ICP C9MPD050F12B1, C9MPD075F12A1, C9MPD075F12B1, C9MPD080J16A2, C9MPD080J16B1 Installation Guide

...Page 1

INSTALLATION INSTRUCTIONS

For Extension Vent Pipe Replacement on N9MP1, N9MP2, *9MPD,

*9MPT & *9MPV Upflow Gas Furnaces.

* Denotes Brand (T, H or C)

Please read these instructions completely before attempting installation.

Parts List for Plastic Bag

Description Part# Qty.

Coupling, Discharge 1002522 1

Clamp, Hose 1013830 2

Gasket, Trap 1013701 1

SMS, #8 X 1/2" Conical 1012537 2

Clamp, 5/8"ID 1012975 2

Clamp, 3/4"ID 1012976 2

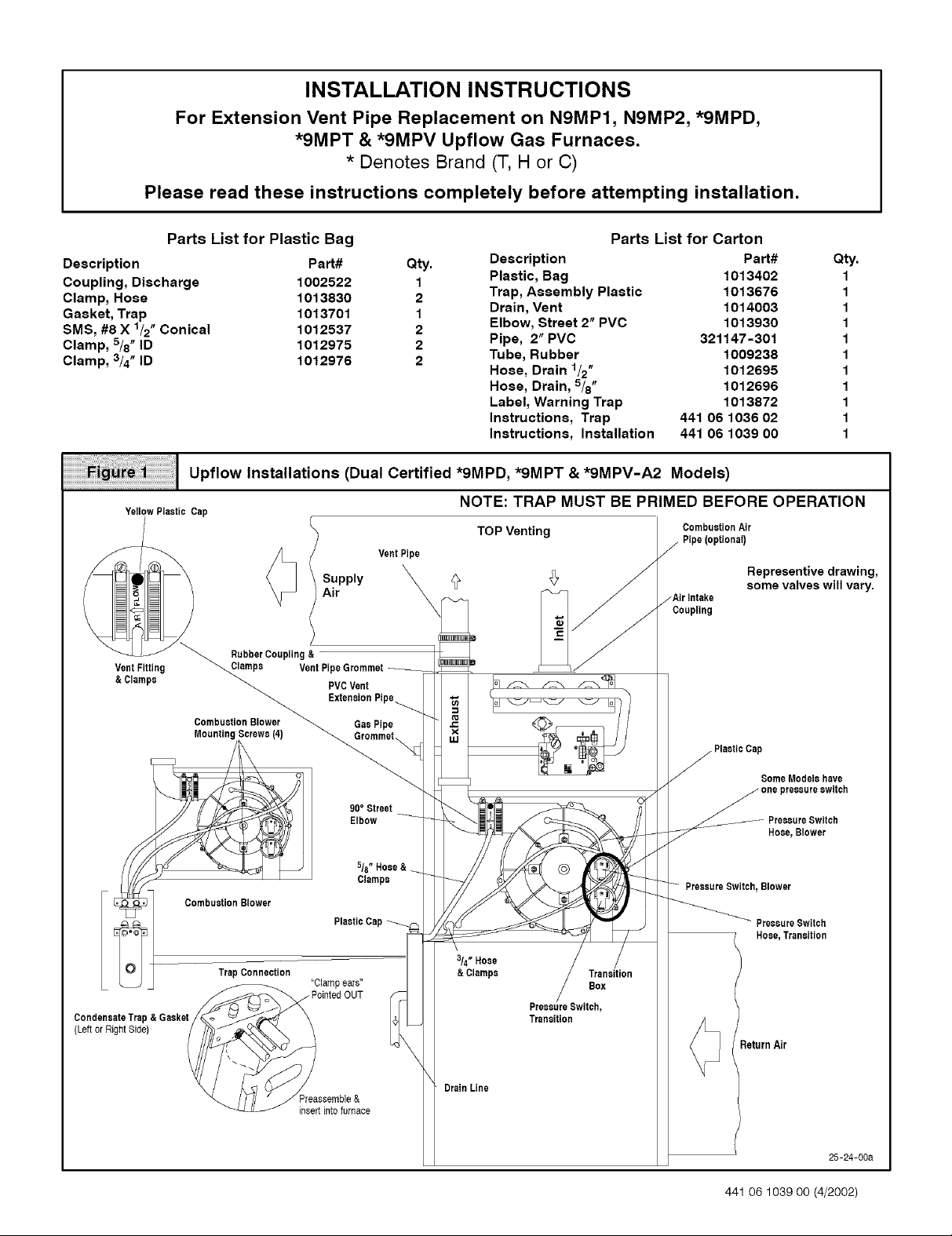

Ii Upflow Installations (Dual Certified *9MPD, *9MPT & *9MPV-A2 Models)

i

YellowPlastic Cap

VentPipe

Air

PipeGrommet

Parts List for Carton

Description Part# Qty.

Plastic, Bag 1013402 1

Trap, Assembly Plastic 1013676 1

Drain, Vent 1014003 1

Elbow, Street 2" PVC 1013930 1

Pipe, 2" PVC 321147-301 1

Tube, Rubber 1009238 1

Hose, Drain 1/2" 1012695 1

Hose, Drain, 5/8" 1012696 1

Label, Warning Trap 1013872 1

Instructions, Trap 441 06 1036 02 1

Instructions, Installation 441 06 1039 00 1

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

TOP Venting

CombustionAir

.-Air Intake

Coupling

Representive drawing,

some valves will vary.

DrainLine

PressureSwitch,

Transition

_ PtasticCaPsome Modelshave

one pressureswitch

PressureSwitch

Hose, Blower

PressureSwitch, Blower

PressureSwitch

Hose,Transition

_eturn Air

25-24-00a

441 06 1039 O0 (4/2002)

Page 2

Upflow Installations - (Dual Certified*9MPD, *9MPT &*9MPV)(See Figure 1)

NOTE: DO NOT make connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 1). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Mount the condensate drain trap in a vertical position to either the

left or right side of the furnace using the two screws and gasket that

are provided. If needed, remove the hole plugs from the furnace

side panel and relocate to the open set of holes in the opposite side

panel.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Ensure that the vent fitting and the 90 ° street elbow are securely

attached to the combustion blower using the clamps.

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Glue the PVC vent extension pipe to the 90 ° street elbow after

checking the fit up. (Follow the procedures outlined in the Joining

Pipe and Fittings section of this manual, page 13.) Disregard the

instruction label on the PVC vent extension pipe. The orientation of

the supplied PVC vent extension pipe is not critical in the vertical

position. The PVC pipe will extend through the top panel about

21/2". Connect the rubber coupling to the end ofthe PVC extension

pipe using the clamp.

NOTE: There will be some misalignment ofthe PVC pipe inside the

furnace. The rubber coupling will straighten outthe misalignment at

the vent pipe connection at the top of the furnace.

For left side venting, remove 90 ° street elbow from the vent fitting

by loosening the clamp on the vent fitting. Securely attach vent fit-

ting to combustion blower.

NOTE: For left side venting, the vent fitting MUST be installed with

the airflow marking arrow pointed toward the vent pipe, with the

drain stub at a 5° to 10 ° downward slope.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

This configuration allows left side venting from the furnace. If right

side venting is required, the combustion blower must be relocated

on the plastic transition box. Loosen the four(4) screws that secure

the blower to the transition approximately1/2 ", Rotate the blower

180 ° and secure with the four(4) screws. Note that some combus-

tion blowers have plastic spacers on the mounting legs of the blow-

er located atthe 6 and 12 o'clock positions (blower snout to the left

or right) that are required for proper fit up of the blower to the transi-

tion. Use caution to not over tighten the screws to prevent stripping

out of the plastic mounting holes.

