现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Fault Tolerant CAN - LDO TLE 6262 G

Final Data Sheet

1Overview

1.1 Features

• Standard fault tolerant differential CAN-transceiver

(TLE6254 LS CAN cell)

• Bus failure management

• Low power mode management

• CAN data transmission rate up to 125 kBaud

• Low-dropout voltage regulator 5V ± 2%

• Two Low Side Switches

• Three High Side Switches

• Power on and under-voltage reset generator

• Vcc supervisor

• Window watchdog

• Programable time base

• Integrated fail-safe mechanism

• Standard 16 bit SPI-Interface

• Wide input voltage and temperature range

• Enhanced power P-DSO-Package

P-DSO-28-6

Enhanced Power

Type Ordering Code Package

TLE 6262 G on request P-DSO-28-6

Description

The TLE 6262 G is a monolithic integrated circuit in a P-DSO-28-6 package, which

incorporates a failure tolerant low speed CAN-transceiver for differential mode data

transmission, a low dropout voltage regulator for internal and external 5V supply as well

as a 16 bit SPI interface to control and monitor the IC. Further there are integrated three

high side switches, two low side switches, a window watchdog circuit and a reset circuit.

Both, the window watchdog and reset function are referring to a time base that is

programmable via an external resistor.

The IC is designed to withstand the severe conditions of automotive applications.

1 version: 2.03 date: 2002-03-20

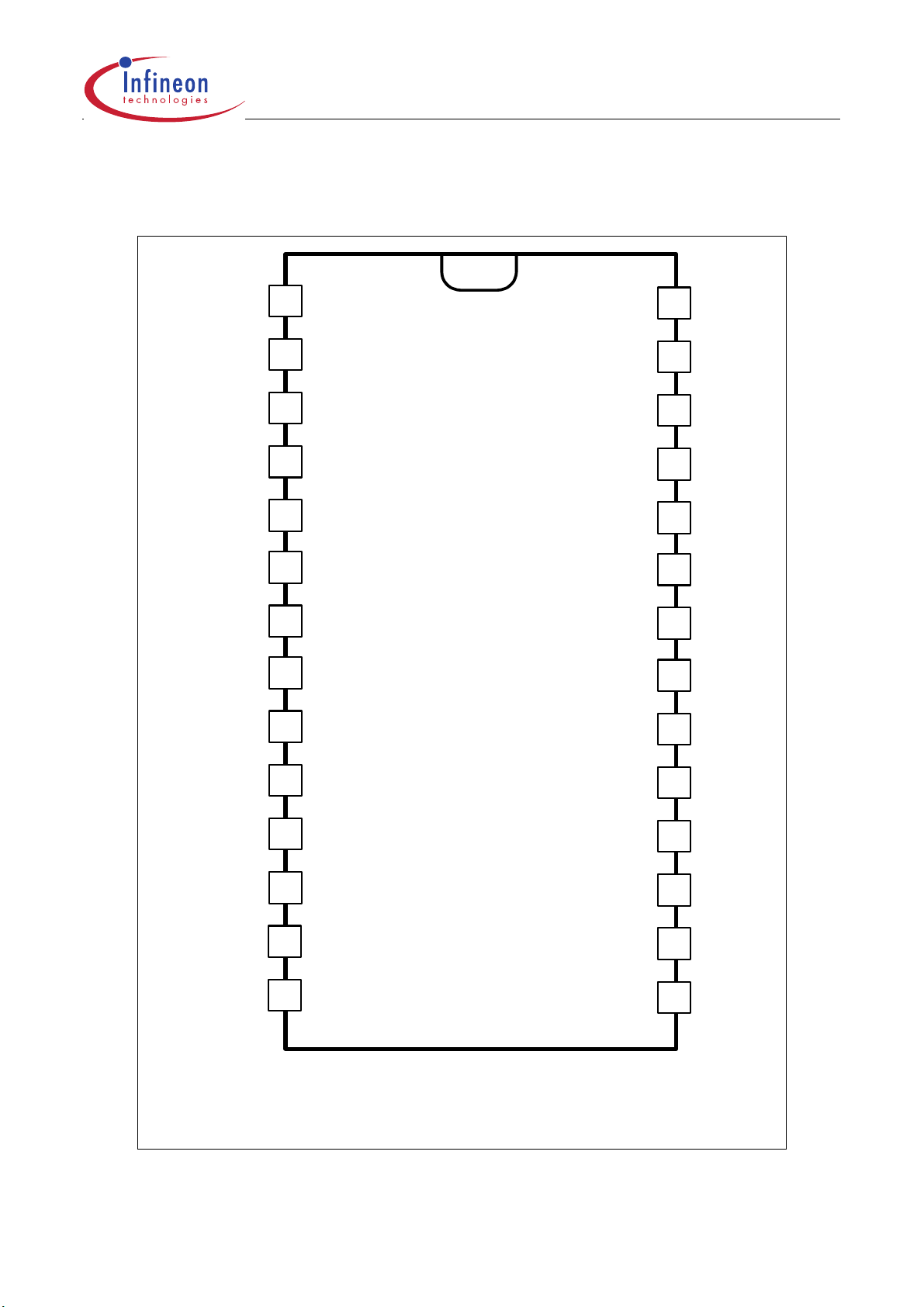

1.2 Pin Configuration

(top view)

Final Data TLE 6262 G

RO

1

2

3

4

5

6

7

8

9

28

27

26

25

24

23

22

21

20

OSC

PWM

TxD

RxD

Vcc

GND

GND

CANH

RTH

CANL

RTL

GND GND

GND

GND GND

GND

Figure 1

OUTH1

OUTL1

OUTL2

OUTH2

OUTH3

10

11

12

13

14

P-DSO-28-6

(enhanced power package)

