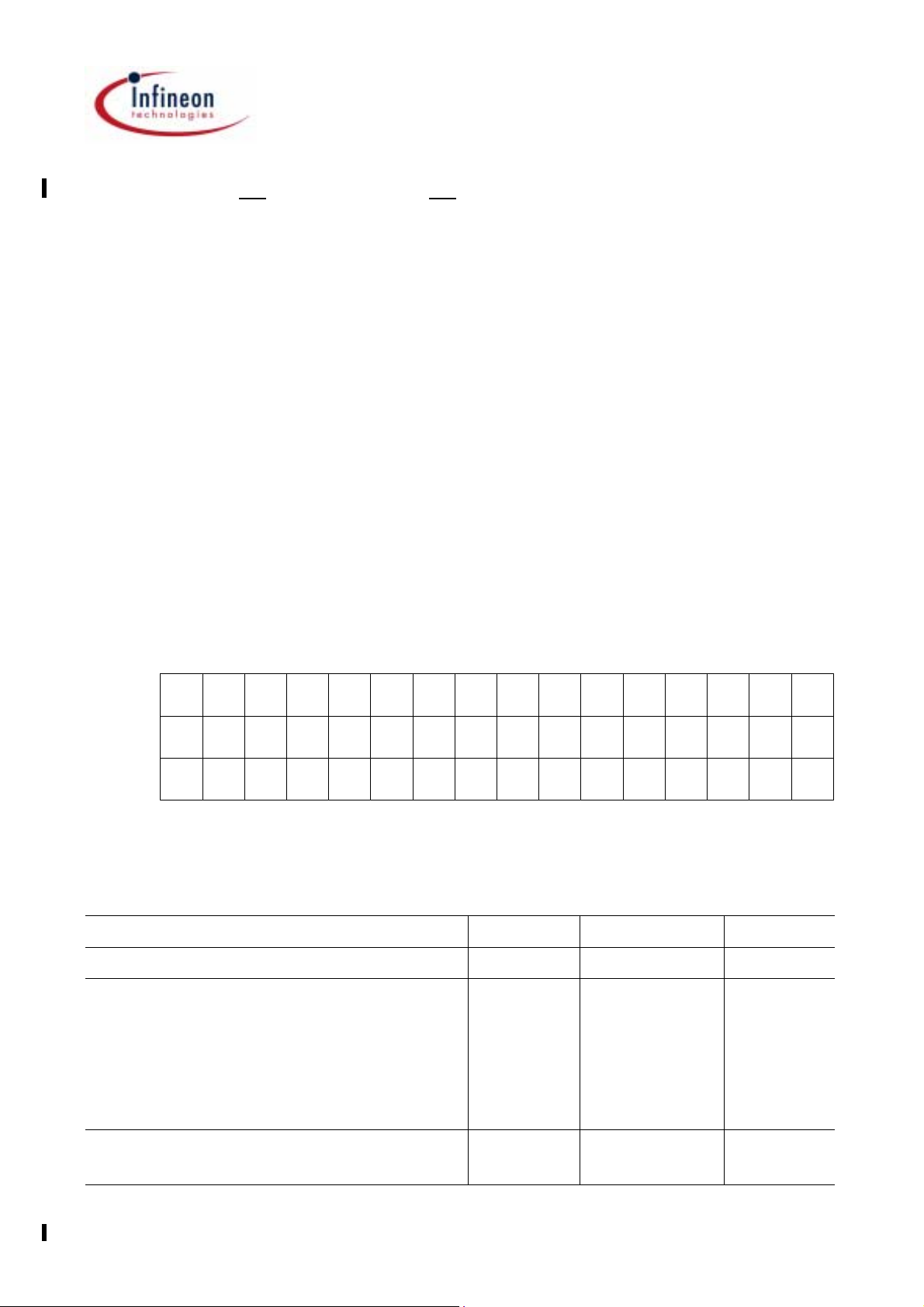

1.3 Pin configuration

TLE 6368 / SONIC

P-DSO-36-12

GND

CLK

CS

DO

ERR

Q_STB

Q_T1

Q_T2

Q_T3

Q_T4

DI

1

2

3

4

5

6

7

8

9

10

11

TLE 6368

36

35

34

33

32

31

30

29

28

27

26

GND

SLEW

WAKE

BOOST

IN

SW

IN

SW

Bootstrap

Q_LDO1

FB/L_IN

Q_T5

Q_T6

Q_LDO3

R3

R2

R1

GND

12

13

14

15

16

17

18

25

24

23

22

21

20

19

FB/L_IN

Q_LDO2

SEL

CCP

C+

C-

GND

Figure 1 Pin Configuration (Top View),

bottom heat slug and GND corner pins are connected

Data Sheet, Rev. 1.32 3 2004-10-15

TLE 6368 / SONIC

rcuit Information

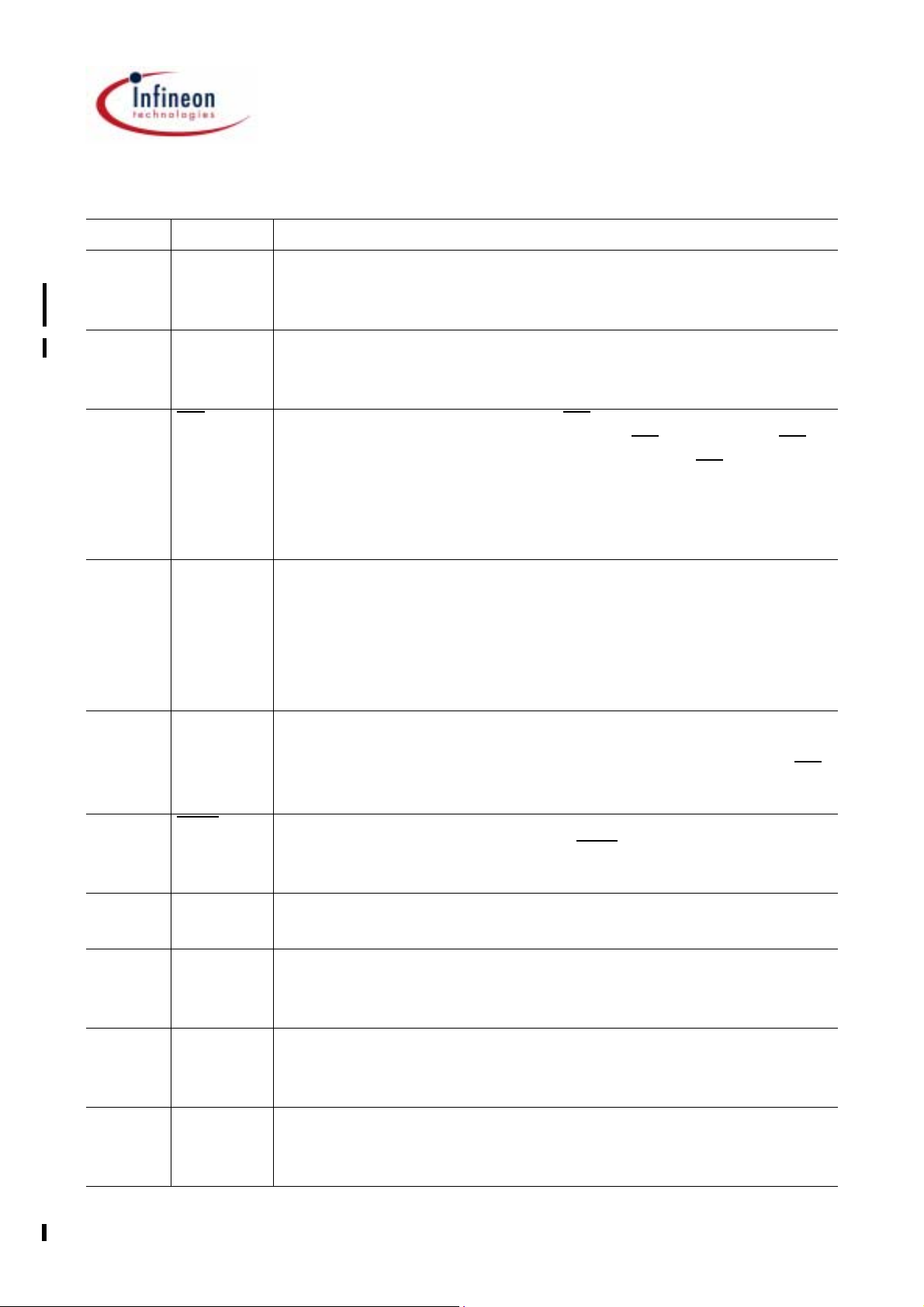

1.4 Pin definitions and functions

Pin No. Symbol Function

1,18,19,36GND Ground; to reduce thermal resistance place cooling areas on

PCB close to these pins. The GND pins are connected internally

to the heat slug at the bottom.

2CLKSPI Interface Clock input; clocks the shift register; CLK has an

internal active pull down and requires CMOS logic level

inputs;see also chapter SPI

3CS

SPI Interface chip select input; CS is an active low input; serial

communication is enabled by pulling the CS

input should only be switched when CLK is low; CS

terminal low; CS

has an

internal active pull up and requires CMOS logic level inputs ;see

also chapter SPI

4DI SPI Interface Data input; receives serial data from the control

device; serial data transmitted to DI is a 16 bit control word with

the Least Significant Bit (LSB) being transferred first; the input

has an active pull down and requires CMOS logic level inputs; DI

will accept data on the falling edge of CLK-signal; see also

chapter SPI

5DOSPI Interface Data output; this tristate output transfers

diagnosis data to the controlling device; the output will remain 3stated unless the device is selected by a low on Chip-Select CS

see also the chapter SPI

6ERR

Error output; push-pull output. Monitors failures in parallel to the

SPI diagnosis word, reset via SPI. ERR

is an active low, latched

output.

;

7Q_STBStandby Regulator Output; the output is active even when the

buck regulator and all other circuitry is in off mode

8 Q_T1 Voltage Tracker Output T1 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

9 Q_T2 Voltage Tracker Output T2 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

10 Q_T3 Voltage Tracker Output T3 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

Data Sheet, Rev. 1.32 4 2004-10-15

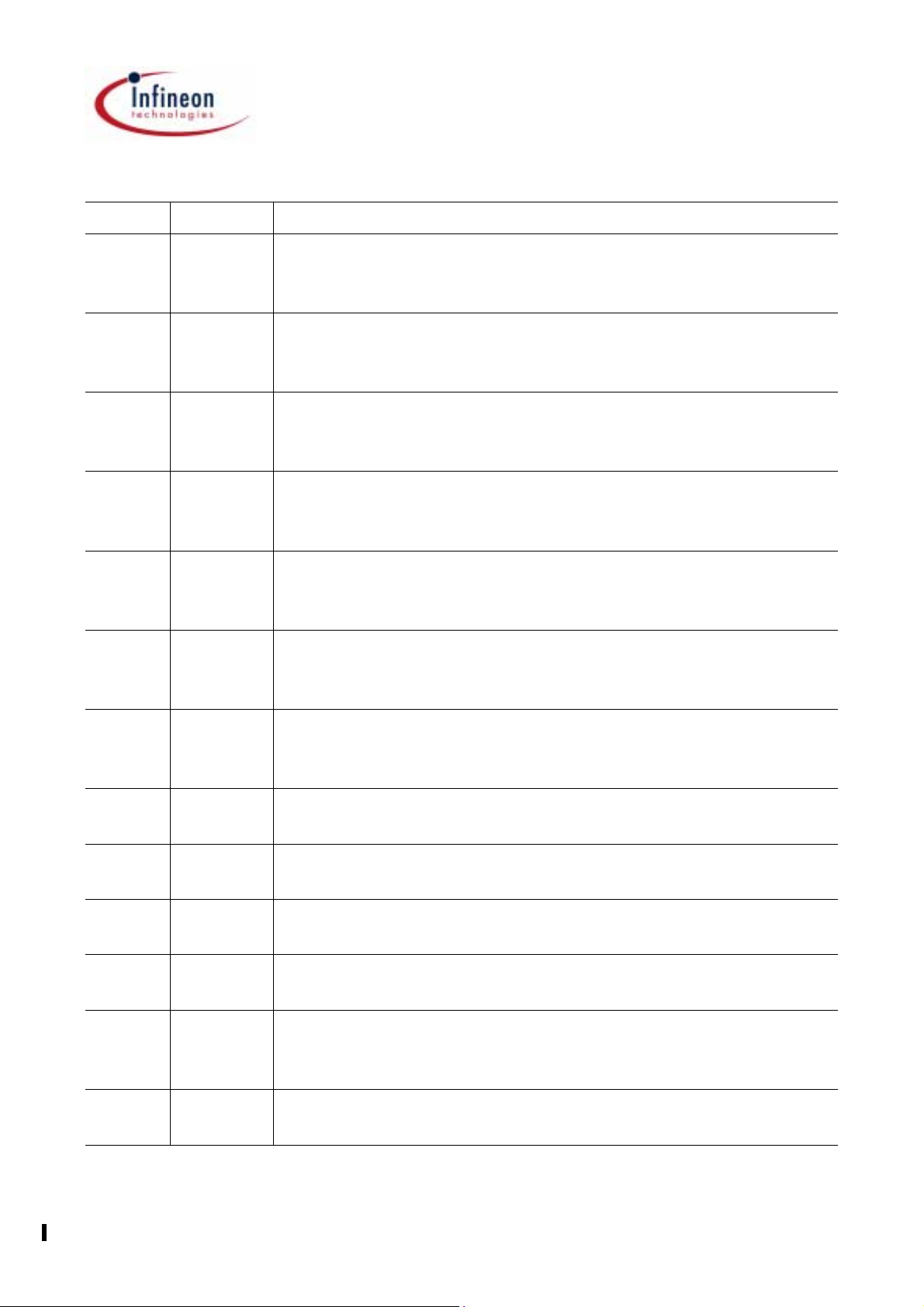

TLE 6368 / SONIC

1.4 Pin definitions and functions (cont’d)

Pin No. Symbol Function

11 Q_T4 Voltage Tracker Output T4 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

12 Q_T5 Voltage Tracker Output T5 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

13 Q_T6 Voltage Tracker Output T6 tracked to Q_LDO1; bypass with a

1µF ceramic capacitor for stability. It is switched on and off by

SPI command. Keep open, if not needed.

14 Q_LDO3 Voltage Regulator Output 3; 3.3V or 2.6V output; output

voltage is selected by pin SEL (see also 2.2.2); For stability a

ceramic capacitor of 470nF to GND is sufficient.

