Page 1

IBM TotalStorage™Network Attached Storage 300

Model 325

Service Guid e

Page 2

Page 3

IBM TotalStorage™Network Attached Storage 300

Model 325

Service Guid e

Page 4

NOTE

Before using this information and the product it supports read the safety information in “Appendix I. Notices” on page 173.

First Edition (July 2001)

This guide applies to the IBM TotalStorage

Order publications through your IBM representative or the IBM branch office servicing your locality. Publications are

not stocked at the address below.

IBM welcomes your comments. A form for reader’s comments is provided at the back of this publication. If the form

has been removed, you may address your comments to:

International Business Machines Corporation

Design & Information Development

Department CGFA

PO Box 12195

Research Triangle Park, NC 27709–9990

U.S.A.

You can also submit comments to www.ibm.com/networking/support/feedback.nsf/docsoverall.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any

way it believes appropriate without incurring any obligation to you.

© Copyright International Business Machines Corporation 2001. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

™

Network Attached Storage 300.

Page 5

Contents

About this guide ........................vii

Frequently used terms ......................vii

Publications ..........................vii

Hardcopy publications shipped with the Network Attached Storage .....vii

Related publications ......................vii

Accessibility .........................viii

Web sites ...........................viii

Getting help online ......................viii

Other helpful sites.......................viii

Online support .........................viii

Chapter 1. General checkout ...................1

Checkout Steps .........................1

Checking out the engines ....................1

Checking out the Fibre Channel hub ................2

Checking out the RAID storage controller and the storage units ......2

Chapter 2. Introduction ......................3

IBM NAS 300 overview ......................3

IBM NAS 300 engines.......................3

Features...........................3

Components .........................4

Fibre Channel hub ........................4

GBICs ...........................5

Serial port connection ......................5

Ethernet connection ......................5

RAID storage controller ......................5

Features...........................6

Components .........................6

Storage Unit ..........................9

Features...........................9

Components .........................10

Supported software applications ..................14

Chapter 3. Troubleshooting....................15

Troubleshooting the engines ....................15

Diagnostic tools overview ....................15

Identifying problems using LEDs .................15

POST ...........................16

Diagnostic programs and error messages ..............17

Recovering BIOS .......................20

Troubleshooting the planar Ethernet controller ............20

10/100 Ethernet Adapter troubleshooting chart ............22

Gigabit Ethernet SX adapter troubleshooting chart ...........23

Running adapter diagnostics ...................25

Power checkout .......................27

Replacing the battery .....................28

Temperature checkout .....................29

Troubleshooting the Fibre Channel hub ................30

System reported error or failure to access a device ..........30

Visually inspect LEDs .....................30

Check for problems on attached devices ..............30

Checking the Fibre Channel hub .................30

© Copyright IBM Corp. 2001 iii

Page 6

Service References ......................31

Troubleshooting the RAID storage controllers and storage units .......35

Checking the LEDs ......................36

Powering the IBM NAS 300 on and off ................42

Powering on when clustering is active ...............42

Powering off when clustering is active ...............43

Emergency Shutdown .....................43

Chapter 4. Symptom-to-FRU index .................45

Engine Symptom-to-FRU index ...................45

Power-on self-test .......................45

Beep symptoms .......................45

No Beep symptoms ......................47

Information panel system error LED ................48

Diagnostic error codes .....................49

Error symptoms .......................52

Fibre Channel hub Symptom-to-FRU index ..............63

RAID storage controller Symptom-to-FRU index.............63

Storage unit Symptom-to-FRU index .................64

Chapter 5. Installing and replacing IBM NAS 300 components ......67

Safety information ........................67

Before you begin ........................67

Handling static-sensitive devices .................67

Working inside a IBM NAS 300 component while power is on.......67

System reliability considerations .................67

Installing and replacing IBM NAS 300 engine components .........68

Major components ......................68

Installation and replacement procedures ..............70

Replacing the entire engine ....................85

Installing and replacing RAID storage controller components ........85

Handling static-sensitive devices .................85

Working with hot-swap drives ..................85

Working with hot-swap cooling fans ................88

Working with hot-swap power supplies ...............89

Working with hot-swap RAID controllers...............93

Replacing the battery in the RAID controller .............96

Installing GBICs and fiber optic cables ...............99

Installing and replacing storage unit components ............102

Handling static-sensitive devices .................102

Working with hot-swap drives ..................103

Working with hot-swap power supplies ...............105

Working with hot-swap ESM boards................107

