Page 1

20000015724a

HRC 2 basic_112017

IKA® HRC 2 basic

Operating instructions EN

Page 2

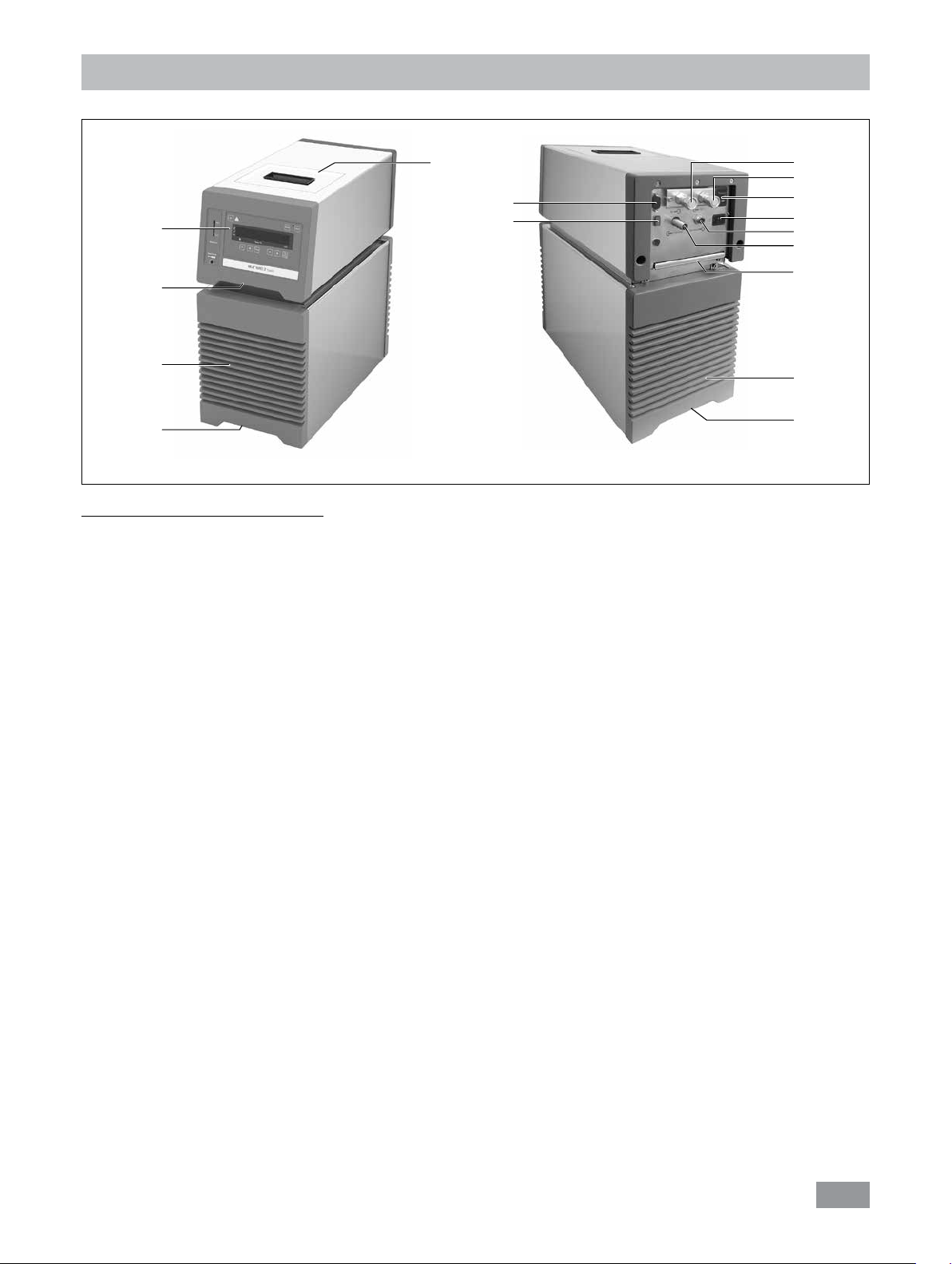

Device setup

1

2

3

2

Fig. 1

Item Designation

1 Operator panel and display

2 Handle

3 Venting grid

4 Filling opening lid

5 RS 232 port

6 USB port

7 Overflow

8 Backflow

9 Power socket

10 Power switch

11 Pump connector OUT

12 Pump connector IN

4

5

6

12

11

10

9

8

7

2

3

2

2

Page 3

Source language: German

EN

Contents

Page

Device setup ................................................................................................................................................. 2

Declaration of Conformity ............................................................................................................................ 4

Explication of warning symbols ................................................................................................................... 4

Safety instructions ....................................................................................................................................... 5

General information ����������������������������������������������������������������������������������������������������������������������������������������������5

Disposal of the device �������������������������������������������������������������������������������������������������������������������������������������������6

Fluids ��������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Correct use ................................................................................................................................................... 6

Use �����������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Range of use (indoor use only) ������������������������������������������������������������������������������������������������������������������������������6

Unpacking .................................................................................................................................................... 7

Unpacking ������������������������������������������������������������������������������������������������������������������������������������������������������������7

Delivery scope �������������������������������������������������������������������������������������������������������������������������������������������������������7

Preparations ................................................................................................................................................. 7

