Ikon IUC48R, IPP94, ISP72M, ISP72, IUC72F User Manual

Sandwich/Salad Units

Under-counter Refrigerators and Freezers

Worktop Refrigerators andFreezers

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment. Notify carrier of damage! Inspect all componentsimmediately.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

Service and Installation Manual

COMMECIAL REFRIGERATOR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

Our product instructions will be uploaded on our company official website.

This is the Safety Alert Symbol. This symbol alerts you to potential hazards that can kill or injure you and others. All safety messages will follow the Safety Alert Symbol and either the words” DANGER”, “WARNING” or “CAUTION”.

Danger means that failure to heed this safety statement may result in severe personal injury or death.

Warning means that failure to heed this safety statement may result in extensive product damage, serious personal injury, or death.

Caution means that failure to heed this safety statement may result in minor or moderate personal injury, or property or equipment damage.

All safety messages will alert you to what the potential hazard is, tell you how to reduce the chance of injury,

and let you know what can happen if the instructions are not followed.

If the power cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This appliance can be used by children aged from 8 years and above and persons with reduced physical

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and user maintenance shall not be made by children without

supervision.

Keep the appliance and its cord out of reach of children less than 8 years.

Do not store explosive substances such as aerosol cans with a flammable propellant in this appliance.

The appliance use flammable insulation blowing gas C5H10, disposal of the appliance shall in accordance

with the regulations of local authorities.

2

Service and Installation Manual

The key for appliance electric box should be safe kept by qualified persons in order to avoid a hazard

WARNING: Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of obstruction.

WARNING: Do not use mechanical devices or other means to accelerate the defrosting process, other than those recommended by the manufacturer.

WARNING: Do not damage the refrigerant circuit.

WARNING: Do not use electrical appliances inside the food storage compartments of the appliance, unless they are of the type recommended by the manufacturer.

Handling, moving, and use of the refrigerator or freezer to avoid either damaging the refrigerant tubing, or increasing the risk of a leak

L’opération, le mouvement et l’utilisation du réfrigérant ou le congélateur doivent éviter les dommages du tuyau réfrigérant ou le rique de la fuite.

Caution – Risk of Fire or Explosion due to Flammable Refrigerant Used. Follow Handling Instructions Carefully in Compliance with U.S. Government Regulations.

Component parts shall be replaced with like components and that servicing shall be done by factory authorized service personnel, so as to minimize the risk of possible ignition due to incorrect parts or improper service.

Les pièces de rechange doivent être remplacées par les components relatifs et les opérations doivent être faites par les professionnels afin de minimaliser le risque d’allumage à cause des parts incorrects ou des opérations impropres.

CAUTION – Risk Of Fire Or Explosion Due To Puncture Of Refrigerant Tubing; Follow Handling Instructions Carefully. Flammable Refrigerant Used

DANGER: Risk of child entrapment. Before you throw away your old refrigerator or freezer: Take off the doors

Leave the shelves in place so that children may not easily climb inside

3

|

Service and Installation Manual |

CONTENTS |

|

RECEIVING & INSPECTING EQUIPMENT |

............................................................................................ 4 |

SPECIFICATIONS .......................................................................................................................................... |

5 |

INSTALLATION ..................................................................................................................................................... |

6 |

OPERATION........................................................................................................................................................... |

7 |

MAINTENANCE ........................................................................................................................................ |

9 |

WIRING DIAGRAM ..................................................................................................................... |

11 |

All rights reserved. Reproduction without written permission is prohibited.

SERIAL NUMBER INFORMATION

The serial number of all self-contained refrigerators and freezers is located inside the unit on the left hand side near the top on the wall.

Always have the serial number of your unit available when calling for parts or service.

This manual covers standard units only. If you have a custom unit, consult the customer service department at the number listed on the last page.

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should be taken during unloading so the equipment is not damaged while being moved into the building.

1.Visually inspect the exterior of the package and skid or container. Any damage should be noted and reported to the delivering carrier immediately.

2.If damaged, open and inspect the contents with the carrier.

3.In the event that the exterior is not damaged, yet upon opening, there is concealed damage to the equipment, notify the carrier. Notification should be made verbally as well as in written form.

4.Request an inspection by the shipping company of the damaged equipment. This should be done within 10 days from receipt of the equipment.

5.Be certain to check the compressor compartment housing and visually inspect the refrigeration package. Be sure lines are secure and base is still intact.

