ICM CONTROLS ICM271 Installation Manual

Fan Control

SEC-2

C15

R23

R17

R24

D2

R25

G

BLOWER OPTION

TEST

R7

R14

R20

R13

R12

GAS3

GAS1

ATO 3-amp Fuse

Center

SEC-1

LIM-2

LIM-1

GAS2

W4

W3

P4

1

C8W5C8

C8

C8

3 AMP

Blower

Option

Vent

Damper

Plug

Connection

Vent

Damper

ICM271

Replacement Description

The ICM271 Fan Control Center is a solid state control designed and

engineered for the replacement market. The ICM271 is designed specically

to replace the Carrier/BDP Gas Furnace Control Centers that have been

used in new equipment for many years. The ICM271 is a form, t and

functional replacement of the OEM control requiring no modications to the

original wiring or to the appliance’s sheet metal.

The ICM271 is a form, t and functional replacement of the OEM control for

the following Carrier/BDP part numbers:

302075-3 HH84AA010 HH84AA013

CES0110017 HH84AA011 HH84AA020

CES0110018 HH84AA012 P771-7002

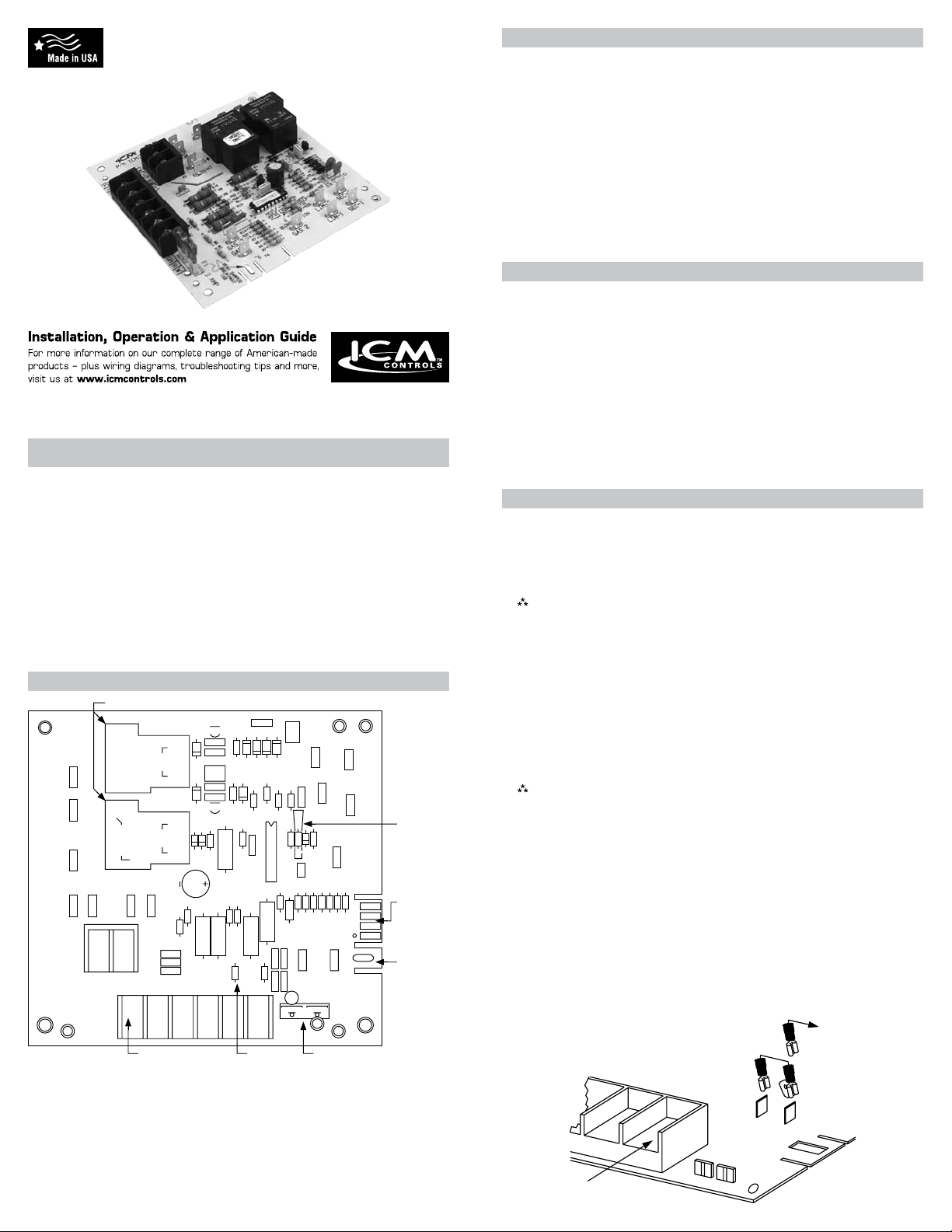

ICM271 Component Layout

SPCB-1

PCB500-1

L2 L1 PR-1

PR-2

COM

1

EAC-2 EAC-1

Blower Relays

NO

C

NC

NO

C

FROM-C

HI

LO

P2

P1

Wall Thermostat

Terminal Block

COILCOIL

Q2

K1

CR7

C7 C6

C5 C2

CR6

C4

K2

Q1

R1

R2

D1

Z1

C3

R15

R8

R9

W2

C10

C11

C12

JW-1

RGH WGCYC

RGH WGCYC

C1

M1

CR4

CR2

CR1

CR3

R5

R6

R3

CR5

R4

R21

U1

R22

C16

R11

R16

R18

R10

R19

C13

C9

W6

C8

C14

61

F1

JW-1

Specifications

• Input Voltage

- Terminals: PR-1, PR-2, L1 and L2 ...............................................120 VAC

- Terminals: SEC-1 and SEC-2 ...................................................18-30 VAC

• Line Frequency ..................................................................................60 Hz

• Operating Temperature .....................................................-40ºF to +176ºF

• Maximum Operating Humidity ...................................................95% R.H.

Non-condensing @ 50ºC

• Time Delays

- Heat ON .................................................................................. 75 Seconds

- Heat OFF .............................................................................. 105 Seconds

- Cool OFF ................................................................................ 90 Seconds

Pre-Installation Instructions

• Turn off gas supply and electrical power to equipment before servicing

CAUTION!

: This device should be installed by a qualied technician

