ICP C9MPT050F12B1, C9MPT075F12A1, C9MPT075F14A2, C9MPT075F14B1, C9MPT100J16A1 Installation Guide

...Page 1

90+2-Stage & *9MPT & *9MPV

VariableSpeed .Dooo,o Orooo.,c,.,,,

FAN ASSISTED,

CategoryIv Furnace DIRECT VENT GAS FURNACE

SAFETY REQUIREMENTS

Recognize safety information. Thisisthesafety-alertsymbolZ_. Whenyouseethissymbolonthefurnaceandininstructions manualsbealertto

the potential for personal injury.

Understand the signal words DANGER, WARNING, or CA UTION. These words are used with the safety-alert symbol. DANGER identifies the most

serious hazards, those that will result in severe personal injury or death. WARN/NGsignifiesahazardthatcouldresultinpersonalinjuryordeath.

CAUTION is used to identify unsafe practices that may result in minor personal injury or product and property damage. NOTE is used to highlight

suggestions that will result in enhanced installation, reliability, or operation.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should

install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels attached

to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) ANSI

Z223.1-2002/NFPA No. 54-2002. In Canada, refer to the current edition of the National Standard of Canada Natural Gas and Propane Installation

Code (NSCNGPIC) CSA B149.1-00. Wear safety glasses and work gloves. Have fire extinguisher available during start-up and adjustment

procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these instructions

exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction practices. We require

these instructions as a minimum for a safe installation.

International Comfort Products, LLC

Lewisburg, TN 37091

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

Table of Contents

1.SafeInstallationRequirements................. 3

2.Installation................................ 4

3.Combustion&VentilationAir .................. 7

4.Vent&CombustionAirPiping ................ 10

5.GasSupply andPiping...................... 28

6.ElectricalWiring ........................... 31

ELECTRIC SHOCK HAZARD

Failure to follow safety

warnings exactly could result

in serious injury, death, and/or

property damage.

Turn Off All Power Before

Servicing.

Printed in U.S.A. 07/15/2004 440 01 2020 (05)

7. DuctworkandFilter ....................... 33

8. ChecksandAdjustments.................... 36

9. FurnaceMaintenance ...................... 38

10.SequenceofOperation&Diagnostics.......... 39

11.ConcentricVentTermination................. 44

TechSupportand Parts ....................... 47

CARBON MONOXIDE POISNING AND FIRE

HAZARD.

Failure to follow safety warnings exactly cou Id

result in serious injury, death, and/or property

damage.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

Page 2

Dealer Name:

START-UP CHECK SHEET

For 90+ Furnace

(Keep this page for future reference)

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas: Natural: _ LP:

Which blower speed tap is used?

High Fire __ Low Fire or (Cooling).

Temperature of Supply Air: High Fire (°F)__ or (°C)__

Low Fire (°F).__or (°C)__

Business Card Here

Manual Gas Shut-Off Upstream

of Furnace/Drip- Leg?

Condensate Drain Connected?

Condensate Drain Trapped? YES

Transition Pressure switch hose relocated for U/D/H

Application? YES _ NO

Blower Speed Checked? YES _ NO

All Electrical Connections Tight? YES _ NO

Gas Valve OK? YES _ NO

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments Sec-

tion). (Lo) & (Hi)

YES

YES

NOE_

NO

NO

Temperature of Return Air: (°F)__ or (°C)__

Temp. Rise Hi Fire (Supply - Return ): (°F) or (°C)__

Lo Fire (Supply - Return ): (°F) or (°C)__

Filter Type and Size:

Fan "Time ON" Setting:.

Fan "Time OFF" Setting:

Dealer Comments:

[_ 44001202005

Temperature Rise (supply-return temperature):(°F)__

Measured Manifold Gas Pressure: (Lo) __ & (Hi) __

Static Pressure (Ducts): Supply Air Return

Date of Start-Up:

CO?

CO2 ?

Page 3

1. Safe Installation Requirements

FIRE, EXPLOSION, AND ASPHIXlATION HAZARD

Improper adjustment, alteration, service,

maintanence or installation could cause serious

injury, death and/or property damage.

Installation or repairs made by unqualified persons

could result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having.jurisdiction.

The information contained in this manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

NOTE: This furnace is design-certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada. Refer to the appropriate codes, along with this manual,

for proper installation.

Use only the Type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnaces

can be converted to L.R gas with approved kit.)

Install this furnace only in a location and position as speci-

fied in "2. Installation"of these instructions.

Provide adequate combustion and ventilation air to the fur-

nace as specified in "4. Combustion and Ventilation Air" of

these instructions.

Combustion products must be discharged outdoors. Con-

nect this furnace to an approved vent system only, as spe-

cified in %. Combustion and Ventilation Air, 6. Horizontal

Venting and 7, Masonry Chimney Venting"of these in-

structions.

Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in

"8. Gas Supply and Piping, Final Check"of these instruc-

tions.

Always install furnace to operate within the furnace's in-

tended temperature-rise range with a duct system which

has an external static pressure within the allowable range,

as specified in "Technical Support Manual" of these in-

structions.

• When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space con-

taining the furnace, the return air shall also be handled by a

duct(s) sealed to the furnace casing and terminating out-

side the space containing the furnace.

• A gas-fired furnace for installation in a residential garage

must be installed as specified in "2. Installation Require-

ments"of these instructions.

• This furnace is not to be used for temporary heating of

buildings or structures under construction.

• This furnace is NOT approved for installation in mo-

bile homes, trailers or recreation vehicles.

• Seal around supply and return air ducts.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Safety Rules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas-fired clothes dryers, gas cooking

stoves, water heaters, furnaces, gas-fired fireplaces, wood

fireplaces, and several other items.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or "CO" is a colorless and odorless

gas produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

Therefore, to help alert people of potentially dangerous ca rbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally recog-

nized testing agency in accordance with Underwriters Labora-

tories Inc. Standard for Single and Multiple Station Carbon

Monoxide Alarms, ANSI/UL 2034 or the CSA 6.19-01 Resi-

dential Carbon Alarming Devices installed and maintained in

the building or dwelling concurrently with the gas- fired furnace

installation (see Note below). The alarm should be installed as

recommended by the alarm manufacturer's installation in-

structions.

B. There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentially dangerous fire or smoke, you should have

fire extinguisher and smoke alarms listed by Underwriters Lab-

oratories installed and maintained in the building or dwelling

(see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safe and efficient operation of your unit, you should

do the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand howyour unit operates and the haz-

ards involved with gas and electricity.

2. Do not use this unit if any part has been under water. Im-

mediately call a qualified service technician to inspect the unit

and to replace any part of the control system and any gas con-

trol which has been under water.

Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion

and ventilation of flue gases.

44001 2020 05 [_

Page 4

FrozenWater PipeHazard

WATER DAMAGE TO PROPERTY HAZARD

Failure to protect against the risk of freezing could

result in property damage and/or personal injury.

Do not leave your home unattended for long periods

during freezing weather without turning off water

supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and

resultant damage.

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety de-

vices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

If your furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in serious water damage.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turn off the water supply to the structure and drain the water

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

-or-

Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-or-

3. Install a reliable remote sensing device that will notify some-

body of freezing conditions within the home.

Winter Shutdown

If you go away during the winter months and do not leave the heat

on in your home, the plastic transition box and the condensate trap

on the furnace must be protected from freeze damage.(See

Figure 9 trough Figure 18)

1. Disconnect the 5/8" OD rubber hose from the vent drain fit-

ting that is located downstream of the combustion blower.

Insert a funnel into the hose and pour four(4) ounces of sani-

tary type (RV) antifreeze into the condensate trap. Recon-

nect the 5/8" OD rubber hose to the stub on the vent drain

fitting. Secure with the hose clamp.

2. Disconnect the 3/4" OD rubber hose from the condensate

trap. Insert a funnel into the hose and and pour four(4)

ounces of sanitary type (RV) antifreeze into the plastic Tran-

sition box. Squeeze the hose together near the end and

quickly reconnect the 3/4" OD rubber hose to the stub on the

condensate trap. Secure with the hose clamp.

When you return home, your furnace will be ready to start, as it is

not necessary to drain the antifreeze from the furnace.

2. Installation

CARBON MONOXIDE POISONING HAZARD

Failure to properly vent this furnace or other

appliances could result in death, personal injury

and/or property damage.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory-built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent and chimney

to prevent oversizing problems for the other

remaining appliance(s). See Venting and Combus-

tion Air Check in the 5. Combusion & Ventilation Air

section. This furnace MUST be vented to the

outside.