19

18

17

16

15

CLK

DI

DO

CSN

Vs

2 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

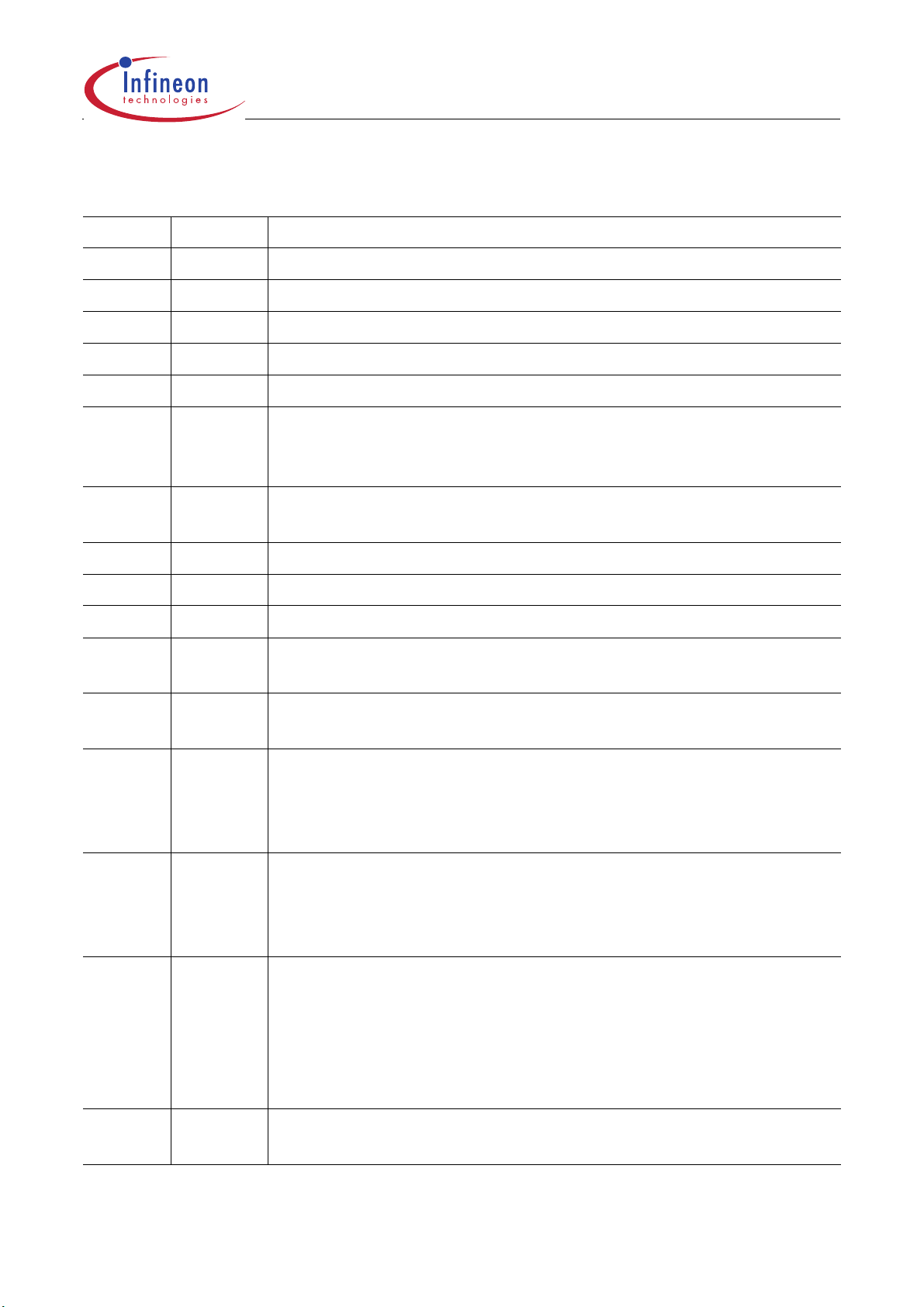

1.3 Pin Definitions and Functions

Pin No. Symbol Function

1CANHCAN-H bus line; HIGH in dominant state

2RTHTermination input for CANH

3ROReset output; open drain output; integrated pull up; active low

4CANLCAN-L bus line; LOW in dominant state

5RTLTermination input for CANL

6, 7, 8, 9,

20, 21,

GND Ground; to reduce thermal resistance place cooling areas on

PCB close to this pins.

22, 23

10 OUTH1 High side output 1; controlled via PWM input and/or SPI input,

short circuit protected

11

OUTL1 Low side output 1; SPI controlled, with active zener

12 OUTL2 Low side output 2; SPI controlled, with active zener

13 OUTH2 High side output 2; SPI controlled

14 OUTH3 High side output 3; SPI controlled, in low power mode controlled

by internal autotiming function if selected

15

VS Power supply; block to GND directly at the IC with ceramic

capacitor

16 CSN SPI interface chip select not; CSN is an active low input; serial

communication is enabled by pulling the CSN terminal low; CSN

input should only be transitioned when CLK is low; CSN has an

internal active pull up and requires CMOS logic level inputs

17 DO SPI interface data out; this tristate output transfers diagnosis

data to the control device; the output will remain 3-stated unless

the device is selected by a low on Chip-Select-Not (CSN); see

table 3 for diagnosis protocol

18 DI SPI interface data in; receives serial data from the control

device; serial data transmitted to DI is a 16 bit control word with

the Least Significant Bit (LSB) being transferred first: the input

has an active pull down and requires CMOS logic level inputs; DI

will accept data on the falling edge of CLK-signal; see table 2 for

input data protocol

19 CLK SPI interface clock input; clocks the shiftregister; CLK has an

internal active pull down and requires CMOS logic level inputs

3 version: 2.03 date: 2002-03-20

1.3 Pin Definitions and Functions (cont’d)

Pin No. Symbol Function

Final Data TLE 6262 G

24 V

CC

Output voltage regulator; 5V logic supply, block to GND with an

100nF external ceramic capacitor directly at the IC + external

capacitor C

³ 22 µF

Q

25 RxD CAN Receive data output;

26 TxD CAN Transmit data input; integrated pull up

27 PWM Pulse width control; for high side switch 1

28 OSC Oscillator input; time base for power on reset, watchdog window

and stand by timer for HS3, to program connect external resistor

to GND

4 version: 2.03 date: 2002-03-20

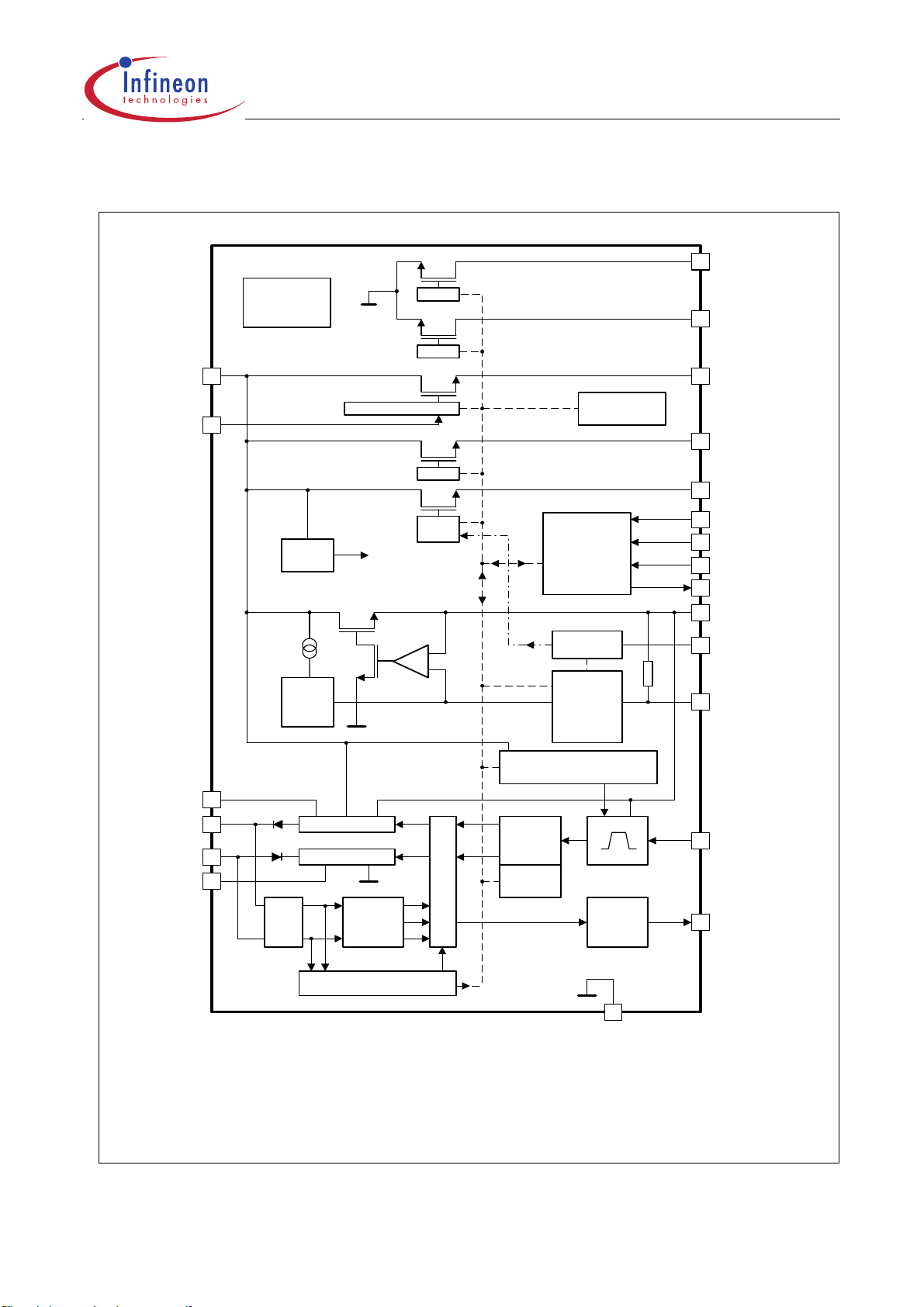

1.4 Functional Block Diagram

Final Data TLE 6262 G

OUTL1

Vs

PWM

RTL

CANH

CANL

RTH

Charge

Pump

UVLO

Band

Gap

Protection + Drive

POR

H Output Stage

L Output Stage

Drive

Drive

Drive

Drive

-

+

Switch

Fail Detect

SPI

Timer

Reset

Generator

+

Window

Watchdog

CAN

Standby / Sleep Control

Driver

Temp.

