FC6A SERIES

User’s Manual

B-1722(8)

SAFETY PRECAUTIONS

Warning

Read the "FC6A Series MICROSmart User’s Manual" to ensure correct operation before starting installation, wiring, operation, maintenance, and

inspection of the FC6A Series MICROSmart.

All FC6A Series MICROSmart modules are manufactured under IDEC’s rigorous quality control system, but users must add a backup or failsafe

provision to the control system when using the FC6A Series MICROSmart in applications where heavy damage or personal injury may be

caused, in case the FC6A Series MICROSmart should fail.

In this manual, safety precautions are categorized in order of importance:

Warning notices are used to emphasize that improper operation may cause severe personal injury or death.

The FC6A Series MICROSmart is not designed for use in applications requiring a high degree of reliability and safety. The FC6A Series

MICROSmart should not be used for such applications.

When using the FC6A Series MICROSmart in applications (not described above) that require a high degree of reliability in terms of functionality

and precision, appropriate measures such as failsafe mechanisms and redundant mechanisms must be taken for the system containing the

FC6A Series MICROSmart. The following are specific examples.

Emergency stop and interlocking circuits must be configured outside the FC6A Series MICROSmart.

If relays or transistors in the FC6A Series MICROSmart output circuits should fail, outputs may remain at on or off state. For output signals

which may cause serious accidents, configure monitor circuits outside the FC6A Series MICROSmart.

The FC6A Series MICROSmart self-diagnostic function may detect internal circuit or program errors, stop programs, and turn outputs off.

Configure circuits so that the system containing the FC6A Series MICROSmart is not jeopardized when outputs turn off.

Turn off power to the FC6A Series MICROSmart before installation, removal, wiring, maintenance, and inspection of the FC6A Series

MICROSmart. Failure to turn power off may cause damage, electrical shocks or fire hazard. If such a circuit is configured inside the FC6A Series

MICROSmart, Failure of the FC6A Series MICROSmart may cause disorder of the control system, damage, or accidents.

Special expertise is required to install, wire, program, and operate the FC6A Series MICROSmart. People without such expertise must not use

the FC6A Series MICROSmart.

Install the FC6A Series MICROSmart according to the instructions described in the "FC6A Series MICROSmart User’s Manual". Improper

installation will result in falling, failure, or malfunction of the FC6A Series MICROSmart.

Suitable for use in Class I,Division 2, Groups A,B,C and D Hazardous Locations, or Non-hazardous locations only.

Warning - Explosion Hazard - Do not disconnect equipment while the circuit is live or unless the area is known to be free of ignitable

concentrations.

Avertissement: Risque d'explosion. Ne pas débrancher tant que le circuit est sous tension, à moins qu'il ne s'agisse d'un emplacement non

dangereux

Warning - Explosion Hazard - Substitution of any components may impair suitability for Class I, Division 2.

Avertissement: Risque d'explosion. La substitution de composants peut rendre ce matériel inacceptable pour les emplacements de classe I,

division 2

This equipment is an open -type device meant to be installed in an enclosure suitable for the environment that is only accessible with the use of

a tool or key.

Warning - Explosion Hazard - The USB port is not for use in Hazardous Locations.

Avertissement: Risque d'explosion. Le port USB ne doit pas être utilisé dans des endroits angereux.

Preface-1 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

Caution notices are used where inattention might cause personal injury or damage to equipment.

Caution

The FC6A Series MICROSmart is designed for installation in a cabinet. Do not install the FC6A Series MICROSmart outside a cabinet.

Install the FC6A Series MICROSmart in environments described in the "FC6A Series MICROSmart User’s Manual". If the FC6A Series

MICROSmart is used in places where the FC6A Series MICROSmart is subjected to high-temperature, high-humidity, condensation, corrosive

gases, excessive vibrations, or excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

The environment for using the FC6A Series MICROSmart is "Pollution degree 2." Use the FC6A Series MICROSmart in environments of pollution

degree 2 (according to IEC 60664-1).

Prevent the FC6A Series MICROSmart from falling while moving or transporting the FC6A Series MICROSmart, otherwise damage or malfunction

of the FC6A Series MICROSmart will result.

Wiring must use lead sizes that are appropriate for the applied voltage and current. Terminal screws must be tightened with the prescribed

tightening torque.

Prevent metal fragments and pieces of wire from dropping inside the FC6A Series MICROSmart housing. Put a cover on the FC6A Series

MICROSmart modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

Use an IEC 60127-approved fuse on the power line outside the FC6A Series MICROSmart. This is required when equipment containing the FC6A

Series MICROSmart is destined for Europe.

Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the FC6A Series MICROSmart is destined for

Europe.

Use an EU-approved circuit breaker. This is required when equipment containing the FC6A Series MICROSmart is destined for Europe.

Make sure of safety before starting and stopping the FC6A Series MICROSmart or when operating the FC6A Series MICROSmart to force outputs

on or off. Incorrect operation of the FC6A Series MICROSmart may cause machine damage or accidents.

Do not connect the ground wire directly to the FC6A Series MICROSmart. Connect a protective ground to the cabinet containing the FC6A Series

MICROSmart using an M4 or larger screw. This is required when equipment containing the FC6A Series MICROSmart is destined for Europe.

Do not disassemble, repair, or modify the FC6A Series MICROSmart modules.

The FC6A Series MICROSmart contains electronic parts and batteries. When disposing of the FC6A Series

MICROSmart, do so in accordance with national and local regulations.

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 Preface-2

ABOUT THIS MANUAL

Thank you for purchasing the FC6A Series MICROSmart manufactured by IDEC Corporation.

This document describes the FC6A Series MICROSmart system configuration, specifications, and installation methods, and it

provides descriptions of the various functions.

Read this manual to ensure the correct understanding of the entire functions of the FC6A Series MICROSmart.

IDEC Corporation makes the latest product manual PDFs available on our website at no additional cost.

Please download the latest product manual PDFs from our website.

Product manual PDF download page (www.idec.com/FC6Amanuals)

This manual describes functions, specifications, installation, and operation basics of the FC6A Series MICROSmart. Also included is

information on the powerful communications tools of the FC6A Series MICROSmart, as well as troubleshooting procedures.

Chapter 1: General Information

General information about the FC6A Series MICROSmart functions and system configuration examples.

Chapter 2: Product Specifications

Specifications of the FC6A Series MICROSmart.

Chapter 3: Installation and Wiring

Methods and precautions for installing and wiring the FC6A Series MICROSmart.

Chapter 4: Operation Basics

General information about setting up the basic FC6A Series MICROSmart system for programming, starting and stopping the FC6A

Series MICROSmart operation, and simple operating procedures. Everything from creating a user program using WindLDR on a

computer to monitoring the FC6A Series MICROSmart operation.

Chapter 5: Functions and Settings

Functions of the FC6A Series MICROSmart and convenient functions that you should know about in using the WindLDR (Windows

compatible) PLC programming software.

Chapter 6: Devices

Descriptions of the allocations of devices such as inputs, outputs, internal relays, registers, timers, and counters that are used in

the basic and advanced instructions, as well as details about the allocations of special internal relays and special data registers.

Chapter 7: HMI Function

Functions that can be used with the HMI module connected to the CPU module and their operating procedures.

