ICM CONTROLS ICM280 Installation Manual

ICM

GOODMAN REPLACEMENT BOARD

REPLACEMENT of B18099-06, B18099-08 and B18099-10 HSI Module with an ICM280 Board

NOTE: DISCONNECT ALL ELECTRICAL POWER AND SHUT OFF GAS TO THE FURNACE BEFORE PROCEEDING

CAUTION! Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

• Remove both access panels.

• Cut the white jumper wire between pins 1 and 4 of the 9-pin connector for

GMP and GMPV series units

• Do not cut the white jumper wire for GMPN and GMN series units.

• Remove the edgecard connector and other wires from the existing module

and discard the thermostat wires removed from the board (R, W, and G).

• Remove existing HSI module. Note: Do not damage the nylon standoffs.

• Install the ICM280.

• Reconnect the edgecard connector ensuring good contact.

• Push the 9-pin connector into the ICM280. Note: It can only go one way. Do

not force it.

• Reconnect the supplied thermostat wires.

REPLACEMENT of B18099-13 HSI Module with an ICM280 Board

NOTE: For GMT, GDT, GMTH and GMNT units, disregard the 9-pin connector supplied with the ICM280.

• Remove both access panels.

• Locate the red, white and green thermostat wires (pigtails) where they pass

through the side of the furnance cabinet. Remove and save the wire nuts

and then disconnect the pigtails from the main thermostat wire assembly.

• Disconnect all wires from the HSI module

• Discard the thermostat wires (pigtails) removed from the board (terminals R,

W, and G).

• Remove the existing HSI module from the control panel. Do not damage the

nylon standoffs.

• Carefully remove the standoffs and insert them into the same locations on

the ICM280.

• Install the ICM280.

• Remove the red wire from the 24-volt side of the transformer’s secondary

side. Discard it.

• Remove the blue ground wire from the transformer, but do not discard it.

• Remove the blue wire from the transformer. Discard it.

• Place the red wire from the 9-pin connector onto 24-volt (hot) of the

secondary side of the transformer.

• Place the blue wire from the 9-pin connector onto common terminal of the

secondary side of the transformer. This wire has a piggy back terminal.

• Place the blue ground wire, which was previously removed, onto the

common terminal of the transformer.

• Replace both access panel.

• Restore gas and electrical power to the furnace.

• Verify the sequence of operation.

• Reconnect the 9-pin connector into the ICM280. Note: It can only go

one way. Do not force it.

• Route the red, white and green thermostat wires (pigtails) supplied

with the ICM280 through the side of the cabinet and then, using the

wire nuts saved earlier, reconnect them to the main thermostat wire.

• Reconnect all other wires to the controls module being careful to

match the wire labels to the thermostat connections.

