Page 1

IBM TotalStorage 3580 Tape Drive

Model

L33/L3H

Setup, Operato r, an d Service Guide

GC26-7708-03

Page 2

Page 3

IBM TotalStorage 3580 Tape Drive

Model

L33/L3H

Setup, Operato r, an d Service Guide

GC26-7708-03

Page 4

Note!

Before using this information and the product it supports, read the information in “Safety and Environmental Notices” on

page xi and “Notices” on page 107.

To ensure that you have the latest publications, visit the web at http://www.ibm.com/storage/lto.

Third Edition (March 2006)

This edition applies to the IBM TotalStorage 3580 Tape Drive Model L33/L3H Setup, Operator, and Service Guide and to

all subsequent releases and modifications until otherwise indicated in new editions.

© Copyright International Business Machines Corporation 2004, 2006. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Read this First

Summary of Changes

|

|

|

Third Edition

v WORM media information

v New part numbers in the Parts List

Second Edition

v Diagnostic functions F, J, and L were modified / added.

v The procedure for aborting a diagnostic function was modified.

v The information for error code A was modified.

v The Troubleshooting flowchart was updated.

Accessing Online Technical Support

For online Technical Support for your Library, visit:

http://www.ibm.com/storage/lto

Registering for My Support

|

|

|

My Support registration provides e-mail notification when new firmware levels

have been updated and are available for download and installation. To register for

My Support, visit the web at http://www.ibm.com/support/mySupport

Sending Us Your Comments

Your feedback is important in helping IBM

information. If you have comments or suggestions for improving this publication,

send your comments by:

v E-mailing IBM:

– Internet or IBMLink

– IBMLink from Canada: STARPUBS at TORIBM

Include the following information in your e-mail:

– Exact publication title

– Form number (for example, GA32–1234–02) or part number (located on the

back cover of the publication)

– Page number to which you are referring

Using the Readers’ Comments form at the back of this publication

v

v Mailing your comments to:

®

provide accurate and useful

™

from US: starpubs@us.ibm.com

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, AZ 85744-0001 USA

© Copyright IBM Corp. 2004, 2006 iii

Page 6

iv IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Page 7

Contents

Read this First . . . . . . . . . . . . iii

Summary of Changes . . . . . . . . . . . iii

Third Edition . . . . . . . . . . . . . iii

||

Second Edition . . . . . . . . . . . . iii

Accessing Online Technical Support . . . . . . iii

Registering for My Support . . . . . . . . . iii

Sending Us Your Comments . . . . . . . . . iii

Figures . . . . . . . . . . . . . . vii

Tables . . . . . . . . . . . . . . .ix

Safety and Environmental Notices . . .xi

Danger Notices . . . . . . . . . . . . .xi

Caution Notices . . . . . . . . . . . . .xi

Performing the Safety Inspection Procedure . . . xii

Tape Drive AC Grounding Inspection . . . . . xii

Product Recycling and Disposal . . . . . . . xiii

Battery Return Program . . . . . . . . . . xiii

Flat Panel Display . . . . . . . . . . . . xiv

End of Life (EOL) Plan . . . . . . . . . . xiv

| |

| |

Preface . . . . . . . . . . . . . .xv

| |

Related Publications . . . . . . . . . . . xvi

| |

| |

Product Description . . . . . . . . .1

Front Panel Components . . . . . . . . . .2

Rear Panel Components . . . . . . . . . .3

3580 Models . . . . . . . . . . . . . .3

Drive Performance . . . . . . . . . . . .4

Supported Servers and Operating Systems . . . .4

Supported Device Drivers . . . . . . . . . .5

TapeAlert Support . . . . . . . . . . . .5

Specifications . . . . . . . . . . . . . .6

Installation . . . . . . . . . . . . .7

Installation Overview . . . . . . . . . . .7

Unpack the Tape Drive . . . . . . . . . . .8

Verify the Shipment . . . . . . . . . . . .8

Install the Rack Mount Kit (optional) . . . . . .8

Inspect the Power Cord and Outlet . . . . . . .9

Set the SCSI ID . . . . . . . . . . . . .9

Position the Tape Drive . . . . . . . . . . .9

Connect Power . . . . . . . . . . . . .10

Run Write Performance Test (Function Code F) . .10

Install the SCSI Host Adapter Card (if required) . .11

Connect the SCSI Bus Cable . . . . . . . . .11

Install Device Drivers . . . . . . . . . . .13

Configure the Tape Drive to a Server/Host . . . .13

Update Drive Firmware . . . . . . . . . .13

Register for My Support . . . . . . . . . .14

Operation . . . . . . . . . . . . .15

Power Button . . . . . . . . . . . . . .15

Unload Button . . . . . . . . . . . . .15

Single-character Display (SCD) . . . . . . . .16

SCD Dot . . . . . . . . . . . . . .16

Status Light . . . . . . . . . . . . . .16

Inserting a Tape Cartridge . . . . . . . . .18

Removing a Tape Cartridge . . . . . . . . .19

Mid-tape Recovery . . . . . . . . . . . .19

Performing Diagnostic and Maintenance Functions 19

Updating Drive Firmware . . . . . . . . .20

ITDT SCSI Firmware Update, Dump Retrieval,

and Library/Drive Test Tool . . . . . . . .20

Updating Firmware through the SCSI Interface 20

Updating the Firmware with an FMR Tape

Cartridge . . . . . . . . . . . . . .21

Cleaning the Drive Head . . . . . . . . . .21

Cleaning the Tape Drive . . . . . . . . . .22

Ultrium Media . . . . . . . . . . . .23

Cartridge Compatibility . . . . . . . . . .23

Data Cartridge . . . . . . . . . . . . .24

Capacity Scaling . . . . . . . . . . . .25

WORM (Write Once, Read Many) . . . . . . .25

WORM Media . . . . . . . . . . . .25

Data Security on WORM Media . . . . . .25

WORM Media Errors . . . . . . . . . .25

Requirements . . . . . . . . . . . . .26

Cleaning Cartridge . . . . . . . . . . . .26

Bar Code Label . . . . . . . . . . . . .26

Guidelines for Using Bar Code Labels . . . .27

Write-Protect Switch . . . . . . . . . . .28

Handling the Cartridges . . . . . . . . . .30

Provide Training . . . . . . . . . . . .30

Ensure Proper Packaging . . . . . . . . .30

Provide Proper Acclimation and Environmental

Conditions . . . . . . . . . . . . . .31

Perform a Thorough Inspection . . . . . . .32

Handle the Cartridge Carefully . . . . . . .33

Examples of Cartridge Problems . . . . . .33

Repositioning or Reattaching a Leader Pin . . . .34

Repositioning a Leader Pin . . . . . . . .34

Reattaching a Leader Pin . . . . . . . . .36

Environmental and Shipping Specifications for Tape

Cartridges . . . . . . . . . . . . . . .40

Disposing of Tape Cartridges . . . . . . . .41

Ordering Media Supplies . . . . . . . . . .42

Ordering Bar Code Labels . . . . . . . .43

Troubleshooting . . . . . . . . . . .45

Procedure 1: Determining Firmware Level and

Capturing Drive Dump . . . . . . . . . .46

Procedure 2: Inspecting a Cartridge for Damage . .46

Procedure 3: Verifying SCSI Address Switch Position 47

Procedure 4: Checking SCSI Connections . . . .47

Procedure 5: Verifying SCSI Interface

Communications . . . . . . . . . . . .48

© Copyright IBM Corp. 2004, 2006 v

Page 8

Resolving Problems Reported by the Server . . .48

Fixing SCSI Bus Errors . . . . . . . . .48

Resolving Media-Related Problems . . . . . .51

Pre-Call Checklist . . . . . . . . . . . .52

Replacing the Tape Drive . . . . . . . . . .53

Features, Replacement Parts, and

|

Power Cords . . . . . . . . . . . .55

||

Optional Features . . . . . . . . . . . .55

||

Replacement Parts . . . . . . . . . . . .55

||

Power Cords . . . . . . . . . . . . . .56

Types of Receptacles . . . . . . . . . . .59

Appendix A. Error Codes . . . . . . .61

Appendix B. Performing Diagnostic and

Maintenance Functions . . . . . . .67

Entering Maintenance Mode . . . . . . . . .68

Function Code 0: Exit Maintenance Mode . . . .68

Function Code 1: Run Drive Diagnostics . . . . .69

Function Code 2: Update Drive Firmware from FMR

Tape . . . . . . . . . . . . . . . . .70

Function Code 3: Create FMR Tape . . . . . .71

Function Code 4: Force a Drive Dump . . . . .72

Function Code 5: Copy Drive Dump . . . . . .73

Function Code 6: Run SCSI Wrap Test . . . . .74

Function Code 7: Not Available . . . . . . . .74

Function Code 8: Unmake FMR Tape . . . . . .75

Function Code 9: Display Error Code Log . . . .75

Function Code A: Clear Error Code Log . . . . .76

Function Code C: Insert Cartridge into Tape Drive 76

Function Code E: Test Cartridge & Media . . . .77

Function Code F: Write Performance Test . . . .78

Function Code H: Test Head . . . . . . . . .79

Function Code J: Run Fast Read/Write Test . . . .80

Function Code L: Load/Unload Test . . . . . .81

Function Code P: Enable Post Error Reporting . . .82

Function Code U: Disable Post Error Reporting . .82

Appendix C. TapeAlert Flags . . . . .83

Tools Required . . . . . . . . . . . . .86

Installing the Shelf . . . . . . . . . . . .87

Removing the Shelf from the Rack . . . . . . .88

Appendix E. Information for Authorized

Service Personnel . . . . . . . . . .89

Removing the Internal Drive . . . . . . . .89

Step 1. Remove the Cover . . . . . . . .89

Step 2. Remove the Internal Drive . . . . . .90

Manually Removing a Tape Cartridge . . . . .92

Before Yo u Begin . . . . . . . . . . .92

Recommended Tools . . . . . . . . . .92

Beginning Procedure . . . . . . . . . .93

Tape Spooled off Supply Reel . . . . . . .95

Tape Pulled from or Broken near Leader Pin . .96

Tape Broken in Mid-tape . . . . . . . . .98

Tape Tangled along Tape Path . . . . . . .99

No Apparent Failure or Damage to Tape . . . 102

Replacing the Internal Drive . . . . . . . . 106

Step 1. Replace the Internal Drive . . . . . 106

Step 2. Replace the Cover . . . . . . . . 106

Notices . . . . . . . . . . . . . . 107

Trademarks . . . . . . . . . . . . . . 108

Electronic Emission Notices . . . . . . . . .110

Federal Communications Commission (FCC)

Class A Statement . . . . . . . . . . .110

Industry Canada Class A Emission Compliance

Statement . . . . . . . . . . . . . .110

Avis de conformité à la réglementation

d’Industrie Canada . . . . . . . . . .110

European Union (EU) Electromagnetic

Compatibility Directive . . . . . . . . .110

Germany Electromagnetic Compatibility

Directive . . . . . . . . . . . . . . 111

Japan VCCI Class A ITE Electronic Emission

Statement . . . . . . . . . . . . . . 111

People’s Republic of China Class A Electronic

Emission Statement . . . . . . . . . . 111

Taiwan Class A Electronic Emission Statement 112

Korea Class A Electronic Emission Statement 112

Appendix D. Installing a 19-inch Rack

Mount Kit . . . . . . . . . . . . .85

Rack Safety . . . . . . . . . . . . . .85

Verify Kit Contents . . . . . . . . . . . .86

vi IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Glossary . . . . . . . . . . . . .113

