Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

GAS CHAR BROILERS

BROILER MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

After the gas supply has been connected to your unit, it is extremely important to check piping for possible

leaks. To do this, use soap and water solution or solutions which are expressly made for this purpose. DO

NOT USE matches, candles, flames, or other sources of ignition since these methods are extremely

dangerous.

Post in a prominent location instructions to be followed in the event you smell gas. Obtain these instructions

from your local gas supplier.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable

!

vapors and liquids in the vicinity of this or any other appliance.

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

Dante SERIES

Models: F, C and L

IMPORTANT INSTRUCTIONS

!

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the Installation,

!

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

+1 (800) 431-2745 US & Canada

+1 (914) 576-0200 Phone sales@bakerspride.com E-Mail

+1 (914) 576-0605 Fax www.bakerspride.com Web Address

Operating and Maintenance Instructions thoroughly before installing or

servicing this equipment.

Destination Countries: (GB) (IE)

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

1

!

P/N 1/07 U4201A

Page 2

CONTENTS

SECTION PAGE

I. INSTALLATION INSTRUCTIONS 3

1 Installation 3

2 Clearances 3

3 Gas Connection 3

4 Burners 4

5 Radiant Units 4

6 Glo-Stone Units 4

7 Grease Drawer & Water Pans 5

8 Griddle Plate 5

9 Smoker Boxes 5

10 Lighting Instructions 5

11 Additional Instructions 6

12 Installation with Casters 6

II. OPERATING INSTRUCTIONS 6

1 Lighting Instructions 6

2 Broiling 6

III. MAINTENANCE 7

1 Service 7

2 Care and Cleaning 7

IV. ILLUSTRATIONS 8 & 9

V. REPLACEMENT PARTS 8

VI SERVICE CENTERS 8

VII. TABLES OF EUROPEAN PRESSURES, GASES & CATAGORIES 10 & 11

VIII. WARRANTY 12

NOTE: Description of Model numbers and Definition of Prefixes used throughout this manual are shown below:

MODEL DEFINITION

F = Floor Model C = Counter Top Model L = Low Profile Model

R = Radiant Type GS = Glo-Stone Type H = High-Heat

MODEL SIZES

(F, C, L) Width (R, GS)- (H) 24 30 36 48 60 72 84

Number of Burners 5 6 8 11 14 17 20

INPUT RATING: KW Hs

Standard 24.25 29.1 38.8 53.35 67.9 82.45 97

High-Heat 29.5 35.4 47.2 64.9 82.6 100.3 118

2

Page 3

I. INSTALLATION INSTRUCTIONS

1. INSTALLATION:

(i) It is advisable to call on a qualified installer to install the appliance and, if the need causes to

convert it for use with other gases.

(ii) Installation of this broiler must conform to the installation regulations in force in the destination

country. For gas categories and pressures please refer to pages 10 & 11. For minimal distances

from adjoining walls please refer to the rating plate on the appliance.

(iii) Use this Broiler only with an adequately sized exhaust hood. The room in which this broiler is

installed must be suitably vented in accordance with the National and or local codes.

2. ACCEPTABLE CLEARANCES:

Due to intense heat generated by radiation, only non-combustible construction should be provided.

(i) Minimum Clearance From Non-Combustible Construction. Right Left Back Floor

0” 0” 0” 4" (100 mm)