NOTE: For right side venting, the vent fitting MUST be installed with

the airflow marking arrow pointed toward the vent pipe, with the

drain stub at a 5 ° to 10 ° downward slope. (See Figure 2)

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

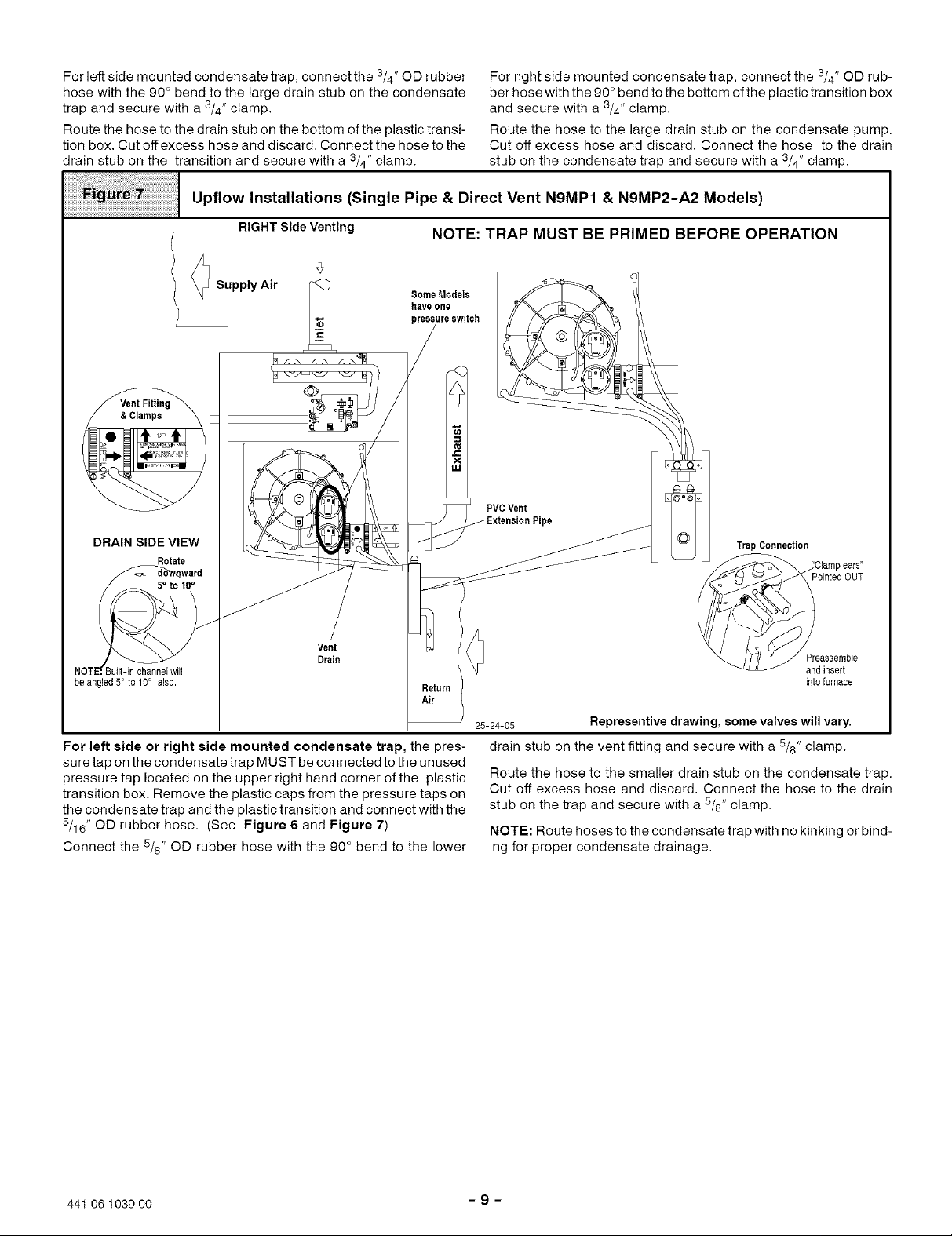

For left side mounted condensate trap, connect the 3/4" OD rubber

hose with the 90 ° bend to the large drain stub on the condensate

trap and secure with a 3/4" clamp.

Route the hose to the drain stub on the bottom ofthe plastic transi-

tion box. Cut off excess hose and discard. Connect the hose to the

drain stub on the transition and secure with a 3/4" clamp.

For right side mounted condensate trap, connect the 3/4" OD rub-

ber hose with the 90 ° bend to the bottom of the plastic transition box

and secure with a 3/4" clamp.

Route the hose to the large drain stub on the condensate trap. Cut

off excess hose and discard. Connect the hose to the drain stub on

the condensate trap and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the lower

drain stub on the vent fitting and secure with a 5/8" clamp.

441 06 1039 O0 - 2 -

Page 3

iiiiiiiiiiiiiiiiil;i!¸I!I¸!i¸i!!gilililil¸¸ll_ggilll!_!iiiiiillll!l!l!l!l!l!gl_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_!

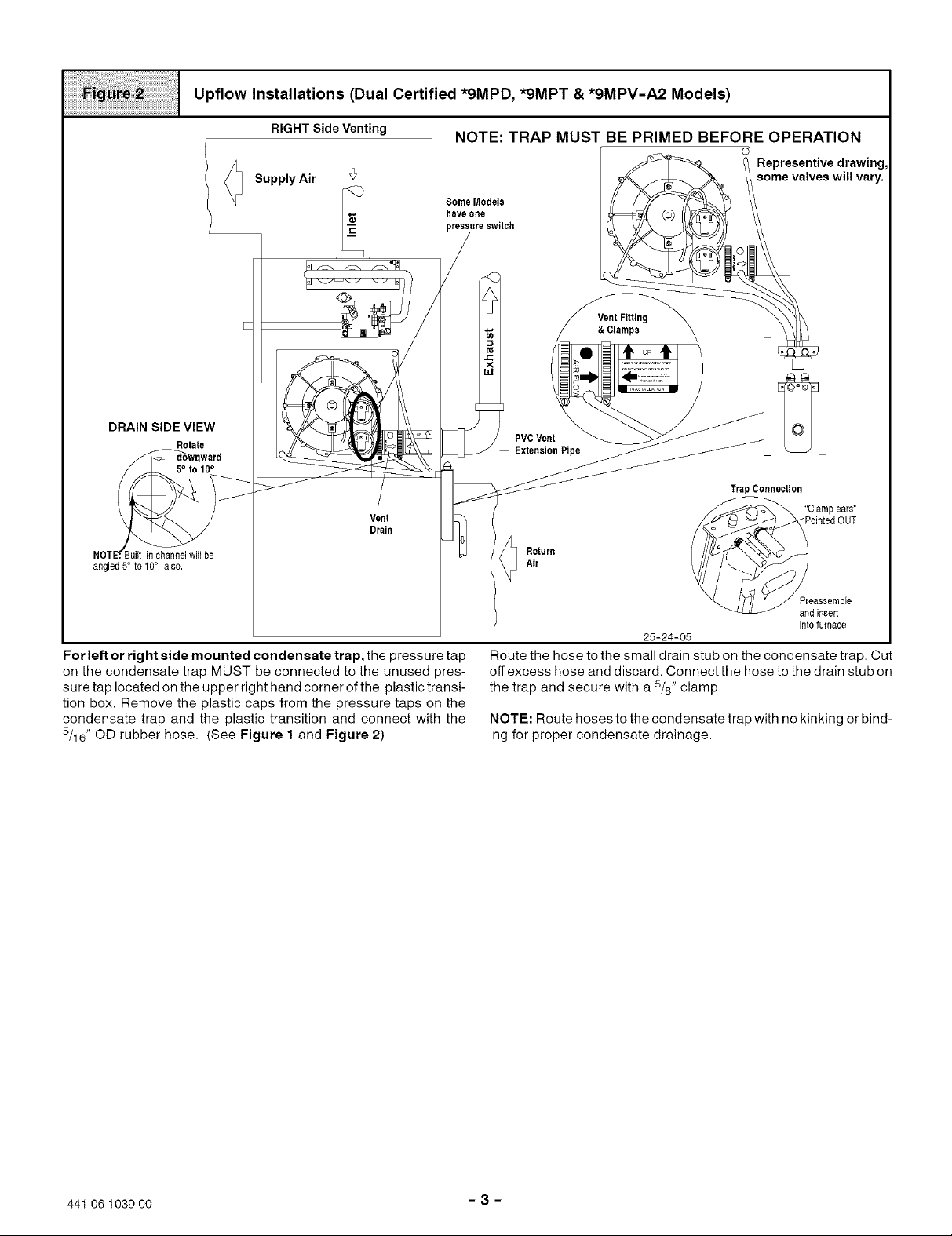

Upflow Installations (Dual Certified *9MPD, *9MPT & *9MPV-A2 Models)

RIGHT Side Venting

Supply Air

Some Models

have one

0

DRAIN SIDE VIEW

Rotate

5° to10°

Vent

Drain

angled5° to 10° also.

