Page 1

Final Datasheet, Version 2.08, 2004-06-07

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

System Basis Chip

TLE 6263

Integrated

LS CAN, LDO and HS Switch

Automotive and

Industrial

Never stop thinking.

Page 2

CAN-LDO-ASIC TLE 6263

Final Datasheet

1Features

• Standard fault tolerant differential CAN-transceiver

• Bus failure management

• Low power mode management

• Receive only mode for CAN

• CAN data transmission rate up to 125 kBaud

• Low-dropout voltage 5V regulator

• High side switch

• 2 wake-up inputs

• Power on and under-voltage reset generator

• Window watchdog

• Fail-safe output

• Early warning feature (V

• Sense comparator input (V

warning)

CC

INT

warning)

• Standard 8 bit SPI-interface

• Flash program mode

• Wide input voltage range

• Wide temperature range

• Enhanced power P-DSO-Package

P-DSO-28-18

Enhanced Power

Type Ordering Code Package

TLE 6263 G Q67007-A9465 P-DSO-28-18

2 Description

The TLE 6263 is a monolithic integrated circuit in an enhanced power P-DSO-28-18

package. The IC is optimized for use in advanced automotive electronic control units for

body and convenience applications.

To support this applications the TLE 6263 covers the main smart power functions such

as failure tolerant low speed CAN-transceiver for differential mode data transmission,

low dropout voltage regulator (LDO) for internal and external 5V supply as well as a SPI

(serial peripheral interface) to control and monitor the IC. Further there are integrated

additional features like a high side switch that can be used e.g. for cyclic supply of an

external wake-up circuitry, two wake-up inputs, a window watchdog circuit with fail safe

output as well as a reset and early warning feature.

The IC is designed to withstand the severe conditions of automotive applications.

Version 2.08 2 2004-06-07

Page 3

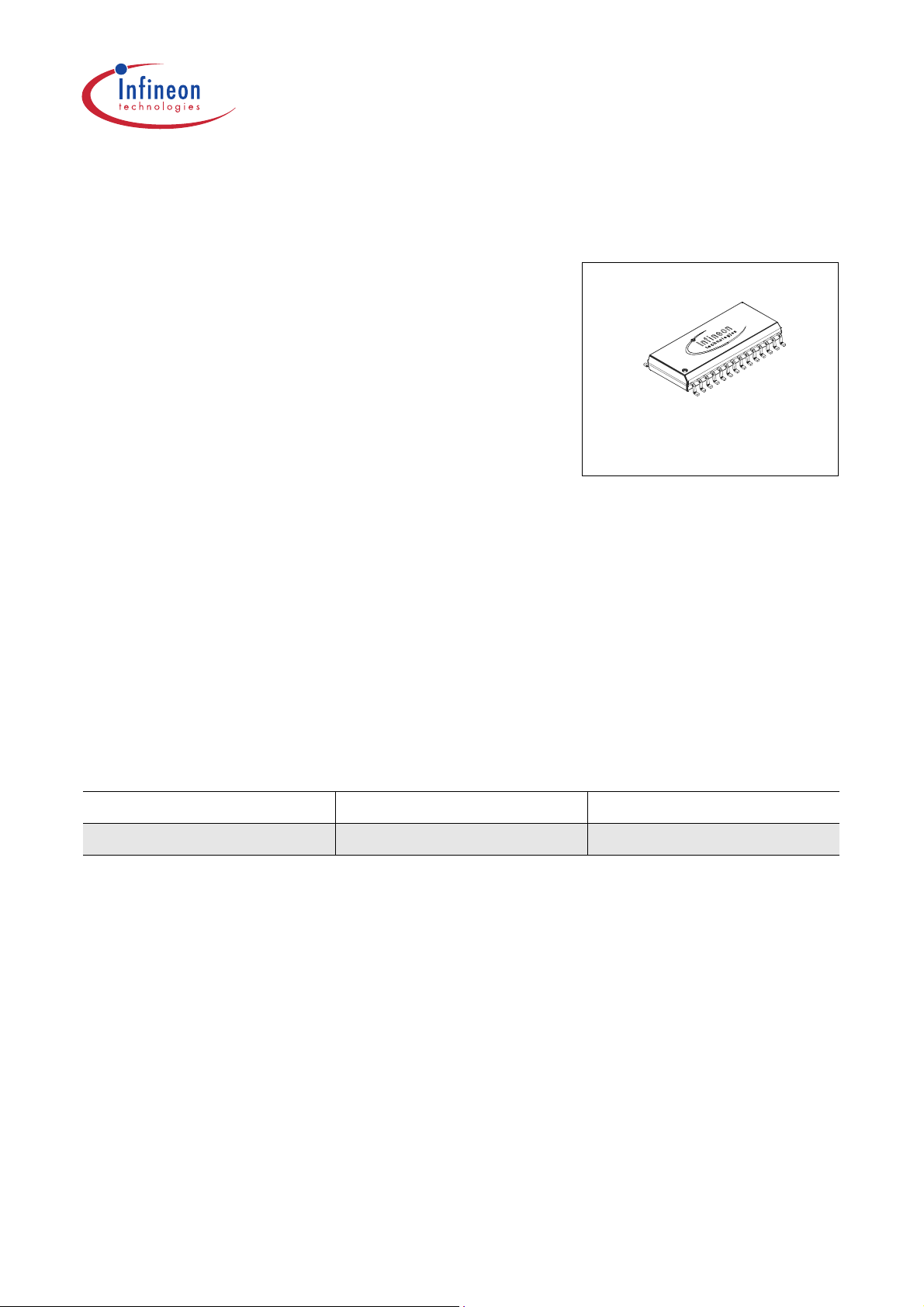

3 Pin Configuration

(top view)

Final Datasheet TLE 6263

TxD

RxD

WK2

WK1

GND GND

GND

GND GND

GND

1

2

(enhanced power package)

3

4

5

6

7

8

9

P-DSO-28-6

28

27

26

25

24

23

22

21

20

INT

RTH

CANHRO

RTL

CANL

GND

GND

DO

CLK

CSN

DI

OUTHS

10

11

12

13

14

19

18

17

16

15

V

CC

V

CI

FSO

SI

V

S

Figure 1: Pin Configuration TLE 6263 G (top view)

Version 2.08 3 2004-06-07

Page 4

Final Datasheet TLE 6263

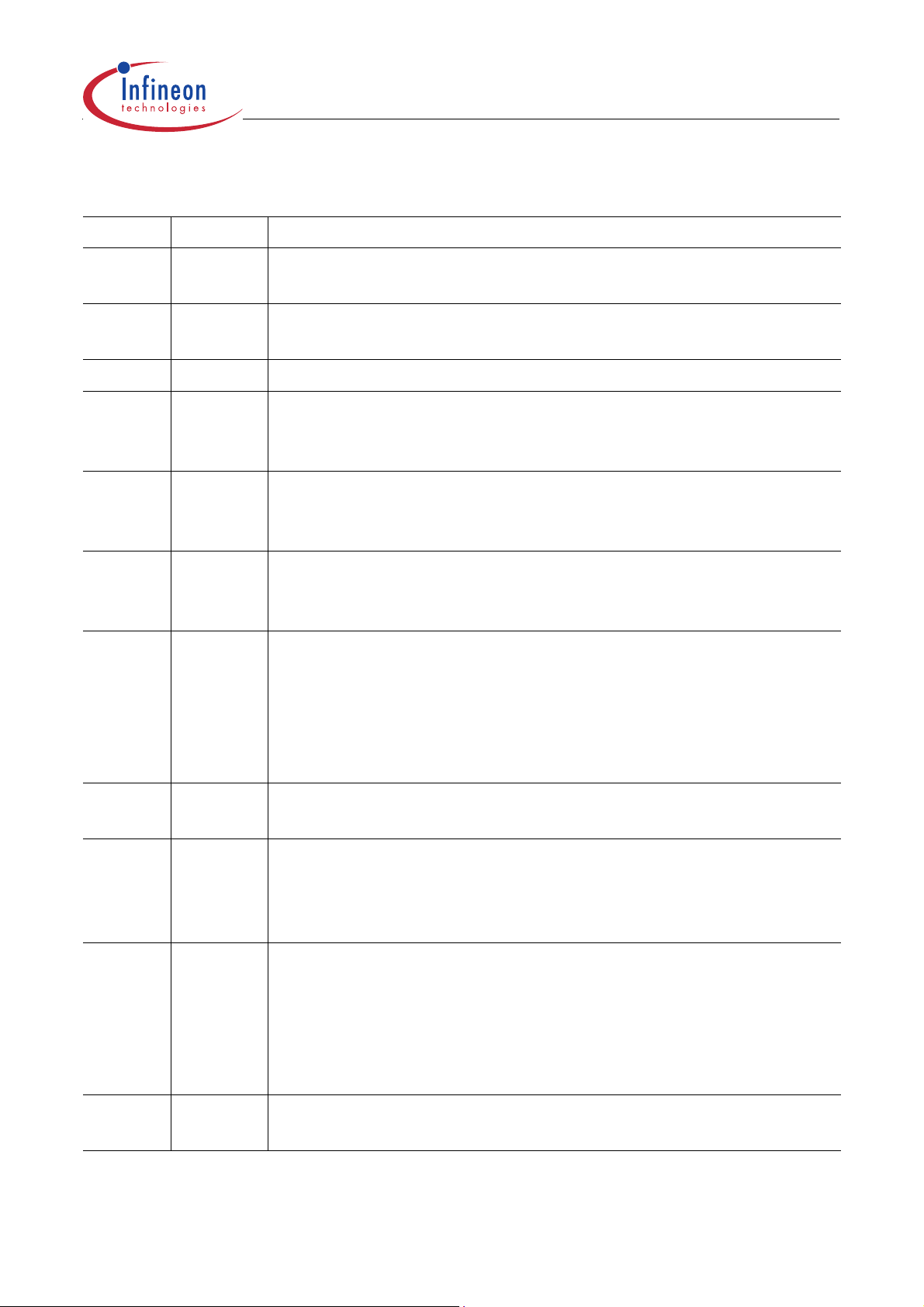

4 Pin Definitions and Functions

Pin No. Symbol Function

1TxDTransmit data input; integrated pull up;

LOW: bus becomes dominant, HIGH: bus becomes recessive

2RxDReceive data output; push-pull output;

LOW: bus becomes dominant, HIGH: bus becomes recessive

3ROReset output; open drain output, integrated pull up, active low

4

WK2 Wake-Up input 2; for detection of external wake-up events, edge

sensitive, in sleep mode monitored by cyclic sense feature when

selected; weak pull up (2µA) to avoid unwanted wake ups

5

WK1 Wake-Up input 1; for detection of external wake-up events, edge

sensitive, in sleep mode monitored by cyclic sense feature when

selected; weak pull up (2µA) to avoid unwanted weak ups

6, 7, 8, 9,

20, 21,

GND Ground; to reduce thermal resistance place cooling areas on

PCB close to this pins.

