FT9Y-B1378(5)

SAFETY PRECAUTIONS

Warning notices are used to emphasize that improper operation may cause severe personal injury or death.

Warning

Caution notices are used where inattention might cause personal injury or damage to equipment.

Caution

• Read the SmartAXIS Pro/Lite User’s Manual to ensure correct operation before starting installation, wiring, operation, maintenance, and

inspection of the SmartAXIS.

• All SmartAXIS modules are manufactured under IDEC’s rigorous qu ality c ontrol sys tem, but users must add a backup or f ailsafe pr ovision to th e

control system when using the SmartAXIS in applications w here hea vy damage or personal injury may be cause d, in case the SmartA XIS should

fail.

• In this user’s manual, safety precautions are categorized in order of importance:

• The SmartAXIS is not designed for use in medical equipment, nuclear power, railways, aviation, passenger vehicle equipment, or similar

applications requiring a high degree of reliability and safety. The SmartAXIS should not be used for such applications.

• When using the SmartAXIS in applications (n ot descri bed abo ve) that require a high degree of reliability in terms of functional it y an d pre cision ,

appropriate measures such as failsafe mechanisms and redundant mechanisms must be taken for the system containing the SmartAXIS.

• Emergency stop and interlocking circuits must be configured outside the SmartAXIS.

• If relays or transistors in the Sm artAXIS output circuits sh ould fail, outputs ma y remain at on or off state . For output signa ls which may cause

serious accidents, configure monitor circuits outside the SmartAXIS.

• The SmartAXIS self-diagnostic f unct ion ma y dete ct inte rna l circ uit or pr ogram errors, stop programs, and turn outpu ts o f f. Configure circuits

so that the system containing the SmartAXIS is not jeopardized when outputs turn off.

• Turn off power to the SmartAXIS before installation, removal, wiring, maintenance, and inspection of the SmartAXIS. Failure to turn power off

may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the SmartAXIS. People without such expertise must not use the SmartAXIS.

• Install the SmartAXIS according to the instructions described in SmartAXIS Pro/Lite user's manual. Improper installation will result in falling,

failure, or malfunction of the SmartAXIS.

• The SmartAXIS is designed for installation in a cabinet. Do not install the SmartAXIS outside a ca binet.

• Install the SmartAXIS in environments described in the SmartAXIS Pro/Lite user's manual. If the SmartAXIS is used in places where the

SmartAXIS is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations, or excessive shocks, then

electrical shocks, fire hazar d, or malfunction will result.

• The environment for using the SmartAXIS is “Pollution degree 2.” Use the SmartAXIS in environments of pollution degree 2 (according to IEC

60664-1).

• Prevent the SmartAXIS from falling while moving or transporting the SmartAXIS, otherwise damage or malfunction of the SmartAXIS will result.

• Wiring must use lead sizes that are appropriate for the applied voltage and current. Terminal screws must be tightened with the prescribed

tightening torque.

• Prevent metal fragments and pieces of wire from dropping inside the SmartAXIS housing. Put a cover on the SmartAXIS modules during

installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the SmartAXIS. This is required when equipment containing the SmartAXIS is

destined for Europe.

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the SmartAXIS is destined for Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the SmartAXIS is destined for Europe.

• Make sure of safety before starting and stoppi ng the SmartAXIS or when operatin g the SmartAXIS to forc e outputs on or off. Incorrect operation

of the SmartAXIS may cause machine damage or accidents.

• Do not connect the ground wire directl y to the Sma rtAXIS. Connect a protectiv e ground to the cabin et contai ning the Sm artAXIS u sing an M4 or

larger screw. This is re quired when equipment containing the SmartAXIS is destined for Europe.

• Do not disassemble, repair, or modify the SmartAXIS modules.

• The SmartAXIS contains electronic parts and batteries. When disposing of the SmartAXIS, do so in accordance

with national and local regulations.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 Preface-1

ABOUT THIS MANUAL

This user’s manual describes functions, specifications, installation, and operation basics of the SmartAXIS. Also included is

information on the powerful communications tools of the SmartAXIS, as well as troubleshooting procedures.

Chapter 1: General Information

General information about the SmartAXIS , featur es, brief description on special functions, and v arious system setup configurations

for communication.

Chapter 2: Product Specifications

Specifications of SmartAXIS, optional adapters, and cartridges.

Chapter 3: Installation and Wiring

Methods and precautions for installing and wiring the SmartAXIS.

Chapter 4: Operation Basics

General information about setting up the basic SmartAXIS system for programming, starting and stopping SmartAXIS operation, and simple

operating procedures. Everything from creating a user program using WindLDR on a computer to monitoring the SmartAXIS operation.

Chapter 5: Special Functions

Stop/reset inputs, run/stop selection at memory backup error, and keep designation. Also included are high-speed counter,

frequency measurement, catch input, interrupt input, t imer interrupt, input filter, user program protection, daylight savings time,

network settings, and many more special functions.

Chapter 6: HMI Function

HMI function on the SmartAXIS Pro by using the LCD and operation buttons on the SmartAXIS.

Chapter 7: Device Addresses

Device addresses available for the SmartAXIS to program basic and advanced instructions. Special internal relays and special data

registers are also described.

Chapter 8: Instructions Reference

List of basic and advanced instructions to program the SmartAXIS.

Chapter 9 through Chapter 11: Maintenance Communication, User Communication Instructions, Modbus

Communication

Various communication functions such as user communication and Modbus communication.

Chapter 12: Remote I/O

Remote I/O communication to incr ease th e number of inputs an d outp uts by conn ecting ot her Smart AXI S as re mote I/O slav es o ve r Ethernet.

Chapter 13: Script

Programming complicated processing with script language using conditional branching, logical operations, arithmetic operations, and functions.

Chapter 14: Troubleshooting

Procedures to determine the cause of trouble and actions to be taken when any trouble occurs while operating the SmartAXIS.

Appendix

Additional information about type numbers, system software upgrade, and USB driver installation.

Index

Alphabetical listing of key words.

Publication history

March 2013 First Edition

August 2013 Second Edition

October 2013 Third Edition

December 2013 Fourth Edition

August 2014 Fifth Edition

May 2019 Sixth Edition

Trademarks

SmartAXIS is a trademark of IDEC Corporation.

Regarding laws and compatible standards

This product adheres to the laws and compatible standards of all countries involved, as shown below.

European laws and standards

This product complies with the following EU directives.

• Low Voltage Directive (Directive 2006/95/EC)

• EMC Directive (Directive 2004/108/EC)

To comply with these directives, this product has been designed and evaluated on the basis of the following international and

European standard.

• IEC/EN 61131-2: 2007 (excluding the Lite digital I/O status indicators)

For details on the compatible standa rds an d EU Dir ectiv es, con tact the distributor fr om which y ou purchased this product or visit our web site.

North America laws and standards

This product complies with the following standards.

• UL508

• CSA C22.2 No.14

Marine standards

This product is certified by the following classification societies. (FT1A Version V130 or later, system software version V2.10 or

later)

- ABS (American Bureau of Shipping)

- DNV (Det Norske Veritas, Norwegian classification society)

- LR (Lloyd's Register)

- NK (Nippon Kaiji Kyokai)

• T o use this pr oduct as a marine ce rtified product, wr ap the power supply cable (ex cluding the earth wire) and the Ethe rnet communication cable

connected to the SmartAXIS around a ferrite core (TDK ZCAT3035-1330) twice.

• Wrap cables connected to the communication cartridge around a ferrite core (TDK ZCAT1730-0730) twice.

• This product is not certified for use on the bridge and deck.

Preface-2 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting from

the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 Preface-3

RELATED MANUALS

The following manuals related to the SmartAXIS are av ailable. Refer to them in conjunction with this manual.

Type No. Manual Name Description

Describes product specifications, installation and wiring instructions, instructions for

FT9Y-B1378

FT9Y-B1382

FT9Y-B1386

FT9Y-B1390

WindLDR Help

WindO/I-NV3 Help

SmartAXIS Pro/Lite

User’s Manual (this manual)

SmartAXIS

Ladder Programming Manual

SmartAXIS

FBD Programming Manual

SmartAXIS Touch

User’s Manual

basic programming operations and special functions, device and instruction lists,

communication functions, and troubleshooting procedures for the SmartAXIS Pro/

Lite series.

Describes basic operations for ladder programming, instructions for monitoring

ladders on the SmartAXIS, available devices and instructio n lis ts, and details o f each

instruction.

Describes basic operations for function block programming, available devices and

function block lists, and details of each function block.

Describes product specifications, installation and wiring instructions, instructions for

setting basic programming actions and special functions, device a nd instruc tion lists ,

communication functions, and troubleshooting procedures for the Touch series.

Describes usage instructions for WindLDR, pr ogram ming softw are fo r the SmartAXI S

Pro/Lite series.

Describes programming for the SmartAXIS Touch series, and usage instructions for

the WindO/I-NV3 configuration software.

Preface-4 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

NAMES AND ABBREVIATIONS USED IN THIS MANUAL

Model Names

Name Used in this Manual Description (Detailed Type No.)

SmartAXIS Name for the FT1A programmable logic controllers.

Modules without LCD.

SmartAXIS Lite

SmartAXIS Pro

SmartAXIS Touch

12-I/O type

24-I/O type

40-I/O type

48-I/O type

AC power type

DC power type

(FT1A-B12RA, FT1A-B12RC, FT1A-B24RA, FT1A-B24RC, FT1A-B40RKA, FT1A-B40RSA, FT1A-B40RC,

FT1A-B48KA, FT1A-B48SA, FT1A-B48KC, FT1A-B48SC)

Modules with LCD.

(FT1A-H12RA, FT1A-H12RC, FT1A-H24RA, FT1A-H24RC, FT1A-H40RKA, FT1A-H40RSA, FT1A-H40RC,

FT1A-H48KA, FT1A-H48SA, FT1A-H48KC, FT1A-H48SC)

Modules that extend the functionality of display.

(FT1A-M12RA-W, FT1A-M12RA-B, FT1A-M12RA-S, FT1A-C12RA-W, FT1A-C12RA-B, FT1A-C12RA-S,

FT1A-M14KA-W, FT1A-M14KA-B, FT1A-M14KA-S, FT1A-M14SA-W, FT1A-M14SA-B, FT1A-M14SA-S,

FT1A-C14KA-W, FT1A-C14KA-B, FT1A-C14KA-S, FT1A-C14SA-W, FT1A-C14SA-B, FT1A-C14SA-S)

SmartAXIS Pro and Lite models with 12 I/O points.

(FT1A-B12RA, FT1A-B12RC, FT1A-H12RA, FT1A-H12RC)

SmartAXIS Pro and Lite models with 24 I/O points.

(FT1A-B24RA, FT1A-B24RC, FT1A-H24RA, FT1A-H24RC)

SmartAXIS Pro and Lite models with 40 I/O points.

(FT1A-B40RKA, FT1A-B40RSA, FT1A-B40RC, FT1A-H40RKA, FT1A-H40RSA, FT1A-H40RC)

SmartAXIS Pro and Lite models with 48 I/O points.

(FT1A-B48KA, FT1A-B48SA, FT1A-B48KC, FT1A-B48SC, FT1A-H48KA, FT1A-H48SA, FT1A-H48KC,

FT1A-H48SC)

SmartAXIS Pro and Lite models with an AC power supply.

(FT1A-B12RC, FT1A-H12RC, FT1A-B24RC, FT1A-H24RC, FT1A-B40RC, FT1A-H40RC, FT1A-B48KC,

FT1A-B48SC, FT1A-H48KC, FT1A-H48SC)

SmartAXIS Pro and Lite models with a DC power supply.

(FT1A-B12RA, FT1A-H12RA, FT1A-B24RA, FT1A-H24RA, FT1A-B40RKA, FT1A-H40RKA,

FT1A-B40RSA, FT1A-H40RSA, FT1A-B48KA, FT1A-B48SA, FT1A-H48KA, FT1A-H48SA)

Abbreviations

Abbreviation Meaning

FBD Function block diagram

FB

Function block

For example, the AND (logical AND) fu nction block is written as AND FB.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 Preface-5

T

ABLE OF

C

HAPTER

C

HAPTER

1: General Information

2: Product Specifications

C

ONTENTS

Safety Precautions .............................. .............................................................................................. Preface-1

About This Manual ................................................ .......................................................................... .. Preface-2

Related Manuals ............................................................................................................................... Preface-4

Names and Abbreviations Used in this Manual..................................................................................... Preface-5

About the SmartAXIS .................................. .................................................................... ............................ 1-1

Features..................................................................................................................................................... 1-3

Special Functions ........................................................................................................................................ 1-4

Communication Functions............... ............................................................................................................. 1-6

Maintenance Communication ....................................................................................................................... 1-7

User Communication................................................................................................................................... 1-8

Modbus Communication .............................................................................................................................. 1-8

Remote I/O ........................................................ ........................................................................................ 1-9

Ethernet Communication ..................................... ........................................................................................ 1-9

Operator Interface Connectivity ....................................................................................... ...........................1-10

Parts Description......................................................................................................................................... 2-1

Communication Cartridge ........................................................... ................................................................2-23

Memory Cartridge ...................................................................................... ................................................2-25

Ethernet Port................................................ .............................................................................................2-27

SD Memory Card........................................................................................................................................2-28

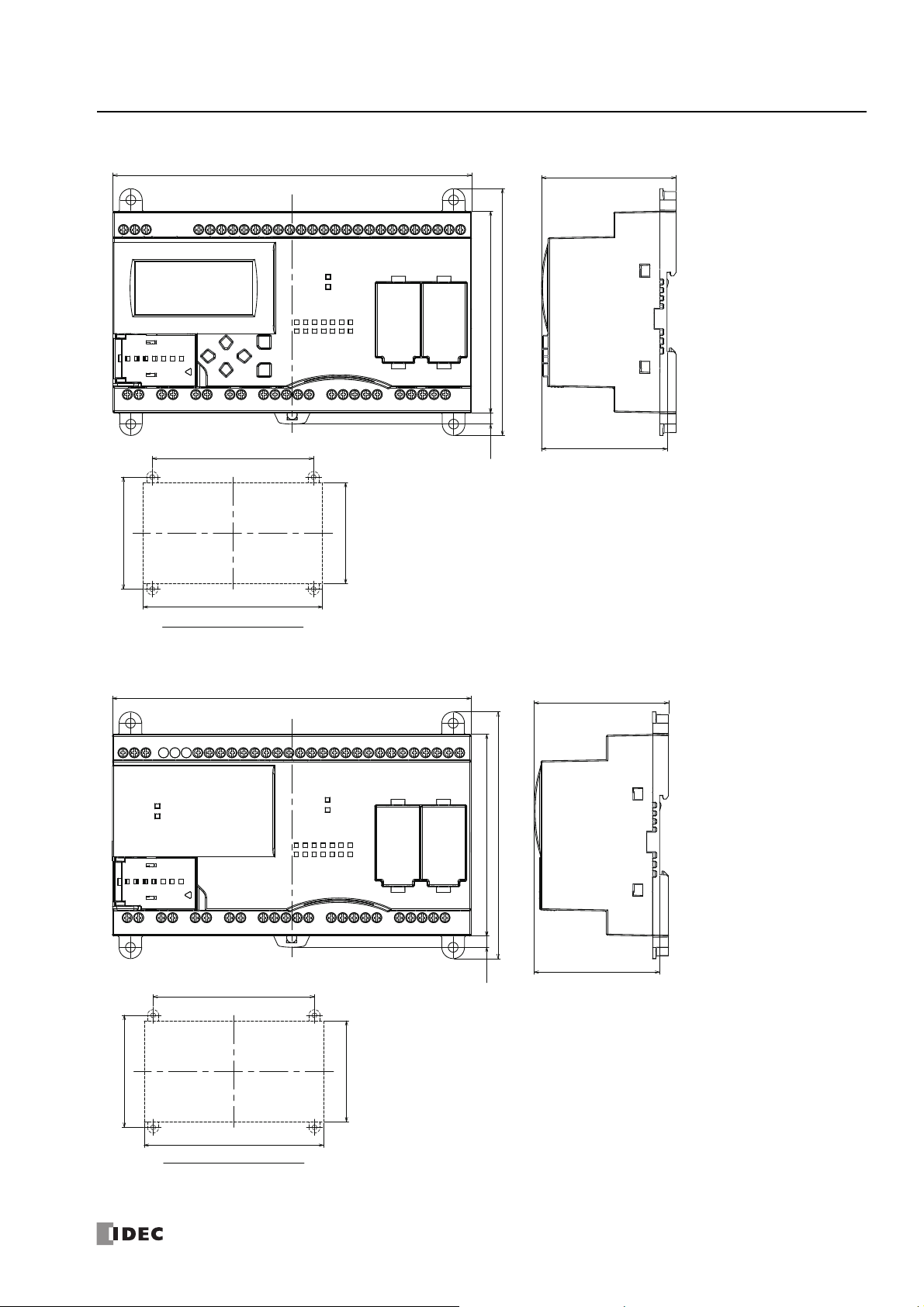

Dimensions................................................................................................................................................2-30