Protect

OUTL2

OUTH1

OUTH2

OUTH3

CSN

CLK

DI

DO

Vcc

OSC

RO

TxD

Figure 2

Filter

Receiver

CAN Fail Detect

Input

Fail Management

Stage

GND

RxD

5 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

1.5 Circuit Description

The TLE 6262 G is a monolithic IC, which incorporates a failure tolerant low speed CANtransceiver for differential mode data transmission, a low dropout voltage regulator for

internal and external 5V supply as well as a SPI interface to control and monitor the IC.

Further there are integrated three high side switches, two low side switches, a window

watchdog circuit and a reset circuit. Both, the window watchdog and reset function are

referring to a time base that is programmable via an external resistor.

Figure 2 shows a block schematic diagram of the TLE 6262 G

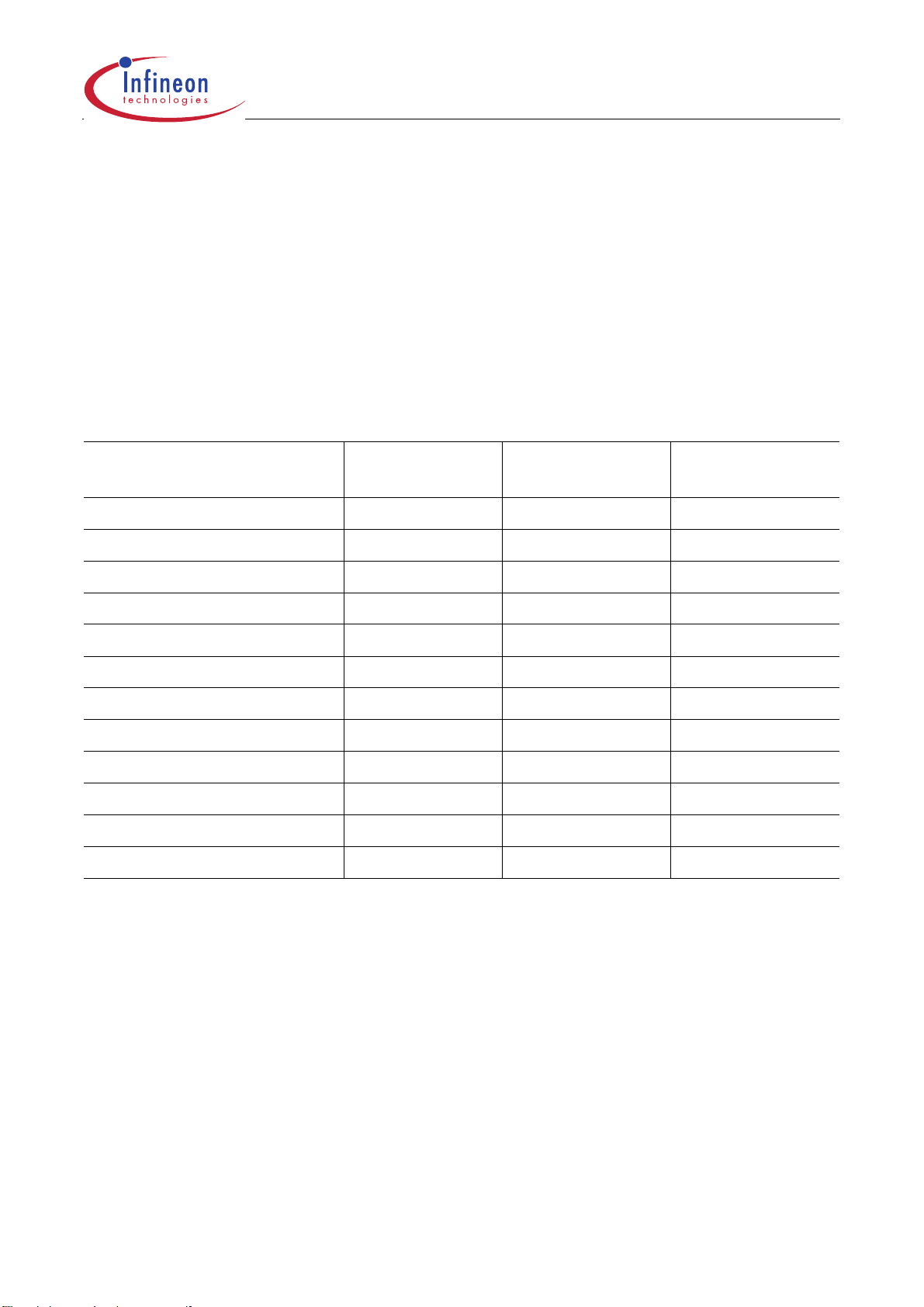

Table 1: mode truth table

Feature normal mode Receive-only

mode

V

CC

ON ON ON

V

BAT

mode

stand-by

Reset ON ON ON

Watchdog ON

1)

ON

1)

ON

1)

SPI ON ON ON

CAN transmit ON OFF OFF

CAN receive ON ON OFF

OUTHS 1

OUTHS 2

OUTHS 3

OUTHS3-auto timing

OUTLS 1

OUTLS 2

1)

at low VCC output current only active when watchdog undercurrent function is not activated

2)

a bus wake-up is monitored by setting the RxD output low

3)

only active when selected via SPI

4)

also active when driven via the PWM input

5)

automatically disabled when a reset occurs

6)

automatically disabled when a reset or watchdog reset respectively, occurs or the watchdog is disabled

by the undercurrent function

3) 4) 5)

3) 5)

3) 5)

3) 6)

3) 6)

3) 5)

ON ON ON

ON ON ON

ON ON ON

OFF ON ON

ON ON ON

ON ON ON

2)

6 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

CAN Transceiver

The TLE 6262 is optimized for low speed data transmission up to 125 kbaud in

automotive applications. Normally a differential signal is transmitted or received

respectively. When a bus wiring failure (see table 4) is detected the device automatically

switches to a dedicated CANH or CANL single-wire mode to maintain the communication

if necessary. Therefore it is equipped with one differential receiver and four single ended

comparators (two for each bus line). To avoid false triggering by external RF influences

the single wire modes are activated after a certain delay time. As soon as the bus failure

disappears the transceiver switches back to differential mode after another time delay.

The bus failures are monitored via the diagnosis protocol of the SPI. Therefore it is

possible to distinguish 6 CAN bus failures or failure groups on the bits 8 to 13 (see table

3).

To reduce EMC caused by the transceiver the dynamic slopes of the CANL and CANH

signals are both limited and symmetric. This allows the use of an unshielded twisted or

parallel pair of wires for the bus. During single-wire transmission (bus-failure) the EMC

performance of the system is degraded from the differential mode.

The differential receiver threshold is set to typ. -2.8 V. This ensures correct reception in

the normal operation mode as well as in the failure cases 1, 2, 3a and 4 with a noise

margin as high as possible. When one of the bus failures 3, 5, 6, 6a, and 7 is detected,

the defective bus wire is disabled by switching off the affected bus termination and output

stage.