Working with GBICs .....................108

Working with hot-swap cooling fans ................108

Working with the Fibre Channel hub.................110

Chapter 6. Using system-level utilities ...............111

Using the Configuration/Setup Utility program .............111

Starting the Configuration/Setup Utility program ...........111

Choices available from the Configuration/Setup main menu .......111

Using passwords .......................115

Using the SCSISelect utility program ................117

Starting the SCSISelect utility program...............117

Choices available from the SCSISelect menu ............117

iv IBM NAS 300 Service Guide

Page 7

Appendix A. FRU information (service only).............121

Removing the LED cover.....................121

Removing the on/off reset board ..................121

Removing the diskette/CDROM drive ................122

Removing the LED board ....................122

Removing the SCSI backplane assembly ...............123

Removing the hot-swap hard disk drive backplane ...........123

Removing the power supply backplane ...............124

Removing the AC Distribution Box .................124

Removing the system board ...................125

Appendix B. Parts listing ....................127

Fibre Channel hub 3535–1RU...................127

Engine 51875–RZ.......................127

RAID storage controller 5191–2RU.................128

Storage Unit 5192–1RU.....................129

Power Cords .........................129

Signal cables .........................129

Appendix C. PCI Adapter Placement................131

Appendix D. Power Cable Placement ...............133

Appendix E. Signal Cable Placement ...............135

Appendix F. Fibre Channel hub Diagnostics.............141

General information.......................141

Isolating a system fault ....................141

Removing power .......................141

Running diagnostics on the Fibre Channel hub.............141

Attaching to the serial port while the Fibre Channel hub is off ......141

Attaching to the serial port while the Fibre Channel hub is on ......142

Running diagnostics from a Telnet session on the Ethernet .......142

Power-on self tests ......................143

Diagnostic commands ......................143

ramTest ..........................144

portRegTest ........................144

centralMemoryTest ......................145

cmiTest ..........................145

camTest ..........................146

portLoopbackTest ......................146

sramRetentionTest ......................148

cmemRetentionTest......................148

crossPortTest ........................148

spinSilk ..........................151

diagClearError........................153

diagDisablePost .......................153

diagEnablePost .......................153

diagShow .........................153

setGbicMode ........................154

supportShow ........................154

Diagnostic error message formats .................155

Error message numbers ....................156

Error message tables .....................156

Appendix G. Shared storage setup ................161

Contents v

Page 8

Starting Enterprise Management ..................162

Renaming storage subsystems .................163

Starting Subsystem Management..................163

Creating arrays and logical drives ................163

Creating Quorum arrays and LUNs under the Storage Manager 7

application ........................163

Format the logical drives ....................164

Configure the fibre-attached storage ...............165

Appendix H. Fast!UTIL options ..................167

Configuration settings ......................167

Host adapter settings .....................167

Selectable boot settings ....................168

Restore default settings ....................168

Raw NVRAM data ......................168

Advanced adapter settings ...................168

Extended Firmware Settings ..................170

Scan Fibre Channel Devices ...................171

Fibre Disk Utility ........................171

Loopback Data Test ......................172

Select Host Adapter ......................172

Appendix I. Notices ......................173

Safety and environmental notices .................173

Safety notices ........................174

Environmental notices .....................209

Index ............................213

vi IBM NAS 300 Service Guide

Page 9

About this guide

This guide provides service procedures for the IBM TotalStorage™Network

Attached Storage 300.

Frequently used terms

The following list of terms, used within this document, have these specific

meanings:

Term Definition in this document

Drive bay A receptacle into which you insert a hard disk drive in an appliance.

Engine The processor that responds to requests for data from clients. This

Storage unit Hardware that contains one or more drive bays, power supplies,

Notes These notices provide important tips, guidance, or advice.

Attention These notices indicate possible damage to programs, devices, or

The bays could be physically located in a separate rack from the

appliance.

is where the operating software for the NAS 300 appliance resides.

and a network interface. Some storage units contain a RAID

controller. There are no other components in a storage unit, and it

is accessed by a NAS appliance.

data. An attention notice is placed just before the instruction or

situation in which damage could occur.

Caution These notices indicate situations that can be potentially hazardous

to you. A caution notice is placed just before descriptions of

potentially hazardous procedure steps or situations.

Danger These notices indicate situations that can be potentially lethal or

extremely hazardous to you. A danger notice is placed just before

descriptions of potentially lethal or extremely hazardous procedure

steps or situations.