Index . . . . . . . . . . . . . . .119

Page 9

Figures

1. AC Grounding Diagram (50 Hz and 60 Hz) xii

2. The IBM TotalStorage 3580 Tape Drive . . . .1

3. Front panel components . . . . . . . . .2

4. Rear panel components . . . . . . . . .3

5. Example of connecting one SCSI device to the

server . . . . . . . . . . . . . .12

6. Example of connecting multiple SCSI devices

to the server . . . . . . . . . . . .13

7. Inserting a cartridge . . . . . . . . . .18

8. The IBM TotalStorage LTO Ultrium 400 GB

Data Cartridge . . . . . . . . . . .23

9. Ultrium 3 WORM Tape Cartridge . . . . .25

||

10. Sample bar code label on the LTO Ultrium 3

Tape Cartridge . . . . . . . . . . .27

11. Setting the write-protect switch . . . . . .29

12. Tape cartridges in a Turtlecase . . . . . .31

13. Double-boxing tape cartridges for shipping 31

14. Checking for gaps in the seams of a cartridge 32

15. Leader pin in the incorrect and correct

positions . . . . . . . . . . . . .34

16. Placing the dislodged leader pin into the

correct position . . . . . . . . . . .35

17. Rewinding the tape into the cartridge . . . .35

18. Leader Pin Reattachment Kit . . . . . . .36

19. Attaching the leader pin attach tool to the

cartridge . . . . . . . . . . . . .37

20. Winding the tape out of the cartridge . . . .38

21. Removing the C-clip from the leader pin 38

22. Attaching the leader pin to the tape . . . .39

23. Flowchart for analyzing maintenance problems 45

24. RID tag on rear panel . . . . . . . . .53

25. Types of Receptacles . . . . . . . . .60

26. Front view of shelf attached to rack rails 87

27. Rear view of shelf with cables attached to rack

rails with tie wraps . . . . . . . . . .88

28. Removing the screws that secure the cover and

internal drive . . . . . . . . . . . .89

29. Removing screws from the rear panel . . . .90

30. Removing cables from the internal drive 90

31. Removing the screws securing the internal

drive . . . . . . . . . . . . . . .91

32. Lifting the chassis from the internal drive 91

33. Removing the cover from the internal drive 93

34. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . .95

35. Drive with cover removed to reveal gear train. 96

36. Leader Block Assembly (LBA) . . . . . .97

37. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . .99

38. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 100

39. Drive with cover removed to reveal gear

train. . . . . . . . . . . . . . . 101

40. Leader Block Assembly (LBA) . . . . . . 102

41. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 103

42. Drive with cover removed to reveal gear

train. . . . . . . . . . . . . . . 104

43. Leader Block Assembly (LBA) . . . . . . 105

© Copyright IBM Corp. 2004, 2006 vii

Page 10

viii IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 11

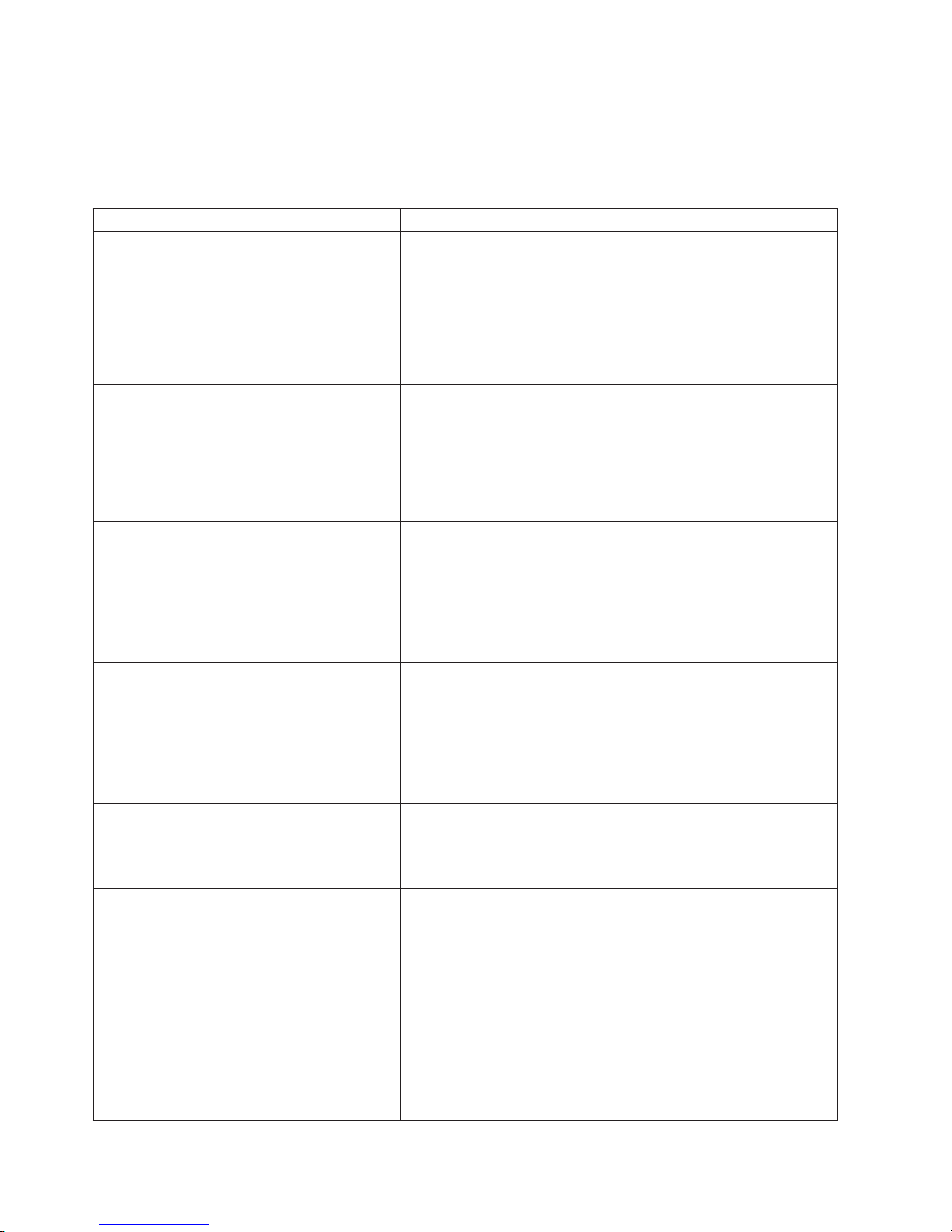

Tables

1. 3580 Models . . . . . . . . . . . . .3

2. Performance characteristics . . . . . . . .4

3. Specifications . . . . . . . . . . . .6

4. Meaning of Status Light and Single-character

Display (SCD) . . . . . . . . . . . .17

5. Ultrium data and cleaning cartridge

compatibility with Ultrium tape drive . . . .23

6. Bar code label requirements for Ultrium tape

drives and libraries . . . . . . . . . .26

7. Environment for operating, storing, and

shipping the LTO Ultrium Tape Cartridge . .40

8. Media Supplies . . . . . . . . . . .42

9. Authorized suppliers of custom bar code labels 43

10. Optional features for the 3580 . . . . . .55

11. Replacement parts for the 3580 . . . . . .55

12. Power cords . . . . . . . . . . . .56

13. Error codes on the Single-character Display 61

14. Diagnostic and maintenance functions . . .67

15. Supported TapeAlert Flags . . . . . . .83

© Copyright IBM Corp. 2004, 2006 ix

Page 12

x IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Page 13

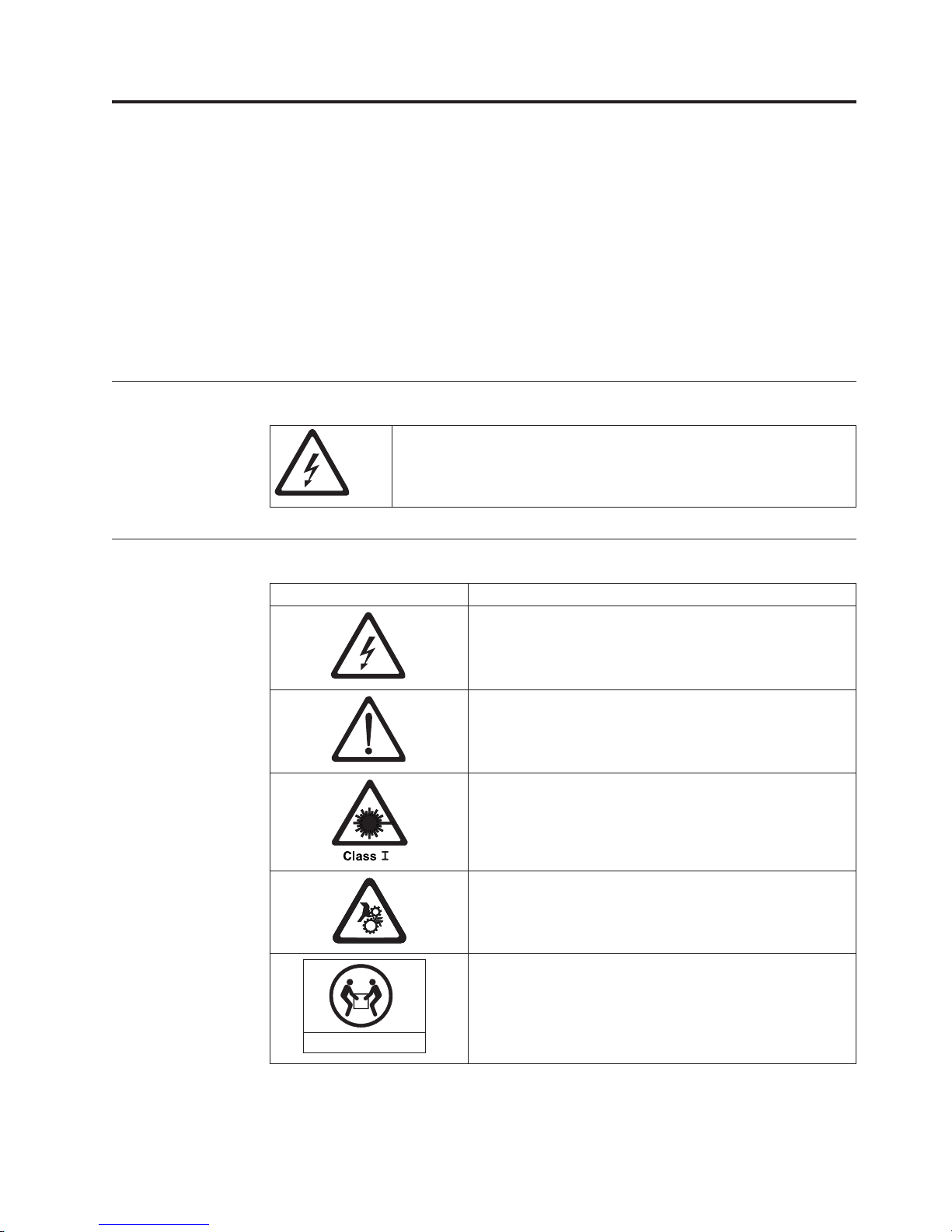

Safety and Environmental Notices

When using this product, observe the danger and caution notices contained in this

guide. The notices are accompanied by symbols that represent the severity of the

safety condition.

Danger notices contain a Dxxxx reference number. Caution notices contain a Cxxxx

reference number. Rack safety notices contain a Rxxxx reference number. Use the

reference number to locate the translation in IBM Translated Safety Notices, 96P0851.

The sections that follow define each type of safety notice.

Danger Notices

A danger notice calls attention to a situation that is potentially lethal or

extremely hazardous to people. A lightning bolt symbol always

accompanies a danger notice to represent a dangerous electrical

condition.