15 R3 Reset output 3, undervoltage detection for output Q_LDO3;

open drain output; an external pullup resistor of 10kΩ is

required

16 R2 Reset output 2, undervoltage detection for output Q_LDO2;

open drain output; an external pullup resistor of 10kΩ is

required

17 R1 Reset output 1, undervoltage detection for output Q_LDO1 and

watchdog failure reset; open drain output ; an external pullup

resistor of 10kΩ is required

20 C- Charge pump capacitor connection; Add the fly-capacitor of

100nF between C+ and C-

21 C+ Charge pump capacitor connection; Add the fly-capacitor of

100nF between C+ and C-

22 CCP Charge Pump Storage Capacitor Output; Add the storage

capacitor of 220nF between pin CCP and GND.

23 SEL Select Pin for output voltage adjust of Q_LDO2 and Q_LDO3

(see also 2.2.2)

24 Q_LDO2 Voltage Regulator Output 2; 3.3V or 2.6V output; output

voltage is selected by pin SEL (see also 2.2.2); For stability a

ceramic capacitor of 470nF to GND is sufficient.

25, 26 FB/L_IN Feedback and Linear Regulator Input; input connection for

the Buck converter output

Data Sheet, Rev. 1.32 5 2004-10-15

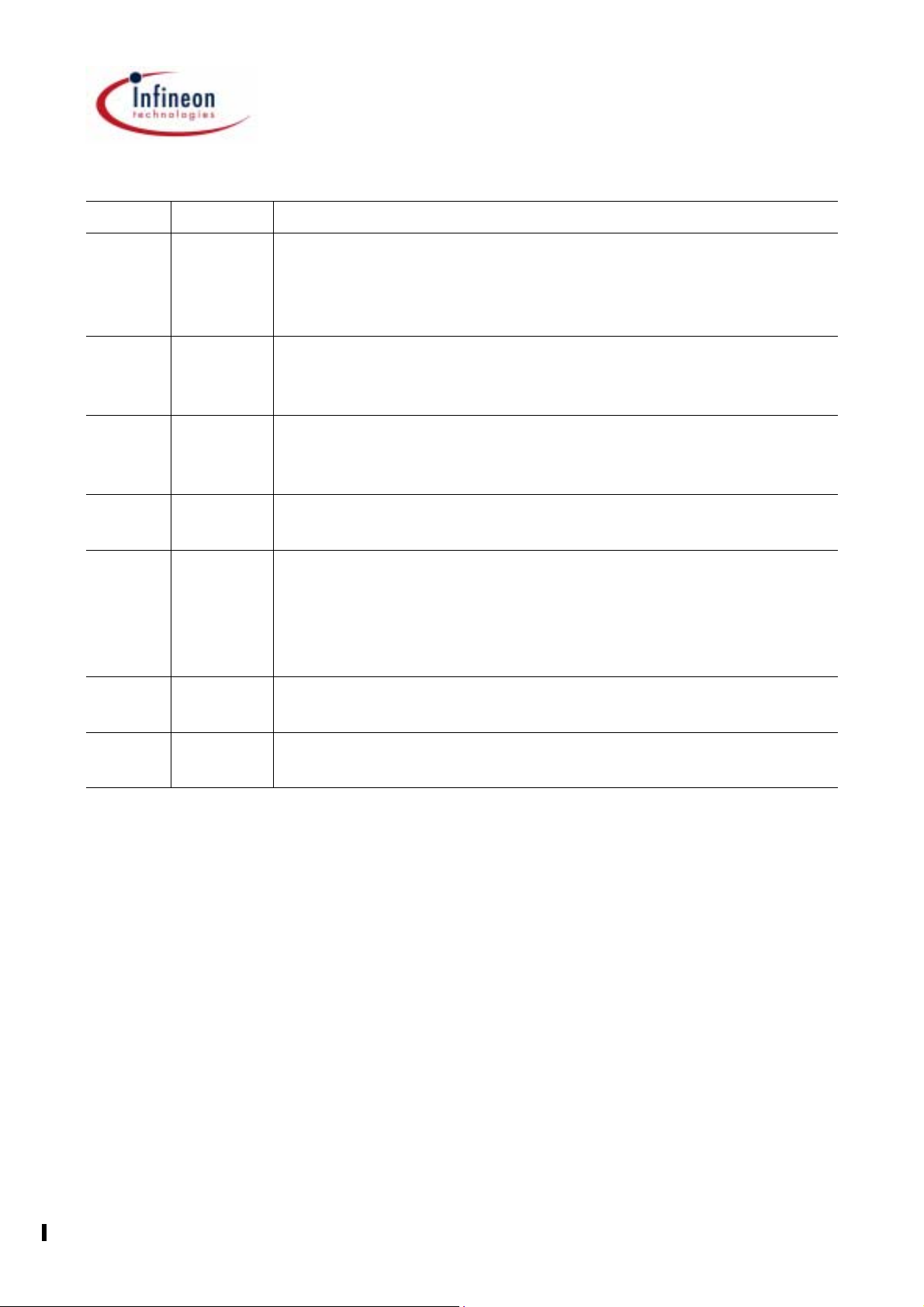

TLE 6368 / SONIC

1.4 Pin definitions and functions (cont’d)

Pin No. Symbol Function

27 Q_LDO1 Voltage Regulator Output 1; 5V output; acts as the reference

for the voltage trackers.The SPI and window watchdog logic is

supplied from this voltage. For stability a ceramic capacitor of

470nF to GND is sufficient.

28 Bootstrap Bootstrap Input; add the bootstrap capacitor between pin SW

and pin Bootstrap, the capcitance value should be 2% of the

Buck converter output capacitance

29, 31 SW Switch Output; connect both pins externally through short lines

directly to the cathode of the catch diode and the Buck circuit

inductance.

30, 32 IN Supply Voltage Input; connect both pins externally through

short lines to the input filter/the input capacitors.

33 BOOST Boost Input; for switching loss minimization connect a diode

(cathode directly to boost pin) in series with a 100nF ceramic

capacitor to the IN pin and from the anode of the diode to the

buck converter output a 22Ω resistor. Recommended for 42V

applications. In 12/24V applications connect boost directly to IN.

34 WAKE Wake Up Input; a positive voltage applied to this pin turns on

the device

35 SLEW Slew control Input; a resistor to GND defines the current slope

in the buck switch for reduced EME

Data Sheet, Rev. 1.32 6 2004-10-15

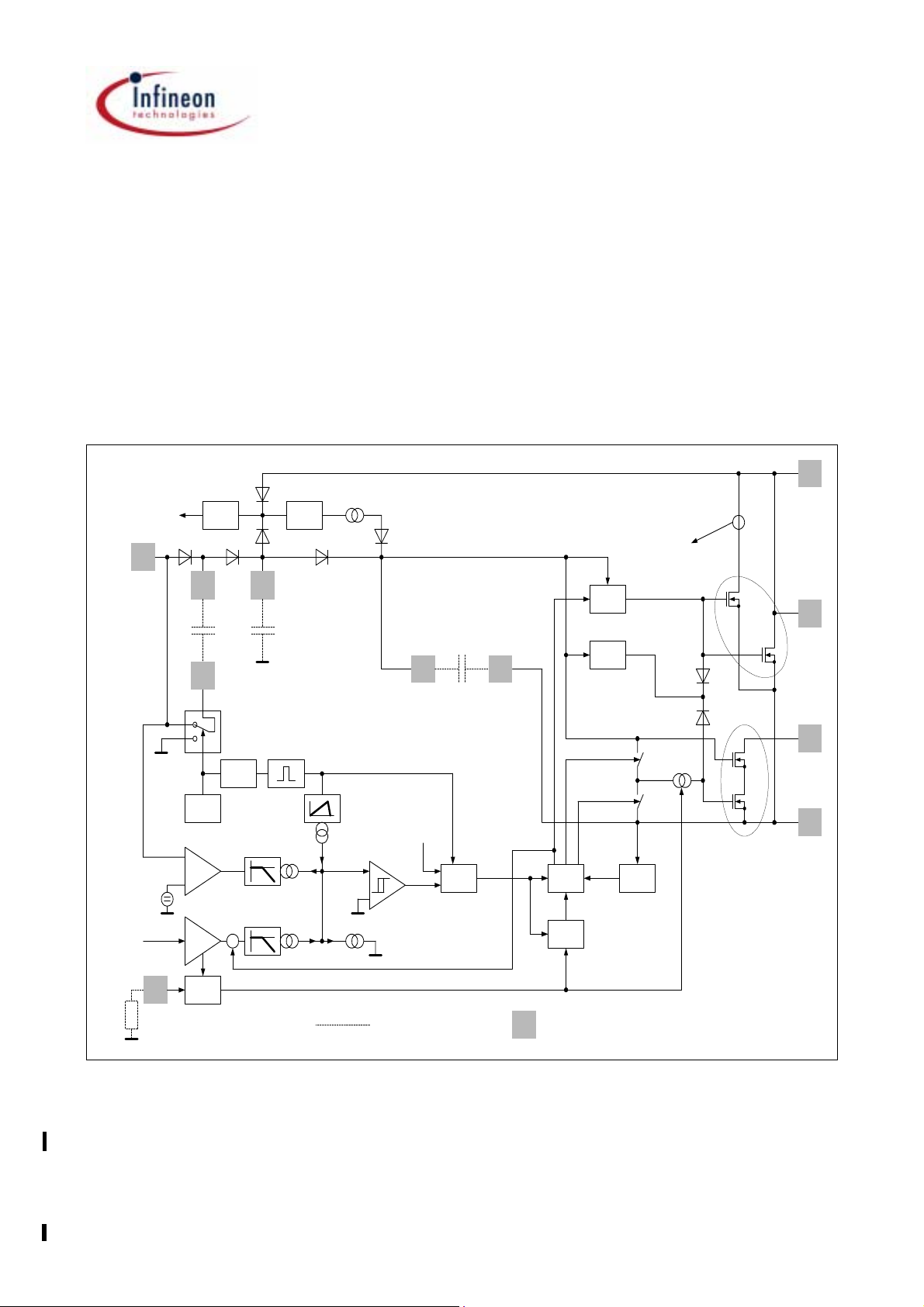

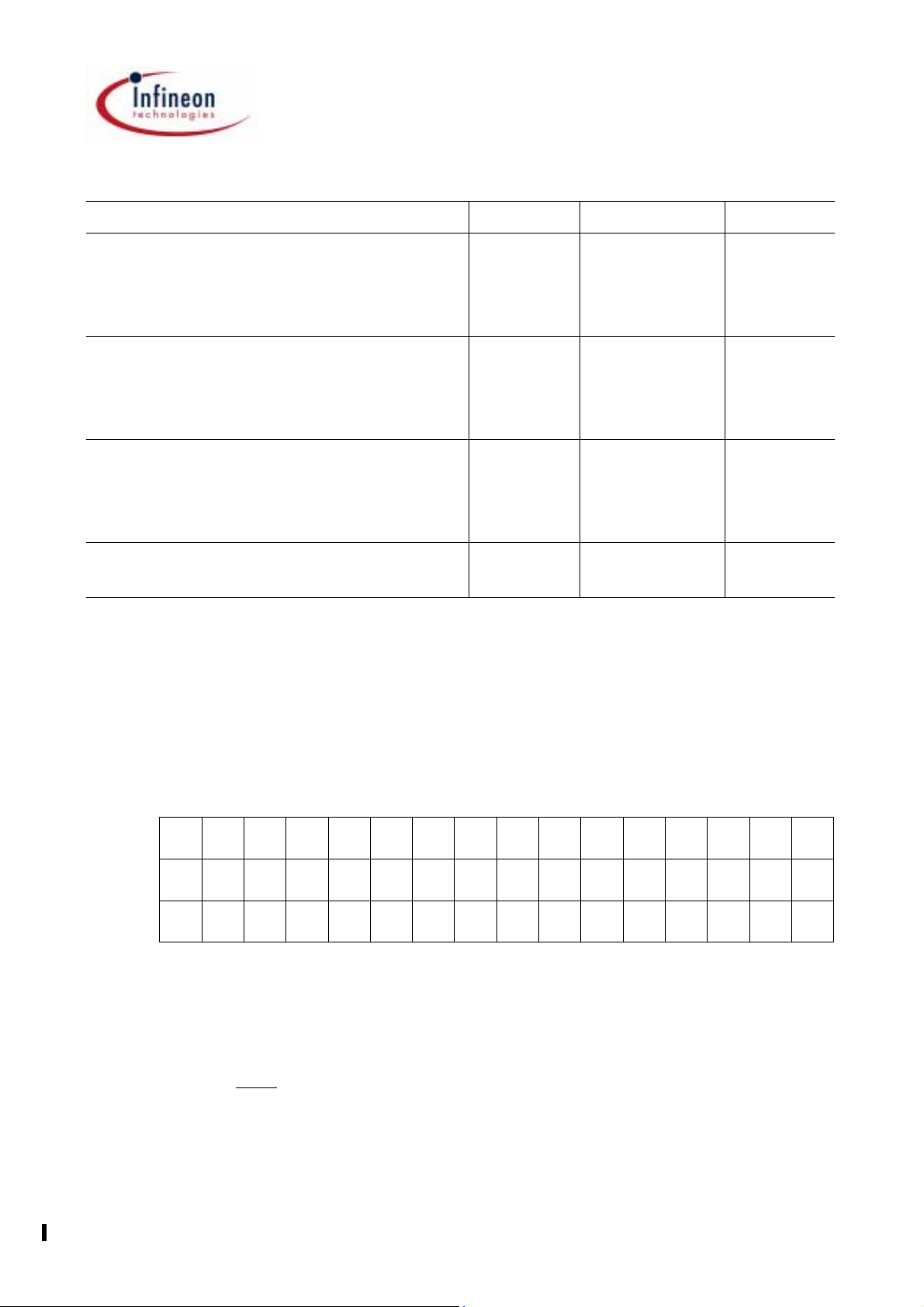

1.5 Basic block diagram

Boost

IN

2*

Slew

OSZ PWM

Driver

TLE 6368

Standby

Regulator

REGULATOR

Error-

Amplifier

feedback

BUCK

Internal

Reference

Q_STB

SW

Bootstrap

FB/L_IN

TLE 6368 / SONIC

2*

2*

Wake

R1

R2

R3

CLK

CS

DI

DO

ERR

Protection

Power

Down

Logic

Reset

Logic

Window

Watchdog

SPI

16 bit

C+

CCP

SEL

Q_LDO1

Q_LDO2

Q_LDO3

Q_T1

Q_T2

Q_T3

Q_T4

Q_T5

Q_T6

C-

µ-controller /

memory

supply

Sensor

supplies

(off board

supplies)

Charge

Pump

Linear

Reg. 1

Linear

Reg. 2

Linear

Reg. 3

ref

Tracker

5V

ref

Tracker

5V

ref

Tracker

5V

ref

Tracker

5V

ref

Tracker

5V

ref

Tracker

5V

GND

4*

Figure 2 Block Diagram

Data Sheet, Rev. 1.32 7 2004-10-15

TLE 6368 / SONIC

2 Detailed circuit description

In the following major buck regulator b locks, the linear vo ltage regul ators and track ers,

the undervoltage reset function, the watchdog and the SPI are described in more detail.