Chapter 8: Instructions Reference

List of basic and advanced instructions to program the FC6A Series MICROSmart and descriptions of their functions.

Chapter 9: Analog I/O Modules

Overview of each analog module and their specifications. Module parameters and configuration methods are also described.

Chapter 10: I/O Cartridges

Overview of the cartridges and their specifications. Cartridge parameters and configuration methods are also described.

Chapter 11: SD Memory Card

Functions that can be used with SD memory card connected to the CPU module and their specifications.

Chapter 12: Module Configuration Editor

Description of the module configuration editor that can be used to configure parameters for the modules and cartridges.

Chapter 13: Troubleshooting

Procedures to determine the cause of trouble and actions to be taken when any trouble occurs while operating the FC6A Series

MICROSmart.

Appendix

Additional information about type numbers, system software upgrade, and USB driver installation.

Index

Alphabetical listing of key words.

Publication history

December 2015 First Edition

February 2016 Second Edition

April 2016 Third Edition

March 2017 Fourth Edition

August 2017 Fifth Edition

December 2017 Sixth Edition

March 2018 Seventh Edition

November 2018 Eighth Edition

Trademarks

FC6A Series MICROSmart is a trademark of IDEC Corporation.

Preface-3 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

Regarding laws and compatible standards

This product adheres to the laws and compatible standards of all countries involved, as shown below.

European laws and standards

This product complies with the following EU directives.

Low Voltage Directive

RoHS Directive

RE Directive (FC6A-PC4 only)

To comply with these directives, this product has been designed and evaluated on the basis of the following international and

European standard.

IEC/EN 61131-2: 2007

EN50581:2012

EN301 489-1 V2.1.1& EN301 489-17 V2.1.1 (FC6A-PC4 only)

For details on the compatible standards and EU Directives, contact the distributor from which you purchased this product or visit our web site.

North America laws and standards

This product complies with the following standards.

UL508

UL61010-1

UL61010-2-201

CSA C22.2 No.142

CSA C22.2 No.61010-1

CSA C22.2 No.61010-2-201

ANSI/ISA 12.12.01

CAN/CSA C22.2 No.213

*1 Certain FC6A Series MICROSmart models are not compatible. For details about applicable standards, please contact IDEC Corporation.

Chinese laws and standards

The FC6A-PC4 complies with the following certification.

SRRC

Marine standards

This product has been certified by the following classification societies.

(Applications have been submitted for certain models.)

ABS (American Bureau of Shipping)

DNV GL (Det Norske Veritas·Germanischer Lloyd)

LR (Lloyd's Register)

NK (Nippon Kaiji Kyokai)

* This product has not been certified for use on the bridge or deck.

For details on applicable standards and EU directives, please contact the dealer where purchased or check the IDEC website.

*1

*1

*1

*1

*1

*1

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting from

the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 Preface-4

ABOUT THE WARRANTY OF THE PRODUCTS

1. Warranty Period

The Products are warranted for 3 years from the date of purchase, or from the date of delivery completion.

* Consumable/maintenance parts such as batteries and relays if the operation exceeds 100,000 times are excluded from

the 3-year warranty.

2. Extent of Warranty

IDEC CORPORATION is responsible for failures or defects of the Products during the above warranty period, either a

replacement part will be provided or the defective parts of the Products will be repaired free of charge. If such failure or

defects should occur, please offer them to the distributor, dealer or IDEC CORPORATION with the materials in which the date

of purchase is specified.

* The expenses for installation and construction at the time of repair will not be borne.

3. Start

May 1, 2017. The Products which were produced after June 1, 2014 and purchased in last three years will also be warranted.

4. Indemnification

IDEC CORPORATION will not be liable under this Warranty and be indemnified and held harmless from any and all demands,

suits, expenses, claims, damages and liabilities in the following event that:

1) The Products are used or operated beyond the conditions or environment range as described in catalog, specifications

or instruction; or

2) The failure or defects of the Products arise from the cause other than the Products; or

3) The Products are improved, modified or altered by the party other than IDEC; or

4) The failure or defects and damages of the Products arise from the usage of the Product in the way that is not

intended; or

5) The failure or defects and damages of the Products arise from the cause beyond IDEC’s control including, but not

limited to, fire, earthquake, flood, lightning, other natural disasters, and acts of God; or

6) The failure or defects and damages of the Products arise from the relocation, transportation or drop after you

purchase the Products; or

7) The failure or defects and damages of the Products arise from improper installation; or

8) Maintenance and inspection are not carried out in accordance with instruction.

IDEC CORPORATION DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

USE OR PURPOSE, AS WELL AS LIABILITY FOR INCIDENTAL, SPECIAL, INDIRECT, CONSEQUENTIAL OR OTHER DAMAGES

RELATING TO THE PRODUCTS

5. Extent of Service

The price of the Products will not include the fee for any service such as sending technicians and engineers, IDEC

CORPORATION will charge you the fee for the following:

1) Instruction for installment and visiting for test operation, including, but not limited to creating application software

and operation tests; and

2) Maintenance and inspection, arrangement and repair; and

3) Technical assistance and technical education; and

4) Product test and inspection based on you request.