Setting up �������������������������������������������������������������������������������������������������������������������������������������������������������������7

Connecting the tubings �����������������������������������������������������������������������������������������������������������������������������������������7

Filling and draining ������������������������������������������������������������������������������������������������������������������������������������������������8

Fluid (Standard information for IKA® fluid) ������������������������������������������������������������������������������������������������������������9

Moving the device ����������������������������������������������������������������������������������������������������������������������������������������������10

Operator panel and display ........................................................................................................................ 10

Setting the safety temperature .................................................................................................................. 11

Commissioning ........................................................................................................................................... 11

Menu settings ............................................................................................................................................ 12

Menu structure ���������������������������������������������������������������������������������������������������������������������������������������������������12

Basic guide to setting the menu options ��������������������������������������������������������������������������������������������������������������12

Operating mode (MODE)�������������������������������������������������������������������������������������������������������������������������������������12

Maximum temperature (HI T) ������������������������������������������������������������������������������������������������������������������������������12

Minimum temperature (LO T) ������������������������������������������������������������������������������������������������������������������������������12

Maximum speed (HI R) ����������������������������������������������������������������������������������������������������������������������������������������12

Minimum speed (LO R) ����������������������������������������������������������������������������������������������������������������������������������������12

Fluid type (FLUI) ��������������������������������������������������������������������������������������������������������������������������������������������������12

Temperature control type (AUTO) ������������������������������������������������������������������������������������������������������������������������13

Alarm and button tone (BEEP)

Calibration (CALI) ������������������������������������������������������������������������������������������������������������������������������������������������13

Interface and output .................................................................................................................................. 14

Maintenance and cleaning ......................................................................................................................... 16

Error codes ................................................................................................................................................. 17

Accessories ................................................................................................................................................. 17

Technical data ............................................................................................................................................ 18

Warranty .................................................................................................................................................... 19

Pump performance curve ........................................................................................................................... 19

������������������������������������������������������������������������������������������������������������������������������13

3

Page 4

Declaration of Conformity

We declare under our sole responsibility that this product corresponds to the regulations 2014/35/EU, 2006/42/EC, 2014/30/EU and

2011/65/EU and conforms with the standards or other normative documents: EN 61010-1, EN 61010-2-010, EN 61326-1,

EN 60529 and DIN 12876-1�

Explication of warning symbols

Indicates an (extremly) hazardous situation, which, if not avoided, will result in death,

DANGER

serious injury�

Indicates a hazardous situation, which, if not avoided, can result in death, serious injury�

WARNING

Indicates a potentially hazardous situation, which, if not avoided, can result in injury�

CAUTION

Indicates practices which, if not avoided, can result in equipment damage�

NOTICE

Indicates a hazardous situation that cause from a hot surface!

CAUTION

Hot surface!

4

Page 5

Safety instructions

General information:

• Read the operating instructions completely before

starting up and follow the safety instructions.

• Keep the operating instructions in a place where it can be

accessed by everyone�

• Ensure that only trained staff work with the device�

• Follow the safety instructions, guidelines, occupational

health, safety and accident prevention regulations�

• Set up the device in a spacious area on an even, stable,

clean, non-slip, dry and fireproof surface�

• Do not operate the device in explosive atmospheres

• Protect the device and accessories from bumping and impacting�

• Check the device and accessories for damage before each

use� Do not use damaged components�

• Safe operation is only guaranteed with the accessories described in the ”Accessories” section�

• The device must only be operated with the original power

cable�

• The socket for the power cable must be easily accessible�

• Socket must be earthed (protective ground contact)�

• The voltage stated on the type plate must correspond to

the power voltage�

•

The device can only be disconnected from the power supply by pulling out the power plug or the connector plug�

• Disconnect the power plug before attaching or changing

any accessories�

• Disconnect the power plug before cleaning, maintenance

or moving the device�

• The device must only be opened by trained specialists,

even during repair� The device must be unplugged from

the power supply before opening� Live parts inside the

device may still be live for some time after unplugging

from the power supply�

NOTICE

safe operation, for example to keep foreign objects and

liquids, etc� from getting into the device�

• The device must only be used as prescribed and as described in the operating instructions� This includes operation by instructed specialist personnel�

• When using critical or hazardous materials in your processes, IKA® recommends to use additional appropriate

measures to ensure safety in the experiment� For example,

users can implement measures that inhibit fire or explosions or comprehensive monitoring equipment�

• Process pathogenic material only in closed vessels under a

suitable fume hood� Please contact IKA® application support if you have any question�

Coverings or parts that can be removed from the device must be put

back on the device again to ensure

�

CAUTION

can be easily accessed must be installed in the work area�

• A laboratory circulator heats/refrigerates and circulates

fluid according to specified parameters� This involves hazards due to high and low temperatures, fire and general

hazards due to electrical energy� The user safety can not

be ensured simply with design requirements on the part

of the device� Further hazard sources may arise due to the

type of tempering fluid, e�g� by exceeding or undercutting

certain temperature thresholds or by the breakage of the

container and reaction with the carrier fluid� It is not possible to consider all eventualities� They remain largely subject to the judgment and responsibility of the operator� For

this reason, it may become necessary for user to take other

precautionary safety measures�

• Insucient ventilation may result in the formation of explosive mixtures� Only use the device in well ventilated

areas�

WARNING

not be exceeded even in the event of a fault� Check the

safe temperature circuit on a regular basis (see section

"Setting the safety temperature")�

• When device is used for external circulation, extra precaution must be taken for hot/cold liquid leakage due to

damaged hose�

- Use suitable hoses for connection�

- Secure hoses and tubes against slippage and avoid kinks�

- Check hoses, tubes and bath at regular intervals for possible material fatigue (cracks/leaks)�

• Power cable should not get in contact with hot parts and

fluids�

WARNING

• Be careful when filling a hot bath�

CAUTION

• After a power failure during operation, the device may

start automatically (depending on operating mode)�

• Transport the device with care (see section “Moving the

device“)�

If the power switch is not within

reach when device is operating, an

EMERGENCY STOP switch that

The safety circuit (safe temperature)

must be adjusted so that the maximum permissible temperature can-

Do not start up the device if:

- It is damaged or leaking

- Cable (not only power cable) is

damaged�

At high operating temperature, the

temperature of housing parts, surfaces and tubes can exceed 70 ° C�

5

Page 6

• Do not transport or empty the bath while it is still hot/

cold� This may result in accidents, especially scalding injuries or frostbite�

Disposal of the device:

• The device must be disposed of in accordance with national or local regulations�

Fluids:

• Continuous monitoring of the bath and the filling level of

the bath fluid is required, especially at high temperatures�

• To ensure a sucient fluid circulation, the viscosity of the

bath fluid must not exceed of 50mm2/s at the lowest operating temperature�

NOTICE

If water is used at higher temperature, there is heavy loss of fluid due

to the evaporation of the steam�

CAUTION

WARNING

the chemical hazards that may be associated with the bath

fluid used� Observe all safety warnings for the fluids�

• Depending on the bath fluid used and the type of operation, toxic or flammable vapors can arise� Ensure suitable

extraction�

• Do not use any fluid which may cause dangerous reactions during processing�

• Only use recommended bath fluids� Only use non-acid

and non corroding fluids�

WARNING

that has been set� The safe temperature limit must always

be set to at least 25 ºC lower than the flash point of the

fluid used� Examine regularly the function of the safety

temperature limiter�

NOTICE

basis (see the chapter “Filling and draining”)�

Beware of the risk of burning due

to delay in boiling!

Only use fluids, which fulfill the requirements for safety, health and

device compatibility� Be aware of

Only process and heat up any fluid

that has a flash point higher than

the adjusted safe temperature limit

Never operate the device without

sucient heat carrier fluid! Check

the fluid level detection at a regular

•

Untreated tap water is not recommended� It is recommended to use distilled water or high purity water (ion exchangers) and add 0�1 g soda (sodium carbonate Na2CO3)

/liter, to reduce corrosive properties�

CAUTION

Risk of burning caused by vapor or

hot water at the outlet of the cooling coil�

Don’t use following fluids:

NOTICE

- Untreated tap water

- Acids or bases

- Solutions with halides: chlorides, fluorides, bromides,

iodides or sulfur

- Bleach (Sodium Hypochlorite)

- Solution with chromates or chromium salts

- Glycerine

- Ferrous water�

NOTICE

ing hoses and external devices)� When doing this, also

open the stopper and union nuts caps of the pump outputs and inputs and blow compressed air through all the

pump outputs and inputs! Beware of the risk of burning

due to delay in boiling!

When changing the bath fluid type,

must remove the remaining water

from the complete system (includ-

Correct use

• Use:

Use HRC 2 (Heated Recirculating Chiller) for tempering

and circulating fluids�

Intended Use: Tabletop device

• Range of use (indoor use only):

- Laboratories - Schools

- Pharmacies - Universities

This instrument is suitable for use in all areas except:

- Residential areas

-

Areas that are connected directly to a low-voltage supply

network that also supplies residential areas�

The safety of the user cannot be guaranteed:

- If the device is operated with accessories that are not supplied or recommended by IKA® �

- If the device is operated improperly or in contrary to the

IKA® specifications�

- If the device or the printed circuit board are modified by

third parties�

6

Page 7

Unpacking

• Unpacking:

- Unpack the device carefully�

- Any damage should be notified immediately to the

shipping agent (post oce, railway network or logistics

company)�

• Delivery scope:

- HRC 2 basic

- Power cables

- Hose olive NW 8 (2 pieces) see Fig� 2

- Hose olive NW 12 (2 pieces) see Fig� 2

- Screwdriver (use for safety circuit) see Fig� 3

- Plastic cap (for “Overflow” connector)

- Plastic cap (for “Backflow” connector)

- USB 2�0 cabel A–micro B

- User guide

- Warranty card�

Preparations

Fig. 3Fig. 2

• Setting up:

- Place the unit on an even, stable, clean, nonslip, dry and

fireproof surface�

- Keep at least 20 cm of open space on the front and rear

side�

- The place for installation should be large enough and

provide sucient air ventilation to ensure the room does

not warm up excessively because of the heat from device radiates to the environment�

- Do not set up the device in the immediate vicinity of

heat sources and do not expose to sun light�

- Cooling machine, pump motor and electronics produce

intrinsic heat that is dissipated via the venting grids (3)!

Never cover these venting grids!

