Page 1

Confirm that the delivered product is what you have ordered. Read this instruction sheet to

make sure of correct operation. Make sure that the instruction sheet is kept by the end

user.

This manual is the instruction sheet of the SmartAXIS Series FT1A Touch.

Unless otherwise specified, SmartAXIS refers to the SmartAXIS Series FT1A Touch.

Touch

The generic term for the SmartAXIS FT1A-*12RA-*, FT1A-*14KA-* and

FT1A-*14SA-*.

SAFETY PRECAUTIONS

● Be certain to read this manual carefully before performing installation, wiring, or

maintenance work, or operating the Touch.

● This product has been manufactured with careful regard to quality. However, if you

intend to use this product in applications where failure of this equipment may result in

damage to property or injury, ensure that it used in conjunction with appropriate fail-safe

backup equipment.

● In this manual, safety precautions are categorized in order of importance to Warning and

Caution:

Warning notices are used to emphasize that improper operation may cause severe

personal injury or death.

Caution notices are used where inattention might cause personal injury or damage to

equipment.

● The Touch is not intended to be used for applications which require high reliability and

safety, such as medical equipment, nuclear equipment, railways, aircraft, and vehicles.

The Touch cannot be used for these applications.

● For other applications which require high reliability in function and precision, provide a

failsafe design and redundant design for the entire system including the Touch.

• Emergency and interlocking circuits must be configured outside of the Touch.

• If relays in the Touch output circuits should fail, outputs may remain at on or off state.

For output signals which may cause serious accidents, configure monitor circuits

outside the Touch.

• The Touch self-diagnostic function may detect internal circuit or program errors, stop

programs, and turn outputs off. Configure circuits so that the system containing the

Touch are not jeopardized when outputs turn off.

1

Page 2

● Emergency and interlocking circuits must be configured outside of the Touch.

Do not use the Touch’s internal touch switches for an emergency circuit. If the Touch

failed, the external equipment connected to the Touch will no longer be protected and

serious injury to operators and equipment damage may be caused.

● Turn off the power to the Touch before installation, removal, wiring, maintenance, and

inspection of the Touch. Failure to turn power off may cause electrical shock or fire

hazard.

● Special expertise is required to install, wire, configure, and operate the Touch. People

without such expertise must not use the Touch.

● The Touch uses an LCD (liquid crystal display) as a display device. The liquid inside the

LCD is harmful to the skin. If the LCD is broken and the liquid attaches to your skin or

clothes, wash the liquid off using soap, and consult a doctor immediately.

● Prevent the Touch from falling while moving or transporting, otherwise damage or

malfunction of the Touch will result.

● Use the product within the environmental limits given in the catalog and manual. Use of

the product in high-temperature or high-humidity environments, or in locations where it

is exposed to condensation, corrosive gas or large shock loads can create the risk of

electrocution and fire.

● The Touch is designed for use in pollution degree 2. Use the Touch in environments of

pollution degree 2. (based on the IEC60664-1 rating)

● Install the Touch according to the instructions in the User’s Manual. Improper installation

will result in falling, failure, electrical shock, fire hazard, or malfunction of the Touch.

● Prevent metal fragments or wire chips from dropping inside the Touch housing. Ingress

of such fragments and chips may cause fire hazard, damage, and malfunction.

● Use a power supply of the rated value. Using a wrong power supply may cause fire

hazard.

● The Touch uses “PS2 of EN61131” as DC power supply. (based on the IEC/EN61131

rating)

● Use wire of a proper size to meet the voltage and current requirements.

● When exporting the Touch to Europe, use an EN60127 (IEC60127) approved fuse on

the power line outside the Touch.

● When exporting the Touch to Europe, use an EU-approved circuit protector.

● Make sure of safety before starting and stopping the Touch. Incorrect operation of the

Touch may cause mechanical damage or accidents.

2

Page 3

● Use the Touch in a local area network if you download, upload or monitor the project

data via the Ethernet port.

● The touch panel of the Touch is made of glass, and will break if exposed to excessive

shock. Take due care when handling it.

● When more than one button is pressed at the same time, due to the detection

characteristics of an analog type touch panel, only the gravity center of the pressed area

is sensed and the unit assumes that only one button is pressed. Thus, when more than

one button is pressed simultaneously, the resulting operation is not guaranteed.

● The screen becomes blank when the backlight is burnt out; however, the touch panel

remains enabled. Incorrect touch panel operation will occur when operating the touch

panel when the backlight appears to be turned off but is actually burnt out. Note that this

erroneous operation may result in damage.

● Do not push hard or scratch the touch panel and protection sheet with a hard object

such as a tool, because they are damaged easily.

● At temperatures over the rated operating temperature, the clock accuracy is affected.

Adjust the clock before use.

● For applications which require clock accuracy, adjust the clock periodically.

● Do not install the Touch in areas subjected to strong ultraviolet rays, since ultraviolet

rays may impair the quality of the LCD.

● Do not attempt to disassemble, repair or modify the Touch. This can create the risk of

fire or electrocution.

● When disposing of the Touch, do so as an industrial waste.

● Do not switch off the power or pull out the USB Flash Drive while it is being accessed, as

this may result in destruction of the stored data. If the data on the USB Flash Drive is

corrupted, format the USB Flash Drive.

3

Page 4

Handling of Batteries and Devices with Built-in Batteries in EU Member States

Note) The following symbol mark is for EU countries only and is according to the directive

2006/66/EC Article 20 information for end-users and Annex II.

This symbol mark means that batteries and accumulators, at their end-of life, should be

disposed of separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol

means that the battery or accumulator contains a heavy metal at a certain concentration.

This will be indicated as follows :

Hg : mercury (0.0005%), Cd : cadmium (0.002%), Pd : lead (0.004%)

In the European Union there are separate collection systems for used batteries and

accumulators.

Please dispose of batteries and accumulators correctly in accordance with each country or

local regulation.