Preface-5 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

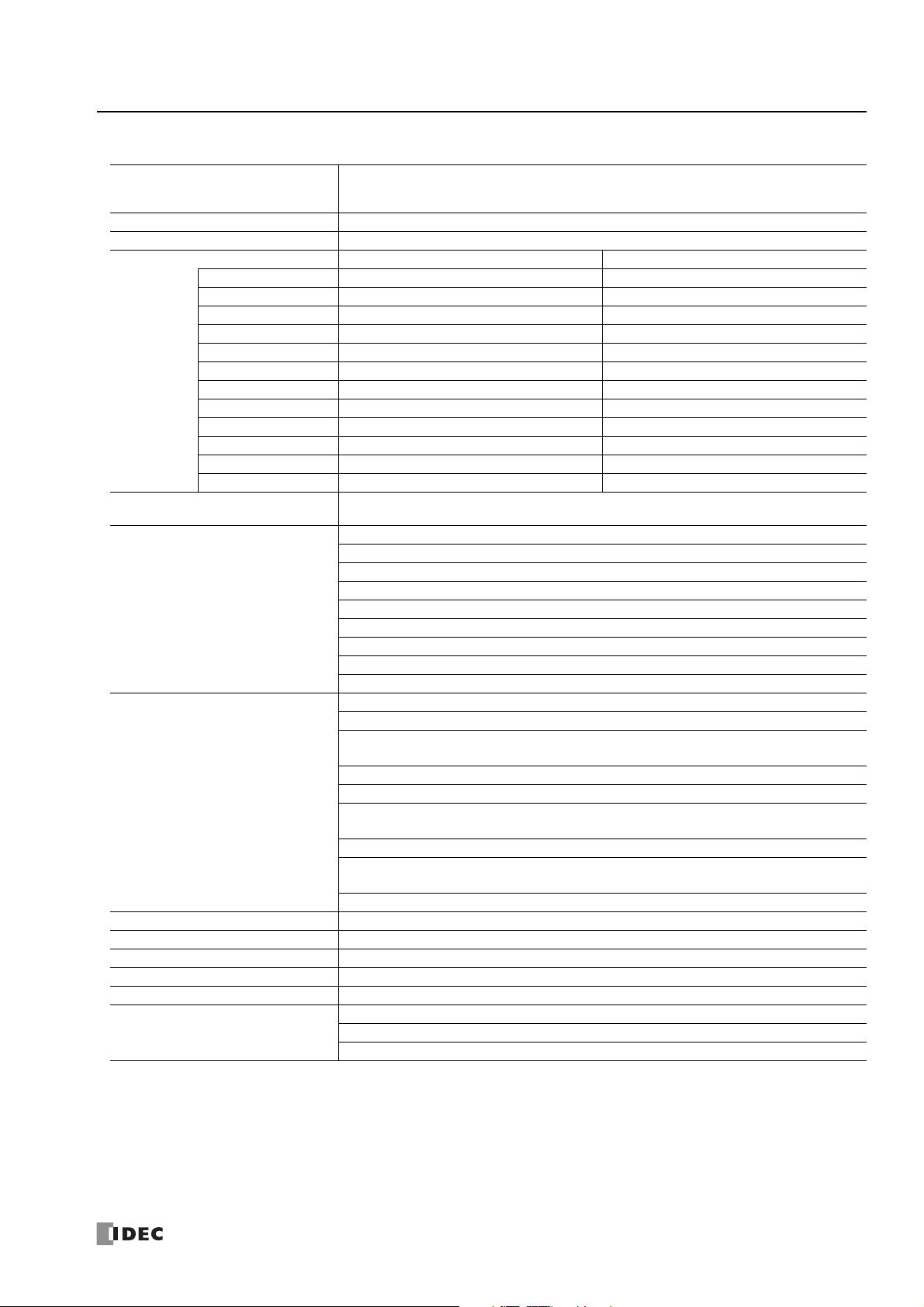

RELATED MANUALS

The following manuals related to the FC6A Series MICROSmart are available. Refer to them in conjunction with this manual.

Type No. Manual Name Description

Describes product specifications, installation and wiring instructions, instructions for

basic programming operations and special functions, device and instruction lists, and

troubleshooting procedures for the FC6A Series MICROSmart.

Describes basic operations for programming with ladders on the FC6A Series

MICROSmart, monitoring methods, device and instruction lists, and details of each

instruction.

Describes specifications related to FC6A Series MICROSmart communication,

descriptions of functions, configuration methods, and usage examples.

Describes PID module specifications and functions.

Describes usage instructions for WindLDR, programming software for the FC6A

Series MICROSmart.

FC9Y-B1722

FC9Y-B1726

FC9Y-B1730

FC9Y-B1734

WindLDR Help

FC6A Series MICROSmart

User’s Manual (this manual)

FC6A Series MICROSmart

Ladder Programming Manual

FC6A Series MICROSmart

Communication Manual

FC6A Series MICROSmart

PID Module User's Manual

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 Preface-6

NAMES AND ABBREVIATIONS USED IN THIS MANUAL

Model Names

Name Used in This Manual Type Number, Part Code, or Official Name

FC6A Series MICROSmart FC6A Series MICROSmart

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE,

All-in-One CPU module

CAN J1939 All-in-One CPU module

Plus CPU module

16-I/O type FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE

24-I/O type FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE

40-I/O type

Plus 16-I/O type FC6A-D16R1CEE, FC6A-D16P1CEE, FC6A-D16K1CEE

CPU module

Expansion

module

Expansion interface module Expander, remote master, remote slave

Cartridge

WindLDR WindLDR application software

USB cable

Plus 32-I/O type FC6A-D32P3CEE, FC6A-D32K3CEE

AC power type FC6A-C16R1AE, FC6A-C24R1AE, FC6A-C40R1AE, FC6A-C40R1AEJ

24V DC power type

DC power type

12V DC power type

Relay output type

Transistor sink output

Transistor output type

I/O module

Communication module Serial communication module

I/O cartridge

Communication cartridge

type

Transistor protection

source output type

Digital I/O module Digital input module, digital output module, digital mixed I/O module

Analog I/O module Analog input module, analog output module, analog mixed I/O module

Digital I/O cartridge Digital input cartridge, digital output cartridge

Analog I/O cartridge Analog input cartridge, analog output cartridge

FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ

FC6A-D16R1CEE, FC6A-D16P1CEE, FC6A-D16K1CEE, FC6A-D32P3CEE,

FC6A-D32K3CEE

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE,

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ

FC6A-C16R1CE, FC6A-C24R1CE, FC6A-C40R1CE, FC6A-C16K1CE,

FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C16P1CE, FC6A-C24P1CE,

FC6A-C40P1CE, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-D16R1CEE, FC6A-D16P1CEE, FC6A-D16K1CEE, FC6A-D32P3CEE,

FC6A-D32K3CEE

FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE, FC6A-C40R1DEJ,

FC6A-C40K1DEJ, FC6A-C40P1DEJ

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C24R1AE, FC6A-C24R1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40R1DE, FC6A-C40R1AEJ,

FC6A-C40R1CEJ, FC6A-C40R1DEJ, FC6A-D16R1CEE

FC6A-C16K1CE, FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C40K1DE,

FC6A-C40K1CEJ, FC6A-C40K1DEJ, FC6A-D16K1CEE, FC6A-D32K3CEE

FC6A-C16P1CE, FC6A-C24P1CE, FC6A-C40P1CE, FC6A-C40P1DE,

FC6A-C40P1CEJ, FC6A-C40P1DEJ, FC6A-D16P1CEE, FC6A-D32P3CEE

PID module

RS232C communication cartridge, RS485 communication cartridge,

Bluetooth communication cartridge

USB maintenance cable (HG9Z-XCM42),

USB Mini-B extension cable (HG9Z-XCE21)

Name Used in this Manual WindLDR Operating Procedure

Function area settings Configuration tab > Function Area Settings group

Monitors Select Online > Monitor > Start Monitor.

PLC status Select Online > PLC > Status.

Communication settings Select Online > Communication > Set Up.

On the Configuration tab, in Function Area Settings, click Communication Ports, and in the

Modbus master request table

Application button

Preface-7 FC6A S

displayed Function Area Settings dialog box, for Communication Mode under Communication

Ports, select Modbus RTU Master or Modbus TCP Client

The button displayed on the left side of the menu bar. Click to display the menu with New, Save, and

Save As, recent projects, WindLDR Options, and Exit WindLDR.

