INDESIT XWDE 961480X WKKK UK User Manual

Instructions for use

Washer-dryer

GB

English,1

XWDE 961480

! This symbol reminds you to read this instruction manual.

Contents

Installation, 2-3-4-5

Unpacking and levelling

Connecting the electricity and water supplies

The first wash cycle

Technical data

Care and maintenance, 6

Cutting off the water and electricity supplies

Cleaning the washer-dryer

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

Precautions and tips, 7

General safety

Disposal

Opening the porthole door manually

GB

Description of the washer-dryer, 8-9

Control panel

Display

How to run a wash cycle or a drying cycle, 10

Wash cycles and options, 11-12

Table of wash cycles

Wash options

Push&Wash+Dry

Detergents and laundry, 13-14

Detergent dispenser drawer

Preparing the laundry

Special wash cycles

Load balancing system

Troubleshooting, 15-16

Assistance, 17-18

1

Installation

GB

! This instruction manual should be kept in a safe

place for future reference. If the washer-dryer is

sold, transferred or moved, make sure that the

instruction manual remains with the machine so

that the new owner is able to familiarise himself/

herself with its operation and features.

! Read these instructions carefully: they contain

vital information relating to the safe installation

and operation of the appliance.

Unpacking and levelling

Unpacking

1. Remove the washer-dryer from its packaging.

2. Make sure that the washer-dryer has not been

damaged during the transportation process. If

it has been damaged, contact the retailer and

do not proceed any further with the installation

process.