22, 23

10 DO SPI data output; this tri-state output transfers diagnosis data to

the control device. Serial data transfered from DO is a 8 bit

diagnosis word with the Least Significant Bit (LSB) transmitted

first. The output will remain 3-stated unless the device is selected

by a LOW on Chip-Select-Not (CSN). DO will accept data on the

rising edge of CLK-signal; see table 4, 5, 6 for Diagnosis protocol

11 CLK SPI clock input; clocks the shiftregister; CLK has a pull down

input, active HIGH, and requires CMOS logic level inputs

12 CSN SPI chip select not input; CSN is a pull up input, active LOW,

serial communication is enabled by pulling the CSN terminal low;

CSN input should only be transitioned when CLK is low; CSN has

an internal active pull up and requires CMOS logic level inputs

13 DI SPI data input; receives serial data from the control device;

serial data transmitted to DI is a 8 bit control word with the Least

Significant Bit (LSB) being transferred first: the input has a pull

down input, active HIGH, and requires CMOS logic level inputs;

DI will accept data on the falling edge of CLK-signal; see table 3

for input data protocol

14 OUTHS High side switch output; controlled via SPI, in sleep mode

controlled by internal cyclic sense function when selected

Version 2.08 4 2004-06-07

Page 5

Final Datasheet TLE 6263

4 Pin Definitions and Functions (cont’d)

Pin No. Symbol Function

15 VS Power supply input; block to GND directly at the IC with ceramic

capacitor

16 SI Sense comparator input; for monitoring of external voltages, to

program the detection level connect external voltage divider

17 FSO Fail safe output; to supervise and control critical applications,

high when watchdog is correctly served, LOW at any reset

condition, open drain output, internal pull up, active LOW

18 V

19 V

CI

CC

Internal voltage supply; for stabilization of internal power

supply, block to GND with an external capacitor C

≥ 100 nF

VI

Voltage regulator output; for 5V supply, to stabilize block to

GND with an external capacitor C

≥ 100 nF

Q

24 CANL CAN-L bus line; LOW in dominant state

25 RTL CANL-Termination output; connect to CANL bus line via

termination resistor

26 CANH CAN-H bus line; HIGH in dominant state

27 RTH CANH-Termination input; connect to CANH bus line via

termination resistor

28

INT Interrupt output; to monitor wake-up events or valid sense input

condition; integrated pull up resistor; active LOW

Version 2.08 5 2004-06-07

Page 6

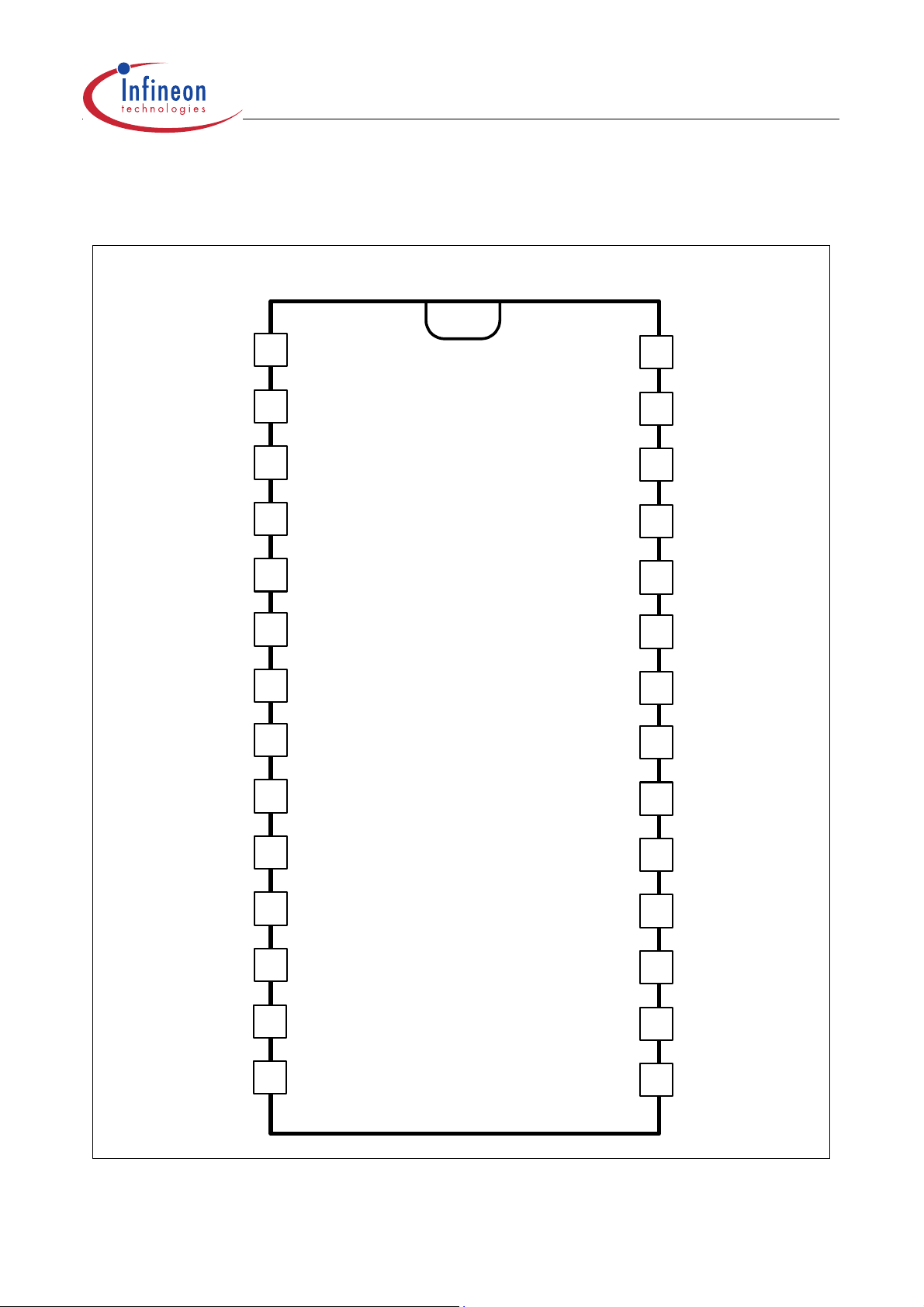

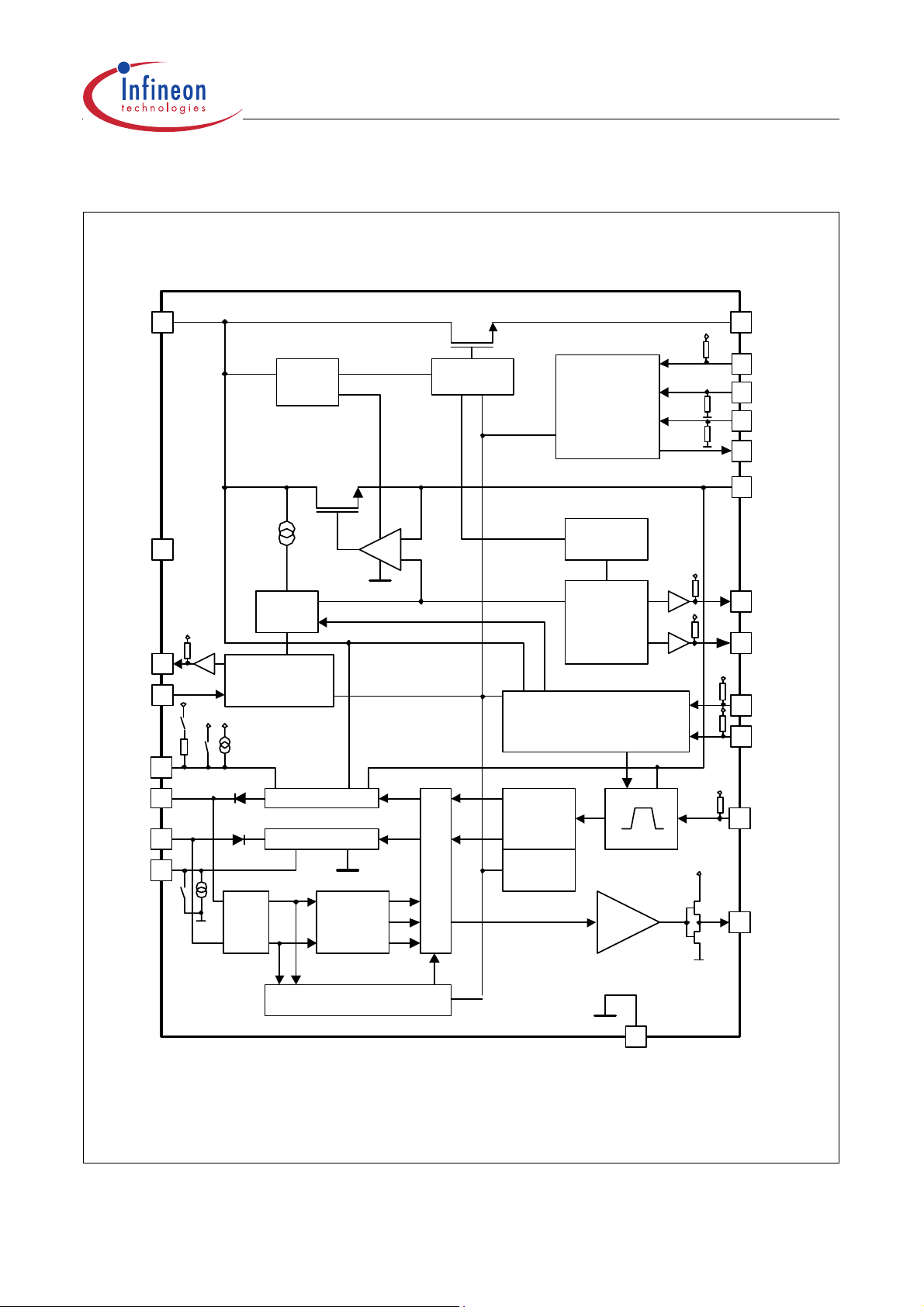

5 Functional Block Diagram

Final Datasheet TLE 6263

V

BAT

V

INT

RTL

CA NH

CA NL

RTH

CI

SI

Vcc

Vs

Vcc

Charge

Pump

Band

Gap

Early Warning

/ V

superv isor

S

H Output Stage

L Output Stage

Vcc

Driv e +

Protection

OUTHS

CSN

CLK

SPI

DI

DO

V

CC

-

+

Standby / Sleep Control

Dr iv er

Temp

Pr o t e c t

Time Bas e

Res et

Gene ra tor

+

Watchdog

CA N

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

RO

FSO

WK1

WK2

TxD

Filter

Re c ei v e r

Fail Management

Input

Stage

Rx D

CA N Fail De t ec t

GND

Figure 2: TLE 6263 G Functional Bloc Diagram

Version 2.08 6 2004-06-07

Page 7

Final Datasheet TLE 6263

6 Circuit Description

The TLE 6263 is a monolithic IC, which incorporates a failure tolerant low speed CANtransceiver for differential mode data transmission, a low dropout voltage regulator for

internal and external 5V supply as well as a SPI (serial peripheral interface) to control

and monitor the IC. Further there are integrated a high side switch, two wake-up inputs,

a window watchdog circuit with fail safe output as well as a reset circuit and early warning

function. Figure 2 shows a schematic block diagram of the TLE 6263. Table 1 shows

the status of the different chip features during the four main operation modes.

