ICM CONTROLS ICM326HN, ICM327HN Installation Manual

ICM326HN / ICM327HN

ICM326HN / ICM327HN

Line Voltage Head Pressure Control

With built-in transformer Optional heat pump override

ICM327HN

Installation, Operation & Application Guide

For more information on our complete range of American-made products – plus wiring diagrams, troubleshooting tips and more, visit us at www.icmcontrols.com

Caution!

Installation of the ICM326HN and ICM327HN shall be performed by trained technicians only. Adhere to all local and national electric codes.

Disconnect all power to the system before making any connections.

Specifications

•Line voltage: 120, 208/240, and 480 VAC

•Frequency: 50-60 Hz

•Output: 10 amp maximum, 100 mA minimum

•Operating temperature: -40ºF to +176ºF (-40°C to +75°C)

•Sensors: 10K ohms at 25°C

•Heat pump override: N.C. or N.O.

Note: A maximum of three sensors can be connected to the control

Note: A maximum of three sensors can be connected to the control

• Weight: 12 ounces (341 grams)

Note: The ICM326HN and ICM327HN should be applied to motors and equipment that have been designated by their respective manufacturers as capable of being speed controlled

Note: The ICM326HN and ICM327HN should be applied to motors and equipment that have been designated by their respective manufacturers as capable of being speed controlled

•Mounting:

–Surface mount using (4) #8 screws

–The ICM326HN and ICM327HN should be surface mounted to a clean metal or other thermally-conductive surface for maximum heat dissipation

–It is recommended that the ICM326HN and ICM327HN be mounted away from the condenser exhaust air to maintain lower operating temperatures

ELECTRICAL SHOCK HAZARD – Installation of the ICM326HN and ICM327HN shall be performed by trained technicians only. Adhere to all local and national electric codes. Disconnect all power to the system before making connections.