Location and Clearances

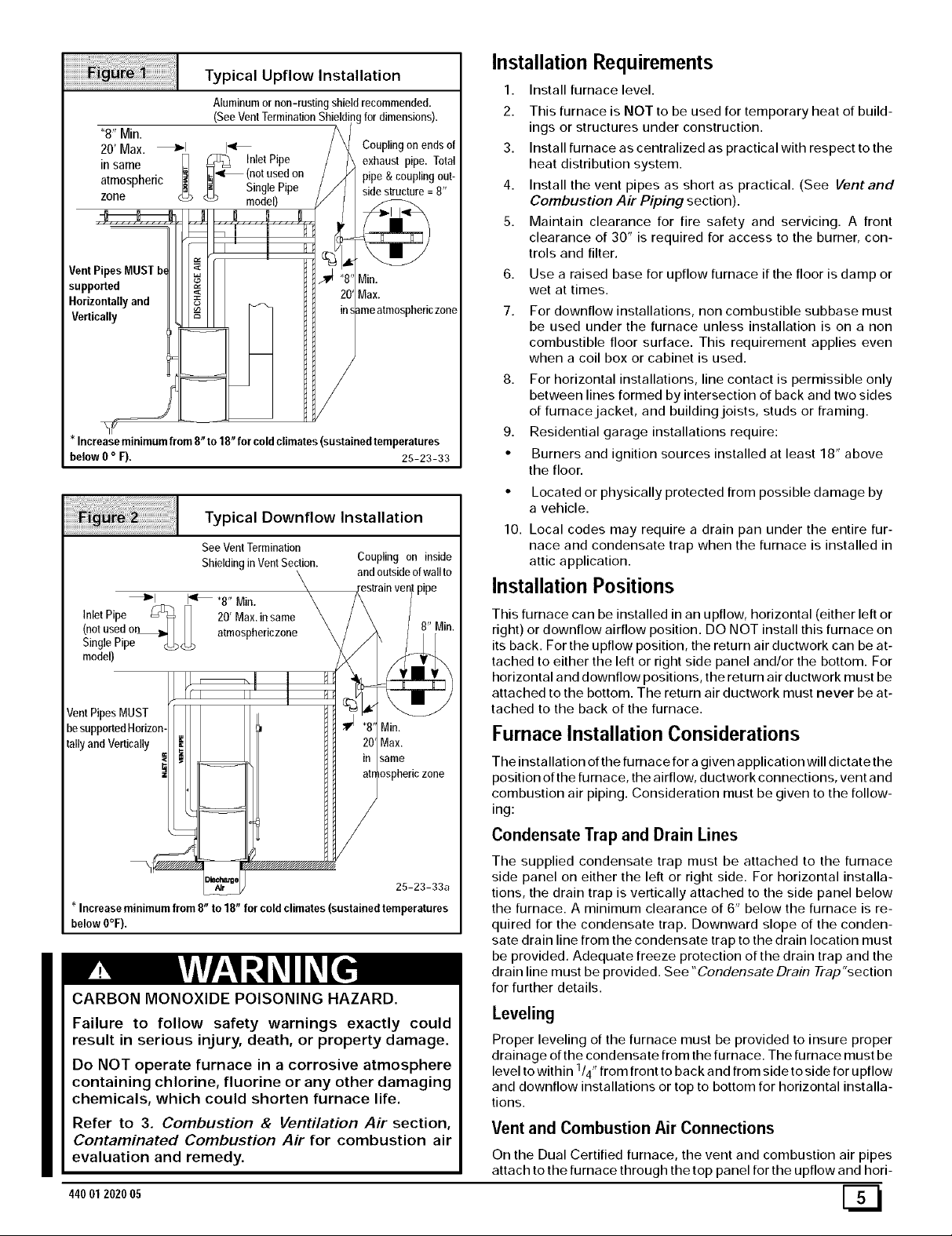

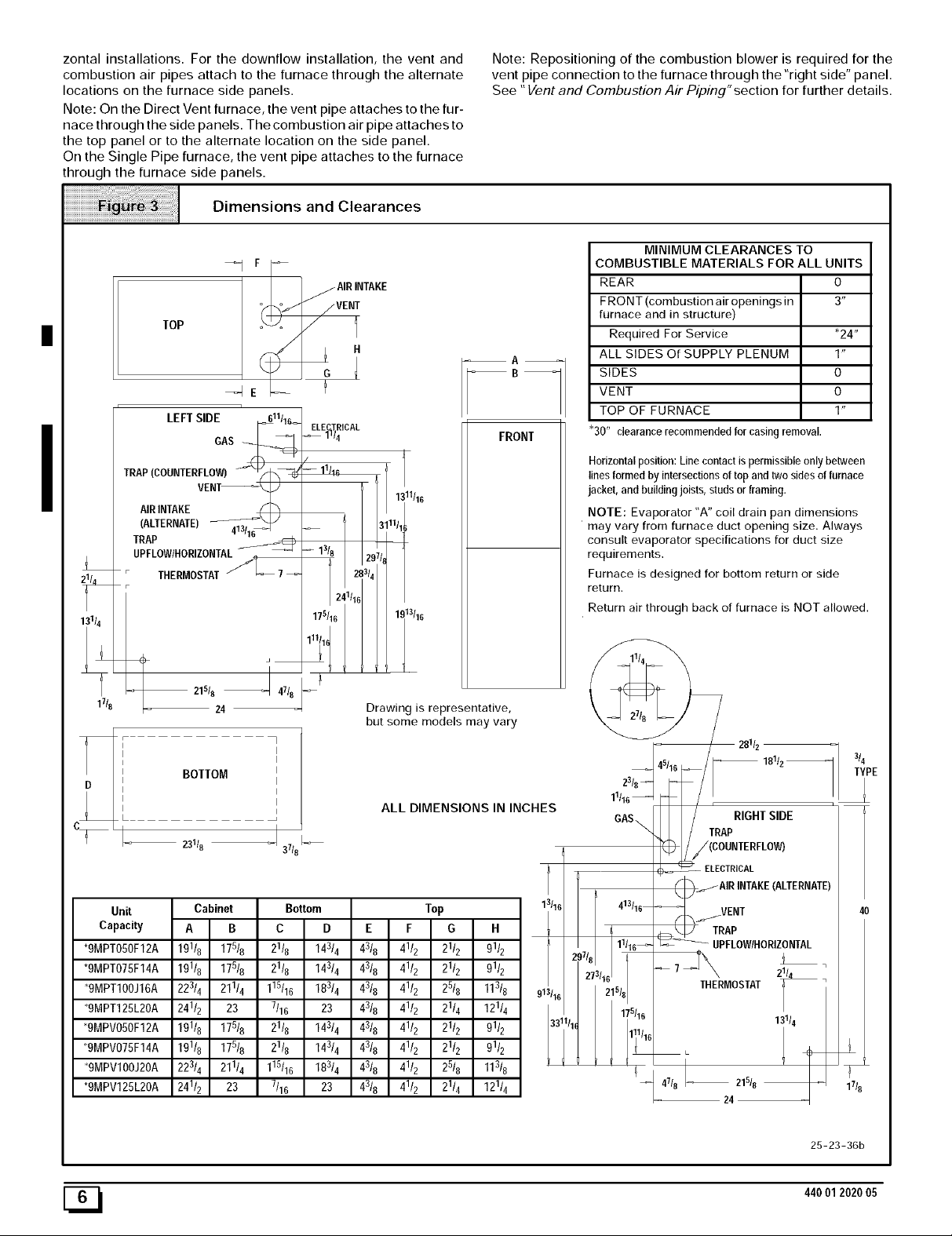

1. Refer to Figure 1 or Figure 2 for typical installation and

basic connecting parts required. Refer to Figure 4 for typi-

cal horizontal direct vent installation and basic connecting

parts required. Supply and return air plenums and duct are

also required.

2. If furnace is a replacement, it is usually best to install the fur-

nace where the old one was. Choose the location or evalu-

ate the existing location based upon the minimum clearance

and furnace dimensions (Figure 3).

FROZEN AND BURST WATER PIPE HAZARD

Failure to protect against the risk of freezing could

result in property damage and/or personal injury.

Special precautions MUST be made if installing

furnace in an area which may drop below freezing.

This can cause improper operation or damage to

equipment. If furnace environment has the potential

of freezing, the drain trap and drainline must be

protected. The use of electric heat tape or RV

antifreeze is recommended for these installations.

(See "Condensate Trap Freeze Protection Section")

[_1 44001 2020 05

Page 5

Typical Upflow Installation

Aluminum or non-rusting shield recommended.

(See Vent Termination Shielding for dimensions).

"8" Min.

20' Max. _1 I_

in same __ (notused on

atmospheric ilL. Single Pipe

zone _ model)

VentPipesMUST b_

supported

Horizontallyand

Vertically

Increaseminimumfrom8 to18 forcoldclimates(sustainedtemperatures

below 0o F), 25-23-33

<_ _ InletPipe

Couplingon endsof

_iexhaust pipe. Total

pipe & coupling;ut-

Typical Downflow Installation

See VentTermination

Shieldingin VentSection.

_1 _ "8" Min.

Inlet Pipe _:_ _ 20' Max.insame

(notused on_ _ atmosphedczone

Single Pipe <_

model)

VentPipes MUST

besupport_dHorizon- Min.

tallyand Vertically ! Max.

i same

Coupling on inside

andoutsideofwallto

osphericzone

zone

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of build-

ings or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical. (See Vent and

Combustion Air Piping section).

5. Maintain clearance for fire safety and servicing. A front

clearance of 30" is required for access to the burner, con-

trols and filter.

6.

Use a raised base for upflow furnace if the floor is damp or

wet at times.

7.

For downflow installations, non combustible subbase must

be used under the furnace unless installation is on a non

combustible floor surface. This requirement applies even

when a coil box or cabinet is used.

8. For horizontal installations, line contact is permissible only

between lines formed by intersection of back and two sides

of furnace jacket, and building joists, studs or framing.

9. Residential garage installations require:

• Burners and ignition sources installed at least 18" above

the floor.

Located or physically protected from possible damage by

a vehicle.

10. Local codes may require a drain pan under the entire fur-

nace and condensate trap when the furnace is installed in

attic application.

Installation Positions

This furnace can be installed in an upflow, horizontal (either left or

right) or downflow airflow position. DO NOT install this furnace on

its back. For the upflow position, the return air ductwork can be at-

tached to either the left or right side panel and/or the bottom. For

horizontal and downflow positions, the return air ductwork must be

attached to the bottom. The return air ductwork must never be at-

tached to the back of the furnace.

Furnace Installation Considerations

The installation of the furnace for a given application will dictate the

position of the furnace, the airflow, ductwork connections, vent and

combustion air piping. Consideration must be given to the follow-

ing:

I_, Y/////////////////////////_,

25-23-33a

* Increaseminimumfrom 8" to 18" for coldclimates(sustainedtemperatures

below 0°F),

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warnings exactly could

result in serious injury, death, or property damage.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals, which could shorten furnace life.

Refer to 3. Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

44001 2020 05

Condensate Trap and Drain Lines

The supplied condensate trap must be attached to the furnace

side panel on either the left or right side. For horizontal installa-

tions, the drain trap is vertically attached to the side panel below

the furnace. A minimum clearance of 6" below the furnace is re-

quired for the condensate trap. Downward slope of the conden-

sate drain line from the condensate trap to the drain location must

be provided. Adequate freeze protection of the drain trap and the

drain line must be provided. See "Condensate Drain Trap"section

for further details.

Leveling

Proper leveling of the furnace must be provided to insure proper

drainage of the condensate from the furnace. The furnace must be

level to within 1/4" from front to back and from side to side for upflow

and downflow installations or top to bottom for horizontal installa-

tions.

Vent and Combustion Air Connections

On the Dual Certified furnace, the vent and combustion air pipes

attach to the furnace through the top panel for the upflow and hori-

Page 6

zontal installations. For the downflow installation, the vent and

combustion air pipes attach to the furnace through the alternate

locations on the furnace side panels.

Note: On the Direct Vent furnace, the vent pipe attaches to the fur-

nace through the side panels. The combustion air pipe attaches to

the top panel or to the alternate location on the side panel.

On the Single Pipe furnace, the vent pipe attaches to the furnace

through the furnace side panels.

Dimensions and Clearances

Note: Repositioning of the combustion blower is required for the

vent pipe connection to the furnace through the "right side" panel.

See "Vent and Combustion Air Piping'section for further details.

I

I

TOP

LEFTSIDE _611tr_

TRAI,_IIIIIREvLEOTW)- Y ± --

T(RAL;ERNATE)4_c

UPFLOWIHORIZONTAL_

i

THERMOSTAT/k_7

31/4

i

T

17/8

2151824 47/8

BOTTOM

--=-IE

GAS

F

__G/AIR INTAKE

1

ELE TR CAL

/

-- 1r/!_

VENI

?

1(;1t4

2 rt

Drawing is representative,

but some models may vary

FRONT

COMBUSTIBLE MATERIALS FOR ALL UNITS

MINIMUM CLEARANCES TO

REAR 0

FRONT (combustion air openings in 3"

furnace and in structure)

Required For Service '24"

ALL SIDES Of SUPPLY PLENUM 1"

SIDES 0

VENT 0

TOP OF FURNACE 1"

"30" clearancerecommendedforcasingremoval.

Horizontalposition:Linecontactispermissibleonlybetween

linesformed by intersectionsoftop and twosidesoffurnace

jacket,andbuildingjoists,studs orframing.

NOTE: Evaporator "A" coil drain pan dimensions

may vary from furnace duct opening size. Always

consult evaporator specifications for duct size

requirements.

Furnace is designed for bottom return or side

return.

Return air through back of furnace is NOT allowed.

281/z

18112

3/

T' E

ALL DIMENSIONS IN INCHES

23118 J 37t8

Unit

Capacity

*9MPT050F12A

*9MPT075F14A

*9MPT100J16A

*gMPT125L20A

*gMPV050F12A

*9MPV075F14A

*9MPV100J20A

*gMPV125L20A

[_ 44001 2020 OS

13116

)7/8

27

913116

3

RIGHTSIDE

TRAP

/(COUNTERFLOW)

(ALTERNATE)

VENT

TRAP

UPFLOW/HORIZONTAL

THERMOSTAT

13114

21518

24

T

17/8

25-23-36b

Page 7

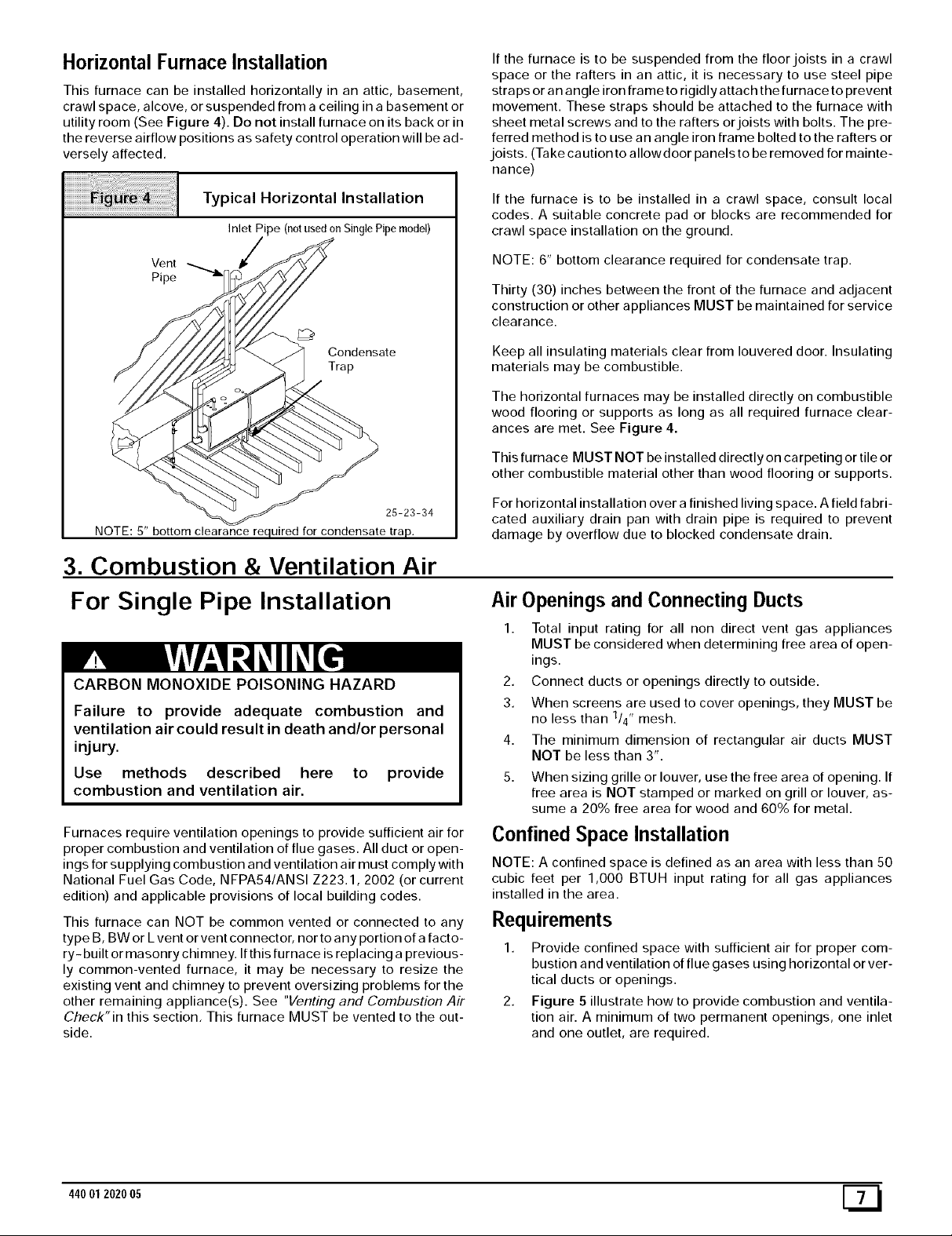

Horizontal Furnace Installation

This furnace can be installed horizontally in an attic, basement,

crawl space, alcove, or suspended from a ceiling in a basement or

utility room (See Figure 4). Do not install furnace on its back or in

the reverse airflow positions as safety control operation will be ad-

versely affected.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to rigidly attach the furnace to prevent

movement. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The pre-

ferred method is to use an angle iron frame bolted to the rafters or

joists. (Take caution to allowdoor panels to be removed for mainte-

nance)

Typical Horizontal Installation

Inlet Pipe (notusedonSinglePipemodel)

Vent

Pipe

Condensate

Trap

25-23-34

NOTE: 5" bottom clearance required for condensate trap.

3. Combustion & Ventilation Air

For Single Pipe Installation

CARBON MONOXIDE POISONING HAZARD

Failure to provide adequate combustion and

ventilation air could result in death and/or personal

injury.

Use methods described here to provide

combustion and ventilation air.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or open-

ings for supplying combustion and ventilation air must comply with

National Fuel Gas Code, NFPA54/ANSI Z223.1, 2002 (or current

edition) and applicable provisions of local building codes.

This furnace can NOT be common vented or connected to any

type B, BW or Lvent or vent connector, nor to any portion of a facto-

ry- built or masonry chimney. Ifthis furnace is replacing a previous-

ly common-vented furnace, it may be necessary to resize the

existing vent and chimney to prevent oversizing problems for the

other remaining appliance(s). See "Venting and Combustion Air

Check"in this section, This furnace MUST be vented to the out-

side.