Table 1: Truth table of the TLE 6263

Feature normal mode receive-only

mode

V

CC

Reset

Watchdog

Fail safe output

-Fail

2)

V

INT

Sense input

Wake-up 1 / 2

HS-switch

4)

HS-cyclic-sense

SPI

CAN transmit

CAN receive

RTL output

ON ON ON OFF

ON ON ON OFF

ON ON

ON ON

ON ON ON ON

ON ON ON OFF

3)

ON

ON ON ON OFF

4)

OFF OFF ON ON

ON ON ON OFF

ON OFF OFF OFF

ON ON OFF OFF

switched to Vcc switched to

ON

Vcc

3)

stand-by

V

bat

mode

1)

ON

5)

ON

ON ON

switched to

Vs

sleep

mode

OFF

OFF

switched to

Vs

RxD output

INT output

1)

at low VCC output current only active when watchdog undercurrent function is not activated

2)

can only be monitored in V

3)

no wake-up interrupt generated, logic level status monitored via SPI

4)

only active when selected via SPI

5)

if watchdog under-current function active, than FSO = low

L = bus dominant;

H = bus recessive

active low early

warning

-stand-by mode via SPI

bat

L = bus dominant;

H = bus recessive

active low early

warning for V

and V

CC

INT

active low wake-up

interrupt

active low early

warning

low

low

Version 2.08 7 2004-06-07

Page 8

Final Datasheet TLE 6263

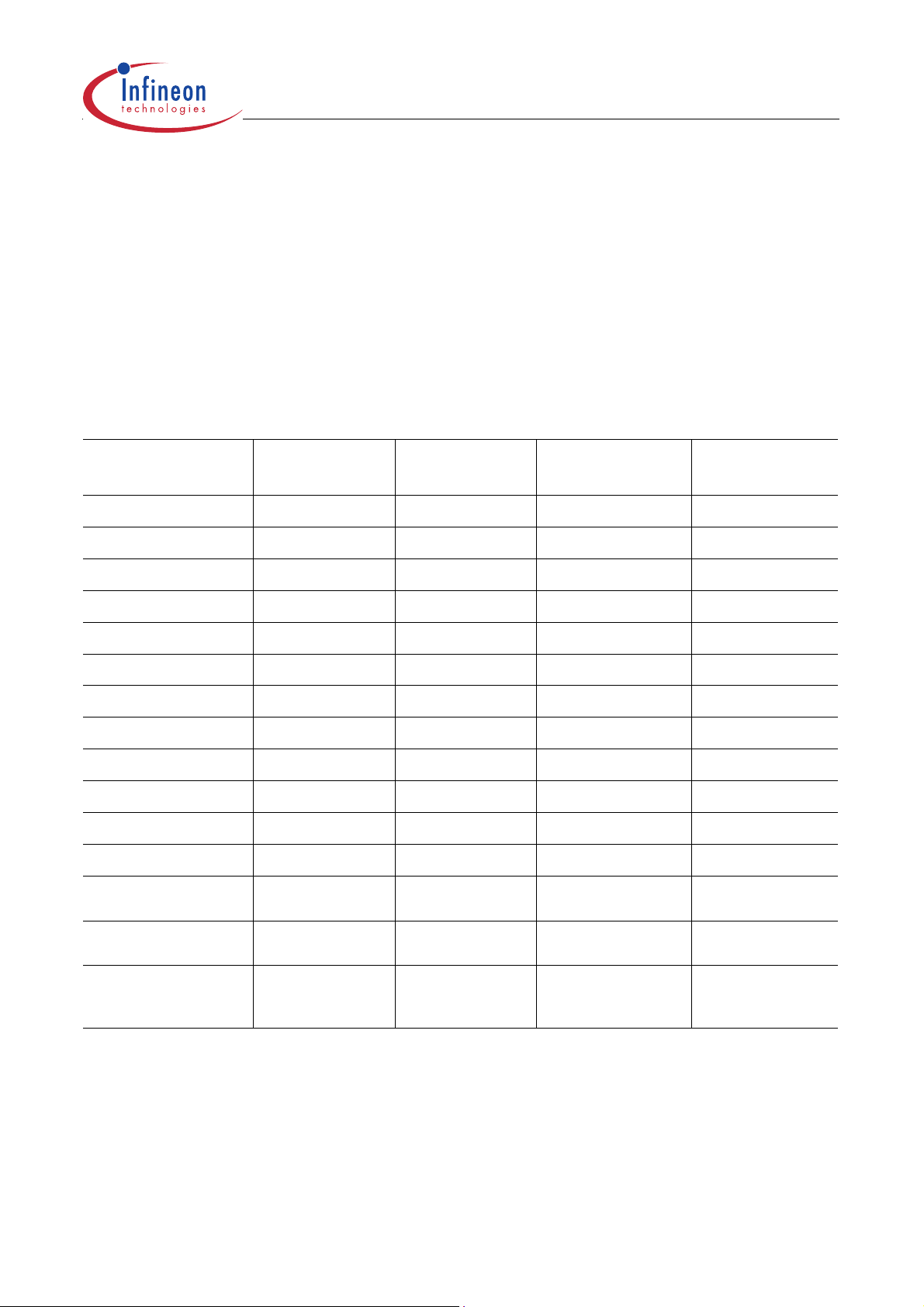

6.1 Operation Modes

The TLE 6263 offers four different operation modes that are controlled via the SPI

interface (NSTB= SPI Input Bit3, ENT=SPI Input Bit2): the normal operation mode, the

receive-only mode, the V

stand-by mode and the sleep operation mode. Please see

bat

the state diagram (figure 3).

Normal and Receive only Mode

In the normal operation mode both is possible, receiving and transmitting of messages,

in the receive-only mode (RxD-only mode) the output stages are disabled which doesn’t

allow the CAN controller to send a message to the bus. In the state diagram (figure 3),

is the status of the voltage regulator.

V

CC

SPI Input Bits:

IBit2 = ENT

IBit3 = NSTB

2)

NSTB 0

Power

Down

Normal Mo de

NSTB

ENT

11

2)

ENT 0

NSTB

2)

RxD-Only

ENT

10

2)

NSTB

2)

ENT

Sleep Mode

Sleep

ENT

NSTB

01

HS switch = OFF

1)

after 64ms1) after 500µs

V

CC

ON

ENT 1

V

CC

ON

0

1

V

CC

OFF

2)

ENT11

2)

NSTB

or

V

CC

2)

NSTB 1

Start Up

Power Up

NSTB

0

V

RT

2)

NSTB

ENT

or

V

V

NSTB

00

RxD = LOW if a wake up

occured by WK1, WK2

or CAN message

Wake Up =

transition on

WK1 or WK 2

for t > t

WU

or

CAN message

2)

ENT 1

CC

Stand-By

bat

ENT

0

0

V

RT

1)

V

ON

after 500µs

CC

1)

after 64ms

V

Stand-By Mode

bat

HS cyclic

sense

ENT

NSTB

01

HS Switch = ON

V

ON

CC

HS cyclic

sense

ENT

NSTB

01

HS Switch = ON

V

OFF

CC

1)

automatic repeated transition only if

HS cycl sense feature is s elected

by SPI IBit 4

2)

NSTB and ENT are bot h SPI Input

Bits (IBits)

Figure 3: State Diagram

V

stand-by mode and sleep mode

bat

In the V

stand-by mode and sleep mode the RTL output voltage is switched to VS.

bat

Both modes are low power modes. In the sleep mode the whole application is switched

Version 2.08 8 2004-06-07

Page 9

Final Datasheet TLE 6263

off by disabling the voltage regulator. That allows the total current consumption to drop

down to less than 100 µA.

When a reset occurs, due to false watchdog triggering, the TLE6263 automatically

switches from normal mode or receive-only mode respectively, to the V

mode. If a watchdog reset occurs in the V

stand-by mode the IC remains in this mode.

bat

stand-by

bat

In sleep mode a wake-up at any of the wake-up inputs as well as via the bus lines

(CANH or CANL) automatically sets the TLE 6263 in V

stand-by mode. In the V

bat

bat

stand-by mode a wake-up is monitored by setting the output RxD low. This feature

works as a flag, to indicate a wake event to the microcontroller. To send and to receive

messages, the CAN-transceiver has to be set to normal operation mode by the

microcontroller.

In case the IC shall directly be set back to sleep mode after a wake-up, an internal wakeflip-flop has to be reseted via the SPI. Therefore IBIT1 has to be set high and then low

again by a second SPI transmission. A transition from the V

stand-by mode to the

bat

normal mode or receive-only mode respectively, automatically resets the wake-flip-flop.

6.2 Low Dropout Voltage Regulator

The integrated low dropout voltage regulator is able to drive the internal loads (e.g.

CAN-circuit) as well as external 5V loads. Its output voltage tolerance is better than ±

2%. The maximum output current is limited to 110 mA.

An external reverse current protection is recommended at the pin Vs to prevent the

output capacitor from being discharged by negative transients or low input voltage.

Stability of the output voltage is guaranteed for output capacitors C

nevertheless it is recommended to use capacitors C

≥ 10 µF to buffer the output

Q

≥ 100 nF,

Q

voltage and therefore improve the reset behavior at input voltage transients.

To stabilize the internal supply a capacitor C

≥ 100 nF directly connected to the pin V

VI

CI

is required.