Caution Notices

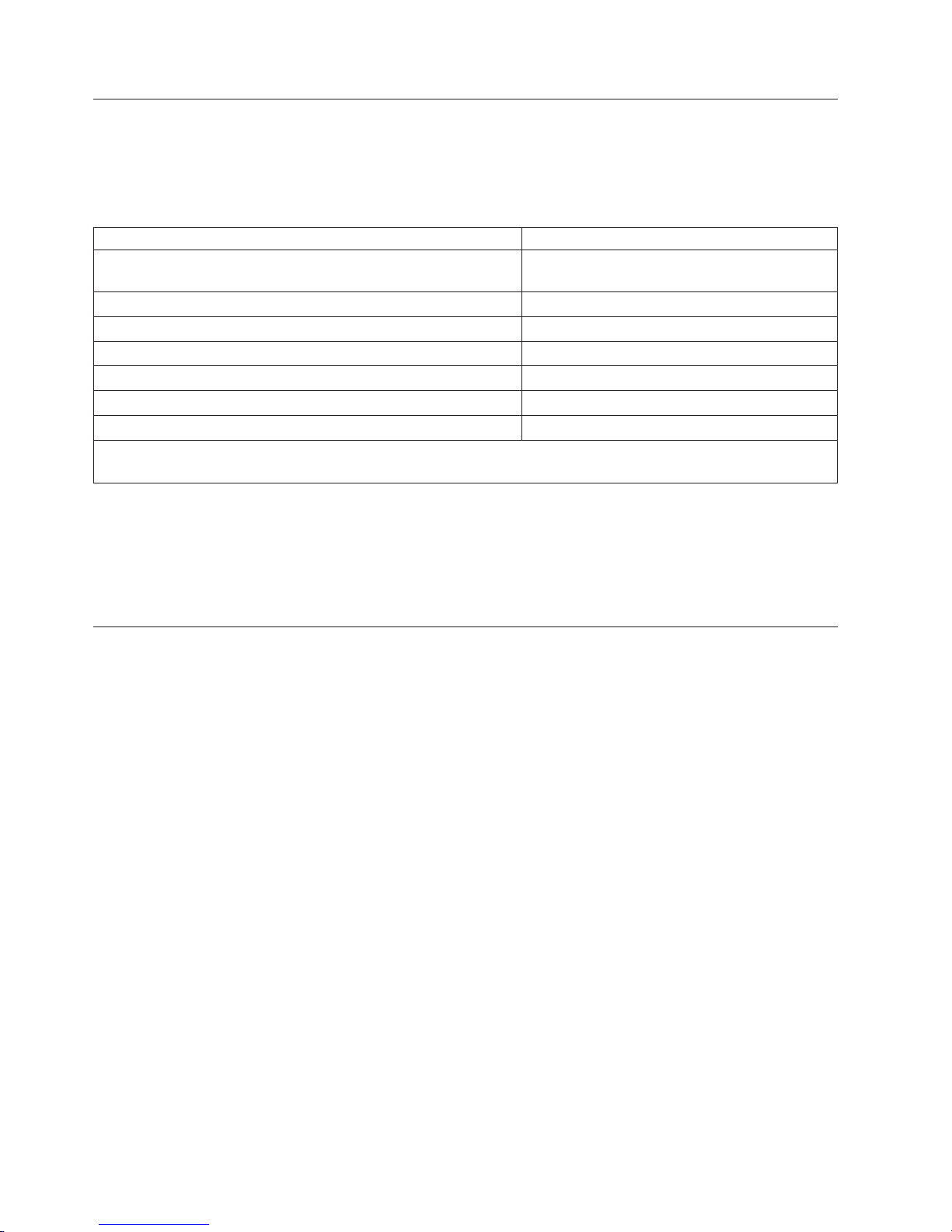

If the symbol is... It means....

A hazardous electrical condition with less severity than

electrical danger.

A generally hazardous condition not represented by other

safety symbols.

A hazardous condition due to the use of a laser in the

product. Laser symbols are always accompanied by the

classification of the laser as defined by the U. S.

Department of Health and Human Services (for example,

Class I, Class II, and so forth).

A hazardous condition due to mechanical movement in or

around the product.

A hazardous condition due to the weight of the unit.

Weight symbols are accompanied by an approximation of

the product’s weight.

18-32 kg (39.7-70.5 lbs)

© Copyright IBM Corp. 2004, 2006 xi

svc00167

Page 14

Performing the Safety Inspection Procedure

Before you service the unit, perform the following safety inspection procedure:

1. Stop all activity on the SCSI bus.

2. Turn off the power to the tape drive.

3. Disconnect the SCSI cable and check the SCSI bus terminator for damage.

4. Unplug the tape drive’s power cord from the electrical outlet.

5. Check the tape drive’s power cord for damage, such as a pinched, cut, or

frayed cord.

6. Check the tape drive’s SCSI bus (signal) cable for damage.

7. Check the cover of the tape drive for sharp edges, damage, or alterations that

expose its internal parts.

8. Check the cover of the tape drive for proper fit. It should be in place and

secure.

9. Check the product label on the bottom of the tape drive to make sure that it

matches the voltage at your outlet.

Tape Drive AC Grounding Inspection

1. Power off the drive.

2. Disconnect all cables.

3. See Figure 1 which is provided for reference only. Disconnect the power cord

from its source.

4. Inspect the power cable for visible cracks, wear, or damage.

Figure 1. AC Grounding Diagram (50 Hz and 60 Hz)

1 AC Ground

2 Chassis Frame

3 AC Ground Terminated in Power Supply

xii IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 15

Product Recycling and Disposal

This unit must be recycled or discarded according to applicable local and national

regulations. IBM encourages owners of information technology (IT) equipment to

responsibly recycle their equipment when it is no longer needed. IBM offers a

variety of product return programs and services in several countries to assist

equipment owners in recycling their IT products. Information on IBM product

recycling offerings can be found on IBM’s Internet site at

http://www.ibm.com/ibm/environment/products/prp.shtml.

Notice: This mark applies only to countries within the European Union (EU) and

Norway.

Appliances are labeled in accordance with European Directive 2002/96/EC

concerning waste electrical and electronic equipment (WEEE). The Directive

determines the framework for the return and recycling of used appliances as

applicable throughout the European Union. This label is applied to various

products to indicate that the product is not to be thrown away, but rather

reclaimed upon end of life per this Directive.

In accordance with the European WEEE Directive, electrical and electronic

equipment (EEE) is to be collected separately and to be reused, recycled, or

recovered at end of life. Users of EEE with the WEEE marking per Annex IV of the

WEEE Directive, as shown above, must not dispose of end of life EEE as unsorted

municipal waste, but use the collection framework available to customers for the

return, recycling and recovery of WEEE. Customer participation is important to

minimize any potential effects of EEE on the environment and human health due

to the potential presence of hazardous substances in EEE. For proper collection and

treatment, contact your local IBM representative.

Battery Return Program

This product may contain sealed lead acid, nickel cadmium, nickel metal hydride,

lithium, or lithium ion battery. Consult your user manual or service manual for

specific battery information. The battery must be recycled or disposed of properly.

Recycling facilities may not be available in your area. For information on disposal

of batteries outside the United States, go to

http://www.ibm.com/ibm/environment/products/batteryrecycle.shtml or contact

your local waste disposal facility.

In the United States, IBM has established a return process for reuse, recycling, or

proper disposal of used IBM sealed lead acid, nickel cadmium, nickel metal

hydride, and other battery packs from IBM Equipment. For information on proper

disposal of these batteries, contact IBM at 1-800-426-4333. Please have the IBM part

number listed on the battery available prior to your call.

For Taiwan:

Safety and Environmental Notices xiii

Page 16

Please recycle batteries

Flat Panel Display

The fluorescent lamp or lamps in the liquid crystal display contain mercury.

Dispose of it as required by local ordinances and regulations.

End of Life (EOL) Plan

This box is a purchased unit. Therefore, it is the sole responsibility of the purchaser

to dispose of it in accordance with local laws and regulations at the time of

disposal.

This unit contains recyclable materials. The materials should be recycled where

facilities are available and according to local regulations. In some areas IBM may

provide a product take-back program that ensures proper handling of the product.

For more information, contact your IBM representative.

xiv IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 17

Preface

®

This guide describes how to install and use the IBM TotalStorage

3580 Tape Drive

in the following chapters:.

“Product Description” on page 1 describes the product, discusses supported

servers, operating systems, and device drivers, and lists hardware specifications.

“Installation” on page 7 gives unpacking, set up, and configuration information.

“Operation” on page 15 describes the Power Button, Unload Button, and Status

Light and explains the function of the Single-character Display. It gives instruction

on inserting and removing a tape cartridge, describes methods of updating drive

firmware, and explains how to clean the tape drive. It also lists diagnostic and

maintenance functions.

“Ultrium Media” on page 23 describes the types of tape cartridges to use and

defines the conditions for storing and shipping them. It also describes how to

handle the cartridges, how to set a cartridge’s write-protect switch, and how to

order additional cartridges.

“Troubleshooting” on page 45 gives tips for solving problems.

“Features, Replacement Parts, and Power Cords” on page 55 lists parts and

supplies and provides information about the power cords that are used in different

countries or regions.

Appendix A, “Error Codes,” on page 61 describes the error and informational

codes that appear on the single-character display.

Appendix B, “Performing Diagnostic and Maintenance Functions,” on page 67

describes the procedures that are used to identify and correct problems.

Appendix C, “TapeAlert Flags,” on page 83 lists TapeAlert messages that are

supported and that may aid during problem determination.

Appendix D, “Installing a 19-inch Rack Mount Kit,” on page 85 describes how to

install the Rack Mount Kit.

Appendix E, “Information for Authorized Service Personnel,” on page 89 gives the

procedure for removing a tape cartridge that will not eject from the drive.

© Copyright IBM Corp. 2004, 2006 xv

Page 18

Related Publications

Refer to the following publications for additional information. To ensure that you

have the latest publications, visit the web at http://www.ibm.com/storage/lto.

v IBM TotalStorage 3580 Tape Drive Quick Reference, GC26-7709, illustrates how to

configure and operate the IBM TotalStorage Ultrium Tape Drive (Generation 3).

v IBM TotalStorage LTO Ultrium Tape Drive SCSI Reference, GA32–0450, gives

information about the supported SCSI commands and protocol for the tape

drive.

v IBM Ultrium Device Drivers Installation and User’s Guide, GA32-0430, provides

instructions for attaching IBM-supported hardware to open-systems operating

systems. It indicates what devices and levels of operating systems are supported,

gives the requirements for adapter cards, and tells how to configure servers to

use the device driver with the Ultrium family of devices.

v IBM Ultrium Device Drivers Programming Reference, GC35-0483, supplies

information to application developers who want to integrate their open-systems

applications with IBM-supported Ultrium hardware. The reference contains

information about the application programming interfaces (APIs) for each of the

various supported operating-system environments. Yo u can obtain this reference

via File Transfer Protocol (FTP) at ftp://ftp.software.ibm.com/storage/devdrvr.

v IBM Translated Safety Notices, 96P0851, provides translation of danger and caution

notices.

xvi IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 19

Product Description

The IBM TotalStorage 3580 Tape Drive Model L33/L3H offers high-capacity,

performance, and technology designed for the midrange open systems

environment. This new model incorporates the new Linear Tape-Open (LTO) IBM

TotalStorage Ultrium Tape Drive (Generation 3), which more than doubles

maximum tape drive performance over the Generation 2 LTO Ultrium Tape Drive

(Ultrium 2). This tape drive comes with a SCSI Ultra160 LV D attachment, for

|

|

connection to a wide spectrum of open system servers. This tape drive is

compliant with Directive 2002/95/EC of the European Parliament.

