Page 1

INSTRUCTION MANUAL

SEPARATION KIT

RMK-5

DUAL-HEAD SEPARATION KIT

RMK-7

Page 2

Thank you for choosing this Icom product.

This product is designed and built with Icom’s state of the art

technology and craftsmanship. With proper care, this product

should provide you with years of trouble-free operation.

IMPORTANT

READ ALL INSTRUCTIONS carefully and completely

before using the product.

SAVE THIS INSTRUCTION MANUAL—This instruction

manual contains important operating instructions for the

RMK-5 and RMK-7.

DISPOSAL

The crossed-out wheeled-bin symbol on your

product, literature, or packaging reminds you

that in the European Union, all electrical and

electronic products, batteries, and

accumulators (rechargeable batteries) must be

taken to designated collection locations at the

end of their working life. Do not dispose of

these products as unsorted municipal waste. Dispose of

them according to the laws in your area.

Refer to the transceiver’s INSTRUCTIONS for details on the

basic operations.

For the IC-F5400D and IC-F6400D series

To use the RMK-5 or RMK-7 with the IC-5400D and

IC-6400D series, the transceivers’ rmware revision must

be 1.6 or later.

Icom, Icom Inc. and the Icom logo are registered trademarks of Icom

Incorporated (Japan) in Japan, the United States, the United Kingdom, Germany,

France, Spain, Russia, Australia, New Zealand, and/or other countries.

EXPLICIT DEFINITIONS

WORD DEFINITION

CAUTION

NOTE

Icom is not responsible for the destruction, damage to, or

performance of any Icom or non-Icom equipment, if the

malfunction is because of:

• Force majeure, including, but not limited to, res, earthquakes,

storms, oods, lightning, other natural disasters, disturbances,

riots, war, or radioactive contamination.

• The use of Icom products with any equipment that is not

manufactured or approved by Icom.

Equipment damage may occur.

If disregarded, inconvenience only. No risk of

personal injury, re or electric shock.

i

Page 3

PRECAUTIONS

TABLE OF CONTENTS

CAUTION: DO NOT use harsh solvents such as Benzine or

alcohol when cleaning, as they will damage the separation

kit’s surfaces.

CAUTION: DO NOT place or leave the transceiver (with

the separation kit) in areas with temperatures below –30°C

(–22°F) or above +60°C (+140°F), or in areas subject to

direct sunlight, such as the dashboard.

CAUTION: DO NOT operate the transceiver (with the

separation kit) if it becomes hot after transmitting for long

periods of time. This may damage the transceiver.

CAUTION: BE SURE that all connectors and jacks are dry

and clean before attachment. Exposing them to dust or

water will result in serious damage to the transceiver and the

separation kit.

BE SURE the transceiver power is OFF and the DC power

cable is disconnected before attaching the separation kits.

USE the specied microphone only. Other, or non-Icom

microphones have different pin assignments and may

damage the transceiver and the separation kit.

IMPORTANT .......................................................................... i

EXPLICIT DEFINITIONS ....................................................... i

DISPOSAL ............................................................................. i

PRECAUTIONS .................................................................... ii

SUPPLIED ACCESSORIES .................................................iii

1. ATTACHMENT .............................................................1–8

Attachment images ......................................................1

■

Opening the transceiver ............................................... 2

■

Detaching the control head from the transceiver .........3

■

Attachment ................................................................... 3

■

2. DUAL-HEAD OPERATION ....................................... 9–11

Individual settings ........................................................9

■

Control Head settings ................................................10

■

3. SPECIFICATIONS AND OPTIONS ...............................12

Specications ............................................................. 12

■

Options ....................................................................... 12