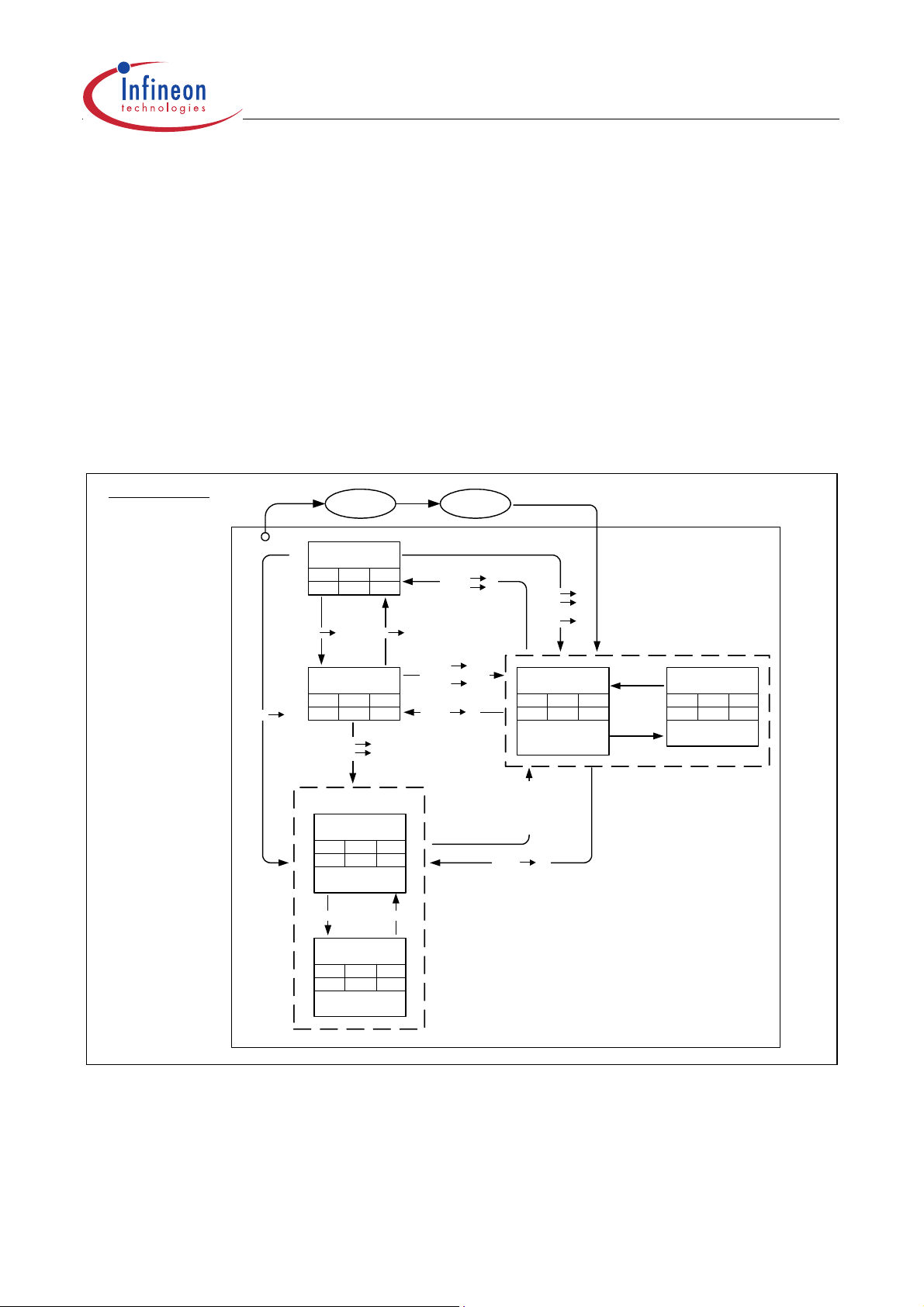

6.3 CAN Transceiver

The TLE 6263 is optimized for low speed data transmission up to 125 kBaud in

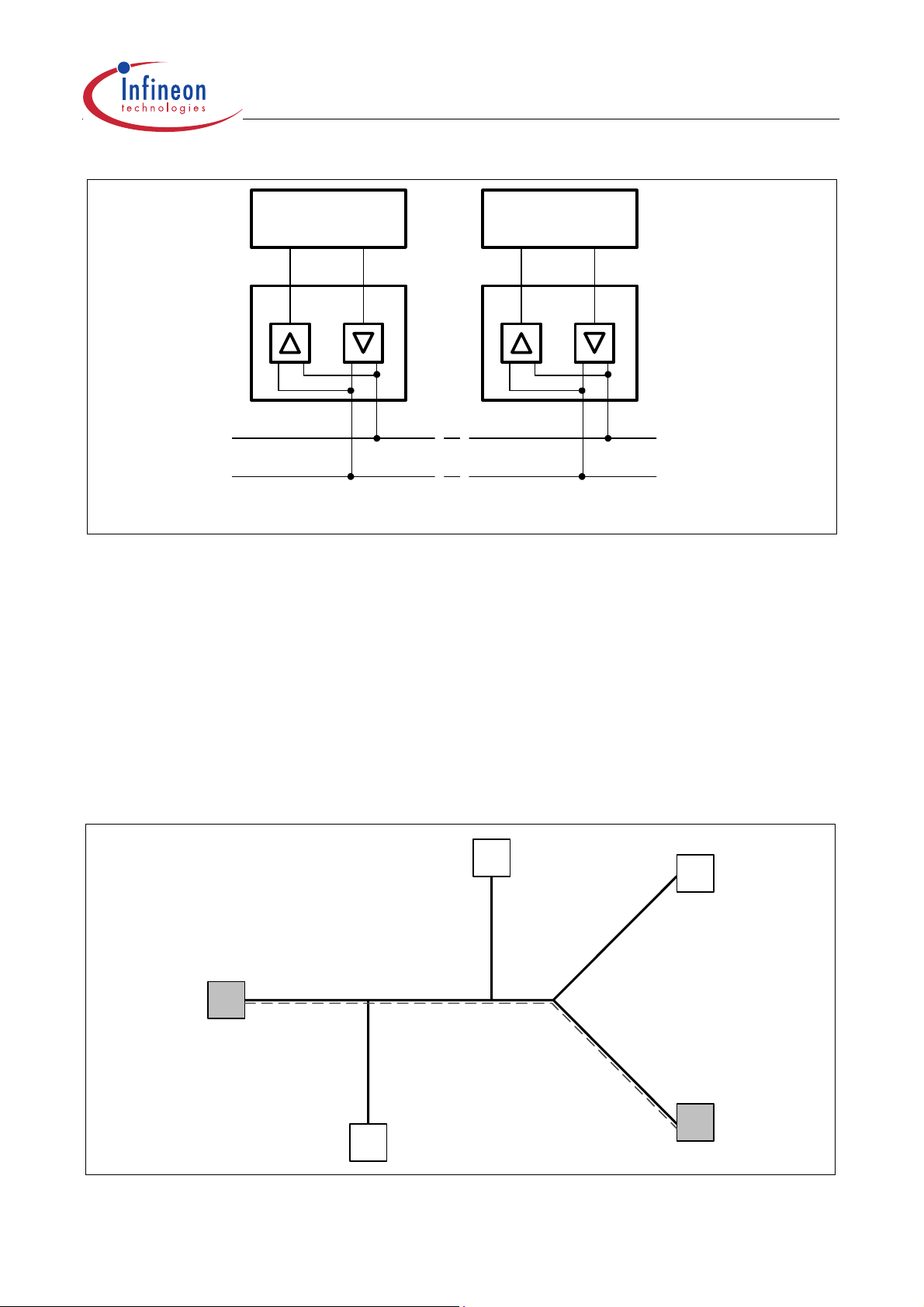

automotive applications. Figure 4 shows the principle configuration of a CAN

network.Normally a differential signal is transmitted and received respectively. When a

bus wiring failure (see table 2) is detected the device automatically switches to a

dedicated CANH or CANL single-wire mode to maintain the communication if

necessary. Further a receive-only mode is implemented that allows a separate CAN

node diagnosis. During normal and RxD-only mode, RTL is switched to V

to GND. During V

stand-by and the cyclic wake mode, RTL is switched to VS and RTH

bat

and RTH

CC

to GND.

Version 2.08 9 2004-06-07

Page 10

Final Datasheet TLE 6263

Controller 1

RxD1

Transceiver1

TxD1

BUS Line

Controller 2

RxD2

Transceiver2

TxD2

Figure 4: CAN Network Example

Receive-only Mode

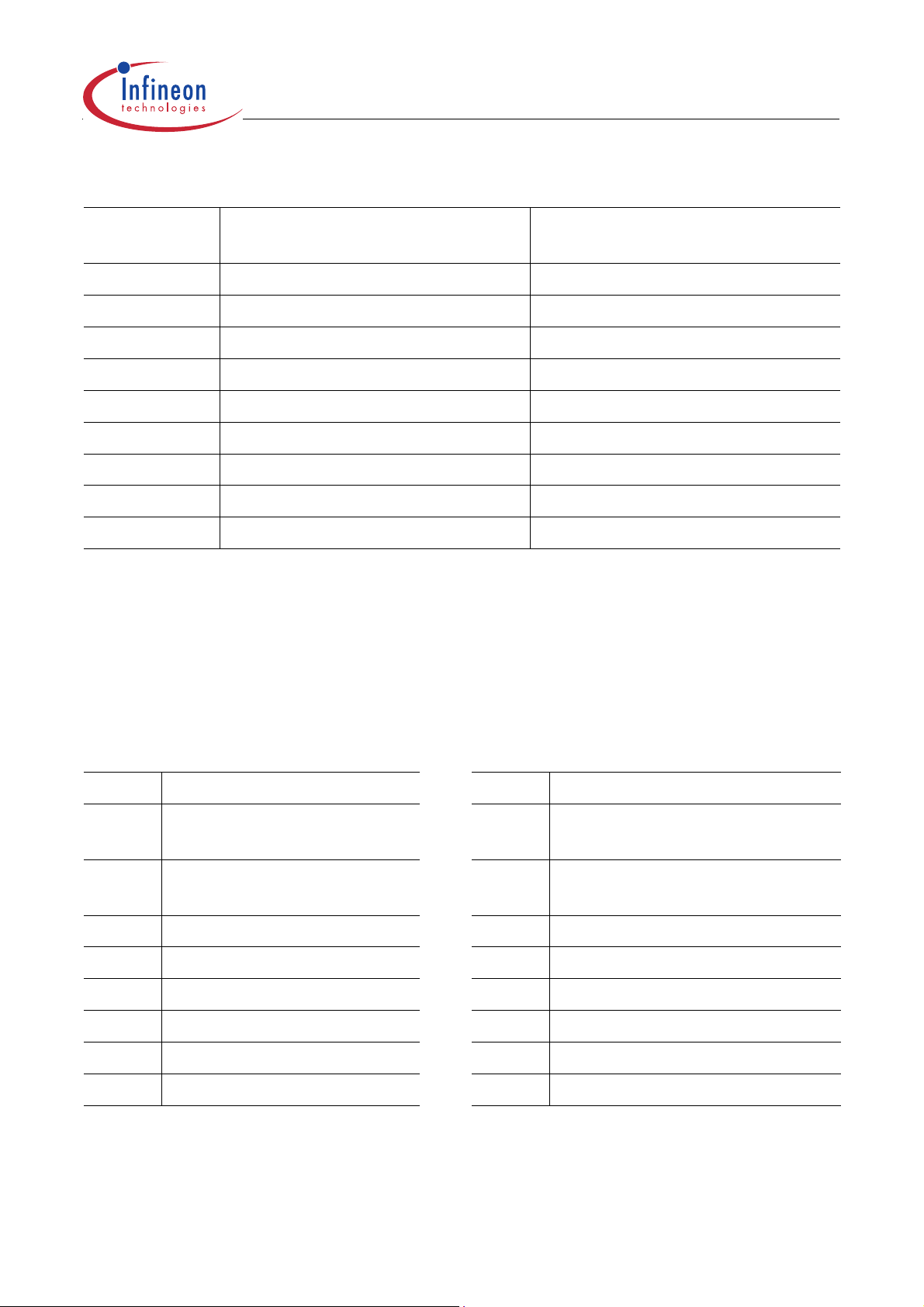

The receive only mode is designed for a special test procedure to check the bus

connections. Figure 5 shows a network consisting of 5 nodes. If the connection between