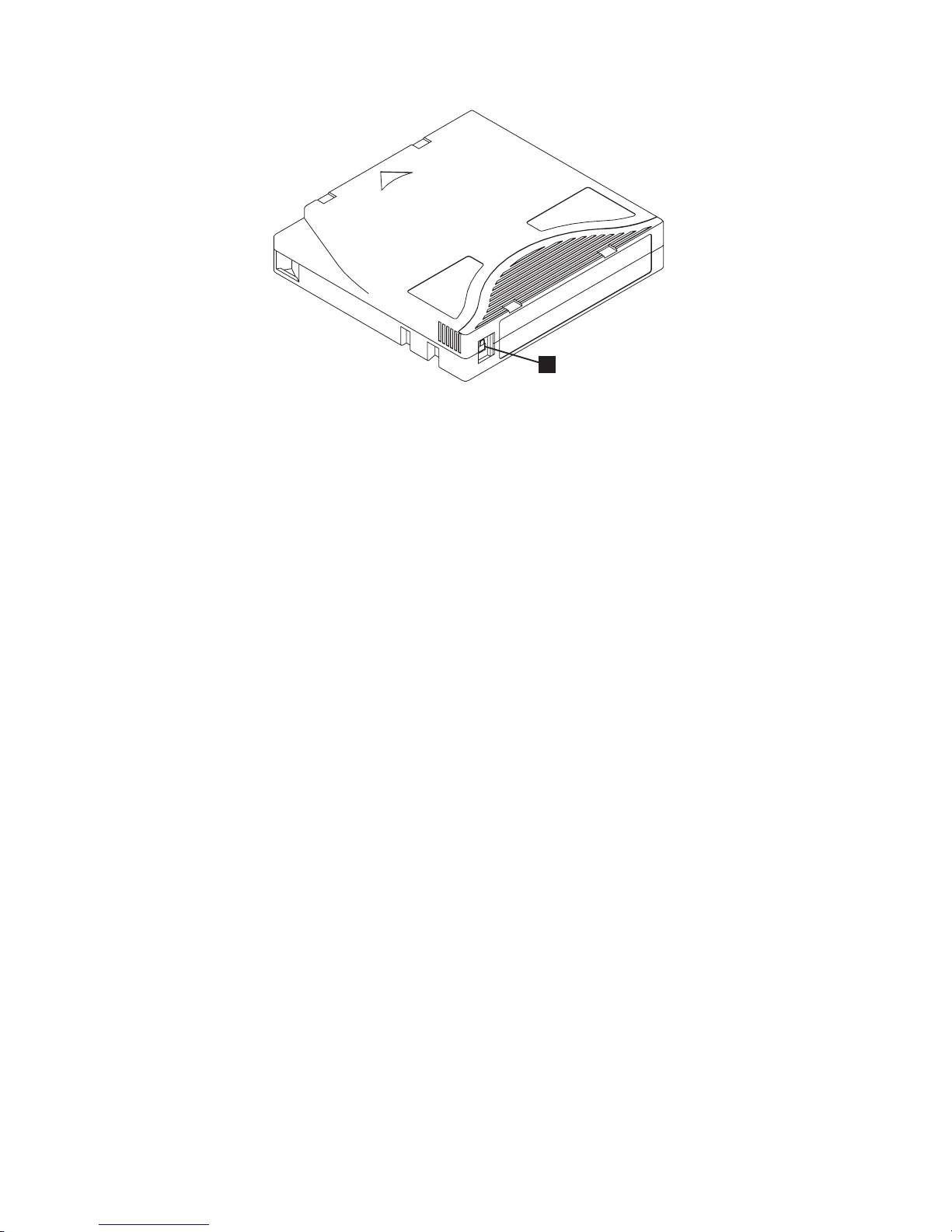

a67ru003

Figure 2. The IBM TotalStorage 3580 Tape Drive

Features include:

v Native storage capacity of 400 GB per cartridge (800 GB at 2:1 compression)

|

|

|

v Supports Ultrium 3 Write Once, Read Many (WORM) media (for more

information on WORM media, see “WORM (Write Once, Read Many)” on page

25)

v Native data transfer rate of up to 80 MB per second

v Burst data transfer rate of 160 MB per second

v New dual stage 16 channel head activator for precision head alignment to help

support higher track density with improved data integrity and backwards

compatibility with previous LTO generations

v Graceful dynamic braking designed to maintain tension until the tape comes to

a complete stop, to help prevent stretching or breaking the tape, and loose tape

wraps

v Larger internal buffer (the size has been doubled over the Ultrium 2 to 128 MB)

v New independent tape loader and threader motors designed to help with

cartridge insertion in the tape drive.

v Highly integrated electronics using IBM engineered copper technology designed

to reduced the total number of components in the drive, lower chip

temperatures, and reduce power requirements, helping to provide for a more

© Copyright IBM Corp. 2004, 2006 1

Page 20

reliable drive. The Generation 3 drive electronics also incorporate on-the-fly

error correction of soft errors in the memory arrays in data and control paths.

tape drive is an external stand-alone or rack-mountable unit and is the entry

The

point for the family of IBM Ultrium tape products. It provides an excellent

migration path from digital linear tape (DLT or SDLT), 1/4-inch, 4mm, or 8mm

tape drives.

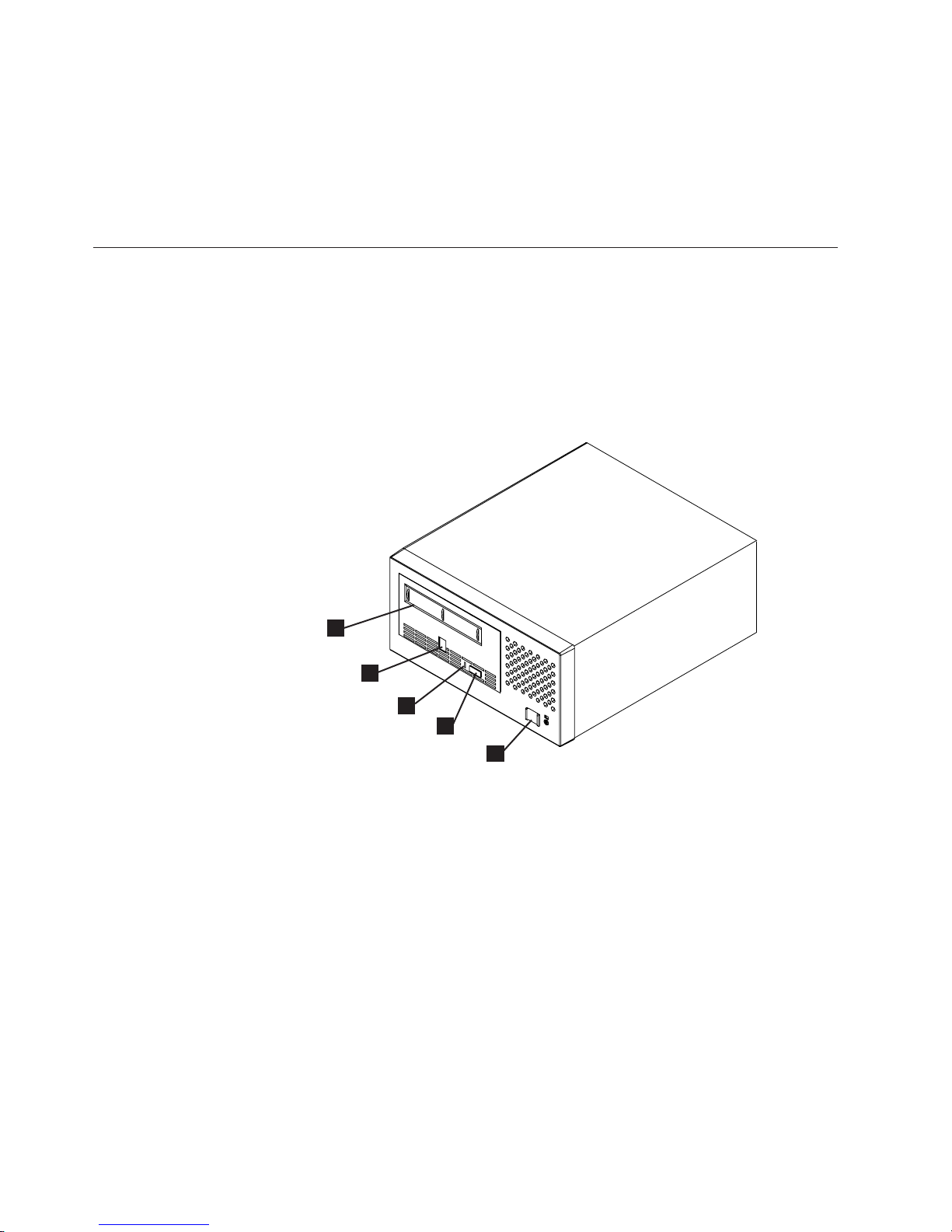

Front Panel Components

1 Cartridge load compartment 4 Unload Button (blue)

2 Single-character Display

(SCD)

5

Power Button (black)

3 Status Light

1

2

3

4

5

Figure 3. Front panel components

2 IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

a67ru007

Page 21

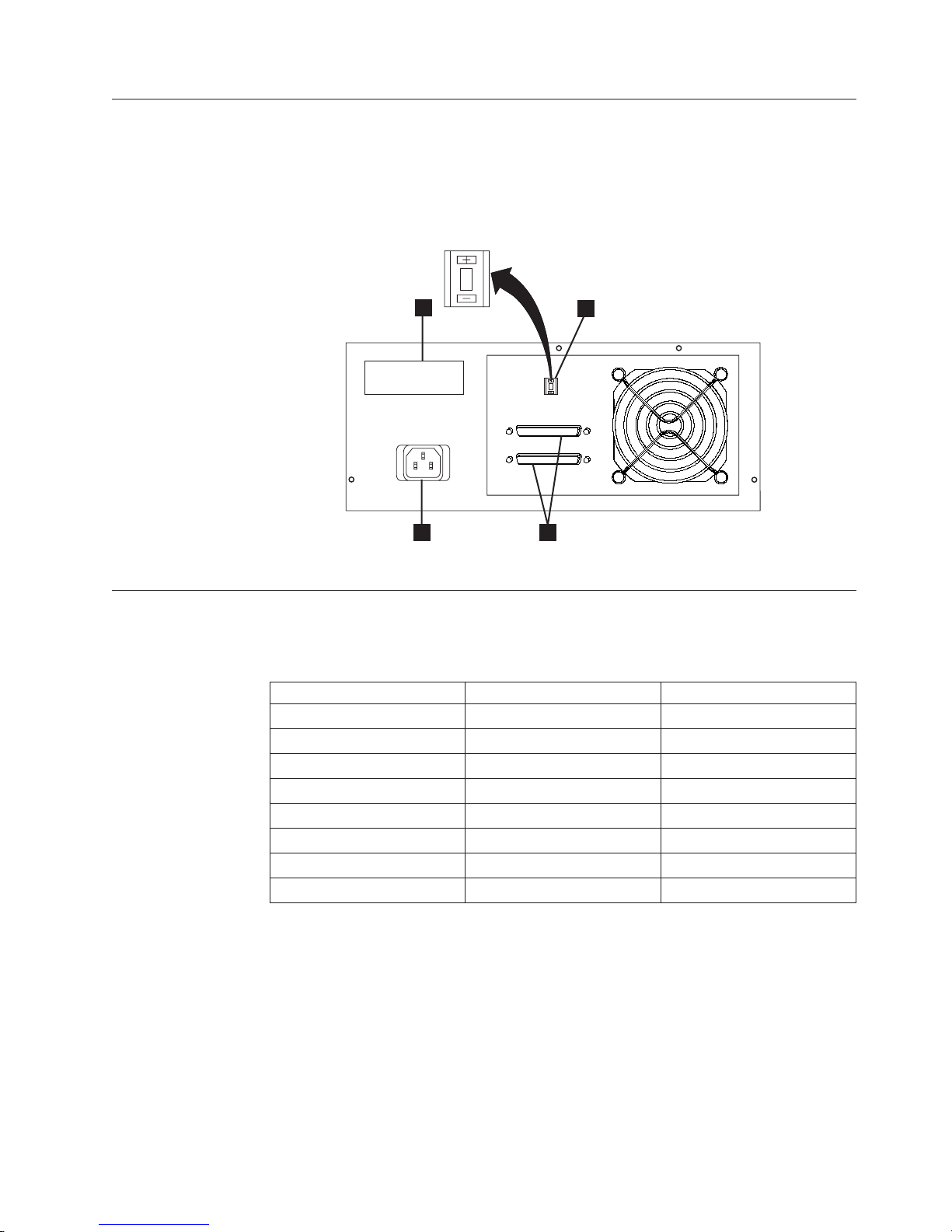

Rear Panel Components

1 Power receptacle 3 SCSI address switch

2 SCSI connectors 4 Serial number label

6

4

1

3

6

a67ru004

2

Figure 4. Rear panel components

3580 Models

Table 1 lists all 3580 models with associated SCSI attachment and drive type.