For left or right side mounted condensate trap, the pressure tap

on the condensate trap MUST be connected to the unused pres-

sure tap located on the upper right hand corner of the plastic transi-

tion box. Remove the plastic caps from the pressure taps on the

condensate trap and the plastic transition and connect with the

5/16"OD rubber hose. (See Figure 1 and Figure 2)

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

Representive drawing,

some valves will vary.

Vent Fitting

&Clamps

PVCVent

ExtensionPipe

TrapConnection

_PointedOUT

Return

Air

'_Clampears"

Preassemble

andinsert

25-24-05

Route the hose to the small drain stub on the condensate trap. Cut

off excess hose and discard, Connect the hose to the drain stub on

the trap and secure with a 5/8" clamp.

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

int0furnace

441 06 1039 O0 - 3 -

Page 4

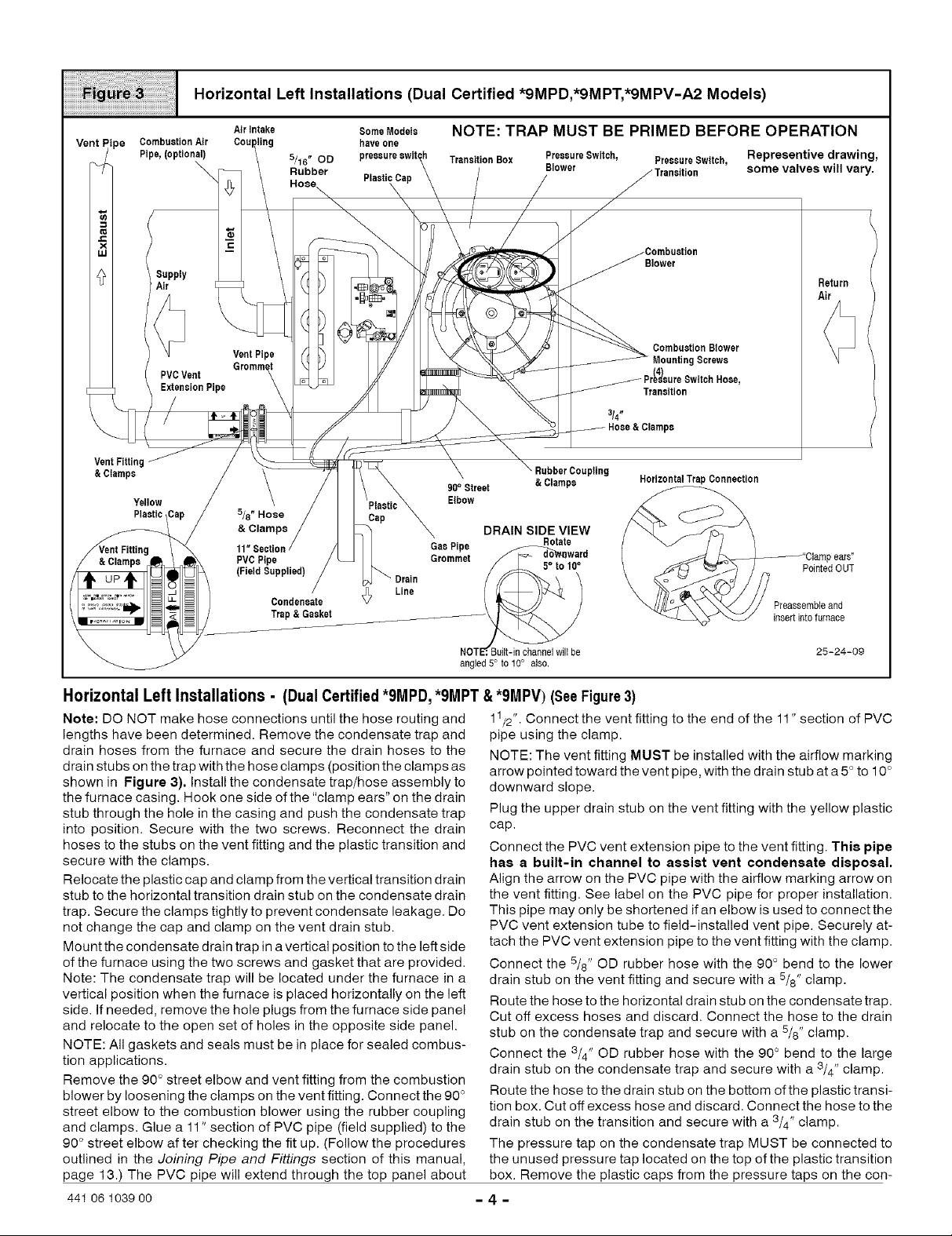

Horizontal Left Installations (Dual Certified *9MPD,*9MPT,*9MPV-A2 Models)

CombustionAir

ipe

Pipe,(optional)

Supply

Air

PVCVent

ExtensionPipe

Vent Fitting

&Clamps

Yellow

Plastic 5/8" Hose

Airlntake $omeModete NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

Coul have one

5/16" OD TransitionBox PressureSwitch, PressureSwitch, Representive drawing,

Rubber Blower somevalveswill vary.

Blower

Return

Air

VentPipe

90° Street & Clamps

Elbow

DRAIN SIDEVIEW

• Rotate

Gas Pipe

Grommet f [,<7- do_ward

RubberCoupling

CombustionBlower

g Screws

Transition

HorizontalTrap Connection

Rose,

Ipears"

PointedOUT

NOTE_.Built-in channelwill be

angled5° to 10° also.

Horizontal Left Installations - (Dual Certified*9MPD, *9MPT &*9MPV) (SeeFigure3)

Note: DO NOT make hose connections until the hose routing and

lengths have been determined, Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 3). Install the condensate trap/hose assembly to

the furnace casing, Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Relocate the plastic cap and clamp from the vertical transition drain

stub to the horizontal transition drain stub on the condensate drain

trap. Secure the clamps tightly to prevent condensate leakage. Do

not change the cap and clamp on the vent drain stub.

Mount the condensate drain trap in a vertical position to the left side

of the furnace using the two screws and gasket that are provided.

Note: The condensate trap will be located under the furnace in a

vertical position when the furnace is placed horizontally on the left

side. If needed, remove the hole plugs from the furnace side panel

and relocate to the open set of holes in the opposite side panel.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Remove the 90 ° street elbow and vent fitting from the combustion

blower by loosening the clamps on the vent fitting. Connect the 90 °

street elbow to the combustion blower using the rubber coupling

and clamps. Glue a 11" section of PVC pipe (field supplied) to the

90 ° street elbow after checking the fit up. (Follow the procedures

outlined in the Joining Pipe and Fittings section of this manual,

page 13.) The PVC pipe will extend through the top panel about

441 06 1039 00 - 4 -

11/2"• Connect the vent fitting to the end of the 11" section of PVC

pipe using the clamp.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a5°to 10°

downward slope.

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting• See label on the PVC pipe for proper installation,

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe, Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

Connect the 5/8" OD rubber hose with the 90° bend to the lower

drain stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the horizontal drain stub on the condensate trap.

Cut off excess hoses and discard. Connect the hose to the drain

stub on the condensate trap and secure with a 5/8" clamp.

Connect the 3/4" OD rubber hose with the 90° bend to the large

drain stub on the condensate trap and secure with a 3/4" clamp.

Route the hose to the drain stub on the bottom ofthe plastic transi-

tion box• Cut off excess hose and discard. Connect the hose to the

drain stub on the transition and secure with a 3/4" clamp.

