ICM CONTROLS ICM275 Installation Manual

Fan Control

Center

Replacement Description

The ICM275 Gas Furnace Control Center is a new generation control for the

replacement market.

The ICM275 Gas Furnace Control Center is designed to function similarly to previous

control center designs, while incorporating some of the latest features in furnace

control center technology.

It is a form, t and functional replacement of the OEM control for the following Carrier

control center part numbers: HH84AA021, HH84AA001, HH84AA003, HH84AA005,

HH84AA009, HH84AA014, HH84AA015, or CESO110019.

Specifications

• Input Voltage

- Terminals: PR-1, PR-2, L1, L2 and COM ..................................................... 120 VAC

- Terminals: SEC-1 and SEC-2 ...................................................................18-30 VAC

• Line Frequency .................................................................................................. 60 Hz

• Operating Temperature .....................................................................-40ºF to +176ºF

• Maximum Operating Humidity ....................................................................95% R.H.

Non-condensing @ 50ºC

• Time Delays

- Heat ON .................................................................................................. 60 Seconds

- Heat OFF ......................................................................................... 60-240 Seconds

- Cool OFF (R18 Cut) ................................................................................ 90 Seconds

Operation with new blower and humidier relays:

The previous design control centers used a SPST-NC or DPST-NC heating fan relay

(HFR of E2) and a DPDT cooling fan relay (CFR or 2F) for blower and humidier

terminal operation. This new control center uses a SPST-NO blower relay (BLWR)

and a SPDT blower speed change relay (hi/lo) for blower operation, and a SPST-NO

humidier relay.

1. The low-speed blower will not operate on a transformer failure as on previous

designs.

2. If JW1 jumper is cut between R and GH terminals, a constant low-speed blower

will occur without any thermostat inputs to the control center. A GC or Y signal to

the control center will not bring on the hi-speed blower for cooling operation. JW1

jumper must not be cut on cooling applications.

3. The humidier H terminal is energized with low-speed blower operation. In cooling

operation, the humidistat and humidier water supply should be turned off to ensure

the humidier does not operate.

24 volt circuit protection:

An automotive type, 3 amp fuse is provided to protect the transformer and thermostat

from shorts in the low-voltage circuitry. An open fuse will initiate a constant low-speed

blower. Refer to the ICM275 Component Layout (Page 3) for location on control center.

Low-speed continuous “G” blower and 90-second hi-speed blower OFF delay

option:

Resistor (R18) on the control center can be cut to achieve heating speed continuous

blower with a thermostat (R-G) call and a hi-speed blower with a 90 second OFF delay

with a thermostat (R-Y) call.

CAUTION!

:

Do not cut R18 on twinned furnace applications.

Installation Instructions

CAUTION!

1. Disconnect wiring from blower control center. Tag each wire as it is disconnected

from the old furnace control center. Disconnect all wiring hookups.

2. Remove existing blower control center.

3. Install the ICM275 fan control center into the control center box. Be sure that the top

edge of the ICM275 is in the mounting slot, just like the original board.

CAUTION!

4. Reconnect all of the wire(s) that were removed in Step 1 above, to the proper

terminals.

5. Turn power to ON position and check unit sequence of operation per unit installation

instructions.

6. These instructions must be placed with the original unit instruction packet, or with

the unit for future reference.

:

Verify power is removed from the control by removing fuse or turning

off circuit breaker.

:

If the

ICM275

is not installed correctly (i.e.: behind the slot), an

electrical short could occur.