If the furnace is to be installed in a crawl space, consult local

codes. A suitable concrete pad or blocks are recommended for

crawl space installation on the ground.

NOTE: 6" bottom clearance required for condensate trap.

Thirty (30) inches between the front of the furnace and adjacent

construction or other appliances MUST be maintained for service

clearance.

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace clear-

ances are met. See Figure 4.

This furnace MUST NOT be installed directly on carpeting or tile or

other combustible material other than wood flooring or supports.

For horizontal installation over a finished living space. A field fabri-

cated auxiliary drain pan with drain pipe is required to prevent

damage by overflow due to blocked condensate drain.

AirOpenings andConnecting Ducts

1. Total input rating for all non direct vent gas appliances

MUST be considered when determining free area of open-

ings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they MUST be

no less than 1/4" mesh.

4. The minimum dimension of rectangular air ducts MUST

NOT be less than 3".

5. When sizing grille or louver, use the free area of opening. If

free area is NOT stamped or marked on grill or louver, as-

sume a 20% free area for wood and 60% for metal.

Confined Space Installation

NOTE: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

Requirements

1. Provide confined space with sufficient air for proper com-

bustion and ventilation of flue gases using horizontal or ver-

tical ducts or openings.

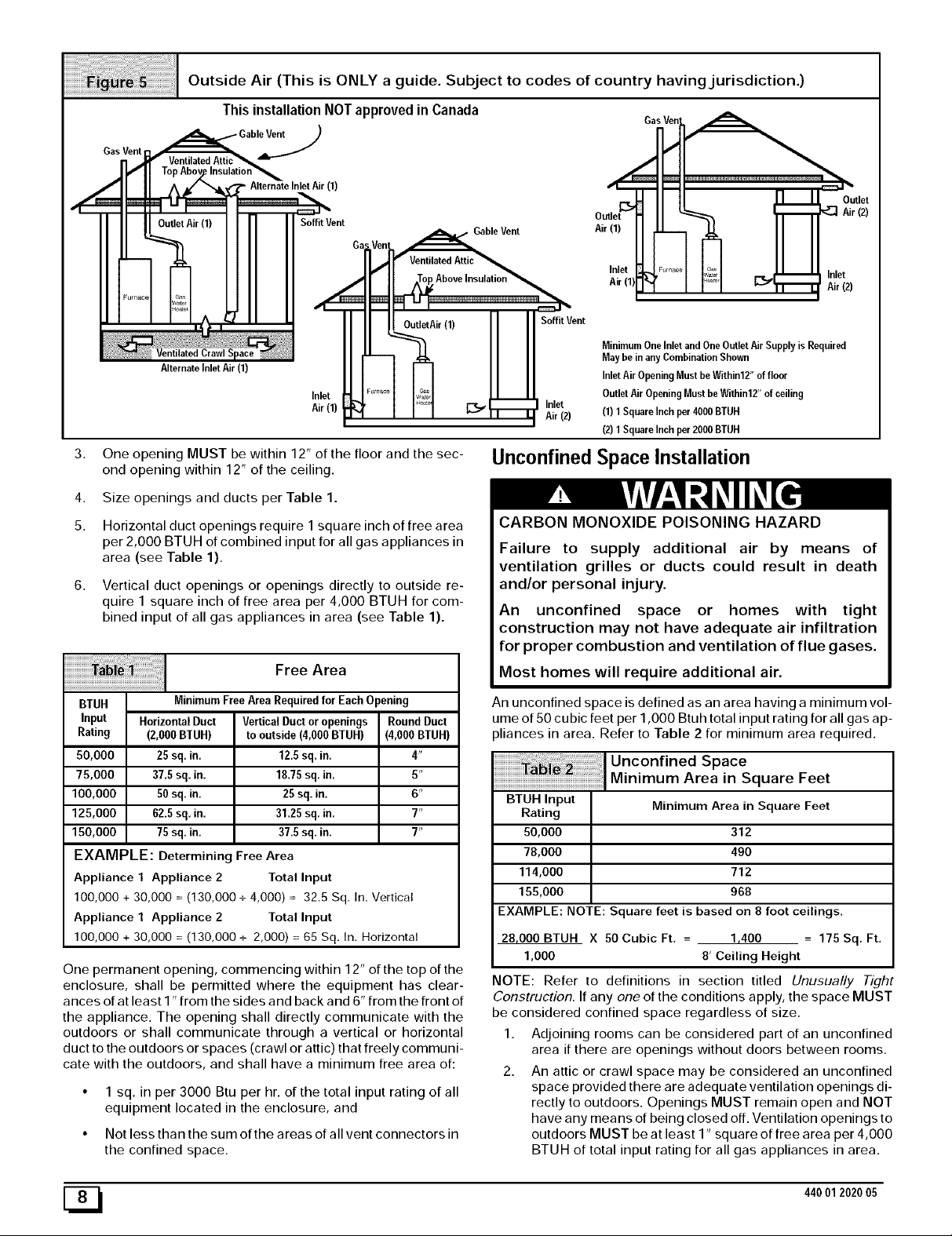

2. Figure 5 illustrate how to provide combustion and ventila-

tion air. A minimum of two permanent openings, one inlet

and one outlet, are required.

44001 2020 05 [_

Page 8

Outside Air (This is ONLY a guide. SubJect to codes of country having jurisdiction.)

ThisinstallationNOTapprovedin Canada

Gas Vent

Soffit Vent Outlet I1 I I _ _ _ " ( )

G_ gen _Gable Vent Air(l) U _-] _ I I

/ fVentilatedAttic_ I_'_[ 1_1 ,I I Inlet

Alternate Inlet Air (1)

Inlet

Air (1)

3.

One opening MUST be within 12" of the floor and the sec-

ond opening within 12" of the ceiling.

4.

Size openings and ducts per Table 1.

5.

Horizontal duct openings require 1 square inch of free area

per 2,000 BTUH of combined input for all gas appliances in

area (see Table 1).

6.

Vertical duct openings or openings directly to outside re-

quire 1 square inch of free area per 4,000 BTUH for com-

bined input of all gas appliances in area (see Table 1).

Free Area

Minimum One Inlet and One Outlet Air Supply is Required

May be in any Combination Shown

InletAir OpeningMust be Within12" offloor

Inlet

Air (2)

Outlet Air Opening Must be Within12" of ceiling

(1) 1Square Inch per4000BTUH

(2) 1Square Inch per2000BTUH

Unconfined Space Installation

CARBON MONOXIDE POISONING HAZARD

Failure to supply additional air by means of

ventilation grilles or ducts could result in death

and/or personal injury.

An unconfined space or homes with tight

construction may not have adequate air infiltration

for proper combustion and ventilation of flue gases.

Most homes will require additional air.

BTUH MinimumFreeArea Requiredfor EachOpening

Input HorizontalDuct VerticalDuctoropenings RoundDuct

Rating (2,000 BTUH) to outside(4,000BTUH) (4,000 BTUH)

50,000 25 sq. in. 12.5 sq. in. 4"

75,000 37.5sq. in. 18.75 sq. in. 5"

100,000 50 sq. in. 25 sq. in. 6"

125,000 62.5sq. in. 3125 sq. in. 7"

150,000 75 sq. in. 37.5sq. in. 7"

EXAMPLE: Determining Free Area

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 2,000) = 65 Sq. In. Horizontal

One permanent opening, commencing within 12" of the top of the

enclosure, shall be permitted where the equipment has clear-

ances of at least 1" from the sides and back and 6" from the front of

the appliance. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces (crawl or attic) that freely communi-

cate with the outdoors, and shall have a minimum free area of:

1 sq. in per 3000 Btu per hr. of the total input rating of all

equipment located in the enclosure, and

Not less than the sum of the areas of all vent connectors in

the confined space.

An unconfined space is defined as an area having a minimum vol-

ume of 50 cubic feet per 1,000 Btuh total input rating for all gas ap-

)liances in area. Refer to Table 2 for minimum area required.

BTUH Input

Rating

50,000

78,000

114,000

155,000

EXAMPLE: NOTE: Square feet is based on 8 foot ceilings.

28,000 BTUH X 50 Cubic Ft, = 1,400 = 175 Sq, Ft.

1,000 8' Ceiling Height

Minimum Area in Square Feet

312

490

712

968

NOTE: Refer to definitions in section titled Unusually Tight

Construction. If any one of the conditions apply, the space MUST

be considered confined space regardless of size.

1. Adjoining rooms can be considered part of an unconfined

area if there are openings without doors between rooms.

2. An attic or crawl space may be considered an unconfined

space provided there are adequate ventilation openings di-

rectly to outdoors. Openings MUST remain open and NOT

have any means of being closed off. Ventilation openings to

outdoors MUST be at least 1" square of free area per 4,000

BTUH of total input rating for all gas appliances in area.

[_ 44001 2020 05

Page 9

3. Install air intake a minimum of 12" above maximum snow

level and clear of any obstruction. Duct or ventilation open-

ing requires one squa re inch of free area per 4,000 BTU H of

total input rating for all gas appliances in area.

4. Air inlet MUST be screened with not less than 114" mesh

screen.

Unusually Tight Construction

In unconfined spaces, infiltration may be adequate to provide air

for combustion, ventilation and dilution of flue gases. However, in

buildings with unusually tight construction, additional air MUST be

provided using the methods described in section titled Confined

Space Installation:

Unusually tight construction is defined as: Construction with

1. Walls and ceilings exposed to the outside have a continu-

ous, sealed vapor barrier. Openings are gasketed or sealed

and

2,

Doors and openable windows are weather stripped and

3.

Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air tempera-

ture across the heat exchanger MUST not fall below 60°F or flue

gases will condense in the heat exchanger. This will shorten the

life of the heat exchanger and possibly void your warranty.

Venting and Combustion Air Check

The following information is supplied to allow the installer to make

adjustments to the setup of existing appliances, IF REQUIRED,

based on good trade practices, local codes, and good judgement

of the installer. Manufacturer does NOT take responsibility for

modifications made to existing equipment.

NOTE: If this installation replaces an existing furnace from a

commonly vented system, the original venting system may no lon-

ger be sized to properly vent the attached appliances. An improp-

erly sized venting system may cause the formation of condensate

in the vent and the leakage or spillage of vent gases. To make sure

there is adequate combustion air for all appliances, MAKE THE

FOLLOWING CHECK.

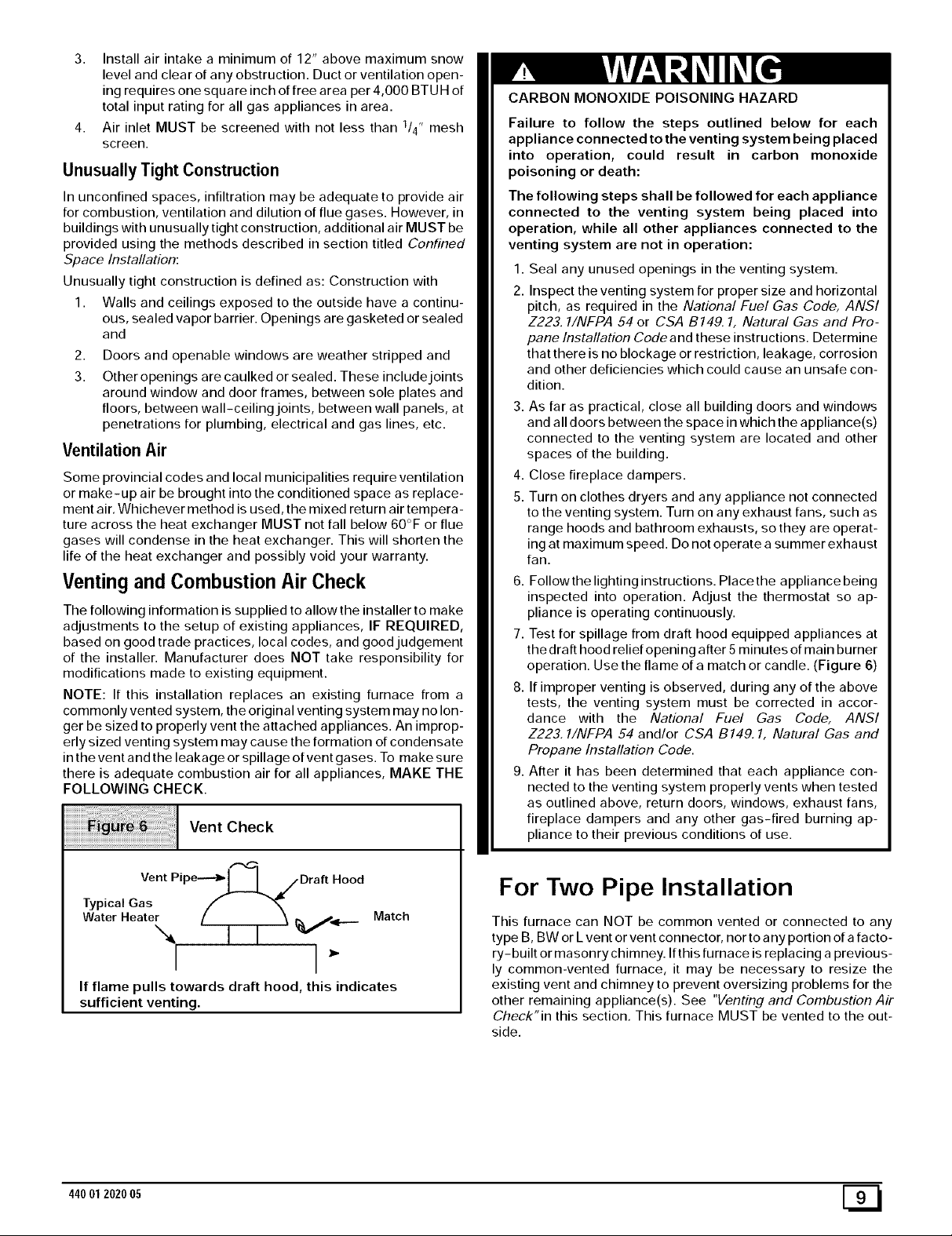

Vent Check

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation, could result in carbon monoxide

poisoning or death:

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223. 1/NFPA 54 or CSA B149.1, Natural Gas and Pro-

pane Installation Code and these instructions. Determine

that there is no blockage or restriction, leakage, corrosion

and other deficiencies which could cause an unsafe con-

dition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are operat-

ing at maximum speed. Do not operate a summer exhaust

fan.