■

4. MOUNTING ...................................................................13

ii

Page 4

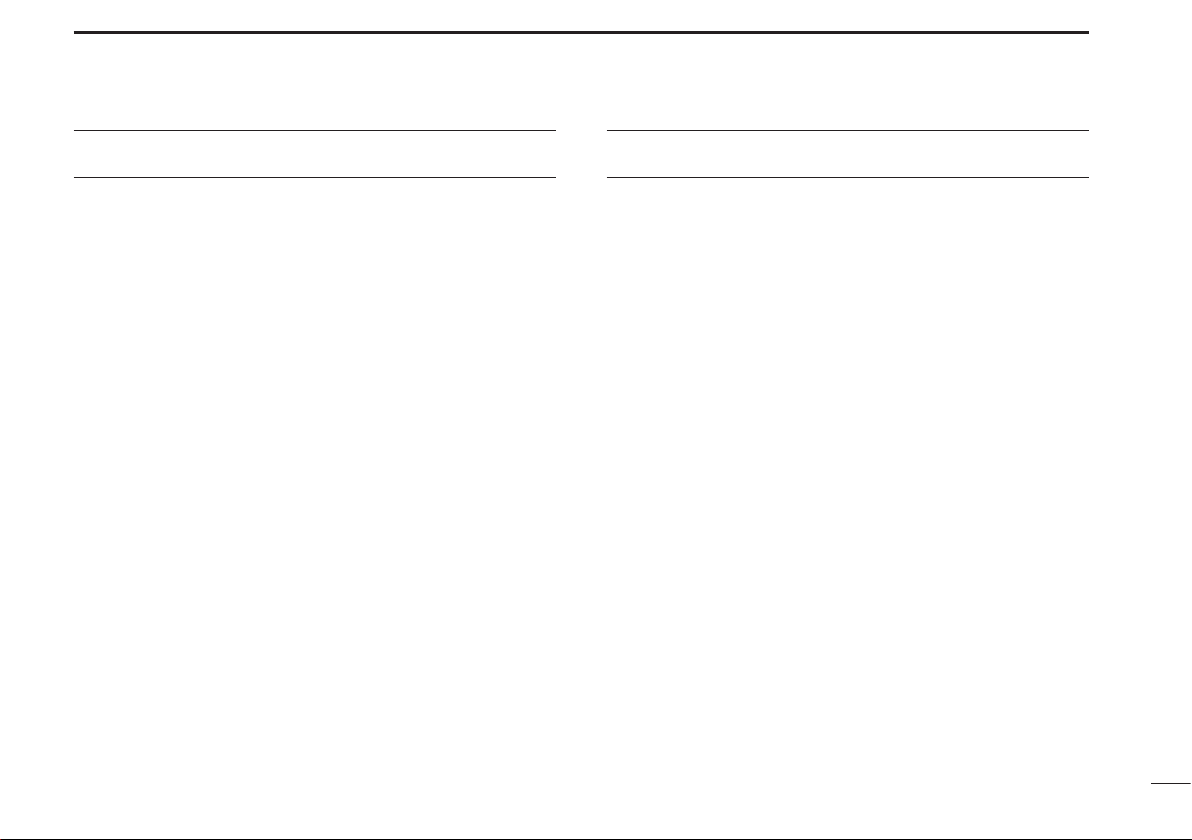

SUPPLIED ACCESSORIES

Separation kit accessories

q w

e r t y

Mounting bracket accessories

i o !0u!1 !2 !3 !4

RMK-5 (Qty.) RMK-7 (Qty.)

q RMK-5/RMK-7

w Control head

e Flat cable (wide)

r Flat cable (narrow)

t Cable bracket

Grounding screw

y

u Connector O-ring

i Mounting bracket

o Bracket screw

!0 Self-tapping screw

!1 Mounting screw

!2 Spring washer

!3 Flat washer

!4 Nut

NOTE:

You need to purchase a separation cable separately.

See page 12 for details on the separation cables.