For applications information e.g. choice of external components, please refer to section

5.

2.1 Buck Regulator

The diagram below shows the internal implemented circuit of the Buck converter, i. e. the

internal DMOS devices, the regulation loop and the other major blocks.

5V 14V

Int. volta ge

regulator

FB/L_IN

C+

C-

Divider

Oscillator

1.4MHz

Voltage

feedback

amplifier

Vref=6V

from

current sensing

Current

sense

amplifier

+

Lowpass

Lowpass

8 to 10V

CCP

Int. charge

pump

150µA

Slope

compensation

Current

comparator

BOOTSTRAP

switchi ng frequency 330kHz

Gate off signal

fr om overtem p or

sleep command

Trigger for

gate off

Trigger for

gate on

PWM logic

Main switch ON/OFF

SW

Slope logi c

Delay unit

Gate driver

Slope switc h

charge signal

Slope switch

discharg e sign al

undervoltage

lockout

Zero cross

detection

to

current sense

amplifi er

Main

DMOS

Slope

DMOS

IN

IN

BOOST

SW

Slope

control

SLEW

exter nal comp onents

pins

Figure 3 Detailed Buck regulator diagram

The 1.5A Buck regulator consists of two internal DMOS power stages including a current

mode regulation scheme to avoid external compensation components plus additional

blocks for low EME and reduced switching loss. Figure 3 indicates also the principle how

Data Sheet, Rev. 1.32 8 2004-10-15

TLE 6368 / SONIC

the gate driver supply is managed by the combination of internal charge pump, external

charge pump and bootstrap capacitor.

2.1.1 Current mode control scheme

The regulation loop is located at the left lower corner in the schematic, there you find the

voltage feedback amplifier which gives the actual information of the actual output voltage

level and the current sense ampl ifier for the load current inform ation to form finally the

regulation signal. To avoid subh armo nic osci llations at duty cycles highe r than 5 0% the

slope compensation block is necessary.

The control signal formed out of those three blocks is finally the input of the PWM

regulator for the DMOS gate turn off command, which means this signal determines the

duty cycle. The gate turn on signal is set by the o scillator periodical ly every 3µs which

leads to a Buck converter switching frequency around 330kHz.

With decreasing input voltag e the de vic e ch anges to the so called pulse skipp ing mode

which means basically that some of the oscillator gate turn off signals are ignored. When

the input voltage is still reduced the DMOS is turned on statically (100% duty cycle) and

its gate is supplied by the internal charge pump. Below typic al 4. 5V at the feedback pin

the device is turned off.During normal switching operation the gate driver is supplied by

the bootstrap capacitor.

2.1.2 Start-up procedure

To guarantee a device startup even under full load condition at the linear regulator

outputs a special start up procedure is impleme nted. At first the bootstrap capa citor is

charged by the internal charge pump. Afterwards the output capacitor is charged where

the driver supply in tha t case is maintained only by the bootstrap capacitor. Once the

output capacitor of the buck converter is charged the external charge pump is activated

being able to supply the linear regulators and finally the linear regulators are released to

supply the loads.

2.1.3 Reduction of electromagnetic emission

In figure 3 it is recognized that two internal DMOS switches are used, a main switch and

an auxiliary switch. The second imp lemented switc h is used to adjust the current slope

of the switching current. The slope adjustment is done by a controlled charge and

discharge of the gate of this DMOS. By choosi ng the external resistor on the SLEW pin

appropriate the current transition time can be adjusted between 20ns and 100ns.

2.1.4 Reducing the switching losses

The second purpose of the slope DMOS is to minimise the switching losses. Once being

in freewheeling mode of the buck regulato r the output volta ge level is sufficient to force

the load current to flow, the in put voltage level is not needed in the first mo ment. By a

feedback network consis ting of a resistor and a diode to th e boost pin (connectio n see

Data Sheet, Rev. 1.32 9 2004-10-15

TLE 6368 / SONIC

section 5) the output voltage level is pres ent at the drain of the switch. As soon as the

voltage at the SW pin passes zero volts the handover to the main switch occurs and the

traditional switching behaviour of the Buck switch can be observed.

2.2 Linear Voltage Regulators

The Linear regulators offer, depending on the version, voltage rails of 5V, 3.3V and 2.6V

which can be determined by a hardware connection (see table at 2.2.2) for proper power

up procedure. Being supplied by the output of the Buck pre-regulator the power loss

within the three linear regulators is minimized.

All voltage regulators are short circuit protected which means that each regulator

provides a maximum cu rrent according to its current li mit when shorted. Together with

the external charge p ump the NPN pass elemen ts of the regulators allow low dropout

voltage operation. By u sing this structu re the linear regulat ors work stable even with a

minimum of 470nF ceramic capacitors at their output.

Q_LDO1 has 5V nominal output voltage, Q_LDO2 has a hardware programmable

output voltage of 3.3V or 2.6V and Q_LDO3 is also programmable to 3.3V or 2.6V (see

section 2.2.2). All th ree regulators are on all the time, i f one regulator is n ot needed a

base load resistor in parallel to the output capacitance for controlled power down is

recommended.

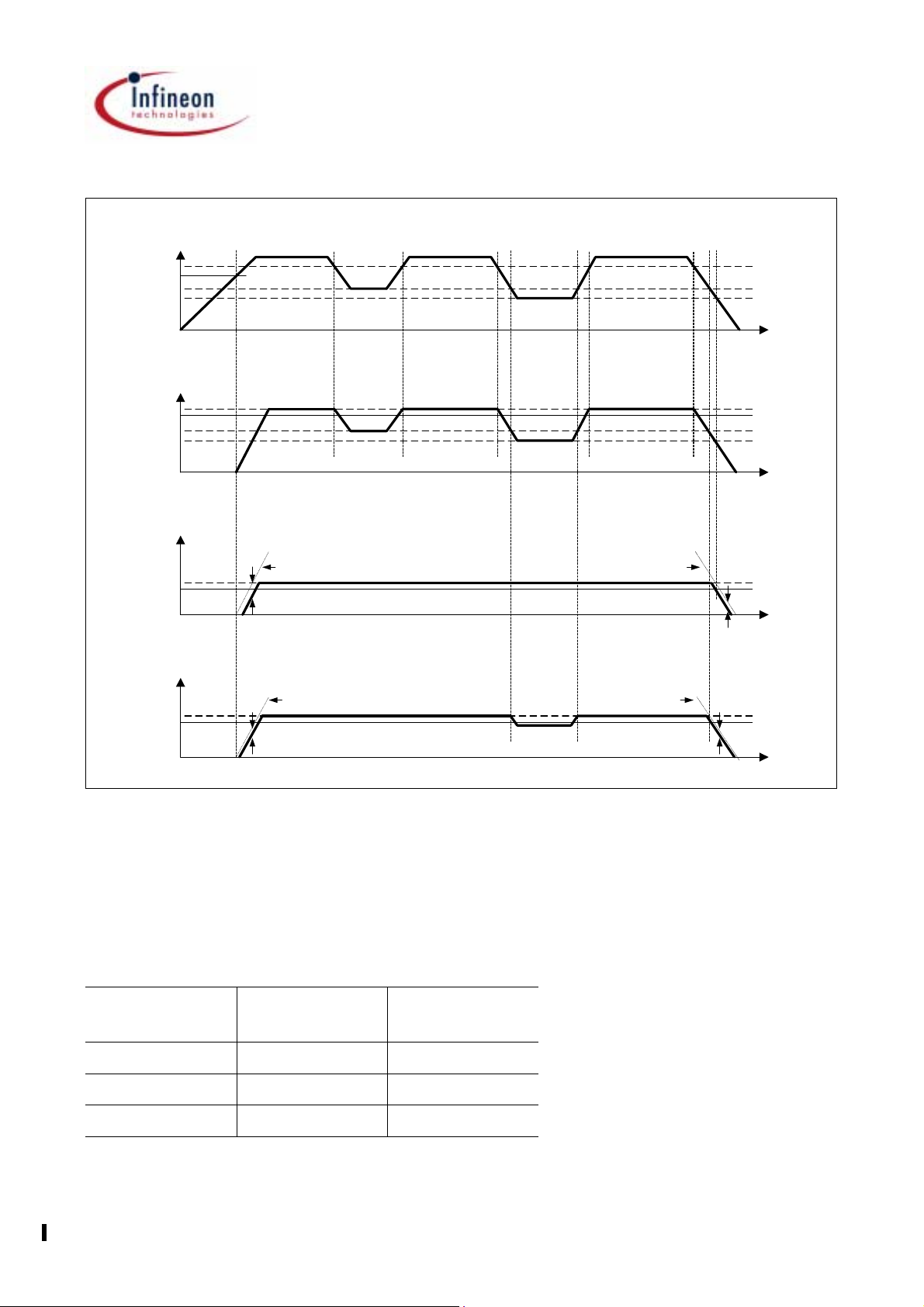

2.2.1 Startup Sequence Linear Regulators

When acting as a 32 bi t µC s uppl y the so-called power seque nci ng (the dependency of

the different voltage rails to each other) is important. Within the TLE 6368 G1 / SONIC,

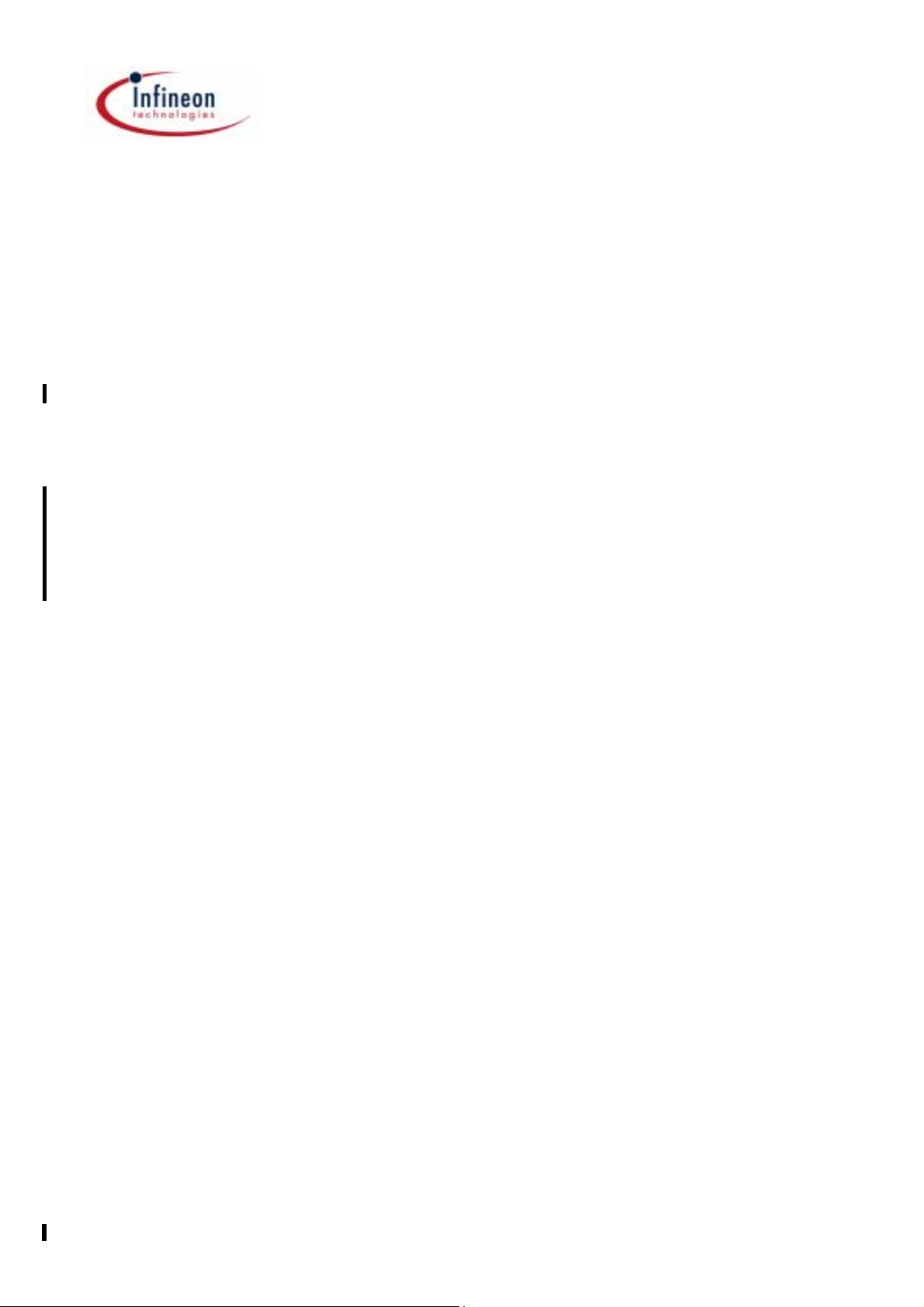

the following Startup-Sequence is defined (see also figure 4):

V

Q_LDO2

with V

≤ V

Q_LDO1

Q_LDO1; VQ_LDO3

=5V, V

Q_LDO2

≤ V

Q_LDO1

= 2.6V or 3.3V and V

Q_LDO3

= 2.6V or 3.3V

The power sequencing refers to the regulator itself, externally voltages applied at

Q_LDO2 and Q_LDO3 are not pulled down actively by the device if Q_LDO1 is lower

than those outputs.

That means for the power down se quencing if different output capa citors and different

loads at the three outputs of the linear regulators are used the voltages at Q_LDO2 and

Q_LDO3 might be higher than at Q_LDO1 due to slower discharging. To avoid this

behaviour three Schottky diodes have to be connected between the three outputs of the

linear regulators in that way that the cathodes of the diodes are always connected to the

higher nominal rail.