6. Followthe lighting instructions. Placethe appliance being

inspected into operation. Adjust the thermostat so ap-

pliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle. (Figure 6)

8. If improper venting is observed, during any of the above

tests, the venting system must be corrected in accor-

dance with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149. 1, Natural Gas and

Propane Installation Code.

9. After it has been determined that each appliance con-

nected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-fired burning ap-

pliance to their previous conditions of use.

,,--.q

Vent Pipe'---_U_ S Draft Hood

Typical Gas / _'_

Water Heate[_l / i i ' V_l--- Match

If flame pulls towards draft hood, this indicates

sufficient venting.

44001 2020 05 [_1

For Two Pipe Installation

This furnace can NOT be common vented or connected to any

type B, BW or Lvent or vent connector, nor to any portion of a facto-

ry-built or masonry chimney. Ifthis furnace is replacing aprevious-

ly common-vented furnace, it may be necessary to resize the

existing vent and chimney to prevent oversizing problems for the

other remaining appliance(s). See "Venting and Combustion Air

Check"in this section, This furnace MUST be vented to the out-

side.

Page 10

4. Vent and Combustion Air Piping

CARBON MONOXIDE POISONING HAZARD.

Failure to properly vent this furnace could result in

death and/or personal injury.

Use methods described here to provide combustion

and ventilation air.

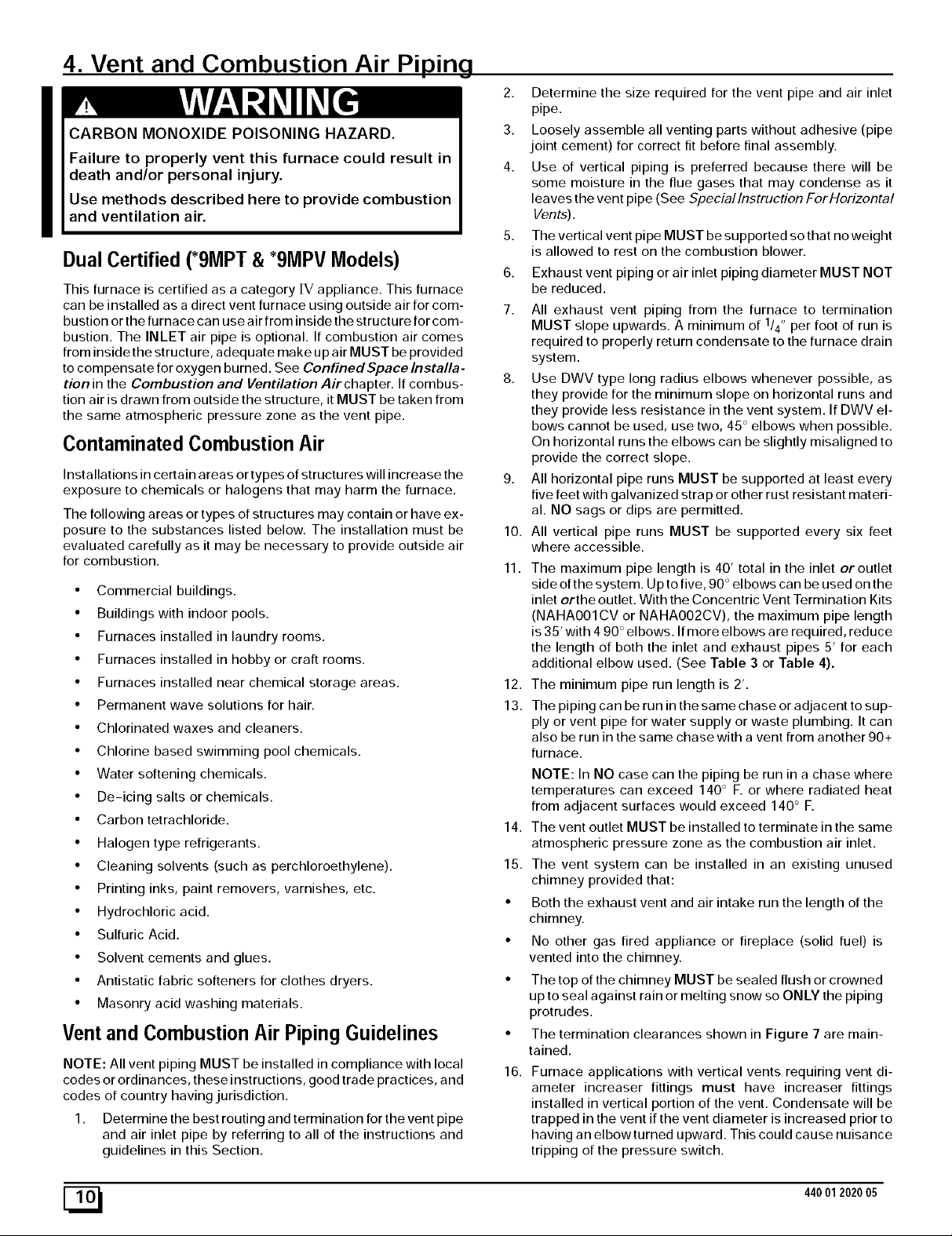

Dual Certified (*9MPT & *9MPV Models)

This furnace is certified as a category IV appliance. This furnace

can be installed as a direct vent furnace using outside air for com-

bustion or the furnace can use air from inside the structure for com-

bustion. The INLET air pipe is optional. If combustion air comes

from inside the structure, adequate make up air MUST be provided

to compensate for oxygen burned. See Confined Space Installa-

tion in the Combustion and Ventilation Air chapter. If combus-

tion air is drawn from outside the structure, it MUST be taken from

the same atmospheric pressure zone as the vent pipe.

Contaminated Combustion Air

Installations in certain areas or types of structures will increase the

exposure to chemicals or halogens that may harm the furnace.

The following areas or types of structures may contain or have ex-

posure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air

for combustion.

• Commercial buildings.

• Buildings with indoor pools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

Vent and Combustion Air Piping Guidelines

NOTE: All vent piping MUST be installed in compliance with local

codes or ordinances, these instructions, good trade practices, and

codes of country having jurisdiction.

1. Determine the best routing and termination for the vent pipe

and air inlet pipe by referring to all of the instructions and

guidelines in this Section.

2,

Determine the size required for the vent pipe and air inlet

pipe.

3.

Loosely assemble all venting parts without adhesive (pipe

joint cement) for correct fit before final assembly.

4.

Use of vertical piping is preferred because there will be

some moisture in the flue gases that may condense as it

leaves the vent pipe (See 5peciallnstruction ForHorizontal

Vents).

5,

The vertical vent pipe MUST be supported so that no weight

is allowed to rest on the combustion blower.

6.

Exhaust vent piping or air inlet piping diameter MUST NOT

be reduced.

7.

All exhaust vent piping from the furnace to termination

MUST slope upwards. A minimum of 1/4" per foot of run is

required to properly return condensate to the furnace drain

system.

Use DWV type long radius elbows whenever possible, as

they provide for the minimum slope on horizontal runs and

they provide less resistance in the vent system. If DWV el-

bows cannot be used, use two, 45 ° elbows when possible.

On horizontal runs the elbows can be slightly misaligned to

provide the correct slope.

All horizontal pipe runs MUST be supported at least every

five feet with galvanized strap or other rust resistant materi-

al. NO sags or dips are permitted.

10.

All vertical pipe runs MUST be supported every six feet

where accessible.

11.

The maximum pipe length is 40' total in the inlet or outlet

side of the system. Up to five, 90 ° elbows can be used on the

inlet orthe outlet. With the Concentric Vent Termination Kits

(NAHAO01CV or NAHAOO2CV), the maximum pipe length

is 35' with 4 90 ° elbows. If more elbows are required, reduce

the length of both the inlet and exhaust pipes 5' for each

additional elbow used. (See Table 3 or Table 4).

12.

The minimum pipe run length is 2'.

13.

The piping can be run in the same chase or adjacent to sup-

ply or vent pipe for water supply or waste plumbing. It can

also be run in the same chase with a vent from another 90+

furnace.

NOTE: In NO case can the piping be run in a chase where

temperatures can exceed 140 ° F. or where radiated heat

from adjacent surfaces would exceed 140 ° F.

14. The vent outlet MUST be installed to terminate in the same

atmospheric pressure zone as the combustion air inlet.

15. The vent system can be installed in an existing unused

chimney provided that:

• Both the exhaust vent and air intake run the length of the

chimney.

• No other gas fired appliance or fireplace (solid fuel) is

vented into the chimney.

• The top of the chimney MUST be sealed flush or crowned

up to seal against rain or melting snow so ONLY the piping

protrudes.

The termination clearances shown in Figure 7 are main-

tained.

16.

Furnace applications with vertical vents requiring vent di-

ameter increaser fittings must have increaser fittings

installed in vertical portion of the vent. Condensate will be

trapped in the vent if the vent diameter is increased prior to

having an elbow turned upward. This could cause nuisance

tripping of the pressure switch.

[_ 44001 2020 05

Page 11

Piping InsulationGuidelines

NOTE: Use closed cell, neoprene insulation or equivalent. If Fiber-

glass or equivalent insulation is used it must have a vapor barrier.

Use Rvalues of 7 upto 10', R-11 if exposure exceeds 10'. If Fiber-

glass insulation is used, exterior to the structure, the pipe MUST

be boxed in and sealed against moisture.

1. .When the vent or combustion air pipe height above the roof

exceeds 30", or if an exterior vertical riser is used on a hori-

zontal vent to get above snow levels, the exterior portion

MUST be insulated.

2. When combustion air inlet piping is installed above a sus-

pended ceiling, the pipe MUST be insulated with moisture

resistant insulation such as Armaflex or other equivalent

type of insulation.

3. Insulate combustion air inlet piping when run in warm, hu-

mid spaces such as basements.

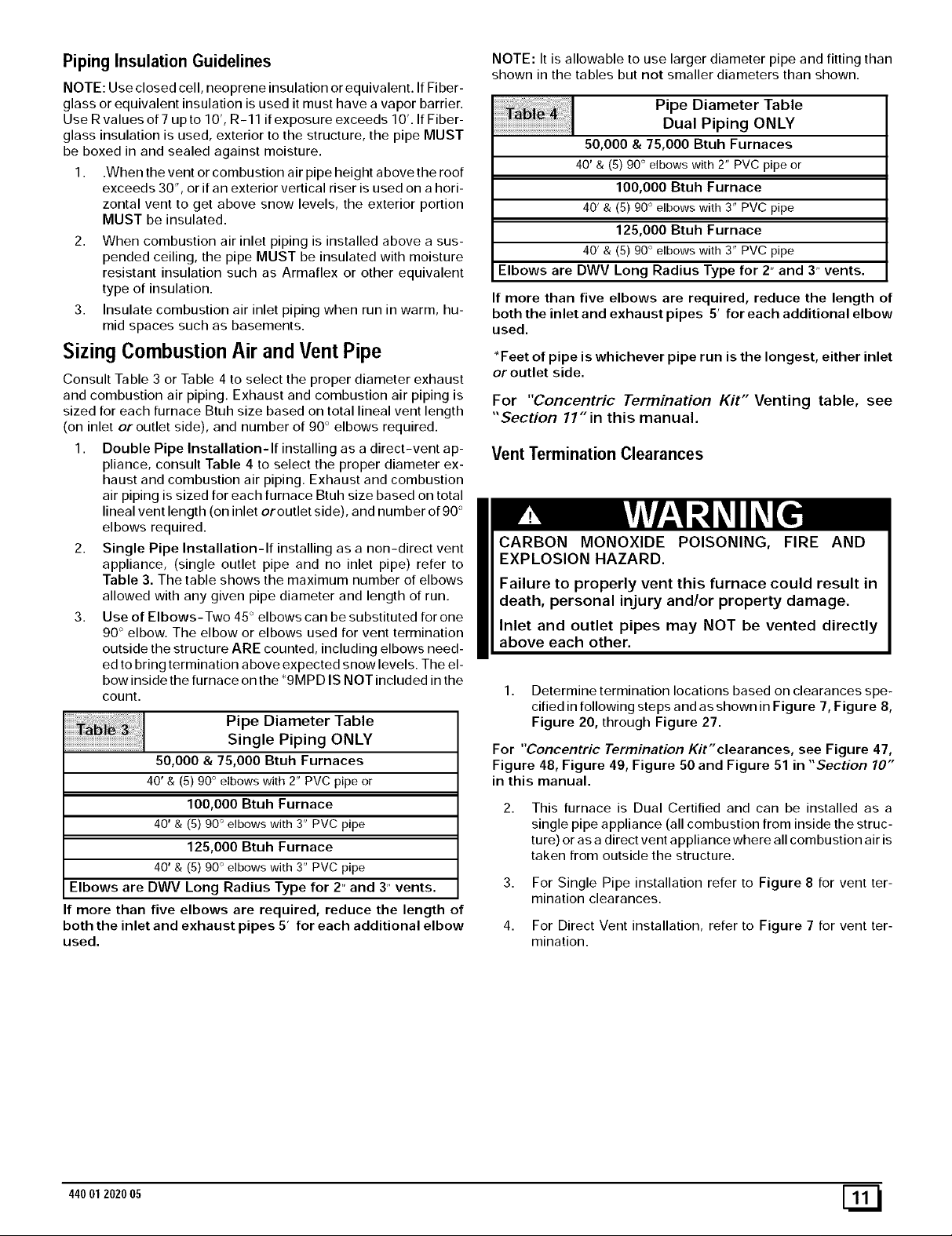

Sizing Combustion Air and Vent Pipe

Consult Table 3 or Table 4 to select the proper diameter exhaust

and combustion air piping. Exhaust and combustion air piping is

sized for each furnace Btuh size based on total lineal vent length

(on inlet or outlet side), and number of 90 ° elbows required.