Note: After setting up the device, wait at least one hour

before starting the operation to avoid the damage to the

cooling system�

• Connecting the tubings:

- Unscrew the union nuts and stoppers using a wrench

(SW 19) from the pump connector IN (12) and OUT (11)�

Stopper

- Screw the hose olive to the pump connection IN

and OUT

onto the olives� The hoses must be secured with suitable clamps�

- Via a hose to the “Overflow” connector (7), overflowing fluid can be directed into a suitable vessel� The vessel should be positioned lower than the “Overflow”

connector�

- Connect the “Backflow” connector (8) to IKA® calorimeter with a suitable hose�

(11)

with union nuts� Slide the hoses (NW 12)

Olives

Union nut

External

system

(12)

Fig. 5

Union nut

Fig. 4

- Connect the hoses for circulating the external system to

the pump connectors M 16 x 1 for IN

directly or with the olives�

(12)

and OUT

(11)

Fig. 6

IKA®

Calorimeter

7

Page 8

Note: Please note the permissible temperature range of

hoses� For hot fluids we recommend the IKA

hoses�

When the external system is not necessary, please seal

the pump connector IN and OUT with the existing union

nuts and stoppers�

When IKA® calorimeter is not connected, please close

the “Backflow” connector with included backflow cap�

In case of closed external system, if there is in any case no

risk of exceeding the maximum fluid level, you can close

the “Overflow” connector with the included overflow

cap� This minimizes the energy loss and protects, in case

of long-term applications with low temperatures and

high humidity, against unwanted water input and the associated volume increase�

Check fluid heat expansion!

• Filling and draining:

- Before filling the fluid into the bath, open the venting

grid as indicated in following figure�

®

LT 5�20

Drain port

Drain valve

Bracket

Fig. 8

Note: Pay attention to the fluid level information:

Low Level

Fig. 7

- Check and make sure that the drain valve is closed (rotate clockwise to the stop position, see Fig� 8)�

Please note information in section “Commissioning”�

Note:

- Connect the power plug and turn on the device with

power switch (10)�

- The low level warning message appear on the display�

Meanwhile, the bottom LED segment of fluid level indicator lights up in red color to indicate the low fluid level

(see Fig� 9)

- Open the filling opening lid (4) and remove the stopper

from the filling opening� Then, fill fluid to the bath�

�

High Level

Red (High Level)

Red (Low Level)

Fig. 9

- To drain the fluid from the bath, connect a hose to the

drain port and turn the drain valve in counter clockwise

direction with a straight screwdriver�

Note: The stopper must be kept being plugged in during during operation except for filling fluids�

Fig. 10

Warning: Do not empty the bath while the fluid is still hot/

cold, there is a risk of burning/freezing�

8

Page 9

• Fluids (Standard information for IKA® fluid):

No.

0

1

2

3

4

5

6

7

8

®

IKA

Designation

CF�EG28�N10�80�8

CF�EG39�N20�80�16

CF�EG44�N25�80�19

CF�EG48�N30�80�22

UF�Si�N30�150�10LV

HF�Si�20�200�50

HF�Si�20�250�50A

Water

Customized

Operating temperature

range for open bath

application

(°C)

-10 ��� 80 -10 … 80 90 115

-20 … 80 -20 … 80 90 115

-25 … 80 -25 … 80 90 115

-30 … 80 -30 … 80 90 115

-30 … 130 -30 … 150

20 … 200 20 … 200 255 > 280

20 … 200 20 … 250 255 > 280

5 … 95 5 … 95 - -

Operating temperature

range for closed bath

applications

(°C)

Safety temperature

(°C)

145

The listed fluid temperature range may deviate from the device operating temperature ranges and settings�

Nomenclaturefor IKA® fluids:

CF�EG28�N10�80�8 --

(5) Addition information

mm²/s

(4) Viscosity (8

)

(3) Temperature range (-10–80 °C)

(2) Chemical composition (Ethylene Glycol 28%)

(1) Classification (Cooling fluid)

Flash point

(°C)

> 170

(1) Classification:

HF: Heating Fluid

CF: Cooling Fluid

UF: Universal Fluid

(2) Chemical composition:

Si: Silicone oil

EG: Ethylene Glycol

(3) Temperature range: (

Minimum temperature� Maximum temperature)

N: Negative Temperature

(4) Viscosity:

Viscosity at 25 °C for Heating Fluid (HF)

Viscosity at -20 °C for Cooling Fluid (CF)

Viscosity at 25 °C for Universal Fluid (UF)

Dynamic viscosity [mPa•s] is a product of kinematic viscosity [mm²/s] and density [kg/m³] of the fluid divided by 1000�

(5) Additional information:

A: Oil Additives

LV: Low Viscosity

Note: for open bath application!

Note: Tap water may be unsuitable for operation because the calcium carbonate content may cause calcification�

High purity water (from icon exchangers) and distilled or bi-distilled water are unsuitable for operation due to corrosive

properties of these media� High purity water and distillates are suitable as a medium after adding 0�1 g soda (Na2CO3,

sodium carbonate) per liter of water�

Note: The temperature limit values are adjustable in accordance with the fluid used�

9

Page 10

• Moving the device:

Empty all fluid in the bath before moving device from one

place to other place�

The device can be lifted up and moved by using the top

handles or the bottom handles�

It can also be moved on flat surface by lifting and pushing

the front of the device� It is easy to move the device with

the help of the wheels�

The angle of inclination should never be more than 10 º

at any direction when move the device!