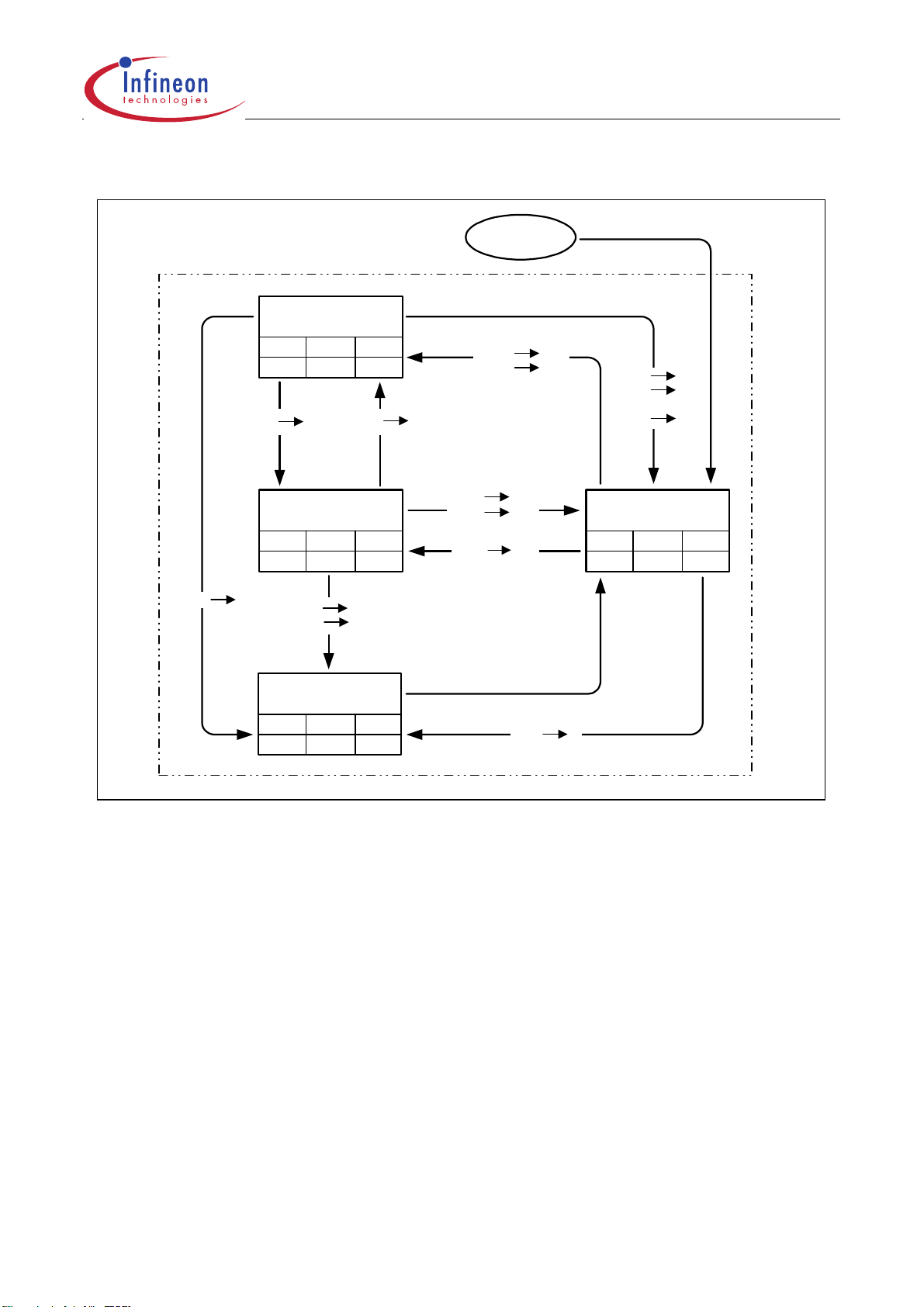

The CAN-transceiver offers three different operation modes that are controlled via the

SPI: the normal operation mode, Receive-only mode and V

see the state diagram (figure 3). In the V

switched to V

.

S

stand-by mode the RTL output voltage is

bat

stand-by mode. Please

bat

In case of a wake-up via the bus lines or one of the bus lines respectively, the TLE 6262

automatically sets the RxD output LOW. To send respectively receive messages the

CAN-transceiver can now be set in normal operation mode or receive-only mode by the

microcontroller.

When a reset occurs the transceiver circuit is automatically switched to V

-stand-by

bat

mode because the SPI input bits are automatically set LOW for this event.

A thermal shutdown of the CAN-transceiver circuit is monitored via the SPI diagnosis

bit 15.

7 version: 2.03 date: 2002-03-20

Normal Mode

Final Data TLE 6262 G

Start Up

Power Up

NSTB 0

NSTB

ENT

11

ENT 0 ENT 1

V

CC

ON

RxD-Only

NSTB

ENT

10

NSTB

ENT

V

CC

ON

0

1

Go- To-Sleep

Mode

NSTB

ENT

01

V

CC

ON

NSTB

V

CC

NSTB

NSTB

ENT

1

1

0 or

V

RT

1

ENT 1

NSTB

ENT

or

V

CC

V

Stand-By

bat

NSTB

ENT

00

0

0

V

RT

V

CC

ON

Figure 3: State Diagram

Low Dropout Voltage Regulator

The TLE 6262 is able to drive external 5V loads up to 45 mA. Its output voltage tolerance

is less than ± 2%. In addition the regulator circuit drives the internal loads like the CANtransceiver circuit.

An external reverse current protection is recommended to prevent the output capacitor

from being discharged by negative transients or low input voltage.

Stability of the output voltage is guaranteed for output capacitors C

³ 100 nF.

VCC

Nevertheless a lot of applications require a much larger output capacitance to buffer the

output voltage in case of low input voltage or negative transients. Furthermore the due

function of e.g. the reset and 3V-supervisor circuit are supported by a larger output

capacitance because of their reaction times. Therefore a output capacitance

C

³ 10 µF is recommended.

VCC

8 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

SPI (serial peripheral interface)

The 16-bit wide programming word or input word (see table 1) is read in via the data input

DI, and this is synchronized with the clock input CLK supplied by the µC. The diagnosis

word appears synchronously at the data output DO (see table 3).

The transmission cycle begins when the chip is selected by the chip select not input CSN

(H to L). After the CSN input returns from L to H, the word that has been read in becomes

the new control word. The DO output switches to tristate status at this point.

For details of the SPI timing please refer to figure 3 to 7.

Oscillator

All internal delay times are referring to the internal oscillator frequency, which is set by

an external resistor from pin OSC to GND. The oscillator frequency and the resulting

internal cycling time can be calculated by the equations:

9

´10 HzW[]

R

OSC

32

------------=

f

OSC

f

OSC

t

CYL

28 45,

-----------------------------------------=

Window Watchdog, Reset and 3V-Supervisor

When the output voltage V

exceeds the reset threshold voltage VRT the reset output

CC

RO is switched HIGH after a delay time of 16 cycles. This is necessary for a defined start

of the microcontroller when the application is switched on. As soon as an under-voltage

condition of the output voltage (V

LOW again. The LOW signal is guaranteed down to an output voltage V

< VRT) appears, the reset output RO is switched

CC

³ 1V. Please

CC

refer to fig.11, reset timing diagram.

Should the output voltage fall short of the 3V-supervisor threshold V

an internal flip-

ST

flop is set LOW. The SPI diagnosis bit 7 monitors this. In normal operation this flip-flop

has to be activated via the SPI input bit 7. This feature is useful e.g. to monitor that the

RAM data of the microcontroller might be damaged or the application is connected to V

the first time.

S

After the above described delayed reset (LOW to HIGH transition of RO) the window

watchdog circuit is started by opening a long open window of 32 cycles. Now the

microcontroller has to service a watchdog trigger signal via the SPI interface (input bit 0).

A watchdog trigger is detected as a falling edge by sampling for 2 cycles a HIGH followed

by 2 cycles LOW of the SPI input bit 0. The long open window ensures a simple and fast

9 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

synchronization of the TLE 6262 watchdog timing to the watchdog services of the

microcontroller.

After the first trigger the watchdog has to be serviced by meeting an open window of 20

cycles that follows a closed window of 12 cycles. A correct watchdog service

immediately results in starting the next closed window. Please refer to fig. 10, watchdog

timing diagram.

If the trigger signal does not meet the open window (trigger to early or to late) the reset

output RO is set LOW for a period of 4 cycles. Afterwards a long open window is started

again. In addition, the SPI diagnosis bit 2 is set HIGH to monitor a watchdog reset.

Both, the undervoltage reset and the watchdog reset are setting all SPI input bits LOW.