node 1 and node 3 shall be tested, the nodes 2,4 and 5 are switched into receive only

mode. Node 1 and node 3 are in normal mode. If node 1 sends a message, node 3 is the

only node which can acknowledge the message, the other nodes can only listen but

cannot send an acknowledge bit. If node 1 receives the acknowledge bit from node 3,

the connection is OK.

5

1

2

4

3

Figure 5: Testing the Bus Connection in Receive-only Mode

Version 2.08 10 2004-06-07

Page 11

Final Datasheet TLE 6263

Electromagnetic Emmision (EME)

To reduce radiated electromagnetic emission (EME), the dynamic slopes of the CANL

and CANH signals are both limited and symmetric. This allows the use of an unshielded

twisted or parallel pair of wires for the bus. During single-wire transmission (one of the

bus lines is affected by a bus line failure) the EME performance of the system is

degraded from the differential mode.

6.4 Bus Failure Management

There are 9 different CAN bus wiring failures defined by the ISO 11519-2/ISO 11898-3

standard. These failures are devided into 7 failure groups (see Table 2). The difference

between ISO11898-3 and ISO 11519-2 is also shown in Table 2. When a bus wiring

failure is detected the device automatically switches to a dedicated CANH or CANL

single-wire mode to maintain the communication if necessary. Therefore it is equipped

with one differential receiver and four single ended comparators (two for each bus line).

To avoid false triggering by external RF influences, the single wire modes are activated

after a certain delay time. As soon as the bus failure disappears the transceiver switches

back to differential mode after another time delay.

The differential receiver threshold is set to typ. -2.5V. This ensures correct reception in

the normal operation mode as well as in the failure cases 1, 2, 3a(6a) and 4(5) with a

noise margin as high as possible. When one of the bus failures 3(6), 5(4), 6(3), 6a(3a),

and 7 is detected, the defective bus wire is disabled by switching off the affected bus

termination and output stage. The failure cases in brackets() are the failure cases

according to ISO 11898-3. Simultaneously the multiplexing output of the receiver circuit

is switched to the unaffected single ended comparator

The bus failures are monitored via the diagnosis protocoll of the SPI. A general indication

of a CAN failure during normal mode at CANH or CANL is reported by OBIT 4 and 5. It

is also possible to distinguish 6 CAN bus failures or failure groups on the SPI output bits

3 to 7 in the RxOnly mode(see Table 2 and 5). The failures are reported until

transmission of the next CAN word begins.

In case the transmission data input TxD is permanently dominant, both, the CANH and

CANL transmitting stage are disabled after a certain delay time t

. This is necessary

TxD

to prevent the bus from being blocked by a defective protocol unit or short to GND at the

TxD input.

In order to protect the transceiver output stages from being damaged by shorts on the

bus lines, current limiting circuits are integrated. The CANL and CANH output stage

respectively are protected by an additional temperature sensor, that disables them as

soon as the junction temperature exceeds the maximum value. In the temperature shutdown condition of the CAN output stages receiving messages from the bus lines is still

possible.

Version 2.08 11 2004-06-07

Page 12

Table 2: CAN bus line failure cases

Final Datasheet TLE 6263

failure

#

failure description

according to ISO 11898-3

failure description

according to 11519-2

1 CANH line interrupted CANL line interrupted

2 CANL line interrupted CANH line interrupted

3 CANH shorted to Vbat CANL shorted to Vbat

3a CANH shorted to Vcc CANL shorted to Vcc

4 CANL shorted to GND CANH shorted to GND

5 CANH shorted to GND CANL shorted to GND

6 CANL shorted to Vbat CANH shorted to Vbat

6a CANL shorted to Vcc CANH shorted to Vcc

7 CANL shorted to CANH CANL shorted to CANH

6.5 SPI (serial peripheral interface)

The 8-bit wide programming word (input word, see table 3) is read in via the data input

DI, and this is synchronized with the clock input CLK supplied by the µC. The diagnostic

information depends on the operation mode. The internal latches for the V

-stand-by

bat

diagnosis are reseted when leaving this mode.

Table 3, Input Data Protocol Table 4, Diagnosis Data Protocol

all modes normal mode

IBIT OBIT

7 Watchdog Undercurrent

7 HS UV / Temp-Shut Down

Control

6Set V

-Fail + VCC Fail

INT

6HS Overcurrent

Flag

5 OUTHS ON 5 CANL bus fail

4 OUTHS Cyclic Sense 4 CANH bus fail

3 Not Standby 3 WK2 logic level

2 Enable Transmit 2 WK1 logic level

1 Reset Internal WK-FF 1 Window Watchdog Reset

0 Watchdog Trigger 0 Temperature Prewarning

H= ON

L= OFF

H= ON

L= OFF

Version 2.08 12 2004-06-07

Page 13

Final Datasheet TLE 6263

The transmission cycle begins when the TLE6263 is selected by the chip select not input

CSN (H to L). After the CSN input returns from L to H, the word that has been read in

becomes the new control word. The DO output switches to tri-state status at this point,

thereby releasing the DO bus circuit for other uses. For details of the SPI timing please

refer to figure 6 to 9.

Table 5, Diagnosis Data Protocol Table 6, Diagnosis Data Protocol

RxD-only mode V

-Stand-by mode

bat

OBIT OBIT

7 CAN Failure 5(4) and 7 7 V

6 CAN Failure 6 (3) 6 V

Not-Fail

CC

Not-Fail

INT

5 CAN Failure 6a (3a) 5 WK1/2 Initialization Fail

4 CAN Failure 2(1) and 4(5) 4 Wake via CAN bus lines

3 CAN Failure 3(6) 3 WK2 voltage level

2 CAN Failure 1(2) and 3a(6a) 2 WK1 voltage level

1 Window Watchdog Reset 1 Window Watchdog Reset

0 Temperature Prewarning 0 Temperature Prewarning

H= ON

L= OFF

H= ON

L= OFF

()... values in brackets according to

ISO11898-3 see table 2

6.6 Window Watchdog, Reset

When the input voltage exceeds the reset threshold voltage the reset output RO is

switched HIGH after a delay time of typ. 8ms. This is necessary for a defined start of the

microcontroller when the application is switched on. As soon as an under-voltage

condition of the output voltage (V

< VRT) appears, the reset output RO is switched

CC

LOW again (power on and under-voltage reset). The LOW signal is guaranteed down to

an output voltage V

≥ 1V. Please refer to figure 13, Reset Timing Diagram.

Q

In sleep operation mode, the watchdog circuit is automatically disabled.

Long Open Window

After the above described delayed reset (LOW to HIGH transition of RO) the window

watchdog circuit is started by opening a long open window of typ. 65ms. The long open

window allows the microcontroller to run his set-up and then to trigger the watchdog via

the SPI, refer to figure 11,Watchdog Timeout Definitions. Within the long open window

Version 2.08 13 2004-06-07

Page 14

Final Datasheet TLE 6263

period a watchdog trigger is detected as a “rising edge” by sampling a HIGH on the IBIT

0. The trigger is accepted when the CSN input becomes HIGH after the transmission of

the SPI word. After each reset as well as after a power on condition the default value of

IBIT 0 is LOW.

Closed and Open Window

A correct watchdog trigger results in starting the window watchdog by opening a closed

window of typ. 6 ms followed by a open window of typ. 10 ms. From now on the

microcontroller has to service the watchdog trigger by inverting the IBIT 0 alternating.

The “negative” or “positive” edge has to meet the open window time. A correct watchdog

service immediately results in starting the next closed window. Please refer to figure 12,

Watchdog Timing Diagram.

Watchdog Reset

Should the trigger signal not meet the open window a watchdog reset is created by

setting the reset output RO low for a period of typ. 2 ms. Then the watchdog starts again

by opening a long open window. In addition, the SPI OBIT 1 (diagnosis bit 1) is set HIGH

until the next successful watchdog trigger to monitor a watchdog reset. OBIT1 is also

HIGH until the watchdog is correctly triggered after power-up / start-up. For fail safe

reasons the TLE6263 is automatically switched in Vbat-stand-by mode if a watchdog

trigger failure occurs. So the power consumption can be minimized in case of a

permanent faulty microcontroller.

In case of either an undervoltage reset or a watchdog reset all SPI input registers (IBIT

0 to IBIT 7) are set low.

Undercurrent Disabling Function

To avoid cyclic wake-up’s of the microcontroller due to missing watchdog pulses when

the microcontroller is in a low power mode, an automatic undercurrent disabling function

of the watchdog circuit can be selected for the TLE 6263 V

activation of this feature, the V

output current in the V

CC

than the undercurrent threshold (I

CC

< I

CCWD

) and in addition the SPI IBIT 7 has to be

-stand-by mode has to be less

bat

-stand-by mode. For

bat

set HIGH. When the microcontroller returns back to normal mode or the output current

becomes higher than I

CC

> I

CCWD

the watchdog circuit is enabled again. A long open

window is started then, to ensure a simple synchronization of the watchdog timing to the

watchdog services of the microcontroller.

6.7 Flash program mode

To disable the watchdog feature a flash program mode is available. This mode is

selected by applying a voltage of 6.8V < V

< 7.2V at pin INT. This is useful e.g. if the

INT

flash-memory of the micro has to be programmed and therefore a regular watchdog

triggering is not possible. If the SPI is required in the flash program mode to change e.g.

the mode of the TLE6263 the first input telegram has to be “00000000”.