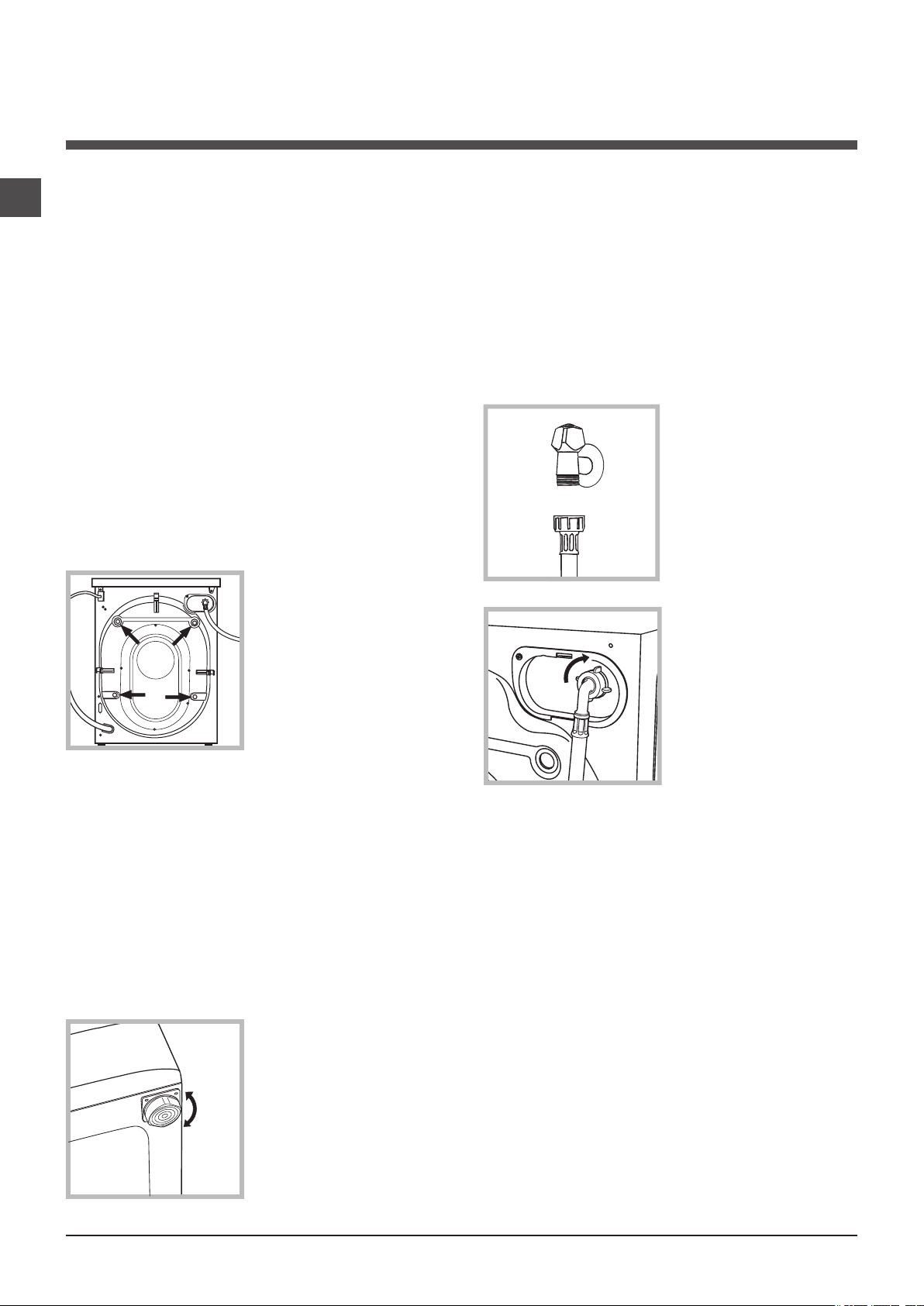

3 . R e m o v e t h e 4

protective screws (used

during transportation)

and the rubber washer

with the corresponding

spacer, locat e d on

the rear part of the

appliance (see figure).

4. Close off the holes using the plastic plugs

provided.

5. Keep all the parts in a safe place: you will

need them again if the washer-dryer needs to

be moved to another location.

! Packaging materials should not be used as

toys for children.

Levelling

Levelling the machine correctly will provide it with

stability, help to avoid vibrations and excessive

noise and prevent it from shifting while it is

operating. If it is placed on carpet or a rug, adjust

the feet in such a way as to allow a sufficient

ventilation space underneath the washer-dryer.