Publications

Hardcopy publications shipped with the Network Attached Storage

The following publications are shipped in hardcopy and are also provided in

softcopy form at www.ibm.com/storage/support/nas:

v IBM TotalStorage Network Attached Storage 300 Hardware Installation Guide,

GA27-4275

This publication provides procedures for setting up, cabling, and replacing

components of the IBM TotalStorage Network Attached Storage .

v Release Notes

This document provides any changes that were not available at the time this

publication was produced.

Related publications

The following publications contain additional information about the NAS 300:

v IBM TotalStorage Network Attached Storage User’s Reference, GA27-4276

v IBM TotalStorage Network Attached Storage Installation Guide, GA27-4275

© Copyright IBM Corp. 2001 vii

Page 10

v Safety Information, 44L2247

Accessibility

The softcopy version of this guide and the other related publications are all

accessibility-enabled for the IBM Home Page Reader.

Web sites

Getting help online

www.ibm.com/storage/support/nas

Here you can visit a support page that is specific to your hardware, complete with

FAQs, parts information, technical hints and tips, technical publications, and

downloadable files, if applicable.

Other helpful sites

www.ibm.com Main IBM home page

www.ibm.com/storage IBM Storage home page

www.ibm.com/storage/support/nas IBM NAS Support home page

www.ibm.com/storage/nas IBM NAS products

www.tivoli.com Tivoli

www.cdpi.com Columbia Data Products

Online support

Use the following Web site to obtain online support:

www.storage.ibm.com/support/nas

viii IBM NAS 300 Service Guide

Page 11

Chapter 1. General checkout

This chapter describes general checkout for the IBM TotalStorage™Network

Attached Storage 300, hereafter referred to as the IBM NAS 300.

For the IBM NAS 300 engines, diagnostic programs are stored in upgradable

read-only memory (ROM). These programs are the primary method of testing the

major internal components of the IBM NAS 300 engines (the system boards, planar

Ethernet controllers, RAM, CD-ROMs, diskette drives, serial ports, hard drives, and

parallel ports). See “Diagnostic programs and error messages” on page 17.

Also, if you cannot determine whether a problem is caused by the hardware or by

the software, you can run the diagnostic programs to confirm that the hardware is

working correctly.

For the RAID storage controllers and storage units, use the status LEDs,

Symptom-to-FRU list, and the storage management software to diagnose problems.

Note: To display certain error messages and run certain diagnostics programs

described in this guide, you need to attach (before power-up) a monitor,

keyboard, and mouse to the engine.

When you run the diagnostic programs, a single problem might cause several error

messages. When this occurs, work to correct the cause of the first error message.

After the cause of the first error message is corrected, the other error messages

might not occur the next time you run the test.

Notes:

1. If multiple error codes are displayed, diagnose the first error code displayed

(see “Diagnostic error codes” on page 49).

2. If the appliance engine hangs with a POST error, go to “POST error codes” on

page 53.

3. If the appliance engine hangs and no error is displayed, go to “Undetermined

problems” on page 62.

4. Power supply problems, see “Power supply LED errors” on page 52.

5. Safety information, see “Appendix I. Notices” on page 173.

6. For intermittent problems, check the error log; see “Event/error logs” on

page 17.

Checkout Steps

Checking out the engines

Perform the following steps:

1. Power-off the engine.

2. Check all cables and power cords.

3. Power-on the engine.

4. Record any POST error messages displayed on the screen. If an error is

displayed, look up the first error in the “POST error codes” on page 53.

5. Check the information LED panel System Error LED; if on, see “Information

panel system error LED” on page 48.

© Copyright IBM Corp. 2001 1

Page 12

6. Check the System Error Log. If an error was recorded by the system, see

“Chapter 4. Symptom-to-FRU index” on page 45.

7. Start the Diagnostic Programs. See “Starting the diagnostic programs” on

page 18 .

8. Check for the following responses:

a. Beeps

b. Readable instructions or the Main Menu

9. If the diagnostics completed successfully and you still suspect a problem, see

“Undetermined problems” on page 62.

Checking out the Fibre Channel hub

Perform the following steps:

1. Verify that all external covers are present and not damaged.

2. Ensure that all latches and hinges are in correct operating condition.

3. Check the power cord for damage.

4. Check the external signal cable for damage.

5. Check the cover for sharp edges, damage, or alterations that expose the

internal parts of the device.