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

T

ABLE OF

C

HAPTER

C

HAPTER

1: General Information

2: Product Specifications

C

ONTENTS

Safety Precautions............................................................................................................................. Preface-1

About This Manual............................................................................................................................. Preface-3

About the Warranty of the Products .................................................................................................... Preface-5

Related Manuals................................................................................................................................ Preface-6

Names and Abbreviations Used in this Manual ..................................................................................... Preface-7

About the FC6A Series MICROSmart ............................................................................................................. 1-1

Features ..................................................................................................................................................... 1-8

Special Functions......................................................................................................................................... 1-9

Communication Functions .......................................................................................................................... 1-12

Maintenance Communication...................................................................................................................... 1-14

User Communication.................................................................................................................................. 1-15

Modbus Communication ............................................................................................................................. 1-15

Data Link Communication .......................................................................................................................... 1-16

Ethernet Communication............................................................................................................................ 1-17

Operator Interface Connectivity .................................................................................................................. 1-18

Using J1939 Communication ...................................................................................................................... 1-18

Normal Operating Conditions........................................................................................................................ 2-1

CPU Module ................................................................................................................................................2-2

Digital I/O Modules.................................................................................................................................... 2-55

Analog I/O Modules ................................................................................................................................... 2-81

PID Module ............................................................................................................................................... 2-95

Communication Modules .......................................................................................................................... 2-105

Expansion Interface Modules .................................................................................................................... 2-110

HMI Module ............................................................................................................................................ 2-127

Cartridge Base Module ............................................................................................................................. 2-129

Cartridges............................................................................................................................................... 2-131

Dimensions ............................................................................................................................................. 2-144

C

HAPTER

C

HAPTER

3: Installation and Wiring

Installation Location .................................................................................................................................... 3-1

Assembly Methods....................................................................................................................................... 3-4

Mounting on DIN Rail ................................................................................................................................ 3-10

Input/Output Wiring .................................................................................................................................. 3-17

Power Supply and Power Supply Wiring ...................................................................................................... 3-19

Using the Ports ......................................................................................................................................... 3-23

Using an SD Memory Card ......................................................................................................................... 3-29

Replacing the Backup Battery ..................................................................................................................... 3-32

Connection Restrictions When Expanding the PLC ........................................................................................ 3-34

Terminal Connection.................................................................................................................................. 3-42

Wiring the CAN J1939 Bus ......................................................................................................................... 3-47

4: Operation Basics

Start WindLDR ............................................................................................................................................4-1

PLC Selection .............................................................................................................................................. 4-2

Create Program........................................................................................................................................... 4-3

Save Project................................................................................................................................................4-8

Simulate Operation ...................................................................................................................................... 4-9

Download Program .................................................................................................................................... 4-10

Monitor Operation ..................................................................................................................................... 4-12

Exit WindLDR ............................................................................................................................................ 4-12

Checking the WindLDR Version Number ...................................................................................................... 4-13

Ladder Program Operation ......................................................................................................................... 4-14

Start/Stop Operation.................................................................................................................................. 4-15

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 Preface-8

T

ABLE OF CONTENTS

C

HAPTER

5: Functions and Settings

Function List............................................................................................................................................... 5-1

Function Area Settings ................................................................................................................................ 5-3

Stop Input and Reset Input ......................................................................................................................... 5-5

Run/Stop Selection at Keep Data Error ......................................................................................................... 5-9

Run/Stop Selection at Power Up..................................................................................................................5-10

Function Switch Configuration.....................................................................................................................5-11

Memory Backup .........................................................................................................................................5-13

High-Speed Counter ...................................................................................................................................5-15

Catch Input ...............................................................................................................................................5-35

Interrupt Input ..........................................................................................................................................5-37

Frequency Measurement ............................................................................................................................5-40

Input Filter ................................................................................................................................................5-42

Analog Voltage Input .................................................................................................................................5-44

Analog Potentiometer.................................................................................................................................5-46

Timer Interrupt..........................................................................................................................................5-48

Forced I/O function....................................................................................................................................5-50

External Memory Devices............................................................................................................................5-54

Log Data File Size ......................................................................................................................................5-55

32-bit Data Storage Setting ........................................................................................................................5-56

User Program Protection.............................................................................................................................5-58

Watchdog Timer Setting .............................................................................................................................5-60

Constant Scan Time ...................................................................................................................................5-61

Daylight Savings Time ................................................................................................................................5-62

Clock Function ...........................................................................................................................................5-63

Battery Monitor..........................................................................................................................................5-66

USB Boot...................................................................................................................................................5-67

User Program Capacity ...............................................................................................................................5-69

Online Edit ................................................................................................................................................5-70

C

HAPTER

C

HAPTER

C

HAPTER

6: Devices

Device Addresses........................................................................................................................................ 6-1

Special Internal Relay.................................................................................................................................. 6-4

Special Data Register .................................................................................................................................6-16

7: HMI Function

HMI Function Overview ............................................................................................................................... 7-1

LCD Settings............................................................................................................................................... 7-3

About the Menu Screen ............................................................................................................................... 7-5

Basic Operations ......................................................................................................................................... 7-6

Switching run/stop ...................................................................................................................................... 7-9

Editing Programs .......................................................................................................................................7-10

FC6A Series MICROSmart Environment Settings ...........................................................................................7-12

Monitoring the FC6A Series MICROSmart .....................................................................................................7-32

Checking/Clearing Error Information............................................................................................................7-38

Displaying Arbitrary Messages .....................................................................................................................7-40

SD Memory Card Maintenance ....................................................................................................................7-41

Reading and Writing Recipe Files ................................................................................................................7-43

Uploading/Downloading the User Program ...................................................................................................7-45

System Menu Hierarchy Diagram ................................................................................................................7-47

Communication Functions ...........................................................................................................................7-48

8: Instructions Reference

Basic Instruction List ................................................................................................................................... 8-1

Advanced Instruction List ............................................................................................................................ 8-3

Structure of an Advanced Instruction ........................................................................................................... 8-6

Input Condition for Advanced Instructions .................................................................................................... 8-6

Source and Destination Devices ................................................................................................................... 8-6

Using Timer or Counter as Source Device ..................................................................................................... 8-6

Using Timer or Counter as Destination Device ............................................................................................... 8-6

Preface-9 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

Data Types for Advanced Instructions ........................................................................................................... 8-7

Discontinuity of Device Areas ..................................................................................................................... 8-11

NOP (No Operation) .................................................................................................................................. 8-11

Device Addressing for Instruction Execution ................................................................................................ 8-12

9: Analog I/O Modules

Analog I/O Module Overview ........................................................................................................................ 9-1

Analog I/O Module Parameter Settings.......................................................................................................... 9-3

Device Allocation ....................................................................................................................................... 9-13

10: I/O Cartridges

Digital I/O Cartridges ................................................................................................................................. 10-1

Analog I/O Cartridge ................................................................................................................................. 10-7

11: SD Memory Card

SD Memory Card Overview......................................................................................................................... 11-1

Save Log Data........................................................................................................................................... 11-6

Recipe Function......................................................................................................................................... 11-7

Downloads and Uploads using the SD Memory Card................................................................................... 11-20

SD Memory Card Maintenance with Data File Manager ............................................................................... 11-38

12: Module Configuration Editor

Module Configuration Editor Overview......................................................................................................... 12-1

Basic Module Configuration Editor Operations .............................................................................................. 12-3

T

ABLE OF CONTENTS

C

HAPTER

A

PPENDIX

I

NDEX

13: Troubleshooting

Reading Error Data .................................................................................................................................... 13-1

Special Data Registers for Error Information ................................................................................................ 13-3

General Error Codes .................................................................................................................................. 13-3

FC6A Series MICROSmart Operating Status, Output, and ERR LED during Errors ............................................ 13-4

Error Causes and Actions ........................................................................................................................... 13-4

User Program Execution Error .................................................................................................................... 13-6

Troubleshooting Diagrams ......................................................................................................................... 13-8

Type List.....................................................................................................................................................A-1

System Software .........................................................................................................................................A-7

USB Driver Installation Procedure ............................................................................................................... A-10

Fonts........................................................................................................................................................ A-12

Cables ......................................................................................................................................................A-14

HMI Screen Transition Diagram .................................................................................................................. A-16

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 Preface-10

T

ABLE OF CONTENTS

Preface-11 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

FC6A - C 40 R 1 A E J

CAN J1939 function

J: CAN J1939 function

None: No CAN J1939 function

Ethernet port

E: Ethernet port ("EE" for two Ethernet ports)

None: No Ethernet port

Power supply

A: AC power type

C: 24V DC power type

D: 12V DC power type

Terminal specification

1: Removable terminal block

3: MIL connector

Output type

R: Relay output

K: Transistor sink output

P: Transistor protection source output

I/O points

16: 16 I/O points

24: 24 I/O points

32: 32 I/O points

40: 40 I/O points

Module type

C: All-in-One CPU module

D: Plus CPU module

ENERAL INFORMATION

Introduction

This chapter describes FC6A Series MICROSmart functions and system configuration examples.