4

Page 5

Contents

1 Packing ........................................................................................................ 6

2 Type Number ............................................................................................... 7

3 Part Names ................................................................................................. 8

4 External Interfaces .................................................................................... 10

4.1 Serial Interface (Port) ......................................................................... 10

4.2 I/O Terminals ..................................................................................... 11

4.3 Input Terminal Specifications ............................................................. 13

4.4 Output Specifications ......................................................................... 17

5 Specifications ............................................................................................ 20

6 Dimensions ................................................................................................ 23

7 Installation ................................................................................................. 25

7.1 Operating Environment ...................................................................... 25

7.2 Ambient Temperature ........................................................................ 25

7.3 Installation ......................................................................................... 27

7.4 Orientation ......................................................................................... 28

7.5 Attaching Cartridges .......................................................................... 29

8 Wiring ........................................................................................................ 30

8.1 Power Supply Terminal ...................................................................... 30

8.2 Cautions when connecting external devices ...................................... 31

8.3 Cautions for using the Touch connected to a personal computer ..... 31

9 USB Cable Lock Pin Attachment ............................................................... 32

10 Maintenance and Inspection ..................................................................... 34

10.1 Maintenance Screen .......................................................................... 35

10.2 System Mode ..................................................................................... 35

10.3 Adjusting the Brightness and Contrast .............................................. 36

10.4 Adjusting the Touch Panel ................................................................. 37

5

Page 6

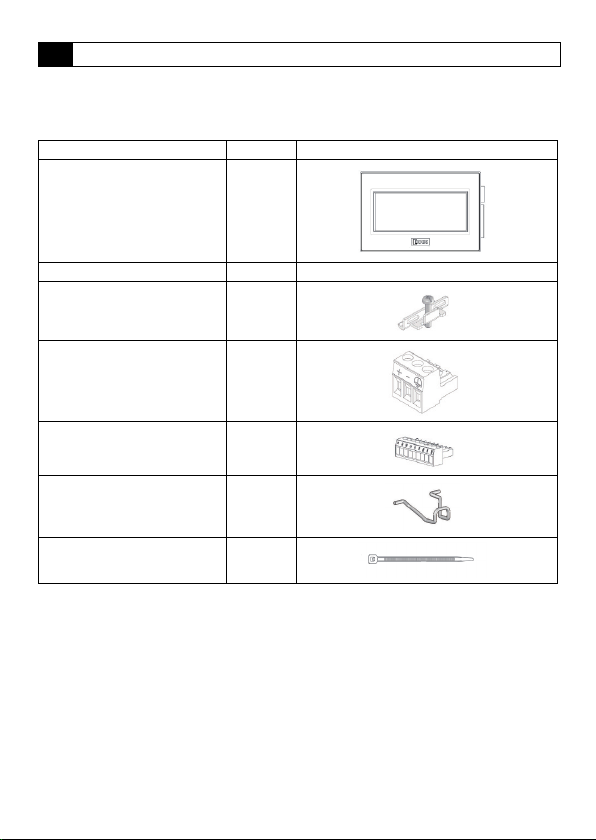

1 Packing

Before installing the Touch, make sure that the specifications of the product conform to

your requirements, and that no parts are missing or damaged due to accidents during

transportation.

Name Pcs/pack

Touch Unit 1

Instruction Sheet [This manual] 1

Mounting clips 2

Power plug

(Attached to the Touch)

Communication I/F plug

(Attached to the Touch)

USB Cable Lock Pin 2

USB Clamp Band 2

1

1

6

Page 7

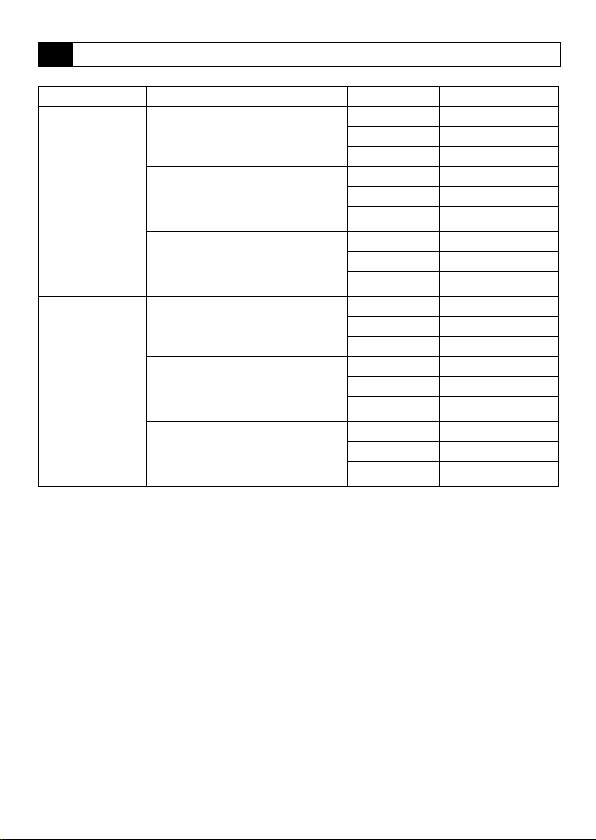

2 Typ e N um ber

LCD size I/O configuration Bezel color Type No.

Light gray FT1A-M12RA-W

Dark gray FT1A-M12RA-B

Silver FT1A-M12RA-S

Light gray FT1A-M14KA-W

Dark gray FT1A-M14KA-B

Silver FT1A-M14KA-S

Light gray FT1A-M14SA-W

Dark gray FT1A-M14SA-B

Silver FT1A-M14SA-S

Light gray FT1A-C12RA-W

Dark gray FT1A-C12RA-B

Silver FT1A-C12RA-S

Light gray FT1A-C14KA-W

Dark gray FT1A-C14KA-B

Silver FT1A-C14KA-S

Light gray FT1A-C14SA-W

Dark gray FT1A-C14SA-B

Silver FT1A-C14SA-S

3.7inch STN

Monochrome LCD

3.8inch TFT Color

LCD

Digital sink in : 6pt

Shared digital sink in / Analog in : 2pt

Relay out : 4pt

Digital source in : 6pt

Shared digital sink in / Analog in : 2pt

Transisitor sink out : 4pt

Analog out : 2pt

Digital sink in : 6pt

Shared digital sink in / Analog in : 2pt

Transisitor source out : 4pt

Analog out : 2pt

Digital sink in : 6pt

Shared digital sink in / Analog in : 2pt

Relay out : 4pt

Digital source in : 6pt

Shared digital sink in / Analog in : 2pt

Transisitor sink out : 4pt

Analog out : 2pt

Digital sink in : 6pt

Shared digital sink in / Analog in : 2pt

Transisitor source out : 4pt

Analog out : 2pt

7

Page 8

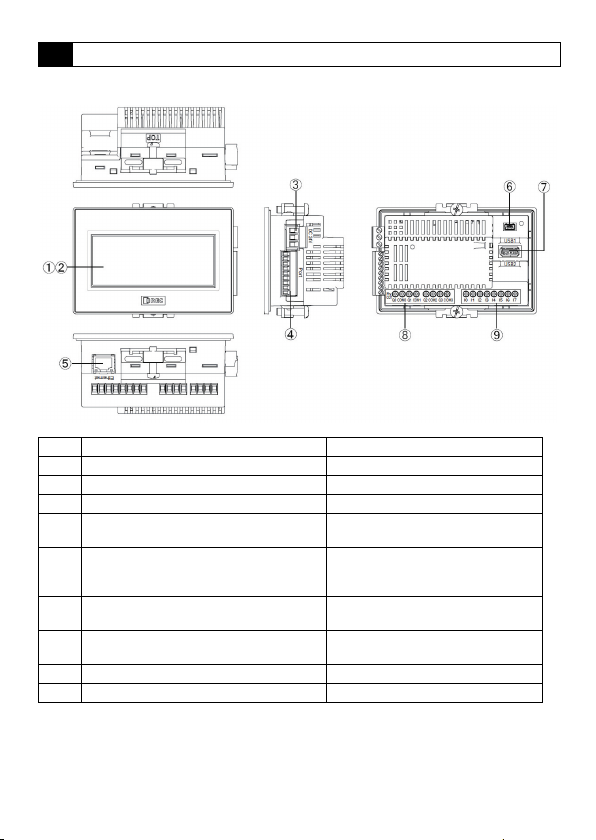

3 Part Names

■ FT1A-*12RA

No. Name Description

(1) Display

(2) Touch Panel

(3) Power Supply Terminal

(4) Serial Interface (Po rt)

