Page 1

Operating instructions EN 4

Source language: German

Veiligheidsaanwijzingen NL 9

Säkerhetsanvisningar SV 10

Sikkerhedshenvisninger DA 11

Sikkerhetsinformasjon NO 12

Turvallisuusohjeet FI 13

BezpeČnostní upozornĕnÍ CS 14

Biztonsági utasitások HU 15

Varnostna navodila SL 16

Bezpečnostné pokyny SK 17

Ohutusjuhised ET 18

Drošības norādījumi LV 19

Saugos nurodymai LT 20

Инструкции за безопасност BG 21

Indicaţii de siguranţă RO 22

Υποδείξεις ασφαλείας EL 23

20000017441

HB eco_092018

HB eco

Page 2

2

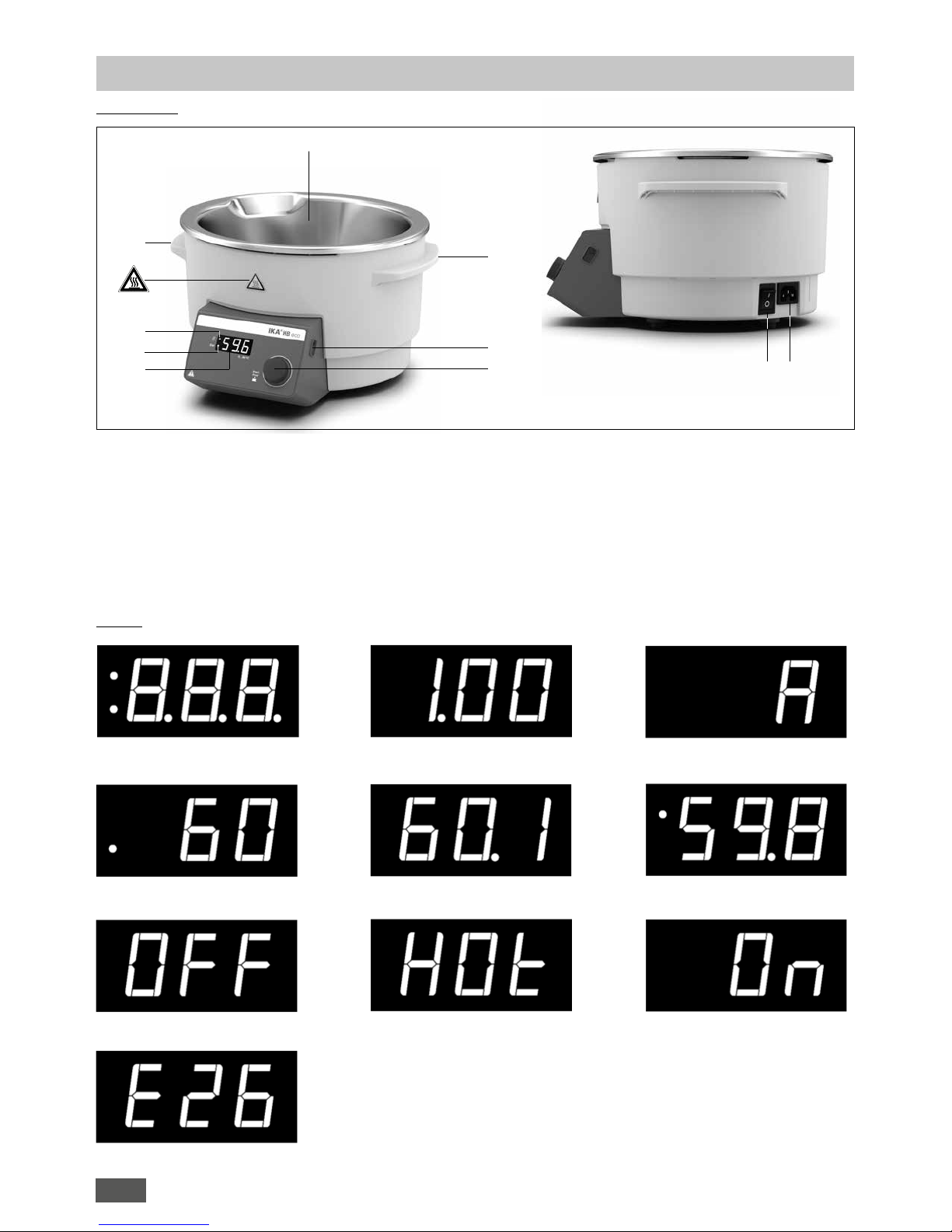

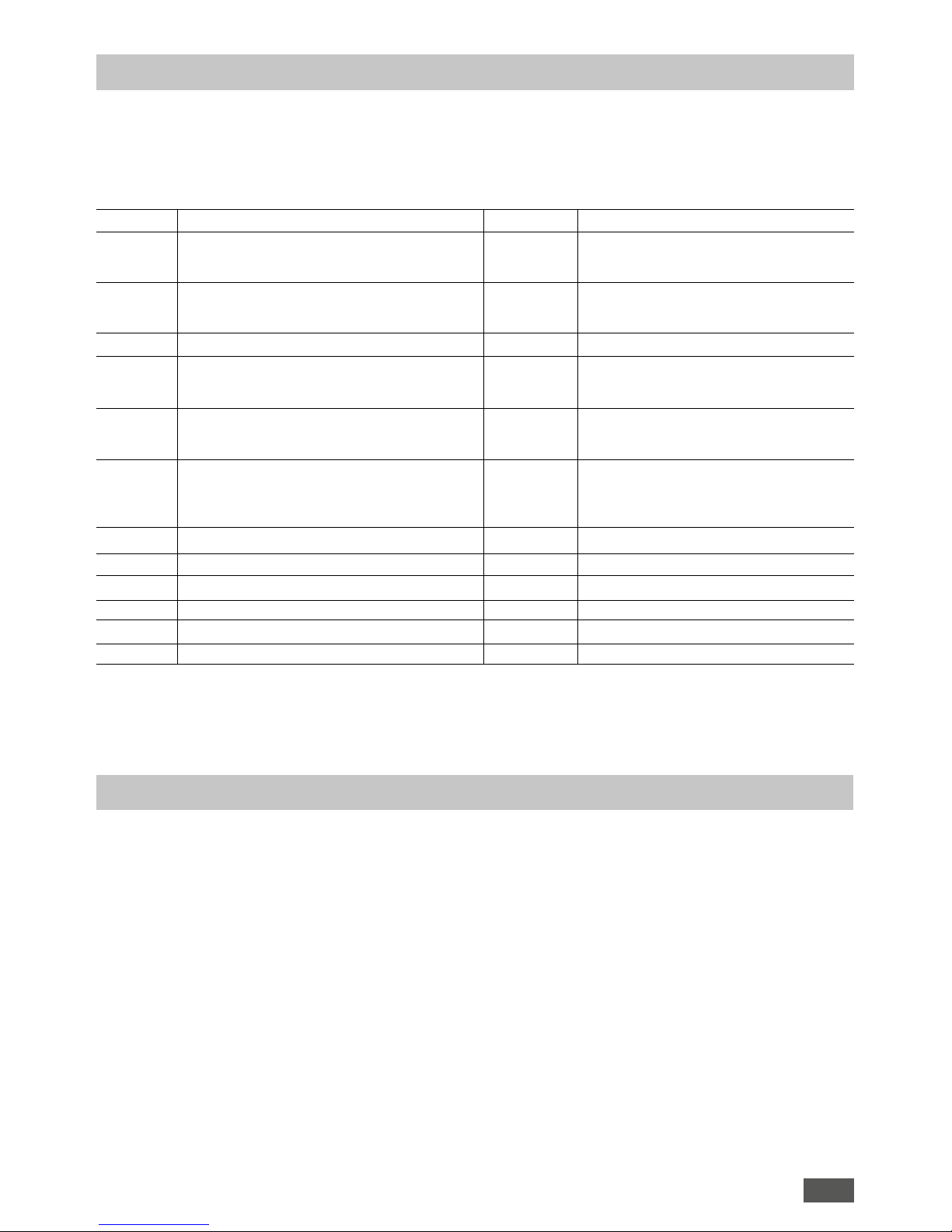

Display

Fig. 2 Fig. 3 Fig. 4

Fig. 7Fig. 6Fig. 5

Fig. 8 Fig. 9 Fig. 10

Fig. 11

A Power socket

B Mains switch

C Rotating/pressing knob

D USB interface

E Handle

Device setup/Display

Device setup

Fig. 1

E

F

C

D

G

H

J

E

B A

F Bath insert

G LED heating

H LED (set = setpoint)

J Display

Page 3

3

EN

Contents

Explication of warning symbols

Declaration of conformity

We declare under our sole responsibility that this product corresponds to the directives 2014/35/EU, 2014/30/EU and 2011/65/EU and

conforms with the following standards or normative documents: EN 61010-1, EN 61010-2-010, EN 61326-1, EN 60529 and EN ISO

12100.

Source language: German

Page

Device setup/Display 2

Declaration of conformity 3

Explication of warning symbols 3

Safety instructions 4

Correct use 4

Unpacking 5

Commissioning 5

Interfaces and outputs 6

Maintenance and cleaning 6

Error codes 7

Warranty 7

Technical Data 8

DANGER

DANGER

CAUTION

WARNING

NOTICE

Indicates an (extremely) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

DANGER - note on hazards arising from a hot surface.

Page 4

4

For your protection

• Read the operating instructions completely before starting up

and follow the safety instructions.

• Keep the operating instructions in a place where they can be

accessed by everyone.

•

Ensure that only trained staff work with the device.

• Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

• Wear your personal protective equipment in accordance with

the hazard category of the medium to be processed. Otherwise

there is a risk of splashing liquids.

• Set up the device in a spacious area on an even, stable, clean,

non-slip, dry and fireproof surface.

• Prior to each use, always check the device for damage. Do not

use damaged components.

CAUTION

Only process and heat up media

that has a flash point higher than

the adjusted safe temperature limit of the heating bath that has

been set.

DANGER

Risk of burns! During operation,

the heating bath housing can get

hot.

•

When

emptying the device use only the

handles

to carry and

hold

it.

• Prior to filling or emptying the heating bath, the device must be

switched off and disconnected from the power supply at the

plug.

• Only fill or empty the heating bath when it is cold.

• Empty the heating bath prior to transporting it.

• Never operate the heating bath without tempering medium.

DANGER

The preferred tempering medium

in the heating bath is water. There

is a risk of burning when using

tempering media with lower flash

-

points!

• Before use, calculate the optimum filling level of the tempering

medium! Pay special attention to the change in volume caused

by heating and the displacement that occurs when immersing

an object, for example, an evaporating flask.

• When using the heating bath in combination with a rotary

evaporator, the heating bath temperature must not be allowed

to rise to a value higher than the boiling point of the solvent

at normal pressure, since if the evaporating flask glass were to

break there would be a hazard due to liquid spraying out (for

instance breakage of the evaporating flask glass during distillation of aether when the medium temperature is at 60 °C).

CAUTION

When working with the IKA rotary

evaporator, be aware of a hazard

arising from breakage of the evaporating flask glass.

CAUTION

Be aware of a hazard due to lack

of grip on a wet evaporating flask.

• The use of demineralised water is recommended.

• Beware of hazards due to flammable materials.

• Only process media that will not react dangerously to the extra

energy produced through processing. This also applies to any

extra energy produced in other ways, e.g. through light irradiation.