About the FC6A Series MICROSmart

The FC6A Series MICROSmart is a small, All-in-One CPU module or Plus CPU module programmable controller with excellent

expandability and a variety of communication functions. The CPU modules are equipped with 16-, 24-, 32-, or 40-I/Os and support

either 100 to 240V AC, 24V DC, or 12V DC power supplies.

Expansion modules, cartridges, HMI modules, and other modules can be connected to the CPU module. Inputs, outputs, and

communication ports can be expanded according to application.

The FC6A Series MICROSmart can also be linked to various types of external devices with communication functions that include

maintenance communication, user communication, and Modbus communication. The FC6A Series MICROSmart is also equipped

with functions for high-speed counters, pulses, flow calculation, and data logging functions.

Programs used on the FC6A Series MICROSmart are created with WindLDR, easy-to-use, Windows-compatible ladder

programming software. This ladder programming software also supports the FC4A Series and the FC5A Series, so you can use your

existing ladder program resources.

Type Numbers

The notation for FC6A Series MICROSmart part numbers is as follows.

For details on the product specifications, see "Product Specifications" on page 2-1.

CPU module

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-1

1: G

FC6A -

M08 BR1

Output type

R: Relay output (Mixed I/O module only)

K: Transistor sink output

P: Transistor protection source output

None: No output

Input type

A1: 120V AC

B: 24V DC

None: No input

Terminal specification

1: Removable terminal block

3: MIL connector

I/O points

08: 8 I/O points

16: 16 I/O points

24: 24 I/O points

32: 32 I/O points

Module type

N: Digital input module

R: Digital output module (Relay output)

T: Digital output module (Transistor output)

M: Digital mixed I/O module

ENERAL INFORMATION

HMI module

FC6A -

Cartridge base module

FC6A -

Digital I/O modules

PH 1

HPH1

Interface specification

1: Communication connector

Module type

PH: HMI module

Module type

HPH1: Cartridge base module

1-2 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

Analog I/O module

FC6A -

J4CN1

Input type

None: Voltage/current input

N: Voltage/current/resistance thermometer input

U: Thermistor/thermocouple input

H: Thermocouple input

Maximum resolution

A: 12 bits

C: 16 bits

Terminal specification

1: Removableterminal block

Isolation

Y: Isolated between channels

None: No isolation

I/O points

2: 2 I/O points

4: 4 I/O points

8: 8 I/O points

03: 3 I/O points

06: 6 I/O points

Module type

J: Analog input module

K: Analog output module

L: Mixed analog I/O module

FC6A -

F2MR1

Output type

None: Voltage/current output

R: Relay output

Input type

M: Multi input

Terminal specification

1: Removable terminal block

Control loop points

2: 2 points

Module type

F: PID module

FC6A -

SIF 5 2

Communication specification

5: RS-232C or RS-485 selectable

Number of ports

2: 2 ports

Module type

SIF: Serial communication module

1: G

ENERAL INFORMATION

PID module

Communication module

Expansion interface module

FC6A -

EXM 2

Module configuration

1M: Remote master

1S: Remote slave

2: Expander

Module type

EXM: Expansion interface module

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-3

1: G

FC6A -

PN4

I/O points

4: 4 I/O points

Module type

PN: Digital input cartridge

PT: Transistor source output cartridge

PK: Transistor sink output cartridge

FC6A -

PC1

Communication/terminal specifications

1: RS232C communication/terminal block

3: RS485 communication/terminal block

4: Bluetooth communication

Module type

PC : Communication cartridge

ENERAL INFORMATION

Digital I/O cartridge

Analog I/O cartridge

FC6A -

Communication cartridge

PK2A V

Output type

V: Voltage output

W: Current output

None: No outputs

Input type

None: Voltage/current input

P: Resistance thermometer/thermocouple input

Maximum resolution

A: 12 bits

C: 16 bits

I/O points

2: 2 I/O points

Module type

PJ: Analog input cartridge

PK : Analog output cartridge

1-4 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

Connector

FC6A -

PM 08PN02TA

Wiring connection configuration

T: Screw fastened type

(no silk printing: for FC6A)

S: Spring clamp type

(no silk printing: for FC6A)

TS: Screw fastened type

(with source output silk printing: for FC4A/FC5A)

TK: Screw fastened type

(with sink output silk printing: for FC4A/FC5A)

C: MIL connector

Terminal specification

A: 5.08 mm pitch, screw connection

B: 5.08 mm pitch, front screw connection

C: 3.81 mm pitch, front connection

D: 5.08 mm pitch, screw connection

(dedicated for use with the CPU module

power supply terminal)

E: Front screw connection with screw flange

(dedicated for use with CAN communication)

None: MIL connector

Quantity per pack

02: 2 items

Number of pins

03: 3 pins

05: 5 pins

08: 8 pins

09: 9 pins

10: 10 pins

11: 11 pins

12: 12 pins

13: 13 pins

17: 17 pins

Sale configuration

PN: 1 pack

Product classification

PM: Connector

FC9Z -

H0 A2050

Input type

A: Shielded straight cable

B: Non-shielded straight cable

Number of pins

20: 20 pins

Cable length

050: 0.5 m

100: 1 m

200: 2 m

300: 3 m

Cable classification

H: Flat cable

1: G

ENERAL INFORMATION

Cable

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-5

1: G

FC6A -

BH N021P

Sale configuration

PN : 1 pack

Quantity per pack

02: 2 items

Type 2

1: Standard product

Product classification

BH: Battery holder

ENERAL INFORMATION

Battery holder

1-6 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

CPU Module Type Numbers and Functions List

USB Maintenance Cable

HG9Z-XCM42

Panel Mount USB Extension Cable

HG9Z-XCE21

External Device/O/I Communication Cable

FC6A-KC1C

O/I Communication Cable

FC6A-KC2C

Type numbers and functions

1: G

ENERAL INFORMATION

Type Number Power Supply

FC6A-C16R1AE

FC6A-C24R1AE 24 (508)

FC6A-C40R1AE 40 (528) 2 (3)

FC6A-C16R1CE

FC6A-C16K1CE

FC6A-C16P1CE

FC6A-C24R1CE

FC6A-C24P1CE

FC6A-C40R1CE

FC6A-C40K1CE

FC6A-C40P1CE

FC6A-C40R1DE

FC6A-C40P1DE

FC6A-C40R1AEJ 100 to 240V AC

FC6A-C40R1CEJ

FC6A-C40P1CEJ

FC6A-C40R1DEJ

FC6A-C40P1DEJ

FC6A-D16R1CEE

FC6A-D16P1CEE

FC6A-D16K1CEE

FC6A-D32P3CEE

FC6A-D32K3CEE

*1 The value in parentheses ( ) is the number of inputs and outputs when using the expansion interface module and the maximum number of

expansion modules are connected.