Blower Operating Modes

Input From

Thermostat

W Lo-speed heating blower* Lo-speed heating blower*

G Hi-speed cooling blower Lo-speed heating blower

Y No blower Hi-speed cooling blower**

Resistor (R18) Uncut Resistor (R18) Cut

* 60-second ON delay

and 60-240 second

adjustable OFF delay

** 90-second OFF delay

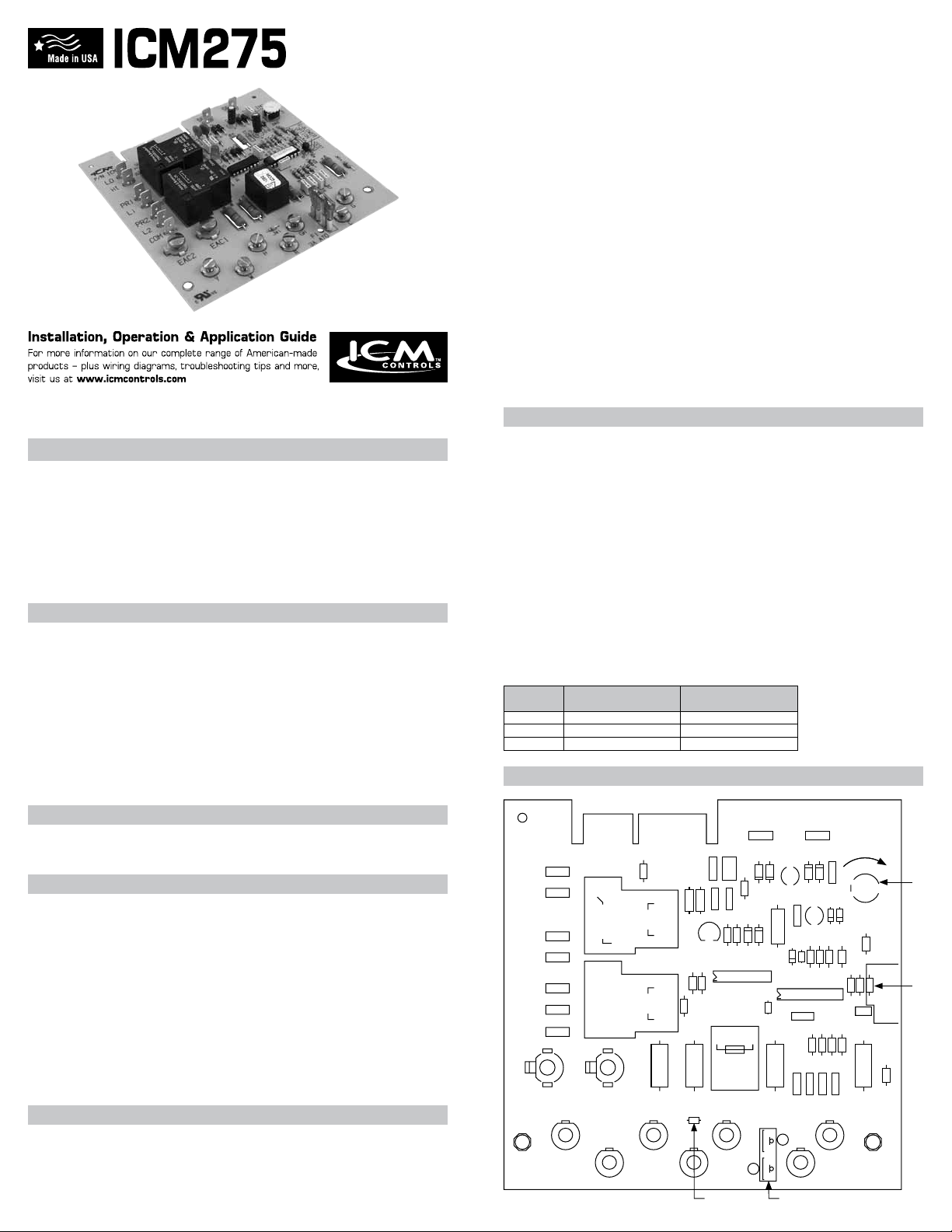

Component Layout

Introduction

This application guide covers the installation of the Gas Furnace Control Center, Part

No. ICM275, in an intermittent ignition, induced draft, or condensing gas furnace.

Safety Considerations

Installing and servicing heating equipment can be hazardous due to gas and electrical

components. Only trained personnel should install or service heating equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils,

or cleaning and replacing lters. All other operations should be performed by trained

personnel only. When working on heating equipment, observe precautions in the

literature, on tags, and on labels attached to the unit.

Follow all safety codes. Wear safety glasses and work gloves. Have a re extinguisher

available.

CAUTION!

:

Before beginning the installation or modication, be sure the main

electrical disconnect switch is in the OFF position.

CAUTION!

:

Failure to carefully read and follow these instructions before servicing

or operating this control, could result in personal injury, death and/or

property damage.

Operational Differences and Added Features

The following is a description of the slight operational differences and added

features. Refer to ICM275 Component Layout (Page 3) for location of control center

components.