The pressure tap on the condensate trap MUST be connected to

the unused pressure tap located on the top of the plastic transition

box• Remove the plastic caps from the pressure taps on the con-

Preassembleand

insertintofurnace

25-24-09

Page 5

densatetrapandtheplastictransitionandconnectwiththe5/16"

ODrubberhose.

NOTE:Thiswillrequiredrillinga5/16"ODholeinthefurnacecasing

nexttothecondensatetrap.

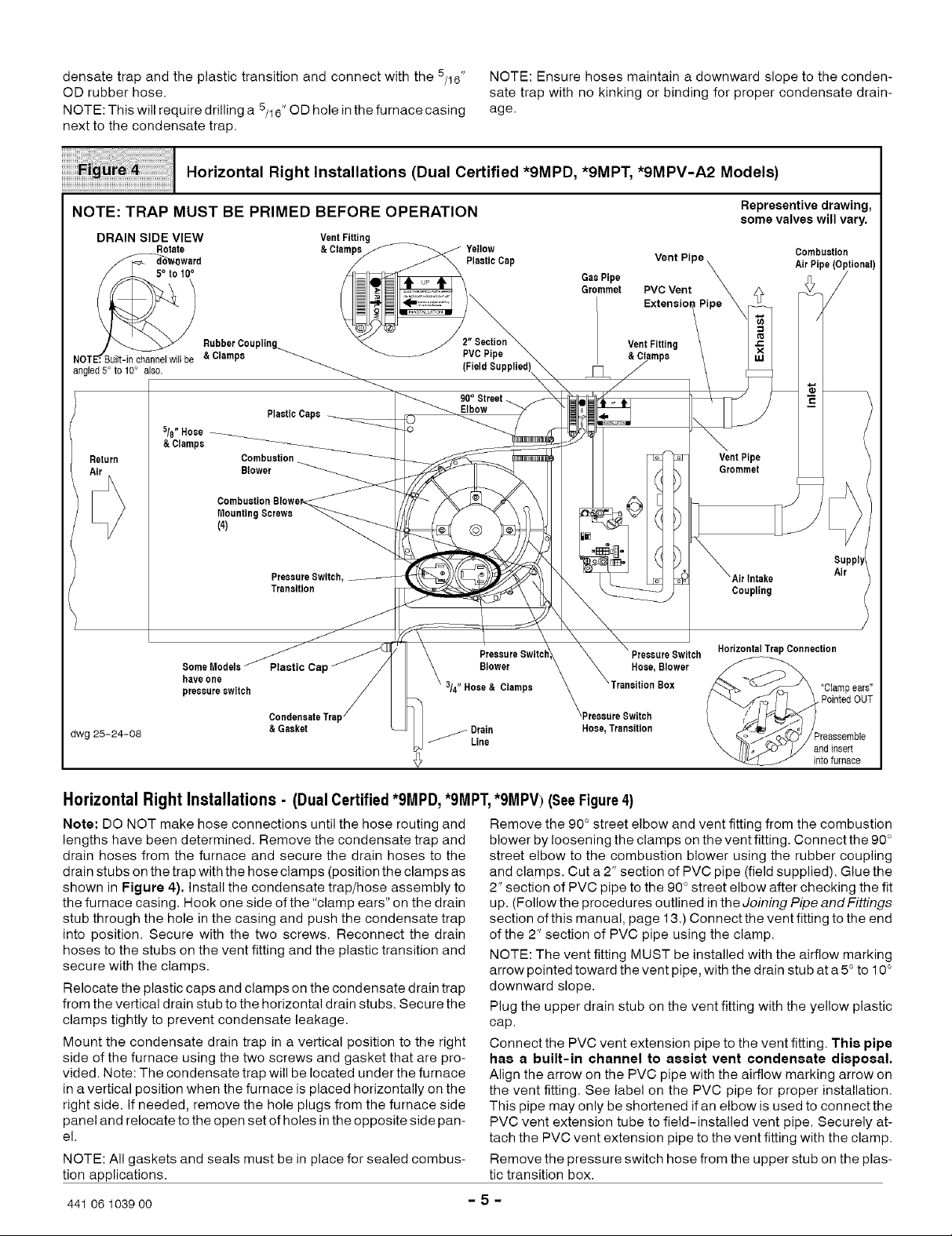

Horizontal Right Installations (Dual Certified *9MPD, *9MPT, *9MPV-A2 Models)

NOTE:Ensurehosesmaintainadownwardslopetotheconden-

satetrapwithnokinkingorbindingforpropercondensatedrain-

age.

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

DRAIN SIDE VIEW VentFitting

_ward f _ _ PlaaticCap

j _ RubberCoupling._ _ /" 2[.Secyion

NOTE_':Built-inchannelwillbe &Clamps _ _ PVCPipe ..

angled 5° to 10° als0. _ (Field Bupplied)\_

Return

Rotate &Clampe_ Yellow

90° Street-__ _ _ c

5/8"Hose _ PlasticCaps_ -1_ _

&Clamps __ _

Combustion _ qo _' _ VentPipe

CombustionBlowek_ _ E

MountingScrews _ O _ )

(4)

Blower _i_c ,___ _ G_ommet I_/_

Transition _<_ __ Coupling

PreaeureSwitch,__ )_'\__o__ Airlntake Air

Representive drawing,

some valves will vary.

Combustion

GasPipe

Grommet

_ _ / Supply

Vent Pipe X

PVCVent _ _¢

Extenoi°n/PiPe _i

V&e;tFmit;isng \ x

AirPipe(Optional)

/

/

3/4"Hose& Clamps --Transition Box ,,pOplart Pde_rus,T

dwg 25-24-08

!ieV_20_ide_t_C_e_ill ' \\ BIowerPressureSwitch_,,_ \Preeeare_X Hose,BIowerSWitch/_> _J\_H°riz°ntalTrapConnection

r i / _'_/_

Horizontal Right Installations - (Dual Certified*9MPD, *9MPT,*9MPV) (SeeFigure4)

Note: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 4). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Relocate the plastic caps and clamps on the condensate drain trap

from the vertical drain stub to the horizontal drain stubs. Secure the

clamps tightly to prevent condensate leakage.

Mount the condensate drain trap in a vertical position to the right

side of the furnace using the two screws and gasket that are pro-

vided. Note: The condensate trap will be located under the furnace

in a vertical position when the furnace is placed horizontally on the

right side. If needed, remove the hole plugs from the furnace side

panel and relocate to the open set of holes in the opposite side pan-

el.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

441 06 1039 oo - 5 -

Remove the 90 ° street elbow and vent fitting from the combustion

blower by loosening the clamps on the vent fitting. Connect the 90 °

street elbow to the combustion blower using the rubber coupling

and clamps. Cut a 2" section of PVC pipe (field supplied). Glue the

2" section of PVC pipe to the 90 ° street elbow after checking the fit

up. (Follow the procedures outlined in the Joining Pipe and Fittings

section of this manual, page 13.) Connect the vent fitting to the end

of the 2" section of PVC pipe using the clamp.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a 5° to 10 °

downward slope.

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

Remove the pressure switch hose from the upper stub on the plas-

tic transition box.

\ II_lo_o" _1 aodinsert

_ int0furnace

Page 6

Relocatetheplasticcapsonthestubsoftheplastictransitionbox

fromthelowerstubstotheupperstubsandsecuretightlywiththe

clamps.

Routethepressureswitchhosetothelowerstubontheplastic

transitionbox.Cutoffexcesshoseanddiscard.Connectthepres-

sureswitchhosetothelowerstubontheplastictransitionbox.En-

surethatthehoseisroutedabovethestubonthetransitionboxso

thatcondensatedoesnotcollectinthehose.NOTE:Failuretocor-

rectlyinstallthepressureswitchhosetothetransitioncanadverse-

lyaffectthesafetycontroloperation.