1. Double Pipe Installation-If installing as a direct-vent ap-

pliance, consult Table 4 to select the proper diameter ex-

haust and combustion air piping. Exhaust and combustion

air piping is sized for each furnace Btuh size based on total

lineal vent length (on inlet oroutlet side), and number of 90 °

elbows required.

2. Single Pipe Installation-If installing as a non-direct vent

appliance, (single outlet pipe and no inlet pipe) refer to

Table 3. The table shows the maximum number of elbows

allowed with any given pipe diameter and length of run.

3. Use of Elbows-Two 45 ° elbows can be substituted for one

90 ° elbow. The elbow or elbows used for vent termination

outside the structure ARE counted, including elbows need-

ed to bring termination above expected snow levels. The el-

bow inside the furnace on the *9MPD IS NOT included in the

count.

Pipe Diameter Table

Single Piping ONLY

50,000 & 75,000 Btuh Furnaces

40' & (5) 90° elbows with 2" PVC pipe or

100,000 Btuh Furnace

40' & (5) 90° elbows with 3" PVC pipe

125,000 Btuh Furnace

40' & (5) 90° elbows with 3" PVC pipe

Elbows are DWV Long Radius Type for 2" and 3" vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5' for each additional elbow

used.

NOTE: It is allowable to use larger diameter pipe and fitting than

shown in the tables but not smaller diameters than shown.

Pipe Diameter Table

Dual Piping ONLY

50,000 & 75,000 Btuh Furnaces

40' & (5) 90 ° elbows with 2" PVC pipe or

100,000 Btuh Furnace

40' & (5) 90° elbows with 3" PVC pipe

125,000 Btuh Furnace

40' & (5) 90° elbows with 3" PVC pipe

Elbows are DWV Long Radius Type for 2" and 3" vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5' for each additional elbow

used.

*Feet of pipe is whichever pipe run is the longest, either inlet

or outlet side.

For "Concentric Termination Kit" Venting table, see

"Section 11" in this manual.

Vent Termination Clearances

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property damage.

Inlet and outlet pipes may NOT be vented directly

above each other.

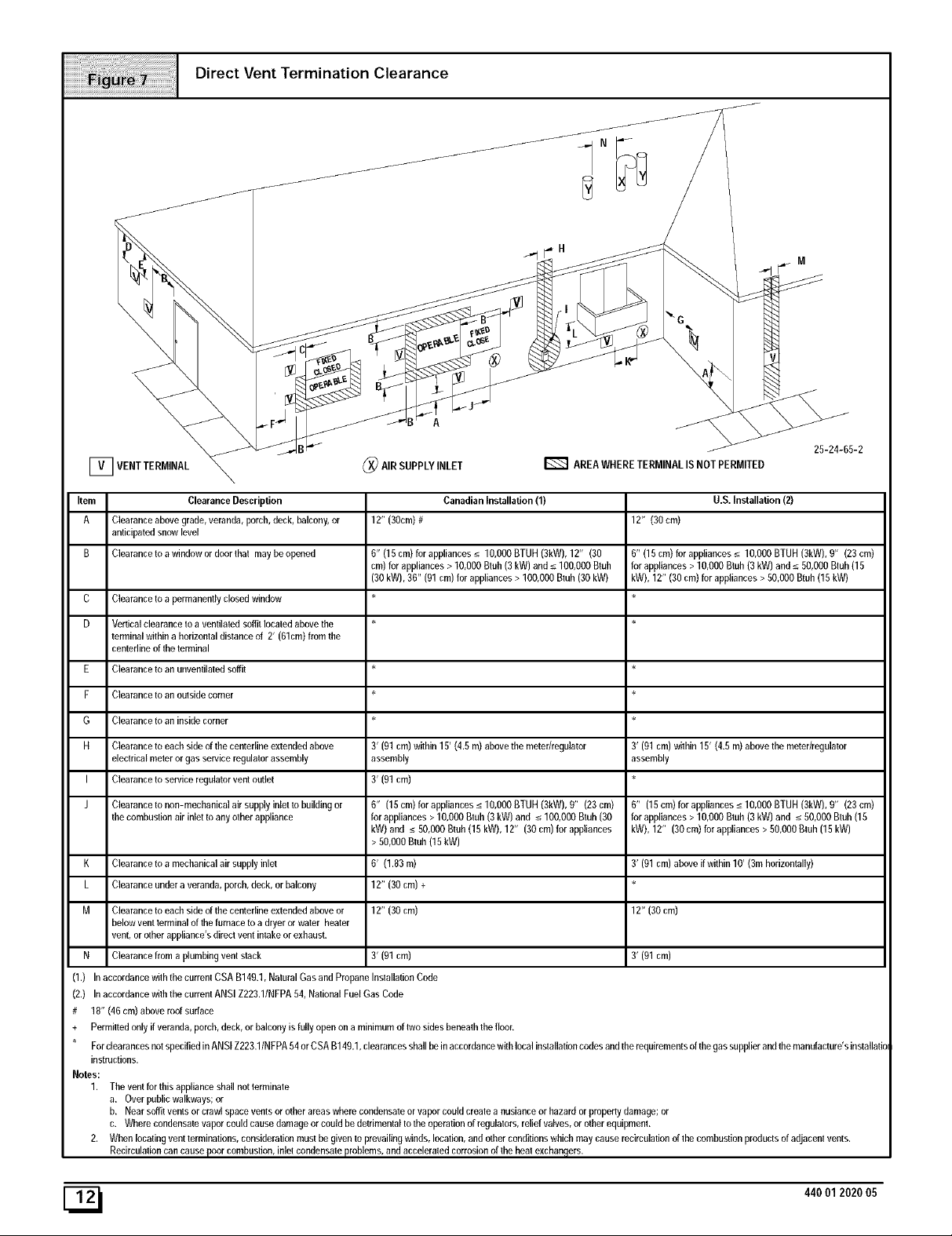

1. Determine termination locations based on clearances spe-

cified in following steps and as shown in Figure 7, Figure 8,

Figure 20, through Figure 27.

For "Concentric Termination Kit"clearances, see Figure 47,

Figure 48, Figure 49, Figure 50 and Figure 51 in "Section 10"

in this manual.

This furnace is Dual Certified and can be installed as a

single pipe appliance (all combustion from inside the struc-

ture) or as a direct vent appliance where all combustion air is

taken from outside the structure.

3. For Single Pipe installation refer to Figure 8 for vent ter-

mination clearances.

4. For Direct Vent installation, refer to Figure 7 for vent ter-

mination.

44001 2020 05 [_1

Page 12

Item Clearance Description

A Clearance above grade, veranda, porch, deck, balcony, or

anticipated snow level

B Clearance to awindow or door thai may be opened

C Clearance to a permanently closed window

D Vertical clearance to a ventilated soffit located above the

terminal within a horizontal distance of 2' (61cm) from the

centedine of the terminal

E Clearance to an unventilated soffit

P Clearance to an outside corner

G Clearance to an inside comer

H Clearance to each side of the centefline extended above

electrical meter or gas service regulator assembly

I Clearance to service regulator vent outlet

J Clearance to non-mechanical air supply inlet _o building or

the combustion air inlet to any other appliance

Canadian Installation (1)

12" (30cm)#

6" (15 cm) for appliances _< 10,000 BTUH (3kW), 12" (30

cm) for appliances > 10,000 Btuh (3 kW) and _<100,000 Btuh

(30 kW), 36" (91 cm) for appliances > 100,000 Btub (30 kW)

3' (91 cm) within 15' (4.5 m) above the meter/regulator

assembly

3' (91 cm)

6" (15cm)forappliances_<10,000BTUH(3kW),0" (23cm)

forappliances> 10,000Btuh (3kW) and _<100,000Btuh(30

kW) and _<50,000Btuh(15kW), 12" (30cm)for appliances

12" (30cm)

6" (15 cm) for appliances _< 10,000 BTUH (3kW), 0" (23 cm)

for appliances >10,000 Bmh (3 kW) and _<50,000 Btuh (15

kW), 12" (30 cm) for appliances > 50,000 Btuh (15 kW)

3' (91 cm) within 15' (4.5 m) above the meter/regulator

assembly

6" (15cm)forappliances_<lO,OOOBTUH (3kW),O" (23cm)

for appliances >10,000 Btuh (3 kW) and _<50,000 Btuh (15

kW), 12" (30 cm) for appliances > 50,000 Bluh (15 kW)

U.S. Installation (2)

> 50,000Bmh (15kW)

K Clearance to amechanical air supply inlet

L Clearance under a veranda, porch, deck, or balcony

M Clearance to each side of the centefline extended above or

below vent terminal of the furnace to a dryer or water heater

vent, or other appliance's direct vent intake or exhaust.

N Clearance from a plumbing vent stack 3' (91 cm)

(1.) In accordance with the currem CSA B149.1, Natural Gas and Propane Installation Code

(2,) In accordance w0h the current ANSI Z223.1/NFPA 54, National Fuel Gas Code

# 18" (46 cm) above roof surface

+ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

For deara nces not specified in AN SI Z223.1/N FPA 54 or CSA B149,1, clearances shall be in accordance with local installation codes and the requirements ofthe gas supplier and the manufacture's installatie

instructions.

Notes:

1. The vent for this appliance shall not terminate

a. Over public walkways; or

b. Near soffit vents or crawl space vents or other areas where condensate or vapor could create a nusiance or hazard or property damage; or

c. Where condensate vapor could cause damage or could be detrimental to the operation of regulalors, relief valves, or other equipment.

2. When locating vent lerminations, consideration must be given to prevailing winds, location, and other conditions which may cause recirculation of the combustion products of adjacent vents.

Recircula0on can cause poor combustion, inlet condensate problems, and accelerated corrosion of the heal exchangers.

6' (1.83m)

12" (30 cm) +

12" (30 cm)

3' (91 cm) above if within 10' (3m horizontally)

12" (30 cm)

3' (91 cm)

[_ 440012020 05

Page 13

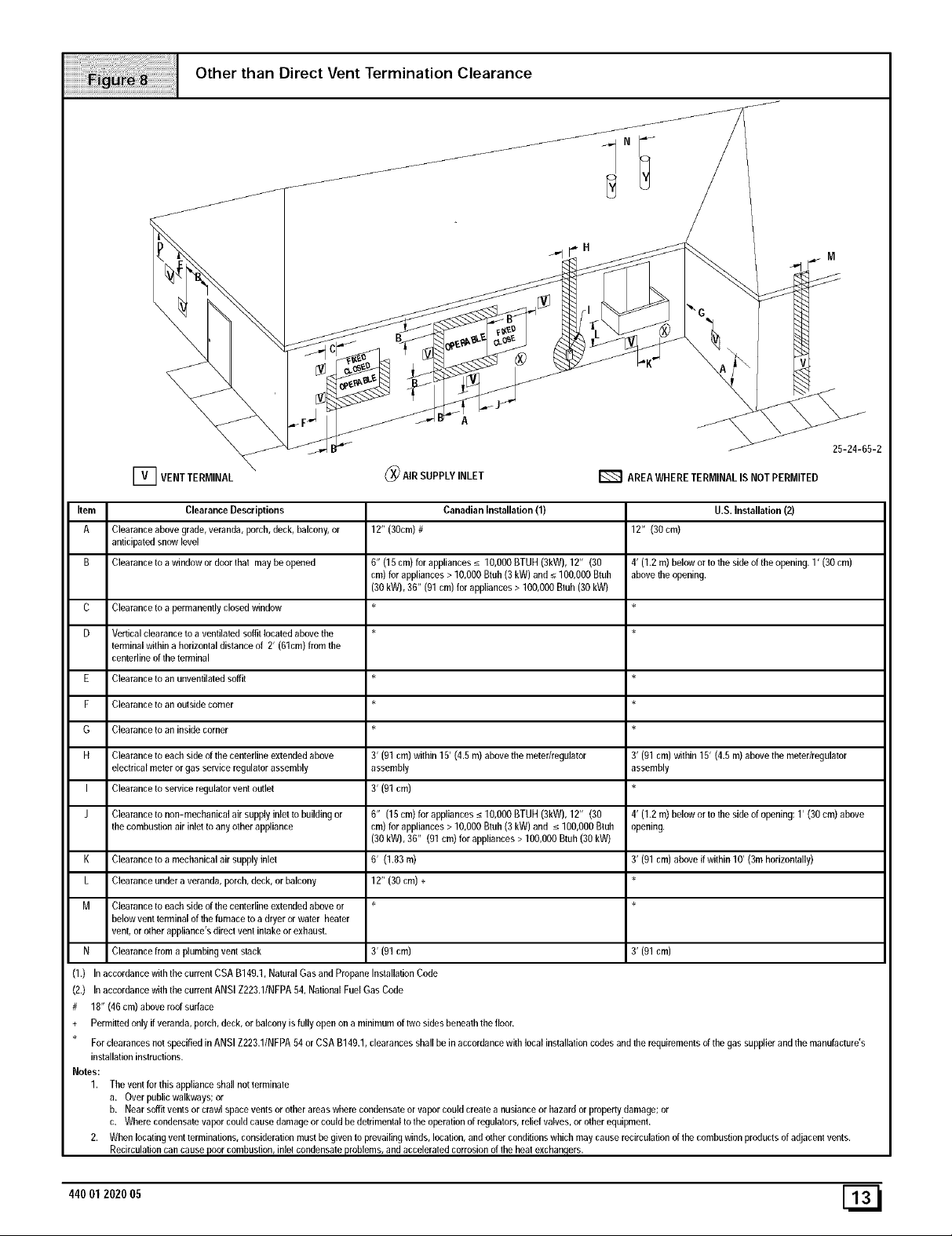

Other than Direct Vent Termination Clearance

Item Clearance Descriptions

A Clearance above grade, veranda, porch, deck, balcony, or

anticipated snow level

B Clearance to awindow or door thai may be opened

C

Clearance to a permanently closed window

D

Vertical clearance to a ventilated soffit located above the *

terminal within a horizontal distance of 2' (61cm) from the

centerline of the terminal

Clearance to an unventilated soffit *

F Clearance to an outside corner *

G Clearance to an inside comer *

H Clearance to each side of the centedine extended above

eleclrical meter or gas service regulator assembly

I Clearance to service regulator vent outlet

J Clearance to non-mechanical air supply inlel to building or

the combustion air inlet to any other appliance

K Clearance to amechanical air supply inlel

L Clearance under a veranda, porch, deck, or balcony

M Clearance to each side of the centedine extended above or *

below vent terminal of the furnace to a dryer or water heater

vent, or other appliance's direct vent intake or exhaust.