T6

HI

T5

LO

K2K1

T3

PR1

T4

L1

T8

PR2

T7

L2

T9

COM

SC9 SC8

EAC-2 EAC-1

EAC-2 EAC-1

SC5

SPCB-1

PCB503-1

NC

FORM-C

SC6

JW8

NO

C

NO

C

SC1

HY GH

COIL

COIL

SEC-2 SEC-1

1

P4

R6

JW4

SC2

R9

LED1

JW5

R7

R22

TS3

JW2

STATUS

M1

C1

R1

C2

C9

R2

R14

U2

C

NO

SC4

CR5

NC

3-amp

CR3

CR6

JW4

ATO

Fuse

CR1

T2T1

C31

R3

C11

D2

R16

U1

C10

R5

C6

SC3

CR4

CR2

C41

R19

R17

JW6

R11

R13

C5C8C7

SC7

INC

60

C12

PT1

OPTION

G-BLOWER

JW3

Blower Off Delay Pot

Resistor (R18)

Z1

D1

240

R20

R15

R21

R18

R4

TS1

TS2

TEST

R8

R10

R12

G

F1

3A ATO

RW

C

ATO 3-amp FuseJW1

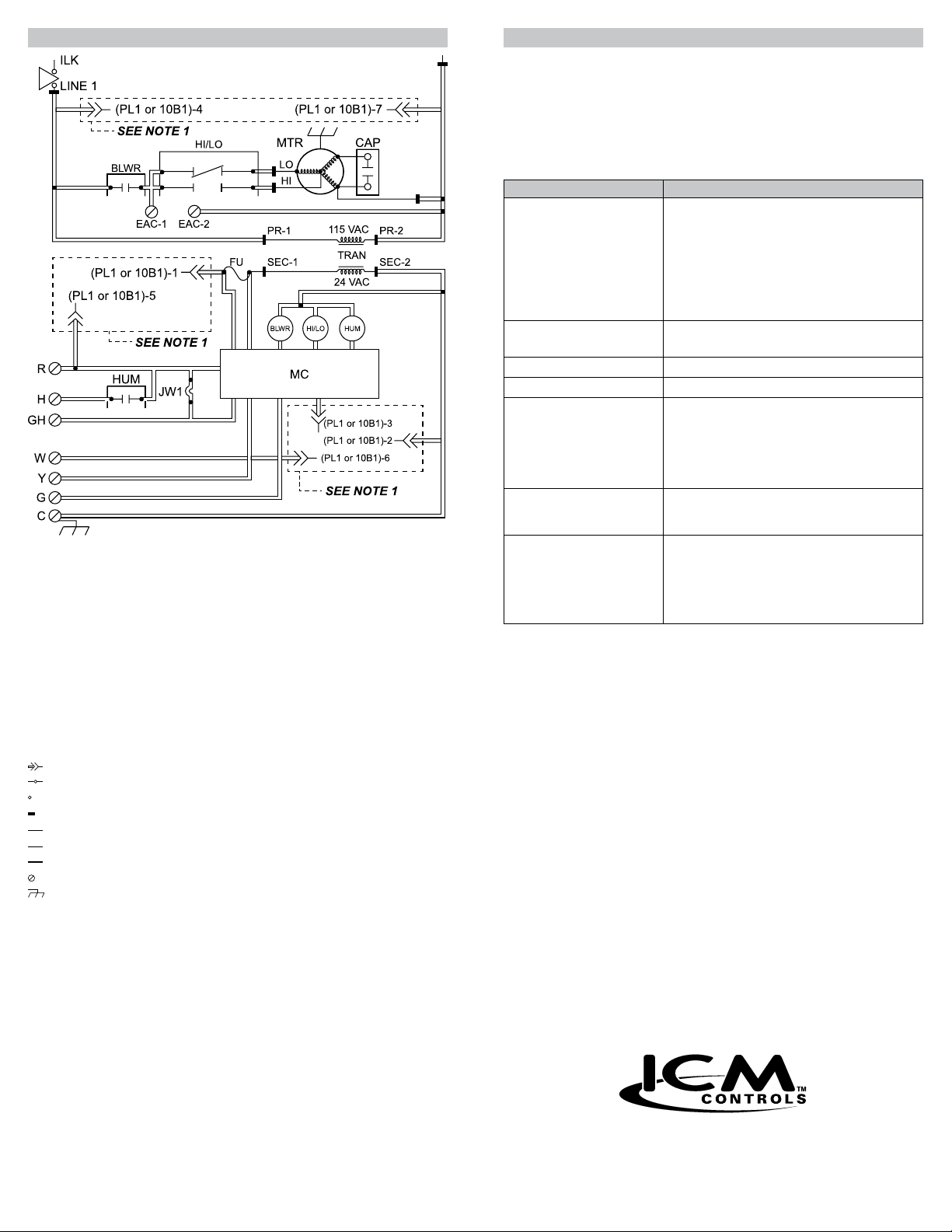

Wiring Diagram

LEGEND:

CAP Run Capacitor

TRAN Transformer

JW1 Jumper Wire

MTR Motor, Blower

MC Microcontroller

FU Fuse (ATO 3-amp)

HI/LO Blower Motor Speed

Change Relay (DPST)

HUM Humidier Relay (SPST-NO)

BLWR Blower Motor Relay (SPST-NO)

ILK Switch, Blower Door Interlock (SPST-NO)

Plug Receptacle

Junction

Unmarked Terminal

Terminal PCB

Factory Wiring (115 VAC)

Factory Wiring (24 VAC)

Conductor on PCB

Screw Connector

Equipment Ground

Note 1: PL1 and 10B1 indicates 7-PIN edge connector terminations that connect to

control center. Refer to unit wiring diagram for specic unit wiring from control

center edge connector.

Troubleshooting

WARNING!

CAUTION!

CAUTION!

Continuous low speed blower • Check for open fuse

Blower speed not correct • Check if R18 is cut

No fan for heating or cooling • Check for 24 VAC at SEC1 and SEC2

No fan delays • Verify test pins are not shorted

No fan on heat call • Check for 24 VAC at R and C terminals

Status LED blinking • Status LED blinks when 24 VAC is applied to

Intermittent fan operation • Check for constant 24 VAC at R and C terminals

:

High voltage! Troubleshooting this fan control board involves

working with high voltage which can result in personal injury, death

and/or property damage.

:

Always disconnect power by removing a fuse or opening a circuit

breaker before doing continuity checks. Verify power is not present

before troubleshooting.

:

Troubleshooting tasks should only be performed by those trained to

install or service HVAC equipment.

Symptom Remedy

• Check for open limit

• Check for 24 VAC at R and C terminals

• Check if JW1 is cut

• Check edge connector slot 1 and slot 5; with no

power applied and the edge connector removed,

there should be continuity between edge

connector slot 1 and slot 5

• Check wiring of LO and HI terminals

• Check for 24 VAC at SEC1 and SEC2

• Check edge connector slot 3 and slot 6; with no

power applied and the edge connector removed,

there should be continuity between edge

connector slot 3 and slot 6

SEC1 and SEC2; there are no fault ash codes

for this control

• Bypass thermostat and test operation of fan

control; with no power applied, remove wires

to thermostat; use a jumper wire to initiate a

call for heat/cool blower; if operation is correct,

thermostat or thermostat wire is faulty

ONE-YEAR LIMITED WARRANTY

The Seller warrants its products against defects in material or workmanship for a period of one (1)

year from the date of manufacture. The liability of the Seller is limited, at its option, to repair, replace

or issue a non-case credit for the purchase prices of the goods which are provided to be defective.

The warranty and remedies set forth herein do not apply to any goods or parts thereof which have

been subjected to misuse including any use or application in violation of the Seller’s instructions,

neglect, tampering, improper storage, incorrect installation or servicing not performed by the Seller.

In order to permit the Seller to properly administer the warranty, the Buyer shall: 1) Notify the Seller

promptly of any claim, submitting date code information or any other pertinent data as requested by

the Seller. 2) Permit the Seller to inspect and test the product claimed to be defective. Items claimed

to be defective and are determined by Seller to be non-defective are subject to a $30.00 per hour

inspection fee. This warranty constitutes the Seller’s sole liability hereunder and is in lieu of any other

warranty expressed, implied or statutory. Unless otherwise stated in writing, Seller makes no warranty

that the goods depicted or described herein are t for any particular purpose.

Patent No. 424,953

7313 William Barry Blvd., North Syracuse, NY 13212

(Toll Free) 800-365-5525 (Phone) 315-233-5266 (Fax) 315-233-5276

www.icmcontrols.com

LIAF083-1

Loading...

Loading...