(5) Ethernet Interface (Ethernet)

(6) USB Interface (USB 1)

(7) USB Interface (USB 2)

(8) Output Terminal (Q0 to Q3) Relay output (10A)

(9) Input Terminal (I0 to I7) Digital input, Analog input

RS232C, RS422/485

Connector : Terminal Block 9 pin

IEEE802.3u

10BASE-T/100BASE-TX

Connector : RJ-45

USB2.0 (Device)

Connector : Mini-B

USB1.1 (External device)

Connector: TypeA

8

Page 9

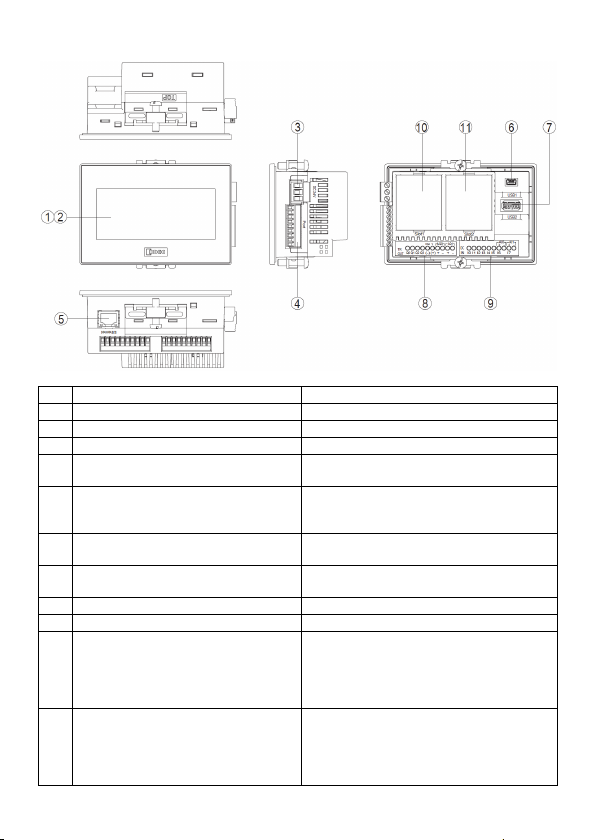

■ FT1A-*14KA/14SA

No. Name Description

(1) Display

(2) Touch Panel

(3) Power Supply Terminal

(4) Serial Interface (Port)

(5) Ethernet Interface (Ethernet)

(6) USB Interface (USB1)

(7) USB Interface (USB2)

(8) Output Terminal (Q0 to Q3, AQ0 to AQ1) Transistor output, analog output

(9) Input Terminal (I0 to I7) Digital input, Analog input

(10) Slot 1

(11) Slot 2

RS232C, RS422/485

Connector : Terminal Block 9 pin

IEEE802.3u

10BASE-T/100BASE-TX

Connector : RJ-45

USB2.0 (Device)

Connector : Mini-B

USB1.1 (External device)

Connector : Type A

Optional product (analog cartridge) expansion

FC6A-PJ2A

FC6A-PK2AV

FC6A-PK2AW

FC6A-PJ2CP

Optional product (analog cartridge) expansion

FC6A-PJ2A

FC6A-PK2AV

FC6A-PK2AW

FC6A-PJ2CP

9

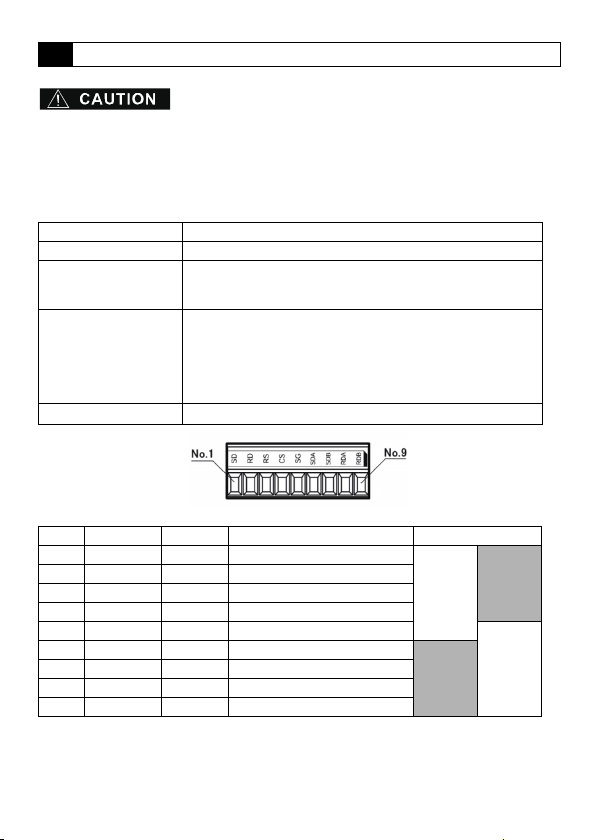

Page 10

4 External Interfaces

● Make sure to turn off the power to the Touch before wiring each interface.

● Always use ferrules when wiring stranded wire and multiple wires to the terminal block.

Otherwise there is a risk of wires becoming disconnected.

4.1 Serial Interface (Port)

Interface Specification RS232C, RS422/485

Connector Detachable Terminal Block 9 pin

Applicable cable

Recommended ferrule

Tightening Torque

No. Name I/O Function Communication type

1 SD OUT Send Data

2 RD IN Receive Data

3 RS OUT Request to Send

4 CS IN Clear to Send

5 SG - Signal Ground

6 SDA OUT Send Data (+)

7 SDB OUT Send Data (-)

8 RDA IN Receive Data (+)

9 RDB IN Receive Data (-)

<Note>

The Touch is not equipped with terminating resistance. When using the RS422/485

interface, insert terminating resistance with the appropriate value (around 100 to 120 )

between terminal No. 8 (RDA) and terminal No. 9 (RDB) as required.