100 to 240V AC

24V DC

12V DCFC6A-C40K1DE

24V DCFC6A-C40K1CEJ

12V DCFC6A-C40K1DEJ

24V DC

Inputs and

Outputs

16 (404)

16 (404)

24 (508)FC6A-C24K1CE

40 (528) 2 (3)

16 (2,044)

32 (2,060)

USB

*1

Ethernet

Port

Port 1

Yes Ye s —

Yes Yes Yes 0 (3) — — Yes Yes (1 each)

Ethernet

Port 2

Number of

Cartridge

Slots

1 (2)

1 (2)

CAN

Serial

Port

Port 1

—Yes

Yes — —

SD

Memory

Card Slot

Yes

Analog

Input/

Volume

Yes (1 e ach )

Options

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-7

1: G

ENERAL INFORMATION

Features

This section describes the features of the FC6A Series MICROSmart.

High-speed Instruction Processing

The FC6A Series MICROSmart is capable of high-speed arithmetic processing of basic instructions (LOD) in 0.042 μs and advanced

instructions (MOV) in 0.120 μs. This improves real time performance during program execution.

Abundant Program Capacity

The FC6A Series MICROSmart has large program capacity.

CPU Module

All-in-One CPU module

CAN J1939 All-in-One CPU module

Plus CPU module 800,000 bytes maximum (100,000 steps equivalent)

Note: "Step" is the unit to calculate the program size. One step is 8 bytes, which is the instruction size of contacts or coils.

384,000 bytes maximum

(48,000 steps equivalent)

640,000 bytes maximum

(80,000 steps equivalent)

Standard When Online Edit Is Used

Online Edit

User programs can be overwritten (run-time programming) and tests can be written while the ladder program is being executed.

Various Communication Functions

The FC6A Series MICROSmart supports the following communications:

Maintenance communication

User communication

Modbus communication

Datalink communication

J1939 communication (CAN J1939 All-in-One CPU module only)

Bluetooth communication

Program Capacity

72,000 bytes maximum

(9,000 steps equivalent)

The following functions using Ethernet are also supported so that a variety of requirements can be achieved, such as remote

monitoring or maintenance.

SNTP

FTP server/client

PING

Send e-mail

Web server

The FC6A Series MICROSmart can be connected to a variety of devices such as computer, operator interface, and printer.

SD Memory Card

The FC6A Series MICROSmart is equipped with an SD memory card slot. The log data of device values, configuration data, user

programs, and system software can be saved to a commercially available SD memory card (32 GB maximum).

Powerful HMI Functions

Device values can be checked and modified on the HMI module's LCD. The LCD can also display the current time, bar charts,

messages, and text. The HMI module is equipped with fonts in the following nine languages and can display messages and text in

those languages. The HMI module can be operated using the operation buttons. Operations such as switching what is shown on

the LCD can be performed using the operation buttons.

Setting Name Character Set Supported Languages

European ISO 8859-1 (Latin-1) English, German, Italian, Spanish, Dutch (Note), French (Note)

Japanese Shift-JIS Japanese (level 1)

Chinese GB2312 Chinese (simplified)

Cyrillic ANSI 1251 Russian

Note: Some of the characters cannot be input.

1-8 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

ENERAL INFORMATION

Special Functions

This section describes the functions of the FC6A Series MICROSmart.

I/O Related Functions

Catch Input

The catch input function is used to receive shot pulses (minimum pulse width: 5 μs) that is shorter than the user program scan

time. A maximum of 6 catch inputs can be used.

Note: The scan time is the time duration for executing one cycle of the user program that is cyclically executed.

Input Filter

The input filter is the function to reduce the influence from the bounce or noise on input contacts by adjusting the filter width

according to the input signal width. The input filter of 0 ms (no filter) or 3 to 15 ms (1 ms increments) can be configured for

individual input.

Interrupt Input

The interrupt input can be used to call an interrupt program to respond to an external input that requires a response faster than

the ladder program scan time. A maximum of six interrupt inputs can be used.

Stop and Reset Inputs

The stop input is a function to stop ladder program execution. The reset input is a function to stop ladder program operation and

clear device values. Any input terminal on the FC6A Series MICROSmart can be designated as a stop or reset input to control the

FC6A Series MICROSmart operation.

Built-in Analog Input Function

This function acquires 0 to 10V DC analog input as a digital value in a special data register. There is one built-in analog input.

Analog Potentiometer Function

This function acquires volume input as a 0 to 1,000 digital value in a special data register according to the position of the volume.

There is one analog potentiometer.

Forced I/O

The inputs and outputs of the FC6A Series MICROSmart can be forced on or off. This function can be used to check the I/O wiring

or the user program operation.

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-9

1: G

Pulse Motor

High-speed Pulse Input

Two-phase Pulses

Rotary

Encoder

FC6A Series MICROSmart

Steady pulse frequency

Initial pulse frequency

ENERAL INFORMATION

High-speed I/O Functions

High-speed Counter

This function counts high-speed pulse inputs that cannot be measured in normal user program processing.

Use this function for applications such as positioning control with a rotary encoder or motor control. The FC6A Series MICROSmart

can use single-phase high-speed counters and two-phase high-speed counters. A maximum of six single-phase high-speed

counters and a maximum of two two-phase high-speed counters (three maximum for Plus CPU module only) can be used

simultaneously.

CPU Module

All-in-One CPU module/

CAN J1939 All-in-One CPU module

Plus CPU module

16-I/O type

40-I/O type

Plus 16-I/O type

Plus 32-I/O type

Single-phase High-

speed Counter

6 maximum

Two-phase High-speed

Counter

2 maximum24-I/O type

3 maximum

Example: Controlling a motor by counting two-phase pulse input with a high-speed counter

Positioning Control

The FC6A Series MICROSmart can perform positioning control with pulse outputs. The FC6A Series MICROSmart features the PULS

instructions that can generate pulse outputs with configured frequency at the fixed pulse width ratio, JOG instructions, pulse-width

modulation (PWM) instructions that can generate pulse outputs with configured pulse width ratio at a fixed frequency, RAMP

instructions for trapezoidal control, ZRN instructions for zero return operation, and ARAMP instructions that can generate pulse

outputs according to a table in which the changes of the frequency are configured.

The FC6A Series MICROSmart also manages coordinates internally and can increment or decrement coordinates according to the

number of pulses that were output and the direction.

After confirming the origin using the ZRN instruction, the target position can also be specified by absolute position.

Example: Pulse output by the RAMP instruction

Frequency Measurement

This function measures the frequency of pulses input to an input terminal. The frequencies of a maximum of six inputs can be

measured.

1-10 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

ENERAL INFORMATION

Convenient Functions

Calendar/Clock

The FC6A Series MICROSmart features a real-time clock on-board. Using the calendar and clock function, the FC6A Series

MICROSmart can operate according to the current date and time. These functions can be used to control a time schedule for

lighting or air conditioning equipments.