6.Freight carriers can supply the necessary damage forms upon request.

7.Retain all crating material until an inspection has been made or waived.

4

Service and Installation Manual

SPECIFICATION

SANDWICH/SALAD UNITS

|

|

|

|

|

|

|

|

|

|

|

STORAGE |

PAN |

|

|

|

SHELF |

|

|

|

|

|

|

|

|

SHIP |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

CAPACITY |

1/6 |

|

|

|

|

CAPACITY |

|

|

|

CHARGE |

|

WEIGHT |

|

NEMA |

||||||||

|

MODEL# |

|

V/Hz/Ph |

|

AMPS |

|

Cu-ft |

Size |

HP |

Sq-ft |

|

|

BTU |

|

OZ |

|

LBS |

|

PLUG |

||||||||||||||

|

KSP29 |

|

115/60/1 |

|

5 |

|

|

7 |

|

8 |

|

3/8 |

|

14 |

|

|

|

3200 |

9.5 |

|

225 |

|

5-15P |

||||||||||

|

KSP48 |

|

115/60/1 |

|

7 |

|

|

12 |

|

12 |

|

1/2 |

|

26 |

|

|

|

5400 |

9.5 |

|

322 |

|

5-15P |

||||||||||

|

KSP60 |

|

115/60/1 |

|

7.5 |

|

|

15.5 |

|

16 |

|

1/2 |

|

30 |

|

|

|

5800 |

10.6 |

|

373 |

|

5-15P |

||||||||||

|

KSP72 |

|

115/60/1 |

|

7 |

|

|

18 |

|

18 |

|

1/2 |

|

36 |

|

|

|

6200 |

10.6 |

|

408 |

|

5-15P |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

SANDWICH/SALAD UNITS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STORAGE |