C

HAPTER

C

HAPTER

C

HAPTER

3: Installation and Wiring

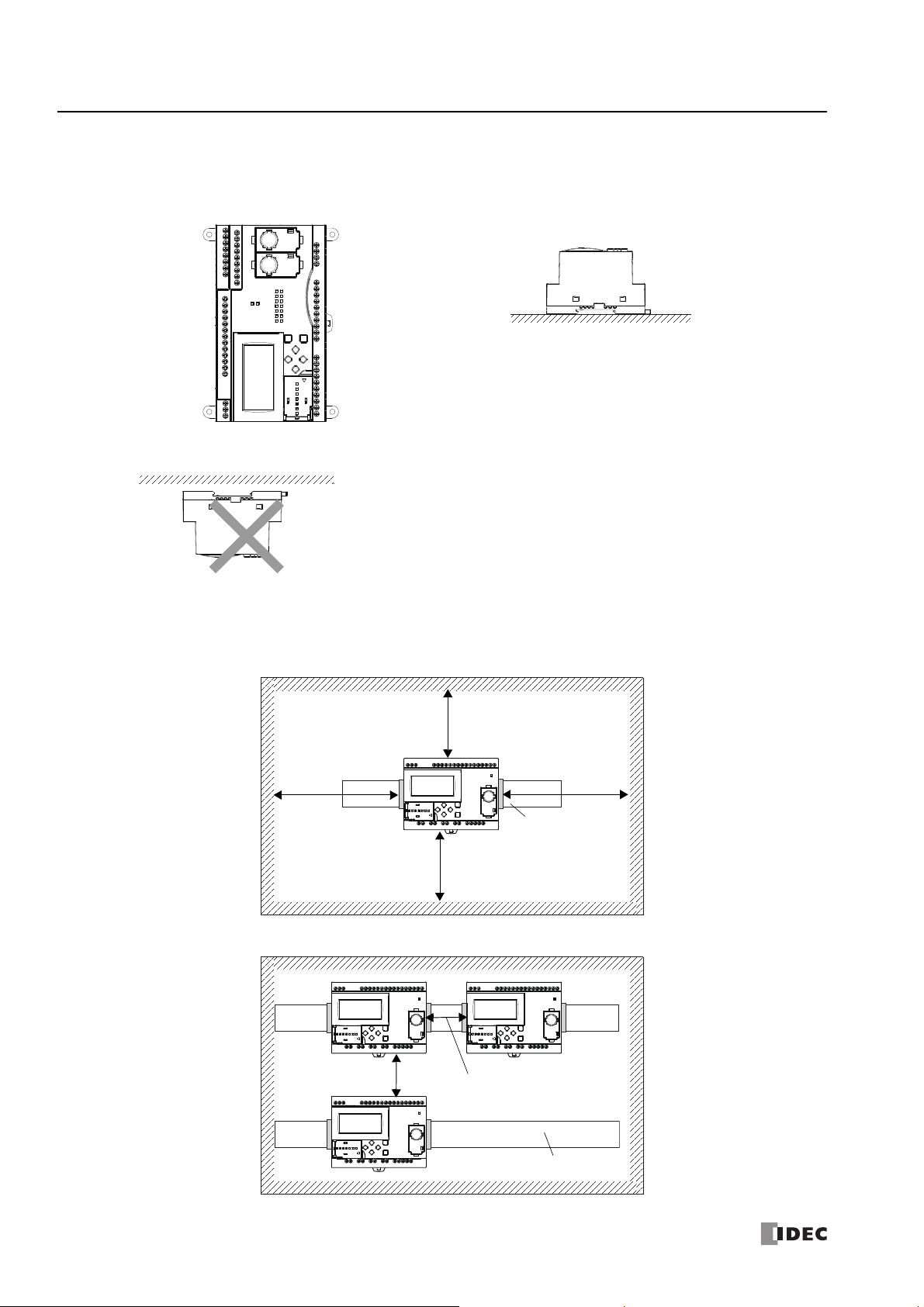

Installation Location......................................... ........................................................................................... 3-1

Mounting Space.. ..................................................................... ................................................................... 3-2

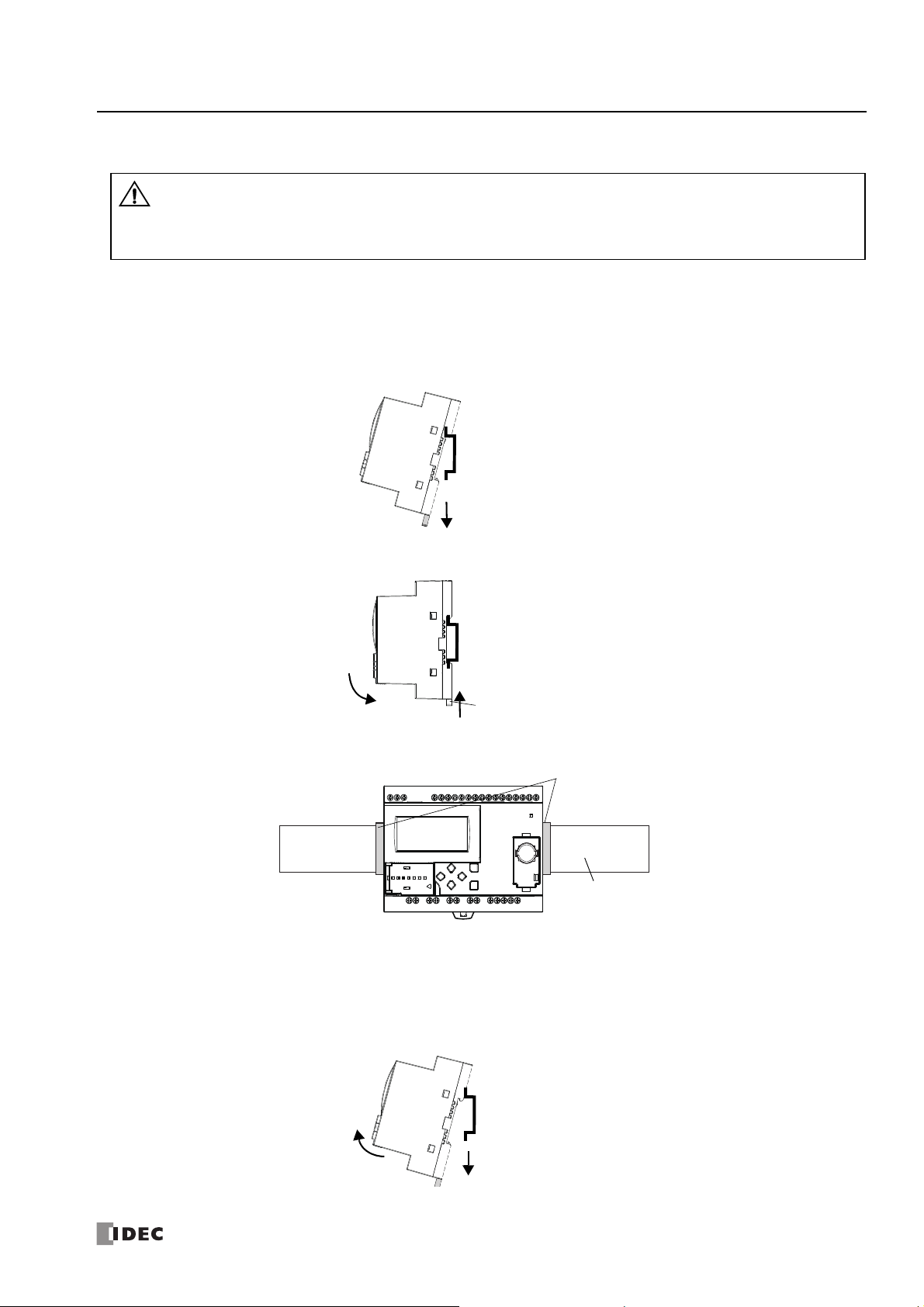

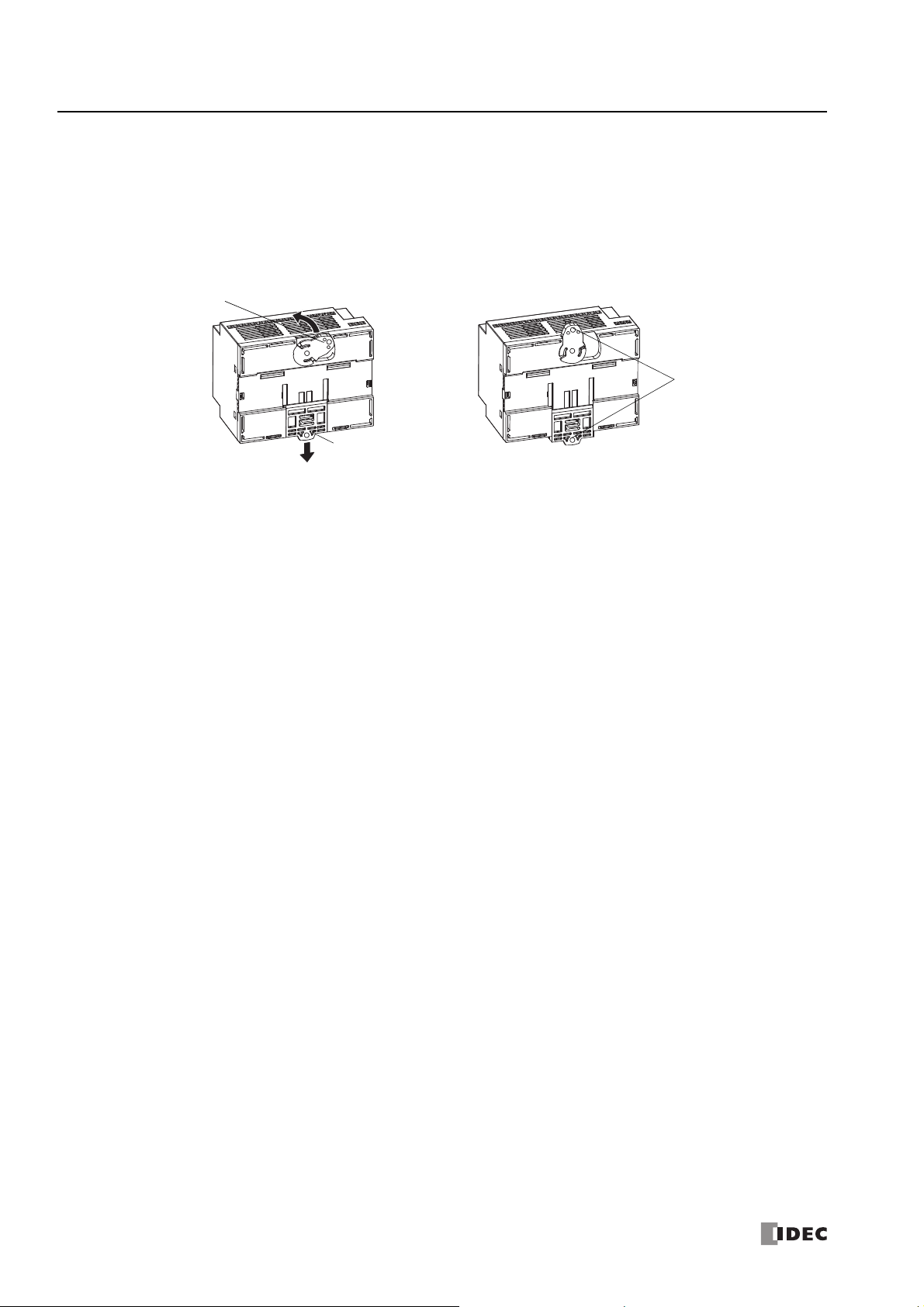

Mounting on DIN Rail.................................. ................................................................................................ 3-3

Removing from DIN Rail. .................................................................... ......................................................... 3-3