Connecting the electricity and

water supplies

Connecting the water inlet hose

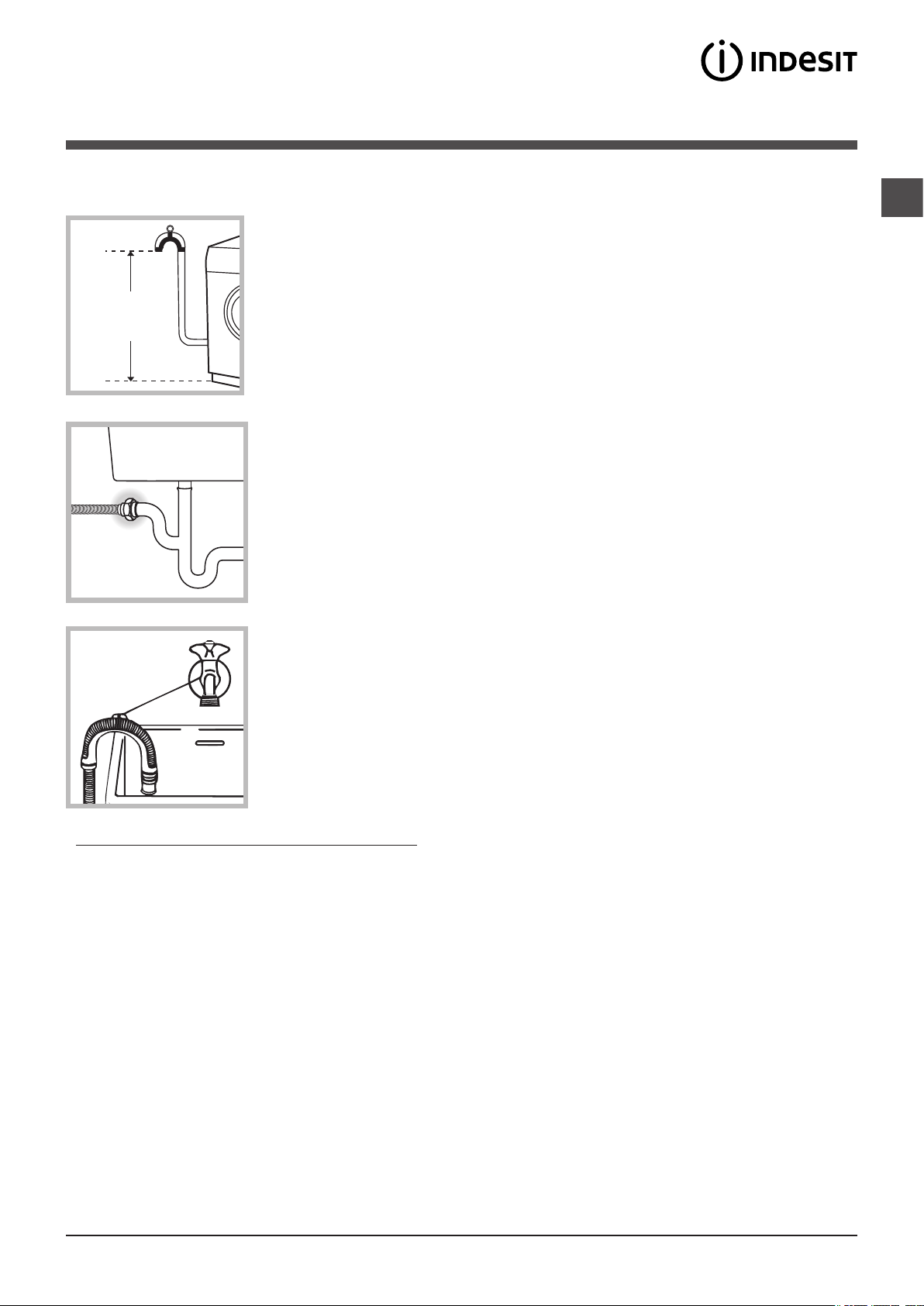

1. Connect the supply

pipe by screwin g it

to a cold water tap

using a ¾ gas threaded

connection (see figure).

Before performing the

connection, allow the

water to run freely until

it is perfectly clear.

2. Connect the inlet

hose to the washerdryer by screwing it

onto the corresponding

wa ter i n le t o f t he

appliance, which is

situated on the top

rig ht-h a nd s i de o f

the rear part of the

appliance (see figure).

3. Make sure that the hose is not folded over

or bent.

! The water pressure at the tap must fall within

the values indicated in the Technical details table

(see next page).

1. Install the washer-dryer on a flat sturdy floor,

without resting it up against walls, furniture

cabinets or anything else.

2. If the floor is not

p e r f e c t l y l e v e l ,

c o m p e n s a t e f o r

any unevenne ss by

tightening or loosening

the adjustable front

feet (see figure); the

angle of inclination,

measured in relation to

the worktop, must not

exceed 2°.

2

! If the inlet hose is not long enough, contact a

specialised shop or an authorised technician.

! Never use second-hand hoses.

! Use the ones supplied with the machine.