N Clearance from a plumbing vent stack

(1.) In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

(2.) In accordance wilh the current ANSI Z223.1/NFPA 04, National Fuel Gas Cede

# 18" (46 cm) above roof surface

+ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

For clearances not specified in ANSI Z223.1/NFPA 04 or CSA B140.1, clearances shall be in accordance with local installalion codes and the requirements of the gas supplier and the manufacture's

installation instructions.

Notes:

1. The vent for this appliance shall not terminale

a. Over public walkways; or

b. Near soffit vents or crawl space venta or other areas where condensate or vapor could create a nusiance or hazard or property damage; or

c. Where condensate vapor could cause damage or could be detrimental to the operafion of regulalors, relief valves, or other equipmenL

2. When locating vent terminations, consideration must be given to prevailing winds, location, and other conditions which may cause recirculation of the combustion products of adjacent vents.

Recirculafion can cause poor combustion, inlet condensate problems, and acceleraled corrosion of the heat exchangers.

12" (30cm)#

0" (10 cm) for appliances _< 10,000 BTUH (3kW), 12" (30

cm) for appliances > 10,000 Btuh (3 kW) and _<100,000 Btuh

(30 kW), 30" (01 cm) for appliances > 100,000 Btuh (30 kW)

3' (91 cm) within 15' (4.5 m) above the meter/regulator

assembly

3' (91 cm)

6" (15cm)forappliances_<10,OOOBTUH(3kW),12" (30

cm)forappliances> 10,000Btuh(3kW) and _<100,000Btuh

(30 kW),30" (91cm) for appliances> 100,000Btuh(30 kW)

6' (1.83m)

12" (30 cm) +

3' (91 cm)

Canadian Installation (1)

U.S.Installation(2)

12" (30cm)

4' (1.2 m) below or to the side of the opening, 1' (30 cm)

above the opening.

3' (01 cm) within 15' (4.5 m) above the meter/regulator

assembly

4' (1.2 m) below or to the side of opening: 1' (30 cm) above

opening.

3' (91 cm) above if within 10' (3m horizontally)

3' (91 cm)

44001 2020 05 [_

Page 14

CondensateDrainTrap

This furnace removes both sensible and latent heat from the prod-

ucts of combustion. Removal of the latent heat results in con-

densation of the water vapor. The condensate is removed from the

furnace through the drains in the plastic transition and the vent fit-

ting. The drains connect to the factory installed internally mounted

condensate drain trap on the left or right side of the furnace.

The startup of a new furnace will involve a cycle or two of the fur-

nace to properly prime the condensate trap with water. Until the

trap is fully primed, some condensate will be pulled into the com-

bustion blower. The furnace may cycle on the pressure switch con-

nected to the plastic transition box due to condensate buildup.

After the trap is primed, the condensate will start draining from the

furnace. The combustion blower will clear out any remaining con-

densate in the blower housing through the vent fitting downstream

of the blower. Note that the condensate trap can also be primed by

pouring water into the 1/2" drain hose. Remove the1/2" ID drain

hose from either the gutter or the white PVC Tee Trap. Using a fun-

nel pour eight (8) ounces of water into 1/2" ID drain hose.Water will

flow through the drain hose and into the condensate drain trap.

This will prime both the vent and the transition sides of the trap. Re-

connect the 1/2, ID drain hose to the original component, either the

gutter or the PVC Tee Trap.

The condensate drain trap supplied with the furnace MUST be

used. The drain connection on the condensate drain trap is sized

for 3/4" PVC or CPVC pipe, however alternate 1/2" CPVC (nominal

5/8" O.D.) or vinyl tubing with a minimum inner diameter (I.D.) of

5/8" may also be used, as allowed by local codes. Alternate drain

pipes and hoses may be used as allowed by local codes.

The drain line must maintain a 1/4" per foot downward slopetoward

the drain. 1/4" per foot is recommended. Installation of an overflow

line is recommended when the 1/4" per foot slope to the conden-

sate drain cannot be maintained. See Figure 18 for proper routing

and installation of the overflow.

DO NOT trap the drain line in any other location than at the con-

densate drain trap supplied with the furnace.

If possible DO NOT route the drain line where it may freeze. The

drain line must terminate at an inside drain to prevent freezing of

the condensate and possible property damage.

A condensate sump pump MUST be used if required by lo-

cal codes, or if no indoor floor drain is available. The con-

densate pump must be approved for use with acidic

condensate.

2. A plugged condensate drain line or a failed condensate

pump will allow condensate to spill. If the furnace is installed

where a condensate spill could cause damage, it is recom-

mended that an auxiliary safety switch be installed to pre-

vent operation of the equipment in the event of pump failure

or plugged drain line. If used, an auxiliary safety switch

should be installed in the R circuit (low voltage) ONLY.

3. If the auxiliary switch in the condensate pump is used, the

furnace may shut down dueto a blocked condensate line or

failed pump. To prevent frozen water pipes see the "Frozen

Water Pipe Hazard" section on Page 4 of this manual.

FROZEN AND BURST WATER PIPE HAZARD

Failure to do so could result in burst water pipes,

serious property damage and/or personal injury.

If a condensate pump is installed, a plugged

condensate drain or a failed pump may cause the

furnace to shut down. Do not leave the home

unattended during freezing weather without turning

off water supply and draining water pipes or

otherwise protecting against the risk of frozen pipes.

Condensate Drain Trap Freeze Protection

Special precautions MUST be made if installing furnace in an area

which may drop below freezing. This can cause improper opera-

tion or damage to the equipment. If the the furnace environment

has the potential of freezing, the drain trap and drain line must be

protected. Use 3 to 6 watt per foot at 115 volt, 40 ° F self-regulating

shielded and waterproof heat tape. Wrap the drain trap and drain

line with the heat tape and secure with the ties. Follow the heat

tape manufacturer's recommendations.

[_ 440012020 05

Page 15

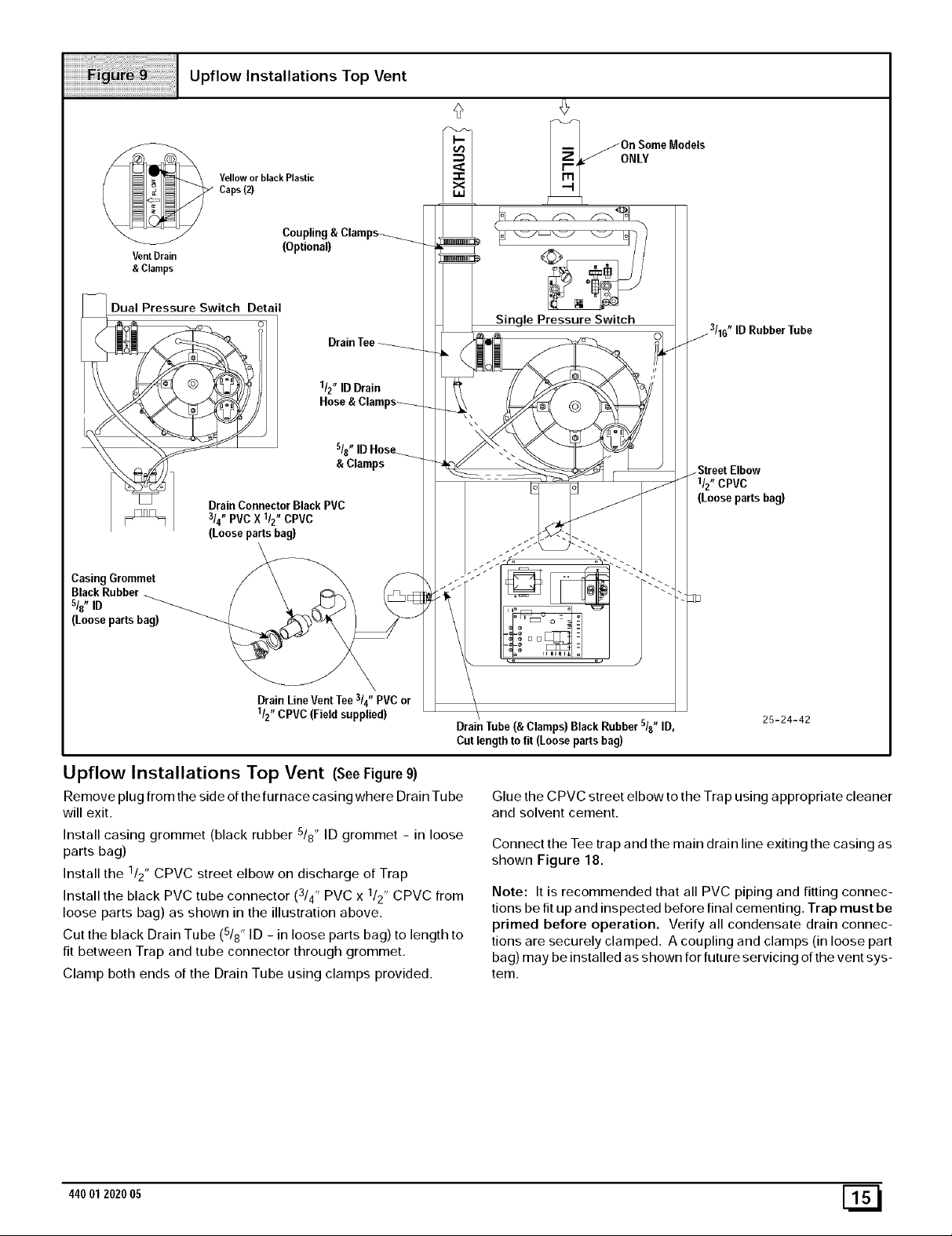

Upflow Installations Top Vent

vo,,oworb,ao,P,as,io SL;meMode,s

Caps(2)

_1 _ Si t le Pressure Switch / I 3 ,

\\ _//_ L_ _))_ l/ 1/2" ID Drain

l I 5/e"IDHose_

____ Hose& Clamps_ !__

I _ 1 DrainConnector BlackPVC __ (Looseparts bag)

3/4"PVCX 1/2"CPVC

(Loosepartsbag) __

Casing Grommet _ _ _

DrainTee_ _ _i _

II

©/ 1 / /16 IDRubberTube

DrainLineVentTee314" PVC or

1/2"CPVC(Field supplied) 25-24-42

Upflow Installations Top Vent (SeeFigure 9)

Remove plug from the side of the furnace casing where Drain Tu be

will exit.

Install casing grommet (black rubber 5/8" ID grommet - in loose

parts bag)

Install the 1/2" CPVC street elbow on discharge of Trap

Install the black PVC tube connector (3/4" PVC x 1/2" CPVC from

loose parts bag) as shown in the illustration above.

Cut the black Drain Tube (5/8" ID - in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

Drain Tube(& Clamps) Black Rubber /8 ID,

Cut length to fit (Loose parts bag)

Glue the CPVC street elbow to the Trap using appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Trap must be

primed before operation. Verify all condensate drain connec-

tions are securely clamped. A coupling and clamps (in loose part

bag) may be installed as shown for future servicing of the vent sys-

tem.

44001 2020 05 [_

Page 16

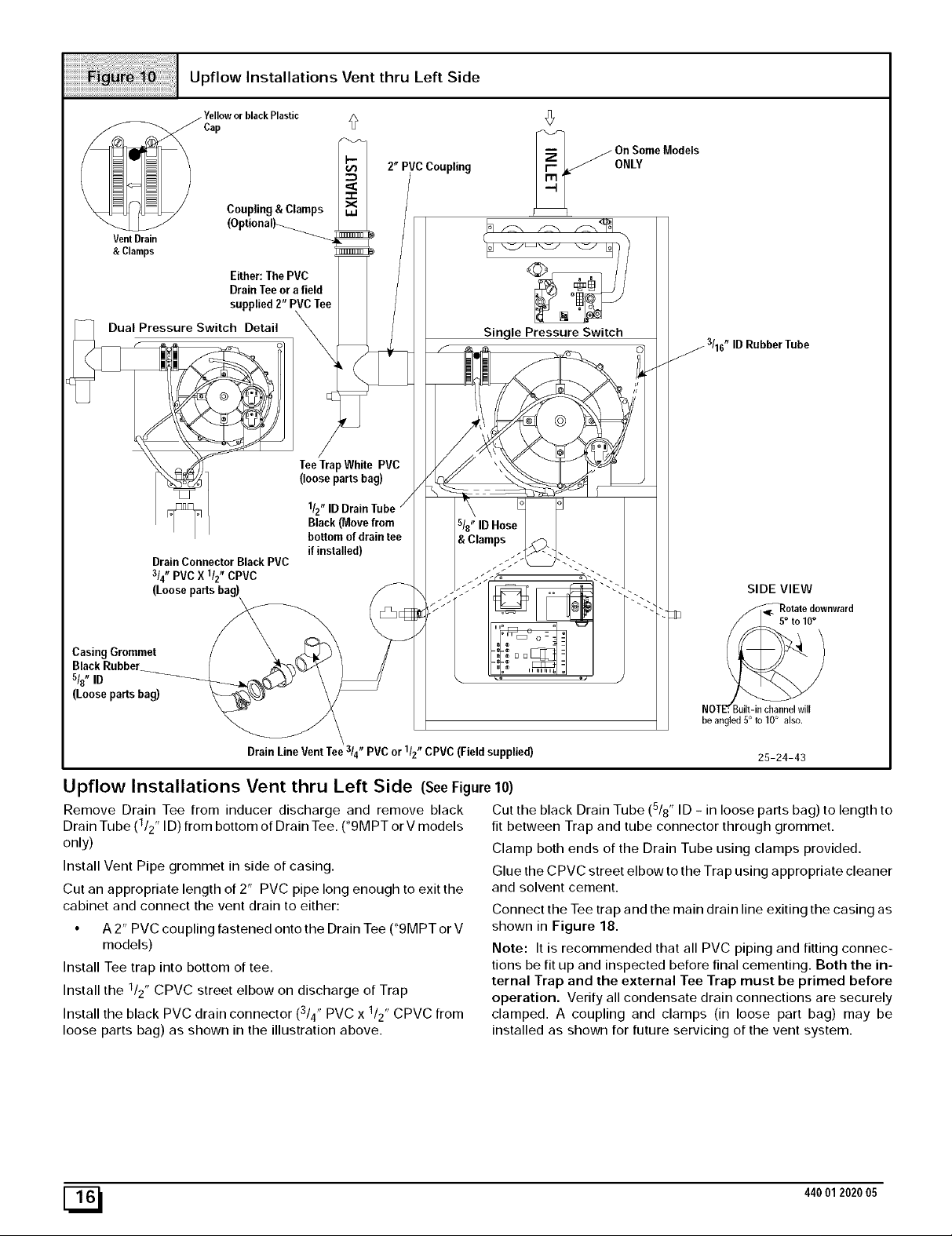

Upflow Installations Vent thru Left Side

. Yellow or black Plastic

Cap @

Coupling & Clamps

VentDrain

& Clamps

Either: ThePVC

DrainTeeor afield

supplied2" PVCTee

Dual Pressure Switch Detail

2" PVCCoupling

TeeTrap White PVC

(looseparts hag)