To avoid a cyclic wake-up of the microcontroller in low power mode (sleep mode) the

watchdog circuit can be automatically disabled at low output currents (I

CC

< I

CCWD

activate this feature the SPI input bit 8 has to be set HIGH. In this under-current mode

the low side switches are switched off automatically by the TLE 6262 to guarantee failsave operation of the application. When the microcontroller returns back to normal mode

> I

(I

CC

CCWD

) the first closed window is transformed to an open window so that the total

open window time is 32 cycles. This ensures a more simple and fast synchronization of

the TLE 6262 watchdog timing to the watchdog services of the microcontroller.

). To

Flash program mode

To disable the watchdog feature a flash program mode is available. This mode is

selected by applying a voltage of 6.8V < V

< 7.2V at pin PWM. This is useful e.g. if

PWM

the flash-memory of the micro has to be programmed and therefore a regular watchdog

triggering is not possible. If the SPI is required in the flash program mode to change e.g.

the mode of the TLE6262 the first input telegram has to be “00000000”.

High Side Switch 1

The high side output OUTH1 is able to switch loads up to 250 mA. Its on-resistance is

1.0 W typ. @ 25°C. This switch can be controlled either via the PWM input or the SPI

input bit 1. When the input PWM is used it has to be enabled by setting the SPI input bit

11 HIGH. In case of both control inputs being active the PWM signal is masked by the

SPI signal (see fig. 8, High Side Switch 1 Timing Diagram).

The SPI diagnosis bit 14 monitors a thermal shutdown of the switches, whereas bit 0

flags a thermal prewarning. By this the microcontroller is able to reduce the power

dissipation of the TLE 6262 by switching off functions of minor priority before the

temperature threshold of the thermal shutdown is reached. Further OUTH1 is protected

against short circuit and overload. The SPI diagnosis bit 1 indicates an overload of

OUTH1. As soon as the under-voltage condition of the supply voltage is met (V

V

UVOFF

), the switches are automatically disabled by the under-voltage lockout circuit.

S

<

10 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

This is flagged by the SPI diagnosis bit 3. Moreover the switches are disabled when a

reset occurs.

High Side Switch 2

The high side output OUTH2 is able to switch loads up to 250 mA. Its on-resistance is

1.0 W typ. @ 25°C. This switch is controlled via the SPI input bit 2.

The SPI diagnosis bit 14 monitors a thermal shutdown of the switches, whereas bit 0

flags a thermal prewarning. By this the microcontroller is able to reduce the power

dissipation of the TLE 6262 by switching off functions of minor priority before the

temperature threshold of the thermal shutdown is reached. As soon as the under-voltage

condition of the supply voltage is met (V

< V

S

UVOFF

disabled by the under-voltage lockout circuit. This is flagged by the SPI diagnosis bit 3.

Moreover the switches are disabled when a reset occurs.

), the switches are automatically

High Side Switch 3

The high side output OUTH3 is able to switch loads up to 150 mA. Its on-resistance is

1.5 W typ. @ 25°C. This switch is controlled via the SPI input bits 3 and 4. To supply

external wake-up circuits in low power mode (sleep mode or Vbat-stand-by mode), the

output OUTH3 can be periodically activated by the internal oscillator circuit. For

activating this feature the SPI input bits 3 and 4 have to be set HIGH. The autotiming

period is 128 internal cycle times; the on-time is 2 cycles. In case of a watchdog reset

the autotiming period may be shorter.

The SPI diagnosis bit 14 monitors a thermal shutdown of the switches, whereas bit 0

flags a thermal prewarning. By this the microcontroller is able to reduce the power

dissipation of the TLE 6262 by switching off functions of minor priority before the

temperature threshold of the thermal shutdown is reached. As soon as the under-voltage

condition of the supply voltage is met (V

< V

S

UVOFF

), the switches are automatically

disabled by the under-voltage lockout circuit. This is flagged by the SPI diagnosis bit 3.

Moreover the switches are disabled when a reset occurs.

Low Side Switches 1/2

The two low side outputs OUTL1 and OUTL2 are able to switch loads up to 100 mA.

Their on-resistance is 1.5 W (typ.) @ 25°C. This switches are controlled via the SPI input

bits 5 and 6. In case of high inrush currents a built in zener circuit (typ. 37 V) activates

the switches to protect them.

The SPI diagnosis bit 14 monitors a thermal shutdown of the switches, whereas bit 0

flags a thermal prewarning. By this the microcontroller is able to reduce the power

dissipation of the TLE 6262 by switching off functions of minor priority before the

temperature threshold of the thermal shutdown is reached. The SPI diagnosis bits 5/6

11 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

are giving a feedback about current status of OUTL1/OUTL2. As soon as the undervoltage condition of the supply voltage is met (V

< V

S

UVOFF

automatically disabled by the under-voltage lockout circuit. This is flagged by the SPI

diagnosis bit 3. In addition the outputs OUTL1 and OUTL2 are also disabled when the

watchdog is switched off in undercurrent state or when a reset occurs.

), the switches are

12 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

Table 2 Table 3

Input Data Protocol Diagnosis Data Protocol

BIT BIT

15 not used 15 Thermal Shutdown Transceiver

14 not used 14 Thermal Shutdown Switches

13 not used 13 CAN Failure 2 and 4

12 not used 12 CAN Failure 1 and 3a

11 PWM Enable 11 CAN Failure 6

10 CAN Enable Transmit 10 CAN Failure 6a

9 CAN Not Stand-By 9 CAN Failure 6a, 5 and 7

8 Watchdog Control 8 CAN Failure 3

7 Supervisor Enable 7 Vcc < 3V

6 LS-Switch 2 6 Status LS2

5 LS-Switch 1 5 Status LS1

4 HS3 Auto Timing 4 not used

3 HS-Switch 3 3 Vs Undervoltage Lockout

2 HS-Switch 2 2 Window Watchdog Reset

1 HS-Switch 1 1 Overload HS1

0 Watchdog Trigger 0 Temperature Prewarning

H= ON

L= OFF

H= ON

L= OFF

13 version: 2.03 date: 2002-03-20

Table 4

CAN bus line failure cases (according to ISO 11519-2)

Final Data TLE 6262 G

failure

failure description

#

1 CANL line interrupted

2 CANH line interrupted

3 CANL shorted to Vbat, CANL > 7.2 V

(no ISO failure) CANL shorted to Vcc; 3.2 V < CANL < 7.2 V

3a

4 CANH shorted to GND

5 CANL shorted to GND

6 CANH shorted to Vbat; CANH > 7.2 V

6a

(no ISO failure) CANH shorted to Vcc; 1.8 V < CANH < 7.2 V

7 CANL shorted to CANH

14 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2 Electrical Characteristics

2.1 Absolute Maximum Ratings

Parameter Symbol Limit Values Unit Remarks

min. max.

Voltages

Supply voltage

V

Supply voltage V

Regulator output voltage V

CAN input voltage

CAN input voltage

(CANH, CANL) V

V

(CANH, CANL)

Logic input voltages (DI, CLK,

CSN, OSC, PWM, TxD)

Logic output voltage

(DO, RO, RxD)

Termination input voltage

(RTH, RTL)

Electrostatic discharge

voltage at pin CANH, CANL

Electrostatic discharge

voltage

V

V

V

V

V

S

S

CC

CANH/L

CANH/L

I

DO/RO/RD

TL /TH

ESD

ESD

-0.3 28 V

-0.3 40 V

-0.3 5.5 V

-10 28 V

-40 40 V

-0.3 V

CC

V

+0.3

-0.3 V

CC

V

+0.3

-0.3 V

S

V

+0.3

-4000 4000 V

-2000 2000 V

–

tp< 0.5s; tp/T < 0.1

VS >0 V

t

< 0.5s; tp/T < 0.1

p

0 V < VS < 24 V

0 V < V

0 V < VS < 24 V

0 V < V

0 V < VS < 24 V

0 V < V

human body model;

C = 100pF, R = 1.5kW

human body model;

C = 100pF, R = 1.5kW

< 5.5 V

CC

< 5.5 V

CC

< 5.5 V

CC

Currents

Output current; Vcc

Output current; OUTH1 I

Output current; OUTH2 I

Output current; OUTH3 I

Output current; OUTL1 I

Output current; OUTL2 I

I

CC

OUTH1

OUTH2

OUTH3

OUTL1

OUTL2

––A

*) 0.3 A

-0.7 0.3 A

-0.5 0.2 A

-0.2 0.4 A

-0.2 0.4 A

15 version: 2.03 date: 2002-03-20

internally limited

*) internally limited

tp< 0.5s; tp/T < 0.1

tp< 0.5s; tp/T < 0.1

tp< 0.5s; tp/T < 0.1

tp< 0.5s; tp/T < 0.1

Final Data TLE 6262 G

2.1 Absolute Maximum Ratings (cont’d)

Parameter Symbol Limit Values Unit Remarks

min. max.