Connectthe3/4"ODrubberhosewiththe90° bendtothelarge

iiiiiiiiiiiiiiiii¸iiiiiiiiiiiiiiii_ii;iiiiiiiiiii¸i¸i¸i¸i¸i¸i¸i!il¸i¸i¸iiiiiiiiiii!!iiiiiiiiiiiiiiiiiiiiiiiiiiii!!i

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

DRAIN SIDE VIEW

Rotate

5° tot0 °

LEFT Side Venting

<Z>

drainstubonthecondensatetrapandsecurewitha3/4"clamp.

Routethehosetothedrainstubonthebottomoftheplastictransi-

tionbox.Cutoffexcesshoseanddiscard.Connectthehosetothe

drainstubonthetransitionandsecurewitha3/4"clamp.

Connectthe5/8"ODrubberhosewiththe90°bendtothelower

drainstubontheventfittingandsecurewitha5/8"clamp.

Routethehosetothesmallerdrainstubonthecondensatetrap.

Cutoffexcesshoseanddiscard.Connectthehosetothedrain

stubonthetrapandsecurewitha5/8"clamp.

NOTE:Routehosestothecondensatetrapwithnokinkingorbind-

ingforpropercondensatedrainage.

RIGHT Side Venting

<Z>

_uilt-in channel will be

angled5 ° to 10° als0.

Horizontal

Trap Connection

PVCVent

Extension

Pipe

ReturnAir

PressureSwitch

Some Models Hose,Traneitio_--

haveone

pressureowi_nbaotion Blower

Screws (4)

Preoaar_

Switch,

Blower-

Preoear(

Switch

Hose,

CombustionBlower

(Rotate 180° for

PreooareSwitch,

Transition

Transition

Box

& Clamps

ReturnAir

Clamps

Representive drawing

some valves will vary.

AirIntake AirPipe,(Optional)

Coupling

Combustion

/

Ven/tPipe

_0 Vent

:oo,oo

PlasticCaps

VentPiPGromm_

Condensate

Trap&Gasket

GasPipe

Grommet

DrainLine

Vent Fitting

SupplyAir

<Z>

SupplyAir

<Z>

Preaeeemble

andinsert

intofurnace

"Clamp ears"

PointedOUT

Downflow Installations - (Dual Certified *9MPD, *9MPT,*9MPV Models) (SeeFigure5)

NOTE: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 5). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

441 06 1039 oo

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Mount the condensate drain trap in a vertical position to either the

right or left side of the furnace using the two screws and gasket that

are provided. If needed, remove the hole plugs from the furnace

side panel and relocate to the open set of holes in the opposite side

panel.

-6-

dwg 25-24-07

Page 7

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

For both right and left side vent, remove the 90 ° street elbow

from the vent fitting by loosening the clamp on the vent fitting.

Ensure that the vent fitting is securely attached to the combustion

blower using the rubber coupling and clamps,

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

This configuration allows left side venting from the furnace. If right

side venting is required, the combustion blower must be relocated

on the plastic transition box. Loosen the four(4) screws that secure

the blower to the transition approximately1/2 ". Rotate the blower

180 ° and secure with the four(4) screws. Note that some combus-

tion blowers have plastic spacers on the mounting legs ofthe blow-

er located at the 6 and 12 o'clock positions (blower snout to the left

or right) that are required for proper fit up of the blower to the transi-

tion. Use caution to not over tighten the screws to prevent stripping

out of the plastic mounting holes.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a 5° to 10 °

downward slope.

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pips

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

Remove the pressure switch hose from the upper stub on the plas-

tic transition box.

Relocate the plastic caps on the stubs of the plastic transition box

from the lower stubs to the upper stubs and secure tightly with the

clamps.

Route the pressure switch hose to the lower stub on the plastic

transition box. Cut off excess hose and discard. Connect the pres-

sure switch hose to the lower stub on the plastic transition box.

NOTE: Failure to correctly install the pressure switch hose to the

transition box can adversely affect the safety control operation.

Connect the 3/4" OD rubber hose with the 90 ° bend to the drain stub

on the bottom of the plastic transition box and secure with a 3/4"

clamp.

Route the hose to the large drain stub on the condensate trap. Cut

off excess hose and discard. Connect the hose to the drain stub on

the transition and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the lower

drain stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller stub on the condensate trap. Cut off

excess hose and discard. Connect the hose to the drain stub on the

trap and secure with a 5/8" clamp.

For left side or right side mounted condensate trap, the pres-

sure tap on the condensate trap MUST be connected to the unused

pressure tap located on the top of the plastic transition box. Re-

move the plastic caps from the pressure tap on the condensate trap

and the plastic transition and connect the 5/16" OD rubber hose.

(See Figure 5)

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

441 06 1039 oo - 7 -

Page 8

iiiiiiiiiiiiiiiiil;i!¸I!I¸!i¸i!!i;i¸iiiilil¸¸lllii_lllllll!_!iiiiiillll!l!l!l!l!llllll_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_l_!

Upflow Installations (Single Pipe & Direct Vent N9MP1 & N9MP2-A2 Models)

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

VentFitting SupplyAir

DRAIN SIDEVIEW 0 I

!B &Clamps PVCVent

: • _. •NOT u_lt_nchannelw_ll

beangled5° to 10° also. VentPi

Combustion Blower

MountingScrews(4)

VentFitting&Clamps

90= VentPipe

Condensate

Trap& Gasket

DrainLine

TrapConnection

5/8"Hose& Clamps

ExtensionPipe

Grommet

LEFT Side Venting

& Clamps

Transition

Box

SomeModelshaveone

pressureswitch

CombasUon

N9MP2ONLY

Combaetion Blower

(Rotate 180° for

RightSide)

PlasticCap

PressureHose,

Blower

I, Blower

PressureSwitchHose,

Transition

PressureSwitch, Transition

Return

Air

_/ PointedOUT

"Ctampears"

/ Representive drawing,

J Preaeeemble& some valves will vary.

insertintofurnace

Upflow Installations - (Single Pipe & DirectVent N9MP1 &

N9MP2 Models) (See Figure 6)

NOTE: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 6). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Mount the condensate drain trap in a vertical position to either the

left or right side of the furnace using the two screws and gasket that

are provided. If needed, remove the hole plugs from the furnace

side panel and relocate to the open set of holes in the opposite side

panel.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Ensure that the vent fitting is securely attached to the combustion

blower using the rubber coupling and clamps.

NOTE: For left side venting, the vent fitting MUST be installed with

the airflow marking arrow pointed toward the vent pipe, with the

drain stub at a 5° to 10 ° downward slope.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

441 06 1039 00 - 8 -

dwg 25-24-06

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

This configuration allows left side venting from the furnace. If right

side venting is required, the combustion blower must be relocated

on the plastic transition box. Loosen the four(4) screws that secure

the blower to the transition approximately1/2 ". Rotate the blower

180 ° and secure with the four(4) screws. Note that some combus-

tion blowers have plastic spacers on the mounting legs of the blow-

er located atthe 6 and 12 o'clock positions (blower snout to the left

or right) that are required for proper fit up of the blower to the transi-

tion. Use caution to not over tighten the screws to prevent stripping

out of the plastic mounting holes.

NOTE: For right side venting, the vent fitting MUST be installed with

the airflow marking arrow pointed toward the vent pipe, with the

drain stub at a 5 ° to 10 ° downward slope. (See Figure 7)

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

Page 9

Forleftsidemountedcondensatetrap,connectthe3/4"ODrubber

hosewiththe90°bendtothelargedrainstubonthecondensate

trapandsecurewitha 3/4" clamp.

Route the hose to the drain stub on the bottom of the plastic transi-

tion box. Cut off excess hose and discard. Connect the hose to the

drain stub on the transition and secure with a 3/4" clamp.

Upflow Installations (Single Pipe & Direct Vent N9MP1 & N9MP2-A2 Models)

RIGHTSideVentinq NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

For right side mounted condensate trap, connect the 3/4" OD rub-

ber hose with the 90 ° bend to the bottom of the plastic transition box

and secure with a 3/4" clamp.

Route the hose to the large drain stub on the condensate pump.

Cut off excess hose and discard. Connect the hose to the drain

stub on the condensate trap and secure with a 3/4" clamp.