Sin qle Pressure Switch

On SomeModels

ONLY

" ID RubberTube

DrainConnector BlackPVC

Black(Movefrom

bottomof draintee

if installed)

s/8"ID Hose

& Clamps

3/4"PVCX 1/2" CPVC

(Loosepartshag)

Casing Grommet

sis"ID

(Loosepartsbag)

DrainLineVentTee3/4"PVC or 1/2"CPVC (Fieldsupplied)

Upflow Installations Vent thru Left Side (SeeFigure 10)

Remove Drain Tee from inducer discharge and remove black

Drain Tube (1/2" ID) from bottom of Drain Tee. (*9MPT or V models

only)

Install Vent Pipe grommet in side of casing.

Cut an appropriate length of 2" PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

• A 2" PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee trap into bottom of tee.

Install the 1/2" CPVC street elbow on discharge of Trap

Install the black PVC drain connector ( 14' PVC x 1/2" CPVC from

3 ,

loose parts bag) as shown in the illustration above.

Cut the black Drain Tube (5/8" ID - in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

Glue the CPVC street elbow to the Trap using appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the in-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

SIDE VIEW

//_otate downward

NOTE'_.Bu_]1-in channel will

be angled 5° to 10° also.

25-24-43

[_ 440012020 0S

Page 17

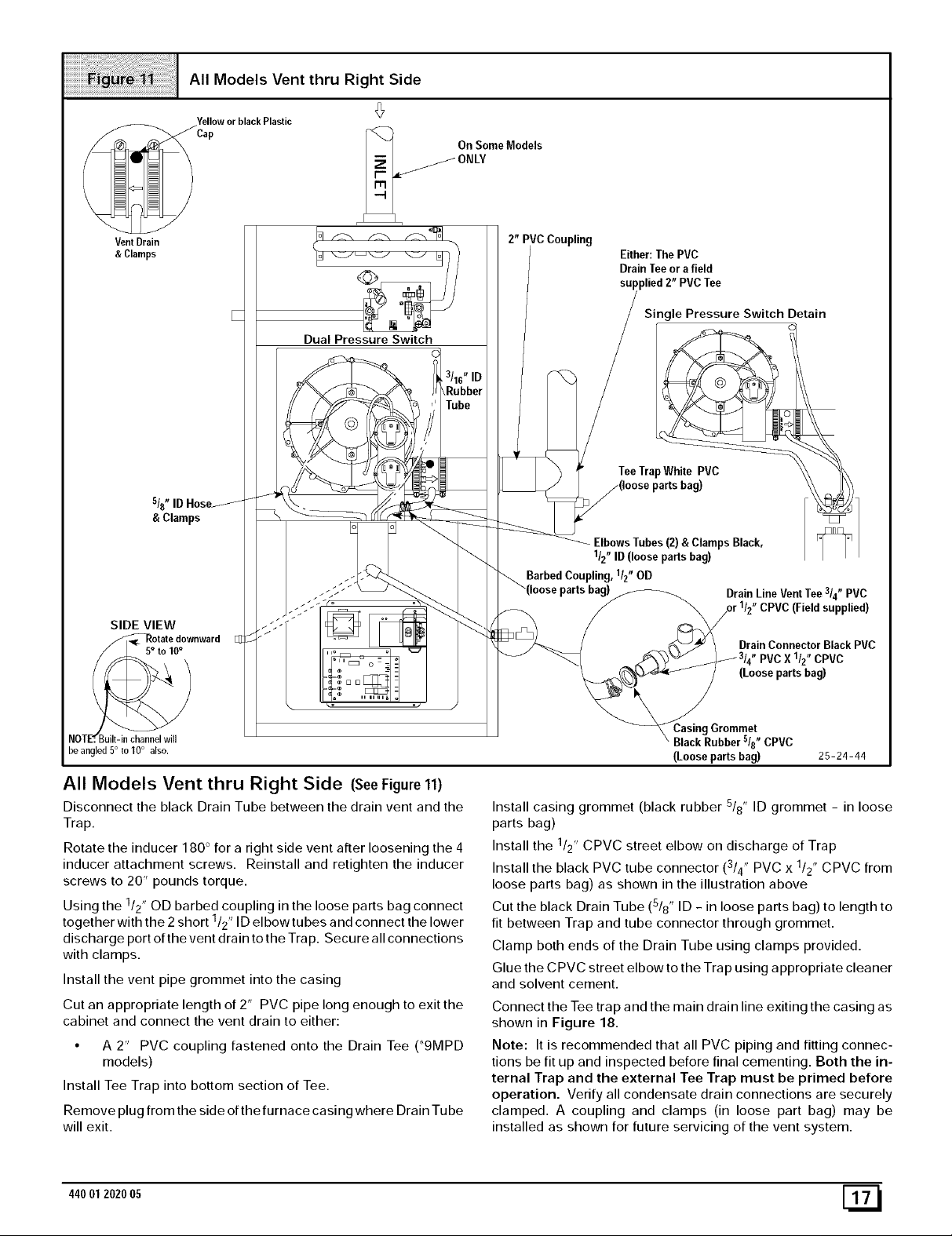

All Models Vent thru Right Side

On Some Models

VentDrain

& Clamps

%,

&Clamps

SIDE VIEW

/,_Rotat e downward

2" PVC Coupling

Either:ThePVC

Drain Teeor a field

supplied 2" PVC Tee

Single Pressure Switch Detain

Dual Pressure Switch

Tee Trap White PVC

ElbowsTubes(2) &Clamps Black,

112"ID(loose parts bag)

Barbed Coupling, 1/2"OD

DrainLine Vent Tee 314"PVC

CPVC(Field supplied)

DrainConnector Black PVC

PVCX 112"CPVC

(Loosepartsbag)

NOTE'r. Built-in channel will

he angled 5° to 10° also.

All Models Vent thru Right Side (SeeFigure 11)

Disconnect the black Drain Tube between the drain vent and the

Trap.

Rotate the inducer 180 ° for a right side vent after loosening the 4

inducer attachment screws. Reinstall and retighten the inducer

screws to 20" pounds torque.

Using the /2' OD barbed coupling in the loose parts bag connect

together with the 2 short /2' ID elbowtubes and connect the lower

discharge port of the vent drain to the Trap. Secure all connections

with clamps.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2" PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

• A 2" PVC coupling fastened onto the Drain Tee (_9MPD

Install Tee Trap into bottom section of Tee.

Remove plug from the side of the furnace casing where Drain Tube

will exit.

1 ,

1 ,

models)

Grommet

Black Rubber 5/8" CPVC

(Loose parts bag) 25-24-44

Install casing grommet (black rubber 5/8" ID grommet - in loose

parts bag)

Install the 1/2" CPVC street elbow on discharge of Trap

Install the black PVC tube connector ( /4' PVC x 1/2" CPVC from

3 ,

loose parts bag) as shown in the illustration above

Cut the black Drain Tube (5/8" ID - in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

Glue the CPVC street elbow to the Trap using appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the in-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

44001 2020 05 [_

Page 18

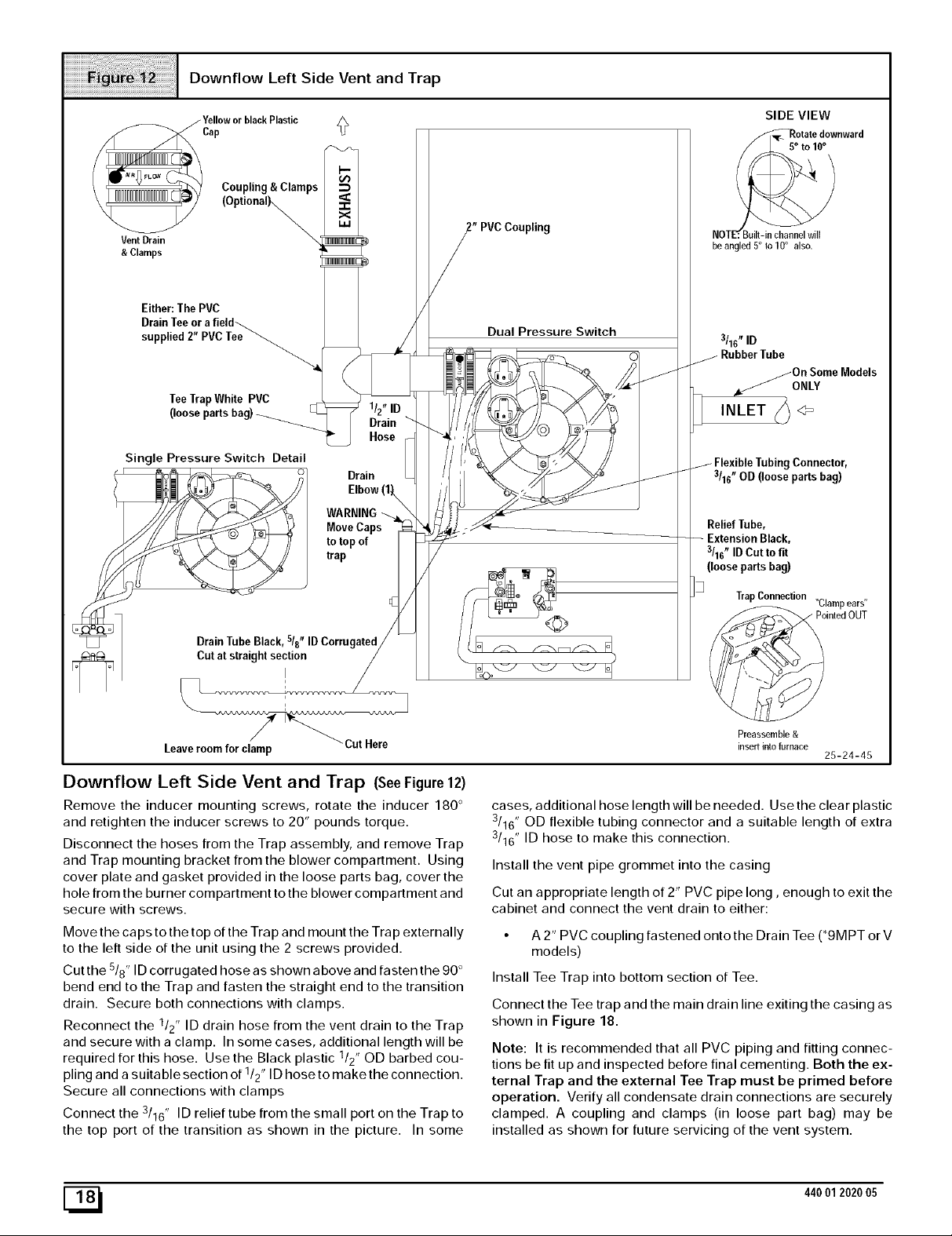

Downflow Left Side Vent and Trap

Cap

Coupling & Clamps .._

SIDE VIEW

/,_'_r_Rotate downward

II / tol0o

!Optiona,

supplied2" PVCTee

TeeTrapWhite PVC

Ooosepa.sbag

Single Pressure Switch Detail

,_1 Elbow(1)_

_1 WARNING

_1 MoveCaps_

4/ )) I totopof

DrainTubeBlack,5/8" ID Corrugated/

Cut at straight section /

_1 Drain

trap _t

Dual Pressure Switch

NOT_

be angled 5° to 10° also.

11 %"ID

_ RubberTube

- [_ /ONLY

t_ Trap Connection

/On Some Models

FlexibleTubingConnector,

3116"OD (loose parts bag)

ReliefTube,

Extension Black,

3/16"IDCut to fit

(It(looseparts bag)

a_ePde(_sT

Leaveroom for clamp _ Cut Here

Downflow Left Side Vent and Trap (SeeFigure 12)

Remove the inducer mounting screws, rotate the inducer 180 °

and retighten the inducer screws to 20" pounds torque.

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

hole from the burner compartment to the blower compartment and

secure with screws.

Move the caps to the top of the Trap and mount the Trap externally

to the left side of the unit using the 2 screws provided.

Cut the 518" ID corrugated hose as shown above and fasten the 90 °

bend end to the Trap and fasten the straight end to the transition

drain. Secure both connections with clamps.