PAN |

|

|

|

SHELF |

|

|

|

|

|

|

|

|

SHIP |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

CAPACITY |

1/6 |

|

|

|

|

CAPACITY |

|

|

|

CHARGE |

|

WEIGHT |

|

NEMA |

||||||||

|

MODEL# |

|

V/Hz/Ph |

|

AMPS |

|

Cu-ft |

Size |

HP |

Sq-ft |

|

|

BTU |

|

OZ |

|

LBS |

|

PLUG |

||||||||||||||

|

KSP29M |

|

115/60/1 |

|

5 |

|

|

7 |

|

12 |

|

3/8 |

|

14 |

|

|

|

3200 |

9.5 |

|

225 |

|

5-15P |

||||||||||

|

KSP48M |

|

115/60/1 |

|

7 |

|

|

12 |

|

18 |

|

1/2 |

|

26 |

|

|

|

5400 |

9.5 |

|

322 |

|

5-15P |

||||||||||

|

KSP60M |

|

115/60/1 |

|

7.5 |

|

|

15.5 |

|

24 |

|

1/2 |

|

30 |

|

|

|

5800 |

10.6 |

|

373 |

|

5-15P |

||||||||||

|

KSP72M |

|

115/60/1 |

|

7 |

|

|

18 |

|

18 |

|

1/2 |

|

36 |

|

|

|

6200 |

10.6 |

|

408 |

|

5-15P |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

PIZZA PREP TABLES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

STORAGE |

PAN |

|

|

|

|

SHELF |

|

|

|

|

|

|

|

|

SHIP |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

CAPACITY |

|

1/3 |

|

|

|

|

CAPACITY |

|

|

|

|

|

CHARGE |

|

WEIGHT |

|

NEMA |

||||||

|

MODEL# |

|

V/Hz/Ph |

AMPS |

|

Cu-ft |

Size |

|

HP |

|

Sq-ft |

|

|

BTU |

|

OZ |

|

LBS |

|

PLUG |

|||||||||||||

|

KPP44 |

|

115/60/1 |

|

|

7 |

|

|

12 |

|

6 |

|

1/2 |

|

16 |

|

|

5600 |

|

9.9 |

|

|

348 |

|

5-15P |

||||||||

|

KPP67 |

|

115/60/1 |

|

|

7.5 |

|

|

22 |

|

9 |

|

1/2 |

|

34 |

|

|

6200 |

|

10.6 |

|

|

432 |

|

5-15P |

||||||||

|

KPP93 |

|

115/60/1 |

|

|

9 |

|

|

32 |

|

12 |

|

3/4 |

|

54 |

|

|

6800 |

|

13.8 |

|

|

582 |

|

5-15P |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

STORAGE |

|

|

|

|

SHELF |

|

|

|

|

|

|

|

|

|

SHIP |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

CAPACITY |

|

|

CAPACITY |

|

|

|

|

|

CHARGE |

|

WEIGHT |

NEMA |

|

||||||||

|

MODEL# |

|

|

V/Hz/Ph |

|

AMPS |

Cu-ft |

|

HP |

|

Sq-ft |

|

|

BTU |

|

|

OZ |

|

|

LBS |

PLUG |

|

|||||||||||

|

KUC27 |

|

115/60/1 |

|

1.5 |

|

6.5 |

|

|

3/8 |

|

|

14 |

|

2800 |

|

2.47 |

|

199 |

|

5-15P |

|

|||||||||||

|

KUC48 |

|

115/60/1 |

|

3 |

|

|

12 |

|

|

3/8 |

|

|

26 |

|

3000 |

|

2.65 |

|

280 |

|

5-15P |

|

||||||||||

|

KUC60 |

|

115/60/1 |

|

3 |

|

|

15.5 |

|

|

3/8 |

|

|

30 |

|

3200 |

|

2.82 |

|

331 |

|

5-15P |

|

||||||||||

|

KUC72 |

|

|

115/60/1 |

|

3.5 |

|

18 |

|

|

1/2 |

|

|

36 |

|

6200 |

|

4.59 |

|

380 |

|

5-15P |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

STORAGE |

|

|

|

|

SHELF |

|

|

|

|

|

|

|

|

|

SHIP |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

CAPACITY |

|

|

CAPACITY |

|

|

|

|

|

CHARGE |

|

WEIGHT |

NEMA |

|

||||||||

|

MODEL# |

|

|

V/Hz/Ph |

|

AMPS |

Cu-ft |

|

HP |

|

Sq-ft |

|

|

BTU |

|

|

OZ |

|

|

LBS |

PLUG |

|

|||||||||||

|

KUC27F |

|

|

115/60/1 |

|

1.9 |

|

6.5 |

|

|

1/2 |

|

|

14 |

|

3500 |

|

3.35 |

|

210 |

|

5-15P |

|

||||||||||

|

KUC48F |

|

|

115/60/1 |

|

2.4 |

|

12 |

|

|

1/2 |

|

|

26 |

|

3800 |

|

3.53 |

|

302 |

|

5-15P |

|

||||||||||

|

KUC60F |

|

|

115/60/1 |

|

5 |

|

|

15.5 |

|

|

5/8 |

|

|

30 |

|

4200 |

|

3.53 |

|

353 |

|

5-15P |

|

|||||||||

|

KUC72F |

|

|

115/60/1 |

|

10 |

|

|

18 |

|

|

5/8 |

|

|

36 |

|

6200 |

|

14.1 |

|

386 |

|

5-15P |

|

|||||||||

5

Service and Installation Manual

INSTALLATION

Location

Units represented in this manual are intended for indoor use only. Be sure the location chosen has a floor strong enough to support the total weight of the cabinet and contents. A fully loaded unit can weigh as much as 1500 pounds. Reinforce the floor as necessary to provide for maximum loading. For the most efficient refrigeration, be sure to provide good air circulation inside and out.

Inside cabinet

Do not pack the units so full that air cannot circulate. The refrigerated air is discharged at the top rear of the unit. It is important to allow for proper air flow from the top rear to the bottom of the unit. Obstructions to this air flow can cause evaporator coil freeze ups and loss of temperature or overflow of water from the evaporator drain pan. The shelves have a rear turn up on them to prevent this. However, bags and other items can still be located to the far rear of the cabinet. Air is brought into the evaporator coil with fans. Prevent obstruction to allow the outlet or inlet of air flow.

Outside cabinet

Be sure that the unit has access to ample air. Avoid hot corners and locations near stoves and ovens. It is recommended that the unit be installed no closer than 2" from any wall

Leveling

A level cabinet looks better and will perform better because the doors will line up with theframes properly. Use a level to make sure the unit is level from front to back and side to side. Units supplied with legs will have adjustable bullet feet to make the necessary adjustments. If the unit is supplied with casters, no adjustments are available. Ensure the floor where the unit is to be located is level.