Table 1. 3580 Models

Model SCSI Attachment Tape Drive

L33 LV D Ultrium 3

L3H LV D Ultrium 3

L23 LV D Ultrium 2

H23 HVD Ultrium 2

L13 LV D Ultrium 1

L11 LVD Ultrium 1

H13 HVD Ultrium 1

H11 HVD Ultrium 1

Product Description 3

Page 22

Drive Performance

If you run applications that are highly dependent on tape-processing speed, take

advantage of the significant performance improvements provided by this tape

drive.

Table 2. Performance characteristics

Performance Characteristics Ultrium 3 Tape Drive

Native data rate 80 MB/s

(with Ultrium 3 media)

Maximum sustained data rate (at maximum compression) 135 MB/s (Ultra160)

Burst data rate for Low Voltage Differential (LVD) SCSI drives 160 MB/s (Ultra160)

Nominal load-to-ready time 15 seconds

Nominal unload time 15 seconds

Average search time to first byte of data 46 seconds

Maximum rewind time 88 seconds

Note: All sustained data rates are dependent on the capabilities of the interconnect (for example, an UltraSCSI bus

is limited to less than 40 MB/sec).

By using the built-in data-compression capability of the tape drive, greater data

rates than the native data transfer rate can be achieved. However, the actual

throughput is a function of many components, such as the host system processor,

disk data rate, block size, data compression ratio, SCSI bus capabilities, and system

or application software.

Supported Servers and Operating Systems

The 3580 attaches to many servers and many operating systems. To determine the

latest supported attachments, visit the web at http://www.ibm.com/storage/lto.

For specific instructions about attaching the 3580 , see “Configure the Tape Drive

to a Server/Host” on page 13.

4 IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Page 23

Supported Device Drivers

IBM offers device drivers which enable the tape drive to interact with a variety of

servers. To properly install an IBM device driver (if required), refer to the IBM

Ultrium Device Drivers Installation and User’s Guide. For applications that use other

device drivers, see the application’s documentation to determine which drivers to

use.

IBM maintains the latest levels of device drivers and driver documentation for the

Ultrium 3 tape products on the Internet. To access this material from your browser

or through the IBM FTP site, perform one of the following procedures. (Note: If

you do not have Internet access and you need information about device drivers,

contact your Marketing Representative.)

v Using a browser, type one of the following:

– http://www.ibm.com/storage/lto

– ftp://ftp.software.ibm.com/storage/devdrvr

– ftp://207.25.253.26/storage/devdrvr

v Using an IBM FTP site, enter the following specifications:

– FTP site: ftp.software.ibm.com

– IP Addr: 207.25.253.26

– Userid: anonymous

– Password: (use your current e-mail address)

– Directory: /storage/devdrvr

IBM

/storage/devdrvr/Doc directory:

v IBM_ultrium_tape_IUG.ps and IBM_ultrium_tape_IUG.pdf contain the current

version of the IBM Ultrium Device Drivers Installation and User’s Guide

v IBM_ultrium_tape_PROGREF.ps and IBM_ultrium_tape_PROGREF.pdf contain

the current version of the IBM Ultrium Device Drivers Programming Reference

Device

/storage/devdrvr/ in the following directories (the device driver for the iSeries

or AS/400

v AIX

v HPUX

v Linux

v Solaris

v Windows

TapeAlert Support

The tape drive is compatible with TapeAlert technology, which provides error and

diagnostic information to the server. For more information, see Appendix C,

“TapeAlert Flags,” on page 83.

provides PostScript- and PDF-formatted versions of its documentation in the

drivers and utilities for each supported server are beneath

®

server is included in the OS/400

®

®

®

®

operating system):

™

Product Description 5

Page 24

Specifications

The following are specifications for the tape drive. Specifications for tape cartridges

are given in “Environmental and Shipping Specifications for Tape Cartridges” on

page 40.

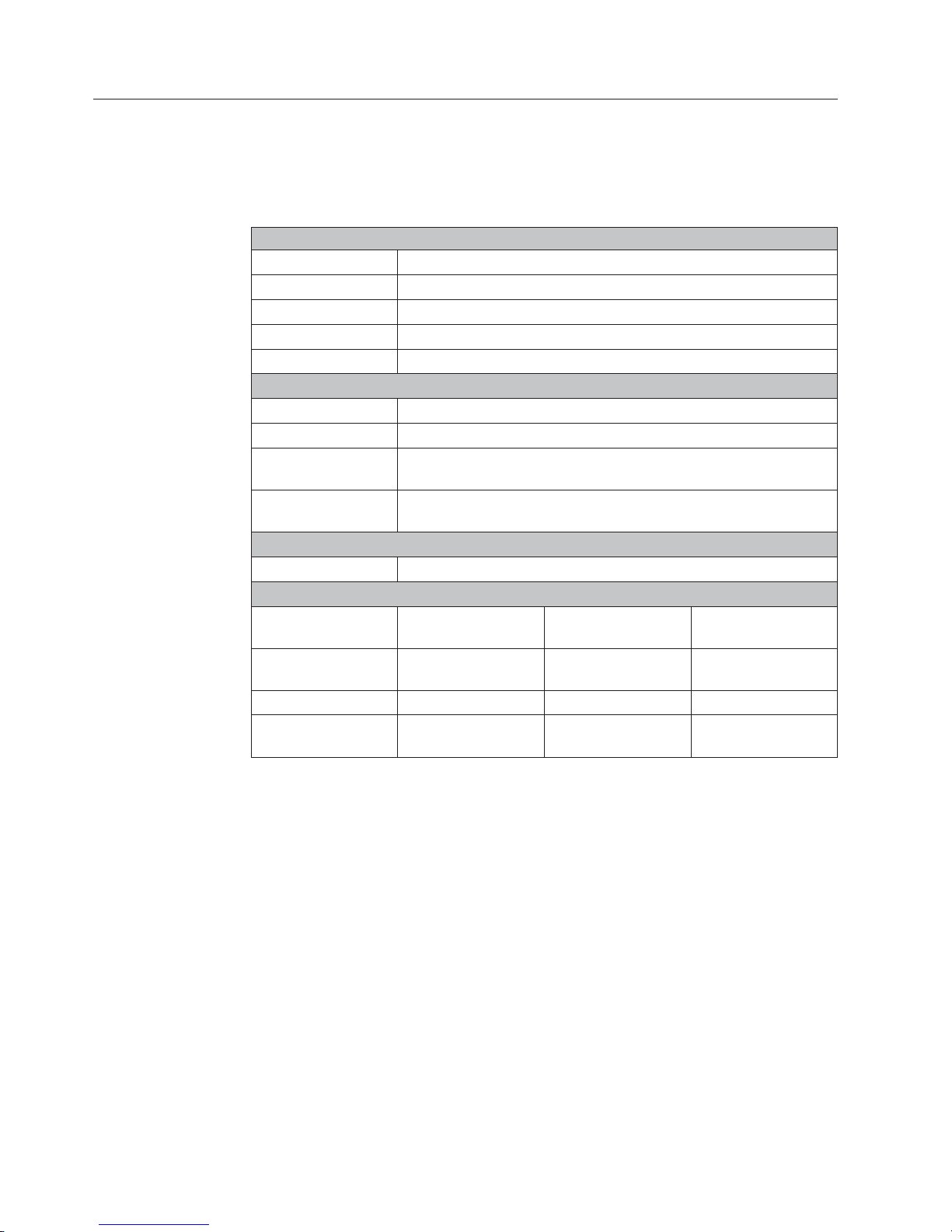

Table 3. Specifications

Physical Specifications

Specification Dimensions

Width 25.02 cm (9.85 in.)

Length 29.21 cm (11.5 in.)

Height 12.06 cm (4.75 in.)

Weight 6.45 kg (14.2 lbs.)

Power Specifications

AC line voltage 100 to 240 Vac

Line frequency 50 to 60 Hz, auto-ranging

Line current at 100

Va c

Line current at 240

Va c

1.0 A

0.5 A

Other Specifications

Maximum altitude 2500 m (8202 ft)

Environmental Specifications

Environmental

Factor

Temperature

Operating Storage Shipping

10 to 38°C

(50 to 100°F)

−40 to 60°C

(−40 to 140°F)

−40 to 60°C

(−40 to 140°F)

Relative humidity 20 to 80% 10 to 90% 10 to 90%

Maximum wet bulb

temperature

26°C

(79°F)

Non-condensing Non-condensing

6 IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Page 25

Installation

Attention

This is a customer setup unit. It is the customer’s responsibility to install this

product.

Installation Overview

Installation involves the following steps:

__ 1. “Unpack the Tape Drive” on page 8

__ 2. “Verify the Shipment” on page 8

__ 3. “Install the Rack Mount Kit (optional)” on page 8

__ 4. “Inspect the Power Cord and Outlet” on page 9

__ 5. “Set the SCSI ID” on page 9

__ 6. “Position the Tape Drive” on page 9

__ 7. “Connect Power” on page 10

__ 8. “Run Write Performance Test (Function Code F)” on page 10

__ 9. “Install the SCSI Host Adapter Card (if required)” on page 11

__ 10. “Connect the SCSI Bus Cable” on page 11

__ 11. “Install Device Drivers” on page 13

__ 12. “Configure the Tape Drive to a Server/Host” on page 13

__ 13. “Update Drive Firmware” on page 13

__ 14. “Register for My Support” on page 14

© Copyright IBM Corp. 2004, 2006 7

Page 26

Unpack the Tape Drive

Attention

If you return the unit for service, ship it in its original or equivalent packing

material, or the warranty may be invalidated.

__ 1. Inspect the unit for shipping damage. If there is damage, do not install the

__ 2. Locate the label on the rear panel of the unit with the machine type, model

Verify the Shipment

Ensure that the following items are included in the shipment:

__ 1. Power cord (For the appropriate cord for your country or region, see

__ 2. IBM TotalStorage LTO Ultrium 400 GB Data Cartridge

__ 3. IBM TotalStorage LTO Ultrium Cleaning Cartridge

__ 4. Single-connector SCSI wrap tool

__ 5. Device driver kit that includes:

6. A 2.5 m host-to-device SCSI bus (signal) cable

__

__ 7. A SCSI terminator

|

__ 8. Optional Rack Mount Kit

__ 9. The IBM TotalStorage 3580 Tape Drive Model L33/L3H Quick Reference,

__ 10. The IBM TotalStorage 3580 Tape Drive Model L33/L3H Setup, Operator, and

__ 11. The IBM Translated Safety Notices manual

unit. Report the damage immediately by contacting your place of purchase.

number, and serial number of the unit (see 4 in Figure 4 on page 3). Make

a note of these numbers and store them in an easily accessible place. Should

you need to contact Technical Support, you will be asked for these numbers.

“Power Cords” on page 56.)

v CD that contains the device drivers, the IBM Ultrium Device Drivers

Installation and User’s Guide, and the IBM Ultrium Device Drivers

Programming Reference

GC26-7709

Service Guide, GC26–7708 (this guide)

Install the Rack Mount Kit (optional)

Refer to Appendix D, “Installing a 19-inch Rack Mount Kit,” on page 85. If you did

not order the optional kit, proceed to “Inspect the Power Cord and Outlet” on

page 9.