Supply Air

DRAIN SIDE VIEW

Rotate

5° to t0°

Vent

Drain

}uilt-in channel will

be angled 5° to 10° als0.

Some Models

haveone

reesureswitch

For left aide or right aide mounted condenaate trap, the pres-

sure tap on the condensate trap MUST be connected to the unused

pressure tap located on the upper right hand corner of the plastic

transition box. Remove the plastic caps from the pressure taps on

the condensate trap and the plastic transition and connect with the

5/16"OD rubber hose. (See Figure 6 and Figure 7)

Connect the 5/8" OD rubber hose with the 90° bend to the lower

PVCVent

25-24-05

drain stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller drain stub on the condensate trap.

Cut off excess hose and discard. Connect the hose to the drain

stub on the trap and secure with a 5/8" clamp.

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

ipe

TrapConnection

Pointed OUT

Preassembte

andinsert

intofurnace

Representive drawing, some valves will vary.

441 06 1039 00 - 9 -

Page 10

iiiiiiiiiiiiiiiiiil;;_!¸I!I¸!i¸i!_i;i;i;i;i;iiiiiiii;:iiiiiiiiiiiiii!i;il;;iiii¸ii¸iil;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;

Horizontal Left Installations (Single Pipe & Direct Vent N9MP1 & N9MP2-A2 Models)

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

Vent P

VentPipe

/ VentFitting

S)

.c

x

uJ

Vent Fitting& Clamps

l Clamps

Supply

Air

> Inlet

/

Combustion

AirPipe,

N9MP2ONLY

L_

CombustionBtowel

(Rotate 180° for Right Side)

MountingScrews(4)

DrainLine

Representive drawing, some valves will vary.

Horizontal Left Installations- (Single Pipe& Direct Vent

NOTE: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 8). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Relocate the plastic caps and clamps on the condensate drain trap

from the vertical drain stubs to the horizontal drain stubs. Secure

the clamps tightly to prevent condensate leakage.

Mount the condensate drain trap in a vertical position to the left side

of the furnace using the two screws and gasket that are provided.

Note: The condensate trap will be located under the furnace in a

vertical position when the furnace is placed horizontally on the left

side. if needed, remove the hole plugs from the furnace side panel

and relocated to the open set of holes in the opposite side panel.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Relocate the combustion blower on the plastic transition box. Re-

move the four(4) screws that secure the blower to the transition

box. Rotate the blower 180 ° so the blower snout is pointing up and

PressureSwitch Hose, Transition

Transition

one pressureswitch

Blower

PressureSwitch Hose, Blower

TransitionBox

518"Hose& Clamps

' Hose & Clamps

PlasticCap

Trap &Gasket

dw_ 25-23-58

Horizontal Trap Connection

Return

Air

"Clampears"

PointedOUT

semble

sert

intofurnace

NgMP1 & NgMP2 Models) (See Figure 8)

secure with the four(4) screws. Note that some combustion blow-

ers have plastic spacers on the mounting legs of the blower located

at the 6 and 12 o'clock positions (blower snout to the left or right)

that are required for proper fit up of the blower to the transition. Use

caution to not over tighten the screws to prevent stripping out of the

plastic mounting holes.

Ensure that the vent fitting is securely attached to the combustion

blower using the rubber coupling and clamps.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe.

Plug the left drain stub on the vent fitting with the yellow plastic cap.

Connect the 3/4" OD rubber hose with the 90 ° bend to the large

drain stub on the condensate trap and secure with a 3/4" clamp.

Route the hose to the drain stub on the bottom ofthe plastic transi-

tion box. Cut off excess hose and discard. Connect the hose to the

drain stub on the transition and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the right drain

stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller drain stub on the condensate trap.

Cut off excess hose and discard. Connect the hose to the drain

stub on the vent fitting and secure with a 5/8" clamp.

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

441 06 1039 00 - 10 -

Page 11

iiiiiiiiiiiiiiiiil_!i!i!i!i!_i!_!i!i!i!iii;l!:;!%!i_iliiiiiiiiiiiiiiiiiiiiiliiiiiiiiil_iiiiiiiiiiili%iiiiiiiiiiiilii

i!i!i!i!i!i!i!i!i!i!i!iiii ii ii i! i ii ii i ii ii i! i ii ii ii ii ii ii ii ii ii ii ii iiiiiiiiiiiiiiiiiiiiili

Horizontal Right Installations (Single Pipe & Direct Vent N9MP1 & N9MP2-A2 Models)

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

Transition Box

Plastic Combustion

Cap Air Pipe,

Combustion Blower

Return

Air

Horizontal TrapConnection

Combustion Blower-

Mounting Screws (4)

"Clampears"

PointedOUT

'reassemble

andinsert

into furnace

5/8"

Clamps

Pressure Switch

Hose, Blower

SomeModels

haveone

pressureswitch

Plastic

Caps

Condensate

Trap & Gasket

Pressure

Switch, Transition

Drain Line

Vent Pipe

Grommet

Vent Fitting

NBMP2 ONLY

E

_ Inlet<3=

Supply

Air

Hose, Transition & Clamps

Switch, Blower

Rspresentivs drawing, some valves will vary.

3/4" Hose

dwg 25-23-59a

Horizontal Right Installations - (Single Pipe & Direct Vent NBMP1 &N9MP2 Models) (SeeFigure9)

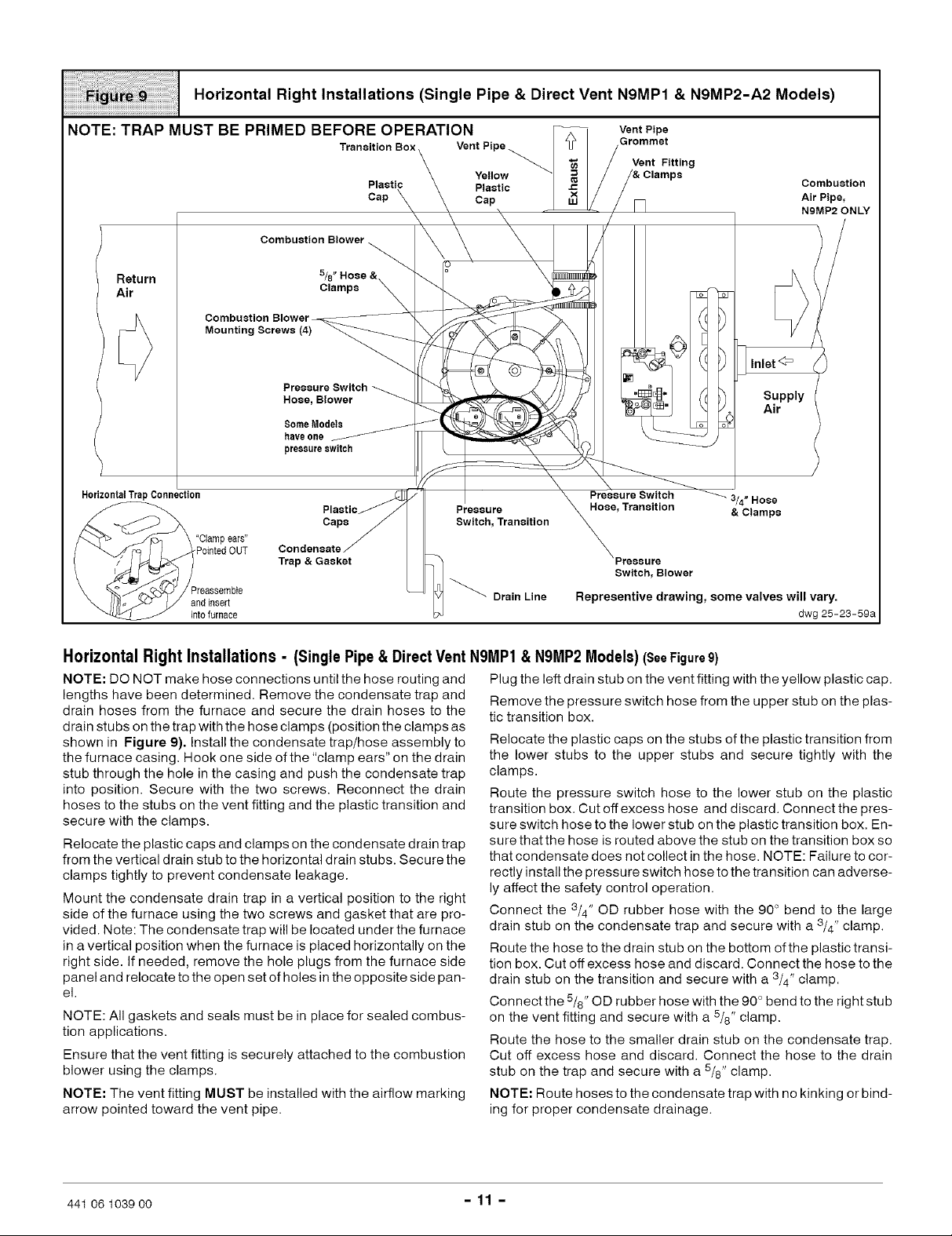

NOTE: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs onthe trap with the hose clamps (position the clamps as