Stabilizing

All models are supplied with casters for your convenience. It is very important, however, that the cabinet be installed in a stable condition with the front wheels locked while in use.

Should it become necessary to lay the unit on its side or back for any reason, allow at least 24 hours before start-up to allow compressor oil to flow back to place. Failure to meet this requirement can cause compressor failure and unit damage.

Unit repairs will not be subject to standard unit warranties if due to improper installation

procedures.

NOTE

Electrical connection

Refer to the amperage data on page 5, the serial tag, your local code or the National Electrical Code to be sure the unit is connected to the proper power source. Each unit must be plugged on a dedicated electric circuit.. Do not use an extension cord. An external electrical surge protector may be required. (not included)

The unit must be turned OFF and disconnected from the power source whenever

performing service, maintenance functions or cleaning the refrigerated area.

DANGER

6

Service and Installation Manual

OPERATION

Donotthrowitemsintothestoragearea. Failuretoheedtheserecommendationscouldresultindamageto

the interior of the cabinet.

CAUTION

Refrigerated cabinets

Temperature range for the internal cabinets is 33°F to 40°F for all food prep units, undercounter and worktop refrigerators, and -7°F to -3°F for undercounter and worktop freezers. The rail’s temperature range for all prep units is 33°F to 41°F.

Food Prep units should operate with pans in place. Operating without pans and/or pan covers in place will lower the efficiency and may damage the unit due to continuous over-use.

Continuous opening and closing of the door will prevent the unit’s ability to maintain optimum refrigeration temperature.

Top section is not intended for overnight storage. Product should be removed from pans. Pans can remain in cabinet if empty.

Defrosting:

Every 6 hours, the unit will turn off so the evaporator coil can defrost. The controller now displays the defrost symbol. When the coil temperature reaches the terminal temperature or after 20 minutes of defrost, the unit will turn on.

SOLID-STATE THERMOSTATDESCRIPTIONS

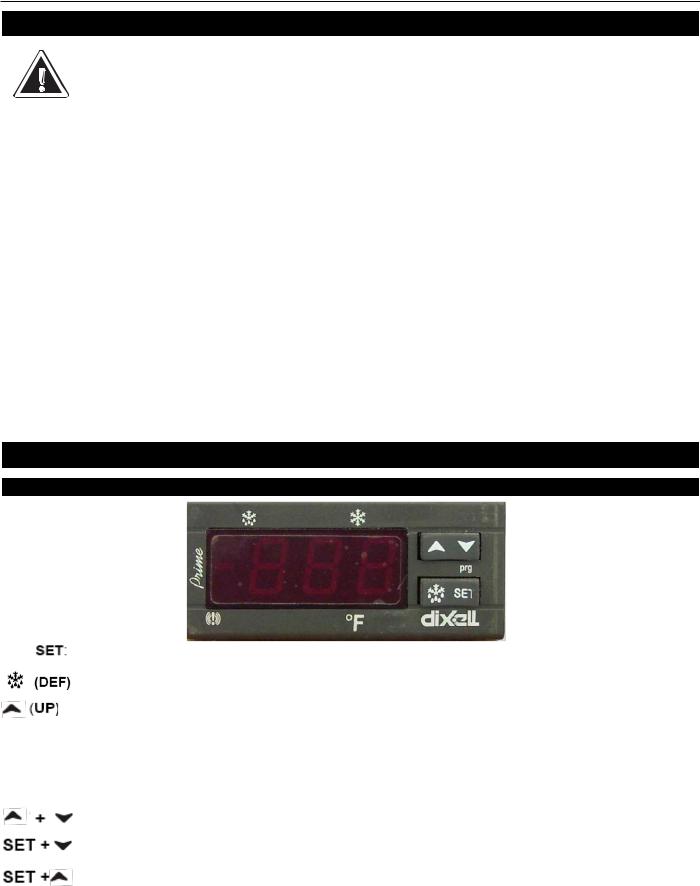

1. FRONT PANELCOMMANDS

To display target set point; in programming mode it selects a parameter or confirms an operation.