RS232C: AWG16 to AWG28

RS422/485: AWG16 to AWG28 Shielded twisted-pair

Stripped wire length 7 mm (Solid wire)

AI 0.34-8 TQ (For AWG22)

AI 0.5-8 WH (For AWG20)

AI 0.75-8 GY (For AWG18)

AI 1-8 RD (For AWG18)

AI 1.5-8 BK (For AWG16)

(Phoenix Contact)

0.25 N ·

m

RS232C

10

RS422/485

Page 11

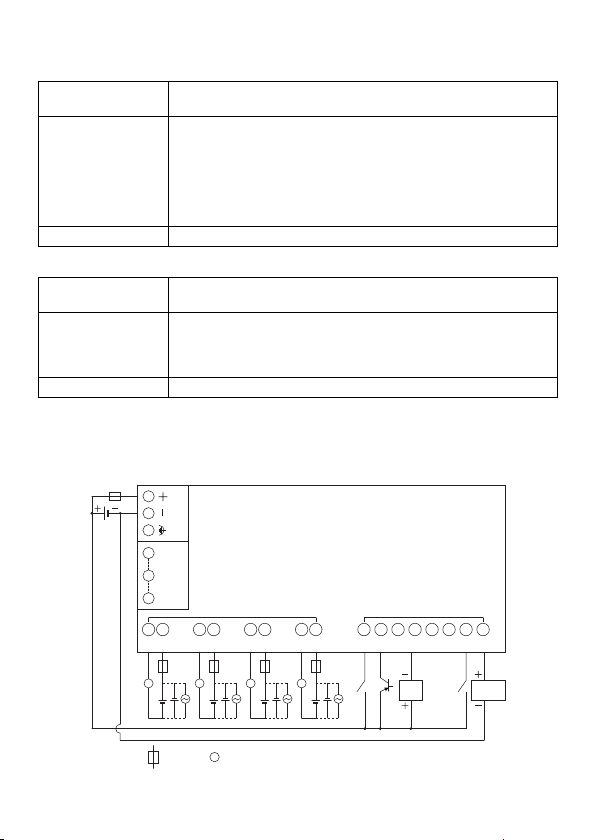

4.2 I/O Terminals

■ FT1A-*12RA

Applicable cable

Recommended ferrule

AWG16 to AWG22

Stripped wire length 6.5 mm, coating diameter 3.4 mm or lower (Solid wire)

AI 0.34-8 TQ (For AWG22, For 1 wire)

AI 0.5-8 WH (For AWG20, For 1 wire)

AI 0.75-8 GY (For AWG18, For 1 wire)

AI 1-10 RD (For AWG18, For 1 wire)

AI 1.5-10 BK (For AWG16, For 1 wire)

AI TWIN 2 x 0.75 10GY (For AWG18, For 2 wires)

(Phoenix Contact)

Tightening Torque 0.5 to 0.6 N•m (Screwdriver SZS 0.6 x 3.5, Phoenix Contact)

■ FT1A-*14KA/14SA

Applicable cable

Recommended ferrule

AWG20 to AWG22

Stripped wire length 5 mm, coating diameter 2.6 mm or lower (Solid wire)

AI 0.34-8 TQ (For AWG22, For 1 wire)

AI 0.5-8 WH (For AWG20, For 1 wire)

AI-TWIN2 x 0.5-8 WH (For AWG20, For 2 wires)

(Phoenix Contact)

Tightening Torque 0.2 N•m (Screwdriver SZS 0.4 x 2.5, Phoenix Contact)

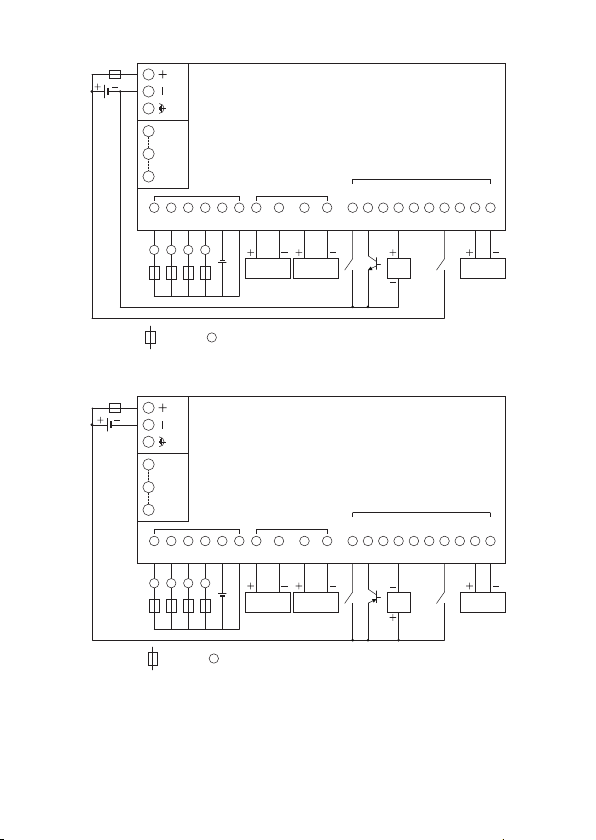

● Terminal Arrangement

• Terminal Arrangement and I/O Wiring Diagrams

■ FT1A-*12RA

Power supply terminal

1 SD

5 SG

Port

9 RDB

Q0 COM0 Q0 COM0 Q0COM0 Q0COM0

Ry OUT

DC IN

I0 I1 I2 I3 I4 I5 I6 I7

L L L L

:

Fuse

:

Load

L

2-wire

Sensor

Analog voltage

output device

11

Page 12

■ FT1A-*14KA

L

: Fuse : Load

Power supply terminal

Q0

LQ1LQ2L

Q3

L

COM

(-)

V

(+)

Tr. OUT Analog OUT

AQ0

(+)

AQ0

(-)

Analog voltage/

current input device

AQ1

(+)

AQ1

(-)

Analog voltage/

current input device

9 RDB

5 SG

1 SD

Port

AI0

(+)

AI0

(-)

AI1

(+)

AI1

(-)

Analog voltage/

current input device

I6 I7

I1 I2 I3 I4 I5I0

2-wire

Sensor

DC IN

■ FT1A-*14SA

Q0

LQ1LQ2L

Power supply terminal

1 SD

5 SG

Port

9 RDB

Tr. OUT Analog OUT

COM

V

Q3

(+)

(-)

L

: Fuse : Load

L

AQ0

AQ0

(+)

(-)

Analog voltage/

current input device

AQ1

AQ1

(+)

(-)

Analog voltage/

current input device

I1 I2 I3 I4 I5I0

2-wire

Sensor

DC IN

AI0

AI0

(+)

(-)

I6 I7

AI1

AI1

(+)

(-)

Analog voltage/

current input device

12

Page 13

4.3 Input Terminal Specifications

Input Points 8

Rated Input Voltage 24V DC

Input Voltage Range 0 to 28.8V DC

Effect of Improper

Input Connection

No damage.

(If any input exceeding the rated value is applied,

permanent damage may be caused.)