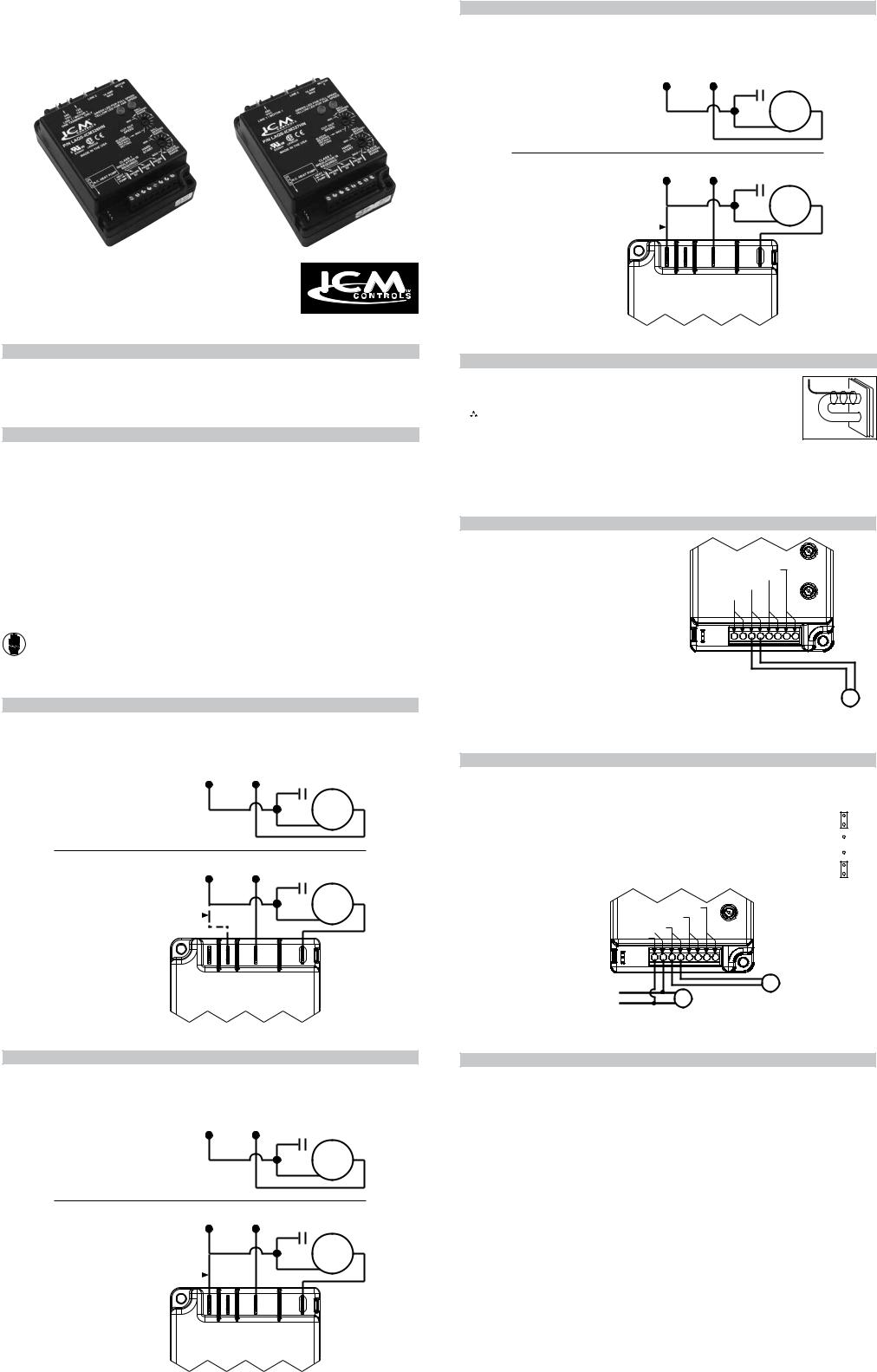

Connections for ICM326HN at 120 VAC

1. Remove power from system. |

|

|

|

4. Make probe and heat pump connections. |

|||

2. Add wire from Line 1 wire to Line 1 terminal. |

5. Verify wiring is correct. |

||||||

3. Cut Line 2 wire; affix motor side to Motor 2 terminal, |

6. Power up system and check operation. |

||||||

and line side to Line 2 terminal. |

|

|

|

|

|

|

|

|

|

|

|

|

Run |

||

|

|

|

|

120 VAC |

Capacitor |

||

|

|

|

|

|

|

|

|

Typical condenser fan |

|

|

|

|

|

|

PSC |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Fan |

|

|

|

|

|

|

|

Motor |

|

|

|

|

|

Run |

||

|

Field |

120 VAC |

Capacitor |

||||

Typical condenser |

|

|

|

PSC |

|||

Installed |

|

|

|

||||

fan with ICM326HN |

Wire |

|

|

|

Fan |

||

|

|

|

|

|

|

Motor |

|

installed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Line |

Line |

Motor |

1 |

2 |

2 |

120 VAC

Connections for ICM326HN at 208/240 VAC

1. Remove power from system. |

|

|

4. Make probe and heat pump connections. |

|||

2. Add wire from Line 1 wire to Line 1 terminal. |

5. Verify wiring is correct. |

|||||

3. Cut Line 2 wire; affix motor side to Motor 2 terminal, |

6. Power up system and check operation. |

|||||

and line side to Line 2 terminal. |

|

|

|

|

|

|

|

|

|

208/240 |

Run |

||

|

|

|

VAC |

Capacitor |

||

Typical condenser fan |

|

|

|

|

|

PSC |

|

|

|

|

|

||

|

|

|

|

|

|

Fan |

|

|

|

|

|

|

Motor |

|

|

|

208/240 |

Run |

||

|

|

|

Capacitor |

|||

|

|

|

VAC |

|||

|

|

|

|

|

|

|

Typical condenser |

Field |

|

|

|

PSC |

|

|

|

|

||||

Installed |

|

|

|

|||

fan with ICM326HN |

|

|

|

Fan |

||

Wire |

|

|

|

|||

|

|

|

Motor |

|||

installed |

|

|

|

|

|

|

|

|

|

|

|

|

|

Line |

Line |

Motor |

1 |

2 |

2 |

240 VAC

Connections for ICM327HN at 480 VAC

1. Remove power from system. |

|

|

4. Make probe and heat pump connections. |

|||

2. Add wire from Line 1 wire to Line 1 terminal. |

5. Verify wiring is correct. |

|||||

3. Cut Line 2 wire; affix motor side to Motor 2 terminal, |

6. Power up system and check operation. |

|||||

and line side to Line 2 terminal. |

|

|

|

|

|

|

|

|

|

|

Run |

||

|

|

|

480 VAC |

Capacitor |

||

Typical condenser fan |

|

|

|

|

|

PSC |

|

|

|

|

|

||

|

|

|

|

|

|

Fan |

|

|

|

|

|

|

Motor |

|

|

|

|

Run |

||

|

|

|

480 VAC |

Capacitor |

||

Typical condenser |

Field |

|

|

|

PSC |

|

|

|

|

||||

Installed |

|

|

|

|||

fan with ICM327HN |

|

|

|

Fan |

||

Wire |

|

|

|

|||

|

|

|

Motor |

|||

installed |

|

|

|

|

|

|

|

|

|

|

|

|

|

Line |

Line |

Motor |

1 |

2 |

2 |

480 VAC

Connecting the Probe

1.Install the temperature probe several bends into the condenser. It can be attached to the

U-bend or placed between the fins in the upper 1/3 of the condenser (see other side for

more information).

Note: The response of the system can be fine tuned by repositioning the probe. Place |

|

the probe on the condenser where it is 100°F when pressures are correct for |

Example |