• Do not operate the device in explosive atmospheres, with hazardous substances or under water.

• The device will automatically restart in mode C following any

interruption to the power supply.

• The device can only be disconnected from the mains supply by

pulling out the mains plug or the connector plug.

• The socket for the mains cord must be easily accessible.

For protection of the equipment

• The voltage stated on the type plate must correspond to the

mains voltage.

•

Socket must be earthed (protective ground contact).

• Protect the device and accessories from bumps and impacts.

• The device may only be opened by experts.

Solvents

• Solvents can be hazardous to health. Therefore comply with the

relevant warnings and refer to the relevant safety data sheet

(Internet).

Safety instructions

Correct use

• Use

The IKA tempering baths HB eco is laboratory device and is suitable for directly tempering substances filled into the bath container.

They are also suitable for indirect tempering of substances filled

in glass containers when the glass containers are immersed in the

actual tempering medium. A rotary glass container is particularly

advantageous, for example, when used in conjunction with an

IKA rotary evaporator.

CAUTION

The device is not intended to prepare food!

• Area of use (only indoors)

- Laboratories - Schools

- Pharmacies - Universities

This device is suitable for use in all areas except:

- Residential areas

- Areas that are connected directly to a low-voltage supply network that also supplies residential areas.

The safety of the user cannot be guaranteed:

- If the device is operated with accessories that are not supplied or

recommended by the manufacturer;

- If the device is operated improperly or contrary to the manufacturer’s specifications;

- If the device or the printed circuit board are modified by the

third parties.

Page 5

5

The safety circuit prevents the temperature of the heating bath

from getting too high as a result of controller error. Once the

safety temperature has been reached, the device switches off permanently.

Furthermore, dry running of the heating bath is detected. The device switches off permanently.

The dry running function detects both accidental heating of the

heating bath without liquid and dry running caused by water

evaporation starting at a set temperature of 60 °C. The error message E 26 (Fig. 11) appears and the heating bath is switched off

permanently. To remedy this error, see “Error codes”.

Safety temperature

Unpacking

Commissioning

• Unpacking

- Unpack the device carefully,

- Any damage should be notified immediately to the shipping

agent (post, rail or logistics company).

• Scope of delivery

- Heating bath IKA HB eco

- Power supply cable

- USB cable

- Operating instructions

- Warranty card

Observe the ambient conditions (temperature, humidity, etc.) listed under “Technical data”.

The unit is ready for service when

the mains plug has been plugged

in.

Prior to commissioning the device, determine the filling quantity

of the tempering medium due to the used evaporator piston size

(approx. 2.5 l tempering medium by using a standard 1 l evaporator piston).

• Switch on the device using the mains switch (B).

• At every start, the display will show all display segments (Fig. 2),

the software version (Fig. 3), and the operating mode (Fig. 4).

• The heating bath temperature is held constant by the control

circuit and is additionally monitored by the safety circuit.

In the event of an error occurred in the control circuit, the heat-

ing bath is switched off permanently by the safety circuit.

An error in the control or safety circuits is shown on the display.

The heating function can no longer be started.

• When switching off the heating function and the medium tem-

perature is higher than 50 °C, the display will alternately show

the set temperature (Fig. 5) and “HOT” (Fig. 9). Otherwise, the

display will alternately show the set temperature (Fig. 5) and

OFF (Fig. 8).

When switching on the heating function, the display will alter-

nately show set temperature (Fig. 5) and the actual temperature

(Fig. 6 or Fig. 7).

Activate the SET function by turning and pressing the rotating/

pressing knob (C).

• Set the desired heating bath temperature by turning the rotating/pressing knob (C).

• The LED setpoint temperature (H) will be always on whenever

the set temperature is shown. (Fig. 5)

• Confirm the value by pressing the rotating/pressing knob (C).

• Start the heating process by pressing the rotating/pressing knob

(C).

Setting the target temperature

Operating mode A

• Switch on the device at the mains switch (B).

• The heating function is switched off.

• The target value is set to 20 °C.

• The target value can be adjusted.

• The heating function must be restarted following a power failure.

• Mode A appears on the display when switching on the device.

Factory setting: Mode A

Operating mode B

• Switch on the device at the mains switch (B).

• The heating function is switched off.

• The target value is set to 20 °C or the most recent set temperature.

• The target value can be adjusted.

•

The heating function must be restarted following a power failure.

• Mode B appears on the display when switching on the device.

Operating mode C

• Switch on the device at the mains switch (B).

• The heating function is switched on or off depending on the last

selected setting.

• The last target value set in mode B applies.

• The target value cannot be adjusted.

• The heating function will be automatically restarted following a

power failure.

• Mode C appears on the display when switching on the device.

Switching the operating modes

• Switch the device off at the mains switch (B).

• Press and hold rotating/pressing knob (C) and switch the device

on at the mains switch (B). Release the rotating/pressing knob

(C) after 2 seconds.

• Sequence A, B, C, A etc.

• The operating mode appears on the display when switching on

the device.

Setting the operating modes

Page 6

6

Interfaces and outputs

Note: Please comply with the system requirements together with

the operating instructions and help section included with the

software.

USB interface

The Universal Serial Bus (USB) is a serial bus for connecting the

device to the PC. Equipped with USB devices can be connected to

a PC during operation (hot plugging). Connected devices and their

properties are automatically recognized.

Use the USB interface to update the firmware.

Controlling the medium temperature

The medium temperature is limited by the set safety temperature

controlled by means of a PID controller and measured by the PT

1000 temperature sensor, and the medium is heated up as quickly

as possible without overshooting to the set temperature.

The PID controller adapts to the different tempering media and

ensures optimum temperature control with minimum temperature drift and fluctuation.

Optimum control is only achieved when the medium is mixed using a rotating evaporator piston.

- Set the desired medium temperature between room temperature and 99 °C by turning the rotating/pressing knob (C).

- Start the

heating function by pressing the rotating/

pressing

knob (C).

- The LED heating (G) appears.

- The heating bath is heated up to the set temperature.

- The set and actual temperature referred to the medium are

shown on the display.

USB cable A - B

This cable is used to connect the USB interface to a PC.

USB Micro B

USB A

Maintenance and cleaning

The device is maintenance-free. It is only subject to the natural

wear and tear of components and their statistical failure rate.

Cleaning

Remove the device from the

mains before cleaning.

Only use cleaning materials recommended by IKA:

Dirt Cleaning agent

Dyes Isopropyl alcohol

Building materials

Water containing detergent/isopropyl alcohol

Cosmetics

Water containing detergent/isopropyl alcohol

Food Water containing detergent

Fuels Water containing detergent

Other materials Please consult IKA

Wear protective gloves during cleaning the devices.

Electrical devices may not be placed in the cleansing agent for the

purpose of cleaning.

Do not allow moisture to get into the device when cleaning.

Before using another than the recommended method for cleaning or decontamination, you must ascertain with IKA that this

method does not destroy the device.

Ordering spare parts

When ordering spare parts, please give:

- Device type,

- Serial number, see rating plate,

- Position number and description of spare part, see

www.ika.com,

- Software version.

Repairs

Please only send devices in for repair that have been cleaned

and are free of materials which might present health hazards.

For this, use the “certificate of compliance” form which you

can obtain from IKA or can download a version for printing from

the IKA website at www.ika.com.

If your appliance requires repair, return it in its original packaging.

Storage packaging is not sucient when sending the device - also

use appropriate transport packaging.

USB device drivers

First, download the latest driver for IKA devices with USB interface from:

http://www.ika.com/ika/lws/download/usb-driver.zip

Install the driver by running the setup file. Then connect the IKA

device through the USB data cable to the PC. The data communication is via a virtual COM port.

Page 7

7

Warranty

In accordance with IKA warranty conditions, the warranty period

is 24 months. For claims under the warranty please contact your

local dealer. You may also send the machine directly to our factory,

enclosing the delivery invoice and giving reasons for the claim.

You will be liable for freight costs.

The warranty does not cover worn out parts, nor does it apply

to faults resulting from improper use, insufficient care or

maintenance not carried out in accordance with the instructions

in this operating manual.

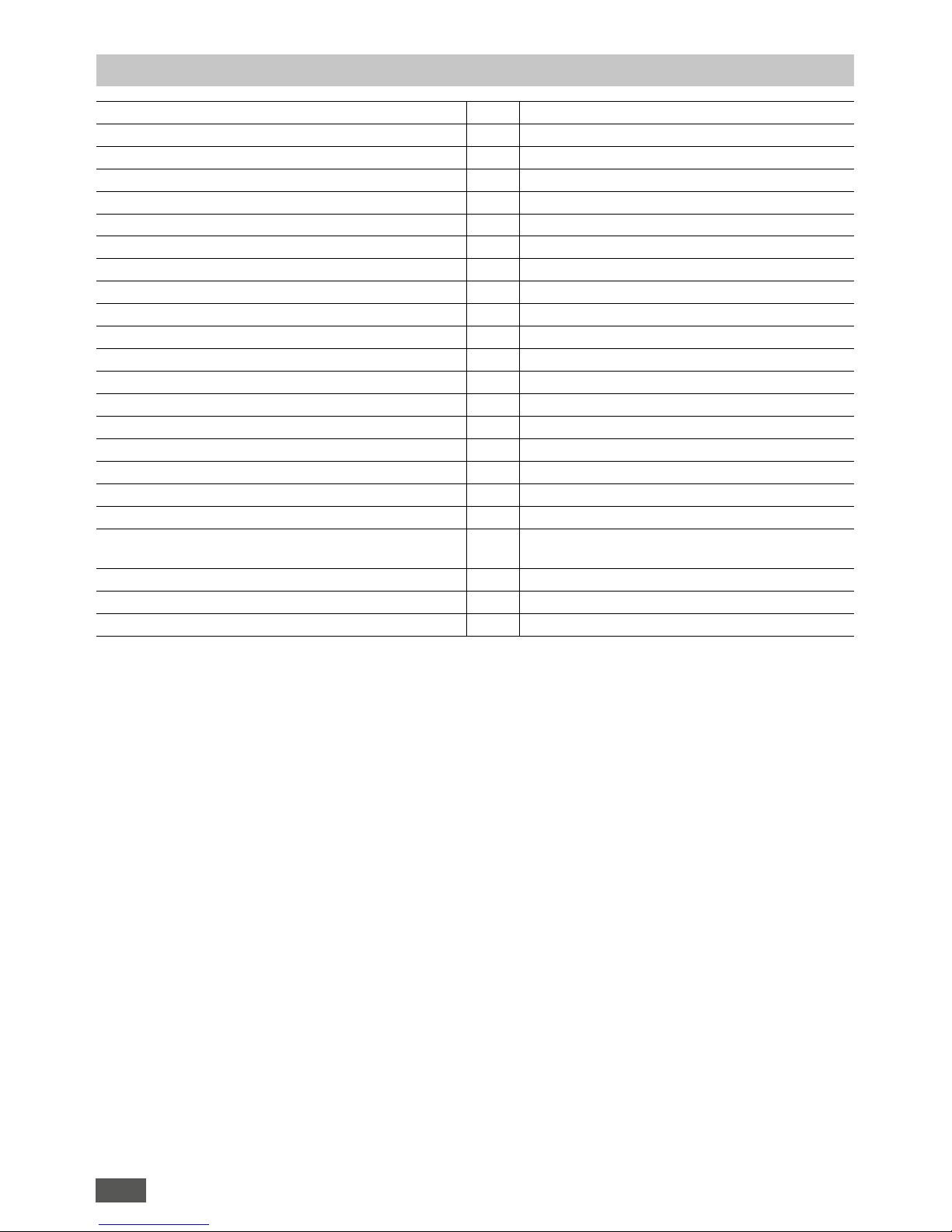

Error code Causes Effect Solutions

E 3 - Temperature inside the device is too high Heating off - Switch off the device

- Let the device cool down

- Switch on the device

E 9 - Fault in storing the safety circuit set temperatures

- Memory chip (EPROM) defective

Heating off - Switch off the device

- Let the device cool down

- Switch on the device

E 21 - Safety relay does not open Heating off - Switch off the device and switch on again

E 24 - Set safety temperature exceeded Heating off - Switch off the device

- Let the device cool down

- Switch on the device

E 25 - The heater control circuit switch (TRIAC) is faulty.

