ICM CONTROLS ICM286 Installation Manual

FEATURES & SPECIFICATIONS

FEATURES

• Controls the gas valve, inducer

draft motor, circulating blower and

hot surface ignitor

• Monitors system pressure and limit

switches

• Microprocessor based precision

• Twinning compatible with another

ICM286 Control Board

• Diagnostic LEDs aid in testing and

troubleshooting

• Replaces: Goodman 0130F00005

SAFETY CONSIDERATIONS

CAUTION!

Only trained personnel should install or service heating equipment. When working with heating equipment, be sure to read and

understand all precautions in the documentation, on labels, and on tags that accompany the equipment. Failure to follow all safety

guidelines may result in damage to equipment, severe personal injury or death.

TIMING

• Inducer Pre-Purge Time: 15 seconds

• Heat Blower On Delay: 30 seconds

• Heat Blower Off Delays: 90/120/150/180

seconds

• Cool Blower On Delay: 5 seconds

• Cool Blower Off Delay: 45 seconds

• Ignitor ON: 7 seconds

• Inducer Post Purge: 15 seconds

• Trials for Ignition: 3 (before soft lockout)

• Auto Reset: 60 minutes

ICM

28 6

FURNACE CONTROL BOARD

Replaces: Goodman 0130F00005

ELECTRICAL

• Voltage Range: Line (98-132 VAC) @ 60Hz

• Cool Blower: 30A, 2 HP, 240 VAC

• Heat: 20A, 240 VAC

• Inducer Motor: 4A FLA, 8A LRA @ 120 VAC

• Ignitor: 10A FLA @ 120 VAC

• Humidifier: 5 amps @ 120 VAC

• Electric Air Cleaner: 5 amps @ 120 VAC

ENVIRONMENT

• Ambient Temperature

– Operating: -40ºF to 176ºF

– Storage: -40ºF to 185ºF

• Humidity: 5% to 95% R.H. (non-condensing) @ +55ºF

• Vibration: 13.8Hz @ 0.2 Gs for one hour in each orthogonal axis

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

Use caution when installing and servicing the furnace to avoid and control electrostatic discharge. ESD can impact electronic components. These

precautions must be followed to prevent ESD from hand tools and personnel. Following these precautions will protect the control from ESD by

discharging static electricity buildup to ground.

1. Disconnect all power to the furnace. Do not touch the control or the wiring prior to

discharging your body’s electrostatic discharge to ground.

2. To ground yourself, touch your hand and tools to a clean, metal (unpainted) furnace

surface near the control board.

3. Service the furnace after touching the chassis. Your body will recharge with static

electricity as you shuffle your feet or move around, and you must reground yourself.

4. Reground yourself if you touch ungrounded items.

5. Before handling a new control, reground yourself; this will protect the

control. Store used and new controls in separate containers before

touching ungrounded objects.

6. ESD damage can also be prevented by using an ESD service kit.

INSTALLATION

Remove Existing Control:

1. Turn thermostat to OFF position or set it to the lowest possible setting.

2. Turn OFF electrical supply to furnace.

CAUTION!

Failure to turn off gas and electric supplies can result in

explosion, fire, death, or personal injury.

3. Label each wire with the correct terminal designation.

4. Disconnect the power supply and the thermostat lead wires from the existing

ignition control.

5. Disconnect any other line/low voltage, accessory wire and ground leads from

the existing ignition control.

6. Remove any screws and any other fasteners, and the old ignition board.

Install New Control:

1. Ground yourself properly before installing the new ICM286 control board.

2. Mount the new control using any screws and fasteners previously removed.

3. Connect all line/low voltage, accessory, thermostat and ground wires.

4. Verify the sequence of operation.

Main Operation:

On the application of power, the control will continuously monitor the rollout switch, limit switch, pressure switch, gas valve output and flame sense. During a Call

for Heat, the control makes sure the limit switch is closed and the pressure switch contact is open before turning on the Inducer blower, which will be energized

for 15-seconds in a pre-purge mode. Following the pre-purge period, the pressure switch contact is closed and power is applied to the hot surface ignitor (there is

a 7-second warm-up period). The gas valve is energized if a flame is sensed during this 7-second trial-for-ignition period, the blower motor will turn on following a

30-second delay. When the call for heat ends, the control will turn off the gas valve, the inducer blower will turn off after a 15-second post-purge period, and the heat

blower will turn off after the jumper-selectable period of time (if jumper is missing, default Heat Blower Off delay is 120 seconds). During a Call for Cool, the control

will energize the cool blower after a 5-second delay. When the call for cool ends, the control will turn the cool blower off after a 45-second delay.

Twinning:

The ICM286 is Twinning compatible with another ICM286 control board only. By connecting the designated “TWIN” screw terminals and the 24 VAC common together,

the controls are designed to turn on/off the blower simultaneously and at the same speed. (NOTE: An external AC relay, whose coil is connected between R & W

of the primary furnace and whose normally open contacts connect R & W of the secondary furnace, must be provided to cause both furnaces to heat). A common

ground between the two furnaces is also required.