28 0

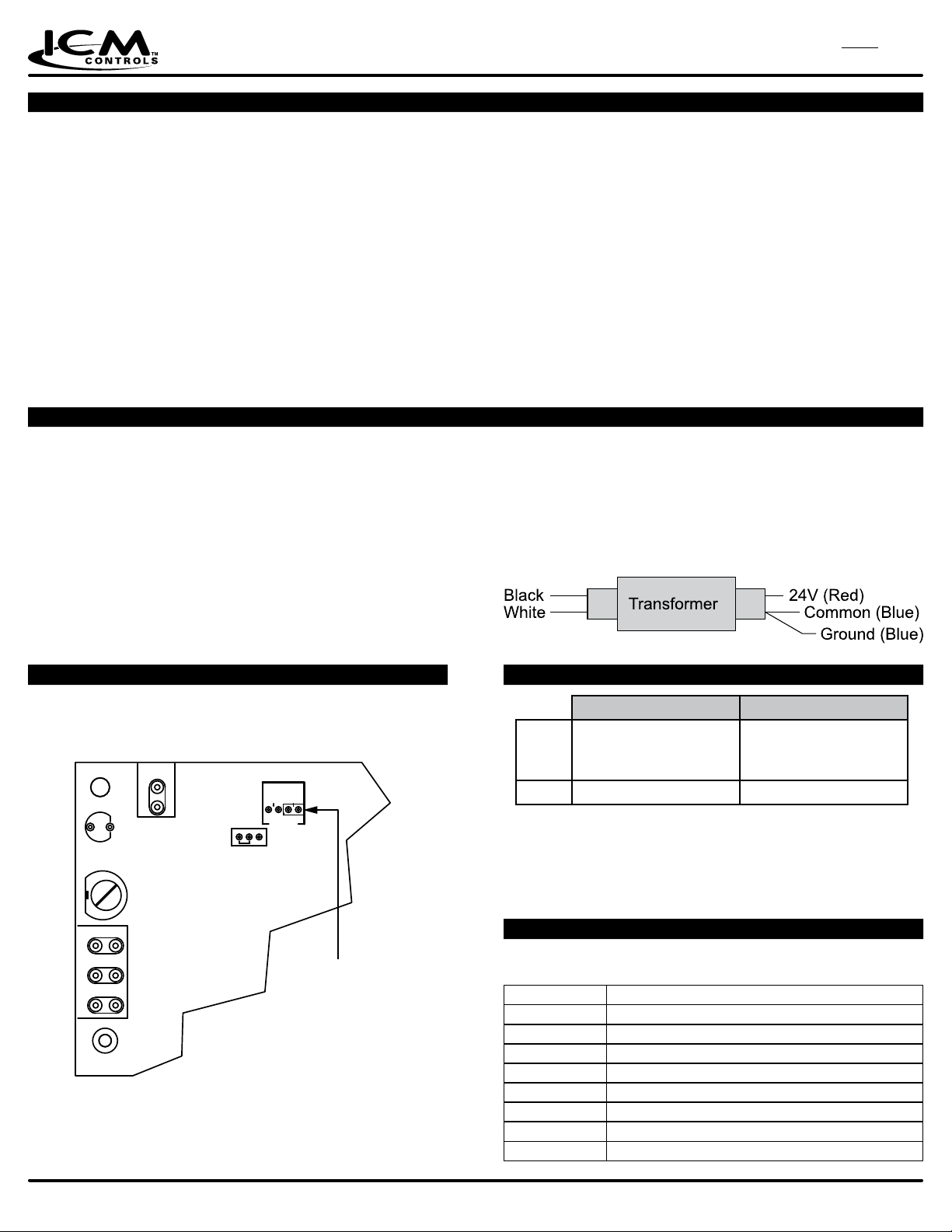

Selecting the Blower Off Delay

In the heating mode, the blower off delay can be used to obtain a 90, 120,

or 150 second period by changing the position of the plastic jumper on the

ignition control. See drawing below for location of this jumper

TWIN

150

90

120

HEAT

STATUS

24V HUM

W

G

R

The control is factory set to give a 150

second blower off delay.

TEST

DELAY

Blower Time O

Jumper

Timing Chart

ON Delay OFF Delay

30 Seconds 90 Seconds

Heat

120 Seconds

150 Seconds (Default)

Cool 7 Seconds 60 Seconds

NOTES

• If the jumper is removed, the control will default to a 150 second blower off

delay in the heating mode

• CAUTION is to be exercised not to bend the metal pins when changing the

time delay from the factory settings

Status LEDs

LED ON: No fault

OFF: Gas valve fault detected

# of LED Flashes Represents

1

2

3

4

5

6

7

Rapid Flashing

Ignition failure (after 3 tries and start of soft lockout)