with due regard for safety as improper installation could

result in hazardous conditions.

CAUTION!

: Failure to carefully read and follow these instructions

before servicing or operating this control, could result in

personal injury, death and/or property damage.

CAUTION!

: Do not short out terminals on the gas valve or the

ignition control module. A short or incorrect wiring will

burn out the thermostat heat anticipator. It could also

result in personal injury, death and/or property damage.

Operational Differences

The ICM271 has the same features and functions as the current Carrier/

BDP replacement (HH84AA020). The ICM271 has additional optional

features and some slight operational differences than the older obsolete

Carrier/BDP units. These options and operational differences are listed

below.

Note: Some older Carrier models did not have a cooling fan relay.

1. On older Carrier/BDP models, the low-speed blower would still function

if the 24 volt transformer malfunctions. This will not happen with the

ICM271.

2. If the JW1 jumper is cut, a constant low-speed blower will occur without

any thermostat signal. Also, a signal applied to the GC or Y terminals will

not bring on the hi-speed blower during the cooling mode. Therefore, the

JW1 jumper must not be cut on cooling applications.

3. The 24 volt circuit is fuse protected which is not true on earlier Carrier/

BDP models. A 3 amp automotive type fuse is used to protect the

thermostat and transformer circuits from shorts.

Note: On the ICM271, a blown fuse will cause the lo-speed blower to

4. The ICM271 has an easy-to-remove vent damper jumper plug. This

jumper plug is factory assembled for use on applications not having a

vent damper. If the application has a vent damper, remove the jumper

plug and connect the vent damper wiring harness connector to the

ICM271 circuit board.

The GAS1-to-GAS3 connection is made by a three-wire ame-proof

switch, but in some standing-pilot applications this device is not present. In

such applications, a jumper must be installed between GAS1 and GAS3

terminals.

A jumper should only be used on applications where a jumper exists on the

previous furnace fan control board. This jumper should also include a male

1/4” spade connector to connect to your current gas valve’s wiring harness.

come on and remain on until the fuse has been replaced.

To

Gas

Valve

W

GAS3

GAS1

Loading...

Loading...