ICM CONTROLS 800.365.5525

www.icmcontrols.com

7313 William Barry Blvd.

North Syracuse, NY 13212

LII356-1

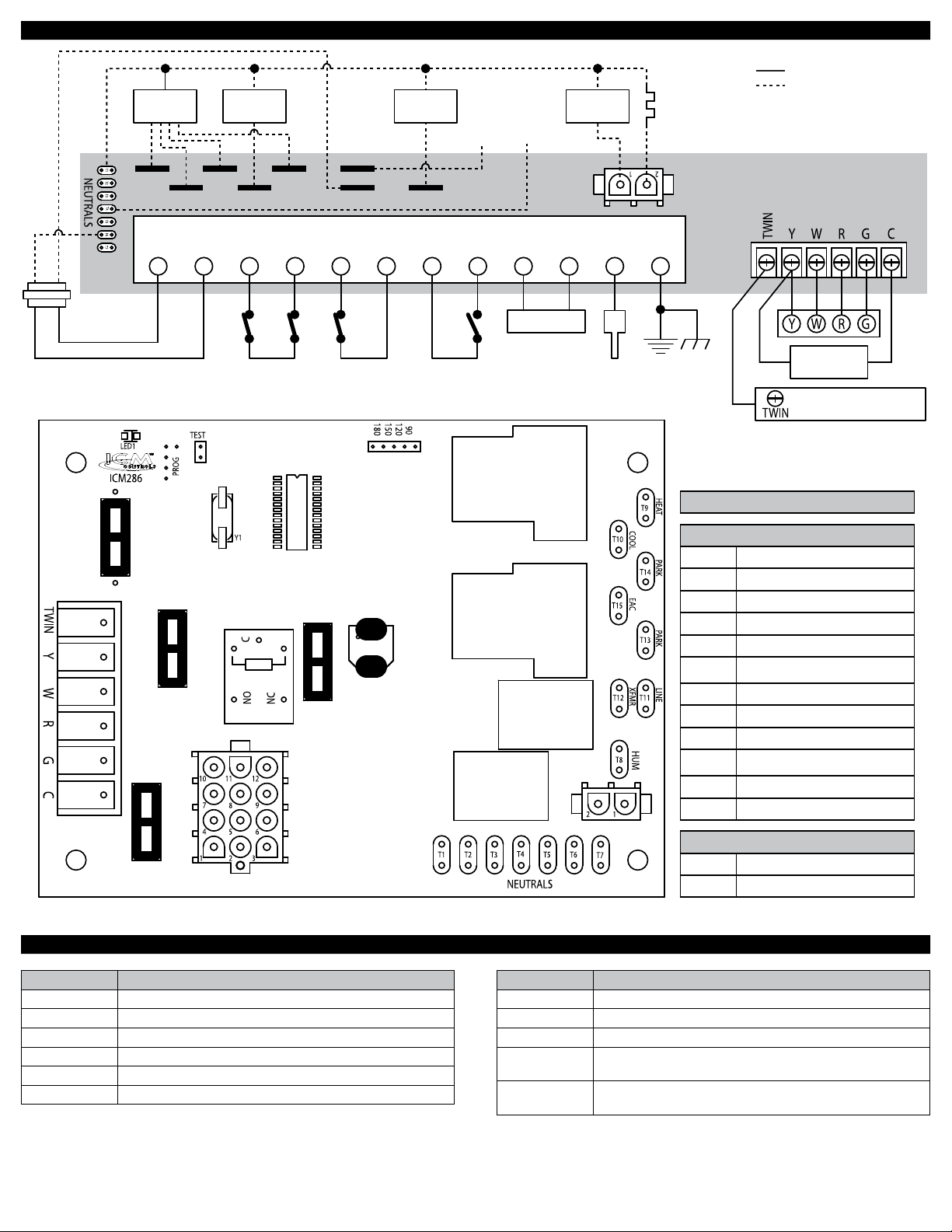

WIRING DIAGRAM

Legend:

Circulator

Blower

Electronic

Air Cleaner

Humidifier

Hot

120 VAC

Neutral

Inducer

Ignitor

(120 VAC)

Low voltage (24 VAC)

High voltage (120 VAC)

N.C. = Normally closed switch

N.O. = Normally open switch

24 VAC 120 VAC

HEAT

24

VAC

PARK PARK LINE

COOL

COM

24

EAC

LIM

IN

Switches

(N.C.)

LIM

OUT

Limit

XFMR HUM

RO

IN

Rollout

Switches

(N.C.)

RO

OUT

PS

IN

Pressure

Switches

(N.O.)

PS

OUT

GV GV FS GND

Gas Valve

Flame

Sensor

Probe

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Compressor

Contactor

Twinning with two

ICM286 controls only

PIN CONNECTIONS

12-Pin Connections

Limit switch (W) (input)

Flame sense input

24 VAC input

Pressure switch (output)

Rollout switch (XFMR) (input)

Common

Limit switch (output)

Gas valve common

Common

Pressure switch (input)

Rollout switch (output)

Gas valve output

FAULT CODES

LED FAULT CONDITION

ON No fault

OFF Control failure

1 flash System lockout

2 flashes Pressure switch stuck closed

3 flashes Pressure switch stuck open

4 flashes Open limit switch

2-Pin Connections

Pin 1

Pin 2

Inducer blower

Hot surface ignitor

LED FAULT CONDITION

5 flashes Flame has been sensed when no flame should be present

6 flashes Open rollout switch

7 flashes Low flame sense signal

8 flashes C terminal must be grounded to frame of furnace or you

have a faulty thermostat

Continuous

115 VAC AC power reversed

Flashing

Loading...

Loading...