The heater or the supply line is disconnected.

Heating off - Switch off the device and switch on again

E 26 - Dry running Heating off - Switch off the device

- Let the device cool down

- Fill up the tempering medium

- Switch on the device

E 27 - Error in calibration Heating off - Switch off the device and switch on again

E 28 - Breakage of the controller sensor Heating off - Switch off the device and switch on again

E 29 - Short-circuit in the safety sensor Heating off - Switch off the device and switch on again

E 30 - Short-circuit in the controller sensor Heating off - Switch off the device and switch on again

E 31 - Breakage of the safety sensor Heating off - Switch off the device and switch on again

E 32 - Temperature deviation is too big Heating off - Switch off the device and switch on again

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department,

- Send the device for repair, including a short description of the fault.

Error codes

The fault is shown by an error code on the display as following if the error occurs.

Proceed as follows in such cases:

- Switch the device off with mains switch,

- Carry out corrective measures,

- Restart the device.

Page 8

8

Technical data

Heating output W 1350

Heating temperature range °C Room temperature...99

Heat control LED

Set temperature resolution K ±1

Filling volume max. l 4

Filling point min. mm 60

Material in contact with medium Stainless steel 1.4404

Fixed safety temperature °C 109

Safety class DIN 12877 II

Outer height mm 190

Inner height mm 130

Dimensions (W x H x D) mm 330 x 190 x 325

Weight kg 3.9

Permissible ambient temperature °C 5...40

Permissible relative humidity % 80

Protection class according to DIN EN 60529 IP 21

RS 232 interface no

USB interface yes

Analog output no

Voltage V 200...240 ±10 %

100...120 ±10 %

Frequency Hz 50/60

Power input W 1350

Power input standby W 3

Subject to technical changes!

Page 9

9

• Bij gebruik van het verwarmings bad in combinatie met een

roterende verdamper mag de temperatuur van het verwarmings bad niet hoger zijn dan de kookpunttemperatuur van het

oplosmiddel bij normale druk, omdat bij breuk van het glas van

de verdampingskolf gevaar ontstaat door naar buiten spattende

vloeistof (het glas van de verdamperkolf kan bv. breken bij de

distillatie van ether, als de mediumtemperatuur 60 °C bedraagt).

VOORZICHTIG

Let op gevaar door glasbreuk van

de verdampingskolf bij bedrijf met

de IKA rotatieverdamper.

VOORZICHTIG

Let op gevaar door slechte grip

van natte verdamperkolven.

• Geadviseerd wordt om gedemineraliseerd water te gebruiken.

• Let op gevaar door brandbare materialen.

• Bewerk uitsluitend media waarbij de energie-inbreng door de

bewerking geen gevaar oplevert. Dit geldt ook voor andere

energie-inbrengen, bijv. door lichtinstraling.

• Gebruik het apparaat niet in explosiegevaarlijke atmosferen,

met gevaarlijke stoffen en onder water.

• Na een onderbreking van de stroomtoevoer start het apparaat

uit zichzelf weer op in de modus C.

• Het apparaat is alleen afgescheiden van het elektriciteitsnet als

de stekker uit het stopcontact is getrokken.

• Het stopcontact voor aansluiting op het elektriciteitsnet moet

gemakkelijk te bereiken en toegankelijk zijn.

Ter bescherming van het apparaat

• De spanning die vermeld staat op de typeplaat moet overeenstemmen met de netspanning.

• Het stopcontact moet geaard zijn (randaarde).

• Voorkom stoten en slagen tegen het apparaat of het toebehoren.

• Het apparaat mag uitsluitend door een vakman worden geopend.

Oplosmiddelen

• Oplosmiddelen kunnen een gevaar voor de gezondheid vormen. Neem de waarschuwingen in acht en neem kennis van

het betreffende veiligheidsinformatieblad (Internet).

Voor uw bescherming

• Lees de gebruikshandleiding voor de inbedrijfstelling helemaal

door en neem de veiligheidsaanwijzingen in acht.

• Bewaar de gebruikshandleiding op een plaats die voor iedereen

toegankelijk is.

• Zorg ervoor dat alleen geschoold personeel met het apparaat

werkt.

• Neem de veiligheidsaanwijzingen, richtlijnen, arbo- en ongevallenpreventievoorschriften in acht.

• Draag de persoonlijke beschermingen die nodig zijn volgens

de gevarenklasse van het medium dat verwerkt wordt. Verder

bestaat er gevaar door spatten van vloeistoffen.

• Plaats het apparaat vrij op een vlakke, stabiele, schone, slipvaste, droge en vuurvaste ondergrond.

• Inspecteer het apparaat en het toebehoren voor elk gebruik op

beschadigingen. Gebruik geen beschadigde onderdelen.

VOORZICHTIG

Met dit apparaat mogen alleen

media verwerkt resp, verwarmd

worden, waarvan het vlampunt

boven de ingestelde veiligheidstemperatuurbegrenzing van

het verwarmings bad ligt.

GEVAAR

Gevaar voor brandwonden! Tijdens de werking kan de behuizing van het verwarmings bad

warm worden.

• Het apparaat bij het legen uitsluitend die als handvat dienst doet

vastpakken en dragen.

• Voor het vullen of legen van het verwarmings bad moet het apparaat worden uitgeschakeld en worden afgekoppeld van het

elektriciteitsnet door de stekker uit het stopcontact te halen.

• Het verwarmings bad mag alleen gevuld of geleegd worden als

het afgekoeld is.

• Leeg het verwarmings bad alvorens het te verplaatsen.

• Gebruik het verwarmings bad nooit zonder warmtedrager.

GEVAAR

Gebruik als warmtedrager in het

verwarmings bad bij voorkeur water. Bij gebruik van warmtedragers met een lager vlampunt, kan

er gevaar voor verbranding

ontstaan!

• Bepaal voor de inbedrijfstelling de optimale hoeveelheid tempermedium! Let hierbij op de volumeverandering door verwarming, alsook de verdringing bij het onderdompelen van een

lichaam, bijvoorbeeld een verdampingskolf.

Veiligheidsaanwijzingen

NL

Oorspronkelijke taal: Duits

Page 10

10

För din egen säkerhet

• Läs hela bruksanvisningen innan drifttagningen och beakta säkerhetsanvisningarna.

• Förvara bruksanvisningen så att den är tillgänglig för alla.

• Se till att endast utbildad personal arbetar med apparaten.

• Följ säkerhetsanvisningarna, riktlinjer för arbetarskydd och

förordningar för förebyggande av olycksfall.

• Personlig skyddsutrustning skall bäras motsvarande riskklassen

för det medium som skall bearbetas. Det finns annars risk för

vätskestänk.

• Ställ apparaten på en plan, stabil, rent, halkfri, torr och brandsäker yta.

• Kontrollera apparat och tillbehör med avseende på skador före

varje användning. Använd inte skadade delar.

FÖRSIKTIGHET

Apparaten får endast användas till

bearbetning, eller uppvärmning,

av medier med en flampunkt som

ligger över inställd säkerhetstemperaturbegränsning.

FARA

Risk för brännskador! Vid drift kan

värmebadshöljet värmas upp.

• Använd de greppen för att bära och hålla värmebadet vid tömning.

• Innan värmebadet fylls eller töms skall det stängas av och kopplas bort från elnätet genom att stickkontakten dras ur.

• Värmebadet skall alltid vara kallt när det fylls och töms.

• Vid transport skall värmebadet vara tömt.

• Använd aldrig värmebadet utan tempereringsmedium.

FARA

Som tempereringsmedium i

värmebadet skall i första hand

vatten användas. Användning av

tempereringsmedier med lägre

flampunkt kan medföra risk för

brännskador!

• Bestäm tempereringsmediets optimala fyllmängd före driftsättningen! Observera härvidlag volymändringen genom uppvärmning, samt förträngningen vid nedsänkning av en kropp, till exempel en förångarkolv.

• Vid användning av värmebadet med en rotationsindunstare får

värmebadstemperaturen inte vara högre än lösningsmedlets

kokpunktstemperatur vid normaltryck, då det råder en risk för

utsprutande vätska om glaset i förångarkolven går sönder (exempelvis kan glaset i förångarens kolv spricka om medeltemperaturen vid destillation av eter uppgår till 60 °C).

FÖRSIKTIGHET

Tänk på risken att förångningskolven brister vid användning av IKA

rotationsevaporator.

FÖRSIKTIGHET

Observera att det finns risk för

sämre grepp när förångarens kolv

blir våt.

• Användning av avmineraliserat vatten rekommenderas.

• Observera riskerna med eldfarliga material.

• Bearbeta endast medier som tål den energitillförsel som bearbetningen innebär. Detta gäller också energitillförsel i annan

form, t.ex. ljusinstrålning.

• Använd inte apparaten i explosiv atmosfär, tillsammans med farliga ämnen och under vatten.

• Apparaten startar om automatiskt i läget C efter strömavbrott.

• Ifrånkoppling av apparaten från strömförsörjningsnätet ska endast ske genom att dra ut nät- eller apparatstickkontakten.

• Uttaget för nätkabeln ska vara lätt tillgängligt och åtkomligt.

För att skydda apparaten

• Spänningen som anges på typskylten måste överensstämma

med nätspänningen.

• Uttaget måste vara jordat (skyddsledare).

• Se till att apparaten eller tillbehören inte utsätts för stötar eller

slag.

• Apparaten får endast öppnas av kompetent fackpersonal.

Lösningsmedel

• Lösningsmedel kan vara hälsofarliga. Följ varningsanvisningarna

för medlet och läs också säkerhetsdatabladet (på Internet).

Säkerhetsanvisningar

SV

Originalspråk: tyska

Page 11

11

Beskyttelse af brugeren

• Læs hele driftsvejledningen før ibrugtagningen og overhold sikkerhedshenvisningerne.

• Driftsvejledningen skal opbevares tilgængeligt for alle.

• Sørg for, at kun skolet personale arbejder med apparatet.

• Overhold sikkerhedshenvisninger, direktiver og bestemmelser

om arbejdsbeskyttelse og forebyggelse af uheld.

• Brug personbeskyttelsesudstyr svarende til fareklassen af det

medie, der skal bearbejdes. Ellers kan da opstå fare pga stænk

af væsker.

• Apparatet skal opstilles frit på en jævn, stabil, ren, skridsikker,

tør og ildfast flade.

• Apparatet og tilbehøret skal kontrolleres for beskadigelser før

hver brug. Brug ikke beskadigede dele.

FORSIGTIGT

Med dette apparat må der kun

bearbejdes hhv. opvarmes medier

med et flammepunkt, der ligger

over varmebadets indstillede sikkerhedstemperaturbegrænsning.