shown in Figure 9). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Relocate the plastic caps and clamps on the condensate drain trap

from the vertical drain stub to the horizontal drain stubs. Secure the

clamps tightly to prevent condensate leakage.

Mount the condensate drain trap in a vertical position to the right

side of the furnace using the two screws and gasket that are pro-

vided. Note: The condensate trap will be located under the furnace

in a vertical position when the furnace is placed horizontally on the

right side. If needed, remove the hole plugs from the furnace side

panel and relocate to the open set of holes in the opposite side pan-

el.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Ensure that the vent fitting is securely attached to the combustion

blower using the clamps.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe.

Plug the left drain stub on the vent fitting with the yellow plastic cap.

Remove the pressure switch hose from the upper stub on the plas-

tic transition box.

Relocate the plastic caps on the stubs of the plastic transition from

the lower stubs to the upper stubs and secure tightly with the

clamps.

Route the pressure switch hose to the lower stub on the plastic

transition box. Cut off excess hose and discard. Connect the pres-

sure switch hose to the lower stub on the plastic transition box. En-

sure that the hose is routed above the stub on the transition box so

that condensate does not collect in the hose. NOTE: Failure to cor-

rectly install the pressure switch hose to the transition can adverse-

ly affect the safety control operation.

Connect the 3/4" OD rubber hose with the 90 ° bend to the large

drain stub on the condensate trap and secure with a 3/4" clamp.

Route the hose to the drain stub on the bottom ofthe plastic transi-

tion box. Cut off excess hose and discard. Connect the hose to the

drain stub on the transition and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the right stub

on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller drain stub on the condensate trap.

Cut off excess hose and discard. Connect the hose to the drain

stub on the trap and secure with a 5/8" clamp.

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

441 06 1039 00 - 11 -

Page 12

iiiiiiiii;;i!¸I¸!i¸i!giill¸iiil;iiiiiii!iiiiiill¸!ii!i!i!i!i!i!i!!iiiii!i!iii!!iiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiii i ii!! i ! ! i!!i!!i!!i!i i ! ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!

Downflow Installations (Single Pipe & Direct Vent N9MP1 & N9MP2-A2 Models)

VentFitting

&Clamps

PVCVent /

Extension

Pipe

LEFT Side Ventinq,_

ReturnAir

CombustionBlower

Mountin! ;crews(4)

- 314"Hose&Clamps

SupplyAir

<Z>

Pressure Switch

Hose,Transition

j Transition Box

Pressure

Switch

Pressure Switch

Hose,Blower

Tral

/_-_PPointed

Preassemble&

insertintofurnace

RIGHT Side Venting

ReturnAir

CombustionBlower

(Rotate 180° for LeftSide)

Pressure

Switch, SomeModels

Transition

pressureswitch

SupplyAir

<Z>

Representive drawing, some

valves will vary.

Airlntake

Combustion

Air Pipe,

PVCVent

Extension

Pipe

Yellow Vent Fitting

&Clamps

DRAIN SIDE Rotate

5°to10°

NOTE: TRAP MUST BE PRIMED BEFORE OPERATION

Downflow Installations - (Single Pipe & DirectVent N9MP1

NOTE: DO NOT make hose connections until the hose routing and

lengths have been determined. Remove the condensate trap and

drain hoses from the furnace and secure the drain hoses to the

drain stubs on the trap with the hose clamps (position the clamps as

shown in Figure 10). Install the condensate trap/hose assembly to

the furnace casing. Hook one side of the "clamp ears" on the drain

stub through the hole in the casing and push the condensate trap

into position. Secure with the two screws. Reconnect the drain

hoses to the stubs on the vent fitting and the plastic transition and

secure with the clamps.

Mount the condensate drain trap in a vertical position to either the

right or left side of the furnace using the two screws and gasket that

are provided. If needed, remove the hole plugs from the furnace

side panel and relocated to the open set of holes in the opposite

side panel.

NOTE: All gaskets and seals must be in place for sealed combus-

tion applications.

Ensure that the vent fitting is securely attached to the combustion

blower using the rubber coupling and clamps.

441 06 1039 00 - 12 -

_uilt-inchannelwill

dwg 25-24-04 be angled 5°to 10° als0.

N9MP2 Models)(SeeFigure10)

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

This configuration allows left side venting from the furnace. If right

side venting is required, the combustion blower must be relocated

on the plastic transition box. Loosen the four(4) screws that secure

the blower to the transition approximately1/2 ". Rotate the blower

180 ° and secure with the four(4) screws. Note that some combus-

tion blowers have plastic spacers on the mounting legs of the blow-

er located atthe 6 and 12 o'clock positions (blower snout to the left

or right) that are required for proper fit up of the blower to the transi-

tion. Use caution to not over tighten the screws to prevent stripping

out of the plastic mounting holes.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a 5 ° to 10 °

downward slope.

Page 13

Plugtheupperdrainstubontheventfittingwiththeyellowplastic

cap.

ConnectthePVCventextensionpipetotheventfitting.Thispipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the clamp.

Remove the pressure switch hose from the upper stub on the plas-

tic transition box.

Relocate the plastic caps on the stubs of the plastic transition box

from the lower stubs to the upper stubs and secure tightly with the

clamps.

Route the pressure switch hose to the lower stub on the plastic

transition box. Cut off excess hose and discard. Connect the pres-

sure switch hose to the lower stub on the plastic transition box.

NOTE: Failure to correctly install the pressure switch hose to the

transition box can adversely affect the safety control operation.

Connect the 3/4" OD rubber hose with the 90 ° bend to the drain stub

on the bottom of the plastic transition box and secure with a 3/4"

clamp.

Route the hose to the large drain stub on the condensate trap. Cut

off excess hose and discard. Connect the hose to the drain stub on

the transition and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the left drain

stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller stub on the condensate trap. Cut off

excess hose and discard. Connect the hose to the drain stub on the

trap and secure with a 5/8" clamp.

For left aide or right aide mounted condenaate trap, the pres-

sure tap on the condensate trap MUST be connected to the unused

pressure tap located on the top of the plastic transition box. Re-

move the plastic caps from the pressure tap on the condensate trap

and the plastic transition and connect the 5/16" OD rubber hose.

(See Figure 10)

NOTE: Route hoses to the condensate trap with no kinking or bind-

ing for proper condensate drainage.

Note: The air intake coupling and gasket can be installed to the top

panel to the alternate air intake locations on either the left or right

side panels of the furnace.

For downflow installation, the air intake coupling and gasket must

be installed to the alternate air intake location on either the left or

right side panels. Remove the 3" hole plug from the side panel and

relocate to the air intake hole in the top panel. Use four screws to

seal the four(4) mounting holes in the top panel next to the hole

plug. Drill four(4) 7/64" diameter holes in the casing using the air in-

take coupling as the template.

The air intake coupling is sized for 2" PVC pipe.

Install the combustion air pipe to the air intake coupling using RTV

sealant to provide for future serviceability.