Note: The device must not be moved during operation�

After moving the device, you must wait at least one hour

before restarting the unit�

Operator panel and display

A

P

O

Fig. 12

Fig. 11

E

L JK

max. 10 ˚

F H

GCB D

IMN

Item Designation Function

A On/Off button: Switch on/off the circulator�

B LED, set: The LED lights up at the same time as the set value is displayed�

C LED, heating:

D LED,

E LED display:

F “Menu” button: Press it once: menu option is display�

Press it once again: back to working screen�

G LED, lock: Indicate the buttons are

H Lock button:

I “OK / Pump” button: Start/stop the pump function�

Confirm the menu options�

J “Pump (+)” button: Increase the pump speed setting�

Change the menu value setting�

K “Pump (-)” button: Decrease the pump speed setting�

Change the menu value setting�

L “Temp” button: Start/stop the tempering function�

M “Temp (+)” button: Increase the temperature setting�

N “Temp (-)” button: Decrease the temperature setting�

O Adjustable safety circuit: Adjust the safety temperature limit�

P Fluid level indicator: Indicate the fluid level (when the fluid level is too low or too high, the bottom or the

refrigerating

: The LED indicates the

Indicate the heating function is activated�

refrigerating

Display the settings and actual values�

deactivated�

Lock/unlock buttons�

Navigation, selecting the settings in the menu

Navigation, selecting the settings in the menu�

top LED segment change into red color)�

function is activated�

�

10

Page 11

Setting the safety temperature

Setting the safety temperature with screwdriver delivered

with the device�

+

-

Fig. 13

Commissioning and operating

Note:

Before commissioning, make sure that the device has

not been moved in one hour�

Check whether the voltage specified on the type plate

matches the power voltage available�

The power socket used must be

earthed (protective earthing)�

If above conditions are met, the instrument is ready for operation after plugging in the power plug�

If these conditions are not met, safe operation is not guaranteed and the device could be damaged�

Observe the ambient conditions (temperature, humidity,

etc�) listed under “Technical Data”�

After switching on the power switch (10) at the back of the

device or pressing the on/off button (A), all LED segments

light up during the self test�

The safety temperature setting will appear on the display�

Safety temperature

Factory setting: approximate max� value

Adjustment range: 0 to 110 °C�

Warning: The safety temperature must always be set to at

least 25 ºC lower than the flash point of the fluid used�

After that, following two screens appear alternately�

Then the device enters standby status and is ready for operation�

Change the temperature setting with “Temp (+)“ button (M)

or “Temp (-)“ button (N)�

Change the pump speed setting with “Pump (+)“ button (J)

or “Pump (-)“ button (K)�

In standby status, activate the tempering function by pressing the “Temp“ button (L)� The device starts tempering

function and pumping function�

After pressing the power switch (10) the start-up of the

compressor is delayed (about 3 minutes)�

Display field

Software version (ver)

Operating mode (mode)

Safety temperature

Working setting

In working status, press the “OK/Pump“ button (I) to stop

pumping and tempering function�

Note: In running status, the pump speed adjusts automatically according to the load� When the actual speed doesn’t

reach the setting speed, the blinking set speed and the actual speed appears alternately�

In standby status, press the “OK/Pump“ button (I) to start

the pump function� The tempering function will not be activated�

In working status, press the “Temp“ button (L) to stop the re

tempering function, the pump keep running�

Pressing the lock button (H) for about 2 seconds, the device

control elements can be locked to prevent accidental changes that can be done during operation (LED (G) will light up)�

To unlock the control elements, press the lock button again

for about 2 seconds (LED (G) goes out)�

11

Page 12

• Menu structure:

MODE

Menu settings

A

B

C

Default settings

Activated

-

-

Maximum temperature (HI T)

Minimum temperature (LO T)

Maximum speed (HI R)

Minimum speed (LO R)

Fluid type (FLUI)

Menu

The type of temperature PID control arithmetic (AUTO)

(Heating)

Alarm and button tone (BEEP)

Calibration (CALI)

• Basic guide to setting the menu options:

F Enter the menu by pressing ”Menu” button (F)�

F Press the

“Temp (+)“ button (M) or “Temp (-)“ button (N)

to change the menu options�

F Press the

“Pump (+)“ button (J) or “Pump (-)“ button (K)

to change the menu value settings�

F Confirm the menu settings by pressing the

key (I)

�

•

Operating mode (MODE):

“OK/Pump“

AUTO 1

AUTO 0

BEEP 0

BEEP 1

CALI 0

CALI 2

CALI 3

• Minimum temperature (LO T):

Proportional coecient of PID (Kp 1)

Integrate time of PID (Ti 1)

Differential time of PID (Td 1)

The minimum adjustable value: - 20 °C�

•

Maximum speed (HI R):

The maximum adjustable value: 4000 rpm�

100 °C

- 20 °C

4000 rpm

2000 rpm

8

Activated

60�0

5�00

0�3

Activated

Activated

-

-

Mode A: After power on/power failure no automatic re-

start of functions�

Mode B: After power on/power failure automatic restart

of functions, depending on previous settings�

Mode

C:

Set values (set in mode A or B) cannot be

changed� After power on/power failure automatic restart

of functions, depending on previous settings�

• Maximum temperature (HI T):