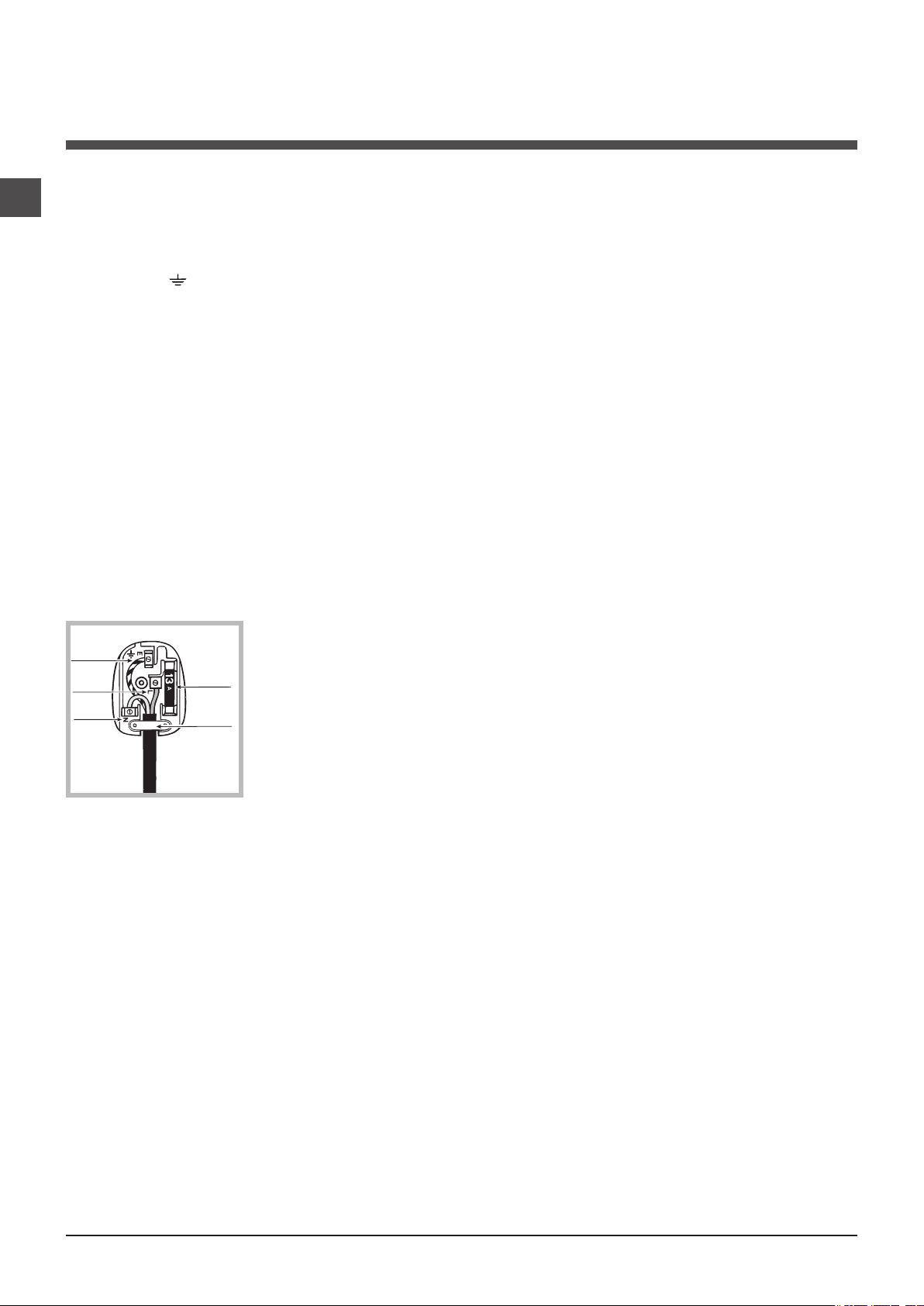

Connecting the drain hose

65 - 100 cm

Where it connects to

the waste water pipe

cut end off spigot or

remove the blanking cap

Con n ect t h e drai n

hose, without bending

it, to a draining duct or

a wall drain situated

between 65 and 100

cm from the floor;

• the supply voltage is included within the values

indicated on the Technical Data Plate fixed on

the machine.

• the socket is compatible with the washing

machine’s plug. If this is not the case, replace

the socket or the plug.

Your appliance is now supplied with a 13 amp

fused plug it can be plugged into a 13 amp

socket for immediate use. Before using the

appliance please read the instructions below.

GB

The drain hose may

b e c on ne c t e d t o

an under-sink trap.

Before connec t i ng

the drain hose from

the machine ensure

that any bl anks or

removable ends have

been taken off the

spigot.

If it is placed over the

edge of a basin or sink

be sure the free end of

the hose should not

be underwater.

! We advise against the use of hose extensions; in

case of absolute need, the extension must have the

same diameter as the original hose and must not

exceed 150 cm in length. Ensure that if the drain

hose is pushed into a standpipe, that the end does

not go down more than 15cms (6 inches). If the hose

is pushed down too far, this may cause the machine

to self -syphon ie. continuously empty as it is filling.

WARNING - THIS APPLIANCE MUST BE EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE

CARRIED OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA

approved fuse to BS 1362 should always be

used, and the fuse cover re-fitted. If the fuse

cover is lost, the plug must not be used until a

replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of

the correct colour as indicated by the coloured

marking or the colour that is embossed in words

on the base of the plug. Replacements can be

obtained directly from your nearest Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded

plug and you should wish to re-route the mains

cable through partitions, units etc., please

ensure that either:

the plug is replaced by a fused 13 ampere

rewireable plug bearing the BSI mark of approval.

or:

the mains cable is wired directly into a 13

amp cable outlet, controlled by a switch, (in

compliance with BS 5733) which is accessible

without moving the appliance.

Electric connection

Before plugging the appliance into the mains

socket, make sure that:

• the socket is earthed and in compliance with

the applicable law;

• the socket is able to sustain the appliance’s

maximum power load indicated on the Technical

Data Plate fixed on the machine;

Disposing of the plug:

Ensure that before disposing of the plug itself,

you make the pins unusable so that it cannot be

accidentally inserted into a socket.