The FC6A Series MICROSmart also supports daylight savings time and the date and time of the switch can be freely set to allow for

use in any region.

User Program Read/Write Protection

The user program in the FC6A Series MICROSmart can be protected against reading and/or writing by including a password in the

user program. This function is effective for security of user programs.

“Keep” or “Clear” Designation of FC6A Series MICROSmart Data

This function specifies whether or not to keep FC6A Series MICROSmart device values when there is a power interruption.

Devices that can be specified as kept are internal relays, shift registers, counter current values, and data registers.

RUN/STOP Selection at Startup when “Keep” Data is Lost

When the backup battery is dead, all data to be kept are lost. The user can select whether the FC6A Series MICROSmart starts to

run or not to prevent undesirable operation at the startup.

Log Data

Device values of the FC6A Series MICROSmart can be saved as CSV files on the SD memory card. The DLOG instruction saves

device values to the SD memory card. The TRACE instruction accumulates device values at each scan and saves them to the SD

memory card at the desired timing.

Constant Scan Time

The variations in scan time that occur when the user program is running can be made constant.

Timer Interrupt

The timer interrupt can be used to call an interrupt program at a predetermined interval of time without being affected by the scan

time.

Script Function

This function allows programming complicated processing with conditional branching, logical operations, arithmetic operations,

and functions as text. Devices can also be read and written. Execute scripts using the SCRPT instruction.

Recipe Function

This function allows the values of device settings to be written to a CSV file to create a recipe file. The values of device settings can

be read from a recipe file and reflected in the FC6A Series MICROSmart devices.

Applicable devices are word devices such as timers, counters, and data registers.

SNTP Function

The current time can be acquired from an SNTP server.

USB Boot Function

This function starts the FC6A Series MICROSmart with power supplied from the USB cable.

This allows the user program and system software to be updated.

During USB boot, USB communication and the SD memory card can be used.

PID Control Function

PID control performs temperature control and other types of control using a PID (proportional-integral-derivative) calculation

algorithm. The FC6A Series MICROSmart can perform PID control by automatically calculating the optimal PID value using the auto

tuning function.

Function Switch

The FC6A Series MICROSmart is equipped with a function switch which can be used to run or stop the user program. The button

can be used for any desired purpose by using the on/off status of the function switch stored in the special internal relay.

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-11

1: G

ENERAL INFORMATION

Communication Functions

The FC6A Series MICROSmart can perform RS232C and RS485 communication using serial port 1. The communication ports can

be expanded by using communication cartridges to allow for multiple instances of RS-232C, RS-485, and Bluetooth

communication. The Ethernet port is standard equipment to enable communication using Ethernet. The CAN J1939 All-in-One CPU

module is equipped with a CAN port to enable J1939 communication.

Communication Functions

Maintenance communication enables you to check the operating status and I/O status of the FC6A Series

Maintenance Communication

User Communication

Modbus Communication

Data Link Communication

J1939 Communication

BACnet Communication

(BACnet/IP)

For details on communication functions, see the "FC6A Series MICROSmart Communication Manual".

MICROSmart, to display and change device values, and download and upload user programs using a

computer or operator interface.

Data can be sent and received by creating commands for external devices (computers, printers, barcode

readers, and other devices).

Data can be sent and received between communication device that conforms to the Modbus protocol and

the FC6A Series MICROSmart.

Data can be sent and received between a master station and slave stations by connecting a maximum of

31 MICROSmarts (slave station) to a MICROSmart (master station).

The CAN J1939 All-in-One CPU module can send and receive data with communication device that

conforms to the SAE-J1939 standard.

The Plus CPU module supports BACnet communication using the Internet protocol (IP).

Communication Ports

USB Port

Ethernet Port 1 and 2

HMI-Ethernet Port

Serial Port 1

RS232C Communication

Cartridge, RS485

Communication Cartridge

(option)

Bluetooth Communication

Cartridge (option)

CAN port The CAN J1939 All-in-One CPU module is capable of J1939 communication using this port.

Communication Module

(option)

Maintenance communication can be performed by connecting the FC6A Series MICROSmart to a

computer using this port.

The FC6A Series MICROSmart can communicate with Ethernet communication-compatible external

devices such as computers and operator interfaces using this port. Maintenance communication, user

communication, and Modbus TCP communication are possible. The Plus CPU module can communicate

with BACnet communication-compatible external devices using Ethernet port 1.

This port connects the HMI module to the CPU module and allows the HMI module to be used. The FC6A

Series MICROSmart can communicate with Ethernet communication-compatible external devices such as

computers and operator interfaces using this port. Maintenance communication is possible.

The FC6A Series MICROSmart can communicate with RS232C/RS485 communication-compatible external

devices such as computers, operator interfaces, and printers using this port. Maintenance communication,

user communication, Modbus RTU communication, and data link communication are possible.

The FC6A Series MICROSmart is capable of maintenance communication, user communication, Modbus

RTU communication, and data link communication using this port.

The FC6A Series MICROSmart is capable of maintenance communication and user communication using

this port.

The FC6A Series MICROSmart is capable of maintenance communication, user communication, Modbus

RTU communication, and data link communication using this port.

1-12 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

ENERAL INFORMATION

Allocations of the Communication Port Numbers

All-in-One CPU module, CAN J1939 All-in-One CPU module, and Plus CPU module support serial communication with the target

device. Serial communication is possible with built-in interface or expanded interface of each CPU module. Interfaces supporting

the serial communication are as follows:

All-in-One CPU module : Serial port 1, cartridge slots 1 and 2, communication module ports

CAN J1939 All-in-One CPU module : Cartridge slots 1 and 2, communication module ports

Plus CPU module : Cartridge slots 1 to 3, communication module ports

In order to use each interface as communication port, the communication parameters must be configured according to the

communication parameters of the target device. Configure the communication parameters in Communiction Ports tab in the

Function Area Settings dialog box. The allocation between each interface and communication port is described below.

For details on each setting, refer to chapter 3 "Communication Port Settings" in the "FC6A Series MICROSmart Communication

Manual".

■ Ports and Cartridge Slots 1 to 3 on the CPU Module and HMI Module

— : Not equipped with the CPU module.

No : Cannot be used as the serial communication ports.

Port Cartridge Slot

CPU Module

16-I/O type

All-in-One CPU module

CAN J1939 All-in-One

CPU module

Plus CPU module

*1 When the HMI module is connected to the CPU module and HMI-Ethernet port is added.

*2 When a communication cartridge is installed on the cartridge slot.

*3 When the cartridge base module is connected to the CPU module and a communication cartridge is installed on the cartridge slot.

*4 When the HMI module is connected to the CPU module and a communication cartridge is installed on the cartridge slot.

*5 The combination of "Data Bits: 7" and "Parity: None" is not possible.

Notes:

For the locations of each port and cartridge slot, see "Part Names and Functions" on page 2-2.

For serial port 1 wiring, see "Other Inputs and Ports" on page 2-35. For communication cartridge wiring, see "Terminal Arrangement and

Wiring Examples" on page 2-142.