● Digital Input Specifications

Input Type

Input Points

(Terminal No. /Common Line Name)

Rated Input Current

Input Impedance

Input System

Transfer Time

Isolation

Input Type Type1 (IEC61131-2)

External Load for I/O Interconnection Not needed

Signal Determination Method Static

Cable Length

(in compliance with EMC standards)

OFF ON 2.5 s + filter value

ON OFF 5 s + filter value

Between input

terminals

Internal circuit Not isolated

Sink (FT1A-*12RA/14SA)

Source (FT1A-*14KA)

6 points in 1 common line

(I0 to I5/Power supply "-" terminal)

4.4mA (Sink Input)

5.2mA (Source Input)

5.5k (Sink Input)

4.7k (Source Input)

Not isolated

3m

● Analog Input Specifications

■ FT1A-*12RA

Input Signal Type Voltage Input

Input Points

(Terminal No. /Common Line Name)

Input Range 0 to 10V DC

Input Impedance 78.0K

Digital Resolution 0 to 1,000 (10bit)

Data Type Binary data: 0 to 1000

Input Value of LSB 10mV

Type of Input Single-ended input

2 points in 1 common line

(I6, I7/internal -terminal, SG terminal for Port)

13

Page 14

Sample Duration Time 2 msec max.

AD Conversion

Input Error

General

Characteristics

Status Display Device Monitor screen (LCD)

Maximum Temporary Error during Electrical

Noise Tests

Recommended Cable for Noise Immunity Twisted pair shielded cable

Calibration or Verification to Maintain Rated

Accuracy

Maximum Permanent Allowed Overload (No

Damage)

Overload Status (Outside Input Range)

Detection

Isolation

Used as Digital

Input

Sample Repetition Time 2 msec max.

Total Input System

Transfer Time

Maximum Error at 25°C ±3.0% of full scale

Temperature Coefficient ±0.04% of full scale/°C

Maximum Error ±5.0% of full scale

Operating Mode Self-scan

Conversion Method type

Between input terminals Not isolated

Between input and

internal circuit

Digit al Input Type — (IEC 61131-2 digital input type is not supported)

Input Threshold

3 msec + filtering time + scan time

±5.0% of full scale

Not possible

28.8V DC

Detectable

Not isolated

ON voltage: 15V min.

(ON current: 0.20 mA min.)

OFF voltage: 5V max.

(OFF current: 0.06 mA max.)

■ FT1A-*14KA/14SA

Input Signal Type Voltage/current input (selectable with software)

Input Points

(Terminal No. /Common Line Name)

Input Range

Input Impedance

Digital Resolution 0 to 1,000 (10bit)

Data Type Binary data: 0 to 1000

Input Value of LSB

Type of Input Single-ended input

1 point in 1 common line

AI0+, AI1+/ AI0-, AI1-

0 to 10V DC (Voltage Input)

4 to 20mA (Current Input)

78.0K (Voltage Input)

250 (Current Input)

10mV (Voltage Input)

16A (Current Input)

14

Page 15

Sample Duration Time 2 msec max.

AD Conversion

Sample Repetition Time 2 msec max.

Total Input System

Transfer Time

3 msec + filtering time + scan time (Voltage Input)

12 msec + filtering time + scan time (Current Input)

Maximum Error at 25°C ±3.0% of full scale

Input Error

Temperature Coefficient ±0.04%/°C of full scale

Maximum Error ±5.0% of full scale

General

Characteristics

Operating Mode Self-scan

Conversion Method SAR

Status Display Device Monitor screen (LCD)

Maximum Temporary Error during Electrical

Noise Tests

±5.0% of full scale

Recommended Cable for Noise Immunity Twisted pair shielded cable

Calibration or Verification to Maintain Rated

Accuracy

Maximum Permanent Allowed Overload (No

Damage)

Overload Status (Outside Input Range)

Detection

Not possible

28.8V DC (Voltage Input)

40mA (Current Input)

Detectable

Between input terminals Not isolated

Isolation

Between input and

internal circuit

Not isolated

Digit al Input Type — (IEC 61131-2 digital input type is not supported)

Used as Digital

Input

Input Threshold

ON voltage: 15V min.

(ON current: 0.20 mA min.)

OFF voltage: 5V max.

(OFF current: 0.06 mA max.)

● Equivalent Circuit

■ FT1A-*12RA

Sink Input (I0 to I5) Shared Digital/Analog Input (I6, I7)

24V DC

24V DC

Input

circuit

4.3kΩ

56kΩ

Input

circuit

1.2kΩ

OV

Internal Circuit

22kΩ

OV

Internal Circuit

15

Page 16

■ FT1A-*14KA

Input

circuit

4.7kΩ

10kΩ

0V

24V DC 24V DC

47kΩ

Internal Circuit

Internal Circuit

Input

circuit

56kΩ

22kΩ

120Ω

130Ω

0V

0V

24V DC

Internal Circuit

Input

circuit

56kΩ

22kΩ

120Ω

130Ω

0V

0V

24V DC

-3.0mA

-6.2mA

Input Current (mA)

5V

15V

24V

Transition Area

ON Area

Input Voltage (V DC)

28.8V

-1.0mA

-5.2mA

OFF Area

Source Input (I0 to I5) Shared Digital/Analog Input (I6, I7)

■ FT1A-*14SA

Sink Input (I0 to I5) Shared Digital/Analog Input (I6, I7)

24V DC

Input

circuit

4.3kΩ

1.2kΩ

OV

● Operating Range

Sink Input (I0 to I5) Source Input

Shared Digital/Analog Input (I6, I7)

Internal Circuit

16

Page 17

4.4 Output Specifications

● Relay Output Specifications

■ FT1A-*12RA

No. of Outputs (Terminal No.) 4 (Q0 to Q3)

Output Type 1a contact

Maximum Load Current 10A

Minimum Switching Load 10 mA/5V DC (reference value)

Initial Contact Resistance 100 m max. (1A, 6V DC)

Electrical Life

Mechanical Life

Rated Load 250V AC/10A, 30V DC/10A

Dielectric

Strength

Status Display Device Monitor screen (LCD display)

Between output terminal

and internal circuit

Between output terminals

(COMs)

100,000 operations min. (rated load 1,800

operations/hour)

20,000,000 operations min. (no load 18,000

operations/hour)

2,300V AC 5mA, 1 minute

Output Delay

17

Page 18

● Transistor Output Specifications

Internal Circuit

COM (+)

Output

V (‒)

■ FT1A-*14KA/14SA

No. of Outputs (Terminal No.) 4 (Q0 to Q3)

Output Type

Sink output (FT1A-*14KA)

Source output (FT1A-*14SA)

Rated Load 24V DC

Operating Load Voltage

Range

20.4 to 28.8V DC

Maximum Load Current 0.3A

Voltage Drop (ON voltage) 1V max. (Voltage between COM and output terminal when ON)

Maximum Inrush Current 1A

Leakage Current 0.1 mA max.