Version 2.08 14 2004-06-07

Page 15

Final Datasheet TLE 6263

6.8 Fail Safe feature

The output FSO becomes HIGH when the watchdog is correctly serviced by the

microcontroller for the fourth time

. As soon as either an under-voltage reset or watchdog

reset occurs, it is set LOW again. This feature is very useful to control critical applications

independent of the due function of the microcontroller e.g. to disable the power supply

in case of a microcontroller failure.

6.9 Sense Comparator (pin SI) and V

INT

-fail

The sense comparator (early warning function) compares a voltage defined by the user

to an internal reference voltage. Therefore the voltage to be supervised has to be scaled

down by an external voltage divider in order to compare it to the internal sense threshold

. This feature can be used e.g. to supervise the battery voltage in front of the reverse

V

SIth

protection diode. The microcontroller is given a pre-warning before an under-voltage

reset due to low input voltage occurs. The pre-warning is flagged by setting the interrupt

output INT low in normal mode, receive only mode and V

-stand-by mode. In sleep

bat

operation mode the sense function is inactive. Calculation of the voltage divider can be

easily done since the sense input current can be neglected. An internal blanking time

prevents from false triggering due to line transients. Further improvement is possible by

the use of an external ceramic capacitor switched between SI and GND (see Application

Diagram Figure 15).

6.10 V

To activate the V

internal flip-flop. This automatically sets the V

internal supply voltage become lower than the internal threshold V

NOT V

INT

- and VCC-fail flag

INT

supervisor feature the SPI IBIT 6 has to be set HIGH to set an

INT

-stand-by OBIT 6 HIGH, too. Should the

bat

VINT,th

(typ. 2.5V) the

-Fail bit becomes LOW to indicate the low voltage condition. All SPI input

registers are set LOW due to a low voltage condition of the internal supply voltage.

Like the wake-up diagnosis the V

stand-by mode. The V

-Fail feature can also be used to give an indication when the

INT

-Fail diagnosis can only be monitored in the V

INT

bat

ECU has been changed and therefore a pre-setting routine of the microcontroller has to

be started.

Further to the reset threshold there is another supervisor threshold implemented, to

monitor the output voltage V

-Fail feature is monitored via OBIT 7 in the V

V

CC

-Fail flag, via IBIT 6 (so both fail features are activated with the IBIT 6 but monitored

V

INT

via OBIT 6 and OBIT 7 during V

. This threshold is called V

CC

-stand-by mode and set, like the NOT

bat

-stand-by).

bat

VCC,th

(typ. 2.5V). The NOT

In the receive-only mode both fail bits cause the interrupt output INT to go low.

Version 2.08 15 2004-06-07

-

Page 16

Final Datasheet TLE 6263

6.11 Wake-Up Inputs WK1, WK2

In addition to a wake-up from sleep mode via the bus lines CANH or CANL it is also

possible to wake-up the TLE6263 from low power mode via the wake-up inputs WK1 and

WK2. The wake-up inputs are sensitive to a transition of the voltage level, either from

high to low or the other way round. They are active in all operation modes. In the normal

mode the current logic level at WK1/2 is monitored via the SPI (see table 4 and 6).

A positive or negative voltage edge at WK1/2 in V

-stand-by mode or sleep mode

bat

immediately results in setting the output RxD low to signal a wake-up. After a wake-up

via WK1/2 the transmission of the SPI diagnosis word in the V

-stand-by mode shows

bat

the logic level that has caused the wake-up. To get the current voltage levels at WK1/2

in the V

-stand-by mode the internal wake flip-flop has to be reseted by the IBIT1 for

bat

each transmission. As long as IBIT1 is set high or the internal wake flip-flop is reseted

respectively, in the V

-stand-by mode the RxD output is blocked to signal a new wake-

bat

up event via the CAN-bus or the wake-up inputs.

Further to the continues sensing at the wake-up inputs a cyclic sense feature is possible.

When the OUTHS cyclic sense feature is selected via the SPI IBIT 4 the high side switch

as well as the WK1/2 inputs are periodically activated by the TLE6263 in the sleep and

-stand-by mode.

V

bat

When switching the TLE6263 into sleep mode (cyclic sense feature activated) the

voltage level at the wake-inputs is sensed 2 times to initialize the reference voltage.

Should this initialisation fail (2 samples are unequal) the device is automatically set in

-stand-by mode and the initialisation error is shown on the OBIT 5. To enter the sleep

V

bat

mode now directly from the V

-stand-by mode, the internal wake flip-flop has to be

bat

reseted by the IBIT 1.

6.12 Interrupt output INT

Like the reset output, the interrupt output is a low active output. It is used to monitor low

voltage conditions at the sense input in normal mode and stand-by mode (see table 8).

In the receive-only mode the V

-fail flag and VCC supervisor are monitored.

INT

6.13 High Side Switch

The high side output OUTHS is able to switch loads up to 150 mA. Its on-resistance is

1.0 Ω typ. @ 25°C. This switch is controlled via the SPI input bits 4 and 5. In normal

mode, receive-only mode and V

-stand-by mode the high side output is switched on

bat

and off, respectively via the SPI input bit 5.

To supply external wake-up circuits in sleep mode and V

-stand-by mode the output

bat

OUTHS can be periodically switched on by the TLE6263 itself. In order to activate this

cyclic sense feature the SPI IBIT 4 has to be set high. The auto-timing period then is typ.

65 ms, the on-time is typ. 1 ms. Should there be any over-current condition at the switch

in the sleep mode (cyclic sense activated) or V

Version 2.08 16 2004-06-07

-stand-by mode a wake-up is flagged

bat

Page 17

Final Datasheet TLE 6263

via the RxD output. The over-current condition is monitored on the SPI OBIT 6 in normal

operation mode.

The SPI OBIT 0 flags a thermal pre-warning of the high side switch. By this the

microcontroller is able to reduce the power dissipation of the TLE6263 by switching off

functions of minor priority until the temperature threshold of the thermal shutdown is

reached. Further OUTHS is protected against short circuit and overload. As soon as the

under-voltage condition of the supply voltage is met (V

< V

S

UVOFF

), the switch is

automatically disabled by the under-voltage lockout circuit. Moreover the switch is

automatically disabled when a reset or watchdog reset occurs.

6.14 Hints for unused pins

SI: connect to V

S

OUTHS: leave open

WK1/2: connect to V

INT: leave open

RO: leave open

FSO: leave open

SI: switch to Vs

or leave open

S

Version 2.08 17 2004-06-07

Page 18

Final Datasheet TLE 6263

7 Electrical Characteristics

7.1 Absolute Maximum Ratings

Parameter Symbol Limit Values Unit Remarks

min. max.

Voltages

Supply voltage

Supply voltage

V

V

Regulator output voltage V

CAN bus voltage

CAN bus voltage

Logic input voltages (DI, CLK,

(CANH, CANL) V

(CANH, CANL) V

V

CSN, OSC, TxD)

Logic output voltage

V

(DO, RO, INT, RxD, FSO)

Termination input voltage

V

(RTH, RTL)

Input voltages at WK1/2 and

V

SI

Electrostatic discharge

V

voltage at pin CANH, CANL,

GND, V

Electrostatic discharge

S

V

voltage at any other pin

S

S

CC

CANH/L

CANH/L

I

DRI,RD

TL /TH

WK/SI

esd

esd

-0.3 28 V

-0.3 40 V

-0.3 5.5 V

-20 28 V

-40 40 V

-0.3 V

CC

V

+0.3

-0.3 V

CC

V

+0.3

-0.3 V

S

V

+0.3

-40 40 V

-3 3 kV

-1 1 kV

tp< 0.5s; tp/T < 0.1

VS >0 V

t

< 0.5s; tp/T < 0.1

p

0 V < VS < 24 V

0 V < V

< 5.5 V

CC

0 V < VS < 24 V

0 V < V

< 5.5 V

CC

0 V < VS < 24 V

0 V < V

< 5.5 V

CC

human body model,

C = 100 pF, R = 1.5 kΩ

human body model,

C = 100 pF, R = 1.5 kΩ

Currents

1)

Output current; Vcc

Output current; OUTHS I

Note 1): Not subject to production test - specified by design

I

CC

OUTH1

––A

1)

0.2 A

Version 2.08 18 2004-06-07

internally limited

1)

internally limited

Page 19

Final Datasheet TLE 6263

7.1 Absolute Maximum Ratings (cont’d)

Parameter Symbol Limit Values Unit Remarks

min. max.

Temperatures

Junction temperature

Storage temperature T

Note: Maximum ratings are absolute ratings; exceeding any one of these values may cause irreversible damage

to the integrated circuit.

T

j

stg

– 40 150 °C

– 50 150 °C

–

–

Version 2.08 19 2004-06-07

Page 20

Final Datasheet TLE 6263

7.2 Operating Range

Parameter Symbol Limit Values Unit Remarks

min. max.

Supply voltage

Supply voltage V

Supply voltage slew rate dV

Logic input voltage (DI, CLK,

V

S

S

/dt –0.5 5 V/µs

S

V

I

CSN, TxD)

Output capacitor

Output capacitor

SPI clock frequency

Junction temperature

C

C

f

T

CC

VI

clk

j

Thermal Resistances

Junction pin

Junction ambient

Note: Calculation of the junction temperature Tj = T

R

R

thj-pin

thj-a

V

UV OFF

V

UV OFF

20 V

40 V

– 0.3 V

CC

V

After VS rising above

V

UV ON

thermally limited

100 nF

100 460 nF

1.5 MHz

– 40 150 °C

–25K/W

–65K/W

+ P x R

amb

thj-a

Version 2.08 20 2004-06-07

Page 21

7.3 Electrical Characteristics

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Quiescent current Pin

Current consumption

IQ = IS - I

CC

Current consumption

IQ = IS - I

CC

Current consumption

IQ = IS - I

CC

Current consumption I

Current consumption I

V

S

I

Q

I

Q

I

Q

Q

Q

–5.510mA

–810mA

– 300 400 µA

–5080µA

3mA

normal mode;

I

=30mA;

CC

TxD recessive

normal mode;

I

=30mA;

CC

TxD dominant

stand-by mode;

T

=25°C; ICC=1mA;

j

Ibit 7 = H

sleep mode; Tj=25°C;

SPI Ibit 4 = L;

V

= V

CC

OUTHS active;

SPI Ibit 4 = H;

sleep mode;