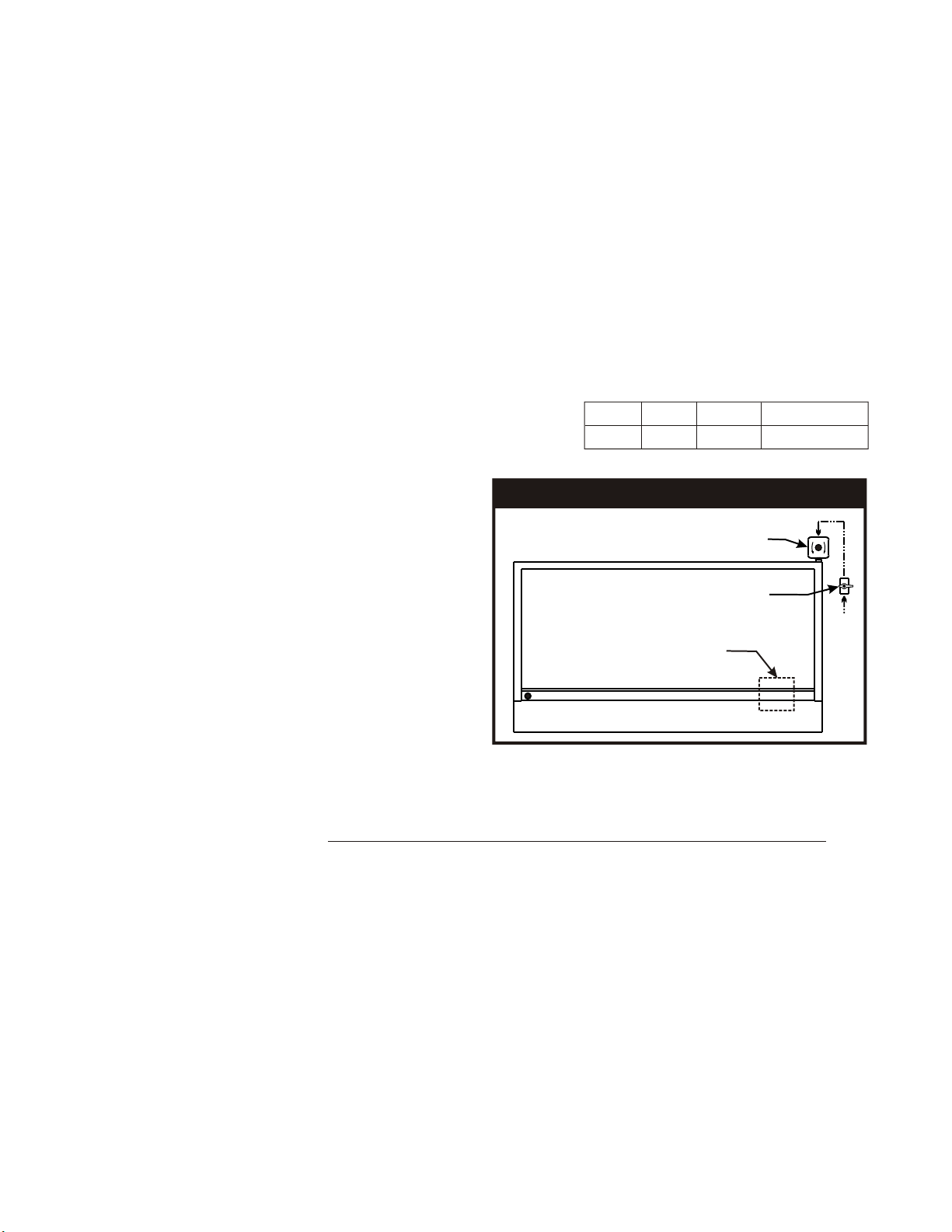

3. GAS CONNECTION:

A separate gas shut off valve (supplied with unit)

Figure “A”

must be installed in a readily accessible location in

the gas line ahead of the pressure regulator (see

PRESSURE REGULATOR

figure “A”). The gas pressure regulator supplied must

be installed on the gas inlet pipe of the broiler (see

below). Each regulator is adjusted to yield a pressure

MAIN SHUT-OFF VALVE

of 3.5" water column (9 mbar) for Natural Gas.

All products used with combustible gas, including gas

SAFETY VALVE

pressure controls, must be installed and used

strictly in accordance with the manufacturer's

instructions and all applicable government codes and

regulations and plumbing practices.

Do not use the gas pressure regulator if it appears to

have been tampered with or damaged in any way as this may affect proper operation and may create

potentially dangerous conditions.

Install the regulator properly with the direction of gas flowing as indicated by the arrow on the casting. (The

arrow must be pointing to the Gas Appliance).

Use a pipe compound or thread sealant that is compatible with the gas supplied to the regulator and apply it

in accordance with the manufacturer's recommendation.