6. Correct any problems that you find.

Checking out the RAID storage controller and the storage units

Use the status LEDs, Symptom-to-FRU list, and the storage management software

to diagnose problems. For information about diagnosing possible problems, see

“Troubleshooting the RAID storage controllers and storage units” on page 35.

Note: If power was just applied to the RAID storage controller, the green and

amber LEDs might turn on and off intermittently. Wait until the RAID storage

controller finishes powering up before you begin checking for faults.

2 IBM NAS 300 Service Guide

Page 13

Chapter 2. Introduction

The IBM NAS 300 is a storage appliance that allows you to easily attach storage to

a network. Because it is an appliance, you do not need to know about the internal

operating system.

IBM NAS 300 overview

The IBM NAS 300 is a rack-mounted storage server consisting of the following

components:

Engines

Two IBM 5187 Network Attached Storage Model 5RZ engines. These act as

a ″gateway″ between your Ethernet network and the network-attached

storage.

Fibre Channel Hubs

Two IBM 3534 Fibre Channel Hub Model 1RUs. These devices connect the

engines to the storage controller.

RAID Storage Controller

An IBM 5191 RAID Storage Controller Model 2RU. This device delivers fast,

high-volume data transfer, retrieval, and storage functions across multiple

drives, to multiple hosts. Optionally, a second storage controller can be

added to the IBM NAS 300 to increase the number of hard drives available.

Storage Units

IBM NAS 300 engines

The IBM NAS 300 comes standard with two IBM TotalStorage Network Attached

Storage Models 5RZ engines.

Features

Each engine includes the following standard features:

v Dual 933 MHz processors

v 1–GB memory

v 1–port Fibre Channel adapter

v 1–built-in 10Base-T/100Base-TX Ethernet controller

v 9.1–GB hard disk drive

v Dual 270–W redundant power supplies

You can add the following features to each of the IBM NAS 300 engines:

v IBM 10/100 Ethernet Server adapters

v IBM Gigabit Ethernet SX Server adapters

v Netfinity Advanced System Management PCI Adapter

v IBM PCI Fast/Wide Ultra SCSI Adapter

Multiple IBM 5192 Network Attached Storage Storage Unit Model 1RU.

These optional 10–drive expansion units add additional Fibre Channel (FC)

disk storage.

For additional information about installing these adapters in the PCI slots, see

“Appendix C. PCI Adapter Placement” on page 131.

© Copyright IBM Corp. 2001 3

Page 14

Components

The following sections show the components of the engine.

Note: The hot-swap features of the engine enable you to remove and replace hard

disk drives, power supplies, and fans without powering off the engine.

Therefore, you can maintain the availability of your system while a hot-swap

device is removed or replaced.

The following is a list of compnents found in each engine:

Microprocessors

Each engine comes with two 933 MHz Pentium III processors.

Memory modules

Each engine contains two 512 MB memory modules.

Non hot-swap drives

Each engine contains a 3.5–inch diskette drive and a compact disk drive.

Hot-swap hard disk drive

Each engine comes with one hot-swap hard disk drive. This drive is used

by the engine’s operating system.

Hot-swap fans

Each engine has three interchangeable hot-swap and redundant fans. If

one fan fails, the other fans continues to operate. All fans must be installed

to maintain proper cooling within your engine, even if one fan is not

operational.

Hot-swap power supplies

PCI adapters

Fibre Channel hub

The IBM NAS 300 Fibre Channel hub is an eight-port Fibre Channel hub that

includes seven fixed short-wave optic ports, one gigabit interface converter (GBIC)

port, and an operating system for building and managing a switched-loop

architecture.

The hub is a high-performance fiber optic hub with the following characteristics:

v Easy-to-use — After the power-on self-test (POST) completes, you need only to

add the IP address of the hub. The remainder of the hub’s configuration is

automated.

v Flexible — GBIC modules and fixed optic ports support fibre transmission media.

v Reliable — Hub uses highly integrated, multifunction application specific

integrated circuit (ASIC) components.

v High Performance — Hub has a data transfer latency of less than 2

microseconds transferring data from any port ot any port at peak Fibre Channel

bandwidth of 100 MB per second when there is no port contention.

Each engine comes with two hot-swap power supplies. Both power supplies

must be installed to maintain proper cooling.

Each engine has four available PCI slots. You can add optional Ethernet,

ASM, and SCSI adapters. For more information about optional adapters,

refer to the IBM NAS 300 Installation Guide.