V

= V

CC

CCI

CCI

= 0 V

= 0 V

Voltage Regulator; Pin V

Output voltage V

Output voltage V

Line regulation ∆V

Load regulation ∆V

CC

CC

CC

CC

CC

4.95.05.1V

4.85.05.2V

50 mV

50 mV

Power supply ripple rejection PSRR 40 dB

Output current limit I

Output current limit I

Drop voltage

VDR = VS - V

note 1) measured when the output voltage V

13.5 V input voltage V

CC

S

CCmax

CCmax

V

DR

110 120 mA

120 mA

0.5 V

has dropped 100 mV from the nominal value obtained at

CC

0.1 mA< ICC<100mA

6V<V

0A < I

6V<VS< 16 V;

I

5mA< ICC< 100mA;

V

VS< 1 Vss;

C

100Hz< f <100kHz

note 1)

V

I

note 1)

=1mA

CC

=6V

S

≥ 10µF

Q

= 0 V

CC

= 80 mA;

CC

<20V

I

< 100 µA

CC

Version 2.08 21 2004-06-07

Page 22

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS=13.5V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Oscillator

internal oscillating frequency

Internal cycling time

-1

(1/64 * f

OSC

)

Internal cycling time

-1

(1/64 * f

OSC

)

f

OSC

t

CYL

t

CYL

0.43 0.51 0.64 ms

0.30 0.51 0.72 ms

125 kHz

sleep mode

Reset Generator; Pin RO

Reset threshold voltage

V

Reset low output voltage V

Reset high output voltage V

RT

RO

RO

4.5 4.65 4.8 V

0.2 0.4 V

4.0 VCC+

V

VCC decreasing

I

= 1mA for

RO

V

= V

or

RT

= 200 µA for

≥ 1V

I

V

CC

RO

CC

0.1

Reset pull up current

Reset reaction time t

Reset delay time (16 cyl.) t

Watchdog Generator

Watchdog trigger

Long open window (128 cyl.)

Closed window (12 cyl.)

Open window (20 cyl.)

Watchdog reset-puls time

(4 cyl.)

Watchdog undercurrent

disable threshold

I

RO

RR

RD

t

WD

t

LW

t

CW

t

OW

t

WDR

I

CCWD

20 200 500 µA

1210µs

V

RO

V

CC

6.9 8.5 12 ms

7.2 10 13.6 ms

55 65 81 ms

5.16.17.7ms

8.6 10.2 13 ms

1.723ms

0.547mA

T

j

Watchdog OFF when

I

CC

Ibit 7= H

= 0V

< V

RT

<85°C;

< I

CCWD

to RO = L

and SPI-

Version 2.08 22 2004-06-07

Page 23

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Watchdog Undercurrent

I

CCWDhys

0.5 mA

disable hysteresis

Watchdog Undercurrent

t

LHR

8µs

Tj=25°C

reaction time

Fail Safe Output; Pin FSO

Watchdog edge count

n

FS

4V

difference to set HIGH

I

Fail Safe low output voltage

V

Fail Safe high output voltage V

FS

FS

0.2 0.4 V

4.0 VCC+

0.1

V

= 1mA for

FSO

V

= V

CC

I

= 200 µA for

FSO

V

≥ 1V

CC

I

= -1mA for

FSO

V

CC ≥VRT

RT

or

Sense Input (Early Warning) SI, V

Sense In threshold voltage

Sense In threshold

V

V

SI,th

SI,hys

hysteresis

Sense Input Current

Sense reaction time t

Interrupt Out high voltage V

Interrupt Out low voltage V

Interrupt pull up current I

VCC-Fail threshold voltage V

-Fail reaction time t

V

CC

V

-Fail threshold voltage V

INT

I

SI

S,r

INThigh

INTlow

INT

VCC,th

VCC,r

VINT,th

-Fail, Interrupt Output INT

INT

2.12.32.5V

200 mV

0.1 µA

51020µs

0.7 x

V

CC

– V

CC

0–0.9V

20 150 500 µA

2.32.83.1V

5µs

1.53.24.3V

V

VSI decreasing until

INT transition to LOW

V

≥ 0V

SI

V

< V

S,th

= 0V

< V

VCC,th

to INT = low

to

-

bat

S

S

I0 = – 20 µA

I0 = 1.25 mA

V

INT

V

CC

Obit 6 = low; V

stand-by mode

proportional to V

Version 2.08 23 2004-06-07

Page 24

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS=13.5V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Wake-Up Inputs WK1 / WK2

Wake-up threshold voltage

Minimum time for wake-up t

Input current I

V

WU

WK

WUth

234V

10 15 32 µs

-2 µA

sleep mode; Vbatstand-by mode

sleep mode; Vbatstand-by mode

VWK= 0 V

High Side Output OUTHS; (controlled by bit 4 and bit 5 of SPI input word)

Static

Drain-Source

R

DSON HS

–1.01.5Ω

–3.0Ω

T

= 25 °C

j

ON-Resistance;

I

OUTH3

= –0.15A

2.5 3.0 Ω

–5.0Ω

5.2 V ≤ VS ≤ 9V

T

= 25 °C

j

5.2 V ≤ VS ≤ 9V

Active zener voltage V

Clamp diode forward voltage V

Leakage current I

Switch ON delay time t

Switch OFF delay time t

Overcurrent shutdown

I

threshold

Shutdown delay time t

Current limit

UV-Switch-ON voltage

I

V

UV-Switch-OFF voltage V

UV-ON/OFF-Hysteresis V

Cyclic sense period

t

(128 cyl.)

OUTHS

OUTHS

QLHS

dONHS

dOFFHS

SDHS

dSDHS

OCLHS

UV ON

UV OFF

UV HY

P CS

–2 V

1V

–4 µA

20 µs

20 µs

–0.8 –0.3 –0.2 A

10 35 50 µs

–1.2 –0.6 –0.3 A

–5.26.0V

4.54.75.2V

–0.5–V

38 65 92 ms

I

I

V

CSN high to OUTHS

CSN high to OUTHS

–

VS increasing

VS decreasing

V

sleep mode

SPI-bit 4 = H,

OUTHS

OUTHS

OUTHS

UV ON

= – 0.15 A

= 0.15 A

= 0 V

– V

UV OFF

Version 2.08 24 2004-06-07

Page 25

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Cyclic sense period

(128 cyl.)

Cyclic sense ON time

t

P CS

t

CS on

55 65 80 ms

0.5 ms

Vbat-stand-by mode;

SPI-bit 4 = H;

watchdog undercurrent feature active

(1 cyl.)

CAN-Transceiver

Receiver Output R×D

HIGH level output voltage

V

OH

V

CC

V

CC

V

I0 = -250 µA

-0.9

LOW level output voltage V

OL

00.9V

I0 = 1.25 mA

Transmission Input T×D

HIGH level input voltage

threshold

LOW level input voltage

threshold

HIGH level input current

LOW level input current I

Bus Lines CANL, CANH

Differential receiver

recessive-to-dominant

threshold voltage

Differential receiver

dominant-to-recessive

threshold voltage

CANH recessive output

voltage

V

IH

V

IL

I

IH

IL

V

dRxDrd

V

dRxDdr

V

CANHr

0.3 ×

V

CC

0.52×

V

CC

0.48×

V

CC

0.7 ×

V

CC

V

V

-150 -30 -10 µA

-600 -300 -40 µA

-2.8 -2.5 -2.2 V

-3.1 -2.9 -2.5 V

0.10.20.3V

Vi = 4 V

Vi = 1 V

TxD = VCC;

R

< 4 kΩ

RTH

Version 2.08 25 2004-06-07

Page 26

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS=13.5V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

CANL recessive output

voltage

CANH dominant output

voltage

CANL dominant output

voltage

CANH output current I

CANL output current I

V

CANLr

V

CANHd

V

CANLd

CANH

CANL

V

CC

V

-0.2

V

CC

-1.4

V

CC

-1.0

V

CC

V

1.0 1.4 V

-110 -80 -50 mA

-5 5 µA

50 80 110 mA

-5 5 µA

TxD = VCC;

R

< 4 kΩ

RTL

TxD = 0 V;

I

= – 40 mA

CANH

TxD = 0 V;

I

= 40 mA

CANL

V

= 0 V;

CANH

TxD = 0 V

sleep mode;

V

= 12 V

CANH

V

= 5 V;

CANL

TxD = 0 V

sleep mode;

V

= 0 V

CANL

Voltage detection threshold

for short-circuit to battery

voltage on CANH and CANL

CANH wake-up voltage

threshold

CANL wake-up voltage

threshold

CANH single-ended receiver

threshold

CANL single-ended receiver

threshold

CANL leakage current I

CANH leakage current I

V

det(th)

V

H,wk

V

L,wk

V

CANH

V

CANL

CANLl

CANHl

6.57.38.0V

1.21.92.7V

2.23.13.9V

1.62.12.6V

2.42.93.4V

-5 5 µA

-5 5 µA

low power modes

low power modes

failure cases 3, 5, 7

recessive to dominant

failure case 6 and 6a

recessive to dominant

VCC=0V, VS=0V,

V

VCC=0V, VS=0V,

V

CANL

CANH

=13.5V

=5V

Version 2.08 26 2004-06-07

Page 27

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Termination Outputs RTL, RTH

I

RTL to V

switch-on

CC

R

RTL

40 95 Ω

=–10 mA;

o

resistance

V

RTL to BAT switch series

resistance

RTH to ground switch-on

R

R

oRTL

RTH

51530kΩ

40 95 Ω

-stand-by or

BAT

sleep mode

I

= 10 mA;

o

resistance

I

RTH output voltage V

RTH pull-down current I

RTL pull-up current I

oRTH

RTHpd

RTLpu

0.7 1.0 V

40 75 120 µA

-120 -75 -40 µA

= 1 mA; sleep mode

o

or V

failure cases 6 and 6a

failure cases 3, 3a, 5

and 7

-stand-by

BAT

RTH leakage current I

RTL leakage current I

CAN-Transceiver

Dynamic Characteristics

CANH and CANL bus output

transition time recessive-todominant

CANH and CANL bus output

transition time dominant-torecessive

Minimum dominant time for

wake-up on CANL or CANH

RTHl

RTLl

t

rd

t

dr

t

wu(min)

-5 5 µA

-5 5 µA

0.61.22.1µs

0.30.61.3µs

12 20 32 µs

VCC=0V, VS=0V,

V

=5V, Tj<85°C

RTH

VCC=0V, VS=0V

V

= 13.5 V,

RTL

T

<85°C

j

10% to 90%;

C

= 10 nF;

1

C

= 0; R

2

10% to 90%;