Apply wrench pressure only to the flat area at the threaded end of the regulator closest to the gas

appliance to avoid fracturing the regulator body.

Make sure markings or paintings on the regulator are not painted over or otherwise obliterated.

Check carefully for gas leaks immediately after the regulator has been installed and the gas turned on. Do

this before attempting to operate the appliance. Use a soap and water solution (or other accepted leak

tester) around all pipe joints. It is a good practice to periodically check for gas leaks during use of the

appliance. Do not use the appliance if a gas leak is detected.

Recommended minimum gas supply lines are listed below for Broilers:

24” to 36” W: 3/4” (19 mm) 48” to 84” W: 1" (25.4 mm)

3

Page 4

When making gas pipe connections, only pipe joint compound resistant to the action of liquefied petroleum

gases should be used.

The broiler and its individual shut-off valve must be disconnected from the gas supply system during any

pressure testing of that system at test pressure in excess of ½ psig (3.45 kpa).

The broiler must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½

psig (3.45 kpa).

4. BURNERS:

Air-Mixer caps on the front of all burners are adjusted and tightened before the unit leaves the factory. If it is

necessary to adjust the Air-Mixer caps, the adjustment must be done by a factory authorized technician

only, who should tighten and seal the adjustment screw after the adjustment. (See Figure “D”)

(i) Place the front venturi end of the burner onto valve assembly by fitting the center hole of the Air-

Mixer cap over the brass orifice accessible through holes in the Chamber Front.

(ii) Drop the rear end flange of the burner into the corresponding slot in the burner support at the rear of

the chamber.

(iii) While most of the Burners are H-shaped Double Burners, the 24”, 48” and 72” models come with

one additional single Burner each. Place all of the H-shaped Burners first, then insert the single

burner into the remaining space.

5. RADIANT UNITS:

(i) If the Broiler was ordered with Grease Catches, place them with the slotted front end over the

upturned fingers of the radiant support in front and rest the back end on top of the upturned

fingers in the rear.

(ii) Place the 'A' shaped radiants over the burners with each end supported on the radiant supports in

front and rear of the chamber. Pushing the radiants all the way to the back will provide more heat in

the front, while pushing them all the way to the front will provide more heat in the back.

(iii) Place the Top Grates, wider flange toward the back, onto the top grate supports in the rear. Every

broiler is supplied with a sufficient number of Top Grates to cover the entire broiling area. Two of

them are 4-1/2” wide and the rest are 6” wide. Flipping these Top Grates upside down and choosing

between two supports in the rear, four positions are possible for different slopes desired.

6. GLO-STONE UNITS:

(i) Hold the Glo-Stone Frame (one or more, depending on the size of the Broiler) over the desired

location and lower it slowly onto the Radiant Supports in the front and back of the chamber until it fits

in between the upturned fingers of the supports. Rock it back and forth to assure proper fit.

(ii) Spread one layer of Glo-Stones covering all of the expanded metal grate exposed.

IMPORTANT NOTE: DO NOT USE MORE THAN ONE LAYER OF GLO-STONES, AS THIS

WILL REDUCE THE AMOUNT OF HEAT REACHING THE TOP GRATES AND CAN CAUSE

OVERHEATING AND PERMANENT DAMAGE TO THE UNIT.

(iii) Place the Top Grates, wider flange toward the back, onto the top grate supports in the rear. Every

broiler is supplied with a sufficient number of Top Grates to cover the entire broiling area. Two of

them are 4-1/2” wide and the rest are 6” wide. Flipping these Top Grates upside down and choosing

between two supports in the rear, four positions are possible for different slopes desired.

4

Page 5

7. GREASE DRAWER, WATER PANS:

(i) A Grease Drawer is provided at the very left of each Broiler to collect the grease from the Grease

Trough above.

(ii) Depending on the size of the Broiler, one or more Water Pans are provided to collect any drippings

from the broiling area above. Water Pans assist in making cleaning simple and easy. Water should

at all times be present, and replenished as needed, to reduce flare-ups and flash-back and to

prevent the bottom of the broiler from getting too hot.

.