Data Sheet, Rev. 1.32 10 2004-10-15

Power Sequencing

V

FB/L_IN

V

LDO_EN

V

Q_LDO1

5V

V

Rth5

3.3V

2.6V

V

(2.6V Mode)

Q_LDO2

TLE 6368 / SONIC

t

t

0.7V

5V LDO 5V LDO

5V LDO 5V LDO

+/- 50mV

0.7V

t

+/- 50mV

t

V

Q_LDO3

2.6V

V

3.3V

V

Rth2.6

Rth3.3

(3.3V Mode)

Figure 4 Power-up and -down sequencing of the regulators

2.2.2 Q_LDO2 and Q_LDO3 output voltage selection*

To determine the output voltage le vels of the three linear regulators, the se lection pin

(SEL, pin 23) has to be connected according to the matrix given in the table below.

Definition of Output voltage Q_LDO2 and Q_LDO3

Select Pin SEL

connected to

Q_LDO2

output voltage

Q_LDO3

output voltage

GND 3.3 V 3.3 V

Q_LDO1 2.6 V 2.6 V

Q_LDO2 2.6 V 3.3 V

* for different output voltages ple as e ref er t o th e m ult i vo lta ge s upply TLE6361

Data Sheet, Rev. 1.32 11 2004-10-15

TLE 6368 / SONIC

2.3 Voltage Trackers

For off board supplies i.e. sensors six voltage trackers Q_T1 to Q_T6 with 17mA output

current capability each are available. The output voltages match Q_LDO1 within

+5 / -15mV. They can be individually turned on and off by the appropriate SPI command

word sent by the microcontroller. A ceramic capacitor with the value of 1µF at the output

of each tracker is sufficient for stable operation without oscillation.

The tracker outputs can be connected in parallel to obtain a higher output current

capability, no matter if on ly two or up to all si x trackers are tied together. For uniform ly

distributed current d ensity in eac h tracker interna l balance res istors at each output are

foreseen internally. By connecting two sets of three trackers in parallel two sensors with

more than 50mA each can be supplied, all six in parallel give more than 100mA.

The tracker outputs can withstand short circuits to GND or battery in a range from -5 to

+60V. A short circuit to GND is detected and indicated individually for each tracker in the

SPI status word. Also a n open load condi tion might be recognised a nd indicated as a

failure condition in the SPI status word. A minimum load current of 2mA is required to

avoid open load failure indica tion. In cas e of connecti ng several tra ckers to a comm on

branch balancing currents can prevent proper operation of the failure indication.

2.4 Standby Regulator

The standby regulator is an ultra low power 2.5V linear voltage regulator with 1mA output

current which is on all the time. It is intended to supply the mic r oco ntrol ler in stop mode

and requires then onl y a minimum of quiescent current (<3 0µA) to extend the battery

lifetime.

2.5 Charge Pump

The 1.6 MHz charge pump with the two external capacitors will serve to supply the base

of the NPN linear regulators Q_LDO1 and Q_LDO3 as well as the gate of the Buck

DMOS transistor in 100% duty cycle operation at low battery condition. The charge pump

voltage in the range of 8 to 10V can be measured at pin 22 (CCP) but is not intended to

be used as a supply for additional circuitry.

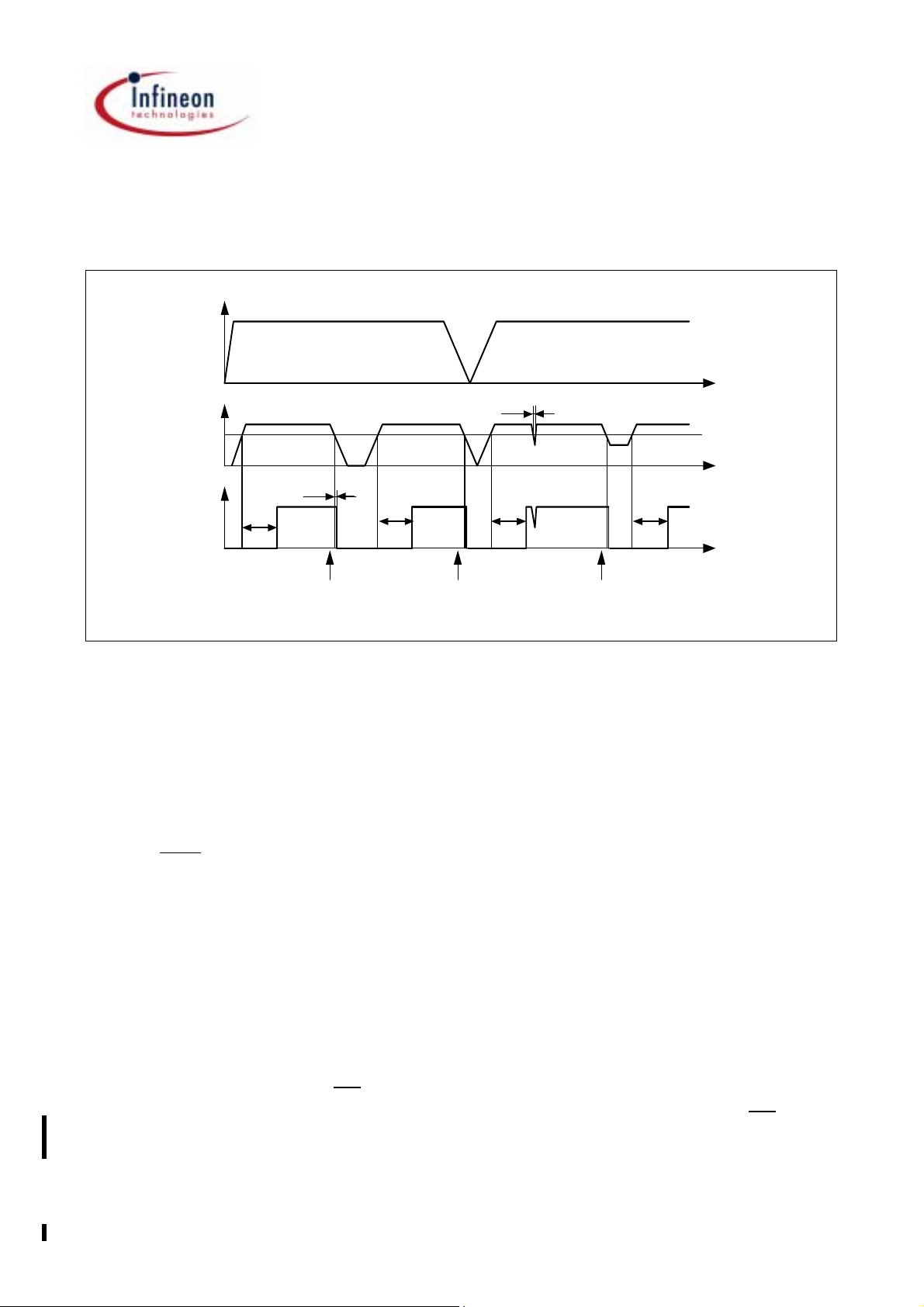

2.6 Power On Reset

A power on reset is available for eac h linear voltage regu lator output. The reset out put

lines R1, R2 and R3 ar e ac tiv e (lo w) d uring sta rt up a nd turn inactive with a rese t delay

time after Q_LDO1, Q_LDO2 and Q_LDO3 have reached their reset threshold. The

reset outputs are open drain, three pull up resistors of 10kΩ each have to be co nne ct e d

to the I/O rail (e.g. Q_LDO1) of the µC. All three reset outputs can be linked in parallel to

obtain a wire d-OR.

The reset delay time is 8 ms by default and can be set to higher values as 16 ms, 32 ms

or 64 ms by SPI command. At each power up of the device in case the output voltage at

Data Sheet, Rev. 1.32 12 2004-10-15

TLE 6368 / SONIC

Q_LDO1 had decreased below 3.3V (max.), the SPI will reset to the default settings

including the 8ms delay time. If the voltage on Q_LDO1 during sleep or power off mode

was kept above 3.3V the delay time set by the last SPI command is valid.

V

FB/L_IN

V

Q_LDOx

< t

rr

t

rr

V

Rx

t

RES

t

RES

t

RES

t

RES

t

V

RTH,Q_LDOx

t

t

thermal

shutdown

under

voltage

over

load

Figure 5 Undervoltage reset timing

2.7 RAM good flag

A RAM good flag will be set within the SPI status word when the Q_LDO1 voltage drops

below 2.3V. A second one wi ll be set if Q_LDO2 drops belo w typical 1.4V. Both RAM

good flags can be read after power up to determine if a c old or warm start n eeds to be

processed. Both RAM good flags will be reset after each SPI cycle.

2.8 ERR

Pin

A hardware error pin indicates any fault conditions on the chip. It should be connected to

an interrupt input of the microcontroller. A low signa l indicates an error condition. The

microcontroller can read the root cause of the error by reading the SPI register.

2.9 Window Watchdog

The on board window watchdog for supervision of the µC works in combination with the

SPI. The window watchdog logic is turned off per default and can be activated by one

special bit combination in the SPI command word. When operating, the window

watchdog is triggered when CS is low and Bit WD-Trig in the SPI command word is set

to “1”. The watchdog trigger is recognized with the low to high transition of the CS

signal.

To allow reading the SPI at any time without getting a reset due to misinterpretation the

WD-Trig bit has to be set to “0” to avoid false trigger conditions.

Data Sheet, Rev. 1.32 13 2004-10-15

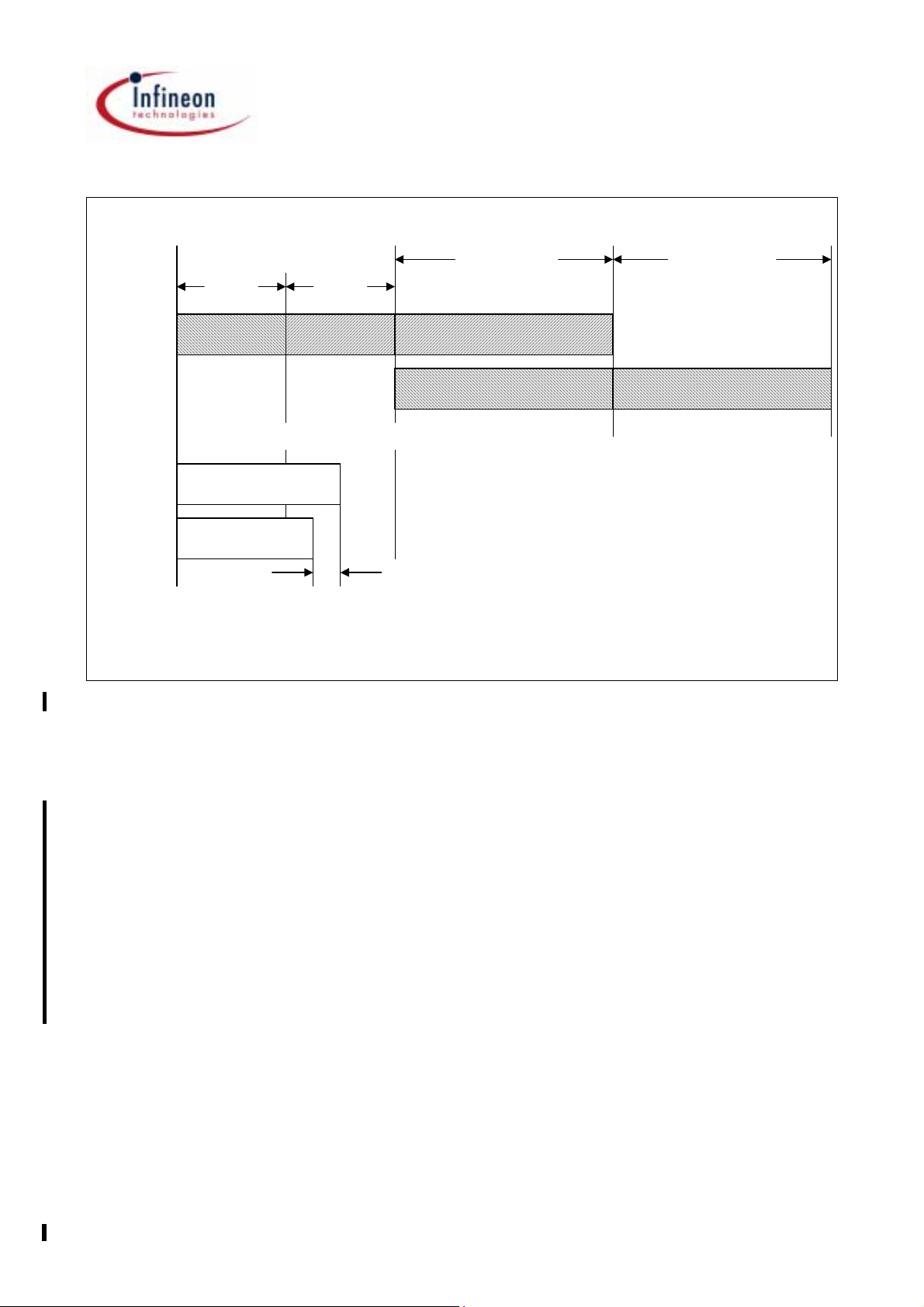

tCW=t

CW

tOW=t

CW

t

= tOW/2

SR

(not the same scale)

TLE 6368 / SONIC

t

= t

WDR

RES

(not the same scale)

definition

definition

closed window open window

ECW

reset delay time without trigger

reset start delay time after window

watchdog timeout

t

= end of open windowt

EOW

reset duration time after window

watchdog time-out

Example with:

=128ms

t

f

OSC=fOSCmax

worst cases

f

OSC=fOSCmin

t

EOW, w.c.

t

ECW, w.c.

= ( tCW+t

= t

(1+∆)

CW

OW

)(1-∆)

t

OWmin

t

OWmin

= t

OW

- ∆ * ( t

OW

+ 2* tCW )Minimum open window time:

CW

∆=25% (oscillator deviation)

t

t

t

= 128(1.25) = 160ms

ECW, w.c.

= (128+128)(0.75) = 192ms

EOW, w.c

= 32ms

owmin

Figure 6 Window watchdog timing definition

Figure 6 shows some guideline s for designing the wa tchdog trigger timing taking the

oscillator deviation of different devices into account. Of importance (w.c.) is the

maximum of the closed window and the minimum of the open window in which the

trigger has to occur.

The length of the OW and CW can be modified by SPI command. If a change of the

window length is desired during the Watchdog function is operating please send the SPI

command with the new tim ing wit h a ’Watchd og tri gger Bit’ D1 5=1.In th is case the next

CW will directly start with the new length.