FARE

Forbrændingsfare! Varmebadhuset kan opvarmes under driften.

• Ved tømning må apparatet kun bæres og holdes i de greb.

• Inden varmebadet fyldes eller tømmes, skal apparatet slukkes

og kobles fra strømforsyningsnettet ved at netstikket trækkes ud

af stikdåsen.

• Varmebadet må kun fyldes eller tømmes i varm tilstand.

• Varmebadet skal tømmes før transport.

• Varmebadet må aldrig drives uden tempereringsmedium.

FARE

Som tempereringsmedium i varmebadet bør der fortrinsvis bruges vand. Ved anvendelse af tempereringsmedier med lavere

flammepunkt kan der være fare

for forbrændinger!

• Find frem til tempereringsmediets optimale påfyldningsmængde

før ibrugtagningen! Vær i denne forbindelse opmærksom på

volumenændringen pga. opvarmning samt fortrængningen,

hvis et legeme, f.eks. en fordamperkolbe, sænkes ned.

• Ved brug af et varme bad i forbindelse med en rotationsfordamper må varmebadtemperaturen ikke ligge over opløsningsmidlets kogepunkttemperatur ved normalt tryk, da der ved

glasbrud på fordamperkolben er fare pga. væske, der sprøjter

ud (f.eks. kan fordamperkolbens glas knække ved destillering af

æter, hvis medietemperaturen er 60 °C).

FORSIGTIGT

Vær opmærksom på fare p.g.a.

glasbrud på fordamperkolben ved

drift med IKA rotationsfordamperen.

FORSIGTIGT

Vær opmærksom på fare, der skyldes, at man ikke har et godt greb

i våde fordamperkolber.

• Det anbefales at bruge demineraliseret vand.

• Vær opmærksom på farer pga antændelige materialer.

• Der må kun bearbejdes medier, hvor energitilførslen fra bearbejdningen er ubetænkelig. Dette gælder også for andre energitilførsler, f.eks. fra lysindstråling.

• Apparatet må ikke drives i atmosfærer med eksplosionsfare,

sammen med farestoffer og under vand.

• Efter en afbrydelse af strømforsyningen starter apparatet igen af

sig selv i tilstand C.

• Apparatet kan kun kobles fra strømforsyningsnettet ved at nethhv. apparatstikket trækkes ud.

• Stikdåsen for netledningen skal kunne nås let og være let

tilgængelig.

Beskyttelse af apparatet

• Typeskiltets spændingsværdi skal stemme overens med netspændingen.

• Stikdåsen skal være jordet (jordledningskontakt).

• Undgå stød eller slag på apparatet eller tilbehør.

• Apparatet må kun åbnes af fagpersonale.

Opløsningsmidler

• Opløsningsmidler kan være sundhedsskadelige. Vær opmærksom på de relevante advarsler og se det tilsvarende sikkerhedsdatablad (internet) for oplysninger.

Sikkerhedshenvisninger

DA

Oprindelsessprog: tysk

Page 12

12

For din egen sikkerhet

• Les bruksanvisningen nøye før du bruker enheten for å ivareta

sikkerheten.

• Hold bruksanvisningen tilgjengelig for tilgang til alle.

• Merk at kun opplært personale må bruke enheten.

• Følg sikkerhetsinstruksjonene, retningslinjene, forskrifter for

yrkesmessig sikkerhet og forebygging av ulykker.

• Bruk ditt personlige verneutstyr i samsvar med fareklassen til

mediumet som skal bearbeides. Ellers kan det være fare for

væskesprut.

• Plasser apparatet på en flat, stabil, ren, sklifri, tørr og brannsikker overflate.

• Før hver bruk av enheten og tilbehøret kontroller disse for skade.

Ikke bruk skadde deler.

FORSIKTIG

Med dette apparatet må kun medier med flammepunkt som ligger

over den innstilte sikkerhetstemperaturbegrensningen til varmebadet, bearbeides hhv. oppvarmes.

FARE

Fare for forbrenning! Varmebadhuset kan bli varmt under bruk.

• Ved tømming skal maskinen bare bæres og holdes i ehåndtakene.

• Før fylling eller tømming av varmebadet må apparatet slås av

og kobles fra strømforsyningen ved å trekke støpselet ut av stikkontakten.

• Kun fylle og tømme varmebadet når det er avkjølt.

• Tøm varmebadet før transport.

• Bruk aldri varmebadet uten tempereringsmediet.

FARE

B

ruk fortrinnsvis v

ann som tempereringsmedium i varmebadet. Ved

bruk av tempereringsmedier med

et

lavere flammepunkt, kan det føre

til

fare gjennom forbrenninger.

• Finn ut optimal påfyllingsmengde for tempreringsmediumet før

bruk! Vær oppmerksom på volumendringen som skjer pga. oppvarmingen samt fortrengningen når en gjenstand dyppes i, for

eksempel en fordamperkolbe.

• Hvis varmebadet brukes sammen med en rotasjonsfordamper,

må temperaturen på varmebadet ikke være over løsemiddelets

kokepunkttemperatur ved normaltrykk. Sprekker glasset i fordamperkolben, vil det være fare for at væske spruter ut (f.eks.

kan glasset til fordamperkolben bryte ved destillasjon av eter når

medietemperaturen er 60 °C).

FORSIKTIG

Vær oppmerksom på faren om

glasset i fordamperkolben sprekker når IKA-rotasjonsfordamperen

benyttes.

FORSIKTIG

Pass på risikoen ved dårlig grep på

våt fordamperkolbe.

• Det er tilrådelig å bruke demineralisert vann.

• Ta hensyn til at det oppstår fare gjennom antennelige materialer.

• Kun behandle media hvor energitilførsel ved behandlingen er

ufarlig. Det gjelder også for andre energitilførsler, som lysbestråling.

• Ikke bruk enheten i områder med eksplosjonsfarlig luft, farlige

stoffer og under vann.

• Etter et strømforsyningsavbrudd kjører enheten i modus C av

seg selv igjen.

• Frakobling av enheten fra strømforsyningen må kun skje ved å

trekke ut nett- eller apparatkontakten.

• Stikkontakten for strømtilførselskabelen må være lett tilgjengelig.

For å beskytte enheten

• Spenningen angitt på typeskiltet må stemme overens med nettspenningen.

• Stikkontakten må jordes (beskyttende jordkontakt).

• Unngå støt og vibrasjoner på enheten eller tilbehøret.

• Enheten må kun åpnes av en autorisert elektriker.

Løsemidler

• Løsemidler kan være helsefarlige. Merk advarsler i denne

forbindelse og informer deg ved det aktuelle sikkerhetsdatabladet (Internett).

Sikkerhetsveiledning

NO

Kildespråk: tysk

Page 13

13

Oman turvallisuutesi tähden

• Lue käyttöohjeet ennen laitteen käyttöönottoa ja noudata turvallisuusohjeita.

• Säilytä käyttöohjeet kaikkien käyttäjien saatavilla.

• Varmista, että laitetta käyttävät vain käyttöön koulutetut henkilöt.

• Noudata turvallisuusohjeita, määräyksiä sekä työturvallisuus- ja

tapaturmantorjuntaohjeita.

• Käytä käsiteltävän materiaalin riskiluokitusta vastaavia henkilö

kohtaisia suojavarusteita. Muuten vaaraa voivat aiheuttaa nesteiden roiskuminen.

• Aseta laite tasaiselle, tukevalle, puhtaalle, pitävälle, kuivalle ja

paloturvalliselle alustalle.

• Tarkasta aina ennen käyttöä, että laite ja lisävarusteet ovat ehjiä.

Älä käytä vahingoittuneita osia.

VARO

Tällä laitteell

a saa käsitellä/lämmittää

vain aineita, joiden leimahduspiste

on

korkeampi kuin kuumennushau-

teen

asetettu lämpötilarajoitus.

VAARA

Palovammojen vaara! Kuumennushauteen kotelo voi kuumentua

käytössä.

• Laitetta tyhjentäessäsi pidä kiinni ainoastaan kahvoista.

• Ennen kuumennushauteen täyttöä tai tyhjennystä laite pitää

kytkeä pois päältä ja irrottaa verkkojännitteestä irrottamalla pistotulppa pistorasiasta.

• Kuumennushauteen saa tyhjentää ja täyttää vain kylmänä.

• Tyhjennä kuumennushaude ennen kuljetusta.

• Älä käytä kuumennushaudetta ilman kuumennusnestettä.

VAARA

Käytä kuumennushauteessa pääasiassa vettä. Jos käytettävän kuumennusnesteen leimahduspiste on

tätä alhaisempi, se voi aiheuttaa

palovaaran!

• Selvitä temperointiaineen optimaalinen täyttömäärä ennen

käyttöönottoa! Huomioi tässä yhteydessä lämpenemisestä johtuva tilavuuden muuttuminen sekä nesteen syrjäytyminen, kun

siihen upotetaan esine, esimerkiksi tislauskolvi.

• Käytettäessä kuumennushaudetta yhdessä kiertohaihduttimen

kanssa kuumennushauteen lämpötila ei saa olla liuottimen kiehumispisteen lämpötilan yläpuolella normaalipaineessa, koska

tislauskolvin lasin murtuessa on olemassa ruiskuavasta nesteestä

aih

eutuva vaara (esim.

haihduttimen

keittopullon

lasi voi murtua

ee

tterin tislauksen yhteydessä, mikäli väliaineen lämpötila on 60

°C).

VARO

Ota huomioon haihdutuspullon rikkou

tumisesta aiheutuva vaarati-

lanne, kun

pulloa käytetään IKA-

ki-

ertohaihdutt

imen kanssa.

VARO

Huomaa, että märästä haihduttimen keittopullosta saa huonosti

otteen, mikä voi aiheuttaa vaaraa.

• Suosittelemme käyttämään demineralisoitua vettä.

• Huomioi syttyvien materiaalien aiheuttamat vaarat.

• Käsittele laitteella vain aineita, jotka eivät reagoi vaarallisesti

käsittelyn aikana muodostuvaan energiaan. Tämä koskee myös

muita energialisäyksiä kuten valon säteilyä.

• Laitetta ei saa käyttää räjähdysalttiissa tiloissa, vaarallisten aineiden käsittelyyn eikä veden alla.

• Sähkökatkoksen jälkeen laite käynnistyy itsestään C-tilaan.

• Laite voidaan irrottaa sähköverkosta vain irrottamalla verkkojohto pistorasiasta tai laitteesta.

• Verkkojohdon pistorasian pitää olla helposti ulottuvilla.

Laitteen suojaamiseksi

• Tyyppikilven jännitemerkinnän on vastattava verkkojännitettä.

• Käytettävän pistorasian on oltava maadoitettu (suojamaadoitettu).

• Varo kohdistamasta iskuja laitteeseen tai tarvikkeisiin.

• Laitteen saa avata vain valtuutettu asentaja.

Liuottimien

• Liuottimet saattavat olla terveydelle vaarallisia. Noudata varoituksia ja lue vastaavat turvallisuusohjeet Internetistä.

Turvallisuusohjeet

FI

Alkukieli: saksa

Page 14

14

Pro vaši ochranu

• Před uvedením zařízení do provozu si přečtěte celý návod k provozu a respektujte bezpečnostní pokyny.

• Návod k provozu uložte na místě dostupném všem.