(iii) One Grease Deflector is provided to prevent burning matter from getting into the Grease Drawer

and igniting the accumulated grease there. To install this Grease Deflector, clip its bottom edge to

the left side of the Water Pan next to the Grease Drawer, push down all the way, then slide the Pan

back into place. (See Figure “F”)

(iv) Grease Drawer, Grease Deflector and Water Pans should be cleaned daily or even more frequently,

if necessary.

8. GRIDDLE PLATE (Optional):

The Griddle plate should not cover more than 50% of the broiling area. The Griddle Plate should be placed

on top of the top grates, which for this purpose should be in the flat position.

9. SMOKER BOX (Optional):

(i) This Smoker Box consists of a Wood Chip Drawer and two covers, the longer one in the back and

the shorter one with the handle in the front. On the F and C models this Smoker Box rests on the

Wire Rack (optional). On the “L” models this Smoker Box slides onto supports (optional) located in

the Water Pan. (See Figure “F”)

10. LIGHTING INSTRUCTIONS:

(i) Depress the blue button fully and light the cross-over lighter tube, while keeping the button fully

depressed for a few second at the same time. See the fig. B

(ii) Slowly release the button and make sure that the cross-over lighter tube remains lit.

(iii) Repeat this procedure on the other side of the unit if equipped with two gas connections (60 in,

72 in and 84 in units).

(iv) To light the main burners turn the burner valves to ON position and adjust the flame size as

required.

(v) Smaller units 24 in through 48 in wide have only one gas connection in the back or the front of

the unit. Larger units 60 in though 84 in have two gas connections in the back or the front of the

units. Each half of the unit can be operated independently and is equipped with separate

manifold and thermoelectric safety device.

Each burner may now be adjusted to the desired flame size by turning the individual burner valve handle.

TO SHUT DOWN THE UNIT, TURN ALL VALVES 'OFF'. WAIT FIVE MINUTES BEFORE ATTEMPTING

TO RE-LIGHT.

NOTE: Carry-over lighting tubes can be extinguished only by turning the shut-off valves to the “OFF”

position.

5

Page 6

11. ADDITIONAL INSTRUCTIONS:

(i) Keep the area around the broiler free and clear of all combustible material.

(ii) Provision of adequate supply of air to your broiler is essential. Provide for sufficient outside air to

enter the broiling area and assure that this air flow is not obstructed.

(iii) Air enters the burner area from the front of your broiler only. Assure that this area is kept open and

unobstructed.

12. INSTALLATION WITH CASTERS:

THIS IS AVAILABLE FOR FLOOR MODELS ONLY.

Four casters (two with wheel brakes) and the mounting hardware is packed and included in the shipment, if

ordered. Install casters with wheel brakes on the front of the unit.

Adequate means must be provided to limit the movement of the appliance without depending on the

connector and any quick disconnect device or its associated piping to limit the appliance movement.

The restraint should be attached to the right side of the back of the unit close to the gas inlet pipe.

If disconnect of the restraint is necessary, the restraint should be reconnected after the appliance has been

returned to its originally installed position BEFORE the gas line is reconnected.

II OPERATING INSTRUCTIONS

ONLY QUALIFIED PERSONNEL, PROPERLY TRAINED AND FAMILIAR WITH THIS EQUIPMENT

SHOULD OPERATE THIS BROILER.

1. LIGHTING INSTRUCTIONS:

See Section 10 of Installation Instructions.

Once each individual Pilot Burner, or the Carry-Over Lighter Tube, is lit, the Main Burners of the broiler may

be turned “ON” , “OFF” or to “Low” by turning the corresponding Control Knob located in the front of the

Broiler under the Work Deck.

Note: The “Low” flame can be adjusted up or down by turning the small screw in the center

of the valve stem. (See Figure “E”)

2. BROILING:

BROILER TOP GRATES MUST BE HOT ENOUGH TO MAKE BLACK CHAR MARKS WHEN

STARTING TO BROIL.

Adequate preheating time is necessary for the food to release from the broiler grates and to cook properly.

Before Broiling, allow Radiant units to preheat for 10-15 minutes and Glo-Stone units for 20-25 minutes.