1 1

Not supplied

1 2

1 1

2 4

2 2

3 4

1 2

2 4

4 8

4 8

4 8

4 8

4 8

1

iii

Page 5

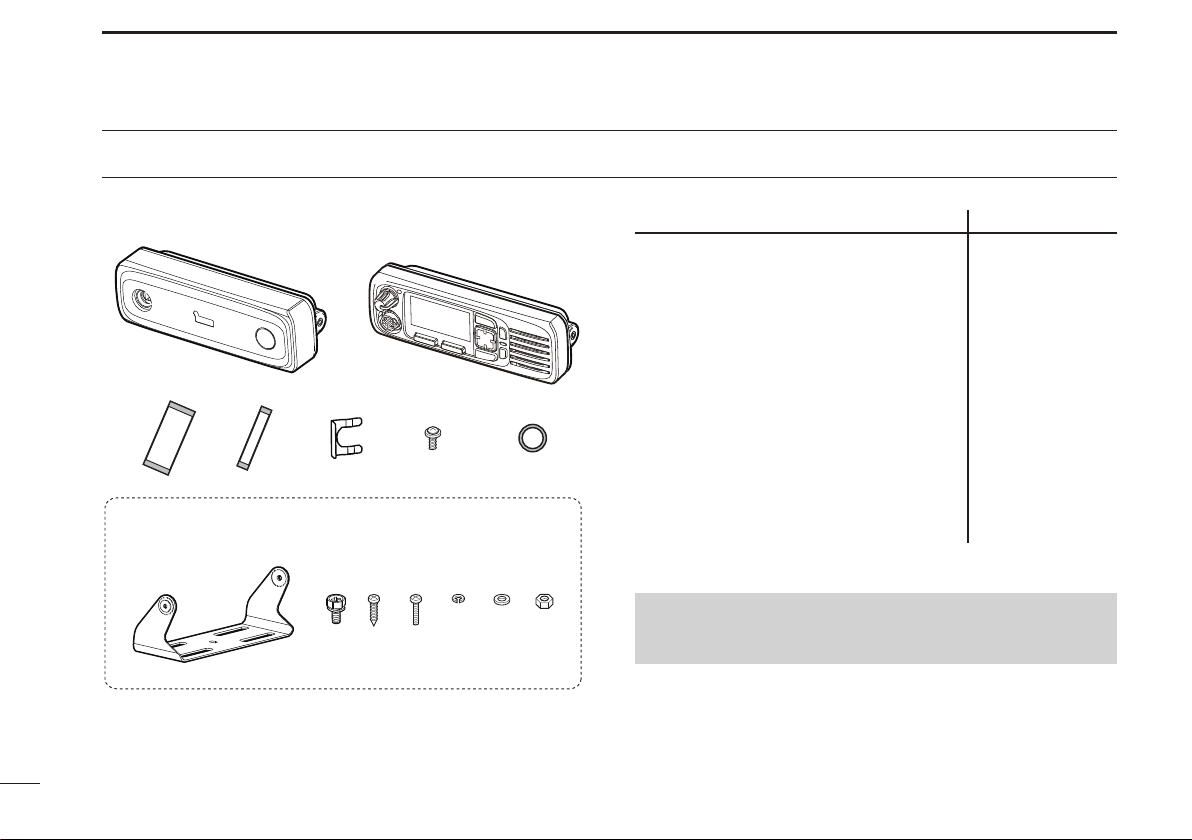

ATTACHMENT

1

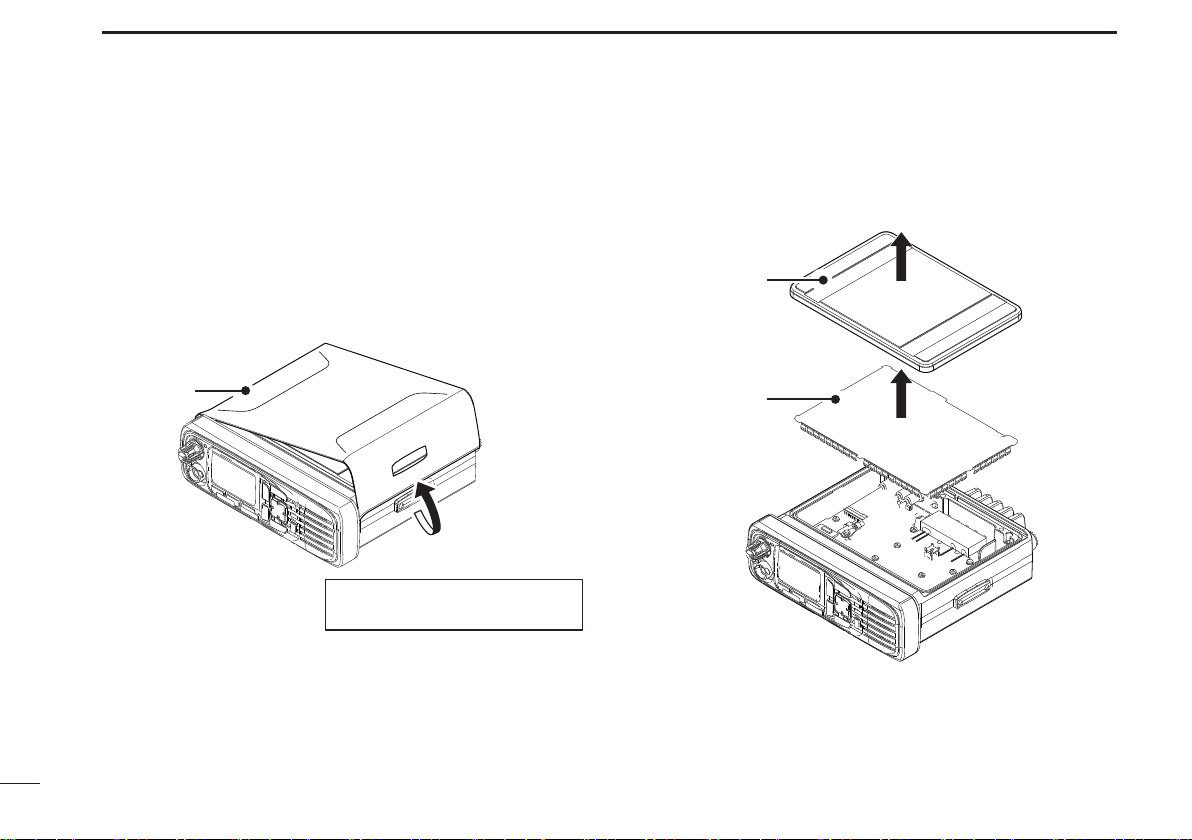

■ Attachment images

RMK-5

Control head

RMK-7

Front panel

Rear panel

Main unit

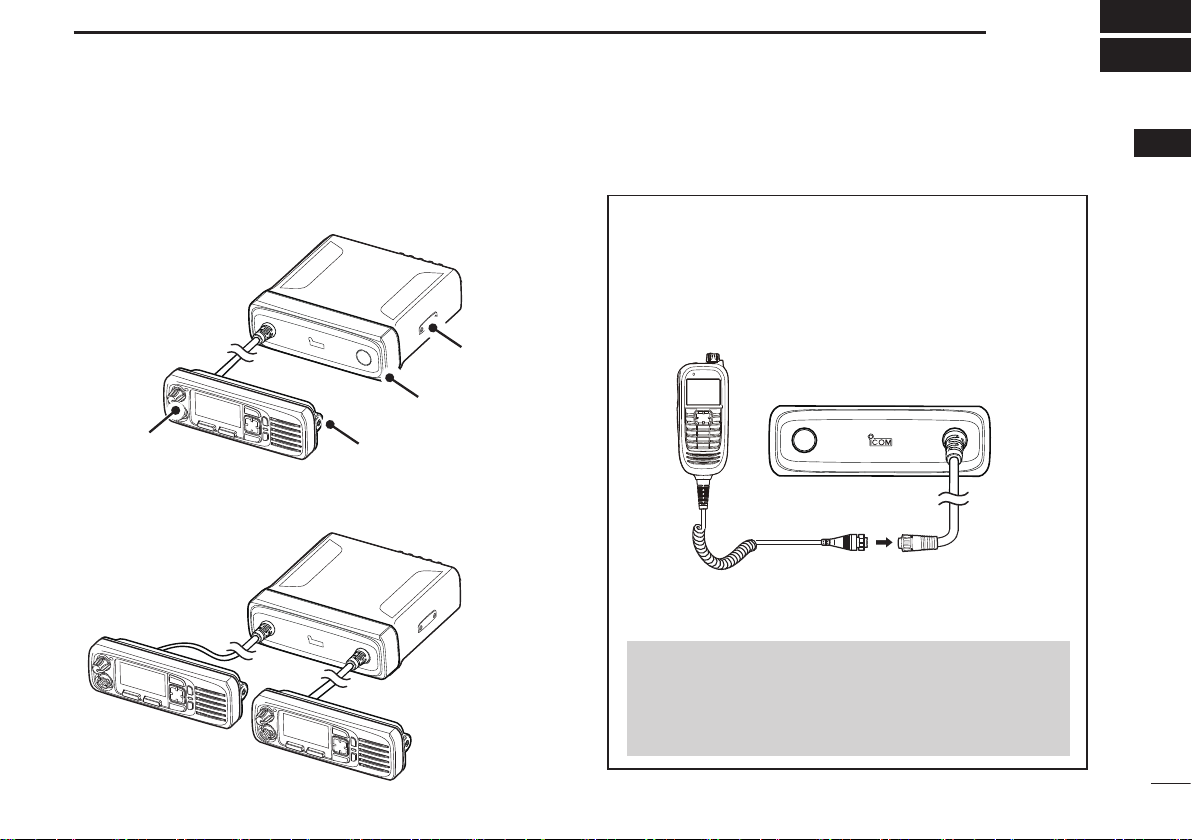

About the HM-218 hand microphone for the rmK-5:

You can use the HM-218

RMK-5.

L Ask your dealers for details on the microphone.

HM-218

* OPC-2373 or OPC-2374 separation cable for command

microphone is required to connect the HM-218.

NOTE:

• You can only attach the HM-218 to the RMK-5’s front

panel.

• You cannot attach the HM-218 to the transceiver’s

control head.

hand microphone with the

RMK-5

Separation

cable*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

Page 6

ATTACHMENT

1

■ Opening the transceiver

1. Turn OFF the transceiver and disconnect the DC power

cable.

2. Carefully pull out the side of the top cover in the

direction of the arrow, and then lift off the top cover.

3. Take out the rubber cover and the shield cover.