24-I/O type

40-I/O type

40-I/O type

Plus 16-I/O type

Plus 32-I/O type

Serial

Port 1

Port 1

—

USB

Ethernet

Port

No No

Port 1

Ethernet

Port 2

—

No —

HMI-

Ehternet

Port

*1

No

CAN

Port

—

No

123

—

Port 2

*2*5

Port 1

*3*5

Port 3

*2*5

Port 2

*3*5

—

Port 3

*4*5

■ Ports on Communication Modules

CPU Module

16-I/O type

All-in-One CPU module

CAN J1939 All-in-One

CPU module

Plus CPU module

*1 Four or more communication modules cannot be connected to the All-in-One CPU module and CAN J1939 All-in-One CPU module.

24-I/O type

40-I/O type

40-I/O type

Plus 16-I/O type

Plus 32-I/O type

FC6A S

ERIES

1st 2nd 3rd 4th ··· 15th

Port 4, 5 Port 6, 7 Port 8, 9

MICROS

MART USER’S MANUAL

Communication Module

*1 *1 *1

Port 10, 11 ··· Port 32, 33

FC9Y-B1722 1-13

1: G

FC6A Series MICROSmart

Windows Computer

USB Port

(USB 2.0 Mini-B Connector)

HG9Z-XCM42 USB Maintenance Cable

Type A Plug Mini-B Plug

USB Port

Windows Computer

FC6A Series MICROSmart FC6A Series MICROSmart FC6A Series MICROSmart

Ethernet Hub

Ethernet Port 1 Ethernet Port 1Ethernet Port 1

ENERAL INFORMATION

Maintenance Communication

The maintenance communication of the FC6A Series MICROSmart enables you to check the operating status and I/O status of the

FC6A Series MICROSmart, monitor and change device values, and download and upload user programs with the PLC programming

software WindLDR installed on a computer. For details on maintenance communication, see the "FC6A Series MICROSmart

Communication Manual".

Supported ports

*1

USB Port Serial Port 1

Yes Yes Yes Ye s No

*1 Depending on the port that will be used, there are differences in maintenance communication functionalities that can be used. For details on the

restrictions, see the "FC6A Series MICROSmart Communication Manual".

*2 Only maintenance communication can be used with the HMI-Ethernet port.

Ethernet Port 1, 2 and

HMI-Ethernet Port

Communication Cartridge

*2

and Communication Module

CAN Port

■ 1:1 Maintenance Communication System

This example shows a 1:1 maintenance communication system in which a FC6A Series MICROSmart and a computer are

connected with USB. The USB maintenance cable (HG9Z-XCM42) is used.

■ 1:N Maintenance Communication System

This example shows a 1:N maintenance communication system in which three FC6A Series MICROSmart and a computer are

connected over Ethernet. The Ethernet cables are connected to the Ethernet port 1 of three FC6A Series MICROSmart, and those

FC6A Series MICROSmart are connected to the computer via an Ethernet hub.

1-14 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

Serial Port 1

(Port 1)

Barcode Reader

FC6A Series MICROSmart

INVERTER

RUN

RVS

ALM

COM

Temperature Controller

Inverter

Serial Port 1

(Port 1)

FC6A Series MICROSmart

ENERAL INFORMATION

User Communication

The user communication of the FC6A Series MICROSmart enables you to control external devices such as computers, printers, and

barcode readers. For details on user communication, see the "FC6A Series MICROSmart Communication Manual".

Supported ports

USB Port Serial Port 1 Ethernet Port 1 and 2

Communication Cartridge

and Communication Module

CAN Port

No Yes Yes Yes No

■ User Communication Using Serial Port 1

This example shows a system in which a FC6A Series MICROSmart receives the data read by a barcode reader. A barcode reader is

connected to port 1 of the FC6A Series MICROSmart.

Modbus Communication

The FC6A Series MICROSmart is compliant with Modbus RTU protocol and can be used as either a Modbus communication master

or slave. With Modbus communication, the FC6A Series MICROSmart can monitor and modify the data of inverters and

temperature controllers.

Ethernet ports 1 and 2 also support the Modbus TCP communication protocol.

For details on Modbus communication, see the "FC6A Series MICROSmart Communication Manual".

Supported ports

*1 Only the RS-232C communication cartridge and RS-485 communication cartridge are supported.

■ Modbus RTU Communication Using Serial Port 1

This example shows a system in which a FC6A Series MICROSmart is communicating with a temperature controller and an inverter

that support Modbus RTU. The A temperature controller is connected to port 1 of the FC6A Series MICROSmart.

USB Port Serial Port 1 Ethernet Port 1 and 2

Communication Cartridge

and Communication Module

*1

No Yes Yes Yes No

FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722 1-15

CAN Port

1: G

FC6A Series MICROSmart

(Slave Station 1)

FC6A Series MICROSmart

(Slave Station 31)

Serial Port 1

(Port 1)

FC6A Series MICROSmart

(Master Station)

ENERAL INFORMATION

Data Link Communication

The FC6A Series MICROSmart supports data link communication, and it can share data between CPU modules using serial port 1

and cartridge slots. The FC6A Series MICROSmart can also share data with FC5A Series and FC4A Series CPU modules. Configure

the settings in WindLDR to enable distributed control of a maximum of 31 CPU modules.

For details about the data link communication, see the "FC6A Series MICROSmart Communication Manual".

Supported ports

USB Port Serial Port 1 Ethernet Port 1 and 2

No Yes No Yes No

*1 Only the RS-232C communication cartridge and RS-485 communication cartridge are supported.

Communication Cartridge*1

and Communication Module

CAN Port

■ Data Link Communication Using Serial Port 1

This example shows communication between multiple CPU modules with the FC6A Series MICROSmart as the master station. A

slave station CPU module is connected to Serial Port 1 of the FC6A Series MICROSmart.

1-16 FC6A S

ERIES

MICROS

MART USER’S MANUAL

FC9Y-B1722

1: G

Ethernet Port 1

Operator Interface

Windows Computer

FC6A Series MICROSmart

Ethernet Hub Ethernet Hub

Ethernet

Barcode Reader

ENERAL INFORMATION

Ethernet Communication

The FC6A Series MICROSmart can be connected to the Ethernet network using Ethernet port 1 and communicate with network

devices over Ethernet.

The All-in-One CPU module and CAN J1939 All-in-One CPU module have eight TCP/IP connections and the Plus CPU module has 16

TCP/IP connections that can be used for Ethernet communication. Different communication protocols can be simultaneously used

on these connections. Each connection can be configured for maintenance communication server, user communication server/

client, or Modbus TCP server/client communication.

Supported ports

USB Port Serial Port 1 Ethernet Port 1 and 2

No No Yes No No

Communication

Cartridge

CAN Port

■ Ethernet Communication Example

This example shows Ethernet communication between the FC6A Series MICROSmart equipped with Ethernet port 1, an operator

interface, and a computer. Among the three connections the FC6A Series MICROSmart has, Connection

1 is configured as

maintenance communication server for the computer to communicate with the FC6A Series MICROSmart. Connection 2 is

configured as Modbus TCP server for the operator interface to communicate with the FC6A Series MICROSmart. Connection 3

communicates with the barcode reader with the user communication. Connection 4 to connection 8 are not used.

Notes:

When accessing the FC6A Series MICROSmart over the Internet, adequate security measures for the network to prevent unauthorized access