(i) Do not press the juice out of the meat as this will dry out the meat.

(ii) After Broiling, allow the meat to sit covered on a heated platter for 2-5 minutes before cutting. This

will allow the juices to 'settle' and the meat will be more moist.

(iii) Do not use forks or other sharp objects to poke holes in the meat. Do not cut the meat as it cooks.

(iv) Thick pieces of meat require longer broiling time with less flare-up. Reduce flare-up by trimming

excess fat for a longer broil time without burning.

(v) Keep the unit clean. Food caught between the grate will not allow hot air to rise around the product.

This will result in uneven heat, increase the cook time and can cause the Broiler to overheat which

may result in permanent damage.

6

Page 7

III. MAINTENANCE

1. SERVICE:

ALL SERVICING SHOULD BE PERFORMED BY A FACTORY AUTHORIZED TECHNICIAN ONLY.

Shut off the main gas supply before attempting any maintenance or service on the unit. If required, contact

your dealer, a local service company or the factory to obtain a qualified technician for the required

maintenance/service. A separate list of Dealer and Service locations has been included with your broiler..

2. CARE AND CLEANING:

(A) FOR ALL MODELS.

(i) TOP GRATES: The top grates should be cleaned daily with a stiff wire brush or steel wool. The rods,

especially the underside of the rods, need to be scraped clean of all accumulated food and fat. A

light coat of oil should be applied to the rods after cleaning.

Under no circumstances should the Top Grates be placed in a dishwasher. Soap, Water, or

any detergent, should never be used on Cast Iron.

(ii) OUTER SIDES AND FRONT: These are stainless steel surfaces. Commercial stainless steel

cleaners are available for this purpose.

(iii) INNER COOKING AREA: These are stainless steel surfaces. Make sure that all residue is removed

before cooking is resumed.

(iv) WOOD CHIP DRAWERS: The Drawers should be removed and cleaned every day or more

frequently if necessary. The Covers should be removed and cleaned frequently so that drippings do

not accumulate.

(v) WATER PANS: Water Pans and the Grease Drawer should be cleaned daily or more often if

necessary.

(B) FOR RADIANT MODELS:

STAINLESS STEEL: These should be removed and cleaned frequently so that drippings do not

accumulate.

CAST IRON: These should be removed and cleaned daily with a stiff wire brush. Under no circumstances

should these Radiants be placed in a dishwasher. Soap, Water, or any detergent, should never be

used on Cast Iron.

(C) FOR GLO-STONE MODELS:

(i) CARE OF GLO-STONES: On a daily basis, when the top grates are removed for cleaning, the Glo-

Stones should be mixed about to break away any carbon deposit so it may fall through the

expanded metal bottom grates. Then spread the Glo-Stones evenly and add more, if necessary, but

only the amount necessary for a single layer.

(ii) CARE OF BOTTOM GRATES: Periodically push all the Glo-Stones to one side and inspect the

bottom grates and underlying support angles. If necessary, remove the Glo-Stones and brush the

grates, top and bottom, with a stiff wire brush.

CAUTION: CLEAN THE UNIT ONLY WHEN IT IS COLD. ALWAYS RUB WITH THE

GRAIN WHEN CLEANING STAINLESS STEEL. DO NOT USE CHLORINE

BLEACH. DO NOT USE ABRASIVE PADS OR STEEL WOOL FOR CLEANING. DO

!

NOT USE CAUSTIC CLEANING COMPOUNDS ON ALUMINIZED SURFACES.

7

!

Page 8

IV. ILLUSTRATIONS:

(i) See Figure “F” for typical Top View and Front Views of a Cabinet Style Broiler. Both Radiant and Glo-

Stone type are shown and so are Single and Double Burners, Lighter Tubes and Carry-Over Lighter

Tube to illustrate and identify the various components utilized. For more details see Figures B, C &

D.

V. REPLACEMENT PARTS

A complete list of Replacement Parts available for this series of Gas Char Broilers is included under

separate cover. Always give the Model number, Serial number and type of Gas when ordering Replacement

Parts.

VI. SERVICE CENTERS:

A complete list of Bakers Pride Factory Authorized Service Centers is included under separate cover.