Rubber cover

Top cover

Be careful!

Do not break your ngernails.

2

Shield cover

Page 7

ATTACHMENT

1

■ Detaching the control head

from the transceiver

1. Disconnect the speaker cable [J803] from the

transceiver’s main unit.

2. Disconnect the flat cable from the transceiver’s control

head.

3. Detach the control head from the main unit.

[J803]

Flat

cable

Main unit

Control head

■ Attachment

D Opening the separation kit

NOTE: The separation kit is supplied with the front panel

and rear panel attached. First you need to open the

separation kit in order to attach the control head to the

separation kit’s rear panel.

Hold the tabs on the separation kit’s front panel, and then

pull out in the directions of the arrows.

Rear panel

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Front panel

3

Page 8

ATTACHMENT

1

■ Attachment (Continued)

D Connecting the separation cable

L The separation cables are purchased separately.

1. Pass the separation cable’s control connector and

ground wire through the supplied connector O-ring.

2. Slide the connector O-ring into the groove.

4. Firmly slide the cable bracket in place to lock the cable

inside the rear panel.

Connector O-ring

3. Pass the separation cable’s control connector and

ground wire through the cable hole from the back of the

rear panel.

Rear panel

Ground wire

Slide

Control connector

Separation

cable

Cable bracket

5. Unfasten the grounding screw from screw hole [3], and

then using the same screw, firmly fasten the ground

wire’s terminal to ground.

6. Connect the control connector to connector [J5].

[3]

[J5]

4

Page 9

D Attaching the control head

1. Insert the flat cable into connector [11] on the

separation kit’s inside panel.

[11]

Recommendation for

easy attachment:

Loosely bend the

at cable as shown

below.

ATTACHMENT

3. Firmly attach the control head to the separation kit’s

rear panel.

1

1

2

3

4

5

6

7

8

9

2. Connect the flat cable on the transceiver’s front panel,

and then connect the speaker cable you disconnected

from the transceiver’s main unit to [J2] on the

separation kit’s rear panel.