• Respektujte, že se zařízením smí pracovat pouze vyškolený personál.

• Respektujte bezpečnostní upozornění, směrnice, předpisy na

ochranu zdraví při práci a prevenci nehod.

• Noste svoje osobní ochranné vybavení v souladu s třídou nebez

pečí zpracovávaného média. Jinak vyvstává ohrožení vlivem

vystřikování kapalin.

• Přístroj postavte volně na rovnou, stabilní, čistou, neklouzavou,

suchou a nehořlavou plochu.

• Před každým použitím zkontrolujte, zda zařízení a příslušenství

nejeví známky poškození. Nepoužívejte poškozené díly.

VÝSTRAHA

S tímto přístrojem se smějí zpracovávat, resp. ohřívat jen média,

jejichž bod vzplanutí je vyšší než

nastavené bezpečnostní omezení

teploty ohřívané lázně.

NEBEZPEČÍ

Nebezpečí popálení! Během provozu může dojít k zahřátí pláště

ohřívací lázně.

• Při přenášení a vyprazdňování držte přístroj výhradně za rukojeti.

• Před naplněním nebo vyprázdněním vyhřívané lázně zařízení

vypněte a odpojte od elektrické sítě vytažením síťové zástrčky ze

zásuvky.

• Vyhřívanou lázeň plňte a vyprazdňujte pouze za studena.

• Vyhřívanou lázeň před dopravou vyprázdněte.

• Vyhřívanou lázeň nikdy nepoužívejte bez tepelného média.

NEBEZPEČÍ

Jako tepelné médium ve vyhřívané

lázni používejte přednostně vodu.

Při použití tepelného média s

nižším bodem vzplanutí může

vzniknout riziko vznícení a požáru.

• Před uvedením do provozu stanovte optimální úroveň naplnění

temperovacího média! Při tomto zohledněte změnu objemu

v důsledku zahřátí a rovněž výtlak kapaliny při ponoření těles,

například odpařovacího válce.

• Při použití ohřevné lázně v kombinaci s rotačním výparníkem

nesmí teplota ohřevné lázně ležet nad úrovní bodu varu

rozpouštědla při normálním tlaku, neboť při prasknutí

skleněného pláště odpařovacího válce vyvstává riziko ohrožení

v důsledku vystříknutí tekutiny (může například dojít k prasknutí

skleněné baňky výparníku při destilaci éteru, pokud teplota média činí 60 °C).

VÝSTRAHA

Při provozu s rotačním výparníkem

IKA dbejte opatrnosti v souvislosti

s nebezpečím v důsledku možného

prasknutí skleněné baňky výparníku.

VÝSTRAHA

Dbejte opatrnosti v souvislosti s

kluzkostí vlhké baňky výparníku.

• Doporučuje se používat demineralizovanou vodu.

• Vyvarujte se nebezpečí vyvolanému použitím hořlavých

materiálů.

• Zpracovávejte pouze média, u kterých je přívod energie zpracováním bez nebezpečí. To platí rovněž pro jiné vstupy energie

například světelným zářením.

• Zařízení neprovozujte v prostorách s atmosférou s nebezpečím

výbuchu, s nebezpečnými látkami ani pod vodou.

• Po ukončení přerušení přívodu elektrické energie se přístroj v

režimu C opět automaticky spustí.

• Odpojení zařízení od elektrické sítě se provádí pouze vytažením

síťové zástrčky, resp. zástrčky zařízení.

• Zásuvka pro připojení k elektrické síti musí být snadno dosažitelná

a přístupná.

Pro ochranu přístroje

• Údaj o napětí na typovém štítku musí odpovídat napětí v síti.

• Zásuvka musí být řádně uzemněna (ochranný vodič).

• Zamezte tvrdým nárazům nebo úderům na zařízení nebo

příslušenství.

• Zařízení smí otevírat pouze kvalifikovaný pracovník.

Rozpouštědla

• Rozpouštědla mohou ohrožovat zdraví osob. Věnujte náležitou

pozornost výstražným upozorněním, která se tohoto tématu

týkají, a informujte se na příslušný bezpečnostní list (Internet).

Bezpečnostní pokyny a informace

CS

Výchozí jazyk: němčina

Page 15

15

Az Ön biztonsága érdekében

• Az üzembe helyezés előtt olvassa végig a kezelési útmutatót, és

ügyeljen a biztonsági tudnivalókra.

• A kezelési útmutatót mindenki számára könnyen elérhető helyen tárolja.

• Ügyeljen arra, hogy csak képzett munkatársak dolgozzanak a

készülékkel.

• Tartsa be a biztonsági tudnivalókat, irányelveket, munkavédelmi

és balesetvédelmi előírásokat.

• Viseljen a feldolgozandó anyag veszélyességi osztályának megfe

lelő személyes védőeszközöket. A veszélyforrások a következők

folyadékok kifröccsenése.

• A készüléket sík, stabil, tiszta, csúszásmentes, száraz és tűzálló

felületre állítsa.

• Minden használat előtt ellenőrizze a készülék és a kiegészítők

épségét. Sérült alkatrészeket ne használjon.

VIGYÁZAT

Ezzel a készülékkel csak olyan anyagokat szabad feldolgozni ill. melegíteni, amelyeknek a lobbanáspontja a melegítőfürdő beállított

biztonsági hőmérsékletkorlátozása

felett van.

VESZÉLY

Égési sérülések veszélye áll fenn!

Üzem közben a hőfürdő burkolata

forró lehet.

• Ürítéskor a készüléket csak a fogantyúkat hogy készítsen és

tartsa.

• A fűtőfürdő feltöltése vagy kiürítése előtt a készüléket ki kell

kapcsolni, és az áramhálózatról le kell választani a hálózati csatlakozódugó kihúzásával.

• A fűtőfürdőt csak hideg állapotban töltse fel, vagy ürítse ki.

• Szállítás előtt ürítse ki a fűtőfürdőt.

• A fűtőfürdőt soha ne működtesse temperáló közeg nélkül.

VESZÉLY

A fűtőfürdőben temperáló közegként elsősorban vizet használjon.

Alacsony gyulladáspontú temperáló közegek alkalmazásakor

égésveszély áll fenn!

• Az üzembe helyezés előtt határozza meg a temperálóközeg optimális mennyiségét! Ennek során vegye figyelembe a felhevülés

miatti térfogatváltozást, illetve egy test, például egy gőzfejlesztő

dugattyú bemártásakor fellépő kiszorítást.

• Ha a hőfürdőt egy rotációs gőzfejlesztővel együtt használja,

a hőfürdő hőmérséklete nem léphet az oldószer forrásponti

hőmérséklete fölé normál nyomáson, mert a gőzfejlesztő dugattyú törése esetén a kifröccsenő folyadék veszélyt jelenthet (pl.

az éter desztillációja során a forraló lombik üvege eltörhet, ha a

közeg hőmérséklete eléri a 60 °C-ot).

VIGYÁZAT

Ügyeljen az IKA rotációs bepárlóval történő üzemeltetés során az

üveg forraló lombik töréséből

eredő kockázatokra!

VIGYÁZAT

Ügyeljen a nedves forraló lombik

nem biztonságos megfogási

lehetőségéből eredő veszélyre.

• Ásványmentesített víz használata ajánlott.

• Vegye figyelembe a gyúlékony anyagok miatti veszélyeket.

• Csak olyan anyagokkal dolgozzon, amelyeknél a feldolgozás

közbeni energiabevitel nem aggályos. Ez az energiabevitel más

formáira, pl. a fénysugárzásra is érvényes.

• Ne használja a készüléket robbanásveszélyes légkörben, veszélyes anyagokkal és víz alatt.

• Az áramellátás megszakítása után a készülék a C módban automatikusan újra elindul.

• A készülék áramtalanítása csak a hálózati csatlakozódugó, ill. a

készülék csatlakozódugója kihúzásával történhet.

• A tápvezeték csatlakozóaljzatának könnyen elérhető és

megközelíthető helyen kell lennie.

A készülék biztonsága érdekében

• A típustáblán szereplő feszültségnek meg kell egyeznie a hálózati feszültséggel.

• Az aljzatnak földeléssel (védőérintkezővel) kell rendelkeznie.

• Kerülje a készüléket és a kiegészítőit érő lökéseket és ütéseket.

• A készüléket csak szakember nyithatja fel.

Oldószerek

• Az oldószer káros lehet az egészségre. Vegye figyelembe az erre

vonatkozó utasításokat, és tájékozódjon a megfelelő biztonsági

adatlap segítségével (az interneten keresztül).

Biztonsági tudnivalók

HU

Forrásnyelv: német

Page 16

16

Za vašo zaščito

• Preden začnete napravo uporabljati, v celoti preberite navodila

za uporabo in upoštevajte varnostne napotke.

• Navodila za uporabo shranite na vsem dostopnem mestu.

• Pazite, da napravo uporablja le za to usposobljeno osebje.

• Upoštevajte varnostne napotke, smernice in predpise za varstvo

pri delu ter preprečevanje nesreč.

• Nosite osebno zaščitno opremo v skladu z razredom nevarnosti medija, ki ga obdelujete, sicer obstaja nevarnost brizganja

tekočin.

• Napravo postavite na ravno, stabilno, čisto, nedrsečo, suho in

ognjevarno podlago tako, da bo okrog nje dovolj prostora.

• Pred vsako uporabo preverite, ali sta naprava in oprema

poškodovani. Ne uporabljajte poškodovanih delov.

PREVIDNO

S to napravo je dovoljeno obdelovati oziroma ogrevati le tiste medije, katerih vnetišče je višje od

nastavljene varnostne temperaturne omejitve grelne kopeli.

NEVARNOST

Nevarnost opeklin! Med delovanjem se lahko segreje ohišje grelne

kopeli.

• Napravo pri praznjenju držite in nosite samo za oprijem.

• Pred polnjenjem ali praznjenjem grelne kopeli napravo izklopite

in vtič izvlecite iz električnega omrežja.

• Grelno kopel polnite ali praznite samo, kadar je hladna.

• Pred transportom spraznite grelno kopel.

• Grelna kopel ne sme obratovati brez temperirnega medija.

NEVARNOST

Kot temperirni medij v ogrevalni

kopeli uporabljajte predvsem

vodo. Pri uporabi temperirnih

medijev z nizkim vnetiščem obstaja nevarnost opeklin!

• Pred zagonom določite optimalno napolnjenost temperirnega

medija! Pri tem upoštevajte spremembe prostornine zaradi segrevanja in izpodrivanje pri potopitvi telesa, na primer izparilne

bučke.

• Pri uporabi grelne kopeli v povezavi z rotacijskim uparjalnikom

temperatura grelne kopeli ne sme presegati temperature vrelišča

topila pri normalnem tlaku, ker pri zlomu stekla izparilne bučke

obstaja nevarnost brizganja tekočin (npr. steklo posode uparjalnika lahko pri destilaciji etra poči, če temperatura medija presega 60 °C).

PREVIDNO

Upoštevajte nevarnost zaradi razbitja steklene izparilne bučke pri

obratovanju z rotavaporjem IKA.

PREVIDNO

Pazite na nevarnost zaradi slabe

oprijemljivosti mokrih posod uparjalnika.

• Priporočamo uporabo demineralizirane vode.

• Bodite pozorni na nevarnost zaradi vnetljivih materialov.

• Obdelujte le snovi, pri katerih je energija, ki se dovaja pri obdelavi, neznatna. To velja tudi za druge dovode energije, npr.

zaradi svetlobnega obsevanja.