Always have the Model Number, the Serial Number and type of Gas available before calling for Service.

FIGURE “B” FIGURE “C”

GLO-STONES

GLO-STONE FRAME

DOUBLE

BURNER

CARRY-OVER

LIGHTER TUBE

LIGHTER GAS

SUPPLY TUBING

CARRY-OVER LIGHTER

TUBE VALVE

FIGURE “D”

Safety Valve

Button

LOW FLAME

ADJUST. SCREW

TURN C.W. TO DECREASE

TURN C.C.W. TO INCREASE

MAIN BURNER VALVE

MAIN BURNER

AIR MIXER CAP

CAP LOCKING SCREW

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

8

SINGLE

BURNER

MANIFOLD

Page 9

Figure “F” TOP & FRONT VIEWS

SINGLE BURNER

(24", 48" & 72" ONLY)

DOUBLE BURNER (TYP)

RADIANT & GLO-STONE

SUPPT. REAR (TYP)

BURNER SUPPT

RADIANTS

DRIP CATCH (OPT)

RADIANT & GLO-STONE

SUPPT. FRONT (TYP)

LIGHTER TUBE

DRAIN PIPE (TYP)

GREASE DRAIN (TYP)

WORK DECK (TYP)

ILLUSTRATED WITH RADIANTS

AND INDIVIDUAL LIGHTER TUBES

(60" MODELS SHOWN)

TOP VIEW

ILLUSTRATED WITH GLO-STONES

AND CARRY-OVER LIGHTER TUBE

TOP GRATES (TYP)

GAS INLET (TYP)

BURNER SUPPT

DOUBLE BURNER (TYP)

RADIANT & GLO-STONE

SUPPT. REAR (TYP)

GLO-STONES

GLO-STONE FRAME

BOTTOM GRATE

BOTTOM GRATE SUPPT

CARRY-OVER

LIGHTER TUBE

RADIANT & GLO-STONE

SUPPT. FRONT (TYP)

TOWEL BAR(S)

GREASE DEFLECTOR (TYP)

GREASE DRAWER

LOW PROFILE

DRIP PAN(S)

LOW PROFILE

REVERSIBLE

TOP GRATES (TYP)

WORK DECK (6", 10" OR 12")

& GREASE DRAIN (TYP)

WIRE RACK(S)

(OPT) F & C ONLY

GREASE DEFLECTOR (TYP)

EXT. GREASE DRAWER

(F & C ONLY)

EXT. DRIP PAN(S)

(F & C ONLY)

4" ADJ. LEGS (OPT)

L - LOW PROFILE MODEL

NOTE: MAY BE USED

WITH OR WITHOUT

4” LEGS - INCLUDED

4" ADJ. LEGS (STD)

C - COUNTER TOP MODEL

TOP GRATE

SUPPORTS (TYP)

OBSERVATION &

IGNITER HOLES

"O" POSITION MARKS

CONTROL PANEL

MAIN BURNER

VALVE KNOBS

WOODCHIP DRAWER(S)

(OPT) F & C ONLY

CARRY-OVER

VALVE KNOBS

F - FLOOR MODEL

FRONT VIEWS

9

6" ADJ. LEGS (STD)

4" CASTERS (OPT)

Page 10

VII. TABLE OF EUROPEAN PRESSURES, GASES AND CATEGORIES (STANDARD) F, L, C SERIES BROILERS

COUNTRY (code)

Applicable Supply Burner

Gas Category Gas Type

to model Pressure Pressure

Nominal Input Rate

(kW)

being tested (mbar) (mbar) Net 1 Net 2 Gross 1 Gross 2 main 1 main 2

I

I

I

I

2ELL

I

I

I

I

I

I

I

I

2E+

I

I

I

2E+

I

2

I

I

I

2

I

I

I

I

I

I

I

2H

X G20 20 8.7 6.3 6.3

X G20/25 20/25 8.7 6.3 6.3

2H

2H

2H

2H

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20/25 20/25 8.7 6.3 6.3

X G25 20 8.7 3.1 6.3

2E

H

2H

2S

2H

2H

2H

2H

E

2L

2H

2E

2H

2H

2H

2H

2H

2H

2H

2H

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G25.1 25 8.7 3.1 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G25 25 8.7 3.1 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