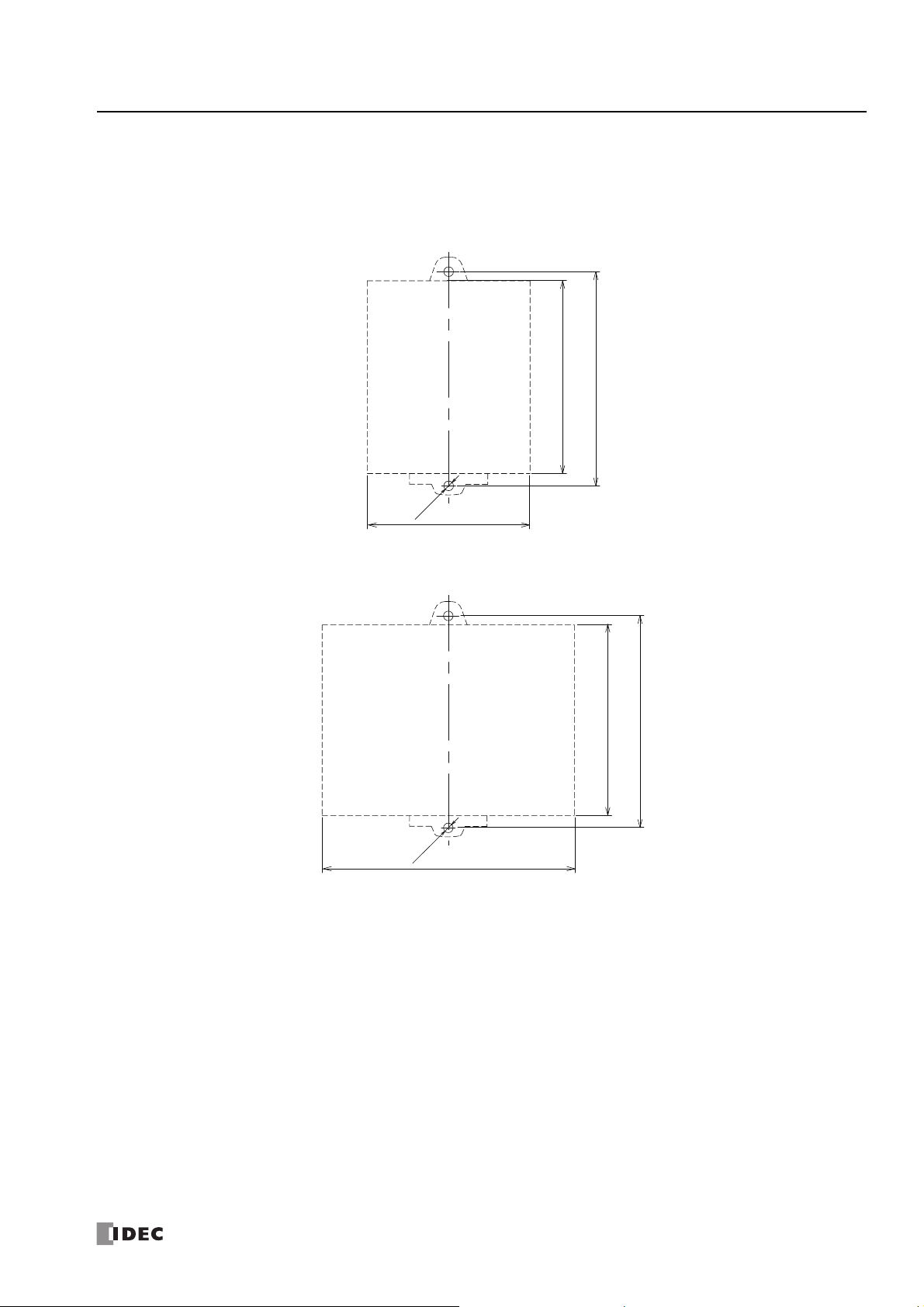

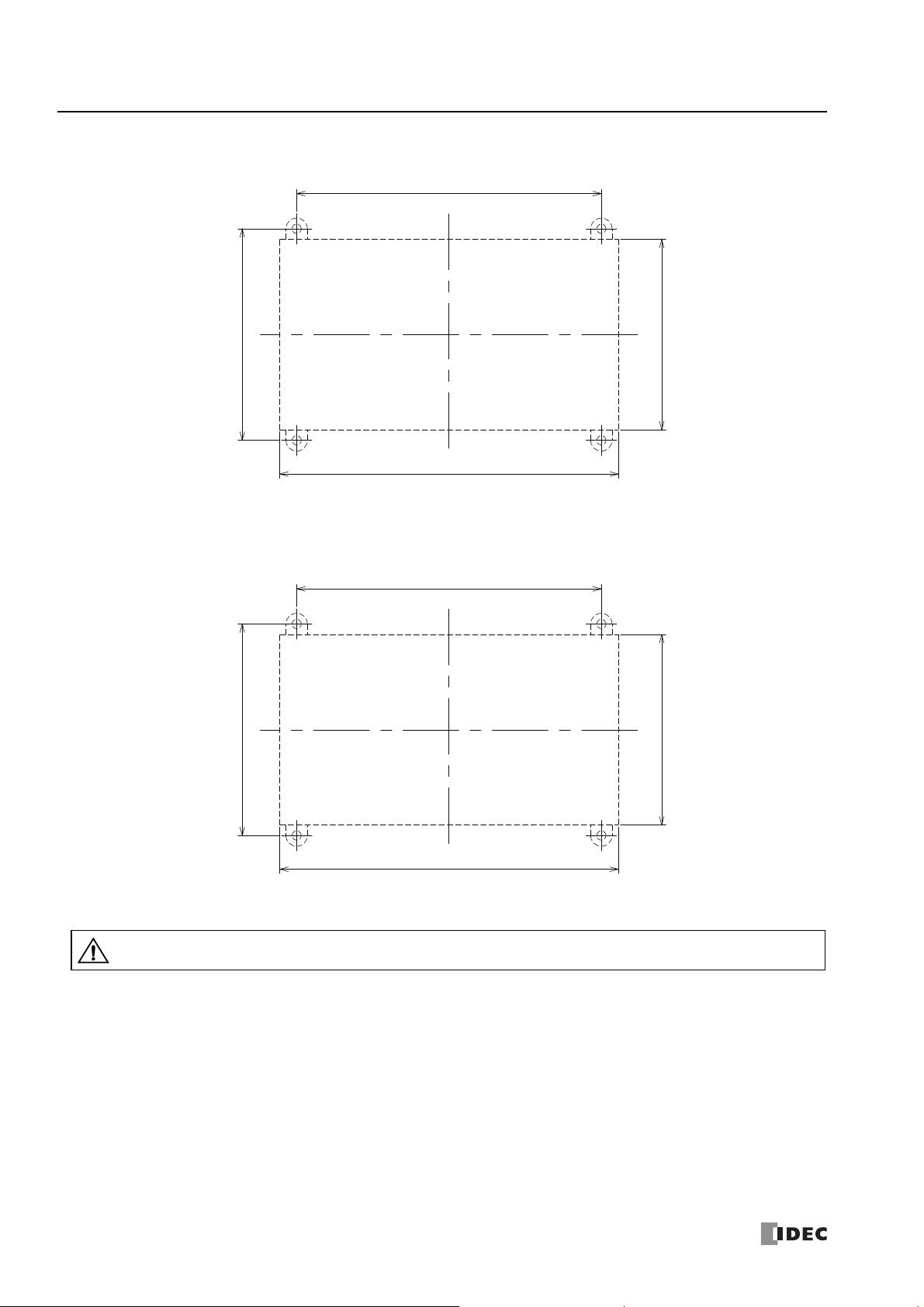

Direct Mounting on Panel Surface................................................................................................................. 3-4

Input/Output Wiring.................................................................................................................................... 3-7

Power Supply ............................................................................................................................................3-11

Terminal Connection ..................................................................................................................................3-13

Securing the Panel Attachment USB Extension Cable ....................................................................................3-14

4: Operation Basics

Start WindLDR............................................................................................................................................ 4-1

PLC Selection...................................... ........................................................................................................ 4-2

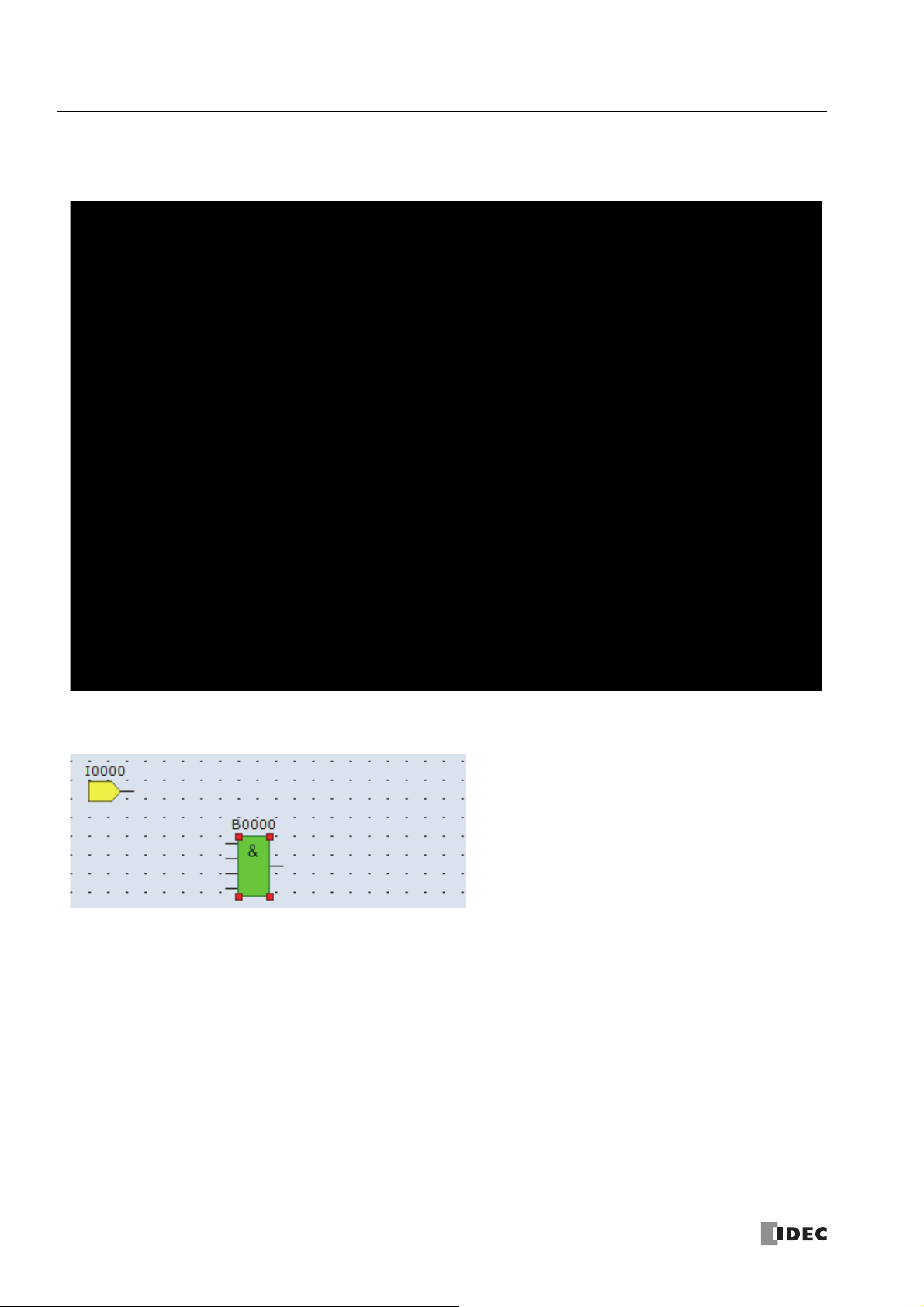

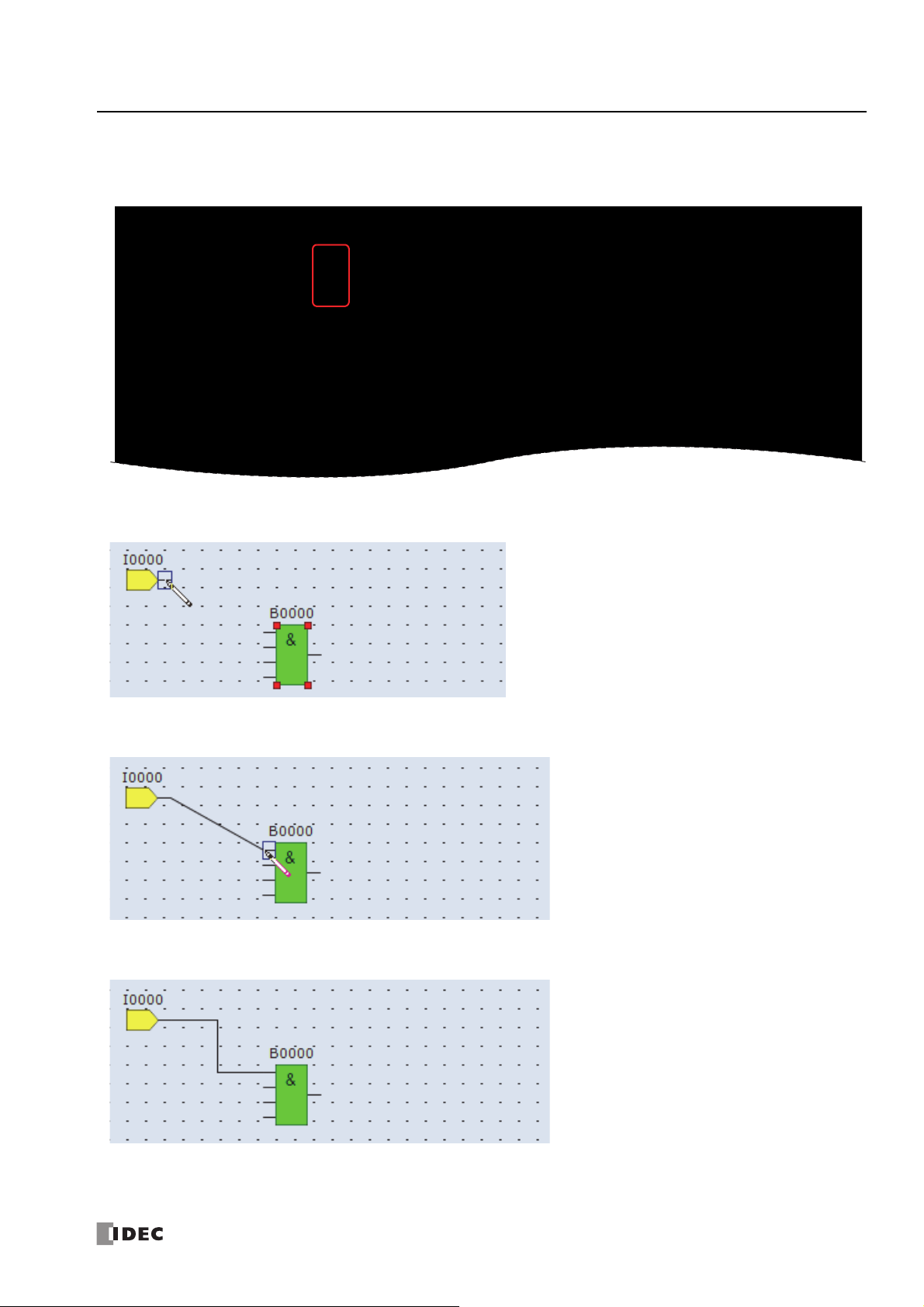

Create Program ............................... ........................................................................................................... 4-3

Convert Program................................................. .......................................................................................4-11

Save Project......................................................... .....................................................................................4-11

Simulate Operation ............................................................... .....................................................................4-12

Download Program .......................................................................................... ..........................................4-14

Monitor Operation......................................................................................................................................4-15

Exit WindLDR ................ ............................................................................................................................4-16

Start/Stop Operation........................................................ ..........................................................................4-17

5: Special Functions

Function Area Settings ................................................................................................................................ 5-2

Stop Input and Reset Input .................... .................................................................... ................................. 5-4

Run/Stop Selection at Memory Backup Error ................................................................................................. 5-5

Run/Stop Selection at Power Up................................................................................................................... 5-6

Keep Designation for Internal Relays, Shif t Registers, Counters, and Data Registers ........................................ 5-7

Data Register ROM Backup................................................................................. ......................................... 5-9

High-Speed Counter....... ............................................................................................................................5-13

Catch Input ...............................................................................................................................................5-32

Interrupt Input ..........................................................................................................................................5-34

Frequency Measurement ................ ............................................................................................................5-36

Input Filter................................................................................................................................................5-38

I FT1A SmartA

XIS

Pro/Lite User’s Manual FT9Y-B1378

C

HAPTER

Analog Input............ ................................................................................................................................. 5-39

Timer Interrupt ............................................................................... .......................................................... 5-41

Forced I/O function ................................................................................................................................... 5-43

Communication Ports........................ .................................................................... ..................................... 5-46

Memory Cartridge.......... ..................................................................... .......................................................5-49

SD Memory Card....................................................................................................................................... 5-52

Backlight ON Time......................... ..................................................................... ....................................... 5-57

Monitoring Ladder Program....................................... .................................................................................5-58

Message Settings .................................................. ....................................................................................5-60

32-bit Data Storage Setting........................................................................................................................5-62

User Program Protection..................... ....................................................................................................... 5-64

Watchdog Timer Setting ............................................................................................................................5-66

Constant Scan Time................................................................................................................................... 5-67

Daylight Savings Time ................. .............................................................................................................. 5-68

Clock Function.................. ..................................................................... ....................................................5-69

Network Settings....................................................................................................................................... 5-72

Connection Settings....................... ..................................................................... .......................................5-73

Remote Host List.......................................................................................................................................5-75

6: HMI Function

About the Menu Screen................................................................................................................................6-2

Basic Operations .........................................................................................................................................6-3

Switching to the System Menu .................................... .................................................................................6-6

Switching run/stop ...................... ................................................................................................................6-7

SmartAXIS Environment Settings............................ .................................................................... ..................6-8

Monitoring the SmartAXIS. .................................. .......................................................................................6-15