[J2]

Speaker cable

Flat cable

10

11

12

13

14

15

16

5

Page 10

ATTACHMENT

1

■ Attachment (Continued)

D Attaching the front panel

1. Pass the separation cable’s control connector and

ground wire through the supplied connector O-ring and

cable hole of the front panel from the front side.

L If you are connecting another separation cable, pass

that cable through the other cable hole.

Control connector

Separation

cable

3. Firmly fasten the ground wire terminal to the front panel

using the supplied grounding screw.

4. Connect the control connector to connector [J4].

Ground wire terminal

[J4]

Front panel

2. Firmly slide the cable bracket in place to lock the cable

inside the front panel.

O-ring

Ground wire

Important for easy attachment:

• Lift the control connector and ground wire upward.

Lift upward

Cable

bracket

6

Page 11

L If you are connecting another control head, connect

that ground wire terminal, and then connect the other

control connector to connector [J3].

Ground wire

terminal here

[J3]

5. Connect the narrow flat cable to connector [J1].

ATTACHMENT

6. Connect the flat cable

transceiver’s main unit

Recommendation for easy attachment:

• Loosely bend the narrow at cable.

LThe wide at cable is originally bent.

you disconnected from the

to connector [J2].

[J2]

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

[J1]

16

Loosely Bend

7

Page 12

ATTACHMENT

1

D Attaching the front panel (Continued)

7. Pass the flat cables through the opening in the main unit, and then attach the separation kit’s front panel to the main unit

by pushing it in place.

8. Connect the narrow flat cable to connector [J409], and

then connect the wide flat cable to connector [J400].

[J409] [J400]

9. Put the shield cover and rubber cover back in the main

unit.

10. Put the main unit’s top cover back on.

8

Page 13

DUAL-HEAD OPERATION

2

This section describes the operations that can be made when two control heads are connected to the transceiver’s main unit.

For the operations and functions that are not mentioned in this section, see the transceiver’s instruction manual.

“Other Head is in use”

Except for the Power key, [VOL], and [Emer] keys, all

keys are locked while one control head is being used, and

“Other Head is in use” is displayed as shown below.

Other Head

is in use

The [PTT] button is also locked while [PTT] is being

pushed on the other control head. This means that you

can only transmit from one control head at a time.

■ Individual settings

You can individually set the following items in each control

head, and also in the HM-218.

L See the transceiver’s instruction manual for details on

setting these items.

Item Options

Audio level

Head SP Out ON/OFF (See page 11 for details)

Backlight ON/Auto OFF/OFF

Brightness 0~7

Dimmer 0~7

LCD Mode Day/Night

NOTE: Except for the audio level setting, you can only set

the items using one control head at a time. While setting

an item on another control head “Other Head is in use” is

displayed.

—

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

9

Page 14

DUAL-HEAD OPERATION

2

■ Control Head settings

When two control heads are connected, the “Control Head”

category is added to the Menu screen. Select “Control

Head’’ to set the following items.

D Intercom

The Intercom function enables you to communicate between

the control heads.

1. Select “Intercom,” and then push [OK].

LThe Intercom function is ON.

2. Hold down or release [PTT] to communicate.

3. Push [OK] to turn the Intercom function OFF.

L While communicating using the Intercom function, you

can use only [PTT], [VOL] and [Emer].

D Hanger

(Options: HEAD 1 & HEAD 2, HEAD 1, HEAD 2)

Select which control head, or simply select both control

heads, to automatically start scanning after putting the

microphone in the hanger (on-Hook).

L To use this function, turn the Hook Scan function ON in

the “Functions” category.

HEAD 1 & HEAD 2: Automatically starts scanning after

putting both microphones in their

hangers.

HEAD 1: Automatically starts scanning

after putting the microphone in the

CONTROL HEAD 1 hanger.

HEAD 2: Automatically starts scanning

after putting the microphone in the

CONTROL HEAD 2 hanger.