Vent PipeConnection

Install the vent pipe grommet to the furnace panel. Locate the

grommet in the furnace panel at a location directly away from the

vent fitting on the combustion blower. The grommet snaps into the

3" hole plug from the furnace panel. NOTE: Depending on the

installation position, the vent pipe grommet will be installed to the

top panel or to the alternate location on the side panels. If needed,

remove the 3" hole plug from the furnace panel and relocate to the

open hole in the furnace panel, (See Figure 5 or Figure 10)

Install the vent pipe to the rubber coupling, the vent fitting or the

PVC vent extension pipe. Securely attach using the clamp or PVC

cement as required.

Note: The vent fitting M UST be installed with the air flow mark-

ing arrow pointed toward the vent pipe. (See Figure 11)

Some installations require the vent fitting to be installed with a

5° to 10° downward slope. (See Figures 8 - 17)

Proper Sealing Procedure for

Combustion Blower

_Vent Pipe

RubbaerpC°upting _

(Top Panel Exit)

ConnectingVent andCombustion Air Piping

Poison carbon monoxide gas hazard.

Cement or mechanically seal all joints, fittings, etc. to

prevent leakage of flue gases.

Failure to properly seal vent piping can result in death,

personal injury and/or property damage.

Refer to Figure 1 through Figure 10 that corresponds to the instal-

lation position of the furnace for the application,

Preassemble the vent and combustion air piping from the furnace

to the vent termination. Do not cement the pipe joints until the pipe

preassembly process is complete.

Combustion Air Pipe Connection (Dual Certified or

Direct Vent)

Install the air intake coupling and gasket to the furnace with the

four(4) screws.

441 06 1039 00 - 13 -

90° Streetl

Elbow

Pipe(SidePanel

Exit)

DRAIN SIDE VIEW

Rotate

//_6v_ward

NOTE',Built-inchannelwill

beanqled5°to10° als0.

_PVC VentExtensionPipe

/ VentFitting

&Clamps

Combustion

Blower

/

)

25-23-35

Page 14

Joining Pipeand Fittings

Fire hazard.

Provide adequate ventilation and do NOT assemble

near heat source or open flame. Do NOT smoke while

using solvent cements and avoid contact with skin or

eyes.

Observe all cautions and warnings printed on material

containers to prevent possible death, personal injury

and/or property damage.

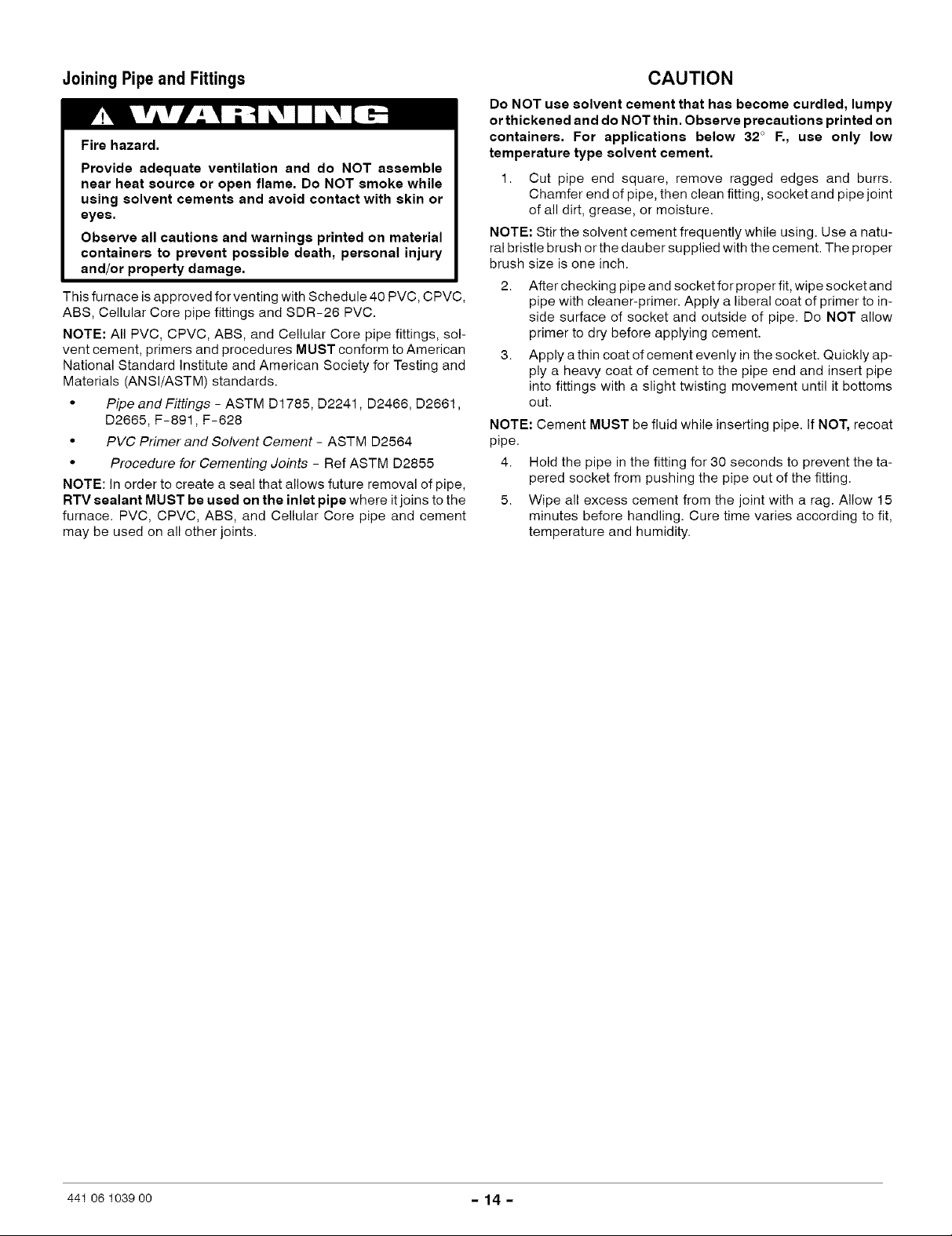

This furnace is approved for venting with Schedule 40 PVC, CPVC,

ABS, Cellular Core pipe fittings and SDR-26 PVC.

NOTE: All PVC, CPVC, ABS, and Cellular Core pipe fittings, sol-

vent cement, primers and procedures MUST conform to American

National Standard Institute and American Society for Testing and

Materials (ANSl/ASTM) standards.

• Pipe and Fittings - ASTM D1785, D2241, D2466, D2661,

D2665, F-891, F-628

• PVC Primer and Solvent Cement - ASTM D2564

• Procedure for Cementing Joints - Ref ASTM D2855

NOTE: In order to create a seal that allows future removal of pipe,

RTV sealant MUST be used on the inlet pipe where it joins to the

furnace. PVC, CPVC, ABS, and Cellular Core pipe and cement

may be used on all other joints.

CAUTION

Do NOT use solvent cement that has become curdled, lumpy

or thickened and do NOT thin. Observe precautions printed on

containers. For applications below 32 ° F., use only low

temperature type solvent cement.

1. Cut pipe end square, remove ragged edges and burrs.

Chamfer end of pipe, then clean fitting, socket and pipe joint

of all dirt, grease, or moisture.

NOTE: Stir the solvent cement frequently while using. Use a natu-

ral bristle brush orthe dauber supplied with the cement. The proper

brush size is one inch.

2. After checking pipe and socket for proper fit, wipe socket and

pipe with cleaner-primer. Apply a liberal coat of primer to in-

side surface of socket and outside of pipe. Do NOT allow

primer to dry before applying cement.

3. Apply a thin coat of cement evenly in the socket. Quickly ap-

ply a heavy coat of cement to the pipe end and insert pipe

into fittings with a slight twisting movement until it bottoms

out.

NOTE: Cement MUST be fluid while inserting pipe. If NOT, recoat

pipe.

4. Hold the pipe in the fitting for 30 seconds to prevent the ta-

pered socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit,

temperature and humidity.

441 06 1039 oo - 14 -

Loading...

Loading...