4 IBM NAS 300 Service Guide

Page 15

GBICs

Each IBM NAS 300 Fibre Channel hub accommodates one short-wavelength (SWL)

GBIC module. The SWL fiber optic GBIC module, with SC connector color-coded

black, is based on short-wavelength lasers supporting 1.0625 GB per second link

speeds. This GBIC module supports 50-micron multimode fiber optic cables (up to

500 meters in length) and 62.5-micron multimode fiber optic cables (up to 175

meters in length). The GBIC module is shipped with a protective plug in place and

should remain in place if no fiber optic cable is connected to the port.

Serial port connection

The Fibre Channel hub includes a serial port, which is used to set the IP address

when setting up, reinitializing the Fibre Channel hub, or running diagnostics. The

serial port connection is not used during normal operation.

The settings of the serial port are as follows:

v 8-bit

v No parity

v One stop bit

v 9600 baud

v Flow Control = None

v Emulation = Auto Detect

Note: The serial port and Telnet connection are mutually exclusive. There can be

only one serial port session active at a time. Telnet takes priority, so the

serial port is terminated when a Telnet connection is made. The serial

connection is restored after the Telnet session is completed. Logging in

again is required. A password is required to login to the serial port session

as password checking is skipped only at initial power on.

Ethernet connection

The Ethernet port allows you to connecting the Fibre Channel hub to an existing

10/100BaseT Ethernet local area network (LAN). This Ethernet port provides the

following functions:

v Provides access to the Fibre Channel hub’s internal SNMP agent

v Permits remote Telnet and Web access for remote monitoring and testing

v Permits the setting or changing of the IP address

Note: The Ethernet port is only for Telnet, SNMP agent, and the Web-based server

access. No fabric connection is used with this connection.

RAID storage controller

The IBM NAS 300 RAID storage controller comes with two RAID controllers, two

power supplies, and two cooling units, and provides dual, redundant controllers,

redundant cooling, redundant power, and battery backup of the RAID controller

cache.

The IBM NAS 300 RAID storage controller supports Fibre Channel.Itisanew

technology, similar to a high-speed network, that you can use to connect large

amounts of disk storage to a controller or cluster of controllers. Fibre Channel

technology provides increased performance, scalability, availability, and distance for

Chapter 2. Introduction 5

Page 16

attaching storage subsystems to network servers. The RAID storage controller

provides for the attachment of Fibre Channel disk drives to give superior

performance and redundancy.

Features

Each RAID storage controller includes the following standard features:

v Dual RAID Controllers

v 10 Fibre Channel 40—pin disk drives

v Dual power supplies and dual modular cooling fan assemblies

v Support for RAID levels 0, 1, 3, 5,and 10

Table 1. RAID storage controller features

General

v Modular components:

– High-capacity disk drives

– RAID controllers

– Power supplies

– Cooling fans

v Technology:

– Support for disk arrays

– Support for clustering

– Fibre Channel host interface

– Redundant data storage, cooling

system, power system, and RAID

controllers

– Hot-swap technology for drives,

power supplies, fans, and RAID

controllers

v User interface:

– Built-in power, activity, and fault light

emitting diodes (LEDs)

– Identification labeling on customer

replaceable units (CRUs), rear LEDs,

switches, and connectors

– Easy-to-replace drives, power

supplies, RAID controllers, and fans

Disk drive storage

Maximum drives per storage server: 10

RAID controllers

v Technology and interfaces:

– Fibre Channel: 40-pin FC disk drives

– Fibre Channel interface: Four Gigabit

Interface Converter (GBIC)

connectors for incoming and

outgoing FC cables (two GBICs on

each RAID controller)

Components

The following sections show the components of the RAID storage controller.

Note: The hot-swap features of the RAID storage controller enable you to remove

and replace hard disk drives, power supplies, RAID controllers, and fans

without powering off the RAID storage controller. Therefore, you can maintain

the availability of your system while a hot-swap device is removed or

replaced.