D TX AF Monitor

(Options: OFF, ON)

The TX AF Monitor function enables you to monitor the

audio that is transmitted on the other control head, when ON

is set.

L While receiving, the received audio can be heard on both

control heads.

10

Page 15

DUAL-HEAD OPERATION

2

1

D SP Link

(Options: OFF, HEAD 1, HEAD 2)

The SP Link function enables you to link the audio volume

settings between the two control heads. Select which control

head controls the audio volume.

OFF: The audio volume settings are not linked, and are

individually set at each control head.

HEAD 1: The audio volume settings are linked, and are

equally set on CONTROL HEAD 1.

HEAD 2: The audio volume settings are linked, and are

equally set on CONTROL HEAD 2.

D Primary Mic

(Options: HEAD 1, HEAD 2)

Select which control head’s microphone to use when

transmitting without pushing [PTT], such as when using the

Auto TX function or PC commands.

HEAD 1: CONTROL HEAD 1’s microphone is used.

HEAD 2: CONTROL HEAD 2’s microphone is used.

D Head SP out

(Options: HEAD 1, HEAD 2)

Select whether or not to output the audio from the control

head.

L You can individually set to each control head, and also the

HM-218.

OFF: The audio is not output.

ON: The audio is output from the control head’s front

speaker or from the HM-218.

■ Updating the rmware

For the IC-F5400D and IC-F6400D series, the rmware of

the control heads are automatically updated when they are

not up-to-date to the transceiver’s main unit.

When the control heads are not up-to-date:

The control head automatically starts updating when you

turn ON the power at the control head.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

11

Page 16

3

SPECIFICATIONS AND OPTIONS

■ Specications

• Audio output power: 3.5 W with a 4 Ω load

(at 5% distortion)

•

Operating temperature range:

• Power supply requirement: 13.6 V DC nominal

• Dimensions:

Front panel: 177 (W) x 55 (H) x 25 (D) mm

7 (W) x 2.2 (H) x 1 (D) in

Rear panel:

6.7 (W) x 2.2 (H) x 1 (D) in

Control head with rear panel:

6.7 (W) x 2.2 (H) x 2.2 (D) in

• Weight (approximately):

Front panel: 100 g / 3.5 oz

Rear panel: 110 g / 3.9 oz

Control head with rear panel:

–30°C ~ +60°C

(–22°F ~ +140°F)

170 (W) x 55 (H) x 26 (D) mm

170 (W) x 55 (H) x 55 (D) mm

250 g / 8.8 oz

■ Options

• OPC-2364, OPC-2365, OPC-2366, and OPC-2367

separation cables

OPC-2364: 1.9 m / 6.3 ft

OPC-2365: 3 m / 9.9 ft

OPC-2366: 5 m / 16.4 ft

OPC-2367: 8 m / 26.3 ft

• HM-218

separation cable for RMK-5

HM-218: Command microphone with a built-in speaker

OPC-2373: Separation cable for command microphones

OPC-2374: Separation cable for command microphones

Some options may not be available in some countries.

Ask your dealer for details.

hand microphone + OPC-2373 or OPC-2374

(1.9 m/ 6.3 ft)

(8 m / 26.3 ft)

12

Page 17

MOUNTING

4

D Mounting on a wall

Securely mount the control head on a wall, using the

following supplied accessories.

• Mounting bracket ......................1

• Bracket screw ...........................2

• Self-tapping screw ....................4

• Spring washer ..........................4

• Flat washer ...............................4

Bracket screw

Self-tapping screw

Spring washer

Flat washer

Mount bracket

D Mounting on a board

Securely mount the control head on a board, using the

following supplied accessories.

• Mounting bracket ......................1

• Bracket screw ...........................2

• Mounting screw ........................4

• Spring washer ..........................4

• Flat washer ...............................4

• Nut ............................................4

Mounting screw

Spring washer

Flat washer

Nut

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

13

Page 18

MEMO

Page 19

MEMO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 20

A7341D-1EX-1

Printed in Japan

© 2016–2017 Icom Inc.

1-1-32 Kamiminami, Hirano-ku, Osaka 547-0003, Japan

Loading...

Loading...