Instructions for connecting cable to an alternative

plug:

Important: the wires in the mains lead are

coloured in accordance with the following code:

Green & Yellow Earth

Blue Neutral

Brown Live

3

GB

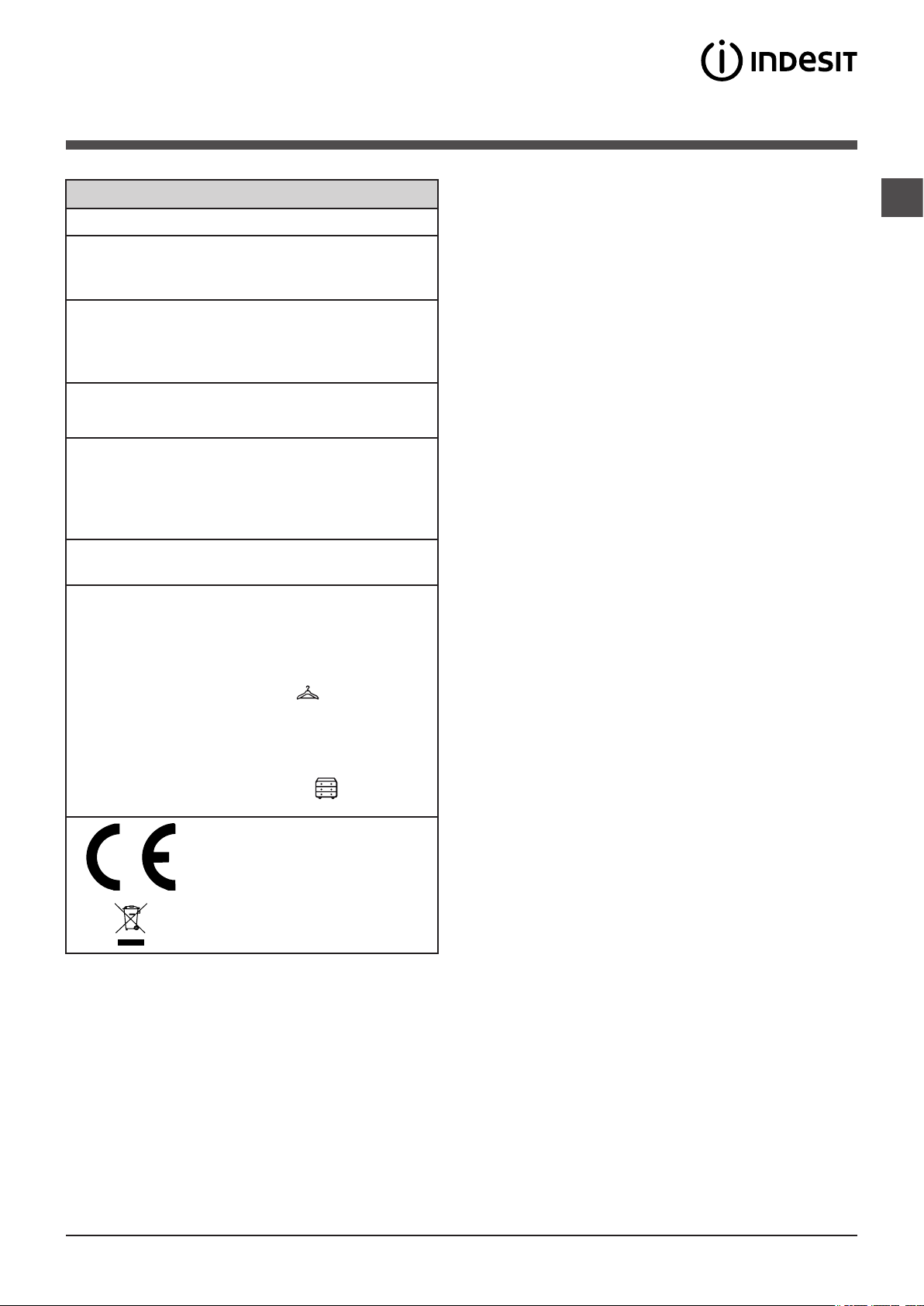

GREEN &

YELLOW

BROWN

BLUE

13 ampere fuse

CROSS-BAR

CORD GRIP

As the colours of the wires in the lead may

not correspond with the coloured markings

identifying the terminals in your plug, proceed

as follows:

Connect Green & Yellow wire to terminal

marked E or or coloured Green or Green &

Yellow.