Reconnect the 1/2" ID drain hose from the vent drain to the Trap

and secure with a clamp. In some cases, additional length will be

required for this hose. Use the Black plastic 1/2" OU barbed cou-

pling and a suitable section of 1/2" ID hose to make the connection.

Secure all connections with clamps

Connect the 3/16" ID relief tube from the small port on the Trap to

the top port of the transition as shown in the picture. In some

Preassemble &

insert into furnace

cases, additional hose length will be needed. Use the clear plastic

3/16" OD flexible tubing connector and a suitable length of extra

3/16" ID hose to make this connection.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2" PVC pipe long, enough to exit the

cabinet and connect the vent drain to either:

• A 2" PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee Trap into bottom section of Tee.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

25-24-45

[_ 440012020 0S

Page 19

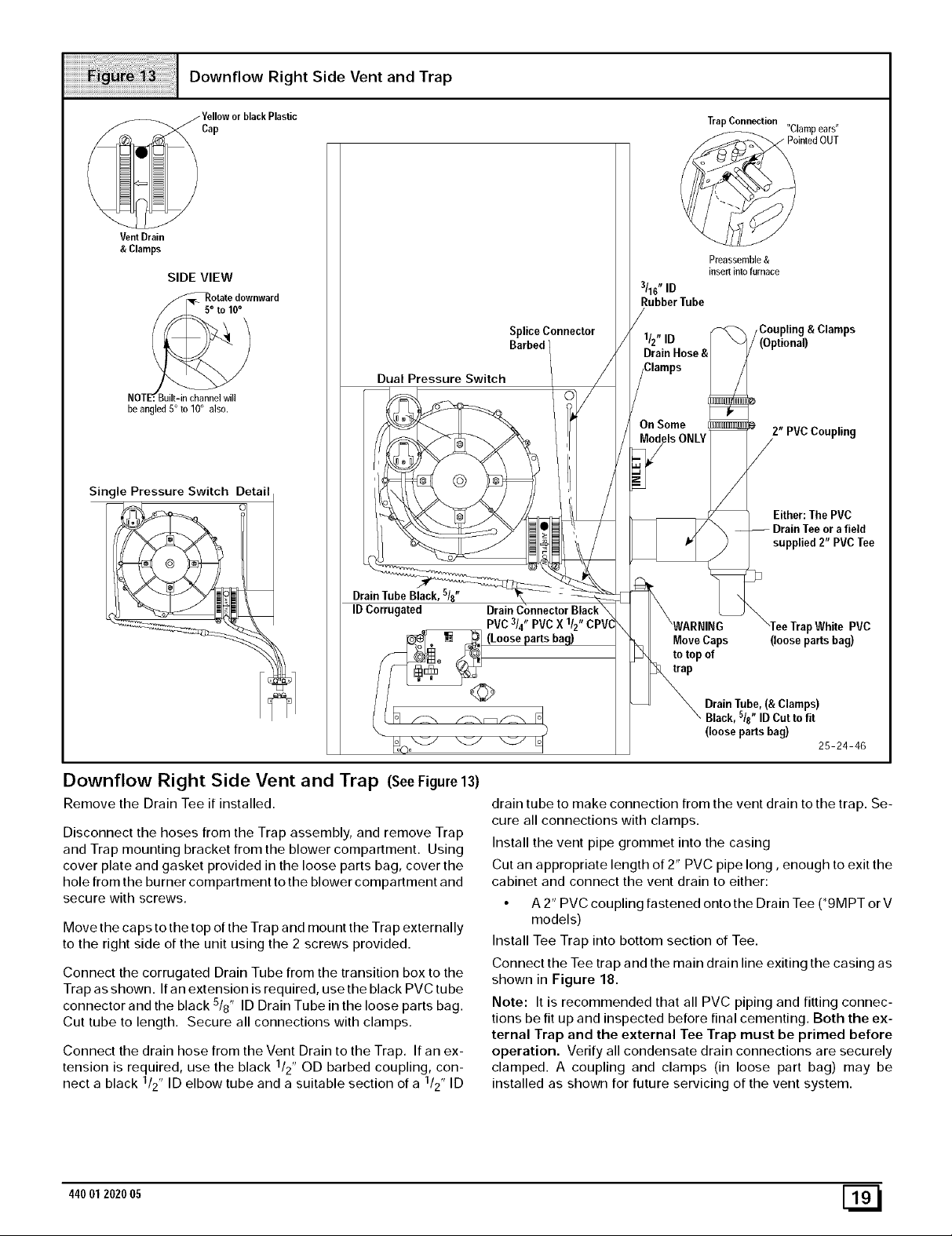

Downflow Right Side Vent and Trap

Yellowor blackPlastic

Cap

Vent Drain

& Clamps

SIDE VIEW

_Rotate downward

NOTE'r. Built-in channel will

he angled 5° to 10° also.

Single Pressure Switch Detail

Dual Pressure Switch

Splice Connector

Barbed

3116" ID

Rubber Tube

1/2" ID

Drain Hose &

OnSome

ModelsONLY

TrapConnection

Preassemble &

insert inlo furnace

Clamps

(Optional)

2" PVCCoupling

Either:The PVC

supplied2" PVC Tee

DrainTubeBlack, s/8"

IDCorrugated DrainC

Downflow Right Side Vent and Trap (SeeFigure 13)

Remove the Drain Tee if installed.

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

hole from the burner compartment to the blower compartment and

secure with screws.

Move the caps to the top of the Trap and mount the Trap externally

to the right side of the unit using the 2 screws provided.

Connect the corrugated Drain Tube from the transition box to the

Trap as shown. If an extension is required, use the black PVC tube

connector and the black 5/8" ID Drain Tube in the loose parts bag.

Cut tube to length. Secure all connections with clamps.

Connect the drain hose from the Vent Drain to the Trap. If an ex-

tension is required, use the black 1/2" OD barbed coupling, con-

nect a black 1/2" ID elbow tube and a suitable section of a 1/2" ID

PVC314"

MoveCaps

White PVC

(loosepartsbag)

to top of

trap

©

DrainTube, (&Clamps)

Black,5_"lD Cutto fit

(loosepa_s bag)

25-24-46

drain tube to make connection from the vent drain to the trap. Se-

cure all connections with clamps.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2" PVC pipe long, enough to exit the

cabinet and connect the vent drain to either:

• A 2" PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee Trap into bottom section of Tee.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

44001 2020 05 [_

Page 20

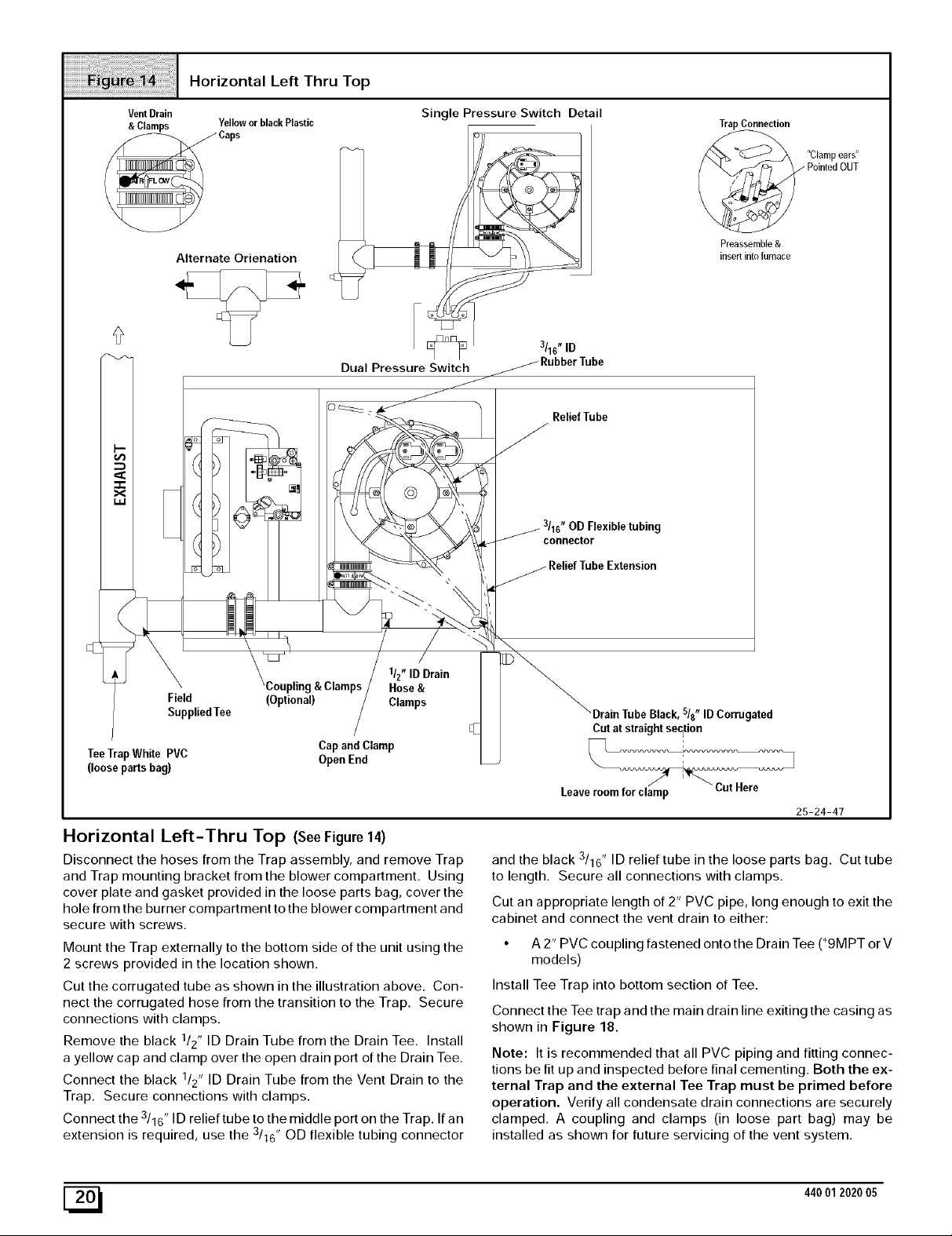

Horizontal Left Thru Top

VentDrain

& Clamps

YelloworblackPlastic

Alternate Orienation

Single Pressure Switch Detail

Dual Pressure Switch

Trap Connection

_ "Clamp ears"

Pointed OUT

Preassemble &

insert into furnace

3/16"ID

ReliefTube

l/z" ID Drain

Field (Optional)

SuppliedTee

Hose&

Clamps

TeeTrapWhite PVC CapandClamp

(looseparts bag) OpenEnd

Horizontal Left-Thru Top (SeeFigure14)

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

hole from the burner compartment to the blower compartment and

secure with screws.

Mount the Trap externally to the bottom side of the unit using the

2 screws provided in the location shown.

Cut the corrugated tube as shown in the illustration above. Con-

nect the corrugated hose from the transition to the Trap. Secure

connections with clamps.

Remove the black 1/2" ID Drain Tube from the Drain Tee. Install

a yellow cap and clamp over the open drain port of the Drain Tee.

Connect the black 1/2" ID Drain Tube from the Vent Drain to the

Trap. Secure connections with clamps.

Connect the 3/16" ID relief tube to the middle port on the Trap. If an

extension is required, use the 3/16" OU flexible tubing connector

ReliefTubeExtension

TubeBlack, /8 IDCorrugated

Cut at straight sec_tion

_Cut Here

Leaveroom for clamp

25-24-47

and the black 3/16" ID relief tube in the loose parts bag. Cut tube

to length. Secure all connections with clamps.

Cut an appropriate length of 2" PVC pipe, long enough to exit the

cabinet and connect the vent drain to either:

• A 2" PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee Trap into bottom section of Tee.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

[_ 44001 2020 0S

Page 21

Alternate Orienation

Horizontal Left-Side Vent

Single Pressure Switch Detail

t

Field

SuppliedTee

TeeTrapWhite PVC

(looseparts bag)

DrainTubeBlack, /8 IDCorrugated

Cutatstraight section

LeaveI_Gom fo'_ Cut Here

I

Level or Sloped towards Tee

Dual Pressure Switch

3/1S"ID Ru/bber Tube

ReliefTube

u

//

SpliceConnector

ReliefTubeExtension

Yelloworblack

Plastic

VentDrain

&Clamps

1/2" IDDrain Elbow

.Drain Hose & Splice

Connector

(Cut-to-fit)

Corrugated

WARNING

MoveCapsto

topof trap

,5/8" ID

25-24-48

Horizontal Left- Side Vent (SeeFigure15)

Remove the Drain Tee from the Vent Drain if installed (*9MPD

models only)

Rotate the inducer 180 ° for a side vent after loosening the 4 induc-

er attachment screws. Reinstall and retighten the inducer screws

to 20" pounds torque.

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

hole from the burner compartment to the blower compartment and

secure with screws.

Mount the Trap externally to the bottom side of the unit using the

2 screws provided in the location shown.

Cut the corrugated tube as shown in the illustration above. Con-

nect the corrugated hose from the transition to the Trap. Secure

connections with clamps.

Connect the black 1/2" ID Drain Tube from the Vent Drain to the

Trap. If an extension is required, use the black 1/2" OD flexible tub-

ing connector and the black 1/2" ID Drain Tube in the loose parts

bag. Cut tube to length. Secure connections with clamps.

Connect the 3/16" ID relief tube to the middle port on the Trap. If an

extension is required, use the 3116"0D flexible tubing connector

44001 2020 05 [_

and the black 3/16" ID relief tube in the loose parts bag. Cut tube

to length.

Cut an appropriate length of 2" PVC pipe, fittings and extension

pipe long enough to exit the cabinet and connect the vent drain to

either:

• A 2" PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee Trap into bottom section of Tee.

Important: The pipe to the Tee Trap must be level or sloping to-

wards the Tee Trap

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

A coupling and clamps (in loose part bag) may be installed as

shown for future servicing of the vent system.

Page 22

Horizontal Right thru Top

TrapConnection

Preassemble&

insertintofurnace

"Clampears" Alternate Orienation