Checking/Clearing Error Information ........................................................................................................... 6-20

Uploading/Downloading the User Program . .................................................................... ............................. 6-22

Displaying Arbitrary Messages ...... ..............................................................................................................6-24

Maintaining the SD Memory Card............................ ....................................................................................6-25

Entering a Password.................................................................................................................................. 6-27

System Menu Hierarchy Diagram................................. ...............................................................................6-28

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

7: Device Addresses

Device Addresses ........................................................................................................................................7-1

Special Internal Relays ................................................................... ..............................................................7-2

Special Data Registers ........................... ......................................................................................................7-8

8: Instructions/Function Blocks Reference

Ladder Program Instructions List ..................................................................................................................8-1

Advanced Instruction List.......................................... ...................................................................................8-3

Advanced Instruction Applicable SmartAXIS .............................. ....................................................................8-6

FB List..... ................................... ................................................................................................................8-9

9: Maintenance Communication

Maintenance Communication via USB Port......................... ............................................................................9-2

Maintenance Communication via Expansion Communica ti on Port ....................................................................9-3

Maintenance Communication via Ethernet Port ..............................................................................................9-5

10: User Communication Instructions

User Communication via Serial Communication.................................. ..........................................................10-1

User Communication Overview....................... .................................................................... ........................10-1

User Communication Mode Specifications.......................... .......................................................................... 10-1

RS232C User Communication System Setup ...................... .......................................................................... 10-2

RS485 User Communication System Setup ............................................................. ..................................... 10-3

Programming WindLDR..................... ......................................................................................................... 10-4

RS232C Line Control Signals................................ ..................................................................................... 10-11

User Communication via Ethernet Communication ..................................................................................... 10-14

Ethernet User Communication Overview................................................................. ................................... 10-14

User Communication Client ...................................................................................................................... 10-16

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 II

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

C

HAPTER

11: Modbus Communication

12: Remote I/O

13: Scripts

User Communication Server......................................................................................................................10-19

Programming WindLDR (User Communication Server) ................................................................................10-20

User Communication Error................ ..................................................................... ...................................10-22

ASCII Character Code Table ................................................ .....................................................................10-23

Sample Program – User Communication TXD .......................................... ...................................................10-24

Sample Program – User Communication RXD..................... ........................................................................10-26

Modbus Communication via RS-232C/RS-485...............................................................................................11-1

Modbus Master Communication...................................................................................................................11-2

Modbus Slave Communication.....................................................................................................................11-8

Communication Format ............................................................................................................................11-12

Modbus Communication via Ethernet Communication .................................................................................11-18

Modbus TCP Client...................................................................................................................................11-19

Modbus TCP Server..................................................................................................................................11-24

Remote I/O Master ............................. .......................................................................................................12-2

Remote I/O Slave ......................................................................................................................................12-8

Script Programming and Management .........................................................................................................13-3

Programming Scripts... ..................................................................... ........................................................13-10

Script Programming Examples...................................................................................................................13-16

Important Notes ......................................................................................................................................13-35

About the Priority of the Operator ............................................................................ .................................13-35

C

HAPTER

A

PPENDIX

I

NDEX

14: Troubleshooting

Reading Error Data ....................................................................................................................................14-1

Special Data Registers for Error Information ................................................................................................14-3

General Error Codes...................................................................................................................................14-3

SmartAXIS Operating Status, Output, and ERR LED during Errors ..................................................................14-4

Error Causes and Actions........................ ....................................................................................................14-4

User Program Execution Error...... ...............................................................................................................14-6

Troubleshooting Diagrams..........................................................................................................................14-7

System Software................................................................... ...................................................................... A-1

USB Driver Installation Procedure................................................................................................................. A-5

Cables........................................................................................................................................................A-8

HMI Screen Transition Diagram.................................................................................................................. A-11

Type List................................................................. ................................................................................. A-15

Fonts ....................................................................................................................................................... A-17

III S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

1: G

Power supply type A: DC power type (24V DC)

C: AC power type (100 to 240V AC)

tuptuo yaleR :Repyt tuptuO

RK: Relay output/transistor sink output

RS: Relay output/transistor source output

K: Transistor sink output

S: Transistor source output

stniop O/I 21 :21stuptuo/stupnI

24: 24 I/O points

40: 40 I/O points

48: 48 I/O points

H: With LCD and operation buttons B: Without LCD and operation buttons

FT1A: Type number

FT1A - H 12 R A

ENERAL INFORMATION

Introduction

This chapter describes SmartAXIS functions and system configuration examples. The SmartAXIS is available in three types: the

SmartAXIS Lite, the SmartAXIS Pro, and the SmartAXIS Touch. The SmartAXIS Lite is equipped with the same various control and

communication functions as a PLC. In addition to the functions of the SmartAXIS Lite, the SmartAXIS Pro is equipped with an LCD

and operation buttons on the front of the module. The SmartAXIS Touch is equipped with the HMI functions of an operator

interface and PLC control functions.

This document describes the SmartAXIS Lite and Pro. Unless otherwise specified, SmartAXIS refers to the SmartAXIS Lite and Pro.

For the SmartAXIS Touch, refer to the SmartAXIS Touch User's Manual.

About the SmartAXIS

The SmartAXIS is a small-size programmable controller that is fully equipped with powerful functions and various communication

functions.

You can select the type of SmartAXIS best-suited for your applications, in such ways as the inclusion of the display function, the

type of power supply, and the number of inputs and outputs.

The SmartAXIS Lite is equipped with basic functions. The SmartAXIS Pro adds to the functionality of the SmartAXIS Lite and is

equipped with an LCD and operation buttons on the module, enabling independent monitor and operation functions.

The SmartAXIS supports 100 to 240V AC and 24V DC power supplies. SmartAXIS with Ethernet port (24-, 40-, 48-I/O types) can

expand the number of inputs and outputs for a maximum of 90 inputs and a maximum of 54 outputs using the remote I/O

function.

User programs can be created using WindLDR, the PLC programming softwa re.

The SmartAXIS supports ladder programs and function block programs. Ladder programs for FT1A are compatible with other IDEC

PLCs including MicroSmart and MicroSmart Pentra, so you can make use of existing software assets.

Type Numbers

The notation for SmartAXIS part numbers is as follows.

Note: For the input specifications , se e "I n put Spec ific at ion s (AC Power Type)" on page 2-8 to "I n put Spec ifica tion s ( DC Power Type)" on page 2-10.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 1-1

1: G

RS232C Communication Cartridge

FT1A-PC1 (Mini-DIN type)

Memory Cartridge

FT1A-PM1

USB Maintenance Cable

HG9Z-XCM42

SD Memory Card (2GB)

HG9Z-XMS2

RS485 Communication Cartridge

FT1A-PC2 (Mini-DIN type)

RS485 Communication Cartridge

FT1A-PC3 (Terminal block type)

Panel Mount USB Extension Cable

HG9Z-XCE21

ENERAL INFORMATION

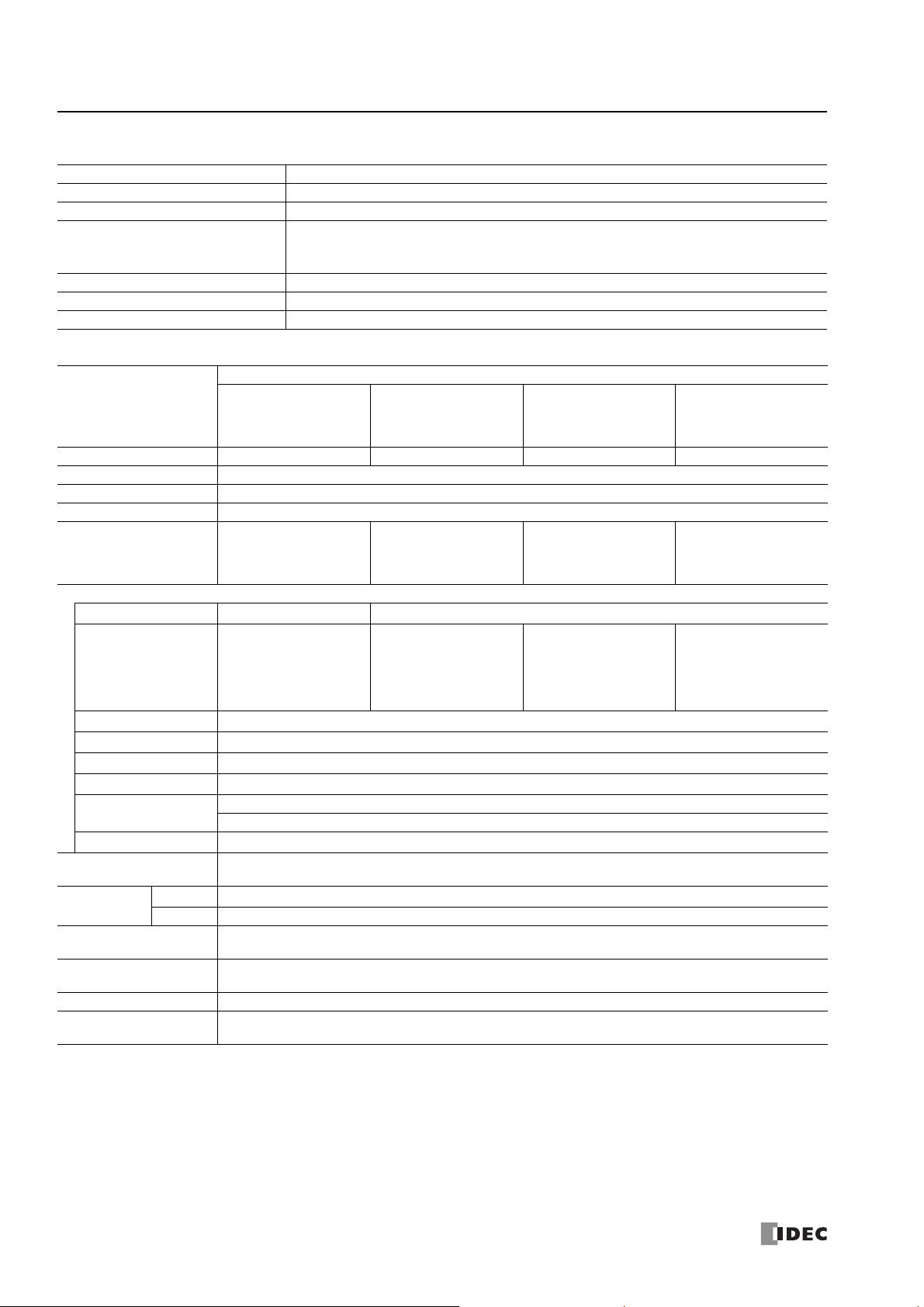

Type List

Type Number Power Supply

FT1A-H12RA 24V DC

FT1A-H12RC 100 to 240V AC

FT1A-B12RA 24V DC

FT1A-B12RC 100 to 240V AC

FT1A-H24RA 24V DC

FT1A-H24RC 100 to 240V AC

FT1A-B24RA 24V DC

FT1A-B24RC 100 to 240V AC

FT1A-H40RKA

FT1A-H40RSA

24V DC

FT1A-H40RC 100 to 240V AC

FT1A-B40RKA

24V DC

FT1A-B40RC 100 to 240V AC

FT1A-H48KA

FT1A-H48SA

FT1A-H48KC

FT1A-H48SC

FT1A-B48KA

FT1A-B48SA

FT1A-B48KC

FT1A-B48SC

24V DC

100 to 240V AC

24V DC

100 to 240V AC

Inputs and

Outputs

(In/Out)

12 (8/4)

24 (16/8)

40 (24/16)

48 (30/18)

LCD,

Operation

Buttons

Yes

—

Yes

—

Yes

—FT1A-B40RSA

Yes

—

USB Port

Yes

Expansion

Communication

Port

Ethernet

Port

——

Yes

1 port

Yes

Yes

2 ports

SD Memory

Card slot

—

Yes

Options

1-2 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

1: G

RS232C Communication Cartridge

FT1A-PC1 (Mini-DIN type)

RS485 Communication Cartridge

FT1A-PC2 (Mini-DIN type)

RS485 Communication Cartridge

FT1A-PC3 (Terminal block type)

Memory Cartridge

FT1A-PM1

ENERAL INFORMATION

Features

This section describes the features of the SmartAXIS.

The SmartAXIS is high-performance programma ble controller in a compact package and is equipped with high speed counters that

can be used for positioning control. The SmartAXIS enables you to build optimum systems to automate factories or control

production lines.

Powerful HMI Functions

The SmartAXIS Pro is equipped with an LCD on the front of the module, enabling you to monitor the device values and the ladde r

program. Customized messages can be programmed to display current time, bar charts, scrolling messages, or simple text on the

LCD. The operation buttons on the module are used for oper ations with LCD such as checking and modifying device values.

Powerful Communication Functions

The SmartAXIS supports various communications such as maintenance communication, user communication, Modbus

communication, and remote I/O.

The SmartAXIS is equipped with RS232C (optional), RS485 (optional), an Ethernet port, and a USB port, and can be connected to

various devices such as computers, operator interfaces, and printers.

Memory Cartridge

A user program of SmartAXIS can be stored in a memory cartridge (FT1A-PM1). When a memory cartridge is inserted into a

SmartAXIS, the user program in the memory cartridge is executed instead of the user program in the SmartAXIS. You can also

download the user program in a memory cartridge to the SmartAXIS.

SD Memory Card

The 40- and 48-I/O types are equipped with an SD memory card slot. The log data of device values can be saved to an optional SD

memory card (HG9Z-XMS2) or a commercial ly available SD memory card (32 GB maximum).

32-bit and Floating Point Data Types

Some advanced instructions can select 32-bit data types from D (double word), L (long), and F (float) in addition to W (word) and

I (integer).

Safety and High-Quality Compliant with International Standards

The SmartAXIS is compliant with international standards and can be used all over the world while maintaining safety and high

quality.

Supports 9 Languages

The SmartAXIS LCD supports the display of the following nine languages:

Setting Name Character Set Supported Languages

European ISO 8859-1 (Latin-1) English, German, Italian, Spanish, Dutch (Note), French (Note)

Japanese Shift-JIS Japanese (level 1)

Chinese GB2312 Chinese (simplified)

Cyrillic ANSI 1251 Russian

Note: Some of the characters cannot be input.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 1-3

1: G

Pulse motor

High-speed pulse input

Two-phase pulses

Rotary

encoder

SmartAXIS

ENERAL INFORMATION

Special Functions

This section describes the functions of the SmartAXIS.

I/O Related Functions

Catch Input

The catch input receives short input pulses from sensors without regard to the scan time. A maximum of 6 catch inputs can be

used.

Input Filter

The input filter can be adjusted, according to the width of input signals, to reject input noises. Selectable input filter v alues to pass

input signals are 0ms, and 3 through 15ms in 1ms increments. The input filter rejects inputs shorter than the selected input filter

value minus 2ms. This function is useful for eliminating input noises and chatter in limit switches.

Interrupt Input

The interrupt input can be used to call an interrupt program to respond to an external input that requires a response faster than

the scan time. A maximum of six interrupt inputs can be used. This can only be used when ladder program is selected as the

programming language.

Stop and Reset Inputs

Stop input is a function to stop SmartAXIS operation. Reset input is a function to stop SmartAXIS operation and clear device

values. Any input terminal on the SmartAXIS can be designated as a stop or reset input to control the SmartAXIS operation.

Remote I/O

When the number of SmartAXIS inputs and outputs is insufficient, the number of inputs and outputs can be expanded to a

maximum of 192 points by connecting additional SmartAXIS as remote I/O slaves over Ethernet. With the remote I/O function, the

analog inputs on the SmartAXIS that are connected as remote I/O slaves can also be used.