Connect Brown wire to terminal marked L or

coloured Red.

Connect Blue wire to terminal marked N or

coloured Black.

If a 13 amp plug (BS 1363) is used it must be

fitted with a 13 amp fuse, either in the plug or

adaptor or at the distribution board.

If you are in any doubt regarding the electrical

supply to your machine, consult a qualified

electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in

accordance with the following code:

BLUE NEUTRAL (N)

BROWN LIVE (L)

GREEN & YELLOW EARTH (E)

! The power supply cable must only be

replaced by an authorised serviceman.

Warning! The company denies all liability if and

when these norms are not respected.

The first wash cycle

Once the appliance has been installed, and

before you use it for the first time, run a wash

cycle with detergent and no laundry, using the

wash cycle “Auto Clean” (see “Cleaning the

washing machine”).

Disposing of the appliance:

When disposing of the appliance please

remove the plug by cutting the mains cable

as close as possible to the plug body and

dispose of it as described above.

! The washing machine should not be installed

in an outdoor environment, not even where

the area is sheltered, because it may be very

dangerous to leave it exposed to damp, rain

and thunderstorms.

! When the washing machine is installed, the

mains socket must be within easy reach.

! Do not use extensions or multiple sockets.

! The power supply cable must never be bent

or dangerously compressed.

4

Technical data

GB

Model

Dimensions

Capacity

Electrical

connections

Water connections

Spin speed

Energy rated

programmes

according to

regulation

EN 50229

XWDE 961480

width 59.5 cm

height 85 cm

depth 60,5 cm

from 1 to 9 kg for wash

programme

from 1 to 6 kg for the drying

programme

please refer to the technical

data plate fixed to the machine

maximum pressure

1 MPa (10 bar)

minimum pressure

0.05 MPa (0.5 bar)

drum capacity 62 litres

up to 1400 rotations per

minute

wash: programme 8; temperature 60°C; using a load

of 9 kg.

drying: the smaller load

(3kg) must be dried by selecting the “

” dryness level. The load must consist of

3 sheets, 2 pillowcases and

1 hand towel; the remainder

of the load must be dried by

selecting the “ ” dryness

level.

This appliance conforms to

the following EC Directives:

- 2004/108/EC (Electromagnetic Compatibility)

- 2006/95/EC (Low Voltage)

- 2012/19/EU

5

Care and maintenance

2

1

1

2

3

GB

Cutting off the water and electricity

supplies

• Turn off the water tap after every wash cycle.

This will limit wear on the hydraulic system inside

the washer-dryer and help to prevent leaks.

• Unplug the washer-dryer when cleaning it and

during all maintenance work.

Cleaning the washer-dryer

• The outer parts and rubber components

of the appliance can be cleaned using a soft

cloth soaked in lukewarm soapy water. Do not

use solvents or abrasives.

• The washer-dryer has a “Auto Clean”

programme for its internal parts that must be

run with no load in the drum.

For maximum performance you may want

to use either the detergent (i.e. a quantity

10% the quantity specified for lightly-soiled

garments) or special additives to clean the

washer-dryer. We recommend running a

cleaning programme every 40 wash cycles.

To start the programme press buttons A and

B simultaneously for 5 seconds (see figure).

The programme will start automatically and

will last approximately 70 minutes. To stop the

cycle press the START/PAUSE button.