To start a manual defrost

To view the last alarm occurrence; in programming mode, it browses the parameter codes or increases the display value

To view the last alarm occurrence; in programming mode, it browses the parameter codes or decreases the display value

To view the last alarm occurrence; in programming mode, it browses the parameter codes or decreases the display value

KEY COMBINATION

To lock & unlock the keyboard

To enter in programming mode

To return to the room temperature display

7

Service and Installation Manual

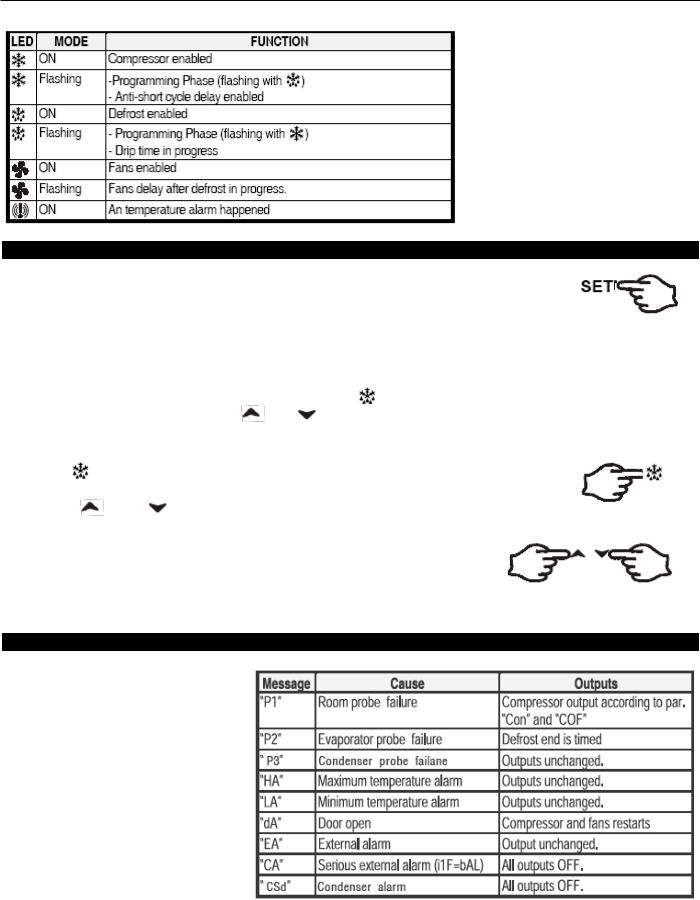

1.1 Function of LEDS

2. MAIN FUNCTIONS

2.1 HOW TO SEE THE SETPOINT

1.Push and immediately release the SET key: the display will show the set point value.

2.Push and immediately release the SET key or wait for 5 seconds to display the sensor value again.

2.2 HOW TO CHANGE THE SETPOINT

1. Push the SET key for more than 2 seconds to change the set point value.

2. |

The value of the set point will be displayed and the |

LED starts blinking. |

||

3. |

To change the set value push the |

or |

key within 10s. |

|

4. |

To set new point value, push the SET key again or wait 10s. |

|||

2.3 HOW TO START A MANUAL DEFFROST

Push the |

key for more than 2 seconds and a manual defrost will start |

|

2.4 HOW TO LOCK THE KEYBOARD |

||

1. Hold the |

and |

keys for more than 3s. |

2.The “POF” message will be displayed and the keyboard will be locked. At this point, it will be possible only to see the set point or the MAX or Min temperature stored.

3.If a key is pressed more than 3s the ”POF” message will be displayed.

2.5 HOW TO UNLOCK THE KEYBOARD

Hold the  and

and  keys together for more than 3s, till the “POF” message is displayed.

keys together for more than 3s, till the “POF” message is displayed.

3. ALARM SIGNALS

HOW TO SEE THE ALARM AND

RESET THE RECORDED ALARM

1.Hold the or

or  key to display the alarm signals.

key to display the alarm signals.

2.When the signal is displayed, hold the SET key until the “rst” message is displayed. Push the SET key again. The “rst” message will start blinking and the normal temperature will be displayed again.

8

Service and Installation Manual

MAINTENANCE

The power switch must be turned OFF and the unit disconnected from the power source

DANGER |

whenever performing service, maintenance functions or cleaning the refrigerated area. |

|

Refrigerators and Freezers

The interior and exterior can be cleaned using soap and warm water. If this isn't sufficient, try ammonia and water or a nonabrasive liquid cleaner. When cleaning the exterior, always rub with the "grain" of the stainless steel to avoid marring the finish.

Do not use an abrasive cleaner because it will scratch the stainless steel and plastic and can damage the breaker strips and gaskets.