Analog Input

Analog input of 0 to 10V DC can be converted to a digital value of 0 to 1000. A maximum of eight inputs can be used as analog

inputs (not including remote I/O slaves analog inputs).

Forced I/O

The inputs and outputs of the SmartAXIS can be forced on or off. This function can be used to check the I/O wiring or the user

program operation.

Pulse I/O Functions

High-speed Counter

This function counts high-speed pulse inputs that cannot be measured in normal user program processing.

Use this function for applications such as positioning control with a rotary encoder or motor control. The SmartAXIS can use single-

phase high-speed counters and two-phase high-speed counters. A maximum of six single-phase high-speed counters and a

maximum of two two-phase high-speed counters can be used simultaneously.

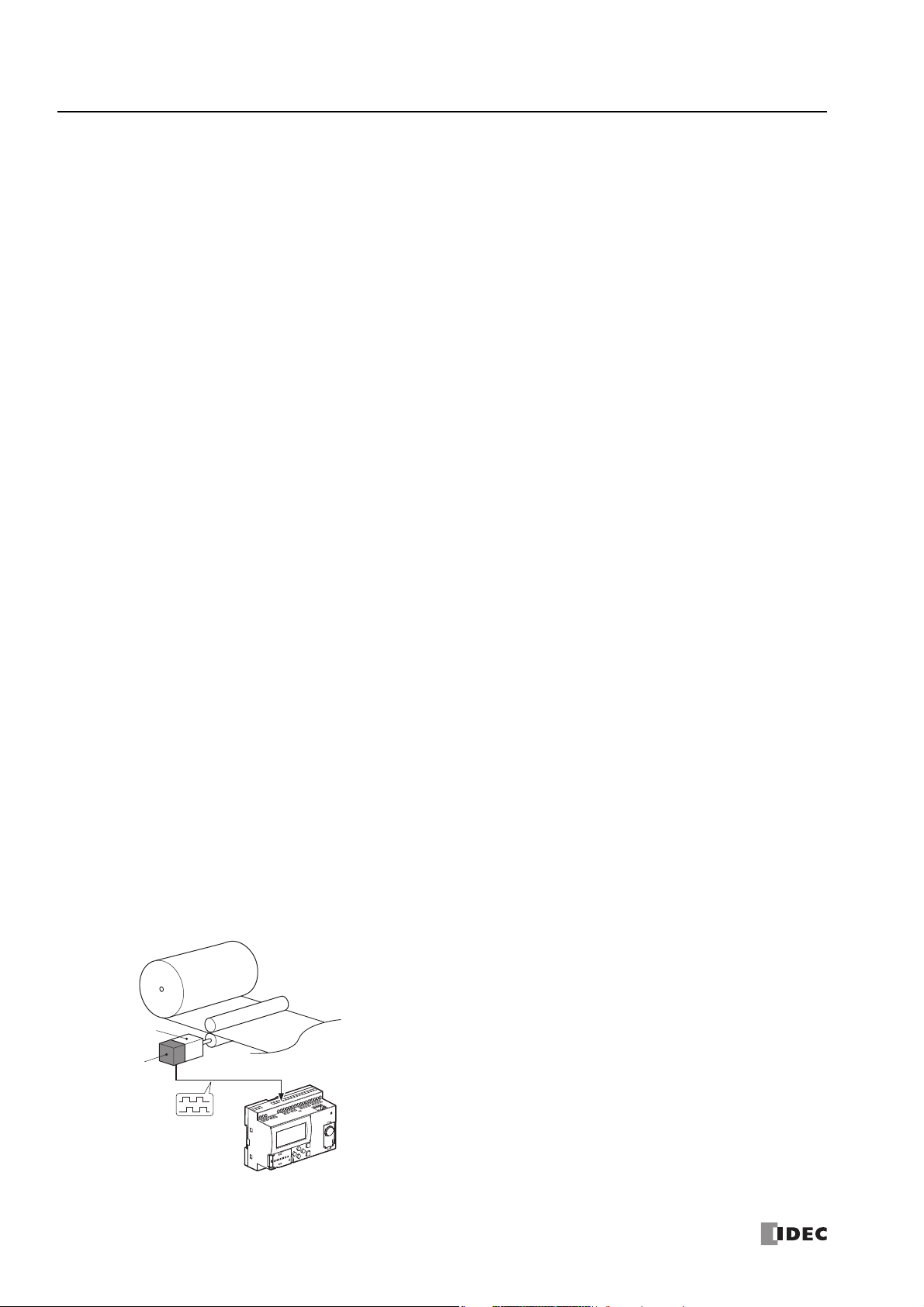

Example: Controlling a motor by counting two-phase pulse input with a high-speed counter

1-4 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

1: G

Steady pulse frequency

Initial pulse frequency

ENERAL INFORMATION

Positioning Control

The SmartAXIS can perform positioning control with pulse outputs. The SmartAXIS features the PULS instructions that can

generate pulse outputs with configured frequency at the fixed pulse width ratio, pulse-width modulation (PWM) instructions that

can generate pulse outputs with configured pulse width ratio at a fixed frequency, RAMP instructions for trapezoidal control, ZRN

instructions for zero return operation, and ARAMP instructions that can generate pulse outputs according to a table in which the

changes of the frequency are configured.

Example: Pulse output by the RAMP instruction

Frequency Measurement

This function measures the frequency of pulses input to an input terminal. The frequencies of a maximum of six inputs can be

measured.

Convenient Functions

Calendar/Clock

The SmartAXIS features a real-time clock on-board. Using the calendar and clock function, the SmartAXIS can operate according

to the current date and time. These functions can be used to control a time schedule for lighting or air conditioning equipments.

User Program Read/Write Protection

The user program in the SmartAXIS can be protected against reading and/or writing by including a password in the user program.

This function is effective for security of user programs.

“Keep” or “Clear” Designation of SmartAXIS Data

Internal relays, shift register bits, counter current values, and data register values can be designated to be kept or cleared when

the SmartAXIS is powered down. All or a specified range of these devices can be designated as keep or clear types.

RUN/STOP Selection at Startup when “Keep” Data is Lost

When the backup battery is dead, all data to be kept are lost. The user can select whether the SmartAXIS starts to run or not to

prevent undesirable operation at the startup.

Log Data

Device values of the SmartAXIS can be saved as CSV files on the SD memory card. The DLOG instruction saves device values to

the SD memory card. The TRACE instruction accumulates device values at each scan and saves them to the SD memory card at

the desired timing.

Constant Scan Time

The variations in scan time that occur when the user program is running can be made constant.

Timer Interrupt

The timer interrupt can be used to call an interrupt program at a predetermined interval of time without being affected by the scan

time. This can only be used when ladder program is selected as the programming language.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 1-5

1: G

Expansion communication ports

ENERAL INFORMATION

Communication Functions

The SmartAXIS features a variety of communication functions.

RS232C and RS485 communication of SmartAXIS is possible by installing the RS232C or RS485 communication cartridges into the

expansion communication ports on the SmartAXIS module. The 24-, 40-, and 48-I/O types also feature an Ethernet port as

standard, enabling communication over Ethernet.

Communication Functions

Maintenance Communication

(Chapter 9)

User Communication

(Chapter 10)

Modbus Communication

(Chapter 11)

Maintenance communication enables you to check th e operating status and I/O status of the SmartAXIS ,

monitor and change device values, and download and upload user programs using a computer or

operator interface.

The SmartAXIS can communicate with external devices equipped with RS232C, RS485, or Ethernet ports

using user communication. This can only be used when ladder program is selected as the programming

language.

The SmartAXIS can send and receive data with Modbus compliant devices on RS232C, RS485, or the

Ethernet port.

For details on the communications functions, refer to the chapter for each function.

Communication Ports

USB Port Maintenance communication can be performed by connecting the SmartAXIS and a computer with USB.

Ethernet Port

Expansion Communication

Ports

The SmartAXIS can communicate with Ethernet devices such as computers and operator interfaces .

Maintenance communication, user communication, Modbus communication, and remote I/O are possible.

Maintenance communication, user communication, and Modbus RTU communication are possible.

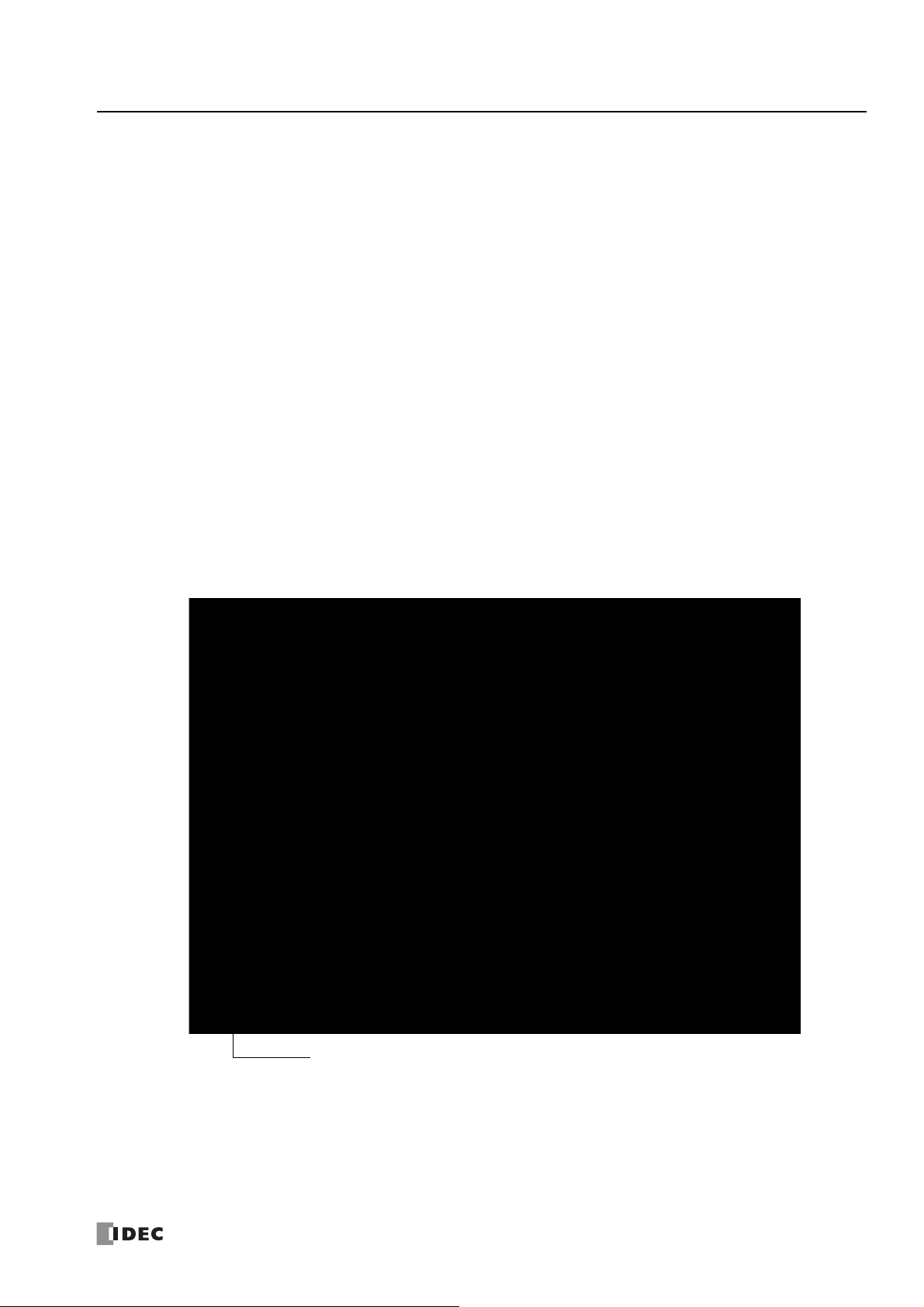

Expansion Communication Ports

The SmartAXIS can perform RS232C/RS485 communication by installing RS232C or RS485 communication cartridges to the

expansion communication ports on the SmartAXIS. The expansion communication ports are available on 24-, 40-, and 48-I/O

types.

Example: 40-I/O type

1-6 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

1: G

SmartAXIS

Windows computer

USB port

(USB 2.0 Mini-B connector)

USB maintenance cable

Type A plug

Mini-B plug

USB port

Windows computer

SmartAXIS SmartAXIS SmartAXIS

Ethernet hub

Ethernet port Ethernet portEthernet port

ENERAL INFORMATION

Maintenance Communication

The maintenance communication of the SmartAXIS enables you to check the operating status and I/O status of the SmartAXIS,

monitor and change device values, and download and upload user programs with the PLC programming software WindLDR

installed on a computer. For details on maintenance communication, see "Maintenance Communication" on page 9-1.

Supported ports: USB port, Ethernet port, and expansion communication ports

• 1:1 Maintenance Communication System

This example shows a 1:1 maintenance communication system in which a SmartAXIS and a computer are connected with USB.

The USB maintenance cable (HG9Z-XCM42) is used.

• 1:N Maintenance Communication System

This example shows a 1:N maintenance communication system in which three SmartAXIS and a computer are connected over

Ethernet. The Ethernet cables are connected t o the Etherne t ports of thr ee SmartAXIS, and those SmartAXIS are connected to the

computer via an Ethernet hub.

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 1-7

1: G

Expansion communication

port

RS232C communication

cartridge (FT1A-PC1)

Barcode reader

SmartAXIS

INVERTER

RUN

RVS

ALM

COM

Shielded twisted-pair cable

Te mperature controller Inverter

Expansion

communication

port

RS485 communication

cartridge

(FT1A-PC3)

SmartAXIS

ENERAL INFORMATION

User Communication

The user communication of the SmartAXIS enab les you to control external devices such as computers, printers, and barcode

readers. For details on user communication, see "User Communication Instructions" on page 10-1.