Temperatures

Junction temperature

Storage temperature T

Note: Maximum ratings are absolute ratings; exceeding any one of these values may cause

irreversible damage to the integrated circuit.

T

j

stg

-40 150 °C

-50 150 °C

–

–

16 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.2 Operating Range

Parameter Symbol Limit Values Unit Remarks

min. max.

Supply voltage

V

Supply voltage slew rate dV

Supply voltage increasing V

Supply voltage decreasing V

Logic input voltage (DI, CLK,

V

CSN, PWM, TxD)

Output current I

Output current

CC

I

CC

Output capacitor C

SPI clock frequency

f

CLK

OSC-Adjust Resistor R

Junction temperature

T

Thermal Resistances

S

/dt -0.5 5 V/ms

S

S

S

I

V

UV OFF

-0.3 V

-0.3 V

-0.3 V

27 V

UV ON

UV OFF

CC

35 mA

45 mA

CC

22 mF

–1MHz

OSC

j

51 680 kW

-40 150 °C

V

V

V

After VS rising above

V

–

Outputs in tristate

Outputs in tristate

–

T < 0.1s

–

Ta=-40°C; f = 10kHz

–

UV ON

Junction pin

R

Junction ambient R

thj-pin

thj-a

–25K/W

–65K/W

Thermal Prewarning and Shutdown (junction temperatures)

Thermal prewarning

T

jPW

120 170 °C

ON temperature

Thermal shutdown temp. T

Ratio of SD to PW temp. T

Thermal shutdown temp. CAN T

jSD

jSD

jSD

/ T

150 200 °C

1.05 – –

jPW

135 160 °C

measured to pin 7

–

bit 0 of SPI diagnosis

word;

hysteresis 30°K (typ.)

hysteresis 30°K (typ.)

–

hysteresis 10°K (typ.)

17 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

Quiescent current Pin

Current consumption I

Quiescent current

I

= IS - I

SSB1

CC

Voltage Regulator; Pin V

Output voltage V

Output voltage V

Line regulation ,V

Load regulation ,V

V

S

–510mA

– 180 280 mA

4.95.05.2V

4.85.05.5V

-20 20 mV

-25 25 mV

CC

S

I

SSB1

CC

CC

CC

CC

Power supply ripple rejection PSRR 40 dB

Output current limit I

Drop voltage

VDR = VS - V

CC

CCmax

V

DR

45 60 mA

0.15 0.45 V

low power mode;

V

=12V; Tj=25°C

S

0.1mA < ICC< 30mA

0A < I

9V<VS< 15 V;

I

CC

0.1mA < ICC< 30mA;

V

S

VS< 1 Vss;

C

Q

100Hz< f <100kHz

1)

I

CC

see note 1)

CC

= 10mA

=9V

³ 22µF;

= 30 mA;

< 100µA

Oscillator; Pin OSC

Oscillating frequency

Internal cycling time

-1

(1/32 * f

1) measured when the output voltage V

voltage V

OSC

S

)

R

R

OSC

OSC

= 453kW

= 453kW

f

OSC

t

CYL

has dropped 100 mV from the nominal value obtained at 13.5 V input

CC

383 509 637 µs

62.8 kHz

18 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

Reset Generator; Pin RO

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

Reset threshold voltage

Reset low output voltage

V

V

Reset high output voltage V

Reset pull up current

I

Reset reaction time t

Reset delay time (16 cyl.) t

RT

RO

RO

RO

RR

RD

4.0 4.3 4.65 V

4.0 VCC+

20 150 500 mA

1310µs

6.1 8.1 10.2 ms

3 V Supervisor; (bit 7 of SPI diagnosis word)

Supervisor threshold voltage

Supervisor reaction time

V

t

ST

SR

2.32.73.1V

2820µs

Watchdog Generator

0.2 0.4 V

V

0.1

I

= 1mA

RO

(V

³ VRT) or

CC

V

³ 1V

CC

(I

= 200 µA)

RO

V

= 0V

RO

V

< V

CC

RO = L

R

OSC

V

CC

diagnosis bit 7 = L

to

RT

= 453kW

< V

to

ST

Watchdog trigger time

Closed window time (12 cyl.) t

Open window time (20 cyl.) t

Watchdog reset-puls time

(4 cyl.)

Watchdog activating current I

Watchdog activating current

hysteresis

t

WD

CW

OW

t

WDR

CCWD

I

CCWDhys

R

7.6 10 12.3 ms

4.66.17.6ms

7.7 10.2 12.7 ms

1.52.02.6ms

2412mA

= 453kW

OSC

R

= 453kW

OSC

R

= 453kW

OSC

R

= 453kW

OSC

Tj<85°C; Watchdog

OFF when

I

< I

CC

input bit 8 = H

CCWD

and SPI-

0.5 mA

19 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

Long open window (32 cyl.) I

Switches

Under-Voltage Lockout (bit 3 of SPI diagnosis word)

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

R

CCWDhys

12.2 16.2 20.4 ms

= 453kW

OSC

sleep mode (WD OFF)

to normal mode

UV-Switch-ON voltage

V

UV-Switch-OFF voltage V

UV-ON/OFF-Hysteresis V

UV ON

UV OFF

UV HY

– 5.35 6.00 V

4.50 4.85 5.20 V

–0.5–V

VS increasing

VS decreasing

V

UV ON

– V

High Side Output OUTH1; (controlled by PWM or bit 1 of SPI input word)

Static Drain-Source

R

ON-Resistance;

I

OUTH1

= -0.25 A

Active zener voltage V

Clamp diode forward voltage V

Leakage current I

Switch ON delay time t

Switch OFF delay time t

Overcurrent shutdown

I

DSON H1

OUTH1

OUTH1

OLH1

dONH1

dOFFH1

SDH1

–1.02.0W

1.5 4.0 W

-5.0 -3.0 -0.5 V

0.8 1 V

-100 -5 – µA

10 100 ms

20 100 ms

-1.0 -0.6 -0.3 A

5.2 V £ VS £ 9V

I

I

V

PWM to OUTH1;

R

PWM to OUTH1;

R

–

OUTH1

OUTH1

OUTH1

= 100 W

L

= 100 W

L

= – 0.25 A

= 0.25 A

= 0 V

threshold

UV OFF

Shutdown delay time t

Current limit

dSDH1

I

OCLH1

10 25 50 ms

-2.0 -1.0 -0.5 A

20 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

PWM Input to control OUTH1; Pin PWM (high active)

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

H-input voltage threshold

V

L-input voltage threshold V

Hysteresis of input voltage V

Pull down current I

Input capacitance C

IH

IL

IHY

I

I

––0.7

V

´

0.2

´V

––V

cc

V

CC

50 200 500 mV

5 25 180 mA

–1015pF

High Side Output OUTH2; (controlled by bit 2 of SPI input word)

Static Drain-Source

R

ON-Resistance;

I

OUTH2

= -0.25 A

Active zener voltage V

Clamp diode forward voltage V

Leakage current I

Switch ON delay time t

Switch OFF delay time t

DSON H2

OUTH2

OUTH2

OLH1

dONH1

dOFFH1

–1.02.0W

1.5 4.0 W

-5.0 -3.0 -0.5 V

0.8 1 V

-100 -5 – µA

10 100 µs

20 100 µs

–

–

–

VI = 0.2 * V

0V < V

5.2 V £ VS £ 9V

I

OUTH2

I

OUTH2

V

OUTH2

CSN high to OUTH2;