A minimum time gap of > 1/48 of the actual OW/CW time between a ’Watchdog disable’

and ’Watchdog enable’ SPI-command should be maintained. This allows the internal

Watchdog counters to be resetted. Thus after the enable command t he Watchdog will

start properly with a full CW of the adjusted length.

Data Sheet, Rev. 1.32 14 2004-10-15

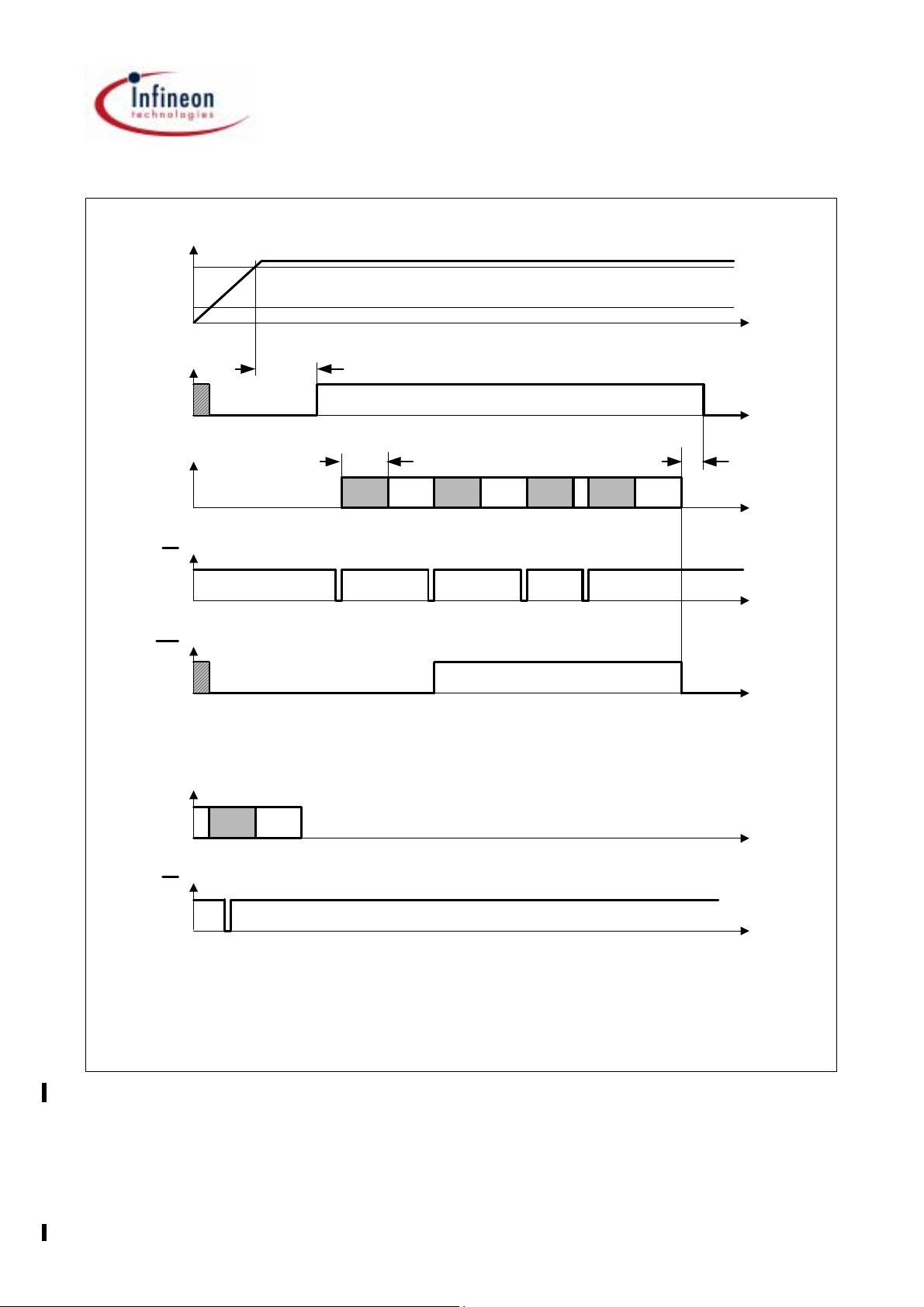

Perfect triggering after Power on Reset

V

Q_LDO1

V

Rth1

1V

t

R1

RES

TLE 6368 / SONIC

t

t

Watchdog

window

CS

ERR

Incorrect triggering

Watchdog

window

CW OW

CS

with WD-

trig=1

3) 4)

t

CW

CW OW CW OW CW CW OW

2)2)2)1)

t

SR

t

t

t

t

t

1) Watchdog enable command with no trigger: D0D9D14D15=0100

2) Watchdog trigger: D15=1

3) Pretrigger

4) Missing trigger

Legend: OW = Open window

CW = Closed window

Figure 7 Window watchdog timing

Figure 7 gives some timing information about the window watchdog. Looking at the

upper signals the perfect triggering of the watchdog is shown. When the 5V linear

regulator Q_LDO1 reaches its reset threshold, the reset delay time has to run off before

Data Sheet, Rev. 1.32 15 2004-10-15

TLE 6368 / SONIC

the closed window (CW) starts. Then three valid watchdog triggers are shown, no effect

on the reset line a nd/or error pin is ob served. With the miss ing watchdog trigger sign al

the error signal turns low immediately where the reset is asserted after another delay of

half the closed window time .

Also shown in the figure are two typica l failure modes, one pretrigger an d one missing

signal. In both cases the error s ignal will go low immedia tely the fai lure is detected with

the reset following after the half closed window time.

2.10 Overtemperature Protection

At a chip temperature of more than 150° an error and temperature flag is set and can be

read through the SPI. The device is switched off if the device reaches the

overtemperature threshold of 170°C. The overtemperature shutdown has a hysteresis to

avoid thermal pumping.

2.11 Power Down Mode

The TLE 6368 G1 / SONIC is starte d by a sta tic high s ignal at the wak e input or a hi gh

pulse with a minim um of 50µs duration at the Wake input (pi n 34). In order to avoid

instabilities of the device voltages applied to the Wake pin (pin 34) have to have a certain

slope, i.e. 1V/3µs. Voltages in the range between the turn on and turn off thresholds for

a few 100µs must be avoided!

By SPI command (“Sleep”-bit, D8, equals zero) all voltage regulators including the

switching regulator except the standby regulator can be turned off completely only if the

wake input is low. In the case the Wake input is permanently connected to battery the

device cannot be turned off by SPI command, it will always turn on again.

For stable “on” operation of the devi ce th e “Sleep ”-b it, D8 has to be set to high at ea ch

SPI cycle!

When powering the device again after power down the status of the SPI controlled

devices (e.g. trackers, watc hdog etc.) depends on th e output voltage on Q_LDO1. D id

the voltage at Q_LDO1 decrease below 3.3V the default status (given in the next section)

is set otherwise the last SPI command defines the status.

2.12 Serial Peripheral Interface

A standard 16 bit SPI is available for control and diagnost ics . It i s c apa ble to op erate in

a daisy chain. It can be written or read by a 16 bit SPI interface as well as by an 8 bit SPI

interface.

The 16-bit control word (write bit assignment, see Figure 8) i s rea d in vi a the dat a input

DI, synchronous to the clock input CLK supp lied by the µC begin ning with the LSB D0.

The diagnosis word appears in the same way synchronously at the data output DO (read

bit assignment, see figure 9), so with the first bit shifted on the DI line the first bit appears

on the DO line.

Data Sheet, Rev. 1.32 16 2004-10-15

TLE 6368 / SONIC

The transmission cycle be gins when the TLE 636 8 G1 / SONIC is sel ected by the “not

chip select” input CS

been read in at the DI line becomes the n ew control word. The DO output switch es to

tristate status at this point, thereby releasing the DO bus circuit for other uses. For details

of the SPI timing please refer to Figures 10 to 13.

The SPI will be reset to d efault valu es given i n the follow ing table “write bit me aning” if

the RAM good flag of Q_LDO1 indic ates a cold start (lower output voltage th an 3.3V).

The reset will be active as long as the power on reset is present so during the reset delay

time at power up no SPI commands are accepted.

The register content of the SPI - including watchdog timings and reset delay timings - is

maintained if the RAM good flag of Q_LDO1 indicates a warm start (i.e. Q_LDO1 did not

decrease below 3.3V).

2.12.1 Write mode

(H to L). After the CS input returns from L t o H, t he wo rd that has

The following tables s how the bit assignment to the different control functions, how to

change settings with the right bit combination and also the default status at power up.

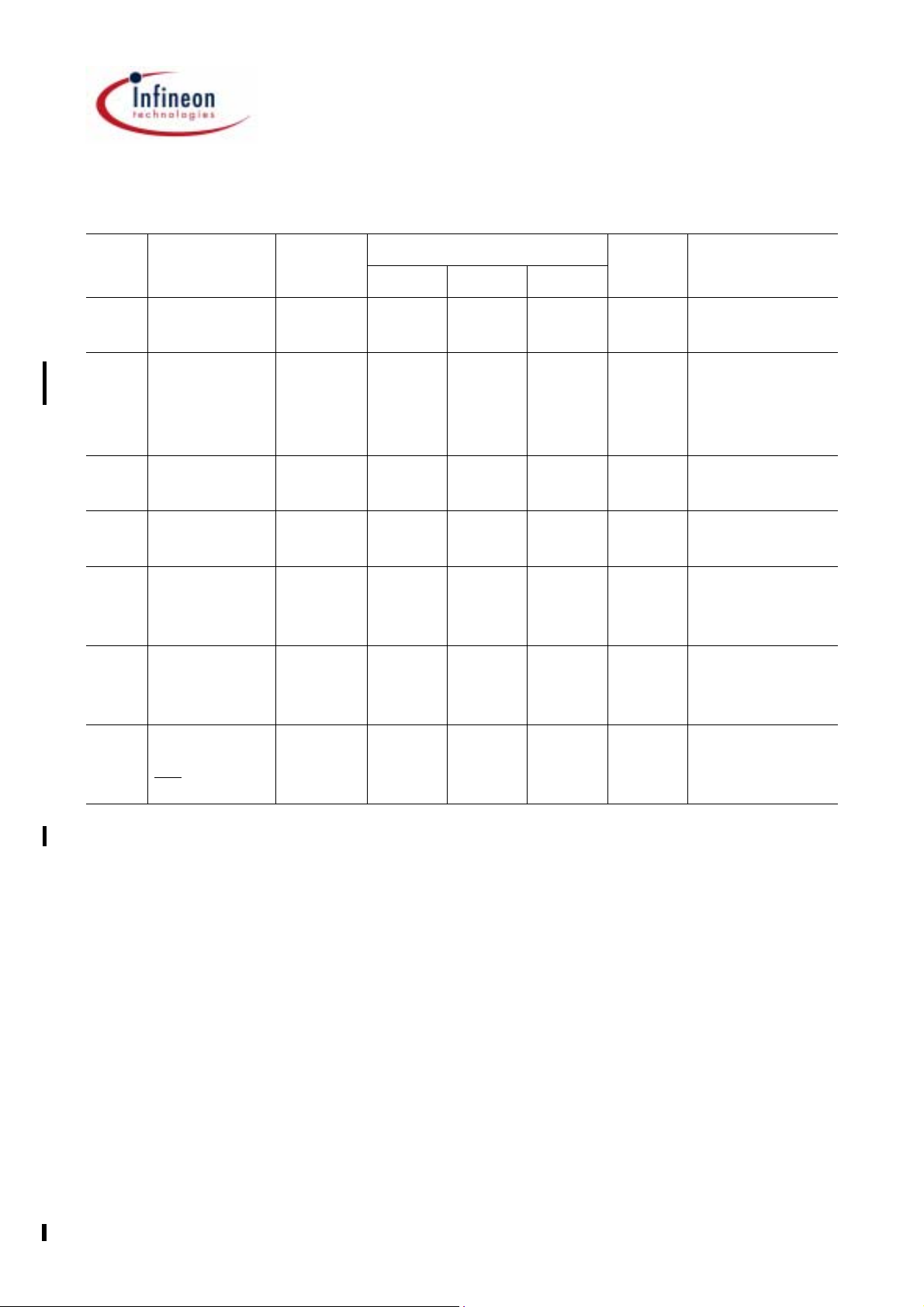

2.12.2 Write mode bit assignment

BIT

Name

Default

WD_

NOT

OFF1

assigned

1 111111X 1 0100110

control

T1-

T2-

control

control

T6-

T4-

control

control

T5-

T6-

control

sleep

WD_

OFF2

WD2WD1reset 2reset 1

WD_

OFF3

D 15D8 D9 D10 D11 D12 D13 D14D7DO D1 D2 D3 D4 D5 D6

WD_

TRIG

Figure 8 Write Bit assignment

Write Bit meaning

Function Bit Combination Default

Not assigned D1 X X

Tracker 1 to 6 - control:

turn on/off the individual trackers

D2

D3

0: OFF

1: ON

1

D4

D5

D6

D7

Power down:

send device to sleep

Data Sheet, Rev. 1.32 17 2004-10-15

D8 0: SLEEP

1: NORMAL

1

TLE 6368 / SONIC

Write Bit meaning

Function Bit Combination Default

Reset timing:

Reset delay time t

valid at warm start

RES

Window watchdog timing:

Open window time t

closed window time t

and

OW

valid at warm start

CW

Window watchdog function:

Enable /disable window watchdog

Window watchdog trigger:

Enable / disable window watchdog trigger

2.12.3 Read mod e

D10D11 00: 64ms

10: 32ms

01: 16ms

11: 8ms

D12D13 00: 128ms

10: 64ms

01: 32ms

11: 16ms

D0D9D14 010: ON

1xx: OFF

x0x: OFF

xx1: OFF

D15 0: not triggered

1: trigger ed

11

00

101

0

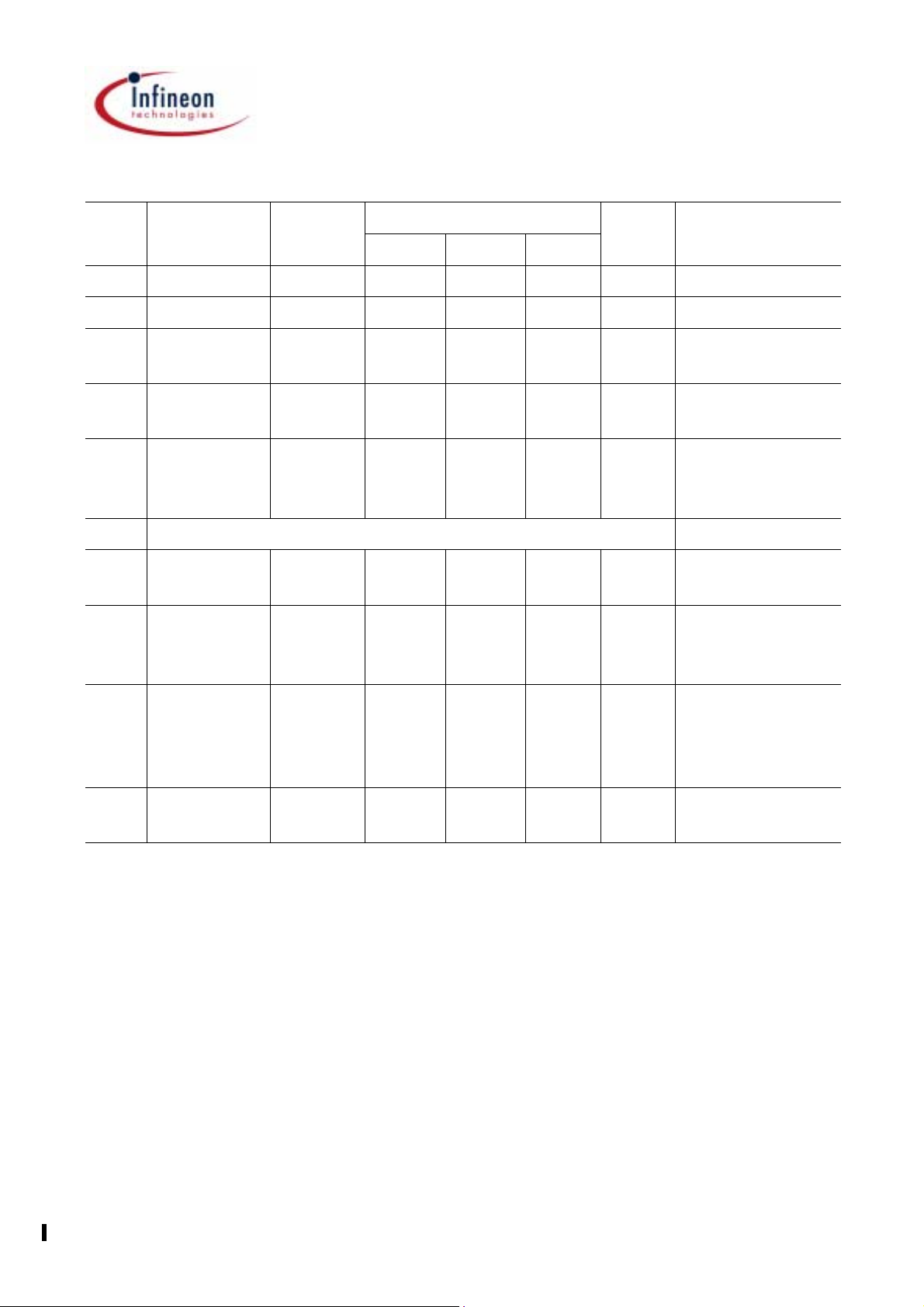

Below the status information word and the bit assignments for diagnosis are shown.

2.12.3.1Read mode bit assignment

BIT

Name

Default

warn

T1-

status

status

status

status

status

status

RAM

Good 1

ERROR

temp_

0 1111110 0 1000000

T6-

T5-

T4-

T3-

T2-

RAM

Good 2

WD

Window

R-Error3R-Error2R-Error1

WD

Error

D 15D8 D9 D10 D11 D12 D13 D14D7DO D1 D2 D3 D4 D5 D6

DC/DC

status

Figure 9 Read Bit assignment

Error bit D0:

The error output ERR

is low and the error bit indic ates fail function if the tempera ture

prewarning or the watchdog error is active, further if one RAM good indicates a cold start

or if a voltage tracker does not settle within 1ms when it is turned on.

Data Sheet, Rev. 1.32 18 2004-10-15

TLE 6368 / SONIC

Read Bit meaning

Function Type Bit Combination Default

Error indication,

explanation see below this

Latched D0 0: normal operation

1: fail function

table

Overtemperature warning Not latched D1 0: normal operation

1: prewarning

Status of Tracker Output

Q_T[1:6],only if output is

ON

Not latched D2

D3

D4

D5

D6

D7

1: settled output

voltage

0:Tracker turned

off or shorted

output. Also open

load may possibly

be indicated as 0.

Indication of cold start/

warm start, Q_LDO1

Indication of cold start/

warm start, Q_LDO2

Indication for open or

closed window

Latched D8 0: cold start

1: warm start

Latched D9 0: cold start

1: warm start

Not latched D10 0: open window

1: closed window

0

0

1

1)

0

0

0

Reset condition at output

Q_LDO1

Reset condition at output

Q_LDO2

Reset condition at output

Q_LDO3

Not latched D11 0: normal operation

1: Reset R1

Not latched D12 0: normal operation

1: Reset R2

Not latched D13 0: normal operation

1: Reset R3

Watchdog Error Latched D14 0: normal operation

1: WD error

DC/DC converter status Not latched D15 0: off

1: on

1)

Min. load current to avoid ’0’ si gnal caused by open load is 2mA.

0

0

0

0

1

Data Sheet, Rev. 1.32 19 2004-10-15

2.12.4 SPI Timings

CS High to Low & rising edge of CLK: DO is enabled.

Status information is transferred to Output Shift Register

C

S

TLE 6368 / SONIC

e.g.

T

c

r

a

o

CLK

DI

DO

c

k

r

t

n

CS Low to High: Data from Register

time

are transferred to e.g. Trackers

0

Data In (N)

D2 D3

D1D0

151413321

01

Data In (N+1)

D1

D15D14D13

D0

+

+

DI: Data will be accepted on the falling edge of CLK-Signal

Data Out (N)

D1

D0

D0

Data Out (N-1)

D3D2D1

D15D14D13

DO: State will change on the rising edge of CLK-Signal

-

e

r

l

o

Setting (N-1)

Setting (N)

e.g.

-

r

e

T

s

r

k

a

c

s

u

t

a

t

Status (N-1)

Status (N)

Figure 10 SPI Data Transfer Timing

Data Sheet, Rev. 1.32 20 2004-10-15

TLE 6368 / SONIC

Figure 11 SPI-Input Timing

t

rIN

CLK

DO

DO

(low to high)

t

VADO

(high to low)

t

<10ns

fIN

0.7 V

Q_LDO1

50%

0.2 V

Q_LDO1

t

rDO

90%

10%

t

fDO

90%

10%

Figure 12 DO Valid Data Delay Time and Valid Time

Data Sheet, Rev. 1.32 21 2004-10-15

TLE 6368 / SONIC

t

fIN

CS

DO

t

ENDO

DO

Figure 13 DO Enable and Disable Time

t

DISDO

t

rIN

<10ns

10k

Ω

Pullup

to V

Q_LDO1

10k

Ω

Pulldown

to GND

0.7 V

50%

0.2 V

50%

50%

Q_LDO1

Q_LDO1

Data Sheet, Rev. 1.32 22 2004-10-15

TLE 6368 / SONIC

3 Characteristics

3.1 Absolute Maximum Ratings

Item Parameter Symbol Limit Values Unit Test Condition

Min. Max.

3.1.1 Supply Voltage Input IN

Voltage

Voltage

Current

V

V

I

IN

IN

IN

-0.5 60

-1.0 60

––

V

V

–

3.1.2 Buck-Switch Output SW

Voltage

Current

V

I

SW

SW

-2 VS+0.5

––

V

–

3.1.3 Feedback and Linear Voltage Regulator Input

Voltage

Current

V

FB/L_IN

I

FB/L_IN

-0.5 8

––

V

–

3.1.4 Bootstrap Connector Bootstrap

Voltage

Voltage V

Current I

V

Bootstrap

Bootstrap

Bootstrap

V

SW

0.5V

-

V

SW

10V

+

-0.5 70

––

V

V

–

–

Tj = -40 °C

–

–

Internally limited

3.1.5 Boost Input

Voltage

Current

V

Boost

I

Boost

-0.5 60

––

V

–

–

Internally limited

3.1.6 Slope Control Input Slew

Voltage

Current

V

I

Slew

Slew

-0.5 6

––

V

–

–

Internally limited

3.1.7 Charge Pump Capacitor Connector C-

Voltage

V

CL

-0.5 V

FB/L_IN

V

+0.5

Current I

Data Sheet, Rev. 1.32 23 2004-10-15

CL

-150 +150

mA

3.1.8 Charge Pump Capacitor Connector C+

TLE 6368 / SONIC

Voltage

Current I

V

CH

CH

-0.5 13

-150 +150 mA

3.1.9 Charge Pump Storage Capacitor CCP

Voltage

Current I

V

CCP

CCP

-0.5 12

-150 –

3.1.10 Standby Voltage Regulator output Q_STB

Voltage

Current

V

Q_Stb

I

Q_Stb

-0.5 6

––

3.1.11 Voltage Regulator output voltage Q_LDO1

Voltage

Current

V

Q_LDO1

I

Q_LDO1

-0.5 6

––

3.1.12 Voltage Regulator output voltage Q_LDO2

Voltage

Current

V

Q_LDO2

I

Q_LDO2

-0.5 6

––

V

V

mA

V

–

V

–

V

–

–

Internally limited

–

Internally limited

–

Internally limited

3.1.13 Voltage Regulator output voltage Q_LDO3

Voltage

Current

V

Q_LDO3

I

Q_LDO3

-0.5 6

––

3.1.14 Voltage Tracker output voltage Q_T1

Voltage

Current

V

Q_T1

I

Q_T1

-5 60

––

3.1.15 Voltage Tracker output voltage Q_T2

Voltage

Current

V

Q_T2

I

Q_T2

-5 60

––

3.1.16 Voltage Tracker output voltage Q_T3

Voltage

Current

V

Q_T3

I

Q_T3

-5 60

––

3.1.17 Voltage Tracker output voltage Q_T4

Voltage

V

Q_T4

-5 60

V

–

V

mA

V

mA

V

mA

V

–

Internally limited

–

Internally limited

–

Internally limited

–

Internally limited

–

Current

Data Sheet, Rev. 1.32 24 2004-10-15

I

Q_T4

––

mA

Internally limited

3.1.18 Voltage Tracker output voltage Q_T5

TLE 6368 / SONIC

Voltage

Current

V

Q_T5

I

Q_T5

-5 60

––

3.1.19 Voltage Tracker output voltage Q_T6

Voltage

Current

V

Q_T6

I

Q_T6

-5 60

––

3.1.20 Select Input SEL

Voltage

Current

V

I

SEL

SEL

-0.5 6

––

3.1.21 Wake Up Input Wake

Voltage

Current

V

Wake

I

Wake

-0.5 60

––

3.1.22 Reset Output R1

Voltage

Current

V

I

R1

R1

-0.5 6

––

V

mA

V

mA

V

–

V

–

V

–

–

Internally limited

–

Internally limited

–

Internally limited

–

–

3.1.23 Reset Output R2

Voltage

Current

V

I

R2

R2

3.1.24 Reset Output R3

Voltage

Current

V

I

R3

R3

3.1.25 SPI Data Input DI

Voltage

Current

V

I

DI

DI

3.1.26 SPI Data Output DO

Voltage

Current

V

I

DO

DO

3.1.27 SPI Clock Input CLK

Voltage

V

CLK

-0.5 6

––

-0.5 6

––

-0.5 6

––

-0.5 6

––

-0.5 6

V

–

V

–

V

–

V

–

V

–

–

–

–

Internally limited

–

Current

Data Sheet, Rev. 1.32 25 2004-10-15

I

CLK

––

–

3.1.28 SPI Chip Select Not Input CS

TLE 6368 / SONIC

Voltage V

Current

CS

I

CS

3.1.29 Error Output Pin

Voltage

Current

V

I

ERR

ERR

3.1.30 Thermal Resistance

Junction-

R

thja

ambient

Junction-

R

thja

ambient

Junction-

R

thjc

case

3.1.31 Temperature

Junction

T

j

temperature

Junction

T

jt

temperature

transient

-0.5 6

––

-0.5 6

––

37

29

V

–

V

–

K/W

K/W

–

–

Internally limited

1)

PCB heat sink area

300mm

1)

PCB heat sink area

600mm

2

2

– 2 K/W

-40 150 °C

175 °C lifetime=TBD

Storage

T

stg

-50 150 °C

temperature

3.1.32 ESD

ESD V

1) Package mounted on FR4 47x50x1.5mm3; 70µ Cu, zero airflow

ESD

-1 1 kV HBM-Model

Note: Maximum ratings are absol ute ratings; exceeding any one of thes e values may

cause irreversible damage to the integrated circuit.

Data Sheet, Rev. 1.32 26 2004-10-15

3.2 Functional Range

TLE 6368 / SONIC

-40°C < T

< 150 °C

j

Item Parameter Symbol Limit Values Unit Condition

min. max.

Supply

Voltage

Supply

V

IN, min

V

IN, max

5.5 V VIN increased from

0V;

WAKE

=5V;

=400mA;

=200mA

V

I

Q_LDO1

I

Q_LDO2

60 V

Voltage

Ripple at

FB/L_IN

V

FB/L_IN

ripple

0150mV

PP

Note: Within the functional range the IC can be operated . The electrical characteristics,

however, are not guaranteed over this full functional range.

Data Sheet, Rev. 1.32 27 2004-10-15

3.3 Recommended Operation Range

TLE 6368 / SONIC

-40°C < T

< 150 °C

j

Item Parameter Symbol Limit Values Unit Condition

min. typ. max.

Buck

L

B

18 100 µH

1)

Inductor

Buck

Capacitor

C

B

10 µF ESR <0.15 Ω,

ceramic

capacitor (X7R)

recommended

Bootstrap

C

BTP

2% of C

B

Capacitor

SLEW

R

SLEW

020kΩ

resistor

Linear

regulator

C

Q_LDO1-3

470 nF ceramic

capacitor (X7R)

capacitors

Tracker

bypass

C

Q_T1-6

1µFceramic

capacitor (X7R)

capacitors

1)

SPI rise and

t

r,f

200 ns

fall timings,

CS

, DI, CLK

1)

C

needs about LB=47µH to avoid instabilities

B, min

Data Sheet, Rev. 1.32 28 2004-10-15

TLE 6368 / SONIC

3.4 Electrical Characteristics

The electrical characteristics involve the spread of values guaranteed within the

specified supply voltage and ambient temperature range. Typic al values represent the

median values at room temperature, which are related to production processes.