The maximum adjustable value: 100 °C�

This value can be limited additionally by the selected fluid

(No�, see “Fluid (Standard information for IKA® fluid)”�

Note: The maximum value is limited by the set safety

temperature�

•

Minimum speed (LO R):

The minimum adjustable value: 2000 rpm�

• Fluid type (FLUI):

The chosen fluid (No�) limits the maximum and minimum

temperature� Customized fluid (No�: 8) enables the whole

working temperature range� See Section “Fluids (Stan-

®

dard information for IKA

fluid)”�

12

Page 13

• Temperature control type (AUTO) (heating):

°C

t

°C

t

°C

t

°C

°C

t

Proportional coecient of PID (Kp 1)

AUTO 1:

AUTO 1 is the default setting� The default PID settings are

used automatically�

Heating up curve in AUTO 1 control (AUTO 1):

Fig. 14

AUTO 0:

For special requirements, AUTO 0 can be used with manual adjustment of the control parameters�

If the PID control (AUTO 0) option is selected, the following items including Kp 1, Ti 1 and Td 1 could be set�

Otherwise they are not displayed in the menu list�

Note: Inappropriate settings may produce the following

heating up curves:

Kp too high

The proportional coecient Kp is the controller amplification and determines how strongly the control deviation (the difference between the target temperature and

actual temperature) directly affects the control variable

(cooling down time)� Kp values that are too large can

lead to the controller overshooting�

Integral time of PID (Ti 1)

The integral time Ti (s) is the correction time and determines how strongly the duration of the control deviation

affects the control variable� Ti compensates an existing

control deviation� A high Ti means a smaller and slower

effect on the control variable� Ti values that are too small

can lead to instability of the controller�

Differential time of PID (Td 1)

The differential time Td (s) is the derivative time and determines how strongly the rate of change of the control

deviation affects the control variable� Td compensates for

rapid control deviations� A high Td means a smaller and

slower effect on the control variable� Td values that are

too small can lead to instability of the controller�

Fig. 15

Ti too low

Kp too low

Ti too high

Td too high

t

•

Alarm and button tone (BEEP):

BEEP 0: no alarm and button tone

BEEP 1: alarm and button tone is activated

•

Calibration and adjustment (CALI):

CALI 0: Reset calibration

CALI 2: 2-point calibration

CALI 3: 3-point calibration

13

Page 14

Example: 2-point calibration:

Dip the temperature sensor of the reference measuring

instrument into the bath fluid�

Select 2-point calibration in the menu� Press the “OK/

Pump“ button (I) to start the 2-point calibration�

The unit now starts and controls to the set value� When

the temperature has reached the set value and has become constant, the “Set” LED (C) no longer flashes and

the following display appears� The temperature measured

by the unit appears on the left hand side�

Set the first point temperature (step 1, e�g� 10 °C) with

“Pump (+)” button (J) or “Pump (-)” button (K)� Confirm

the setting by pressing “OK/Pump“ button (I)�

Left area of the display appears the set value (10 °C) and

the right area of the display appears the actual temperature value measured� The “Set” LED (C) flashes briefly�

Interface and output

The device can be operated in “Remote” mode via the RS 232

port (5) or the USB port (6) connected to a PC and with the

laboratory software Labworldsoft®�

Note: Please observe the system requirements together

with the operating instructions and help section included

with the software�

USB interface:

The Universal Serial Bus (USB) is a serial bus for connecting

the device to the PC� Equipped with USB devices can be

connected to a PC during operation (hot plugging)� Connected devices and their properties are automatically recognized� The USB port can also be used to update firmware�

USB device driver:

First, download the latest driver for IKA® devices with USB

port from:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Install the driver by running the setup file� Then connect the

IKA® device through the USB data cable to the PC�

The data communication is via a virtual COM port� Configuration, command syntax and commands of the virtual COM

ports are as described in RS 232 interface�

Device software update:

For device software update, visit IKA® website www.ika.

com and enter the “Service” menu� Download and run the

Firmware Update Tool�

Input the calibration value from the reference measuring

instrument (e�g� 10�1 °C) with “Pump (+)” button (J) or

“Pump (-)” button (K)�

Confirm the value by pressing the “OK/Pump“ button (I)�

Back to previous screen for input a new value by pressing

“Temp” button (L)�

Back OK

The first point calibration is finished now�

Calibration of the other points is performed in the same

way�

Find and click the Firmware Update Tool in your PC after

installation� Register your E-mail and password�

Connect the device to your PC via the USB cable� Then, you

can update the device software according to instructions of

the Firmware Update Tool�

RS 232 interface:

Configuration:

- The functions of the interface connections between the

stirrer machine and the automation system are chosen

from the signals specified in EIA standard RS 232 in accordance with DIN 66 020 Part 1�

- For the electrical characteristics of the interface and the allocation of signal status, standard RS 232 applies in accordance with DIN 66 259 Part 1�

- Transmission procedure: asynchronous character transmission in start-stop mode�

- Type of transmission: full duplex�

- Character format: character representation in accordance

with data format in DIN 66 022 for start-stop mode� 1

start bit; 7 character bits; 1 parity bit (even); 1 stop bit�

- Transmission speed: 9600 bit/s�

- Data flow control: none

- Access procedure: data transfer from the stirrer machine to

the computer takes place only at the computer’s request�

14

Page 15

Command syntax and format:

The following applies to the command set:

- Commands are generally sent from the computer (Master)

to the device (Slave)�

- The device sends only at the computer’s request� Even

fault indications cannot be sent spontaneously from the

device to the computer (automation system)�

- Commands are transmitted in capital letters�

The above details correspond as far as possible to the recommendations of the NAMUR working party (NAMUR recommendations for the design of electrical plug connections for analogue and digital signal transmission on individual items of

laboratory control equipment, rev� 1�1)�

The NAMUR commands and the additional specific IKA® co mmands serve only as low level commands for communication between the device and the PC� With a suitable terminal or communications programme these commands can be

transmitted directly to the circulator equipment� The IKA® software package, Labworldsoft®, provides a convenient tool for

controlling circulating equipment and collecting data under MS Windows, and includes graphical entry features, for pump

motor speed ramps for example�

Commands:

NAMUR Commands Function

IN_PV_2 Read the internal actual temperature

IN_PV_3 Read the safety actual temperature

IN_PV_4 Read the pump actual speed

IN_SP_1 Read the internal setting temperature

IN_SP_3 Read the safety setting temperature

IN_SP_4 Read the pump setting speed

OUT_SP_1 xxx Set the internal setting temperature XXX

OUT_SP_12@n Set the WD safety temperature with echo of the set (defined) value�

OUT_SP_4 xxx Set the pump speed XXX

OUT_SP_42@n Set the WD-safety speed with echo of the set (defined) value�

OUT_WD1@n Start the watchdog mode 1 and set the time for the watchdog to n (20���1500) seconds�

Echo of the Watchdog time�

During a WD1-event, the tempering and pump functions are switched off�

This command needs to be send within the watchdog time�

OUT_WD2@n Start the watchdog mode 2 and set the watchdog time to n (20���1500) seconds�

Echo of the watchdog time�

During a WD2-event, the set temperature is changed to the WD safety temperature and the

pump set speed is set to the WD safety speed�

This command needs to be send within the watchdog time�

RESET Reset the PC control and stop the device functions�

START_1 Start the tempering function�

START_4 Start the pump function�

STOP_1 Stop the tempering function�

STOP_4 Stop the pump function�

- Commands and parameters including successive parameters are separated by at least one space (Code: hex 0x20)�

- Each individual command (incl� parameters and data) and

each response are terminated with CR LF (Code: hex 0x0d

hex 0x0A) and have a maximum length of 80 characters�

- The decimal separator in a number is a dot (Code: hex

0x2E)�

15

Page 16

Connections between device and external devices:

9

6

7

8

9

PC 1�1 Cable:

This cable is required to connect RS 232 interface (5) to a PC�

Fig. 16

1

2

3

4

5

RxD 2

TxD 3

GND 5

RTS 7

CTS 8

9

8

7

6

1

4

6

9

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

PC

5

4

3

2

1

USB 2�0 cable A - micro B:

This cable is required to connect USB interface (6) to a PC�

A

USB micro B

Fig. 17

USB A

Maintenance and cleaning

To avoid contamination, it is essential to change the bath

fluid regularly�

If water is used for bath fluid, we recommend to add Water bath protective media� The protective media stops the

growth of algae, bacteria and other microorganisms�

To keep the full cooling performance, the dust filter of the

cooler must be checked regularly and cleaned if necessary�

• Switch off the device and disconnect power cable�

• Open the front venting grid (3)�

• Remove the bracket�

• Clean condenser dust protection sheet with a vacuum

cleaner or wash the sheet in the water and dry the sheet

before assembly�

Note: Don’t touch the condenser surface with hard parts�

Cleaning:

Disconnect main plug prior to

cleaning!

Use only cleaning agents which have been approved by

®

to clean the device�

IKA

Dirt Cleaning agent

Dye Isopropyl alcohol

Construction material

Water containing tenside/

isopropyl alcohol

Cosmetics

isopropyl alcohol

Foodstuff

Water containing tenside/

isopropyl alcohol

Water containing tenside

Water containing tenside

Fuel Water containing tenside

For materials which are not listed, please request information from IKA® application support.

Wear protective gloves while cleaning the devices�

Electrical devices may not be placed in the cleansing agent

for the purpose of cleaning�

Do not allow moisture to get into the device when cleaning�

If a different cleaning or decontamination method than the

method defined by IKA® is planned, the user must ascertain

with IKA® that this method does not damage the device�

Spare parts order:

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

- item and designation of the spare parts,

see www.ika.com

- software version�

Repair:

Please send in device for repair only after it has been

cleaned and is free from any materials which may

constitute a health hazard.