R

= 100 W

L

CSN high to OUTH2;

R

= 100 W

L

CC

< 5.25 V

CC

= – 0.25 A

= 0.25 A

= 0 V

High Side Output OUTH3; (controlled by bit 3 and bit 4 of SPI input word)

Static Drain-Source

R

ON-Resistance;

I

OUTH3

= -0.15 A

Active zener voltage V

Clamp diode forward voltage V

Leakage current I

DSON H3

OUTH3

OUTH3

OLH3

–1.53.0W

2.0 5.0 W

-5.0 -3.0 -0.5 V

0.8 1 V

-100 -5 – µA

21 version: 2.03 date: 2002-03-20

5.2 V £ VS £ 9V

I

= – 0.15 A

OUTH3

I

= 0.15 A

OUTH3

V

OUTH3

= 0 V

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

Leakage current I

Switch ON delay time t

Switch OFF delay time t

Auto time period

OLH3

dONH3

dOFFH3

t

PH3

–5 µA

10 100 µs

20 100 µs

49 65 82 ms

(128 cyl.)

Auto time ON duty cycle

D.C. 1/64

(2 cyl.)

Low Side Output OUTL1 (bit 5 of SPI input word)

Static Drain-Source

R

ON-Resistance;

I

OUTL1

= 0.1 A

Active zener clamp voltage V

Leakage current I

Switch ON delay time t

Switch OFF delay time t

DSON L1

OUTL1

OLL1

dONL1

dOFFL1

–1.53.0W

2.0 5.0 W

32 37 42 V

550µs

550µs

V

CSN high to OUTH3;

R

CSN high to OUTH3;

R

R

SPI-bit 4 = H,

no WD reset

referring to t

5.2 V £ VS £ 9V

I

OUTL1

5µA

V

T

CSN high to OUTL1;

R

CSN high to OUTL1;

R

OUTH3

= 100 W

L

= 100 W

L

= 453kW;

OSC

= – 0.1 A

OUTL1

< 85°C

j

= 100 W

L

= 100 W

L

= 5 V

PH3

=15 V;

Low Side Output OUTL2 (bit 6 of SPI input word)

Static Drain-Source

R

ON-Resistance;

I

OUTL2

= 0.1 A

Active zener clamp voltage V

Leakage current I

Switch ON delay time t

Switch OFF delay time t

DSON L2

OUTL2

OLL2

dONL2

dOFFL2

–1.53.0W

2.0 5.0 W

32 37 42 V

550µs

550µs

22 version: 2.03 date: 2002-03-20

5.2 V £ VS £ 9V

I

OUTL2

5µA

V

T

CSN high to OUTL2;

R

CSN high to OUTL2;

R

= – 0.1 A

OUTL2

< 85°C

j

= 100 W

L

= 100 W

L

=15 V;

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

CAN-Transceiver

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

Receiver Output R

HIGH level output voltage

´D

V

LOW level output voltage V

Transmission Input T´D

HIGH level input voltage

V

threshold

LOW level input voltage

V

threshold

HIGH level input current I

LOW level input current I

Bus Lines CANL, CANH

Differential receiver

V

recessive-to-dominant

threshold voltage

OH

OL

IH

IL

IH

IL

dRxD(rd)

V

CC

–

V

CC

V

– 0.9

0–0.9V

0.30´

V

CC

0.52´

V

CC

0.48´

V

CC

0.70´

V

CC

V

V

-140 -40 -10 µA

-600 -200 -40 µA

-2.8 -2.5 -2.2 V

I0 = – 250µA

I0 = 1.25mA

Vi = 4 V

Vi = 1 V

Differential receiver

dominant-to-recessive

threshold voltage

CANH recessive output

voltage

CANL recessive output

voltage

CANH dominant output

voltage

V

dRxD(dr)

V

CANHr

V

CANLr

V

CANHd

-3.1 -2.9 -2.5 V

0.1 0.2 0.3 V

V

CC

––

V

- 0.2

V

CC

-1.4

23 version: 2.03 date: 2002-03-20

V

CC

-1.0

V

CC

V

TxD = VCC;

R

< 4 kW

RTH

TxD = VCC;

R

< 4 kW

RTL

TxD = 0 V;

I

= – 40 mA

CANH

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

CANL dominant output

voltage

CANH output current I

CANL output current I

Voltage detection threshold

for short-circuit to battery

voltage on CANH and CANL

CANH wake-up voltage

threshold

CANL wake-up voltage

threshold

CANH single-ended receiver

threshold

V

CANLd

CANH

CANL

V

det(th)

V

WAKEH

V

WAKEL

V

CANH

–1.01.4V

-110 -80 -50 mA

-5 0 5 µA

50 80 110 mA

-5 0 5 µA

6.5 7.3 8.0 V

1.2 1.9 2.7 V

2.2 3.1 3.9 V

1.6 2.1 2.6 V

TxD = 0 V;

I

= 40 mA

CANL

V

= 0 V;

CANH

TxD = 0 V

sleep mode;

V

= 12 V

CANH

V

= 5 V;

CANL

TxD = 0 V

sleep mode;

V

= 0 V;

CANL

V

= 0 V

S

normal operation

mode

–

–

failure cases 3, 5 and

7

CANL single-ended receiver

V

threshold

CANL leakage current I

CANH leakage current I

CANLl

CANHl

Termination Outputs RTL, RTH

RTL to V

switch-on

CC

R

resistance

RTL to BAT switch series

R

resistance

CANL

RTL

oRTL

2.4 3.0 3.4 V

-5 0 5 µA

-5 0 5 µA

–4095W

51530kW

failure case 6 and 6a

VCC=0V, VS=0V,

V

T

VCC=0V;VS=0V;

V

T

Io =–10 mA;

V

CANL

<85°C

j

CANH

<85°C

j

-stand-by

BAT

=13.5V,

=5V;

24 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

RTH to ground switch-on

R

resistance

RTH output voltage V

RTH pull-down current I

RTL pull-up current I

RTH

oRTH

RTHpd

RTLpu

– 40 95 W

– 0.7 1.0 V

40 75 120 µA

-120 -75 -40 µA

Io = 10 mA

Io = 1 mA;

Vbat-stand-by mode

failure cases 6 and 6a

failure cases 3, 3a, 5

and 7

25 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

CAN-Transceiver

Dynamic Characteristics

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

CANH and CANL bus output

t

rd

0.6 1.2 2.1 µs

transition time recessive-todominant

CANH and CANL bus output

t

dr

0.3 0.6 1.3 µs

transition time dominant-torecessive

Minimum dominant time for

t

wu(min)

12 20 38 µs

wake-up on CANL or CANH

Failure cases 3 and 6

t

fail

30 45 80 µs

detection time

Failure case 6a detection

2.04.88.0ms

time

Failure cases 5, 6, 6a and 7

30 45 80

µs

recovery time

Failure cases 3 recovery time 250 500 750 µs

Failure cases 5 and 7

1.02.04.0ms

detection time

10% to 90%;

C

= 10 nF;

1

C

= 0; R1 = 100 W

2

10% to 90%;

C

= 1 nF; C2 = 0; R1 =

1

100 W

stand-by mode;

V

= 13.5 V

S

Failure cases 5 detection

time

Failure cases 6, 6a and 7

detection time

Failure cases 5, 6, 6a and 7

recovery time

t

fail

0.41.02.4ms

0.84.08.0ms

0.4 1.0 2.4 µs

stand-by modes;

V

= 13.5 V

S

stand-by modes;

V

= 13.5 V

S

stand-by modes;

V

= 13.5 V

S

26 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

Propagation delay

TxD-to-RxD LOW (recessive

to dominant)

Propagation delay

TxD-to-RxD HIGH (dominant

to recessive)

t

PD(L)

t

PD(H)