If you ordered a 24-inch rack mount kit, refer to the installation instructions

included in the kit.

8 IBM TotalStorage 3580 Tape Drive Setup, Operator, and Service Guide

Page 27

Inspect the Power Cord and Outlet

__ 1. Inspect the power cord plug to ensure that it matches the power receptacle.

If it does not match, see “Power Cords” on page 56 to determine the

appropriate power cord.

__ 2. Ensure that all associated electrical outlets are properly grounded and that

the circuit breaker is turned on.

Set the SCSI ID

DANGER

An

electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices that

attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent

an electrical shock. (D004)

The SCSI ID is a unique address that identifies the unit to the server. To set the

SCSI ID:

__ 1. Refer to the following notes and decide what ID to assign to the unit.

Notes:

a. The range of SCSI IDs is 0 through 15. The priority of SCSI IDs is:

6, 5, 4, 3, 2, 1, 0, 15, 14, 13, 12, 11, 10, 9, 8.

7,

b. Do not select an ID that is already in use by any device on the SCSI bus.

c. Do not select the SCSI ID of the SCSI host adapter card. The priority of

this ID is usually higher than any device on the SCSI bus. Generally, the

SCSI ID for the host adapter is set to 7.

__ 2. Locate the SCSI address switch on the rear panel (see 3 in Figure 4 on

page 3).

__ 3. With a small, pointed object (such as a ballpoint pen), press the + or − push

button until the ID that you want displays on the switch.

Attention

If the SCSI ID is changed after installation, cycle power (turn it off then on

again) to activate the new SCSI ID.

Position the Tape Drive

Position the unit so it is convenient to the server. The only restrictions are the

length of the power cord and the length of the SCSI cable. Recommended locations

are:

v Away from high-traffic areas, especially if the floor is carpeted.

v Out of printer or copy rooms to avoid toner and paper dust. Do not store paper

supplies next to any unit.

v Away from moving air, such as doorways, open windows, fans, and air

conditioners.

v Off the floor.

v In a horizontal position.

Installation 9

Page 28

Connect Power

v Where the tape cartridge can be easily inserted.

The unit should not be stacked. Do not place anything on top of the unit.

__ 1. Ensure that the unit is powered off.

__ 2. Plug the power cord into the rear panel (see 1 in Figure 4 on page 3), then

plug the other end into a grounded electrical outlet.

__ 3. Ensure that a terminator (or SCSI bus with termination) is connected to one

of the two SCSI connectors at the rear of the unit. The Power-On Self Test

(POST) may not complete without SCSI termination.

__ 4. Power-on the unit by pressing the Power Button. The POST runs, which

checks all hardware except the drive head. During the POST, the

Single-character Display (SCD) flashes several segmented characters. Each

segmented character represents a test performed during the POST. When the

POST finishes, the SCD momentarily lights all segmented characters and

then goes blank.

Run Write Performance Test (Function Code F)

Approximate Run Time = 5 minutes

Total Number of Loops = 10

Function Code

to tape.

The diagnostic loops ten times. Press the Unload Button to stop the diagnostic and

exit maintenance mode. Pressing the Unload Button once will abort the test at the

end of the current test loop. Pressing the Unload Button twice will abort the test

immediately.

Attention

|

For this test, insert only a customer-supplied scratch (blank) data cartridge or

a cartridge that may be overwritten. During the test, the drive overwrites the

data on the cartridge.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 68.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

|

4. Insert a customer-supplied scratch (blank) data cartridge that is not

write-protected (or the tape drive will exit maintenance mode). The SCD

changes to a flashing

F

performs tests to ensure that the drive can read from and write

F

. The tape drive runs the tests.

F

appears in the SCD. (If you

C

.

10 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 29

Note: If you inserted an invalid or write-protected tape cartridge,

in the SCD. The tape drive unloads the cartridge and exits maintenance

mode.

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

temporarily appears in the SCD. The drive rewinds and unloads the tape,

partially ejects the cartridge, then exits maintenance mode. The solid amber

Status Light turns off.

v If the number of written data sets is at least 6% less than the total number of

data sets expected, the Status Light flashes amber, the tape drive posts an

error code to the SCD. To determine the error, locate the code in Table 13 on

page 61. The tape drive unloads the cartridge and exits maintenance mode.

To clear the error, turn the power off, then on again.

Install the SCSI Host Adapter Card (if required)

If there are no other devices attached to your server, an LV D SCSI host adapter

card may need to be installed in the server. To install an adapter, refer to the

instructions that accompany it, as well as to the section about SCSI card

installation in your server’s documentation. For a list of supported adapters and

required interposers, visit the web at http://www.ibm.com/storage/lto.

7

appears

0

Although the LV D hardware in the tape drive is capable of operating in the

single-ended (SE) mode, SE operation is not recommended or supported.

Connect the SCSI Bus Cable

For maximum performance, the quantity of tape drives that can be attached to one

SCSI bus is limited, and is based on the type of bus that you have and the amount

of data compression achieved. Ultra SCSI buses have a bandwidth of 40 MB per

second; Ultra2 SCSI buses have a bandwidth of 80 MB per second; Ultra160 SCSI

buses have a bandwidth of 160 MB per second. The tape drive is capable of data

transfer rates of up to 80 MB per second with no compression. For maximum

performance, it is recommended that you attach only one tape drive to an Ultra

SCSI bus, an Ultra2 SCSI bus, or an Ultra160 SCSI bus.

The SCSI bus cable connects the tape drive to the server. You can connect the SCSI

bus cable (and the terminator) to either SCSI connector on the tape drive. To

connect the cable:

__ 1. Ensure that the tape drive is powered off and plugged into the electrical

outlet.

__ 2. If the server’s SCSI bus is in operation, stop all activity on the bus that you

are connecting to (for instructions about how to stop SCSI bus activity, see

your server’s documentation).

__ 3. Determine the maximum allowable length of your bus cable.

v For an LV D bus with a single device, do not use a total cabling length

that exceeds 25 m (82 ft).

v For an LV D bus with multiple devices, do not use a total cabling length

that exceeds 12 m (39 ft).

Installation 11

Page 30

Attention

v Do not mix LVD and HVD SCSI host adapters, tape drives, or

terminators on the same bus, as they could become damaged.

v Data transfer protocol timeouts for tape and disk drives are very

dissimilar. For that reason, it is strongly recommended that you

avoid running tape and disk drives on the same host adapter. A

configuration with tape and disk on a single host adapter gives a

slow and unreliable performance.

|

|

|

v When connecting the tape drive to a server, be sure to use the SCSI

terminator (Part #23R5841), not the SCSI wrap tool (Part #23R5840

with white "Wrap Tool" label), to terminate the SCSI bus.

__ 4. Configure your tape drive similar to one of the following examples:

v If the tape drive is the only device on the SCSI Bus, connect the SCSI

bus cable to the server (see Figure 5).

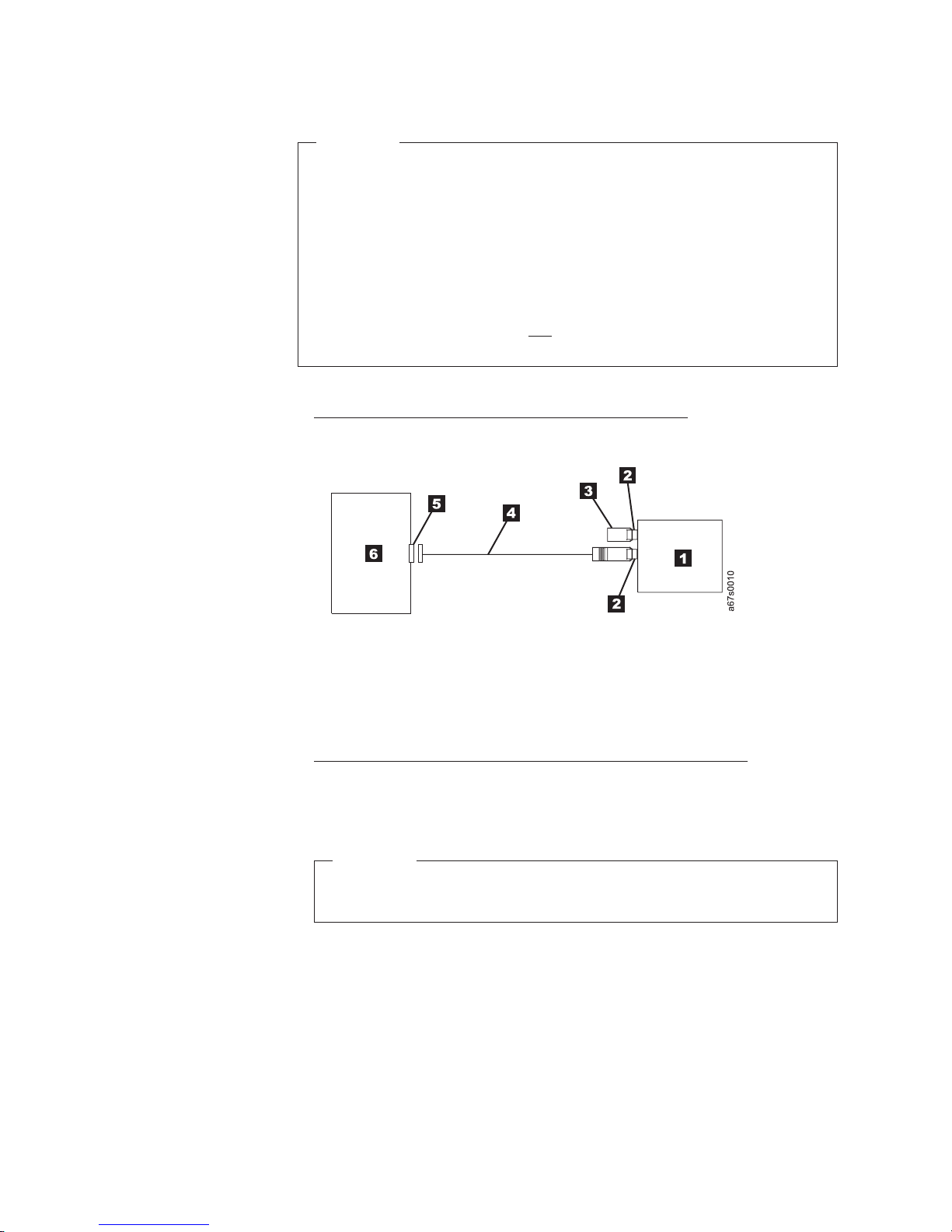

Figure 5. Example of connecting one SCSI device to the server. The view is from the top.

1 Tape drive 4 SCSI bus cable

2 SCSI connectors 5 SCSI host adapter card

3 Terminator 6 Server

v If the tape drive is one of multiple devices on the SCSI Bus, connect the

SCSI bus cable to the next device on the bus, and move the terminator to

the last device on the bus (see Figure 6 on page 13). For a drive with an

LV D SCSI interface, use a cable with a total length of 12 m (39 ft) or less.

Attention

Do not mix LV D and HVD/DIFF SCSI host adapters, tape drives, or

terminators on the same bus, as they could become damaged.

12 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 31

Figure 6. Example of connecting multiple SCSI devices to the server. The view is from the

top.