Clamping Voltage 39V ±1V

Maximum Lamp Load 8W

Inductive Load L/R=10 ms (28.8V DC, 1 Hz)

External Current Draw

100 mA max., 24V DC

Sink output: power voltage at the +V terminal

Source output: power voltage at the +COM terminal

Isolation Photocoupler isolate d

Status Display Device Monitor screen (LCD display)

● Equivalent Circuit

■ FT1A-*14KA/14SA

Sink Output (Q0 to Q3) Source Output (Q0 to Q3)

V (+)

Internal Circuit

Output

COM (‒)

18

Page 19

● Analog Output Specifications

■ FT1A-*14KA/14SA

No. of Outputs (Terminal No.) 2 (AQ0 to AQ1)

Output Type Voltage/current output

Output Range

Output Load

D/A

Conversion

Digital Resolution 0 to 1,000 (10bit)

Output Value of LSB

Data Type Binary data: 0 to 1000

Monotonicity Yes

Output Error

Open Current Loop Cannot be detected

*1. Overshoot may occur at light loads.

The occurrence of overshoot can be controlled by inserting damping resistance into the

circuit. A general guide for the damping resistance value is about 150 including the input

line impedance for the destination.

Impedance

Load Type Resistance load

Scan Time 1 scan

Settling Time 1 msec or lower

Total Output System

Transfer Time

Maximum Error at 25°C ±0.3% of full scale

Temperature Coefficient ±0.02%/°C of full Scale

Reproducibility After

Stabilization Time

Non-linearity ±0.01% of full scale

Output Ripple 30 mV max.

Overshoot 0% *1

Maximum Error ±1.0% of full scale

0 to 10 V (Voltage output)

4 to 20 mA (Current output)

2 k min. (Voltage output)

500 max. (Current output)

1 msec + 1 scan

10 mV (Voltage output)

16 A (Current output)

±0.4% of full scale

19

Page 20

Specifications

5

● Applicable Standards

Safety Standard

EMC Standard*1 IEC/EN 61131-2:2007

*1.

When using the Touch as the EMC Standard Approved Products, attach a ferrite core (ZCAT30351330 manufactured by TDK Corporation) to the power cables and the communication cables.

If there a risk of an error occurring due to noise, install the product separated from sources of noise

such as power lines, high voltage lines, and load lines. Also attach a ferrite core to the

I/O cable (ZCAT3035-1330 manufactured by TDK Corporation).

UL508

CSA C22.2 No.142 (c-UL)

● Environmental Specifications

Operating

Temperature*2

Relative 10 to 95% RH (No condensation)

Storage Temperature -20 to +60°C (No freezing)

Storage Humidity 10 to 95% RH (No condensation)

Altitude

Pollution Degree 2

Corrosion Immunity Free from corrosive gases

*2. The UL and c-UL certified operating temperature of the FT1A-*12RA-* is 0 to 50ºC.

0 to 55°C: FT1A-M (Monochrome LCD models)

-20 to 55°C: FT1A-C (Color LCD models) (No freezing)

Operation: 0 to 2,000m

Transport: 0 to 3,000m

● Electrical Specifications

■FT1A-*12RA

Rated Voltage 24V DC

Power Consumption 9.2W max. When USB2 is unused: 5.8W max.

Power Voltage Range 20.4 to 28.8V DC

Allowable Momentary

Power Interruption

Inrush Current 50A max.

Dielectric Strength

10 msec max.

Between power and FE terminals: 500V AC, 5mA,1 minute

Between power and output terminals: 2,300V AC, 5mA, 1 minute

■FT1A-*14KA/14SA

Rated Voltage 24V DC

Power Consumption 11.0W max. When USB2 is unused: 8.1W max.

Power Voltage Range 20.4 to 28.8V DC

Allowable Momentary

Power Interruption

Inrush Current 50A max.

Dielectric Strength

10 msec max.

Between power and FE terminals: 500V AC, 5mA,1 minute

Between power and output terminals: 500V AC, 5mA, 1 minute

20

Page 21

● Construction Specifications

Vibration Resistance

Shock Resistance

5 to 8.4Hz amplitude 3.5mm, 8.4 to 150Hz acceleration 9.8m/s

10 times on each of three mutually perpendicular axes (100 minutes)

(IEC61131-2)

147m/s2, 11ms (5 shocks on each of three mutually perpendicular axes)

(IEC61131-2)

● Performance Specifications

Type Number

LCD Type STN Monochrome LCD TFT Color LCD

Display Colors

Effective Display Area

[mm]

Display Resolution 240 (W) x 100 (H) pixels

View angle Left/Right/Top/Bottom: 45°

Contrast Adjustment 32 levels –

Brightness of LCD only

Brightness Adjustment 32 levels

Backlight

Backlight Life*3 50,000 hours nominal

Display

Switch Type Analog Resistive Film

Operating Force 0.2 to 2.5 N

Multiple Operations Impossible

Life 1,000,000 operations

Touch Panel

User Memory 5MB

Backup Battery*4

Backup Data 128KB

Buzzer Output Single tone (tone length is adjustable)

Degree of Protection IP 66F (IEC60529) *5

FT1A-M

(Monochrome LCD models)

2 Colors (Black, White)

8 shades

87.59(W) × 35.49 (H) 88.92 (W) × 37.05 (H)

White: 740 [cd/m2]

Red: 135 [cd/m2]

LED (White, Red)

Screen color: White, Pink, Red

Lithium secondary battery

Backup Duration: Approx. 30 days (typical) (Operating

temperature: 25°C)

Charging Time: Approx. 15 hours for charging from 0% to 90% of

full charge

Battery Life: 5 years in cycles of 9-hour charging and 15-hour

discharging

Replaceability: Not possible to replace battery

FT1A-C (Color LCD models)

65,536 Colors

Left/Right: 40°, Top: 20°,

Bottom: 60°

400 [cd/m2]

LED (White)

2

21

Page 22

Weight (approx.)

*3. The backlight life refers to the time until the surface brightness reduces to a half after using

continuously at room temperatures.

*4. In high temperature environments battery life may be affected, so retention time may be

reduced.

*5. The degree of protection for the operating section after the panel is attached. The compliance

test has been passed, but this is not a guarantee of operation in all environments.