X G20 20 8.7 6.3 6.3

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

4.4

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.8

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

4.85

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

9.7

Austria (AT)

Belgium (BE)

Chech Republic (CZ)

Denmark (DK)

Estonia (EE)

Finland (FI)

France (FR)

Germany (DE)

Greece (GR)

Hungary (HU)

Ireland (IE)

Italy (IT)

Latvia (LV)

10

Lithuania (LT)

Luxembourg(LU)

Netherlands (NL)

Norway (NO)

Poland (PL)

Portugal (PT)

Slovenia (SL) X G20 20 8.7 6.3 6.3

Slovakia (SK)

Spain (ES)

Sweden (SE)

Switzerland (CH)

Turkey (TR)

United Kingdom (GB)

* ONLY FOR CERTAIN TYPES OF NON-DOMESTIC APPLIANCES

(1) if convertible in field must supply additional instructions G20 NATURAL GAS

# THE COUNTRY HAS THE GAS BUT THEY DO NOT MARKET THE GAS AS A CATEGORY G30 BUTANE GAS

EN Standards require the orifice size to be displayed on spud body and air shutters sealed in position. G31 PROPANE GAS

(FR) - I3B, I3P--50mbar supply for catering appliances G30/31 BUTANE / PROPANE

(IT) - I2M-- LPG/Air mixture 42.29 MJ/m3 G20/25 Natural gas / Low heating value natural gas

+ indicates unregulated appliance or regulator is put out of action and sealed at the factory.

Burners - Main 1, Net/Gross 1= single burner venturi. Main 2, Net/Gross 2= Dual burner venturi

(Orifice)

Injector size (mm)

main 1 main 2 pilot

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.1

2.0

2.0

2.0

2.1

2.0

2.0

2.0

2.0

2.0

2.1

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.9

2.9

2.9

2.9

2.9

2.9

2.9

3.25

2.9

2.9

2.9

3.25

2.9

2.9

2.9

2.9

2.9

3.25

2.9

2.9

2.9

2.9

2.9

2.9

2.9

2.9

2.9

2.9

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.50

1.35

1.35

1.35

1.50

1.35

1.35

1.35

1.35

1.35

1.50

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

opening (mm)

Air shutter

Page 11

TABLE OF EUROPEAN PRESSURES, GASES AND CATEGORIES (HIGH-HEAT) F, L, C SERIES BROILERS

COUNTRY (code)

Applicable Supply Burner

Gas Category Gas Type

to model Pressure Pressure

Nominal Input Rate

(kW)

being tested (mbar) (mbar) Net 1 Net 2 Gross 1 Gross 2 main 1 main 2

I

I

I

I

I

2ELL

I

I

I

I

I

I

I

I

2E+

I

I

2E+

I

2

I

I

I

2

I

I

I

I

I

I

I

2H

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20/25 20/25 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

2H

2H

2H

2H

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20/25 20/25 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G25 20 8.7 5.3 10.55 5.9 11.7 2.15 3.5 1.50 3.1 6.3

2E

H

2H

2S

2H

2H

2H

2H

E

2L

2H

2E

2H

2H

2H

2H

2H

2H

2H

2H

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G25.1 25 8.7 5.3 10.55 5.9 11.7 2.15 3.5 1.50 3.1 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G25 25 8.7 5.3 10.55 5.9 11.7 2.15 3.5 1.50 3.1 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

Austria (AT)

Belgium (BE)

Chech Republic (CZ)

Denmark (DK)

Estonia (EE)

Finland (FI)

France (FR)

Germany (DE)

Greece (GR)

Hungary (HU)

Ireland (IE)

Italy (IT)

Latvia (LV)

11

Lithuania (LT)

Luxembourg(LU)

Netherlands (NL)

Norway (NO)

Poland (PL)

Portugal (PT)

Slovenia (SL) X G20 20 8.7 5.3 10.55 5.9 11.7 2.05 3.1 1.35 6.3 6.3

Slovakia (SK)