For repair, please request the “Decontamination Clearance

Certificate” from IKA®, or download printout of it from the

IKA® website www.ika.com�

If you require servicing, return the device in its original packaging� Storage packaging is not sucient� Please also use

suitable transport packaging�

16

Page 17

Error codes

Any malfunctions during operation will be identified by an error message on the display�

Proceed as follows in such cases:

F Switch off device using the main switch at the back of the device

F Carry out corrective measures

F Restart device

Error code Effect Cause Solution

Err 02 Pump off

Heating/refrigerating off

Err 04 Pump off

Heating/refrigerating off

Err 06 Pump off

Heating/refrigerating off

Err 09 Pump off

Heating/refrigerating off

Err 11 Pump off

Heating/refrigerating off

Err 12 Pump off

Heating/refrigerating off

Err 13 Pump off

Heating/refrigerating off

Err 15 Pump off

Heating/refrigerating off

Err 16 Pump off

Heating/refrigerating off

Err 17 Pump off

Heating/refrigerating off

Err 20 Pump off

Heating/refrigerating off

Motor over current (rate

current)

Motor hall signal missing - Reduce pump motor speed

Too low liquid level - Check the fluid level and buoyage

Device internal temperature is

too high

Temperature difference

between control sensor and

safety sensor is too much

Safety temperature alarm

Heater switched off by safety

circuit

Safety shutdown of the

compressor

Errors at the compressor

(suction side)

Errors at the compressor

(pressure side)

Fan cooling system error - Restart the device

- Reduce pump motor speed

- Use fluid with lower viscosity

- Check if the pump impeller is blocked

- Use fluid with lower viscosity

- Check if the pump impeller is blocked

- Check the ambient temperature and let the

device cool down

- Check the fan and clean the grids at the rear side

- Check safety temperature circuit and bath fluid

- Check the bath temperature measurement

- Check safety temperature set value, fluid level

- Restart the device

- Restart the device

- Restart the device

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department

- Send the device for repair, including a short description of the fault�

Accessories

Tubing and hoses:

LT 5.20 Metal hose (isolated M16 x 1)

LT 5.21 PTFE hose (isolated M16 x 1)

H.PVC.8 PVC tube (nominal width 8 mm)

H.PVC.12 PVC tube (nominal width 12 mm)

H.SI.8 Silicone tube (nominal width 8 mm)

H.SI.12 Silicone tube (nominal width 12 mm)

H.PUR.8 PUR tube (nominal width 8 mm)

H.PUR.12 PUR tube (nominal width 12 mm)

H.FKM.8 FKM tube (nominal width 8 mm)

H.FKM.12 FKM tube (nominal width 12 mm)

See more accessories on www.ika.com�

Tubing insulations:

ISO. 8 Insulation (8 mm)

ISO.12 Insulation (12 mm)

Additional accessories:

PC 1.1 Cable (RS 232)

Labworldsoft

®

17

Page 18

Technical data

Operating voltage VAC

Frequency Hz 50 / 60

Max� input power W 1800 (230 VAC) / 1500 (115 VAC) / 1210 (100 VAC)

Working temperature range °C - 20 ��� + 100

Operating temperature range

Temperature stability – internal temperature control

70

°C, water

Temperature control PID

Temperature measurement, absolute accuracy K ± 0�5

Temperature setting Button

Temperature setting resolution K 0�1

Temperature display LED

Temperature display resolution K 0�1

Classification according to DIN 12876-1 Class III (FL) suitable for flammable and non-flammable fluids

Safety circuit (adjustable) °C 0 ��� + 110

Safety temperature display LED

Heating capacity W 1500 (230 VAV) / 1200 (115 VAC) / 910 (100 VAC)

Cooling capacity according to DIN 12876 (at 4000 rpm):

+ 20 °C

+ 10 °C

0 °C

- 10 °C

- 20 °C

Refrigerant

Refrigerant quantity g 230

Max� refrigerating system pressure bar 20

Pump speed (adjustable) rpm 2000 ��� 4000

Max� pump pressure/suction bar 0�5 / 0�25

Max� flow rate (at 0 bar) l/min 21

Bath volume I 1�4–4�0

Fluid maximum viscosity mm

Low fluid level protection Yes

Interface USB, RS 232

Permitted on-time % 100

IP code according to EN 60 529

Protection class

Excess voltage category II

Contamination level 2

Permitted ambient temperature °C + 5 ��� + 32

Permitted ambient humidity % 80

Dimension (W x D x H) mm 220 x 525 x 475

Weight kg 28�5

Operation at a terrestrial altitude m max� 2000

(according to DIN 12876)

°C - 20 ��� + 100

K ± 0�1

W 400

230 ± 10 % / 115 ± 10 % / 100 ± 10 %

370

320

240

130

R134a

2

/s 50

IP 21

I

Note: Refrigerant must be disposed of in accordance with local and national regulations�

Subject to technical changes!

18

Page 19

Warranty

0 5 10 15 20

500

-

-200

-300

In accordance with IKA® warranty conditions, the warranty

period is 24 months� For claims under the warranty please

contact your local dealer� You may also send the machine

direct to our factory, enclosing the delivery invoice and giving reasons for the claim� You will be liable for freight costs�

The warranty does not cover worn out parts, nor does it apply to faults resulting from improper use, insucient care or

maintenance not carried out in accordance with the instructions in this operating manual�

Pump performance curve

Pumpenkennlinie gemessen mit Wasser:

(Messung nach DIN 12876-2 mit Wasser bei 20°C, geschlossener Pumpen-Kreislauf)�

400

300

200

100

ΔP [mbar]

0

100

Fig. 18

4000 rpm

3200 rpm

2000 rpm

Q [l/min]

19

Page 20

IKA®-Werke GmbH & Co.KG

Janke & Kunkel-Str� 10

D-79219 Staufen

Tel� +49 7633 831-0

Fax +49 7633 831-98

sales@ika�de

www.ika.com

Loading...

Loading...