1 Tape drive 5 SCSI host adapter card

2 SCSI connectors 6 Server

3 Terminator 7 Another tape device

4 SCSI bus cable

Install Device Drivers

A device driver is firmware that enables the tape drive to interact with a variety of

servers. Refer to “Supported Device Drivers” on page 5 for instructions on

downloading the latest device drivers (the CD contains device drivers current at

time of manufacturing). Install device drivers as follows:

Note: If you intend to use the tape drive with a commercial software application,

it is recommended that you do not install any device driver from the CD

that was shipped with the tape drive, as conflicts could occur over which

driver controls the drive. Only install a device driver from the CD if the

instructions from your commercial software application tell you to do so.

v If you intend to use the tape drive with a commercial software application, refer

to that application’s installation instructions to install the device driver and

configure the tape drive.

v If you do not intend to use the tape drive with a commercial software

application, install the device driver from the CD that was shipped with the

drive. Refer to the installation instructions in the IBM Ultrium Device Drivers

Installation and User’s Guide, which is on the CD. The CD contains drivers and

installation instructions for supported operating systems.

Configure the Tape Drive to a Server/Host

__ 1. Power-on the unit.

__ 2. To configure the tape drive, refer to the documentation for your server/host

and application software.

Update Drive Firmware

As with all devices, it is recommended that you run the latest level of firmware

which can be downloaded by visiting http://www.ibm.com/storage/lto. Verify that

the latest level of firmware is installed on your machine before contacting IBM for

technical support (see “Procedure 1: Determining Firmware Level and Capturing

Drive Dump” on page 46). For information on updating drive firmware, see

“Updating Drive Firmware” on page 20.

Installation 13

Page 32

Register for My Support

My Support registration provides email notification when new firmware levels have

been updated and are available for download and installation. For more

information, see “Registering for My Support” on page iii.

14 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 33

Operation

Operation of the tape drive involves the following front panel components:

v Power Button

v Unload Button

v Single-character Display (SCD)

v Status Light

components allow the user to:

These

v Insert and remove a tape cartridge

v Perform diagnostic and maintenance functions

v Update drive firmware

Power Button

Unload Button

The Power Button is a push button that turns the tape drive on or off. The button

is located on the front panel (see 5 in Figure 3 on page 2). When the Power

Button is in the off position, the primary electrical power within the enclosure is

still active. To remove all electrical power to the enclosure, unplug the power cord

from the receptacle at the rear of the drive (see 1 in Figure 4 on page 3).

When the unit is powered-on but idle, the Status Light (see 3 in Figure 3 on page

2) is solid green; when it is performing a function, the Status Light is flashing

green.

The Unload Button (4 in Figure 3 on page 2) enables the following functions to

be performed:

v Rewind the tape into the cartridge and eject the cartridge.

v Enter or exit maintenance mode, or perform diagnostic or maintenance

functions. For more information, see Appendix B, “Performing Diagnostic and

Maintenance Functions,” on page 67.

v A panic reset.

Attention

If you press the Unload Button during host operation, the tape drive ends the

command that is being processed, and unloads and ejects the tape cartridge.

Note that (depending on its location on the reel) the tape may take as long as

10 minutes to completely rewind and eject.

© Copyright IBM Corp. 2004, 2006 15

Page 34

Single-character Display (SCD)

The SCD (2 in Figure 3 on page 2) presents a single-character code for:

v Error conditions and informational messages

v Diagnostic or maintenance functions (while in maintenance mode only)

Appendix

informational messages. If multiple errors occur, the code with the highest priority

(represented by the lowest number) displays first. When the error is corrected, the

code with the next highest priority displays, and so on until no errors remain.

Appendix B, “Performing Diagnostic and Maintenance Functions,” on page 67 lists

the single-character codes that represent diagnostic or maintenance functions. To

initiate a function the unit must be in maintenance mode. The SCD is blank during

normal operation.

SCD Dot

While in maintenance mode, the drive may display a single red dot in the

lower-right corner of the single character display

dump is available for downloading.

The dot flashes if a dump is in flash memory. The dot turns off when a dump is

copied to the server/host, to a tape cartridge, or to flash memory (see “Function

Code 5: Copy Drive Dump” on page 73).

A, “Error Codes,” on page 61 lists the codes for error conditions and

8

. This indicates that a drive

Attention

If you power off the drive before downloading the dump, the dump will be

lost.

Status Light

The Status Light (3 in Figure 3 on page 2) provides information about the state

of the unit. The light can be green or amber, and (when lit) solid or flashing.

Table 4 on page 17 lists the conditions of the Status Light and Single-character

Display (SCD) and provides an explanation of what each condition means. For any

condition other than those listed, the Status Light is not illuminated.

16 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 35

Table 4. Meaning of Status Light and Single-character Display (SCD)

If the

Status Light

is...

and the

SCD is...

Meaning

Off Off The drive has no power or is powered off.

Green Off The drive is powered on and in an idle state.

Flashing

Green

Flashing

Green

Off The drive is reading from the tape, writing to the tape, rewinding the tape, locating data

on the tape, loading the tape, or unloading the tape.

Off The drive contains a cartridge during the power-on cycle. In this case, the drive

completes POST and slowly rewinds the tape (the process may take up to 10 minutes).

The light stops blinking and becomes solid when the drive completes the recovery and is

ready for a read or write operation. To eject the cartridge, press the Unload Button.

Amber Displaying

Error Code

The drive is displaying error code(s) from the error code log on the SCD. For more

information, see “Function Code 9: Display Error Code Log” on page 75 and

Appendix A, “Error Codes,” on page 61.

Amber Red

The drive is powering on, resetting, or in maintenance mode.

numbers,

letters, or

segments

Amber Flashing

0

Amber Flashing

The drive is exiting from maintenance mode. For more information, see “Function Code

0: Exit Maintenance Mode” on page 68.

The drive is executing the selected function while in maintenance mode.

selected

function

Flashing

Amber once

per second

Flashing

Amber once

per second

Flashing

Amber

twice per

second

Displaying

error code

Displaying

C

Displaying

Function

Code

8

An error occurred and the drive or media may require service, or it may require cleaning.

Note the code on the SCD, then go to Table 13 on page 61 to determine the action that is

required.

The drive needs cleaning.

1

The drive is updating firmware.

The SCD will display a

8

if using an FMR cartridge.

The SCD will be off if using the SCSI interface. For more information, see “Updating

Drive Firmware” on page 20.

or Off

Flashing

Amber

Off The drive detected an error and is performing a firmware recovery. It will reset

automatically.

twice per

second

Flashing

Amber

twice per

Flashing

C

The drive is requesting a cartridge to be loaded.

second

Flashing

Off There is a drive dump in flash memory.

Amber

twice per

second

1

Power should not be removed from the drive until the microcode update is complete. The drive indicates that the

update is complete by resetting and performing POST.

Operation 17

Page 36

Inserting a Tape Cartridge

To insert a tape cartridge:

1. Power on the unit.

2. Ensure that the write-protect switch (1 in Figure 7) is set to the unlock

position (see “Write-Protect Switch” on page 28).

3. Grasp the cartridge so that the write-protect switch faces you.

4. Slide the cartridge into the tape load compartment (1 in Figure 3 on page 2)

until the cartridge loader draws the cartridge into the drive.

The Status Light will flash green, then become solid green. The Single-character

Display (SCD) will remain blank.

Notes:

a. If the cartridge is already in an ejected position and you want to reinsert it,

remove the cartridge then insert it again.

b. If the cartridge is already loaded and you cycle power (turn it off, then on),

the cartridge will reload.

c. If you set the write-protect switch so that data cannot be written to it (in the

locked position), the SCD will flash amber.

1

Figure 7. Inserting a cartridge

18 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

a67ru005

Page 37

Removing a Tape Cartridge

Attention

Failure to remove a cartridge before powering off the unit may result in

damage to the cartridge or to the drive.

To remove a cartridge:

1. Ensure that the unit is powered on.

Note: In the following step, the tape may take as long as 10 minutes to completely

rewind and eject (depending on its location on the reel).

Press the Unload Button. The Status Light will flash green while the tape

2.

rewinds. The drive then partially ejects the cartridge, and the Status Light will

turn off.

3. After the cartridge partially ejects, grasp the cartridge and remove it.

Mid-tape Recovery

If a power cycle or reset occurs while a cartridge is loaded, the drive will slowly

rewind the tape and eject the cartridge. The slow rewind may take up to 10

minutes.

Performing Diagnostic and Maintenance Functions

The tape drive can:

v Run drive diagnostics

v Update drive firmware from a field microcode replacement (FMR) tape

v Create an FMR tape

v Force a drive dump

v Copy a drive dump to tape

v Copy a drive dump to flash memory

v Erase flash memory

v Run a SCSI wrap test

v Convert an FMR tape to a blank tape

v Display the error code log

v Clear the error code log

v Test the tape cartridge and media

v Test the read/write function

v Test the drive head

To perform the preceding diagnostic and maintenance functions, place the drive in

|

maintenance mode. It is recommended that a customer-supplied scratch (blank)

data cartridge be used for diagnostic testing. For complete instructions about

performing each operation, see Appendix B, “Performing Diagnostic and

Maintenance Functions,” on page 67.

Operation 19

Page 38

Updating Drive Firmware

Attention:

v To ensure optimum performance, use the latest level of drive firmware. It is

the customer’s responsibility to obtain and install drive firmware.

v When updating firmware, do not power-off the drive until the update is

complete, or the firmware may be lost.

Periodically check for updated levels of drive firmware and the following

diagnostic tools by visiting the web at http://www.ibm.com/storage/lto. Update

drive firmware using:

v The ITDT tool

v The SCSI interface

v A field microcode replacement (FMR) tape cartridge

For instructions on obtaining a new firmware image or FMR tape, visit

http://www.ibm.com/storage/lto. To update the firmware, refer to the following

sections. To be notified by email of new levels of firmware available for

downloading, see “Registering for My Support” on page iii.

ITDT SCSI Firmware Update, Dump Retrieval, and

Library/Drive Test Tool

The ITDT tool offers multiple functional capabilities that simplify the task of

updating tape and library firmware. It is available for most major platforms

|

|

(Windows, AIX, Sun, Linux, and so on), and requires no special device drivers.

Note: The ITDT tool is available on the IBM website

http://www.ibm.com/storage/support/lto. In addition to the executable file

(.exe), a README file will be posted on the web page. The README file

describes the features and capabilities of the ITDT tool, provides

downloading instructions, and gives detailed information on how to use the

tool.

Yo u use the ITDT tool to perform the following tasks:

v Update firmware using SCSI to all IBM LT O Tape Drive and many Tape Library

products (non-IBM devices may not be selected).

v Upload drive and library dump files

v Perform drive and library diagnostics, including drive read/write diagnostics

ITDT tool is a command line utility. To invoke it, enter the executable itdt

The

from the directory where the tool is located. The Help feature gives a brief

explanation of each function and shows the required syntax.

Updating Firmware through the SCSI Interface

When updating drive firmware by using the SCSI interface, the procedure varies,

depending on whether your server uses an IBM tape device driver or a non-IBM

tape device driver (such as a driver from Sun, Hewlett-Packard, or Microsoft®).

20 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 39

For instructions about updating firmware from a server that uses an IBM tape

device driver, refer to the IBM Ultrium Device Drivers Installation and User’s Guide.

To update firmware from a server that uses a non-IBM tape device driver, refer to

the documentation for that device.

Updating the Firmware with an FMR Tape Cartridge

Tip

After creating an FMR tape (see “Function Code 3: Create FMR Tape” on

page 71), the firmware of multiple drives can be updated with the same FMR

tape. After updating the drive firmware, unmake the FMR tape (see

“Function Code 8: Unmake FMR Tape” on page 75) and use it as a data

cartridge.

To update the drive’s firmware from an FMR tape cartridge:

1. Ensure that a cartridge is not loaded in the drive.

2. Place the drive in maintenance mode by pressing the Unload Button three

times within two seconds. The Status Light becomes solid amber, which means

that the drive is in maintenance mode.

3. Press the Unload Button once per second until

hold the button for three seconds. When

cartridge.

4. Insert the FMR tape cartridge.

firmware from the cartridge, and the Status Light flashes amber. When the

update completes successfully,

8

flashes, the drive loads the updated

0

displays and the cartridge automatically

ejects.