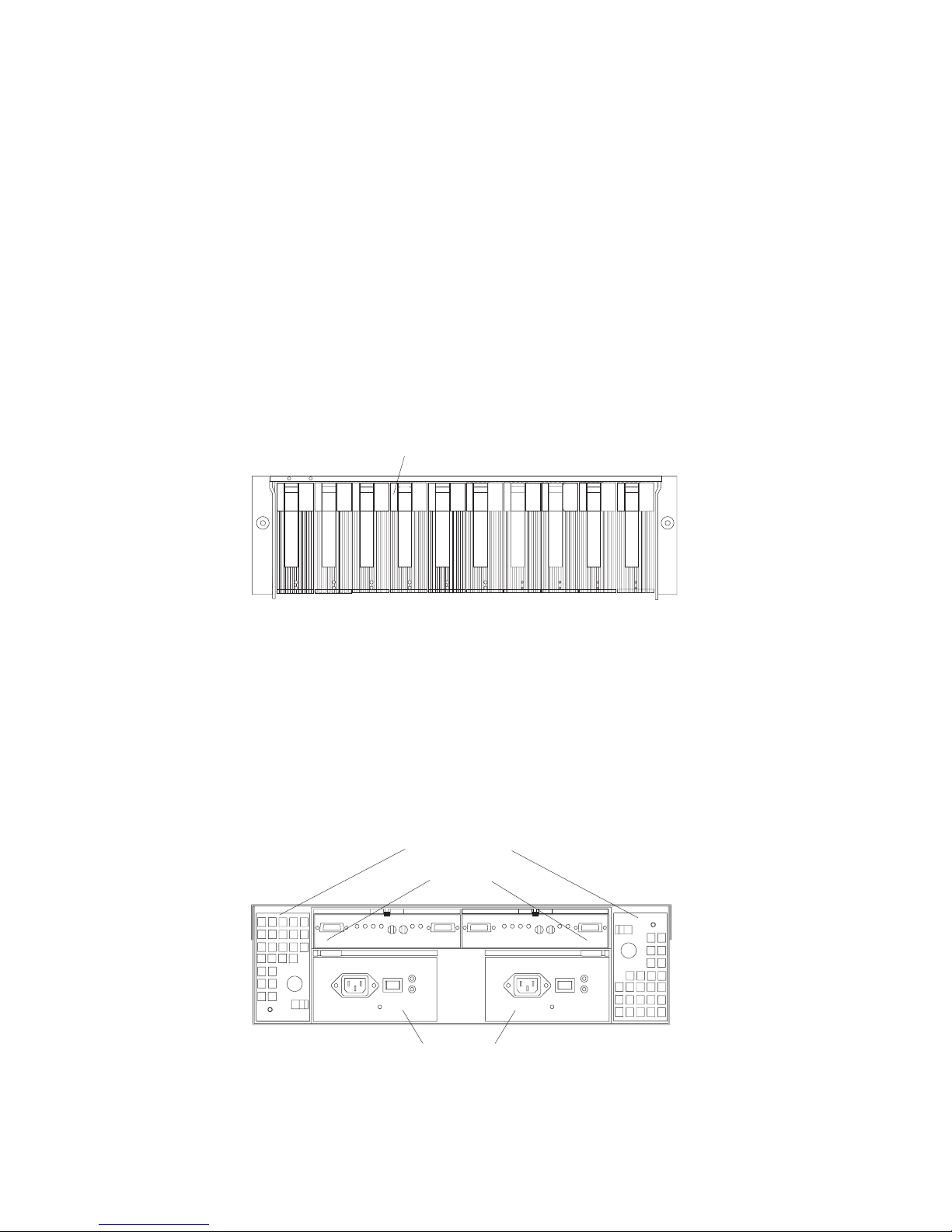

Front view

The following illustration shows the components and controls on the front of the

RAID storage controller.

Power-on LED

Latch

Hot-swap

drive CRU

Drive activity LED

Drive fault LED

General-systemerror LED

Tray handle

6 IBM NAS 300 Service Guide

Page 17

Power-on LED

When on, this green light indicates that the unit has good dc power.

General-system-error LED

When on, this amber LED indicates that the RAID storage controller has a

fault, such as in a power supply, fan unit, or hard disk drive.

Note: If the General-system-error LED is on continuously (not flashing),

there is a problem with the RAID storage controller. Use the

storage-management software to diagnose and repair the problem.

Hot-swap drive CRU

Your RAID storage controller comes standard with 10 hot-swap drive

customer replaceable units (CRUs) in the storage server. Each drive CRU

consists of a hard disk drive and tray.

Drive activity LED

Each drive CRU has a green Drive activity LED. When flashing, this green

LED indicates drive activity. When on continuously, this green LED indicates

that the drive is properly installed.

Drive fault LED

Each drive CRU has an amber Drive fault LED. When on, this amber LED

indicates a drive failure. When flashing, this amber LED indicates that a

drive identify or rebuild process is in progress.

Latch This multipurpose blue latch releases or locks the drive CRU in place.