Supported ports: Ethernet port and expansion communication ports

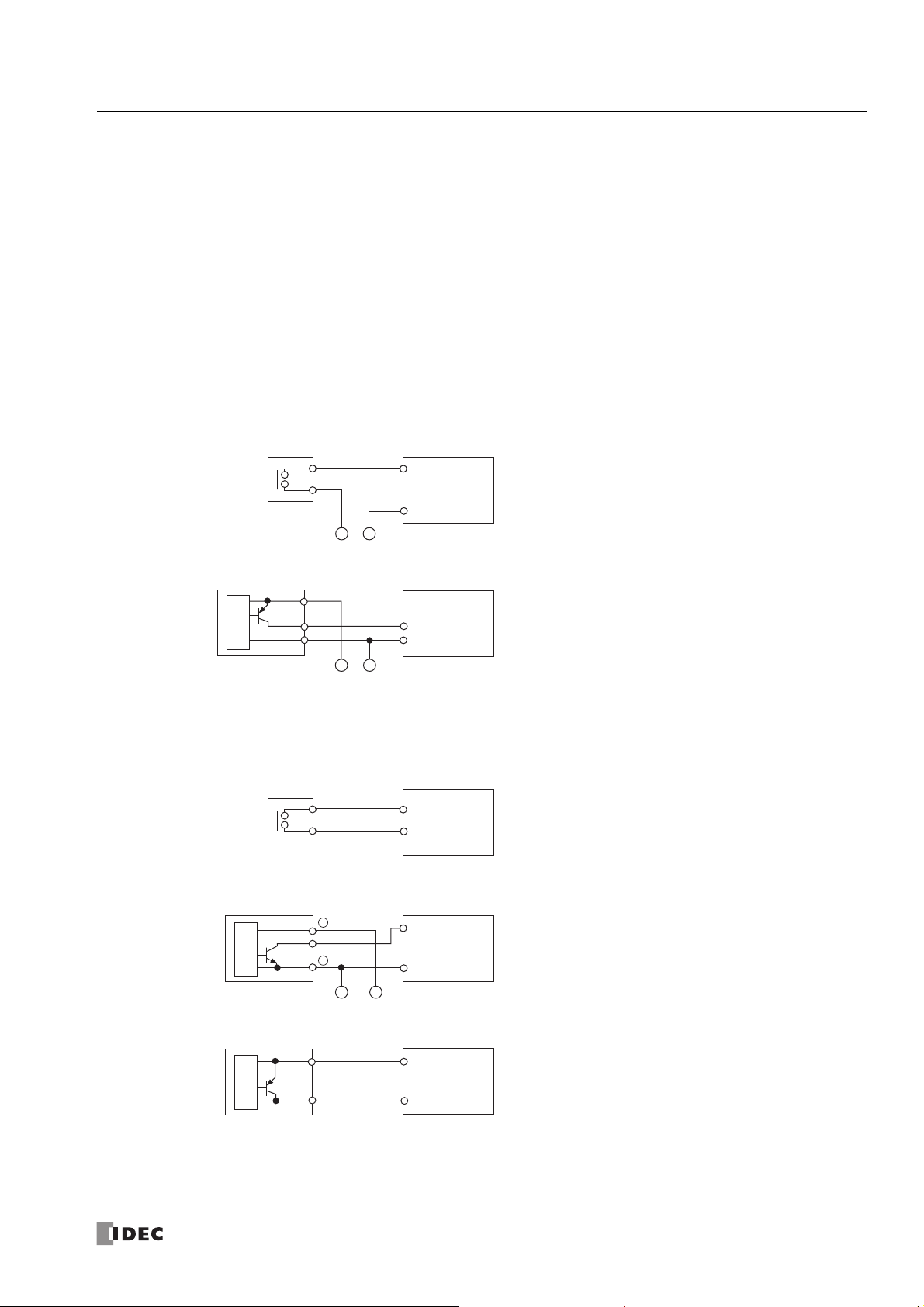

• User Communication on RS232C

This example shows a system in which a SmartAXIS receives the data read by a barcode reader. The RS232C communication

cartridge (FT1A-PC1) is installed in a SmartAXIS expansion communication port, and then the barcode reader is connected to the

RS232C port.

Modbus Communication

The SmartAXIS is compliant with Modbus protocol and can be used as either a Modbus communication master or slave. When

used as a Modbus master, the SmartAXIS can monitor and modify the data of Modbus compliant devices, such as inverters and

temperature controllers, using Modbus communication.

For details on Modbus communication, see "Modbus Communication" on page 11-1.

Supported ports: Ethernet port and expansion communication ports

• Modbus Communication on RS485

This example shows a system in which a SmartAXIS is communicating with a temperature controller and an inverter that support

Modbus RTU. The RS485 communication cartridge (FT1A-PC3) is installed in an expansion communication port on the SmartAXIS.

1-8 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

1: G

Ethernet hub

Master

48-I/O type

48-I/O type (master) + 48-I/O type (slave) + 48-I/O type (slave)

(30 inputs, 18 outputs)+ (30 inputs, 18 outputs) + (30 inputs, 18 outputs)

= 90 inputs, 54 outputs

Slave

48-I/O type

Slave

48-I/O type

Ethernet port Operator interface Windows computerSmartAXISSmartAXIS

Ethernet Hub Ethernet Hub

Ethernet

ENERAL INFORMATION

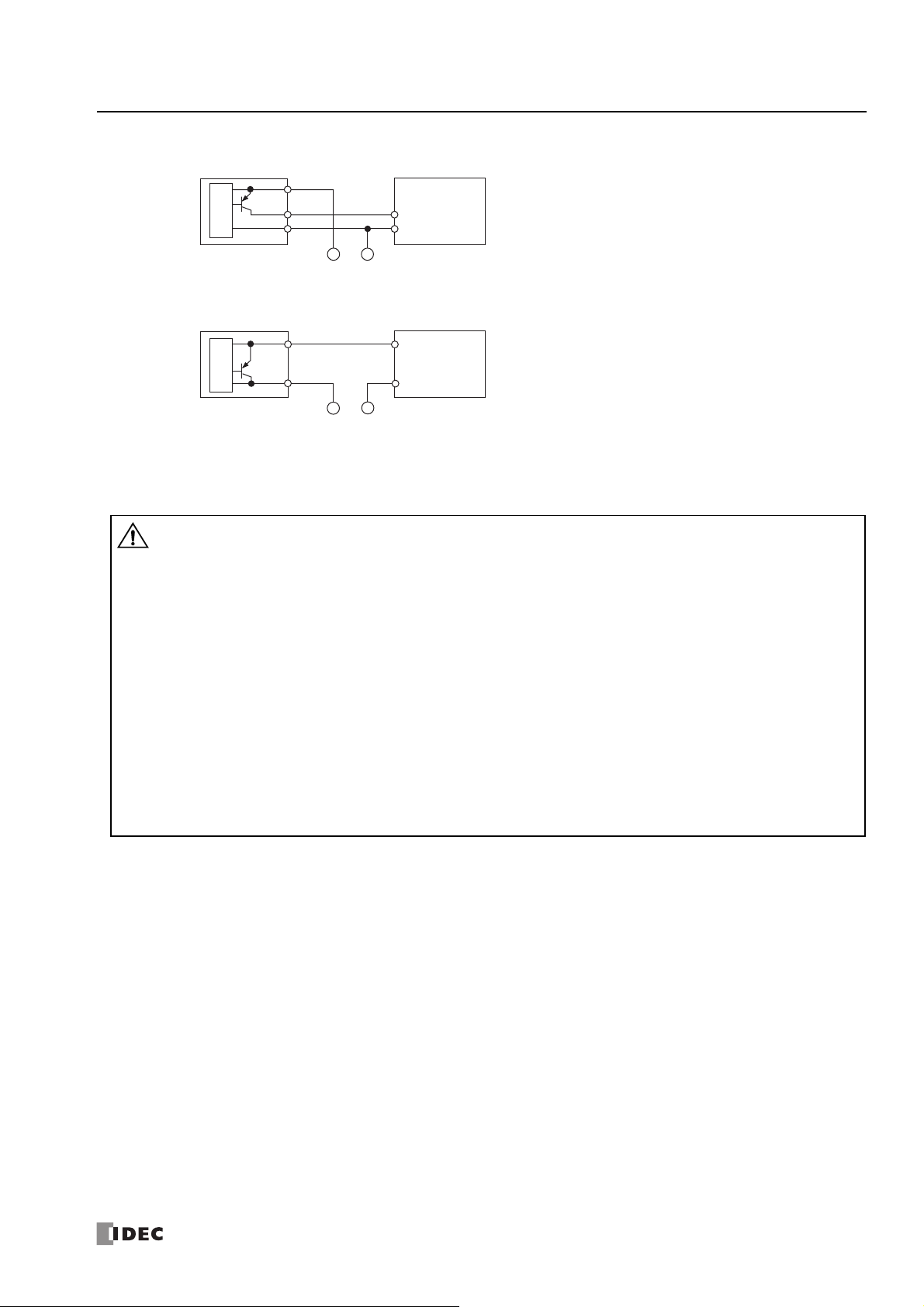

Remote I/O

The remote I/O of the SmartAXIS enables you to expand the number of inputs and outputs by connecting separate SmartAXIS

modules over Ethernet as remote I/O slaves when you run out of inputs and outputs. The SmartAXIS remote I/O master can use

the digital inputs and outputs and analog inputs on the remote I/O slaves.

This function can be used on the Ethernet port only . Remote I/O cannot be used with the expansion communication ports (RS232C

and RS485).

• Remote I/O System Example

A SmartAXIS is connected to an Ethernet network as a remote I/O master. Two other SmartAXIS are used as remote I/O slaves.

Up to a maximum of 3 SmartAXIS can be connected to a remote I/O master as remote I/O slaves.

Ethernet Communication

The SmartAXIS can be connected to the Ethernet network via Ethernet port and communicat e with network devi ces ov er Ethe rnet.

The SmartAXIS has three TCP/IP connections that can be used for Ethernet communication functions. Each of these connections

can simultaneously be used for a different communication protocol. Each connection can be configured for maintenance

communication, user communication, Modbus TCP, or remote I/O master.

• Ethernet Communication Example

This example shows a system in which a SmartAXIS communicates with another SmartAXIS, an operator interface, and a

computer simultaneously over Ethernet. Among the three connections the SmartAXIS has, Connection

maintenance communication for the computer to communicate with the SmartAXIS. Connection 2 is configured as Modbus TCP

server for the operator interf ace to communicate with the SmartAXIS. Connection 3 is configured as the remote I/O master to

communicate with another SmartAXIS.

Notes:

• When accessing the SmartAXIS over the Internet, adequate safety measures are required. Be sure to consult your network administrator or

Internet service provider. IDEC bears no responsibility for damages or problems caused due to security in Ethernet communication.

• Restrict the access to SmartAXIS with IP addresses and ports by using appropriate measures such as the firewall.

1 is configured as

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 1-9

1: G

O/I communication cable

For RS232C: FC4A-KC1C/FC4A-KC2C

For RS485: FC2A-KP1C (open end at operator interface side)

Operator interface

SmartAXIS

Expansion communication ports

RS232C communication cartridge

(FT1A-PC1)

RS485 communication cartridge

(FT1A-PC3)

ENERAL INFORMATION

Operator Interface Connectivity

The SmartAXIS can perform maintenance communication with IDEC operator interfaces using the Ethernet port and expansion

communication ports. Device values of the SmartAXIS can be monitored and modified with the connected operator interface. An

Ethernet cable or an O/I communication cable (see Note) is used to connect the SmartAXIS and the operator interface.

For details on communication settings, refer to the operator interface manuals.

Note: For details on O/I communication cables, see "Cables" on page A-8.