Cleaning the Condenser Coil

The condenser coil requires regular cleaning. Cleaning is recommended every 90 days. In some instances, you may find that there is a large amount of debris and dust or grease accumulated prior to the 90 day time frame. In these cases the condenser coil should be cleaned every 30 days.

If the build up on the coil consists of only light dust and debris, the condenser coil can be cleaned with a simple brush. Heavier dust build-up may require a vacuum or even compressed air to blow through the condenser coil.

If heavy grease is present, there are de-greasing agents available for refrigeration use and specifically for the condenser coils. The condenser coil may require cleaning with the de-greasing agent and then blown through with compressed air.

Failure to maintain a clean condenser coil can initially cause high temperatures and excessive run times. Continuous operation with dirty or clogged condenser coils can result in compressor failures. Neglecting the condenser coil cleaning procedures will void any warranties associated with the compressor or cost to replace the compressor.

Never use a high pressure water wash for this cleaning procedure as water can damage the electrical components located near or at the condenser coil.

DANGER

In order to maintain proper refrigeration performance, the condenser fins must be cleaned of dust, dirt and grease regularly. It is recommended that this be done at least every three months. If conditions are such that the condenser is totally blocked in three months, the frequency of cleaning should be increased. Clean the condenser with a vacuum cleaner or stiff brush. If extremely dirty, a commercial-grade condenser cleaner may

be required.

Stainless Steel Care and Cleaning

To prevent discoloration of rust on stainless steel, several important steps need to be taken. First, we need to understand the properties of stainless steel. Stainless steel contains 70-80% iron which will rust. It also contains 12-30% chromium which forms an invisible passive film over the steels surface which acts as a shield against corrosion. As long as the protective layer is intact, the metal is still stainless. If the film is broken or contaminated, outside elements can begin to breakdown the steel and begin to form rust of discoloration. Proper cleaning of stainless steel requires soft cloths or plastic scouring pads,

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

DANGER

9

Service and Installation Manual

MAINTENANCE

Cleaning solutions need to be alkaline based or non-chloride based. Any cleaner containing chlorides will damage the protective film of the stainless steel. Chlorides are commonly found in hard water, salts, and household and industrial cleaners. If cleaners containing chlorides are used, be sure to rinse and dry thoroughly.

Routine cleaning of stainless steel can be done with soap and water. Extreme stains or grease should be cleaned with a non-abrasive cleaner and plastic scrub pad. It is always good to rub with the grain of the steel. There are also stainless steel cleaners available which can restore and preserve the finish of the steels protective layer.

Early signs of stainless steel breakdown can consist of small pits and cracks. If this has begun, clean thoroughly and start to apply stainless steel cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution Many food products have an acidic content which can deteriorate the finish. Be sure to clean the stainless steel surfaces of ALL food

products.

CAUTION

Gasket Maintenance

Gaskets require regular cleaning to prevent mold and mildew build up and also to keep the elasticity of the gasket. Gasket cleaning can be done with the use of warm soapy water. Avoid full strength cleaning products on gaskets as this can cause them to become brittle and prevent proper seals. Do not use sharp tools or knives to scrape or clean the gasket which could possibly tear the gasket and rip thebellows.

Gaskets can easily be replaced and don’t require the use of tools or authorized service technicians. The gaskets are "Dart" style and can be pulled out of the grove in the door and replaced by pressing the new one back into place.

Doors/Hinges

Over time and with heavy use, door hinges may become loose. If the door is beginning to sag, tighten the screws that mount the hinge brackets to the frame of the unit. If the doors are loose or sagging this can cause the hinge to pull out of the frame which may damage to both the doors and the door hinges.

Drain Maintenance

Each unit has a drain located inside the unit which removes the condensation from the evaporator coil and evaporates it into an external condensate evaporator pan. Each drain can become loose or disconnected from moving or bumping the drain. If you notice excessive water accumulation on the inside of the unit, be sure the drain tube is connected from the evaporator housing to the condensate evaporator drain pan. If water starts to collect underneath the unit, you may want to check the condensate evaporator drain tube to be sure it is still located inside the drain pan. The leveling of the unit is important as the units are designed to drain properly when on a level surface. If your floor is not level this can also cause drain problems. Be sure all drain lines are free of obstructions because this may cause water to back up and overflow the drain pans.

10

Loading...

Loading...