– 1.5 2.1 µs

– 1.7 2.4 µs

– 1.8 2.5 µs

– 2.0 2.6 µs

– 1.5 2.0 µs

– 2.5 3.5 µs

– 1.0 2.1 µs

C1 = 100 pF;

C

= 0; R1 = 100 W; no

2

failures and bus failure

cases 1, 2, 3a and 4

C1 = C2 = 3.3 nF;

R

= 100 W; no bus

1

failure and failure

cases 1, 2, 3a and 4

C1 100 pF; C2 = 0;

R

= 100 W; bus failure

1

cases 3, 5, 6, 6a and 7

C1 = C2 = 3.3 nF;

R

=100 W; bus failure

1

cases 3, 5, 6, 6a and 7

C1 = 100 pF;

C

= 0; R1 =100 W; no

2

failures and bus failure

cases 1, 2, 3a and 4

C1 = C2 = 3.3 nF;

R

= 100 W; no bus

1

failure and failure

cases 1, 2, 3a and 4

C1 100 pF; C2 = 0;

R

= 100 W; bus failure

1

cases 3, 5, 6, 6a and 7

Edge-count difference

(falling edge) between CANH

and CANL for failure cases 1,

2, 3a and 4 detection

Edge-count difference (rising

edge) between CANH and

CANL for failure cases 1, 2,

3a and 4 recovery

TxD permanent dominant

disable time

n

t

e

TxD

– 1.5 2.6 µs

C1 = C2 = 3.3 nF;

R

= 100 W; bus failure

1

cases 3, 5, 6, 6a and 7

– 4 ––

– 2 ––

1.32.03.5ms

27 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC= -100 mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

SPI-Interface

Logic Inputs DI, CLK and CSN

< 125 °C; all voltages with respect to ground; positive current

j

min. typ. max.

H-input voltage threshold

V

L-input voltage threshold V

Hysteresis of input voltage V

Pull up current at pin CSN I

Pull down current at pin DI

I

and CLK

Input capacitance

C

at pin CSN, DI or CLK

Logic Output DO

H-output voltage level

V

L-output voltage level V

Tri-state leakage current I

Tri-state input capacitance C

IH

IL

IHY

ICSN

ICLK/DI

I

DOH

DOL

DOLK

DO

––0.7 *

V

CC

0.3 *

V

CC

––V

V

50 200 500 mV

-100 -25 -5 mA

525100mA

–1015pF

V

V

CC

– 1.0

CC

– 0.7

–V

– 0.2 0.4 V

-10 – 10 mA

–1015pF

–

–

–

V

VDI = 0.2 ´ V

0V < VCC < 5.25 V

I

DOH

I

DOL

V

0V < VDO < V

V

0 V < VCC < 5.25 V

= 0.7 ´ V

CSN

=1 mA

= – 1.6 mA

= V

CSN

= V

CSN

CC

CC

CC

CC

CC

Data Input Timing

Clock period

Clock high time t

Clock low time t

Clock low before CSN low t

t

pCLK

CLKH

CLKL

bef

1000 – – ns

500 – – ns

500 – – ns

500 – – ns

–

–

–

–

28 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

2.3 Electrical Characteristics (cont’d)

9V<VS<16V; ICC=-100mA; normal mode; all outputs open; – 40 °C<Tj< 150 °C; CAN-

T

transceiver circuitry: – 40 °C<

defined flowing into pin; unless otherwise specified.

Parameter Symbol Limit Values Unit Test Condition

<125°C; all voltages with respect to ground; positive current

j

min. typ. max.

CSN setup time t

CLK setup time t

Clock low after CSN high t

DI setup time t

DI hold time t

Input signal rise time

at pin DI, CLK and CSN

Input signal fall time

at pin DI, CLK and CSN

Data Output Timing

DO rise time

DO fall time t

DO enable time t

DO disable time t

DO valid time t

lead

lag

beh

DISU

DIHO

t

rIN

t

fIN

t

rDO

fDO

ENDO

DISDO

VADO

500 – – ns

500 – – ns

500 – – ns

250 – – ns

250 – – ns

– – 200 ns

– – 200 ns

– 50 100 ns

– 50 100 ns

– – 250 ns

– – 250 ns

– 100 250 ns

–

–

–

–

–

–

–

CL = 100 pF

CL = 100 pF

low impedance

high impedance

VDO < 0.2 VCC;

V

> 0.7VCC;

DO

C

= 100 pF

L

29 version: 2.03 date: 2002-03-20

3 Timing Diagrams

CSN High to Low & rising edge of CLK: DO is enabled. Status information is transfered to Output Shift Register

CSN

CSN Low to High: Data from Shift-Register is transfered to Output Power Switches

Final Data TLE 6262 G

time

CLK

DI

DO

eg.

HS1

12345678910

0

0 141312

1

__

0 141312

1

Figure 4

Data Transfer Timing

14

15

15

15

______________

11 12

actual Data

__

432

5

DI: Data will be accepted on the falling edge of CLK-Signal

432

5

DO: State will change on the rising edge of CLK-Signal

76

8

previous Status

76

8

109

109

13

11

11

10

new Data

01

++

actual Status

0

1

actual Dataold Data

30 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

Figure 5

SPI-Input Timing

Figure 6

Turn OFF/ON Time

31 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

Figure 7

DO Valid Data Delay Time and Valid Time

Figure 8

DO Enable and Disable Time

32 version: 2.03 date: 2002-03-20

Figure 9: High Side Switch1 Timing Diagram

SPI input

bit 1

H

L

Final Data TLE 6262 G

PWM

(SPI input

bit 11 = H)

HS-

Switch1

t

H

L

t

ON

OFF

t

33 version: 2.03 date: 2002-03-20

Figure 10: Watchdog Time-out Definitions

t

WD

Final Data TLE 6262 G

t

CW

closed window open window

Figure 11: Watchdog Timing Diagram

t

CWtOW

WD

Trigger

t

LOW

tCW+t

OW

t

LOW

t

t

LOW

OW

t

CWtOW

t / ms

t

LOW

t

CW

t

CWtOW

Reset

Out

Watchdog

timer reset

normal

operation

t

WDR

timeout

(to long)

t

t

normal

operation

timeout

(to short)

normal

operation

34 version: 2.03 date: 2002-03-20

Figure 12: Reset Timing Diagram

Final Data TLE 6262 G

Vcc

WD

Trigger

Reset

Out

SPI

diagnosis

bit 7

V

RT

V

ST

t

Watchdog

timer reset

RD

t

LOW

t

WDR

start up start up

HIGH

LOW

activation by

microcontroller

t < t

RR

t

t

LOW

CWtOW

normal operation

t

t

CW

t

RR

RD

undervoltage

t

SR

t

LOW

t

t

CW

t

t

t

35 version: 2.03 date: 2002-03-20

4 Application

Final Data TLE 6262 G

V

bat

CAN bus

22 µF

68 nF

+V

S

CANH

CANL

RTH

RTL

OUTL2

OUTL1

OUTH3

OUTH2

OUTH1

CSN

CLK

DI

DQ

TxD

RxD

PWM

RQ

Vcc

OSC

GND

453 k

µP

22 µF

9

GND

Figure 13

Application Circuit

TLE 6262 G

36 version: 2.03 date: 2002-03-20

5 Package Outlines

P-DSO-28-6

(Plastic Dual Small Outline Package)

Final Data TLE 6262 G

Sorts of Packing

Package outlines for tubes, trays etc. are contained in our

Data Book “Package Information”.

GPS05123

Dimensions in mm

37 version: 2.03 date: 2002-03-20

Final Data TLE 6262 G

Edition 1999-10-12

Published by Infineon Technologies AG

St.-Martin-Strasse 53

D-81541 München

© Infineon Technologies AG1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding circuits, descriptions and

charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest Infineon Technologies Office

in Germany or our Infineon Technologies Representatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in question please contact

your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure of that life-suppor t device or system, or to affect

the safety or effectiveness of that device or system. Life support devices or systems are intended to be implanted in the human body, or to

support and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other

persons may be endangered.

38 version: 2.03 date: 2002-03-20

Loading...

Loading...