Spain (ES)

Sweden (SE)

Switzerland (CH)

Turkey (TR)

United Kingdom (GB)

* ONLY FOR CERTAIN TYPES OF NON-DOMESTIC APPLIANCES

(1) if convertible in field must supply additional instructions G20 NATURAL GAS

# THE COUNTRY HAS THE GAS BUT THEY DO NOT MARKET THE GAS AS A CATEGORY G30 BUTANE GAS

EN Standards require the orifice size to be displayed on spud body and air shutters sealed in position. G31 PROPANE GAS

(FR) - I3B, I3P--50mbar supply for catering appliances G30/31 BUTANE / PROPANE

(IT) - I2M-- LPG/Air mixture 42.29 MJ/m3 G20/25 Natural gas / Low heating value natural gas

+ indicates unregulated appliance or regulator is put out of action and sealed at the factory.

Burners - Main 1, Net/Gross 1= single burner venturi. Main 2, Net/Gross 2= Dual burner venturi

(Orifice)

Injector size (mm)

main 1 main 2 pilot

opening (mm)

Air shutter

Page 12

VIII. BAKERS PRIDE LIMITED WARRANTY

914 / 576 - 0200 ♦ US & Canada: 1 - 800 - 431 - 2745 ♦ fax 914 / 576 - 0605

30 Pine Street New Rochelle, New York 10801

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Full size gas and electric deck ovens: Two (2) year limited parts and labor: Cyclone Convection Ovens: BCO Models: One (1)

WARRANTY This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

COVERAGE representative up to (100) miles. round trip, and (2) hours travel time. The purchaser. however, shall be responsible for all

EXCEPTIONS All removable parts in BAKERS PRIDE Char-broilers, including but not limited to: Burners, Grates. Radiants, Stones and

EXCLUSIONS

♦ Negligence or acts of God,

♦ Thermostat calibrations after (30) days from equipment

installation date,

♦ Air and Gas adjustments,

♦ Light bulbs,

♦ Glass doors and door adjustments.

♦ Fuses,

♦ Char-broiler work decks and cutting boards,

♦ Tightening of conveyor chains,

♦ Adjustments to burner flames and cleaning of pilot burners,

♦ Tightening of screws or fasteners.

providing that:

♦ The equipment has not been accidentally or intentionally damaged, altered or misused;

♦ The equipment is properly installed, adjusted, operated and maintained in accordance with National and local codes. and

in accordance with the installation instruction provided with the product;

♦ The serial number rating plate affixed to the equipment has not been defaced or removed.

Year limited parts and labor; GDCO Models: Two (2) Year limited parts and labor; CO II Models: Two (2) Year limited parts

and labor; (5) Year limited door warranty.

All Other Products: One (1) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date from BAKERS PRIDE whichever comes first.

expenses related to travel, including time. mileage and shipping expenses on smaller counter models that may be carried into

a Factory Authorized Service Center, including the following models: PX-14. PX-16, PI8, and BK-I8.

Valves, are covered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks is the

responsibility of the purchaser.

The extended Cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor, travel, milage or

any other charges.

♦ Failures caused by erratic voltages or gas supplies,

♦ Unauthorized repair by anyone other than a BAKERS PRIDE

Factory Authorized Service Center,

♦ Damage in shipment,

♦ Alteration, misuse or improper installation,

♦ Thermostats and safety valves with broken capillary tubes.

♦ Accessories - spatulas, forks. steak turners, grate lifters,

oven brushes, scrapers, peels. etc.,

♦ Freight - other than normal UPS charges,

♦ Ordinary wear and tear.

INSTALLATION Leveling and installation of decks. as well as proper installation and check out of all new equipment - per appropriate

REPLACEMENT BAKERS PRIDE genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation by a

PARTS BAKERS PRIDE Factory Authorized Service Center.

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturers part. BAKERS PRIDE

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excess of the purchase price of the unit. The

repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

installation and use materials - is the responsibility of the dealer or installer, not the manufacturer.

Form #U4177A 1/07

12

Loading...

Loading...