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

Buck regulator

3.4.1 Switching

f

SW

280 370 425 kHz

frequency

3.4.2 Current

t

r_I_SW

20 ns RSL=0Ω;

1)

transition

time, min.,

rising edge

3.4.3 Current

t

r_I_SW

100 ns RSL=20kΩ;

1)

transition

time, max.,

rising edge

3.4.4 Current

t

f_I_SW

20 ns RSL=0Ω;

1)

transition

time, min.,

falling edge

3.4.5 Current

t

f_I_SW

100 ns RSL=20kΩ;

1)

transition

time, max.,

falling edge

3.4.6 Voltage rise /

t

f_V_SW

25 ns

1)

fall time

3.4.7 Static on

resistance

3.4.8 Static on

resistance

3.4.9 Current limit I

3.4.10 Output

voltage

Data Sheet, Rev. 1.32 29 2004-10-15

R

R

MAX

V

ON

ON

OUT

160 mΩ Tj=25°C

in static operation

280 400 mΩ Tj=150°C

in static operation

1.5 3.2 A V

5.40 6.05 V I

V

FB/L_IN

=1.5A

OUT

=13.5 V

IN

=5.4V

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.11 Output

voltage

3.4.12 Bootstrap

V

OUT

I

BTSTR

5.4 6.3 V I

80 160 220 µA

OUT

=13.5 V

V

IN

=0.1A

charging

current at

start-up

3.4.13 Bootstrap

voltage

(internal

V

BTSTR

10 15 V V

FB/L_IN

=6.5V,

Buck converter

off

charge

pump)

3.4.14 Bootstrap

undervoltage

V

BTSTR,

turn on

59V

lockout, Buck

turn on

threshold

3.4.15 Bootstrap

undervoltage

lockout,

hysteresis

3.4.16 External

charge

pump

voltage

3.4.17 Max. Duty

Cycle

3.4.18 Min. Duty

Cycle

Voltage Regulator Q_LDO1

3.4.19 Output

voltage

3.4.20 Output

voltage

V

BTSTR,

turn on

V

BTSTR,

turn off

V

CCP

duty

duty

V

Q1

V

Q1

-

max

min

2.5 V

7.9 11.0 V I

Q_LDO1

V

C

C

FB/L_IN

=100nF,

FLY

=220nF

CCP

= 800mA,

=6.0V,

95 % Switching

operation

0%Static-off

operation

4.9 5.1 V 100mA < I

< 800mA

5.0 V I

Q_LDO1

= 800mA

Q_LDO1

Data Sheet, Rev. 1.32 30 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.21 Load

Regulation

3.4.22 Current limit I

3.4.23 Ripple

∆V

Q_LDO1

40 mV 100mA< I

<800mA;

=5.5V

=4V

Q_LDO1limit

V

800 1050 1400 mA V

FB/L_IN

Q_LDO1

PSRR1 26 40 dB f=330kHz;

Q_LDO1

1)

rejection

3.4.24 Output

Capacitor

C

Q_LDO1

470 nF Ceramic type,

value for stability

Voltage Regulator Q_LDO2

3.4.25 Output

voltage 3.3V

V

Q_LDO2

3.14 3.46 V 50mA < I

400mA;

Q_LDO2

3.3V mode

3.4.26 Output

voltage 3.3V

V

Q_LDO2

3.32 V I

Q_LDO2

=400mA;

3.3V mode

<

3.4.27 Output

voltage 2.6V

3.4.28 Output

voltage 2.6V

3.4.29 Output

voltage 2.6V

3.4.30 Load

Regulation

3.4.31 Load

Regulation

3.4.32 Current limit I

V

Q_LDO2

V

Q_LDO2

V

Q_LDO2

∆V

Q_LDO2

∆V

Q_LDO2

Q_LDO2limit

2.500 2.750 V 50mA < I

400mA;

2.6V mode

2.62 V I

Q_LDO2

=400mA;

2.6V mode

2.50 2.70 V 85mA < I

400mA;

2.6V mode

50 mV 50mA< I

<400mA;

V

FB/L_IN

=5.5V

3.3V mode

50 mV 50mA< I

<400mA;

V

FB/L_IN

=5.5V

2.6V mode

500 650 850 mA V

Q_LDO2

3.3V mode

Q_LDO2

Q_LDO2

Q_LDO2

Q_LDO2

= 2.8V;

<

<

3.4.33 Current limit I

Q_LDO2limit

500 650 850 mA V

Q_LDO2

= 2V;

2.6V mode

Data Sheet, Rev. 1.32 31 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.34 Ripple

PSRR2 26 40 dB f=330kHz;

1)

rejection

3.4.35 Output

Capacitor

C

Q_LDO2

470 nF Ceramic type,

value for stability

Voltage Regulator Q_LDO3

3.4.36 Output

voltage 3.3V

V

Q_LDO3

3.14 3.46 V 20mA < I

300mA;

Q_LDO3

3.3V mode

3.4.37 Output

voltage 3.3V

3.4.38 Output

voltage 2.6V

V

Q_LDO3

V

Q_LDO3

3.32 V I

Q_LDO3

=300mA;

3.3V mode

2.500 2.750 V 20mA < I

300mA;

Q_LDO3

2.6V mode

<

<

3.4.39 Output

voltage 2.6V

3.4.40 Load

Regulation

3.4.41 Load

Regulation

3.4.42 Current limit I

3.4.43 Current limit I

3.4.44 Ripple

rejection

3.4.45 Output

Capacitor

V

Q_LDO3

2.625 V I

Q_LDO3

=300mA;

2.6V mode

∆V

Q_LDO3

30 mV 20mA< I

Q_LDO3

<300mA;

V

FB/L_IN

=5.5V

3.3V mode

∆V

Q_LDO3

30 mV 20mA< I

Q_LDO3

<300mA;

V

FB/L_IN

=5.5V

2.6V mode

Q_LDO3

limit

Q_LDO3

limit

350 500 600 mA V

3.3V mode

350 500 600 mA V

2.6V mode

Q_LDO3

Q_LDO3

=4V;

=2.8V;

PSRR3 26 40 dB f=330kHz;

C

Q_LDO3

470 nF Ceramic type,

value for stability

1)

Voltage Tracker Q_T1

Data Sheet, Rev. 1.32 32 2004-10-15

TLE 6368 / SONIC

-40 < Tj <150 °C; VIN=13.5V unless otherwise specified

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.46 Output

voltage

tracking

accuracy

3.4.47 Output

voltage

tracking

accuracy

3.4.48 Overvoltage

threshold

3.4.49 Undervoltage

threshold

3.4.50 Current limit I

3.4.51 Ripple

rejection

3.4.52 Tracker load

capacitor

∆V

Q_T1

-15 -2 5 mV V

1mA < I

Q_T1-VQ_LDO1

Q_T1

17mA

∆V

Q_T1

V

OVQ_T1

V

UVQ_T1

-10 mV V

I

V

Q_T1,

nom

V

Q_T1

-

mV I

mV

1)

Q_T1-VQ_LDO1

= 17mA

Q_T1

= 0mA; 1)

Q_T1

15mV

Q_T1 limit

17 30 mA V

Q_T1

=4V

PSRR 26 dB f=330kHz;

C

Q_T1

1 µF Ceramic type,

minimum for

stability

;

<

;

1)

Voltage Tracker Q_T2

3.4.53 Output

voltage

tracking

accuracy

3.4.54 Output

voltage

tracking

accuracy

3.4.55 Overvoltage

threshold

3.4.56 Undervoltage

threshold

3.4.57 Current limit I

3.4.58 Ripple

rejection

∆V

Q_T2

-15 -2 5 mV V

1mA < I

Q_T2-VQ_LDO1

Q_T2

17mA

∆V

Q_T2

V

OVQ_T2

V

UVQ_T2

-10 mV V

I

V

Q_T2,

nom

V

Q_T2

-

mV I

mV

1)

Q_T2-VQ_LDO2

= 17mA

Q_T2

= 0mA;

Q_T2

15mV

Q_T2 limit

17 30 mA V

Q_T2

=4V

PSRR 26 dB f=330kHz;

;

<

;

1)

1)

Data Sheet, Rev. 1.32 33 2004-10-15

TLE 6368 / SONIC

-40 < Tj <150 °C; VIN=13.5V unless otherwise specified

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3. 4 .5 9 Tracker load

capacitor

Voltage Tracker Q_T3

3.4.60 Output

voltage

tracking

accuracy

3.4.61 Output

voltage

tracking

accuracy

3.4.62 Overvoltage

threshold

3.4.63 Undervoltage

threshold

C

Q_T2

∆V

Q_T3

∆V

Q_T3

V

OVQ_T3

V

UVQ_T3

1 µF Ceramic type,

minimum for

stability

-15 -2 5 mV V

Q_T3-VQ_LDO1

1mA < I

Q_T3

<

17mA

-10 mV V

V

Q_T3,

nom

V

Q_T3

-

mV I

mV

Q_T3-VQ_LDO3

I

= 17mA

Q_T3

= 0mA;

Q_T3

1)

1)

15mV

;

;

3.4.64 Current limit I

3.4.65 Ripple

rejection

3. 4 .6 6 Tracker load

capacitor

Voltage Tracker Q_T4

3.4.67 Output

voltage

tracking

accuracy

3.4.68 Output

voltage

tracking

accuracy

3.4.69 Overvoltage

threshold

Q_T3 limit

17 30 mA V

Q_T3

=4V

PSRR 26 dB f=330kHz;

C

Q_T3

1 µF Ceramic type,

minimum for

stability

∆V

Q_T4

-15 -2 5 mV V

Q_T4-VQ_LDO1

1mA < I

Q_T4

17mA

∆V

Q_T4

V

OVQ_T4

-8 mV V

I

V

Q_T4,

nom

mV I

Q_T4-VQ_LDO4

= 17mA

Q_T4

= 0mA;

Q_T4

1)

;

<

;

1)

Data Sheet, Rev. 1.32 34 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.70 Undervoltage

threshold

3.4.71 Current limit I

3.4.72 Ripple

V

UVQ_T4

V

Q_T4

-

mV

15mV

Q_T4 limit

17 30 mA V

PSRR 26 dB f=330kHz;

1)

Q_T4

=4V

1)

rejection

3.4.73 Tracker load

capacitor

C

Q_T4

1 µF Ceramic type,

minimum for

stability

Voltage Tracker Q_T5

3.4.74 Output

voltage

tracking

∆V

Q_T5

-15 -1 5 mV V

1mA < I

17mA

Q_T5-VQ_LDO1

<

Q_T5

;

accuracy

3.4.75 Output

voltage

tracking

accuracy

3.4.76 Overvoltage

threshold

3.4.77 Undervoltage

threshold

3.4.78 Current limit I

3.4.79 Ripple

rejection

3.4.80 Tracker load

capacitor

Voltage Tracker Q_T6

3.4.81 Output

voltage

tracking

accuracy

∆V

Q_T5

V

OVQ_T5

V

UVQ_T5

-9 mV V

I

V

Q_T5,

nom

V

Q_T5

-

mV I

mV

1)

Q_T5-VQ_LDO5

= 17mA

Q_T5

= 0mA;

Q_T5

15mV

Q_T5 limit

17 30 mA V

Q_T5

=4V

PSRR 26 dB f=330kHz;

C

Q_T5

1 µF Ceramic type,

minimum for

stability

∆V

Q_T6

-15 -1 5 mV V

1mA < I

Q_T6-VQ_LDO1

Q_T6

17mA

;

1)

1)

;

<

Data Sheet, Rev. 1.32 35 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.82 Output

voltage

∆V

Q_T6

-9 mV V

I

Q_T6-VQ_LDO6

= 17mA

Q_T6

;

tracking

accuracy

3.4.83 Overvoltage

V

OVQ_T6

V

Q_T6

mV I

Q_T6

= 0mA;

1)

threshold

3.4.84 Undervoltage

threshold

3.4.85 Current limit I

3.4.86 Ripple

V

UVQ_T6

V

Q_T6

-

mV

15mV

Q_T6 limit

17 30 mA V

PSRR 26 dB f=330kHz;

1)

Q_T6

=4V

1)

rejection

3. 4 .8 7 Tracker load

capacitor

C

Q_T6

1 µF Ceramic type,

minimum for

stability

Standby Regulator

3.4.88 Output

voltage

3.4.89 Current limit I

3.4.90 Standby

load

capacitor

Current consumption in off-mode and Wake block

3.4.91 Supply

current from

battery

3.4.92 Supply

current from

battery

3.4.93 Turn on

Wake-up

threshold

V

Q_STB

Q_STB limit

C

Q_STB

I

q,off

I

q,off

V

wake th, on

2.2 2.4 2.6 V 0µA

Q_STB

<500µA

=2V

<I

136mAV

Q_STB

100 nF Ceramic type,

minimum for

stability

10 30 µA VIN=13.5V,

=0

V

wake

I

Q_STB

=0µA

10 30 µA VIN=42V,

V

=0

wake

I

2.4 2.8 V V

=0µA

Q_STB

increasing

wake

Data Sheet, Rev. 1.32 36 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.94 Turn off

V

wake th, off

1.8 2.35 V V

decreasing

wake

Wake-up

threshold

3.4.95 Wake-up

I

wake

50 150 µA V

wake

=5V

input current

3.4.96 W ake up

input on time

t

wake,min

41050µsV

V

>

wake

wake th, max

1)

;

Reset R1

3.4.97 Reset

threshold

V

RTH

Q_LDO1, de

4.5 4.65 4.8 V V

decreasing

Q_LDO1

Q_LDO1

3.4.98 Reset

threshold

V

RTH

Q_LDO1, in

4.55 4.70 4.9 V V

increasing

Q_LDO1

Q_LDO1

3.4.99 Reset output

low voltage

3.4.100 Reset output

low voltage

3.4.101 Reset output

low sink

current

3.4.102 Reset High

leakage

current

Reset R2

3.4.103 Reset

threshold

Q_LDO2

3.4.104 Reset

threshold

hysteresis

Q_LDO2

V

R1 L

V

R1 L

I

R1 L

I

R1 H

V

RTH

Q_LDO2, de

V

RTH

Q_LDO2, in

V

RTH

Q_LDO2, de

0.4 V IR1=1.6mA;

V

Q_LDO1

0.3 V IR1=0.3mA;

V

Q_LDO1

10 µA V

Q_LDO1

> 25°C

T

j

1µA

2.6 2.8 3.0 V 3.3V mode;