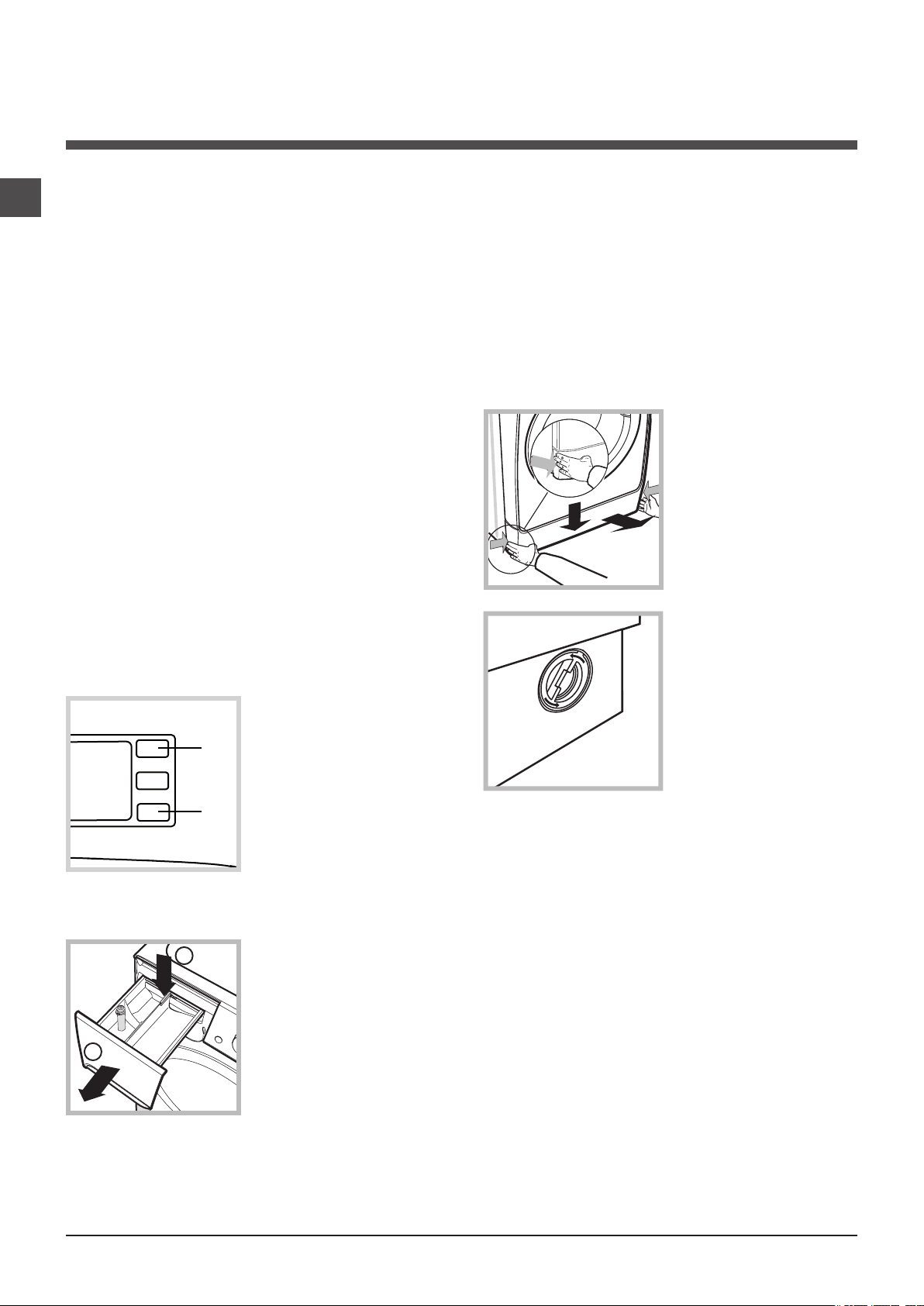

Cleaning the pump

The washer-dryer is fitted with a selfcleaning pump which does not require any

maintenance. Sometimes, small items (such

as coins or buttons) may fall into the protective

pre-chamber at the base of the pump.

! Make sure the wash cycle has finished and

unplug the appliance.

To access the pre-chamber:

1. Take off the cover

panel on the front

of the machine by

first pressing it in

the centre and then

pushing downwards

on both sides until

you can remove it

(see figures).

2. Unscrew the lid

by rotating it anticlockwise (see figure):

a little water may

trickle out. This is

perfectly normal.

A

B

Cleaning the detergent dispenser

drawer

To remove the drawer,

press lever (1) and pull

the drawer outwards

(2) (see figure).

Wash it under running

water; this procedure

should be repeated

frequently.

Caring for the door and drum of your

appliance

• Always leave the porthole door ajar in order to

6

prevent unpleasant odours from forming.

3. Clean the inside thoroughly.

4. Screw the lid back on.

5. Reposition the panel, making sure the hooks

are securely in place before you push it onto

the appliance.

Checking the water inlet hose

Check the inlet hose at least once a year. If

there are any cracks, it should be replaced

immediately: during the wash cycles, water

pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

Loading...

Loading...