FT1A-*12RA: 300 g

FT1A-*14KA/SA: 250 g

● EMC Specifications

Type Number FT1A-*12RA FT1A-*14KA/SA

Radiated Emission

Electrostatic Discharge

Electromagnetic Field

Fast Transient Burst

Surge Immunity

Conducted Radio

Frequency Immunity

Class A : 10m

40dBµV/m quasi-peak (30M to 230MHz)

47dBµV/m quasi-peak (230M to 1GHz)

Contact : ±6kV

Air : ±8kV

10V/m (80 to 1000 MHz)

3V/m (1.4 to 2.0 GHz)

1V/m (2.0 to 2.7 GHz)

80% AM (1kHz)

±2kV (Power, Output terminal)

±1kV (Port, Ethernet, Input

terminal)

±500V (between +24V-0V)

±1kV (between +24V-FE, 0V-FE)

10V (Power, Port, Ethernet, Input terminal, Output terminal)

(150kHz to 80MHz)

80% AM (1kHz)

±2kV (Power)

±1kV (Port, Ethernet, Input

terminal, Output terminal)

22

Page 23

Dimensions

6

■ FT1A-*12RA

<Cable Attached Dimensions>

Unit: mm

Depending on the type of connection cable used the dimensions shown above will change.

The dimensions given here are intended for reference only.

23

Page 24

■ FT1A-*14KA/14SA

Unit: mm

77.0

116.0

4.0 54.9

(58.9)

104.5

65.5

<Cable Attached Dimensions>

30

15

20

Depending on the type of connection cable used the dimensions shown above will change.

The dimensions given here are intended for reference only.

50

24

Page 25

7 Installation

Output Current

10A

5A

1A

0

Ambient Temperature

45°C 50°C 55°C

7.1 Operating Environment

For designed performance and safety of the Touch, do not install the Touch in the following

environments:

• Where dust, briny air, or iron particles exist.

• Where oil or chemical splashes for a long time.

• Where oil mist is filled.

• In direct sunlight.

• Where strong ultraviolet rays exist.

• Where corrosive or combustible gasses exist.

• Where the Touch is subjected to shocks or vibrations.

• Where condensation occurs due to rapid temperature change.

• Where high-voltage or arc-generating equipment (electromagnetic contactors or circuit

protectors) exists in the vicinity.

7.2 Ambient Temperature

• Allow sufficient space for ventilation, and install the equipment away from heat sources.

• Allow at least 100mm between the Touch and walls or other equipment.

• Do not install the Touch where the ambient temperature exceeds the rated operating

ambient temperature range. When mounting the Touch in such locations, provide a

forced air-cooling fan or air-conditioner to keep the ambient temperature within the rated

temperature range.

• The Touch is designed to install on a vertical plane so that natural air-cooling is provided.

If you install it using any other orientation, use forced-air cooling, or lower the ambient

operating temperature.

Derating

■ FT1A-*12RA

When using the Touch at an ambient temperature of 45°C or higher, reduce the output

current of each output terminal as shown in the figure below.

Installed upright in landscape orientation

25

Page 26

<Note>

100%

40%

10%

0

30ºC 40ºC 55ºC

Brightness

Ambient Temperature

50ºC

Power Supply Voltage: 20.4 to 24 V

Unit Analog Output: Cannot be used,

Cartridge: Voltage/current output cartridge cannot be used

Power Supply Voltage: 20.4 to 28.8 V

Unit Analog: No restrictions,

Cartridge: No restrictions

If operating the Touch in a high-temperature environment, reducing the brightness of the

backlight can help to limit the temperature rise of internal components.

The relationship between ambient temperature, the output current of each output terminal,

and brightness is approximately as shown in the figure below.

Brightness

100%

50%

0

The values shown above may vary with individual products. Please use this information as

a reference at the time of design.

Output Current10A

Output Current5A

Output Current1A

35°C 45°C 50°C 55°C

Output terminal not used

Ambient Temperature

■ FT1A-*14KA/14SA

When used at ambient temperatures of 40ºC or higher, limit the usage of analog current

output and the analog cartridge as shown in the figure below.

Power Voltage

Range

20.4 to 24V DC

20.4 to 28.8V DC

Touch Analog Output Cartridge

Voltage/current

output cannot be

used

Current output cannot

be used

20.4 to 28.8V DC No restrictions

20.4 to 28.8V DC

Current output cannot

be used

Voltage output (FC6A-PK2AV)/

current output (FC6A-PK2AW)

cannot be used

Voltage output (FC6A-PK2AV)/

current output (FC6A-PK2AW)

cannot be used

Voltage output (FC6A-PK2AV)/

current output (FC6A-PK2AW)

cannot be used

Current output (FC6A-PK2AW)

cannot be used

Operating

Temperature

55ºC

50ºC

45ºC

45ºC

20.4 to 28.8V DC No restrictions No restrictions 40ºC

<Note>

If operating the FT1A-*14KA/14SA in a high-temperature environment, reducing the

brightness of the backlight can help to limit the temperature rise of internal components.

The relationship between ambient temperature and brightness is approximately as shown

in the figure below.

The values shown above may vary with individual products. Please use this information as

a reference at the time of design.

26

Page 27

7.3 Installation

• Make a panel cut-out on the panel with the dimensions shown below.

$

#

• The Touch has the mounting clip positions not only on the top and bottom side (0.3 to

0.35 N

·

m).

TOP

BOTTOM

Mounting Clip Position

A B Panel Cut-out

66.0

+1.0

0

105.0

+1.0

0

Unit: mm

1.0 to 5.0

● Do not tighten excessively, otherwise the Touch may warp and cause wrinkle on the

display, or impair the waterproof characteristics.

● If the mounting clips are tightened obliquely to the panel, the Touch may fall off the

panel.

● When installing the Touch into a panel cut-out, make sure that the gasket is not twisted.

Especially when re-installing, take special care because any twists in the gasket will

impair the waterproof characteristics.

● Even in the panel thickness range, there is a risk that the waterproof characteristics

cannot be maintained due to the panel materials and size.

27

Page 28

7.4 Orientation

The Touch is designed to install on a vertical landscape. If you install it with any other

orientation, confirm the limitations about operating temperature.

Orientation

(Monochrome LCD models)

Landscape

Operating Temperature

FT1A-M

FT1A-C

(Color LCD models)

0 to 55°C

Portrait (Clockwise)

0 to 50°C

Portrait (Counter Clockwise)

0 to 55°C

Vertical

<Note>

• When installing the Touch in a diagonal, the limitations are same as a horizontal.

Horizontal

0 to 50°C

-20 to 55°C

(No freezing)

-20 to 50°C

(No freezing)

-20 to 55°C

(No freezing)

-20 to 50°C

(No freezing)

• Confirm the visibility of the display in a final installation.

28

Page 29

7.5 Attaching Cartridges

Cartridge

Step 1 Insert two flat head screwdrivers into the screwdriver insertion slots in both

locations of the unit, and while pushing the tabs of the cartridge cover, pull the

cartridge cover directly upward to remove it.

Step 2

Pay careful attention to the direction of the cartridge and attach it directly onto the unit.

Screwdriver insertion slot

Screwdriver

insertion slot

Cartridge cover

To remove the cartridge, perform the work detailed in step 1.

● Attach the cartridge directly onto the unit. If the cartridge is attached when tilted, it may

be damaged or cause operating problems.

● Always use ferrules when wiring stranded wire and multiple wires to the terminal block.