Pressure switch stuck closed

Pressure switch failed to close

Limit switch failed open

Flame present with gas valve output off

Brownout voltage

Fault twinning

Wrong polarity of 120 VAC and Neutral

ICM CONTROLS

www.icmcontrols.com

7313 William Barry Blvd.

North Syracuse, NY 13212

800-365-5525

LII318-2

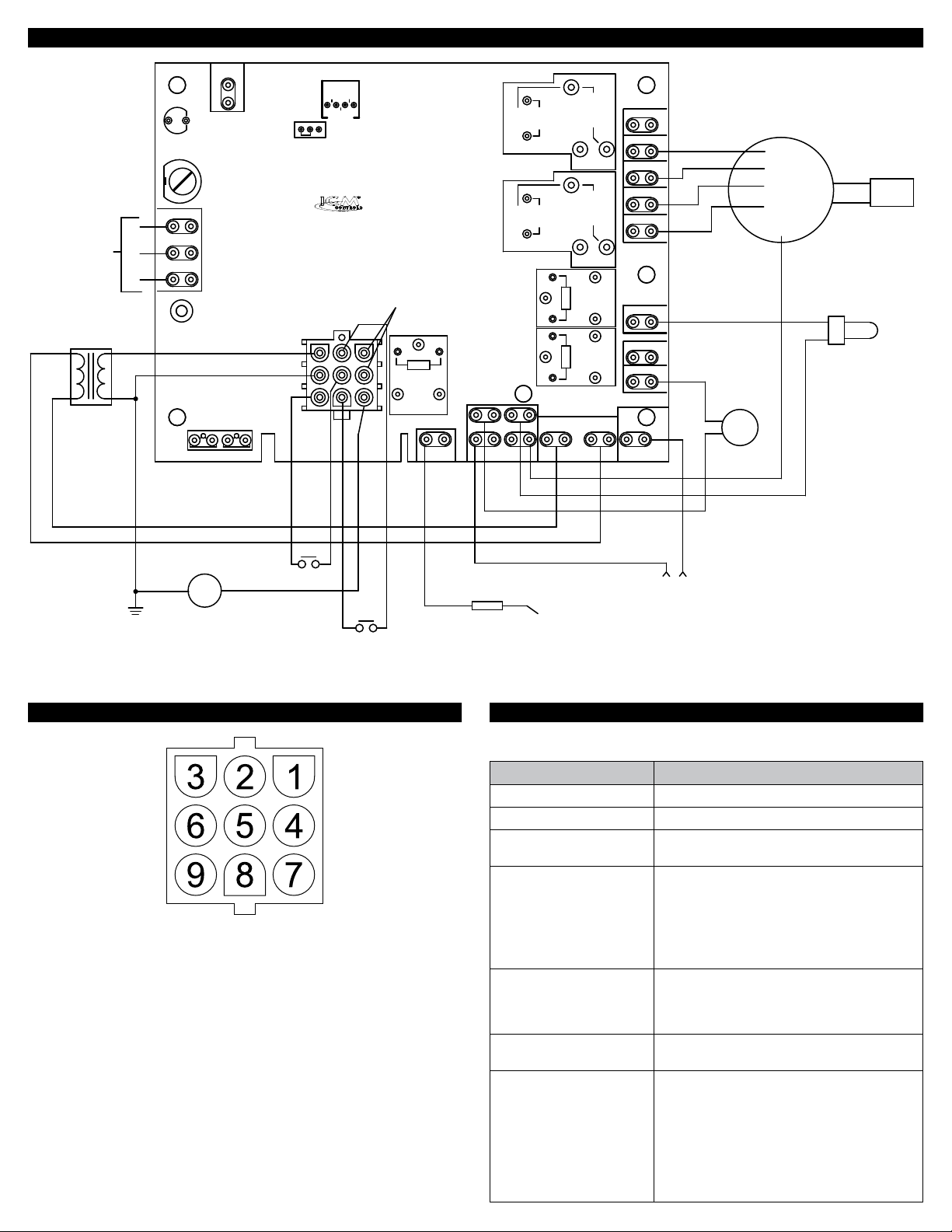

Wiring Diagram

TO ROOM

THERMOSTAT

115V

24V

XFMR

STATUS

24V HUM

W

G

R

TWIN

TEST

150

90

120

HEAT

DELAY

COIL

C

FORM-C

C

EAC

NC

NO

COOL

BLOWER

HI

HEAT

ICM280

ICM280

JUMPER NECESSARY

BETWEEN PINS 1 & 4

FOR 90+ SELECTION

CON2

P1

23

1

C

456

89 7

NO

NC

COIL

C

NO

C

C

PRI TRANS

FORM-C

C

NC

NO

NC

NO

NC

M1

M2

HSI

115V HUM

IND

BLK

VENT

MOTOR

MH

ML

LO

COM

BRN

BRN

HOT SURFACE

CAP

IGNITOR

F1

GAS VALVE

ATO 3A

LIMI

LIMO

LPS

PSI

PSO

90+O

GV

90+I

N/U

FS

NEUTRALS

FLAME

SENSOR

FS

PS

ICM280 Molex Plug Pin Out Trouble Shooting

Should be done by competent technician only.

Symptom Remedy

Fault light is blinking Check status led chart to determine problem

Blower fan runs constantly Check for open limit

No ame Check hot surface ignitor, verify voltage to hot

Furnace turns off when gas

valve turns on

1 = 90+ IN

2 = Pressure switch OUT

3 = 24V hot (R)

Furnace turns on and off

rapidly

4 = 90+ OUT

5 = Limit switch IN

Flame not being sensed Verify ame sense rod is clean, verify second-

6 = 24V common (C)

7 = Gas valve

Furnace turns off when

blower fan turns on

8 = Pressure switch IN

9 = Limit switch OUT

L2

115VAC SUPPLY

surface ignitor is present

1. Verify pressure switch is not opening, test

by placing temporary jumper across pressure switch when inducer fan turns on to

simulate a good pressure switch.

2. Verify secondary of transformer is adequately grounded.

Verify thermostat is functioning correctly, test

by removing thermostat wiring from ICM280

and placing temporary short between the R

and W terminals

ary of transformer is grounded

Verify thermostat is functioning correctly, test

by removing the thermostat wiring from the

ICM280 and place jumper from R to W. If

furnace functions properly then replace defective thermostat.

If furnace still functions incorrectly then check

the wiring of the secondary of the transformer,

swap connections at R and C at the ICM280.

Loading...

Loading...