C

= 1 nF; C2 = 0; R1 =

1

100 Ω

Stand-by modes

= 100 Ω

1

Version 2.08 27 2004-06-07

Page 28

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS=13.5V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Failure cases 3 and 6

t

fail

25 45 80 µs

detection time

Failure case 6a detection

2.0 4.8 8.0 ms

time

Failure cases 5 and 7

1.02.04.0ms

detection time

Failure cases 5, 6, 6a and 7

25 45 80 ms

recovery time

Failure cases 3 recovery time 250 500 750 µs

Failure cases 5 and 7

t

fail

0.41.02.4ms

Stand-by modes

detection time

Failure cases 6 and 6a

0.84.08.0ms

Stand-by modes

detection time

Failure cases 5, 6, 6a and 7

recovery time

Propagation delay

TxD-to-RxD LOW (recessive

to dominant)

t

PD(L)

0.41.02.4ms

–1.52.1µs

–1.72.4µs

–1.82.5µs

–2.02.6µs

Stand-by modes

C1 = 100 pF;

C

failures and bus failure

cases 1, 2, 3a and 4

C1 = C2 = 3.3 nF;

R

failure and failure

cases 1, 2, 3a and 4

C1 100 pF; C2 = 0;

R

cases 3, 5, 6, 6a and 7

C1 = C2 = 3.3 nF;

R

cases 3, 5, 6, 6a and 7

= 0; R

2

= 100 Ω; no bus

1

= 100 Ω; bus failure

1

=100 Ω; bus failure

1

= 100 Ω; no

1

Version 2.08 28 2004-06-07

Page 29

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Propagation delay

TxD-to-RxD HIGH (dominant

to recessive)

Edge-count difference

t

PD(H)

n

e

–1.32.0µs

–2.53.5µs

–1.32.1µs

–1.72.6µs

–4––

C1 = 100 pF;

C

= 0; R

2

failures and bus failure

cases 1, 2, 3a and 4

C1 = C2 = 3.3 nF;

R

= 100 Ω; no bus

1

failure and failure

cases 1, 2, 3a and 4

C1 100 pF; C2 = 0;

R

= 100 Ω; bus failure

1

cases 3, 5, 6, 6a and 7

C1 = C2 = 3.3 nF;

R

= 100 Ω; bus failure

1

cases 3, 5, 6, 6a and 7

=100 Ω; no

1

(falling edge) between CANH

and CANL for failure cases 1,

2, 3a and 4 detection

Edge-count difference (rising

edge) between CANH and

CANL for failure cases 1, 2,

3a and 4 recovery

TxD permanent dominant

t

disable time

SPI-Interface

Logic Inputs DI, CLK and CSN

H-input voltage threshold

V

L-input voltage threshold V

Hysteresis of input voltage V

Pull up current at pin CSN I

TxD

IH

IL

IHY

ICSN

–2––

1.32.03.5ms

– – 0.7 x

V

CC

0.3 x

V

CC

––V

V

50 200 500 mV

–100 –25 –5 µA

–

–

–

V

CSN

= 0.7 × V

CC

Version 2.08 29 2004-06-07

Page 30

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS=13.5V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

V

Pull down current at pin DI

I

ICLK/DI

525100µA

= 0.2 × V

DI

CC

and CLK

Input capacitance

at pin CSN, DI or CLK

C

I

–1015pF

Not subject to

production test specified by design

Logic Output DO

I

H-output voltage level

V

L-output voltage level V

Tri-state leakage current I

Tri-state input capacitance C

DOH

DOL

DOLK

DO

V

V

CC

– 1.0

CC

– 0.7

–V

– 0.2 0.4 V

– 10 – 10 µA

–1015pF

=1 mA

DOH

I

= – 1.6 mA

DOL

V

= V

CSN

0V < VDO < V

Not subject to

production test specified by design

CC

CC

Data Input Timing

Not subject to production test - specified by design

Clock period t

Clock high time t

Clock low time t

Clock low before CSN low t

CSN setup time t

CLK setup time t

Clock low after CSN high t

DI setup time t

DI hold time t

Input signal rise time

pCLK

CLKH

CLKL

bef

lead

lag

beh

DISU

DIHO

t

rIN

at pin DI, CLK and CSN

Input signal fall time

t

fIN

at pin DI, CLK and CSN

1000 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

500 – – ns

250 – – ns

250 – – ns

– –200ns

– –200ns

–

–

–

–

–

–

–

–

–

–

–

Version 2.08 30 2004-06-07

Page 31

7.3 Electrical Characteristics (cont’d)

Final Datasheet TLE 6263

VS= 13.5 V; I

characteristics); all voltages with respect to ground; positive current defined flowing into pin; unless otherwise

specified.

= 1 mA; normal mode; all outputs open; – 40 °C<Tj<150°C (max. 125°C for CAN circuit

CC

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Data Output Timing

Not subject to production test - specified by design

DO rise time t

DO fall time t

DO enable time t

DO disable time t

DO valid time t

rDO

fDO

ENDO

DISDO

VADO

– 50 100 ns

– 50 100 ns

– – 250 ns

– – 250 ns

– 100 250 ns

CL = 100 pF

CL = 100 pF

low impedance

high impedance

VDO < 0.1 VCC;

V

> 0.9 VCC;

DO

= 100 pF

C

L

Thermal Prewarning and Shutdown (junction temperatures)

Not subject to production test - specified by design

OUTHS thermal prewarning

T

jPW

120 145 170 °C

ON temperature

OUTHS thermal prewarning

∆T –30 –K

hyst.

OUTHS thermal shutdown

T

jSD

150 175 200 °C

temp.

OUTHS thermal switch-on

T

jSO

120 – 170 °C

temp.

OUTHS thermal shutdown

∆T –30 –K

hyst.

OUTHS ratio of SD to PW

T

jSD

/ T

jPW

1.20 – –

temp.

Vcc thermal shutdown temp. T

OUTHS thermal shutdown

T

jSD

jSD

155 185 200 °C

150 °C

temp.

bit 0 of SPI

diagnosis word

–

–

–

–

–

hysteresis 15°K

(typ.)

hysteresis 15°K

(typ.)

Version 2.08 31 2004-06-07

Page 32

8 Timing Diagrams

N

C

S

h

H

g

i

S

N

C

Final Datasheet TLE 6263

t

o

o

L

w

&

s

g

i

r

n

i

e

g

d

e

f

o

C

L

:

K

D

O

s

i

e

e

l

b

a

n

a

.

d

t

S

t

s

u

n

i

f

m

r

a

o

n

i

o

i

t

s

t

n

a

r

s

f

e

r

e

d

t

o

O

t

t

u

u

p

S

-

f

i

h

t

s

i

g

R

e

t

r

e

CSN Low to High: Data from Shift-Register is

transfered to e.g. HS-Switch

CLK

DI

DO

0

actual Data

10

DI: Data will be accepted on the falling edge of CLK-Signal

previous Status

0

DO: State will change on the rising edge of CLK-Signal

eg.

OUTHS

Figure 6: SPI-Data Transfer Timing

time

7654321

765423

654321

7

01

a

w

e

D

n

1

0

+

+

actual Status

1

0

t

a

actual Dataold Data

Figure 7: SPI-Input Timing

Version 2.08 32 2004-06-07

Page 33

Final Datasheet TLE 6263

Figure 8: Turn OFF/ON Time

Figure 9: DO Valid Data Delay Time and Valid Time

Version 2.08 33 2004-06-07

Page 34

Final Datasheet TLE 6263

Figure 10: DO Enable and Disable Time

t

WD

t

CWmax

t

CWmin

closed window

min.

5.1

max.

7.2

t

OWmin

open window

10.0

save trigger area

t

OWmax

min.

13.6

max.

t / ms

18.9

Figure 11: Watchdog Time-Out Definitions

Version 2.08 34 2004-06-07

Page 35

Final Datasheet TLE 6263

t

CWtOW

WD

t

CWtOW

tCW+t

OW

t

LW

Trigger

IBIT 0

t

Reset

WDR

Out

Watchdog

timer reset

normal

operation

timeout

(to long)

Figure 12: Watchdog Timing Diagram

t

LW

operation

t

CWtOW

normal

t

CW

timeout

(to short)

t

LW

t

CWtOW

t

t

normal

operation

V

CC

WD

Trigger

IBIT 0

Reset

Out

SPI

diagnosis

bit 6

-Fail

V

INT

Flag in

V

-

Stb

mode

V

RT

Watchdog

timer reset

HIGH

LOW

activation by

microcontroller

t < t

RR

V

INT-Fail

t

RD

start up start up

t

LW

t

WDR

normal operation

t

t

CWtOW

LW

t

RR

t

SR

t

RD

undervoltage

t

CW

t

LW

t

t

t

t

Figure 13: Reset Timing Diagram

Version 2.08 35 2004-06-07

Page 36

Final Datasheet TLE 6263

5 V

C

1

C

2

C

1

13.5 V

100 nF

RxD

R

1

RTH

CANH

CANL

TxD

20 pF

CSN

DO

CLK

R

1

RTL

SI

WK1

WK2

DI

INT

RO

FSO

OUTHS

V

CC

+VS

GND

V

CI

22 µF

100 nF

Figure 14: Test Circuit

Version 2.08 36 2004-06-07

Page 37

9 Application

TLE 6263

26

CANH

24

CANL

Final Datasheet TLE 6263

V

bat

CAN

bus

2

RxD

1

TxD

1 k

Ω

160 k

Ω

*)

100 k

Ω

1 k

Ω

*)

only for improvement refer to 6.9)

10 k

10nF

Ω

68 µF

27

25

16

5

100 nF

RTH

RTL

SI

OUTHS

WK2

WK1

+V

S

GND

6 - 9;

20 - 23

CSN

CLK

DO

DI

INT

RO

V

CC

FSO

V

12

11

10

13

µP

e.g. C505C,

2814

34

19

1715

18

CI

100 nF

22 µF

100 nF

C164C

GND

Figure 15: Application Circuit

Version 2.08 37 2004-06-07

Page 38

10 Package Outlines

P-DSO-28-18

(Plastic Dual Small Outline Package)

Final Datasheet TLE 6263

Sorts of Packing

Package outlines for tubes, trays etc. are contained in our

Data Book “Package Information”.

SMD = Surface Mounted Device

GPS05123

Dimensions in mm

Version 2.08 38 2004-06-07

Page 39

Final Datasheet TLE 6263

Published by

Infineon Technologies AG,

St.-Martin-Strasse 53,

D-81669 München

© Infineon Technologies AG 2001

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as a guarantee of

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Version 2.08 39 2004-06-07

Page 40

Infineon goes for Business Excellence

“Business excellence means intelligent approaches and clearly

defined processes, which are both constantly under rev iew and

ultimately lead to good operating results.

Better operating results and business excellence mean less

idleness and wastefulness for all of us, more professional

success, more accurate information, a better overview and,

thereby, less frustration and more satisfaction.”

Dr. Ulrich Schumacher

http://www.infineon.com

Published by Infineon Technologies AG

Loading...

Loading...