8

C

displays, then press and

flashes, the drive is waiting for a

drive resets itself and automatically activates the new firmware.

The

If the update fails, an error code displays. To resolve the error, locate the code in

Table 13 on page 61.

Cleaning the Drive Head

Attention

When cleaning the drive head, use the IBM TotalStorage LTO Ultrium

|

Cleaning Cartridge (part number 35L2086). Yo u may use another LT O

cleaning cartridge, but it may not meet the standards of reliability established

by IBM.

Clean the drive head whenever

the Status Light is flashing amber once per second. It is not recommended that you

clean the drive head on a periodic basis; only when the drive requests to be

cleaned.

C

displays on the Single-character Display and

Operation 21

Page 40

To clean the head, insert the cleaning cartridge into the tape load compartment (see

Figure 7 on page 18). The drive performs the cleaning automatically. The cleaning

cycle takes less than two minutes. When the cleaning is finished, the drive ejects

the cartridge.

|

Note: Anytime a cleaning cartridge is inserted, the drive detects the cleaning

|

|

|

|

|

The IBM TotalStorage LTO Ultrium Cleaning Cartridge is valid for 50 uses.

Cleaning the Tape Drive

Clean the exterior surface of the tape drive with a damp towel. If a liquid

all-purpose cleaner is used, apply it to the towel. Do not spray the enclosure.

cartridge and starts one cleaning cycle. After the cleaning cycle is finished,

the drive will eject the cartridge.

If an expired or defective cleaning cartridge is inserted, the drive will eject

this cartridge without cleaning the drive, and the cleaning bit will remain

on.

22 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 41

Ultrium Media

To ensure that your IBM Ultrium Tape Drive conforms to IBM’s specifications for

reliability, use only IBM LTO Ultrium Tape Cartridges. You may use other

LTO-certified data cartridges, but they may not meet the standards of reliability

that are established by IBM. The IBM TotalStorage LTO Ultrium 400 GB Data

Cartridge cannot be interchanged with the media used in other IBM non-LTO

Ultrium tape products.

Figure 8 shows the IBM TotalStorage LTO Ultrium 400 GB Data Cartridge and its

components.

1 LTO cartridge memory 4 Write-protect switch

2 Cartridge door 5 Label area

3 Leader pin 6 Insertion guide

Figure 8. The IBM TotalStorage LT O Ultrium 400 GB Data Cartridge

Cartridge Compatibility

© Copyright IBM Corp. 2004, 2006 23

Table 5. Ultrium data and cleaning cartridge compatibility with Ultrium tape drive

IBM Ultrium Tape Drive

Ultrium 3 Read/Write Read/Write Read only

Ultrium 2 Read/Write Read/Write

Ultrium 1 Read/Write

IBM TotalStorage LTO Ultrium Data Cartridges

400 GB

(Ultrium 3)

200GB

(Ultrium 2)

(Ultrium 1)

100GB

Page 42

Data Cartridge

The different generations of IBM TotalStorage Ultrium data cartridges can be

identified by color:

Data Cartridge Case Color

Ultrium 3 Slate Blue

|

Ultrium 3 Write Once, Read Many (WORM) Slate Blue top; Grey bottom

Ultrium 2 Purple

Ultrium 1 Black

All three generations contain 1/2-inch, dual-coat, metal-particle tape. The native

data capacity of Ultrium data cartridges is as follows:

Data Cartridge Native Data Capacity

Ultrium 3 400 GB (800 GB at 2:1 compression)

Ultrium 2 200 GB (400 GB at 2:1 compression)

Ultrium 1 100 GB (200 GB at 2:1 compression)

When processing tape in the cartridges, Ultrium Tape Drives use a linear,

serpentine recording format.

v The Ultrium 3 drive reads and writes data on 704 tracks, 16 tracks at a time.

v The Ultrium 2 drive reads and writes data on 512 tracks, 8 tracks at a time.

v The Ultrium 1 drive reads and writes data on 384 tracks, 8 tracks at a time.

The first set of tracks (16 for Ultrium 3; 8 for Ultrium 2 and 1) is written from near

the beginning of the tape to near the end of the tape. The head then repositions to

the next set of tracks for the return pass. This process continues until all tracks are

written and the cartridge is full, or until all data is written.

The cartridge door (2 in Figure 8 on page 23) protects the tape from

contamination when the cartridge is out of the drive. Behind the door, the tape is

attached to a leader pin (3). When the cartridge is inserted into the drive, a

threading mechanism pulls the pin (and tape) out of the cartridge, across the drive

head, and onto a non-removable take-up reel. The head can then read or write data

from or to the tape.

The write-protect switch 4 prevents data from being written to the tape cartridge

(see “Write-Protect Switch” on page 28). The label area 5 provides a location to

place a label (see “Bar Code Label” on page 26). The insertion guide 6 is a large,

notched area that prevents the cartridge from being inserted incorrectly.

Yo u can order tape cartridges with bar code labels included, or you can order

custom labels. To obtain tape cartridges and bar code labels, see “Ordering Media

Supplies” on page 42.

All generations of the LTO Ultrium Data Cartridge have a nominal cartridge life of

5000 load and unload cycles.

24 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 43

Capacity Scaling

To control the capacity of the cartridge (for example, to obtain a faster seek time)

issue the SCSI command SET CAPACITY. For information about this command,

refer to the IBM TotalStorage LTO Ultrium Tape Drive SCSI Reference.

|

WORM (Write Once, Read Many)

|

|

|

|

|

|

|

|

|

|

|

WORM Media

|

|

|

|

|

|

||

|

Certain records retention and data security applications require a Write Once, Read

Many (WORM) method for storing data on tape. To meet this data storage

requirement, a new WORM feature has been made available on IBM LTO Ultrium

generation 3 drives. The WORM feature can be enabled by upgrading to

WORM-capable drive firmware and using a special WORM tape cartridge (see

“WORM Media”).

No physical hardware changes are required to make Ultrium 3 drives compatible

with the WORM feature; however, appropriate WORM-capable drive firmware

must be installed. See “Requirements” on page 26 for minimum drive firmware

requirements.

Because standard read/write media are incompatible with the WORM feature, a

specially formatted WORM tape cartridge (see Figure 9) is required. Each WORM

cartridge has a unique, worldwide cartridge identifier (WWCID), which comprises

the unique CM chip serial number and the unique tape media serial number. See

“Ordering Media Supplies” on page 42 for information on how to choose and

purchase the appropriate WORM tape cartridges for your library.

|

|

Figure 9. Ultrium 3 WORM Tape Cartridge

|

|

|

|

|

|

|

|

|

|

|

|

Data Security on WORM Media

Certain built-in security measures help ensure that the data written on a WORM

cartridge does not become compromised, for example:

v The format of an IBM Ultrium 3 400 GB WORM Tape Cartridge is unlike that of

standard read/write media. This unique format prevents a drive that lacks

WORM-capable firmware from writing on a WORM tape cartridge.

v When the drive senses a WORM cartridge, the firmware prohibits the changing

or altering of user data already written on the tape. The firmware keeps track of

the last appendable point on the tape.

WORM Media Errors

The following conditions cause WORM media errors to occur:

a66ug050

Using Ultrium Media 25

Page 44

|

|

|

|

|

|

|

|

|

Requirements

|

|

|

|

|

|

|

|

Cleaning Cartridge

v Information in the servo manufacturer’s word (SMW) on the tape must match

information from the cartridge memory (CM) module in the cartridge. If it does

not match, a media Error Code 7 will post on the drive’s single-character display

(SCD).

v Inserting a WORM tape cartridge into a drive that is not compatible with

WORM causes the cartridge to be treated as an unsupported medium. The drive

will report a media Error Code 7. Upgrading the drive firmware to the correct

code level will resolve the problem.

To add WORM capability to your IBM LTO Ultrium generation 3 drive(s), you

need the following:

v IBM Ultrium 3 400 GB WORM tape cartridge(s) (see “Ordering Media Supplies”

on page 42)

v Firmware release 54xx or higher

Note: See “Updating Drive Firmware” on page 20 for instructions on upgrading

drive firmware.

With each drive, a universal IBM LTO Ultrium Cleaning Cartridge is supplied to

clean the drive heads. The drive itself determines when a head needs to be

cleaned. It alerts you by displaying

C

on the single-character display and the

status light flashing amber. To clean the head, insert the cleaning cartridge into the

tape load compartment (see Figure 7 on page 18). The drive performs the cleaning

automatically. When the cleaning is finished, the drive ejects the cartridge.

Bar Code Label

|

Note: If a cleaning cartridge is inserted when the drive does not need to be

cleaned or when the cartridge has expired, the drive will automatically eject

the cartridge. (The IBM Cleaning Cartridges are valid for 50 uses.)

To remove a cleaning cartridge, see “Removing a Tape Cartridge” on page 19.

A bar code label contains:

v A volume serial number (VOLSER) that is human-readable

v A bar code that a bar code reader can read

Table 6. Bar code label requirements for Ultrium tape drives and libraries

Ultrium Tape Drive/Library Bar Code Label Requirements

3580 Not required

3581 Required

3582 Required

3583 Required

TS3310 (3576) Required

3584 Required

26 IBM TotalStorage 3580 Ta pe Drive Setup, Operator, and Service Guide

Page 45

When read by a bar code reader, the bar code identifies the cartridge’s VOLSER to

the library. The bar code also identifies the cartridge is a data cartridge or cleaning

cartridge. In addition, the bar code includes the two-character media-type identifier

Lx, where x equals 1, 2, or 3. L identifies the cartridge as an LTO cartridge. 1

indicates that the cartridge is the first generation of its type; 2 indicates that the

cartridge is the second generation of its type; 3 indicates that the cartridge is the

third generation of its type. Figure 10 shows a sample bar code label for the LT O

Ultrium Tape Cartridge.

Tape cartridges can be ordered with the labels included or with custom labels. To

order tape cartridges and bar code labels, see “Ordering Media Supplies” on page

42. Bar code usage in IBM tape products must meet predefined specifications. They

include (but are not limited to):

v Eight uppercase alphanumeric characters, where the last two characters must be

L3, L2, or L1

v Label and printing to be non-glossy

v Nominal narrow line or space width of 0.423 mm (0.017 in.)

v Wide to narrow ratio of 2.75:1

v Minimum bar length of 11.1 mm (0.44 in.)

determine the complete specifications of the bar code and the bar code label,

To

visit the web at http://www.ibm.com/storage/lto, or contact your IBM Sales

Representative.

When attaching a bar code label to a tape cartridge, place the label only in the

recessed label area (see 5 in Figure 8 on page 23). A label that extends outside of

the recessed area can cause loading problems in the drive.

Attention

Do not place any type of mark on the white space at either end of the bar

code. A mark in this area may prevent a bar code reader from reading the

label.

TO123L3

L

Figure 10. Sample bar code label on the LTO Ultrium 3 Tape Cartridge. The volume serial

number (LTO123) and bar code are printed on the label.

Guidelines for Using Bar Code Labels

Apply the following guidelines whenever using bar code labels:

v Use only IBM-approved bar code labels on cartridges to be used in an IBM tape

product.

v Do not reuse a label or reapply a used label over an existing label.

a69i0082

Using Ultrium Media 27

Page 46

v Before applying a new label, remove the old label by slowly pulling it at a right

angle to the cartridge case.

v Use peel-clean labels that do not leave a residue after being removed. If there is

glue residue on the cartridge, remove it by gently rubbing it with your finger.

Do not use a sharp object, water, or a chemical to clean the label area.

v Examine the label before applying it to the cartridge. Do not use the label if it

has voids or smears in the printed characters or bar code (a library’s inventory

operation will take much longer if the bar code label is not readable).

v Remove the label from the label sheet carefully. Do not stretch the label or cause