1-10 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

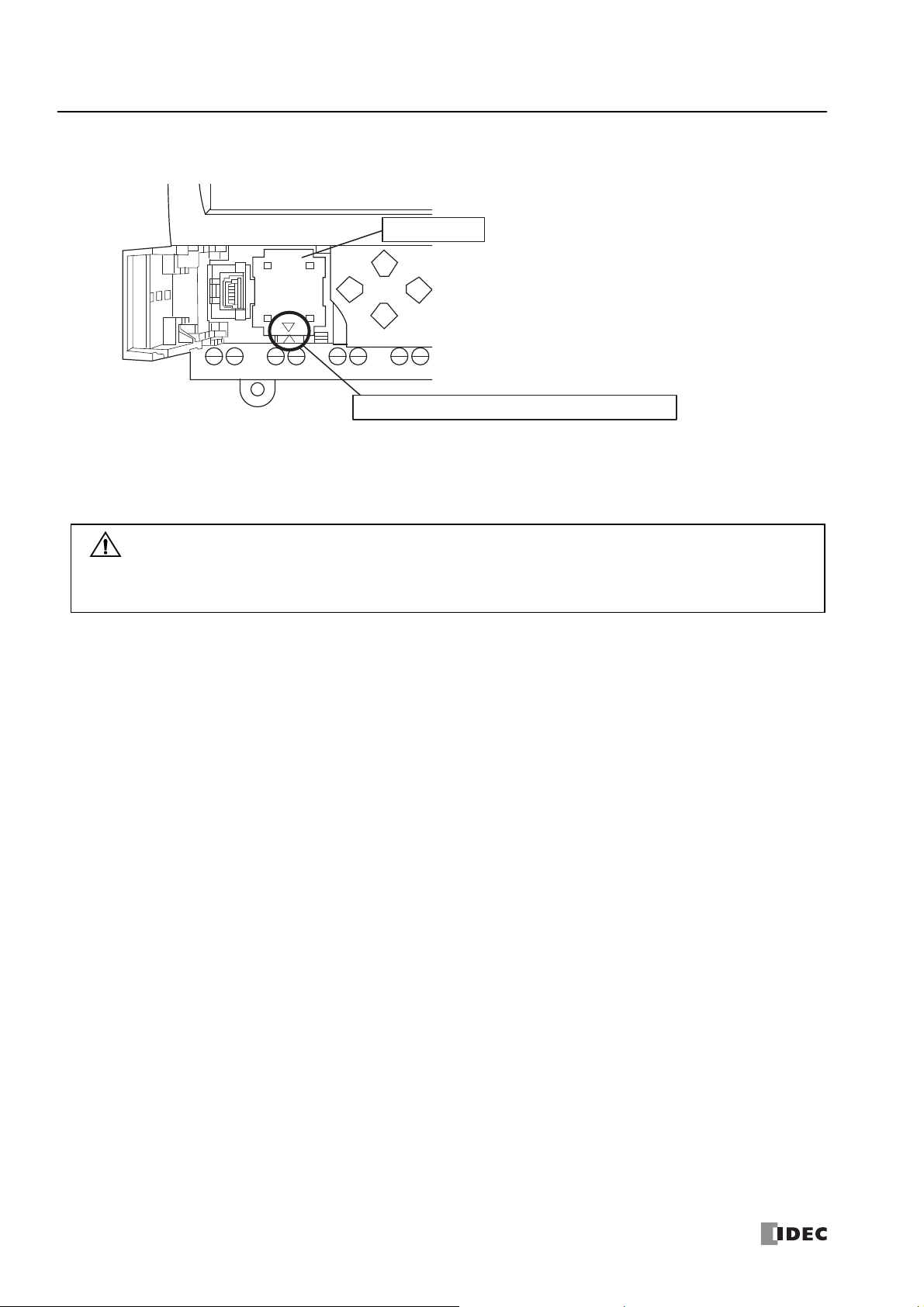

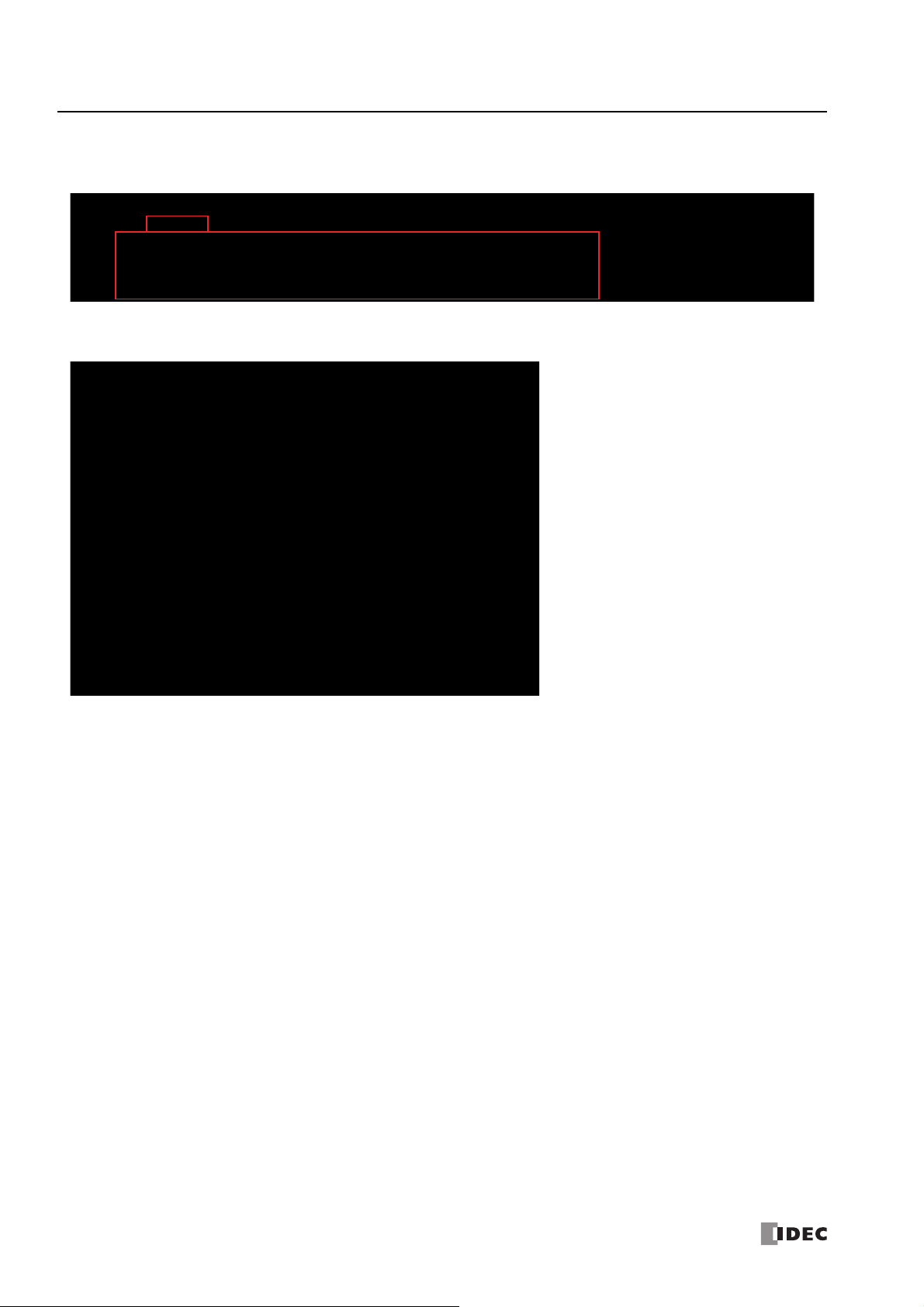

2: P

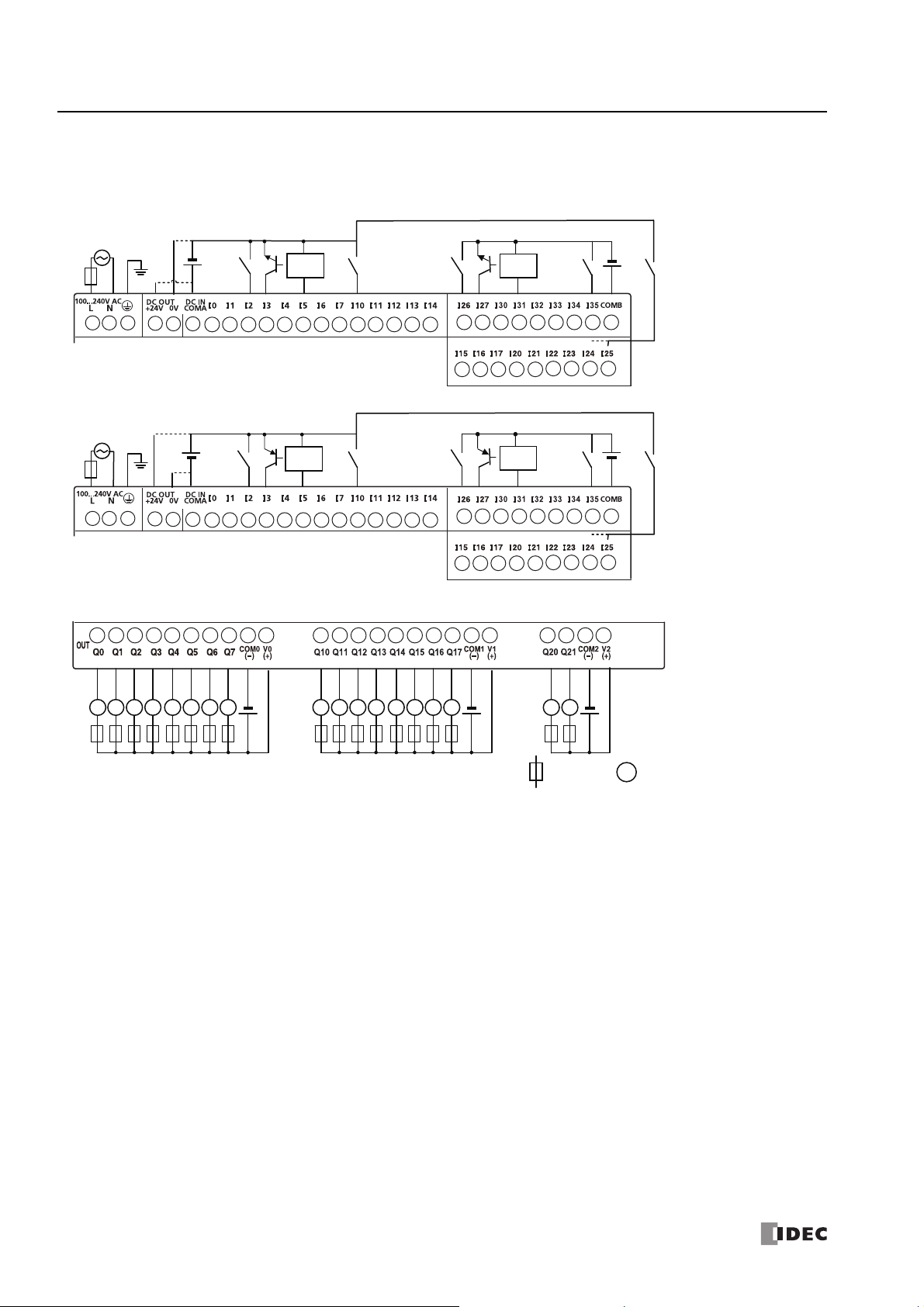

(2) Input Terminals

(1) Power Supply Terminals

(14) LCD

(9) SD Memory Card Slot

(13) Operation Buttons

(12) USB Port (USB 2.0 Mini-B Connector)

(11) Memory Cartridge Connector

(4) Ethernet Status LED [Ethernet]

(5) SD Memory Card Status LED

[SD Access]

(10) USB Port Cover

(17) Sensor Power Terminals

(3) Ethernet Port

(7) Expansion Communication Port (Port 3)

(6) Expansion Communication Port (Port 2)

(8) Output Terminals

SmartAXIS Pro

Example: FT1A-H48KA

(15) Power/Run Status LED

[PWR/RUN]

(16) Error Status LED [ERR]

SmartAXIS Lite

Example: FT1A-B48KA

RODUCT

S

PECIFICATIONS

Introduction

This chapter describes part names and specifications of the SmartAXIS.

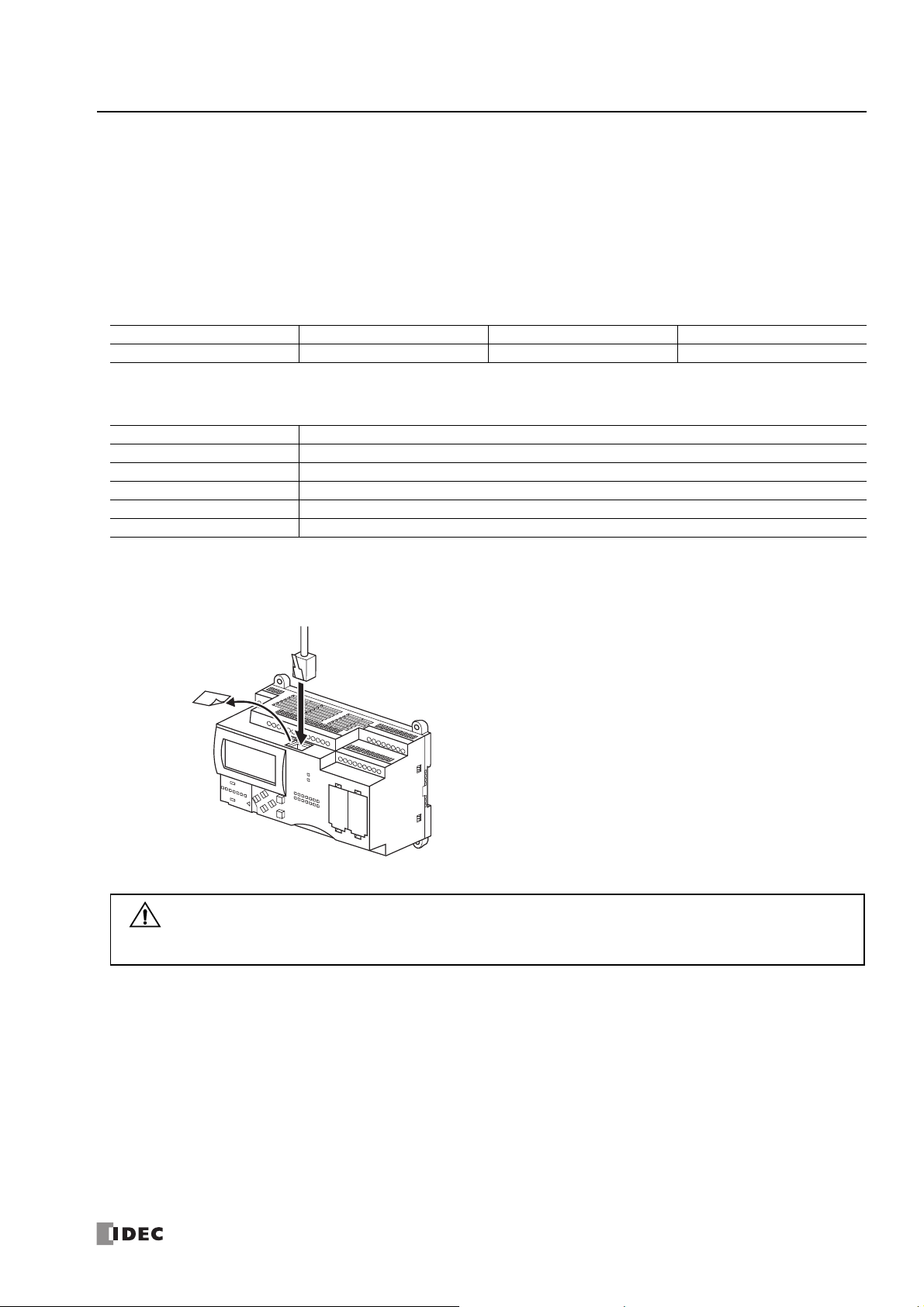

SmartAXIS is available in 12-, 24-, 40-, and 48-I/O types. The 12-I/O type has 8 input and 4 output terminals, the 24-I/O type has

16 input and 8 output terminals, the 40-I/O type has 24 input and 16 output terminals, and the 48-I/O type has 30 input and 18

output terminals. The 24-, 40-, and 48-I/O types have 1 or 2 port connectors to install an optional RS232C or RS485

communication cartridge for maintenance communication, user communication, or Modbus RTU communication. The 24-, 40-, and

48-I/O types have built-in Ethernet port for maintenance communication, user communication, Modbus TCP, or Remote I/O. The

40- and 48-I/O types have SD memory card slot to install an SD memory card for logging the device data. Every type of SmartAXIS

has a cartridge connector to install an optional memory ca rtr id ge.

Parts Description

(1) Power Supply Terminals

(2) Input Terminals

Connect power supply to these terminals.

For connecting input signals from input devices such as sensors and pushbuttons.

DC power type can use high-speed input of up to 100 kHz and 0 to 10V DC analog input, which is shared with digital input.

S

MART

AXIS PRO/L

The text in square brackets is printed on the SmartAXIS to describe LED.

ITE USER'S MANUAL

FT9Y-B1378 2-1

2: P

RODUCT SPECIFICATIONS

(3) Ethernet Port

This port is used for Ethernet connection. An Ethernet cable can be connected to enable the SmartAXIS to communicate with

network devices, such as computers or PLCs. Not available on the 12-I/O type.

(4) Ethernet Status LED [Ethernet]

Turns on or blinks when an Ethernet cable is connected to the SmartAXIS and the SmartAXIS communicates with network

devices. Not available on the 12-I/O type.

Ethernet Status LED Status

OFF Ethernet cable is not connected.

ON Ethernet cable is connected and communication is possible.

Flashing Ethernet cable is connected and data is being sent or received.

(5) SD Memory Card Status LED [SD Access]

Turns on or blinks when the SD memory card is being accessed. Not available on the 12- or 24-I/O type.

SD Memory Card Status LED Status

• When the SD memory card is not inserted

OFF

ON The standby state where the SD memory card can be written or read

Slow Flash (1-sec interval)

Quick Flash (100ms interval) Reading or writing to the SD memory card

• When an unsupported or unformatted SD memory card was inserted

• When access to the SD memory card was stopped by SD memory card access stop flag (M8076)

• When the SmartAXIS power is off

• When the SmartAXIS is recognizing the SD memory card

• When the SmartAXIS is stopping access due to SD memory card access stop flag (M8076)

turning on (slow flashing, then off)

(6) Expansion Communication Port (Port2)

(7) Expansion Communication Port (Port3)

This port is used to install a communication cartridge for communication with external devices. The 24-I/O type has one

expansion communication port while the 40- and 48-I/O types have two. Not available on the 12-I/O type.

(8) Output Terminals

For connecting output signals to output devices such as electromechanical relays and solenoid valves. Relay output (10A and

2A types) and transistor output (sink/source) are available.

(9) SD Memory Card Slot

Insert SD memory card to this slot. Not available on the 12- or 24-I/O type.

(10) USB Port Cover

Protects the USB port and the memory cartridge. If the pa nel mount USB extension c able is to be connec ted permanent ly, it

can be secured to the USB port cover using a cable tie.

(11) Memory Cartridge Connector

For connecting an optional memory cartridge.

(12) USB Port

A Mini-B type USB 2.0 connector. A USB maintenance cable or panel mount USB extension cable can be attached and

connected to a PC to download and upload user programs using WindLDR.

(13) Operation Buttons

For operating the menus displayed on the LCD to access functions. There are six operation buttons: [ ], [ ], [ ],

[ ], [OK], and [ESC].

Not available on the SmartAXIS Lite.

(14) LCD

Displays operation menus, status, and setting of the SmartAXIS. Not available on the SmartAXIS Lite.

2-2 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

(15) Power/Run Status LED [PWR/RUN]

A green LED that turns on or flashes to indicate the power supply and operation status.

Power/Run Status LED Status

OFF Power is not supplied.

ON Power is supplied and the user program is being executed.

Slow Flash (1-sec interval) Power is supplied and the user program is stopped.

Not available on the SmartAXIS Pro .

(16) Error Status LED [ERR]

A red LED that turns on if an error occurs.

Error Status LED Status

OFF Normal operation

ON An error has occurred.

Slow Flash (1-sec interval) The SmartAXIS is running and the forced I/O function is enabled.

Quick Flash (100 ms interval) The user program is stopped and the forced I/O function is enabled.

Not available on the SmartAXIS Pro .

(17) Sensor Power Terminals

For supplying power to sensors (24V DC). Not available on the DC power type.