V

Q_LDO2

decreasing

40 mV 3.3V mode

-

=5V

=1V

=0.75V;

Data Sheet, Rev. 1.32 37 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.105 Reset

threshold

Q_LDO2

3.4.106 Reset

threshold

hysteresis

Q_LDO2

3.4.107 Reset output

low voltage

3.4.108 Reset output

low voltage

3.4.109 Reset output

low sink

V

RTH

Q_LDO2, de

V

RTH

Q_LDO2, in

V

RTH

Q_LDO2, de

V

R2 L

V

R2 L

I

R2 L

2.3 2.4 2.5 V 2.6V mode;

V

Q_LDO2

decreasing

40 mV 2.6V mode

-

0.4 V IR2=1.6mA;

V

Q_LDO2

0.3 V IR2=0.3mA;

V

Q_LDO2

10 µA V

Q_LDO2

> 25°C

T

j

=2.5V

=1V

=0.75V;

current

3.4.110 Reset High

leakage

current

Reset R3

3.4.111 Reset

threshold

Q_LDO3

3.4.112 Reset

threshold

hysteresis

Q_LDO3

3.4.113 Reset

threshold

Q_LDO3

3.4.114 Reset

threshold

hysteresis

Q_LDO3

I

R2 H

V

RTH

Q_LDO3, de

V

RTH

Q_LDO3, in

V

RTH

Q_LDO3, de

V

RTH

Q_LDO3, de

V

RTH

Q_LDO3, in

V

RTH

Q_LDO3, de

1µA

2.7 2.85 3.0 V 3.3V mode;

V

Q_LDO3

decreasing

40 mV 3.3V mode

-

2.3 2.35 2.5 V 2.6V mode;

V

Q_LDO3

decreasing

40 mV 2.6V mode

-

3.4.115 Reset output

V

R3 L

low voltage

Data Sheet, Rev. 1.32 38 2004-10-15

0.4 V IR3=1.6mA;

V

Q_LDO3

=3.3V

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.116 Reset output

low voltage

3.4.117 Reset output

low sink

V

I

R3 L

R3 L

0.3 V IR3=0.3mA;

V

10 µA V

T

Q_LDO3

Q_LDO3

> 25°C

j

=1V

=0.75V;

current

3.4.118 Reset High

I

R3 H

1µA

leakage

current

3.4.119 Reset

reaction time

t

rr

1210µs

1)

Valid for R1, R2

and R3

3.4.120 Reset Delay

t

NORM,RES

0.75 1 1.25 1

Norm factor

3.4.121 Reset Delay

time

t

RES

0.75 1 1.25 t

RES(SPI)

Valid for R1, R2

and R3; t

RES (SPI)

is defined by the

SPI word (see

section 2.12)

RAM Good

3.4.122 V

3.4.123 V

3.4.124 V

threshold V

Q1

threshold V

Q2

threshold V

Q2

Window Watchdog

3.4.125 Closed

window time

tolerance

3.4.126 Open

window time

tolerance

Th Q1

Th Q2

Th Q2

t

CW_tol

t

OW_tol

2.3 2.8 3.3 V

1.2 1.4 1.7 V 3.3V mode

1.2 1.4 1.7 V 2.6V mode;

0.75 1 1.25 Multiply with

watchdog

window time set

by SPI to obtain

the limits (2.12)

0.75 1 1.25 Multiply with

watchdog

window time set

by SPI to obtain

the limits (2.12)

1)

Data Sheet, Rev. 1.32 39 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.127 Watchdog

t

WRL

t

RES

reset low

time

3.4.128 Watchdog

t

SR

tCW/2

reset delay

time

Error Output ERR

3.4.129 H-output

voltage level

3.4.130 L-output

V

V

ERR,H

ERR,L

V

– 2.0

Q_LDO1

V

Q_LDO1

– 0.7

–VI

–0.30.5VI

ERR, H

ERR, L

=1 mA

=– 1.6 mA

voltage level

SPI

3.4.131 SPI clock

frequency

f

CLK

02.5MHzProduction test

up to 1MHz;

For 2.5MHz:

1)

SPI Input DI

3.4.132 H-input

voltage

threshold

3.4.133 L-input

voltage

threshold

3.4.134 Hysteresis of

input voltage

3.4.135 Pull down

current

3.4.136 Input

capacitance

3.4.137 Input signal

rise time

3.4.138 Input signal

fall time

V

V

V

I

C

t

t

–

–

1)

V

Q_LDO1

Q_LDO1

<

IH

IL

IHY

I

I

–4070% of

V

Q_LDO1

20

36 – % of

V

Q_LDO1

50 200 500 mV

5 25 100 µA VDI = 0.2 *

–1015pF0V < V

5.25 V

r

f

– – 200 ns

– – 200 ns

1)

1)

SPI Clock Input CLK

Data Sheet, Rev. 1.32 40 2004-10-15

TLE 6368 / SONIC

-40 < Tj <150 °C; VIN=13.5V unless otherwise specified

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.139 H-input

voltage

threshold

3.4.140 L-input

voltage

threshold

3.4.141 Hysteresis of

input voltage

3.4.142 Pull down

current

3.4.143 Input

capacitance

3.4.144 Input signal

rise time

3.4.145 Input signal

fall time

SPI Chip Select Input CS

V

V

V

I

C

t

t

IH

IL

IHY

I

I

–4070% of

V

Q_LDO1

20

36 – % of

V

Q_LDO1

50 200 500 mV

525100µA V

–1015pF0V < V

–

–

1)

CLK

V

Q_LDO1

= 0.2 *

Q_LDO1

<

5.25 V

r

f

– –200ns

– –200ns

1)

1)

3.4.146 H-input

voltage

threshold

3.4.147 L-input

voltage

threshold

3.4.148 Hysteresis of

input voltage

3.4.149 Pull up

current at pin

CS

3.4.150 Input

capacitance

3.4.151 Input signal

rise time

3.4.152 Input signal

fall time

V

V

V

I

I, CS

C

t

r

t

f

IH

IL

IHY

I

–3970% of

V

Q_LDO1

20

35 – % of

V

Q_LDO1

50 200 500 mV

–

–

1)

– 100 – 25 – 5 µA VCS = 0.2 *

V

Q_LDO1

–1015pF0V < V

Q_LDO1

5.25 V

– –200ns

– –200ns

1)

1)

<

Data Sheet, Rev. 1.32 41 2004-10-15

TLE 6368 / SONIC

-40 < T

<150 °C; VIN=13.5V unless otherwise specified

j

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

Logic Output DO

3.4.153 H-output

voltage level

3.4.154 L-output

V

V

DOH

DOL

V

– 1.0

Q_LDO1

V

Q_LDO1

– 0.8

–VI

– 0.2 0.4 V I

=1 mA

DOH

= – 1.6 mA

DOL

voltage level

3.4.155 Tri-state

leakage

current

3.4.156 Tri-state

input

capacitance

I

DO_TRI

C

DO

– 10 – 10 µA VCS = V

0V < V

V

Q_LDO1

–1015pFVCS=V

0V < V

5.25 V

Q_LDO1

DO

Q_LDO1

Q_LDO1

<

<

;

Data Input Timing

3.4.157 Clock period

3.4.158 Clock high

time

3.4.159 Clock low

time

3.4.160 Clock low

before CS

low

3.4.161 CS setup

time

3.4.162 CLK setup

time

3.4.163 Clock low

after CS

high

3.4.164 DI setup time t

3.4.165 DI hold time t

t

pCLK

t

CLKH

t

CLKL

t

bef

t

lead

t

lag

t

beh

DISU

DIHO

1000 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

250 – – ns

250 – – ns

1)

1)

1)

1)

1)

1)

1)

1)

1)

Data Output Timing

Data Sheet, Rev. 1.32 42 2004-10-15

TLE 6368 / SONIC

-40 < Tj <150 °C; VIN=13.5V unless otherwise specified

Item Parameter Symbol Limit Values Unit Test Conditions

min. typ. max.

3.4.166 DO rise time t

3.4.167 DO fall time

3.4.168 DO enable

time

3.4.169 DO disable

time

3.4.170 DO valid time

General

3.4.171 Temperature

warning flag

3.4.172 Over

Temperature

shutdown

3.4.173 Over-

Temperature

shutdown

Hysteresis

rDO

t

fDO

t

ENDO

t

DISDO

t

VADO

T

J,Flag

T

J,Shutdown

∆T

sd_hys

–50100nsCL = 100 pF

–50100nsCL = 100 pF

– –250nslow impe dan ce

– –250nshigh impedance

–100250nsVDO < 10%

V

> 90%

DO

= 100 pF

C

L

140 °C

150 170 200 °C

2)

2)

30 K

3.4.174 Delta of TWF

to TSD

1)

Specified by design, not s ubject to production test

2)

Simulated at w afer test only, no t absolutely measured

Data Sheet, Rev. 1.32 43 2004-10-15

T

J,Shutdown

- T

J,Flag

20 K

4 Typical performance

charcteristics

TLE 6368 G1 / SONIC

Buck converter switching frequency

vs. junction temperature

420

f

SW

kHz

400

380

360

340

320

300

280

-50 -20 10 40 70 100 130 160

°C

Buck convert er DMOS on-resistance

vs. junction temperature

400

R

ON

m

Ω

350

300

250

200

150

100

50

T

j

-50 -20 10 40 70 100 130 160

°C

T

j

Buck converter output voltage at 1.5A load

vs. junction temperature

6.0

V

FB/L_IN

V

5.9

5.8

5.7

5.6

5.5

5.4

5.3

-50 -20 10 40 70 100 130 160

°C

T

j

Buck converter current limit

vs. junction temperature

4.0

I

MAX

A

3.5

3.0

2.5

2.0

1.5

1.0

0.5

-50 -20 10 40 70 100 130 160

°C

T

j

Data Sheet, Rev. 1.32 44 2004-10-15

TLE 6368 G1 / SONIC

Start-up bootstrap charging current

vs. junction temperature

280

I

BTSTR

µA

240

200

160

120

80

40

0

-50 -20 10 40 70 100 130 160

T

°C

Bootstrap UV lockout, turn on threshold

vs. junction temperature

V

8.5

BTSTR,

turn on

V

8.0

7.5

7.0

6.5

6.0

5.5

5.0

j

-50 -20 10 40 70 100 130 160

T

°C

j

Device start-up voltage (acc. to spec. 3.2)

vs. junction temperature

6.0

V

IN

V

5.5

5.0

4.5

4.0

3.5

3.0

2.5

-50 -20 10 40 70 100 130 160

°C

T

j

Device wake up thresholds

vs. junction temperature

wake th

V

2.8

2.7

2.6

2.5

V

2.4

2.3

2.2

2.1

-50 -20 10 40 70 100 130 160

wake th , on

V

V

wake th, off

T

°C

j

Data Sheet, Rev. 1.32 45 2004-10-15

TLE 6368 G1 / SONIC

Q_LDO1 output voltage at 800mA load

vs. junction temperature

5.20

V

Q_LDO 1

V

5.15

5.10

5.05

5.00

4.95

4.90

4.85

-50 -20 10 40 70 100 130 160

°C

Q_LDO1 current limit

vs. junction temperature

1400

I

Q_LDO1

V

1300

1200

1100

1000

900

800

700

T

j

-50 -20 10 40 70 100 130 160

°C

T

j

Reset1 threshold at decreasing V_LDO1

vs. junction temperature

V

4.80

RTH

Q_LDO1, de

V

4.75

4.70

4.65

4.60

4.55

4.50

4.45

-50 -20 10 40 70 100 130 160

T

°C

Q_LDO2 output voltage at 400mA load

(2.6V mode) vs. junction temperature

2.80

V

Q_LDO2

V

2.75

2.70

2.65

2.60

2.55

2.50

2.45

j

-50 -20 10 40 70 100 130 160

T

°C

j

Data Sheet, Rev. 1.32 46 2004-10-15

TLE 6368 G1 / SONIC

Q_LDO2 current limit (2.6V mode)

vs. junction temperature

850

I

Q_LDO2

V

800

750

700

650

600

550

500

-50 -20 10 40 70 100 130 160

°C

Reset2 threshold at decreasing V_LDO2

(2.6V mode) vs. junction temperature

V

2.60

RTH

Q_LDO2, de

V

2.55

2.50

2.45

2.40

2.35

2.30

2.25

T

j

-50 -20 10 40 70 100 130 160

T

°C

j

Q_LDO3 output voltage at 300mA load

(3.3V mode) vs. junction temperature

3.50

V

Q_LDO 3

V

3.45

3.40

3.35

3.30

3.25

3.20

3.15

-50 -20 10 40 70 100 130 160

°C

Q_LDO3 current limit (3.3V mode)

vs. junction temperature

600

I

Q_LDO3

V

550

500

450

400

350

300

250

T

j

-50 -20 10 40 70 100 130 160

°C

T

j

Data Sheet, Rev. 1.32 47 2004-10-15

TLE 6368 G1 / SONIC

Reset3 threshold at decreasing V_LDO3

(3.3V mode) vs. junction temperature

V

3.00

RTH

Q_LDO3, de

V

2.95

2.90

2.85

2.80

2.75

2.70

2.65

-50 -20 10 40 70 100 130 160

T

°C

Tracker accuracy with respect to V_LDO1

vs. junction temperature

dV

j

4

Q_Tx

mV

2

0

-2

-4

-6

-8

-10

-50 -20 10 40 70 100 130 160

T

°C

j

Tracker current limit

vs. junction temperature

32

I

Q_Tx

mA

30

28

26

24

22

20

18

-50 -20 10 40 70 100 130 160

T

°C

Q_STB output voltage at 500µA load

vs. junction temperature

V

j

2.8

Q_STB

V

2.7

2.6

2.5

2.4

2.3

2.2

2.1

-50 -20 10 40 70 100 130 160

T

°C

j

Data Sheet, Rev. 1.32 48 2004-10-15

TLE 6368 G1 / SONIC

Q_STB current limit

vs. junction temperature

4.0

I

Q_STB

mA

3.5

3.0

2.5

2.0

1.5

1.0

0.5

-50 -20 10 40 70 100 130 160

T

°C

Device current consumption in off mode

vs. junction temperature

35

I

q, off

µA

30

25

20

15

10

5

0

j

-50 -20 10 40 70 100 130 160

°C

T