best response. |

2.Connect the two wires from the sensor to the terminal block where it is marked PROBE S1. If additional probes are necessary for multiple refrigerant circuits, they may be attached to terminals marked PROBE S2 and PROBE S3.

Note: The control will respond to the probe that senses the highest temperature.

Note: The control will respond to the probe that senses the highest temperature.

Connections for Air Conditioning Only

1.For non-heat pump applications, the heat pump select jumper must be in the Default (N.O.) position, and the HP terminals must be left

unconnected. |

|

|

|

Probe S3 |

|||

|

|

Probe S2 |

|

|

|||

|

|

|

|||||

|

Probe S1 |

|

|

|

|

||

|

|

||||||

|

HP |

|

|

|

|

|

|

|

|

||||||

Heat Pump

Select Jumper

Default Position

Temperature

Probe

Connections for Heat Pump Systems

Note: HP terminals will not recognize 24 VAC. Line voltage must be applied (120, 208/240, or 480 VAC).

Note: HP terminals will not recognize 24 VAC. Line voltage must be applied (120, 208/240, or 480 VAC).

1.The heat pump terminals accept the line voltage signal from the reversing valve holding coil. Make a parallel connection from the reversing valve to HP terminals.

2. |

If the heat pump is in the Heating mode and the reversing valve is energized, then the Heat Pump |

N.O. |

|

Select jumper must be in the Default (N.O.) position. |

|

3. |

If the heat pump is in the Heating mode and the reversing valve is not energized, then the Heat |

N.C. |

|

Pump Select jumper must be in the N.C. position. |

Probe S3

Probe S2

Probe S1

HP

Heat Pump

Select Jumper

Default Position

RV |

Temperature |

|

Probe |

Connect Parallel to

Reversing Valve

Mode of Operation

Normal Function

With probe temperatures above 100°F, the control applies full voltage to the motor. The green light is illuminated (full speed LED).

With probe temperatures between 70°F and 100°F, the motor speed is proportional to the probe temperature. The yellow light is illuminated (variable speed LED).

When the motor starts at temperatures between 70°F and 100°F, it will hard start for the length of time dictated by the setting of the Hard Start dial. After the hard start time has elapsed, the motor speed is controlled by the probe temperature.

As the temperature being sensed decreases, the output voltage decreases. The output voltage may decrease to the determined cutout speed. Upon reaching the Cutout Speed dial setting, the output voltage will go to zero volts.

System restart occurs when the temperature exceeds 70°F.

With probe temperatures below 70°F, the motor remains off. The green light and the yellow light are off.

Heat Pump Bypass Operation

Heat Pump Bypass mode runs the fan at full speed when the system is operating in Heat mode. This moves as much air across the condenser coil as possible.

If the Heat Pump Select jumper is in the N.O. position and line voltage is present at the HP terminals, the motor will be brought to full speed.

If the Heat Pump Select jumper is in the N.C. position and line voltage is not present at the HP terminals, the motor will be brought to full speed.

A separate relay is not needed.

Loading...

Loading...