• Naprave ne uporabljajte v eksplozivnih atmosferah, z nevarnimi

snovmi in pod vodo.

• Po prekinitvi električnega napajanja se naprava samodejno

ponovno zažene v načinu C.

• Napravo izključite iz električnega omrežja le, če izvlečete omrežni

vtič oziroma vtič naprave.

• Vtičnica napajalnega kabla mora biti lahko dostopna in dosegljiva.

Za zaščito naprave

• Nazivna napetost na tipski ploščici se mora ujemati z omrežno

napetostjo.

• Vtičnica mora biti ozemljena (ozemljitveni kontakt).

• Preprečite sunke ali udarce ob napravo ali opremo.

• Napravo lahko odpre le strokovno osebje.

Topila

• Topila lahko ogrožajo zdravje. Upoštevajte ustrezne varnostne

napotke in informacije na varnostnem listu (splet).

Varnostni napotki

SL

Izvorni jezik: nemščina

Page 17

17

Vaša ochrana

• Prečítajte si celý návod na obsluhu už pred uvedením zariadenia

do prevádzky a rešpektujte bezpečnostné pokyny.

• Návod na obsluhu uložte tak, aby bol prístupný pre každého.

• Dbajte, aby so zariadením pracovali iba zaškolení pracovníci.

• Dodržiavajte bezpečnostné pokyny, smernice, predpisy na

ochranu zdravia pri práci a na predchádzanie úrazom.

• Používajte osobné bezpečnostné pomôcky zodpovedajúce

triede nebezpečenstva upravovaného média. Nedodržaním tejto požia davky vzniká ohrozenie v dôsledku možnosti odstrekujúcich kvapalín.

• Zariadenie uložte voľne na rovný, stabilný, čistý, nekĺzavý, suchý

a nehorľavý povrch.

• Pred každým použitím skontrolujte, či zariadenie ani príslušenstvo

nie je poškodené. Nepoužívajte žiadne poškodené diely.

UPOZORNENIE

Týmto zariadením možno

spracovávať resp. ohrievať iba médiá, ktorých bod vzplanutia je

vyšší ako nastavená bezpečnostná

obmedzovacia teplota ohrievacieho kúpeľa.

NEBEZPEČENSTVO

Nebezpečenstvo popálenia! Počas

prevádzky vykurovania kúpeľ bývanie môžu ohrievať.

• Pri prenášaní a vyprázdňovaní držte zariadenie vždy za uchopovacie.

• Pred plnením alebo vyprázdňovaním ohrievacej vane sa zariadenie musí vypnúť a odpojiť od elektrickej napájacej siete vytiahnutím sieťovej vidlice zo sieťovej zásuvky.

• Ohrievací kúpeľ sa môže plniť a vyprázdňovať iba v studenom

stave.

• Ohrievací kúpeľ pred premiestňovaním vyprázdnite.

• Ohrievací kúpeľ nikdy neuvádzajte do činnosti bez temperovacieho média.

NEBEZPEČENSTVO

Ako temperovacie médium do

ohrievacieho kúpeľa je dovolené

používať najlepšie vodu. Pri použití

temperovacích médií s nižším bodom vzplanutia hrozí riziko popálenia!

• Pred uvedením do prevádzky stanovte optimálne množstvo

temperovacieho média! Zohľadňujte pritom zmeny objemu pri

ohreve a takisto vytesňovanie pri ponorení určitého telesa, napríklad odparovacej banky.

• Pri použití ohrievacieho kúpeľa s rotačným destilačným prístrojom teplota ohrievacieho kúpeľa nesmie prekročiť teplotu bodu

varu rozpúšťadla pri normálnom tlaku, pretože pri prasknutí skla

odparovacej banky hrozí riziko vystreknutia kvapaliny (odparovacia banka môže prasknúť napríklad počas destilácie éteru pri

teplote média 60 °C).

UPOZORNENIE

Pozor na nebezpečenstvo v

dôsledku prasknutia skla odparovacej banky pri prevádzke rotačnej

odparky IKA.

UPOZORNENIE

Pozor na zvýšené riziko spôsobené

klzkosťou vlhkých odparovacích

baniek.

• Odporúča sa použitie demineralizovanej vody.

• Pri použití zápalných materiálov je potrebná zvýšená opatrnosť.

• Pracujte výhradne s médiami, u ktorých zvýšenie energie pri

úprave nespôsobuje žiadne nebezpečenstvo. Platí to aj pre ostatné príčiny zvýšenia energie, napr. dopadajúcimi slnečnými

lúčmi.

• Zariadenie neuvádzajte do chodu v prostredí s nebezpečenstvom

výbuchu, s nebezpečnými látkami ani pod vodou.

• Po výpadku dodávky elektrickej energie sa zariadenie v režime C

uvedie znova samočinne do prevádzky.

• Odpojenie zariadenia od napájacej siete sa dosiahne iba vytiahnutím sieťovej alebo prístrojovej vidlice.

• Elektrická zásuvka pre sieťový napájací kábel musí byť voľne

prístupná.

Ochrana zariadenia

• Údaj o napätí na typovom štítku sa musí zhodovať s napätím v

elektrickej sieti.

• Sieťová zásuvka musí byť uzemnená (s ochranným kontaktom).

• Vyhýbajte sa udieraniu alebo nárazom do zariadenia alebo

príslušenstva.

• Zariadenie môže otvárať iba kvalifikovaný odborník.

Rozpúšťadlá

• Rozpúšťadlá môžu byť nebezpečné pre zdravie. Rešpektujte

príslušné varovania a informujte sa na vhodnú Kartu

bezpečnostných údajov (Internet).

Bezpečnostné pokyny

SK

Zdrojový jazyk: nemčina

Page 18

18

Teie kaitseks

• Enne seadme kasutuselevõttu lugege läbi kasutusjuhend ja järgige ohutusjuhiseid.

• Hoidke kasutusjuhendit kõigile ligipääsetavas kohas.

• Jälgige, et seadmega töötaks vaid väljaõpetatud personal.

• Järgige ohutusjuhiseid, direktiive, töökaitset ja õnnetuste ennetamise eeskirju.

• Kandke isiklikku kaitsevarustust vastavalt töödeldava vahendi

ohuklassile. Vastasel korral esineb oht, mis tuleneb vedelike pritsimisest.

• Asetage seade tasasele, stabiilsele, puhtale, libisemiskindlale,

kuivale ja tulekindlale pinnale.

• Kontrollige enne iga kasutuskorda seadet ja tarvikuid võimalike

kahjustuste suhtes. Ärge kasutage kahjustunud detaile.

ETTEVAATUST!

Käesoleva seadmega tohib töödelda ja kuumutada üksnes meediume, mille leekpunkt on kõrgem

kuumutusvanni ohutu temperatuuri piirangust.

OHT

Põletusoht! Soojendusvanni korpus võib käitamisel kuumeneda.

• Tühjendamisel kandke ja hoidke seadet ainult haare.

• Enne kuumutusvanni täitmist või tühjendamist tuleb seade välja

lülitada ja lahutada vooluvõrgust, tõmmates selleks toitepistikust.

• Täitke või tühjendage kuumutusvanni üksnes külmalt.

• Tühjendage kuumutusvann enne transportimist.

• Ärge kasutage kuumutusvanni kunagi ilma kuumutatava meediumita.

OHT

Kasutage kuumutusvannis kuumutatava ainena alati vett. Madala

leekpunktiga kuumutatavate meediumide kasutamisel tekib põletuste oht!

• Enne käitamist tehke kindaks optimaalne karastuse täitemaht!

Seejuures jälgige soojenemisest ja eseme, näiteks aurusti kolbi

sissekastmisest tulenevat mahumuutust.

• Kuumavanni kasutamisel koos pöörlevaurustiga ei tohi vanni

temperatuur normaalrõhul lahusti keemistemperatuuri ületada,

kuna aurusti kolbi klaasi purunemisel tekib vigastusoht läbi vedeliku pritsmete (näiteks võib aurustikolbi klaas eetri destilleerimisel puruneda, kui aine temperatuur on 60 °C).

ETTEVAATUST!

IKA pöördaurusti kasutamisel

arvestage aurustikolvi klaasi purunemisest tuleneva ohuga.

ETTEVAATUST!

Arvestage ohuga, mis on tingitud

sellest, et niiske aurustikolbi käeshoidmine on raskendatud.

• Soovitatav on kasutada demineraliseeritud vett.

• Ärge unustage ohtu, mida võivad põhjustada süttivad materjalid.

• Töödelge ainult selliseid aineid, mille korral on töötlemisel tekkiv

energia ohutu. See kehtib ka teiste sisendenergiate kohta, nt

valguskiirguse tõttu.

• Seadet ei tohi kasutada plahvatusohtlikes keskkondades, koos

ohtlike materjalidega ega vee all.

• Pärast voolukatkestust käivitub seade iseseisvalt režiimis C.

• Seadme saab vooluvõrgust lahutada ainult toite- või seadmepistiku väljatõmbamisega.

• Seadme vooluvõrku ühendamiseks kasutatav pistikupesa peab

olema kergesti ligipääsetav.

Varustuse kaitseks

• Tüübisildil märgitud pinge peab vastama võrgupingele.

• Pistikupesa peab olema maandatud (kaitsejuhiga ühendatud

kontakt).

• Vältige mükse ja lööke seadme või tarvikute pihta.

• Seadet võivad avada vaid spetsialistid.

Lahustid

• Lahustid võivad olla tervisele kahjulikud. Pidage silmas sellega

seotud hoiatusmärkuseid ja viige ennast kurssi asjakohaste ohutuskaartidega (teave on internetis).

Ohutusjuhised

ET

Lähtekeel: saksa

Page 19

19

Jūsu drošībai

• Pirms nodošanas ekspluatācijā pilnībā izlasiet lietošanas instrukciju un ievērojiet drošības norādījumus.

• Glabājiet lietošanas instrukciju visiem pieejamā vietā.

• Uzraugiet, lai tikai apmācīts personāls strādā ar ierīci.

• Levērojiet drošības norādījumus, vadlīnijas, darba aizsardzību un

nelaimes gadījumu novēršanas noteikumus.

• Lietojiet personisko aizsargaprīkojumu atbilstoši apstrādājamā

materiāla bīstamības klasei. Pretējā gadījumā pastāv risks, jo var

izšļakstīties šķidrums.

• Novietojiet ierīci uz brīvas, stabilas, tīras, neslīdošas, sausas un

ugunsdrošas virsmas.

• Pirms katras lietošanas reizes pārbaudiet, vai ierīce un tās piederumi nav bojāti. Nelietojiet bojātas detaļas.

ESIET UZMANĪGI

Ar šo aparātu drīkst apstrādāt vai

karsēt tikai tādas vielas, kuru

uzliesmošanas temperatūra ir

augstāka par iestatīto termovannas drošības temperatūras robežu.

RISKS

Apdegumu rašanās risks! Darbības

laikā var uzkarst korpuss.

• Lztukšojot ierīci, vienmēr satveriet un turiet to tikai aiz rokturi.

• Pirms termovannas piepildīšanas vai iztukšošanas aparāts ir

jāizslēdz un jāatvieno no sprieguma, izvelkot tīkla spraudni no

rozetes.

• Termovannu piepildiet vai iztukšojiet tikai aukstā stāvoklī.

• Pirms transportēšanas iztukšojiet termovannu.