2: P

RODUCT SPECIFICATIONS

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 2-3

2: P

RODUCT SPECIFICATIONS

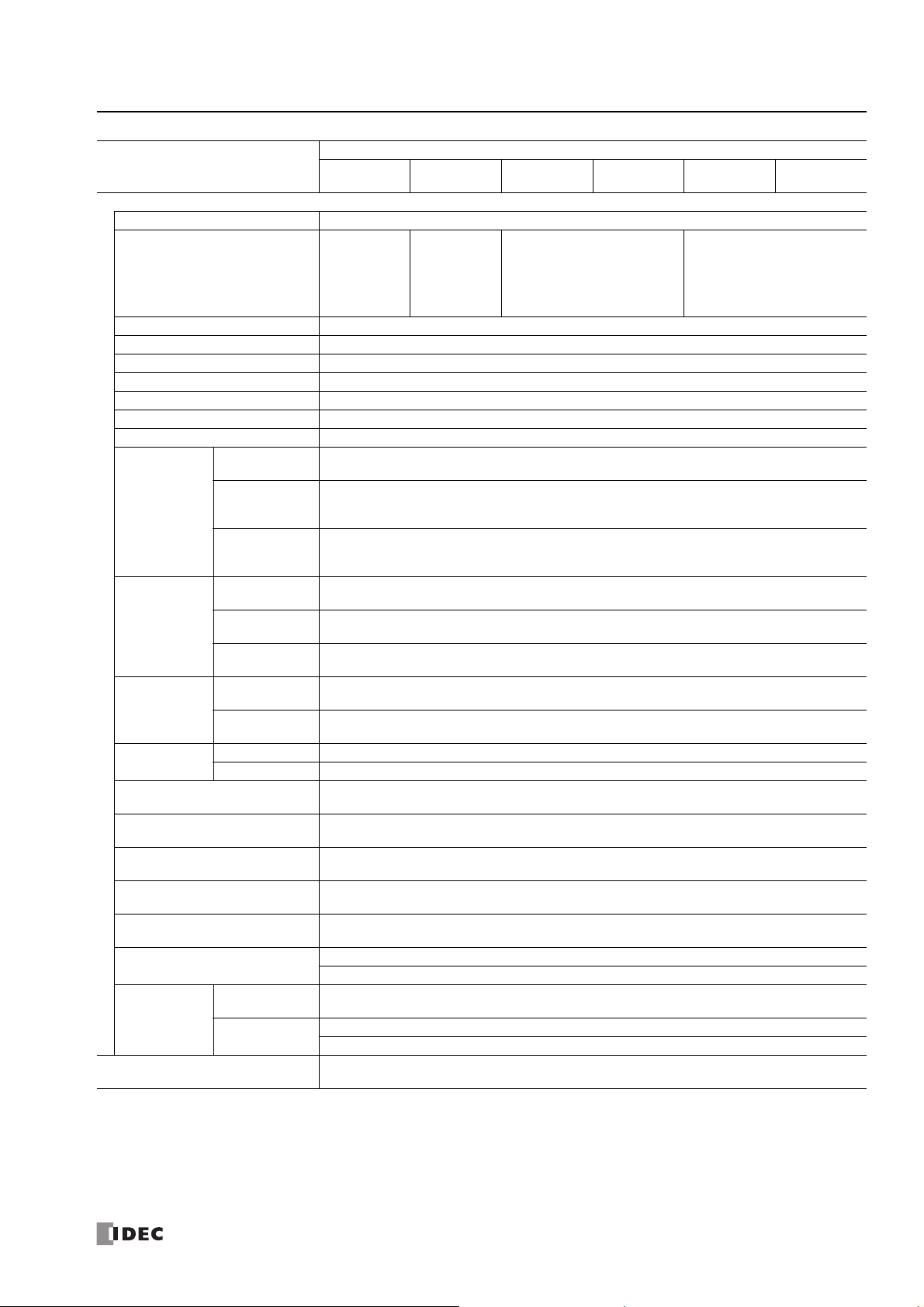

General Specifications

AC Power Type

FT1A-

Type Number

Normal Operating Conditions

Operating Temperature 0 to +55°C (operating ambient temperature) (Note 2)

Storage Temperature –25 to +70°C (no freezing)

Relative Humidity 10 to 95% (non-condensing, operating and storage humidity)

Pollution Degree 2 (IEC60664-1)

Degree of Protection IP20 (IEC60529)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Installation Location Inside cabinet (Note 1)

Device Class Open equipment

Overvoltage Category II

Vibration Resistance

Shock Resistance 147 m/s2 (15G), 11ms duration, 3 shocks per axis on three mutually perpendicular axes

Power Supply (Note 3)

Rated Power Voltage 100 to 240V AC

Allowable Voltage Range 85 to 264V AC

Rated Power Frequency 50/60Hz (47 to 63Hz)

Maximum Power Consumption 18VA 41VA 48VA 43VA

Allowable Momentary Power Interruption 10ms maximum (at the rated power voltage)

Dielectric Strength Voltage

EMC Immunity IEC/EN 61131-2:2007 compliant

Inrush Current 35A maximum (Cold start with Ta = 25°C, 200V AC)

Ground D-type ground (Class 3 ground)

Grounding Wire UL1007 AWG16

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Effect of Improper Power Supply

Connection

Weight Approx. 230g Approx. 400g Approx. 580g Approx. 540g

Note 1: Use in environments that satisfy product specifications.

Note 2: UL, c-UL Listed at 0 to +50°C (FT1A Version V110).

Note 3: Supports input/output overvoltage protection. When ov ervoltage pro tection occurr ed, the power supply output is shu t off. In this situation,

shut off the AC input, wait for one minute or longer, and then turn on the AC input again.

H12RC, B12RC H24RC, B24RC H40RC, B40RC

Operation: 0 to 2,000m (0 to 6,565 feet)

Transport: 0 to 3,000m (0 to 9,840 feet)

When mounted on a DIN rail or panel surfac e:

5 to 8.4Hz amplitude 3.5mm, 8.4 to 150Hz acceleration 9.8m/s2 (1G)

2 hours per axis on each of three mutually perpendicular axes

Between power and PE terminals: 1,500V AC, 1 minute

Between input and PE terminals: 1,500V AC, 1 minute

Between transistor output and PE terminals: 1,500V AC, 1 minute

Between relay output and PE terminals: 2,300V AC, 1 minute

Between power and input terminals: 1,500V AC, 1 minute

Between power and transistor output terminals: 1,500V AC, 1 minute

Between power and relay output terminals: 2,300V AC, 1 minute

Between input and transistor output terminals: 1,500V AC, 1 minute

Between input and relay output terminals: 2, 300V AC, 1 minute

Reverse polarity: Normal operation

Improper voltage or frequency: Permanent damage may be caused

Improper lead connection: Permanent damage may be caused

H48KC, H48SC

B48KC, B48SC

2-4 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

2: P

RODUCT SPECIFICATIONS

DC Power Type

FT1A-

Type Number

Normal Operating Conditions

Operating Temperature 0 to +55°C (operating ambient temperature) (Note 2)

Storage Temperature –25 to +70°C (no freezing)

Relative Humidity 10 to 95% (non-condensing, operating and storage humidity)

Pollution Degree 2 (IEC60664-1)

Degree of Protection IP20 (IEC60529)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Installation Location Inside cabinet (Note 1)

Device Class Open equipment

Overvoltage Category II

Vibration Resistance

Shock Resistance 147m/s

Power Supply

Rated Power Voltage 24V DC

Allowable Voltage Range 20.4 to 28.8V DC (Including ripple voltage)

Maximum Power Consumption 4.3W 4.8W 7.9W 6.0W

Allowable Momentary Power Interruption 10ms maximum (Rated voltage, PS2)

Dielectric Strength Voltage

EMC Immunity IEC/EN 61131-2:2007 compliant

Inrush Current 30A maximum

Ground D-type ground (Class 3 ground)

Grounding Wire UL1007 AWG16

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Effect of Improper Power Supply

Connection

Weight Approx. 190g Approx. 310g Approx. 420g Approx. 380g

Note 1: Use in environments that satisfy product specifications.

Note 2: UL, c-UL Listed at 0 to +50°C (FT1A Version V110).

H12RA, B12RA H24RA, B24RA

Operation: 0 to 2,000m (0 to 6,565 feet)

Transport: 0 to 3,000m (0 to 9,840 feet)

When mounted on a DIN rail or panel surface:

5 to 8.4Hz amplitude 3.5 mm, 8.4 to 150Hz acceleration 9.8m/s

2 hours per axis on each of three mutually perpendicular axes

2

(15G), 11 ms duration, 3 shocks per axis on three mutually perpendicular axes

Between power/input and FE terminals: 500V AC, 1 minute

Between transistor output and FE terminals: 500V AC, 1 minute

Between relay output and FE terminals: 2,300V AC, 1 minute

Between power/input and transistor output terminals: 500V AC, 1 minute

Between power/input and relay output terminals: 2,300V AC, 1 minute

Reverse polarity: No operation, no damage

Improper voltage or frequency: Permanent damage may be caused

Improper lead connection: Permanent damage may be caused

H40RKA, H40RSA

B40RKA, B40RSA

2

(1G)

H48KA, H48SA

B48KA, B48SA

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 2-5

2: P

RODUCT SPECIFICATIONS

Function Specifications

Function Specifications

FT1A-

Type Number

Program

Capacity

(Note 1)

Number of

Function

Blocks (Note 2)

Input

Points

Digital Input

(Terminal No.)

Shared Analog Input

(Terminal No.)

Output Points 48 1618

10A Relay Output

(Terminal No.)

2A Relay Output

(Terminal No.)

Transistor Output

(Terminal No.)

User Program Storage Flash ROM (10,000 rewriting life)

Backup Function

RAM

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Battery Lithium secondary battery

Charging Time Approx. 15 hours for charging from 0% to 90% of full charge

Battery Life 5 years in cycles of 9-hour charging and 15-hour discharging

Replaceability Not possible to replace battery

Clock Function (Note 4) Clock accuracy: ±30 sec/month (typical) at 25°C

Control System Stored program system

Instruction Words (Ladder)

Basic Instructions 42

Advanced Instructions 99 107 DC type: 125, AC type: 111

Function Block (FBD)

Function Blocks 45

Processing Time

Ladder

FBD

Internal Relay 1024

Shift Register 128

Ladder

FBD 10,000 bytes 38,000 bytes

Block (B) 200 1,000

Timer (T) 100 200

Counter (C) 100 200

Basic Instruction 0.95 ms (1000 steps)

END Processing 640 s

Logical

Operation FB

Execution Time

Scan End

Processing

H12RA

B12RA

12,000 bytes

(3,000 steps)

6

(I0 to I5)8(I0 to I7)

2

(I6, I7)

Backup data: Internal relay, shift register, counter current value, data register (Note 3), clock data (year,

month, and day)

1.3 ms

(100 FBs)

1 ms

H12RC

B12RC

8162430

—

—

——

H24RA

B24RA

12

(I0 to I7,

I10 to I13)

4

(I14 to I17)

(Q0 to Q3)

(Q4 to Q7)

H24RC

B24RC

16

(I0 to I7,

I10 to I17)

—

4

4

H40RKA

H40RSA

B40RKA

B40RSA

47,400 bytes

(11,850 steps)

18

(I0 to I7,

I10 to I17,

I20, I21)

6

(I22 to I27)

8

(Q4 to Q7,

Q10 to Q13)

4

(Q14 to Q17)

H40RC

B40RC

24

(I0 to I7,

I10 to I17,

I20 to I27)

—

12

(Q4 to Q7,

Q10 to Q13,

Q14 to Q17)

—

H48KA

H48SA

B48KA

B48SA

22

(I0 to I7,

I10 to I17,

I20 to I25)

8

(I26, I27,

I30 to I35)

(Q0 to Q7, Q10 to Q17,

H48KC

H48SC

B48KC

B48SC

30

(I0 to I7,

I10 to I17,

I20 to I27,

I30 to I35)

—

—

—

18

Q20, Q21)

2-6 S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378

2: P

RODUCT SPECIFICATIONS

FT1A-

Type Number

Data Register

Counter (adding, reversible) 100 200

Timer (1-sec, 100ms,

10ms, 1ms)

Input Filter Without filter, 3 to 15ms (selectable in increments of 1ms)

Catch Input/Interrupt Input

Input Points 46

Self-diagnostic Function

High-speed Counter

Points

Maximum Counter

Frequency

Counting Range 0 to 4,294,967 ,295 (32 bits)

Operation Mode Rotary encoder mode and adding counter mode

Pulse Output (Maximum frequency: 100kHz)

Points —

Pulse Output (Maximum frequency: 5kHz)

Points —

Analog Voltage Input

Points (Terminal No.) 2 (I6, I7) —

Input voltage Range 0 to 10V DC

Digital Resolution 0 to 1000

USB

Port

Points 1

USB Standard USB 2.0

Connector Mini-B type

Expansion Communication Ports

Points —1 2

Ethernet Port

Points —1

Memory Cartridge Connectors

Points 1

SD Memory Card Slots

Points —1

Note1: 1 step is equivalent to 4 bytes.

Note2: When FBD program is selected as the programming language.

Note3: Among data registers D0 to D1999, only D0 to D999 are backed up.

Note4: Set the calendar/clock using WindLDR to use the clock function.

H12RA

B12RA

12-I/O type: 400

24-I/O type, 40-I/O type, 48-I/O type: 2,000

100 200

Keep data

Power failure

Clock error

Watchdog timer

Timer/counter preset value change error

User program syntax

User program execution

System error

Memory cartridge transfer error

Total

4 points

Single/two-phase

selectable: 100kHz

(2 points)

Single-phase: 100kHz

(2 points)

H12RC

B12RC

—

H24RA

B24RA

Total

6 points

Single/two-phase selectable: 100kHz (2 points)

Single-phase: 100kHz (4 points)

4

(I14 to I17)

H24RC

B24RC

—

—

H40RKA

H40RSA

B40RKA

B40RSA

Total

6 points

2

(Q14, Q15)

2

(Q16, Q17)

6

(I22 to I27)

H40RC

B40RC

—

—

—

—

H48KA

H48SA

B48KA

B48SA

Total

6 points

2

(Q14, Q15)

2

(Q16, Q17)

8 (I26, I27,

I30 to I35)

H48KC

H48SC

B48KC

B48SC

—

—

S

MART

AXIS PRO/L

ITE USER'S MANUAL

FT9Y-B1378 2-7

2: P

RODUCT SPECIFICATIONS

LCD Specifications (SmartAXIS Pro only)

Description/Specifications

Type STN monochrome LCD

Resolution 64 x 192 pixels

24 digits x 8 lines (8 x 8 pixel font)

Number of Characters

Display Content System menus, messages, operation status monitor

Contrast Adjustment Not possible

Backlight Yes (backlight can be turned on and off)

12 digits x 8 lines (16 x 8 pixel font)

12 digits x 4 lines (16 x 16 pixel font)

Input Specifications (AC Power Type)

FT1A-

Type Number

Input Points 8162430

Rated Input Voltage 24V DC

Input Voltage Range 0 to 28.8V DC

Terminal Arrangement See "Terminal Arrangement" on page 2-16.

Input External Power

Supply

Voltage Fluctuation

Range/Capacity (Note 1)

Digital Input

Input Type Contacts Sink/Source

Input Points

(Terminal No./

Common Line Name)

Rated Input Current 5.3mA

Input Impedance 4.3k

Turn ON Time 40 s + filter value

Turn OFF Time 150 s + filter value

Isolation

Input Type Type 1 (IEC61131-2)

Shared Digital/Analog

Inputs

Status

Display

External Load for I/O

Interconnection

Signal Determination

Method

Cable Length 100m in compliance with electromagnetic immunity

Effect of Improper

Input Connection

Note 1: When an overload state occurs such as a short circuit in the input external power supply, the power supplied to the internal circuit of the

SmartAXIS is stopped. When the overload state is cleared, the output automatically recovers.

Pro LCD display

Lite —

—

8 points in 1 common line

(I0 to I7/COM)

Between input terminals: Not isolated

Internal circuit: Photocoupler isolated

No

Not needed

Static

No damage. If any input exceeding the rated value is applied, permanent damage may be caused.

H12RC

B12RC

H24RC

B24RC

DC20.4 to 26.4V

250mA

16 points in 1 common

line

(I0 to I7, I10 to I17/COM)

H40RC

B40RC

DC20.4 to 26.4V

300mA

24 points in 1 common

line

(I0 to I7, I10 to I17, I20

to I27/COM)

DC20.4 to 26.4V

300mA

30 points in 2 common

lines

(I0 to I7, I10 to I17, I20

to I25/COMA, I26, I27,