Otherwise there is a risk of wires becoming disconnected.

29

Page 30

8 Wiring

● Turn off the power supply before wiring.

● Make the wiring as short as possible and run all wires as far away as possible from

high-voltage and large-current cables. Follow all the procedures and precautions when

wiring the Touch.

● Separate the Touch power supply wiring from the power lines of I/O devices and motor

equipment.

● Ground the functional earth terminal to make sure of correct operation.

● Always use ferrules when wiring stranded wire and multiple wires to the terminal block.

Otherwise there is a risk of wires becoming disconnected.

8.1 Power Supply Terminal

• Pin assignment is shown in the following table.

+ Power supply 24V DC (+24V)

- Power supply 0V (0V)

Functional Earth (FE)

• Use applicable cables for wiring and recommended ferrules (made by Phoenix Contact)

as follows.

Applicable cable

Recommended ferrule

Tightening Torque

AWG16 to AWG22

Stripped wire length 7 mm (Solid wire)

AI 0.34-8 TQ (For AWG22)

AI 0.5-8 WH (For AWG20)

AI 0.75-8 GY (For AWG18)

AI 1-8 RD (For AWG18)

AI 1.5-8 BK (For AWG16)

AI-TWIN 2×0.5-8 WH (For AWG20, TWIN Pressure Terminal)

AI-TWIN 2×0.75-8 GY (For AWG18, TWIN Pressure Terminal)

(Phoenix Contact)

0.5 to 0.6 N ·

m

30

Page 31

8.2 Cautions when connecting external devices

The Touch power supply is non-isolating. Interference or external noise from external

devices due to wiring may cause adverse effects on the internal circuits of the Touch or

external devices.

To prevent such damage, choose a proper solution depending on your system setup.

• Use a separate earth ground from the external noise source device.

• The wire for grounding should be thick and short in order to direct the noise from the

noise source device to the earth ground.

• Use a separate power supply from the external noise source device.

• Insert an isolator on the communication line of the Touch and the non-isolated

communication device (i.e. PLC) to prevent damage.

8.3 Cautions for using the Touch connected to a personal computer

When connecting the Touch to a computer via the Serial Interface (Port) or USB Interface,

the Touch or the computer may break down depending on the conditions of the computer.

Make sure of the following cautions, in order to prevent an accident.

• If the computer has a 3-pin power plug or power plug with a ground lead type.

Make sure to use a plug socket including a ground input electrode or ground the earth

lead, respectively.

• If the computer has a 2-pin power plug without ground lead, follow the procedure below

when connect the Touch to the computer.

(1) Pull out the power plug of the computer from the AC outlet.

(2) Connect the Touch to the computer.

(3) Insert the power plug of the computer into the AC outlet.

31

Page 32

9 USB Cable Lock Pin Attachment

When using the USB interface (USB1, USB2), attach the USB cable lock pin to prevent

disconnecting the USB cable from the Touch.

1 Insert the USB cable into the USB port.

2 Strain the “Edge part” of the USB cable lock pin, and insert the “Edge part” to the 2 holes

upper the USB port.

3 Fasten the USB clamp band around the USB cable and the clamp part, secure them

tightly.

32

Page 33

<Note>

Fasten the USB clamp band without the space between the clamp part and it, and the

inclination.

OK

NG

33

Page 34

10 Maintenance and Inspection

Maintain and inspect the Touch periodically to ensure the best performance. Do not

disassemble, repair, or modify the Touch during inspection.

Wipe any stain of the display using a soft cloth slightly dampened with

Display

Terminals, Connectors

Mounting Clips

Backlight

Touch Panel

neutral detergent or alcoholic solvent.

Do not use solvents such as thinner, ammonia, strong acid, and strong

alkaline.

Check the terminals and connectors to make sure of no loose screws,

incomplete insertion, or disconnected lines.

Make sure that all mounting clips and screws are tightened sufficiently.

If the mounting clips are loose, tighten the screw to the recommended

tightening torque.

The Touch backlight cannot be replaced by the customer.

When the backlight needs to be replaced, contact IDEC.

A gap may be caused in the operation accuracy of the touch panel by

the secular distortion, etc.

Adjust the touch panel according to the following procedure when

there is a gap in the operation of the touch panel.

34

Page 35

10.1 Maintenance Screen

Turn on the power to the Touch, then press and hold the upper-left corner of the screen for

three seconds or longer.

The Maintenance Screen appears on the screen.

Maintenance Screen (Color LCD models) Maintenance Screen (Monochrome LCD models)

• Permission to show the Maintenance Screen can be set using the configuration software.

Refer to the User’s Manual for details.

• The Maintenance Screen is not displayed in the System Mode.

10.2 System Mode

Press the System Mode at the top of the Maintenance Screen. The Top page Screen

appears.

Top Page (Color LCD models) Top Page (Monochrome LCD models)

• Initial Setting, Self Diagnosis and Initialization of the data, etc can be executed in the

System mode.

35

Page 36

10.3 Adjusting the Brightness and Contrast

The brightness and contrast of the Touch display can be adjusted on the Adjust

Brightness/Contrast Screen. Adjust the brightness and contrast to the best condition as

required.

1 Press the Brightness (color LCD models) or Brightness/Contrast (monochrome LCD

models) on the Maintenance Screen.

The Adjust Brightness/Contrast Screen appears.

Color LCD models Monochrome LCD models

2 Press << and >> at the bottom the Adjust Brightness/Contrast Screen to adjust the

contrast to the optimal setting.

Color LCD models Monochrome LCD models

3 Press X to close the Adjust Brightness/Contrast Screen.

To adjust the brightness and Contrast in the System Mode, use << and >> located at the

bottom of the Top Page.

Top Page (Color LCD models) Top Page (Monochrome LCD models)

<Note>

Since contrast adjustment is not possible on color LCD models, the contrast adjust function

is not displayed.

36

Page 37

10.4 Adjusting the Touch Panel

A gap may be caused in the operation accuracy of the touch panel by the secular

distortion, etc. Adjust the touch panel according to the following procedure when there is a

gap in the operation of the touch panel.

1 Press Main Menu on Top Page in System Mode. The Main Menu appears.

Top Page (Color LCD models) Top Page (Monochrome LCD models)

2 Press Init Set, Initialize, and then Touch PnlAdj. The confirmation screen appears and

asks “Touch Panel setting?” is displayed. Press Yes.

The Touch Panel Adjust Screen is displayed.

3 Press the center of the X, then the position of the symbol changes one after another.

Press five symbols sequentially.

<Note>

When pressing the X, make sure to press the center of the symbol. This will ensure the

accuracy of the touch panel operation.

4 When normally recognized, the confirmation screen of 2 is restored.

3, when pressing a point away from the center of the X, a recognition error will

At step

result. Then the X returns to the initial position, then repeat the step of

37

3 again.

Loading...

Loading...