• Nekad nelietojiet termovannu bez karsējamās vielas.

RISKS

Kā karsējamo vielu termovannā ir

ieteicams iz mantot ūdeni. Lzmantojot karsējamo vielu ar zemāku

uzliesmošanas temperatūru,

pastāv risks gūt apdegumus!

• Pirms nodošanas ekspluatācijā nosakiet atlaidināšanas vielas

optimālo temperatūru! Ņemiet vērā apjoma izmaiņas, kas rodas uzkaršanas gadījumā, tāpat arī, iegremdējot kādu objektu,

piemēram, iztvaicēšanas kolbu.

• Lietojot sildīšanas vanniņu kopā ar rotācijas tvaicētāju, sildīšanas

vanniņas temperatūra nedrīkst pārsniegt šķīdinātāja vārīšanās

temperatūru pie atmosfēras spiediena, pretējā gadījumā var

saplīst tvaicēšanas kolbas stikls, kas var rasties šļakstoties

šķidrumam (piem., ētera destilēšanas laikā var saplīst tvaicēšanas

kolbas stikls, ja vielas temperatūra sasniedz 60 °C).

ESIET UZMANĪGI

Ņemiet vērā iespējamo risku, ka

iztvaicēšanas kolbas stikls var

saplīst, kad IKA rotācijas

iztvaikotājs atrodas darbībā.

ESIET UZMANĪGI

Pastāv apdraudējums, ja tvaicēšanas

kolbu mitruma dēļ ir grūti satvert.

• Leteicams izmantot demineralizētu ūdeni.

• Ņemiet vērā bīstamību, ko rada degoši materiāli.

• Apstrādājiet tikai tādu elementu, kuram apstrādes laikā nav

strāvas padeves. Tas pats attiecas arī uz citiem enerģijas veidiem,

piemēram, gaismas apstarošana.

• Nelietojiet ierīci sprādzienbīstamā vidē, ar bīstamām vielām vai

zem ūdens.

• Pēc strāvas pārtraukuma ierīce darbosies C režīmā, pašai

atkārtoti ieslēdzoties.

• Lerīces atdalīšanu no strāvas avota var veikt, tikai atvienojot

kontaktdakšu vai ierīci.

• Vada kontaktligzdai ir jābūt viegli sasniedzamai un pieejamai.

Aprīkojuma drošībai

• Uz informācijas plāksnītes norādītajam sprieguma rādījumam

jāsakrīt ar tīkla spriegumu.

• Kontaktdakšai jābūt iezemētai (zemējuma kontakts).

• Lzvairieties no triecieniem un vibrācijām ierīcei vai piederumiem.

• Lerīci drīkst atvērt tikai kvalificēts elektriķis.

Šķīdinātāji

• Šķīdinātāji var kaitēt veselībai. Ievērojiet brīdinošās norādes

saistībā ar šo tēmu un izlasiet attiecīgo drošības datu lapu

(internetā).

Drošības norādījumi

LV

Oriģinālvaloda: vācu

Page 20

20

Jūsų apsauga

• Prieš pradėdami naudoti prietaisą perskaitykite visą naudojimo

instrukciją ir laikykitės joje pateiktų saugos nurodymų.

• Laikykite naudojimo instrukciją visiems lengvai pasiekiamoje vietoje.

• Su prietaisu gali dirbti tik išmokytas personalas.

• Laikykitės saugos nurodymų, reikalavimų bei darbų saugos ir

nelaimingų atsitikimų prevencijos taisyklių.

• Atsižvelgdami į apdorojamos medžiagos pavojaus klasę, naudoki te asmens apsaugos priemones. To nedarant, pavojų gali

sukelti tyškantis skystis.

• Pastatykite prietaisą laisvai ant lygaus, stabilaus, švaraus, neslidaus, sauso ir ugniai atsparaus paviršiaus.

• Prieš naudodami kaskart patikrinkite prietaisą ir priedus, ar jie

nepažeisti. Nenaudokite pažeistų dalių.

ATSARGIAI

Su šiuo prietaisu galima perdirbti ar

kaitinti tik tokias medžiagas, kurių

įsiliepsnojimo temperatūros vertė

neviršija nustatytos saugios kaitinimo vonelės temperatūros ribos.

PAVOJUS

Nudegimo pavojus! Naudojant

gali įkaisti šildymo vonios korpusas.

• Jei reikia įtaisą ištuštinti, neškite laikydami jį tik rankenos.

• Prieš pildant ar tuštinant kaitinimo vonelę būtina įrenginį išjungti

ir, iš kištukinio lizdo ištraukus tinklo kištuką, atjungti nuo srovės

šaltinio.

• Kaitinimo vonelę pildykite ir tuštinkite tik tada, kai ji atvės.

• Prieš transportuodami kaitinimo vonelę ištuštinkite.

• Jokiu būdu neeksploatuokite kaitinimo vonelės be temperavimo

terpės.

PAVOJUS

Kaip temperavimo terpę

kaitinimo

vonelėje geriausia naudoti vandenį.

Naudojant žemesnės pliūpsnio

temperatūros temperavimo terpes

kyla pavojus nusideginti!

• Prieš paleisdami nustatykite optimalų šilumnešio pripildymo

kiekį! Tai darydami atkreipkite dėmesį į temperatūros sąlygotus

apimties pokyčius, taip pat į išstūmimo efektą dėl panardinto

kūno, kaip, pavyzdžiui, garintuvo kolba.

• Naudojant kaitinimo vonią su sukamuoju garintuvu, šildymo

vonios temperatūra negali viršyti tirpiklio virimo temperatūros

esant normaliam slėgiui, nes sudužus garintuvo kolbai atsiranda susižalojimo pavojus dėl trykštančių skysčių (pvz., garintuvo

kolbos stiklas distiliuojant eterius gali sudužti, kai medžiagos

temperatūra yra 60 °C).

ATSARGIAI

Atsižvelkite į pavojų, kurį kelia

garinimo kolbos stiklo įtrūkimas,

kai kolba naudojama su IKA rotaciniu garintuvu.

ATSARGIAI

Atkreipkite dėmesį į pavojų, kurį

kelia drėgno garintuvo kolbos slidumas.

• Rekomenduojama naudoti demineralizuotą vandenį.

• Atsižvelkite į pavojus, kuriuos kelia liepsniosios medžiagos.

• Apdorokite tik tokias medžiagas, kurias apdorojant saugiai

tiekiama energija. Tas pats taikoma kitai tiekiamai energijai, pvz.,

dėl spinduliuojamos šviesos.

• Neeksploatuokite prietaiso potencialiai sprogioje aplinkoje, su

pavojingomis medžiagomis ir po vandeniu.

• Nutraukus elektros srovės tiekimą prietaisas vėl savaime pradeda

veikti C režimu.

• Nuo elektros srovės tiekimo tinklo prietaisas atjungiamas tik

ištraukus tinklo arba prietaiso kištuką.

• Prijungimo prie tinklo laido kištukinis lizdas turi būti lengvai

pasiekiamas.

Įrangos apsauga

• Specifikacijų lentelėje nurodyta įtampa turi sutapti su maitinimo

tinklo įtampa.

• Kištukinis lizdas turi būti įžemintas (apsauginio laido kontaktas).

• Saugokite prietaisą ir priedus nuo smūgių ir jų nestumdykite.

• Prietaisą leidžiama atidaryti tik specialistui.

Tirpikliai

• Tirpikliai gali būti kenksmingi sveikatai. Atkreipkite dėmesį į susijusius įspėjimus ir susipažinkite su atitinkamos medžiagos saugos duomenų lapo (internete) informacija.

Saugos nurodymai

LT

Originalo kalba: vokiečių

Page 21

21

За Вашата защита

• Преди въвеждането в експлоатация прочетете внимателно

ръководството за експлоатация и вземете предвид указанията за безопасност.

• Съхранявайте ръководството за експлоатация достъпно за

всички.

• Имайте предвид, че с устройството може да работи само

обучен персонал.

• Вземете предвид указанията за безопасност, регламентите,

промишлената безопасност и предписанията за избягване

на инциденти.

• Носете личните си предпазни средства в съответствие с

категорията на опасност на веществото, с което се работи.

В противен случай съществува риск от пръски от течности.

• Разположете устройството свободно върху равна, стабилна,

чиста, неплъзгаща се, суха и огнеустойчива повърхност.

• Преди всяка употреба проверявайте устройството и

принадлежностите за повреди. Не използвайте повредени

части.

ВНИМАНИЕ

С този уред могат

да се обработват

респ. нагряват само флуиди,

чиято пламна температура е над

н

астроеното ограничение за

безопасна температура на

нагревателната баня.

ОПАСНОСТ

Опасност от изгаряне! При

експлоатация корпусът на

нагревателната баня може да се

загрее.

• Носете и дръжте уреда при изпразване само за дръжки.

• Преди напълване или изпразване на нагревателната

баня уредът трябва да се изключи и да се отдели от

електрозахранващата

мрежа, като щепселът се извади от контакта.

• Да се пълни и изпразва само когато нагревателната баня е

студена.

• Изпразвайте нагревателната баня преди транспортиране.

• Никога не работете с нагревателната баня без темпериран

флуид.

ОПАСНОСТ

Като темпериран флуид в

нагревателната баня

използвайте предимно вода.

Употребата на темпериращи

флуиди с по-ниска пламна

температура може да

предизвика риск от изгаряния!

• Преди въвеждането в експлоатация определете

оптималното количество за пълнене от темперираната

течност! При това вземете под внимание промяната на

обема вследствие нагряване, както и изместването при

потапяне на тяло, например на изпарителна колба.

• При използване на нагревателната баня заедно с ротационен

изпарител температурата на нагревателната баня не трябва

да е по-висока от температурата на кипене на разтворителя

при нормално налягане, тъй като при счупване на

изпарителната колба съществува опасност от разплискване

на течността (напр. стъклото на изпарителната колба може

да се счупи при дестилация на етер, ако температурата на

флуида е 60 °C).

ВНИМАНИЕ

Имайте предвид опасността от

счупване на стъклото на

изпарителната колба при работа

с ротационния изпарител IKA.

ВНИМАНИЕ

Имайте предвид, че съществува

опасност мократа изпарителна

колба да се изплъзне при

хващане.

• Препоръчва се използването на деминерализирана вода.

• Обърнете внимание на опасността от запалими материали.

• Обработвайте само агенти, при които внасянето на енергия

при обработката е безопасно. Това е валидно и за други

внасяния на енергия, например от светлинно лъчение.

• Не работете с устройството във взривоопасни атмосфери, с

опасни вещества и под вода.

• Когато подаването на ток бъде прекъснато, устройството

само започва да работи отново в режим C.

• Разделянето на устройството от електрическата мрежа се

извършва само чрез издърпване на мрежовия щепсел,

съотв. щепсела на устройството.

• Контактното гнездо за свързване към мрежата трябва да се

достига лесно и да е достъпно.

За защита на устройството

• Данните за напрежението на фабричната табелка трябва да

съответстват на мрежовото напрежение.

• Контактното гнездо трябва да бъде заземено (контакт със

защитен проводник).

• Избягвайте удари и вибрации на устройството или

принадлежностите.

• Устройството може да се отваря само от специалист.

Разтворителите

• Разтворителите могат да бъдат опасни за здравето.

Спазвайте съответните предупредителни указания и се

информирайте от съответния информационен лист за

безопасност (Интернет).

Указания за безопасност

BG

Изходен език: немски

Page 22

22

Pentru protecția dumneavoastră

• Citiți cu atenție instrucțiunile de utilizare înainte de punerea în

funcțiune și respectați indicațiile de siguranță.

• Păstrați Instrucțiunile de utilizare într-un loc accesibil pentru întreg personalul.

• Asigurați-vă că numai personalul instruit lucrează cu aparatul.

• Respectați indicațiile de siguranță, directivele și normele pentru

protecția muncii și prevenirea accidentelor.

• Purtaţi echipamentul personal de protecţie în conformitate cu

clasa de risc a mediului prelucrat. În plus, pot exista următoarele

pericole stropire cu lichide.

• Așezați aparatul pe o suprafață plană, stabilă, curată,

antiderapantă, uscată și rezistentă la foc.

• Înaintea fiecărei utilizări, verificați ca aparatul și accesoriile să nu

fie deteriorate. Nu folosiți piese deteriorate.

ATENȚIE

Cu acest aparat pot fi încălzite/

prelucrate numai medii a căror

temperatură de infl amare este

peste temperatura limită de

siguranţă a băii de încălzire.

PERICOL

Pericol de arsuri! Carcasa băii de

încălzire se poate încălzi.

• Purtaţi şi ţineţi aparatul la golire, numai prin prindere de mânerele.

• Înainte de umplerea sau golirea băii de încălzire aparatul trebuie

oprit şi deconectat de la reţeaua de alimentare prin scoaterea

ştecherului din priză.

• Umpleţi sau goliţi baia de încălzire numai când aceasta este

rece.

• Goliţi baia de încălzire înainte de a transporta aparatul.

• Nu folosiţi niciodată baia de încălzire fără substanţă de temperare.

PERICOL

Ca substanţă de temperare în baia

de încălzire folosiţi în special apă.

La utilizarea substanţelor de tem

perare cu punct de aprindere

scăzut, se poate ajunge la punerea

în pericol a personalului prin arsuri!

• Determinați înainte de punerea în funcțiune cantitatea maximă

de umplere cu mediu de temperare! Aveți în vedere modificarea

volumului prin încălzire, precum și a dezlocuirii la scufundarea

unui corp, ca de exemplu a unui cilindru vaporizator.

• La utilizarea băii de încălzire în combinație cu un evaporator rotativ, la presiune normală, temperatura băii de încălzire nu are

voie să fie peste punctul de fierbere a solventului, deoarece, în

caz de spargere a sticlei cilindrului vaporizatorului, există o periclitare datorită lichidului care se degajă (de ex. spargerea sticlei

balonului de vaporizare la distilarea eterului, dacă temperatura

mediului este de 60 °C).

ATENȚIE

Aveţi grijă la o periclitare datorită

spargerii sticlei pistonului vaporizatorului la exploatarea cu vaporizatorul rotativ IKA.

ATENȚIE

Țineți cont de pericolele cauzate

de priza proastă pe baloanele de

vaporizare ude.

• Se recomandă utilizarea apei demineralizate.

• Aveţi în vedere o periclitare prin materiale inflamabile.

• Procesați numai substanțe în cazul cărora surplusul de energie

apărut în timpul procesării este inofensiv. Acest lucru este valabil

și în privința energiei produse sub alte forme, de exemplu prin

iradiere luminoasă.

• Nu utilizați aparatul în atmosferă explozivă, cu substanțe periculoase sau sub apă.

• După o întrerupere a alimentării electrice, aparatul pornește automat în modul C.

• Separarea aparatului de rețeaua de alimentare cu tensiune se

realizează numai prin tragere de ștecherul de rețea sau ștecherul

aparatului.

• Priza de alimentare a aparatului trebuie să fie ușor accesibilă.

Pentru protecția aparatului

• Tensiunea indicată pe plăcuța de identificare trebuie să

corespundă cu cea a rețelei de alimentare.

• Priza trebuie să fie legată la pământ (contact de protecție).

• Evitați șocurile și loviturile asupra aparatului sau accesoriilor.

• Aparatul poate fi deschis numai de personal calificat.

Solvenţii

• Solvenţii pot fi periculoşi pentru sănătate. Respectaţi

instrucţiunile de siguranţă cu privire la aceştia şi informaţi-vă cu

privire la fişa corespunzătoare de date de securitate (Internet).

Instrucțiuni de siguranță

RO

Limba originală: germană

Page 23

23

Για τη δική σας προστασία

• Διαβάστε στο σύνολό τους τις οδηγίες χρήσεις, προτού θέσετε

τη συσκευή σε λειτουργία και λάβετε υπόψη τις υποδείξεις

ασφάλειας.

• Φυλάξτε τις οδηγίες χρήσης σε μέρος στο οποίο έχουν

πρόσβαση όλοι.

• Διασφαλίστε ότι η λειτουργία της συσκευής διεξάγεται

αποκλειστικά από εκπαιδευμένο προσωπικό.

• Λαμβάνετε υπόψη τις υποδείξεις ασφαλείας, τις οδηγίες, καθώς

επίσης την πολιτική προστασίας των εργαζομένων και πρόληψης

ατυχημάτων.

• Φοράτε τον ατομικό προστατευτικό εξοπλισμό σας ανάλογα με

την κατηγορία κινδύνου του προς επεξεργασία μέσου. Κίνδυνος

μπορεί να προκληθεί επίσης από πιτσιλιές υγρών.

• Τοποθετήστε τη συσκευή σε επίπεδη, σταθερή, καθαρή,

αντιολισθητική, στεγνή και πυράντοχη επιφάνεια.

• Πριν από κάθε χρήση, ελέγχετε τη συσκευή και τα εξαρτήματα

για τυχόν ζημίες. Μη χρησιμοποιείτε ελαττωματικά εξαρτήματα.

ΕΓΡΗΓΟΡΣΗ

Με τη συσκευή αυτήν μπορεί να

γίνει επεξεργασία ή θέρμανση

μόνο εκείνων των μέσων, των

οποίων το σημείο ανάφλεξης είναι

ψηλότερο από το ρυθμισμένο όριο

θερμοκρασίας ασφαλείας του

θερμαινόμενου λουτρού

.

ΚΙΝΔΥΝΟΣ

Κίνδυνος εγκαύματος! Κατά τη

διάρκεια της λειτουργίας, το

περίβλημα του λουτρού θέρμανσης

ενδέχεται να θερμανθεί.

• Μεταφέρετε και κρατάτε τη συσκευή κατά την εκκένωση μόνο

από τις λαβές.

• Πριν την πλήρωση ή την εκκένωση του θερμαινόμενου λουτρού

η συσκευή πρέπει να απενεργοποιείται και να αποσυνδέεται

από το δίκτυο τροφοδοσίας ρεύματος με τράβηγμα του

ρευματολήπτη από την πρίζα.

• Γεμίζετε ή αδειάζετε το θερμαινόμενο λουτρό μόνο όταν είναι

κρύο.

• Αδειάζετε το θερμαινόμενο λουτρό πριν το μεταφέρετε.

• Το θερμαινόμενο λουτρό δεν πρέπει να λειτουργεί ποτέ χωρίς

μέσο ρύθμισης θερμοκρασίας.

ΚΙΝΔΥΝΟΣ

Ως μέσο ρύθμισης θερμοκρασίας

στο θερμαινόμενο λουτρό

χρησιμοποιήστε κατά προτίμηση

νερό. Η χρήση μέσων ρύθμισης

θερμοκρασίας με χαμηλότερο

σημείο ανάφλεξης μπορεί να

προκαλέσει κίνδυνο εγκαύματος!

• Πριν από την έναρξη λειτουργίας υπολογίστε τη βέλτιστη

ποσότητα πλήρωσης του μέσου ισοστάθμισης! Πρέπει να

ληφθεί υπόψη η αλλαγή όγκου λόγω θέρμανσης, καθώς και

η εκτόπιση κατά τη βύθιση ενός σώματος, π.χ. μιας φιάλης

εξάτμισης.

• Εάν το λουτρό θέρμανσης χρησιμοποιείται σε συνδυασμό με

έναν περιστροφικό εξατμιστήρα, η θερμοκρασία του λουτρού

θέρμανσης δεν πρέπει να υπερβαίνει τη θερμοκρασία του

σημείου ζέσεως του διαλύτη σε κανονική πίεση, επειδή σε

περίπτωση θραύσης της φιάλης εξάτμισης ενυπάρχει κίνδυνος

εξαιτίας εκτιναζόμενων υγρών (π.χ., το γυαλί του δοχείου

εξατμιστήρα μπορεί να σπάσει κατά την απόσταξη αιθέρα, όταν

η θερμοκρασία του μέσου ανέρχεται σε 60 °C).

ΕΓΡΗΓΟΡΣΗ

Λαμβάνετε υπόψη τον κίνδυνο

θραύσης της γυάλινης φιάλης

εξατμιστήρα κατά τη λειτουργία με

τον περιστροφικό εξατμιστήρα IKA.

ΕΓΡΗΓΟΡΣΗ

Λάβετε υπόψη τον κίνδυνο από

κακό κράτημα των υγρών δοχείων

εξατμιστήρα.

• Συνιστάται να χρησιμοποιείτε απιονισμένο νερό.

• Λάβετε υπόψη σας ενδεχόμενους κινδύνους από εύφλεκτα

υλικά.

• Επιτρέπεται η επεξεργασία υλικών, η εκλυόμενη ενέργεια των

οποίων κατά τη διάρκεια της επεξεργασίας είναι ακίνδυνη.

Αυτό ισχύει και για άλλου τύπου εκλυόμενης ενέργειας, π.χ.,

ακτινοβολία φωτός.

• Μην θέτετε τη συσκευή σε λειτουργία σε περιβάλλον όπου

υπάρχει κίνδυνος έκρηξης, σε περιοχές με επικίνδυνες ουσίες

και κάτω από το νερό.

• Μετά από τυχόν διακοπή ηλεκτρικού ρεύματος, η συσκευή θα

μεταβεί ξανά αυτόματα σε λειτουργία C.

• Η αποσύνδεση της συσκευής από το δίκτυο παροχής ρεύματος

εξασφαλίζεται μόνο με αποσύνδεση του ρευματολήπτη

ηλεκτρικού καλωδίου ή του ρευματολήπτη της συσκευής.

• Ο ρευματολήπτης του καλωδίου σύνδεσης με την παροχή

ηλεκτρικού ρεύματος πρέπει να είναι εύκολα προσβάσιμος.

Για την προστασία της συσκευής

• Η ένδειξη τάσης στην πινακίδα τύπου πρέπει να ταυτίζεται με

την τάση δικτύου.

• Ο ρευματοδότης πρέπει να είναι γειωμένος (επαφή αγωγού

προστασίας).

• Αποφεύγετε τραντάγματα και κτυπήματα στη συσκευή ή στα

παρελκόμενα.

• Η συσκευή μπορεί να ανοίγεται μόνο από ειδικό τεχνικό.

διαλύτες

• Οι διαλύτες μπορούν να είναι επιβλαβείς για την υγεία.

Λαμβάνετε υπόψη τις σχετικές υποδείξεις προειδοποίησης και

ενημερώνεστε σχετικά με το αντίστοιχο δελτίο δεδομένων

ασφαλείας (Διαδίκτυο).

Υποδείξεις ασφαλείας

EL

Γλώσσα πρωτοτύπου: γερμανική

Page 24

IKA-Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

20015815

Loading...

Loading...