Tray handle

You can use this multipurpose handle to insert and remove a drive CRU in

the bay.

For information on installing and replacing drive CRUs, see “Chapter 5. Installing

and replacing IBM NAS 300 components” on page 67. For more information about

the LEDs, see the IBM NAS 300 User’s Reference.

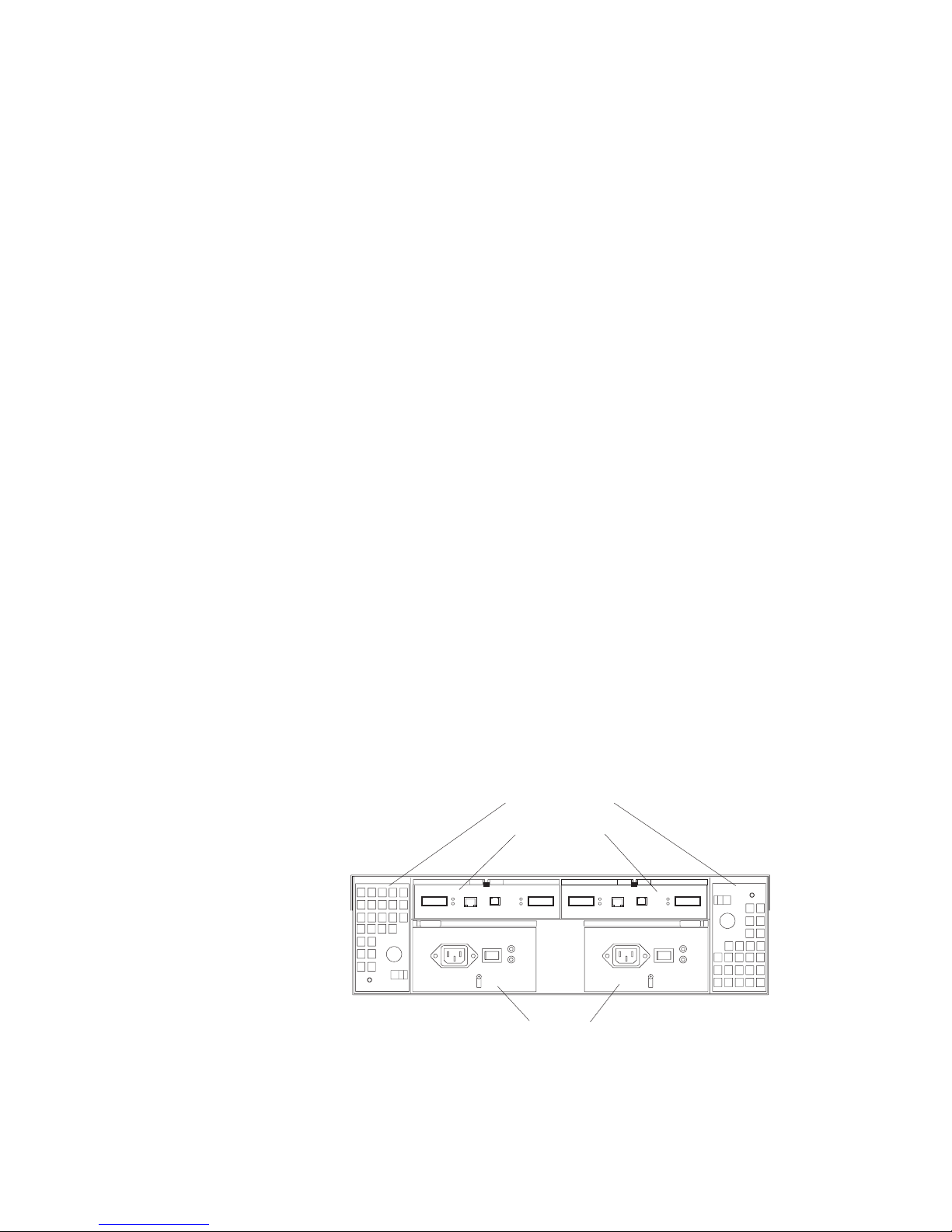

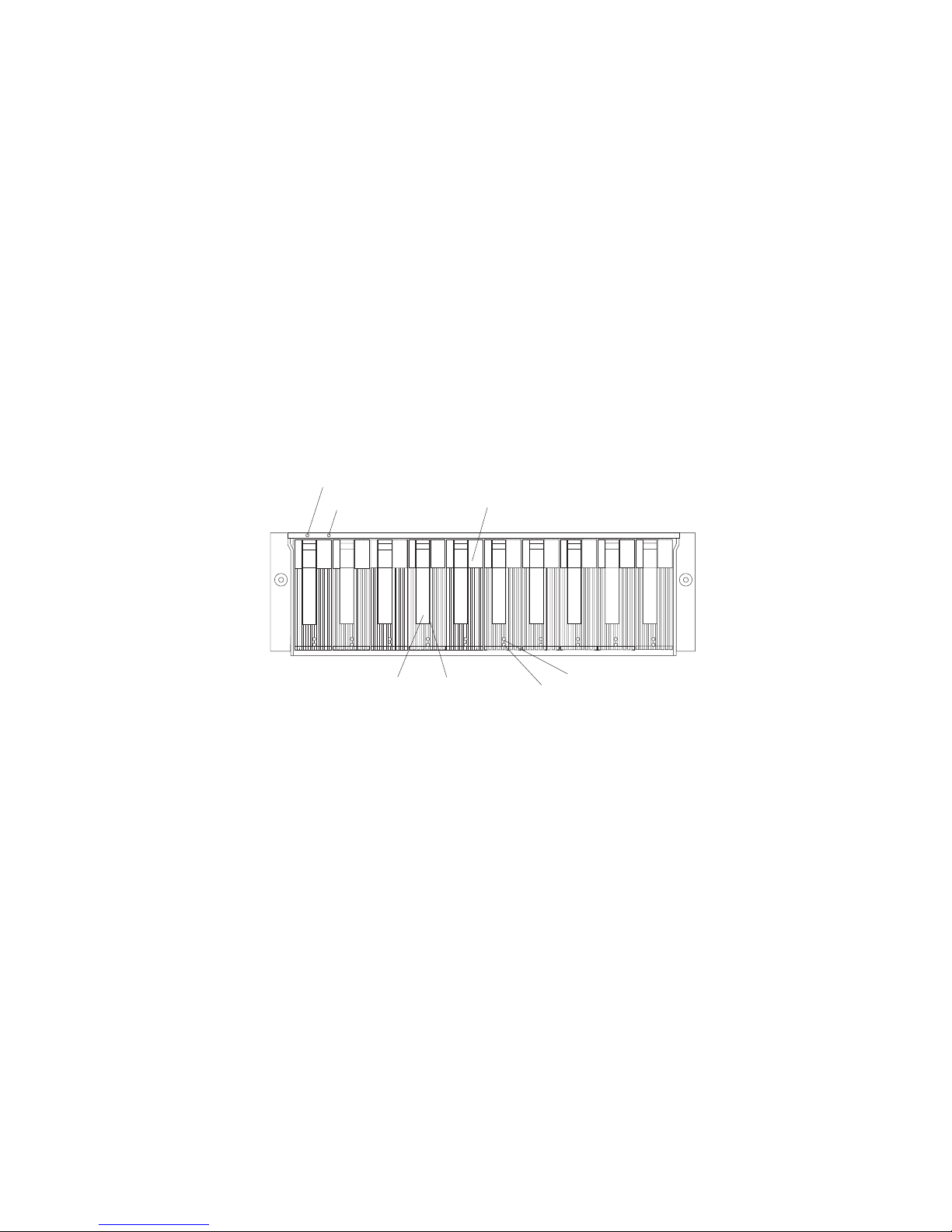

Back view

The following illustration shows the components at the back of the IBM NAS 300

RAID storage controller.

Hot-swap fan bays

Raid controllers

Hot-swap

power supplies

RAID controller

The RAID storage controller comes with one or two hot-swap RAID

controllers. Each RAID controller contains two ports for Gigabit Interface

Chapter 2. Introduction 7

Page 18

Converters (GBICs), which connect to the Fibre Channel cables. One GBIC

connects to a host system. The other GBIC is used to connect additional

storage units to the RAID controller.

Each RAID controller also contains a battery to maintain cache data in the

event of a power failure.

Hot-swap fans

The RAID controller has two interchangeable hot-swap and redundant fan

CRUs. Each fan CRU contains two fans. If one fan CRU fails, the second

fan CRU continues to operate. Both fan CRUs must be installed to maintain

proper cooling within your RAID controller, even if one fan CRU is not

operational.

Hot-swap power supplies

The RAID controller comes with two hot-swap power supplies. Both power

supplies must be installed to maintain proper cooling.

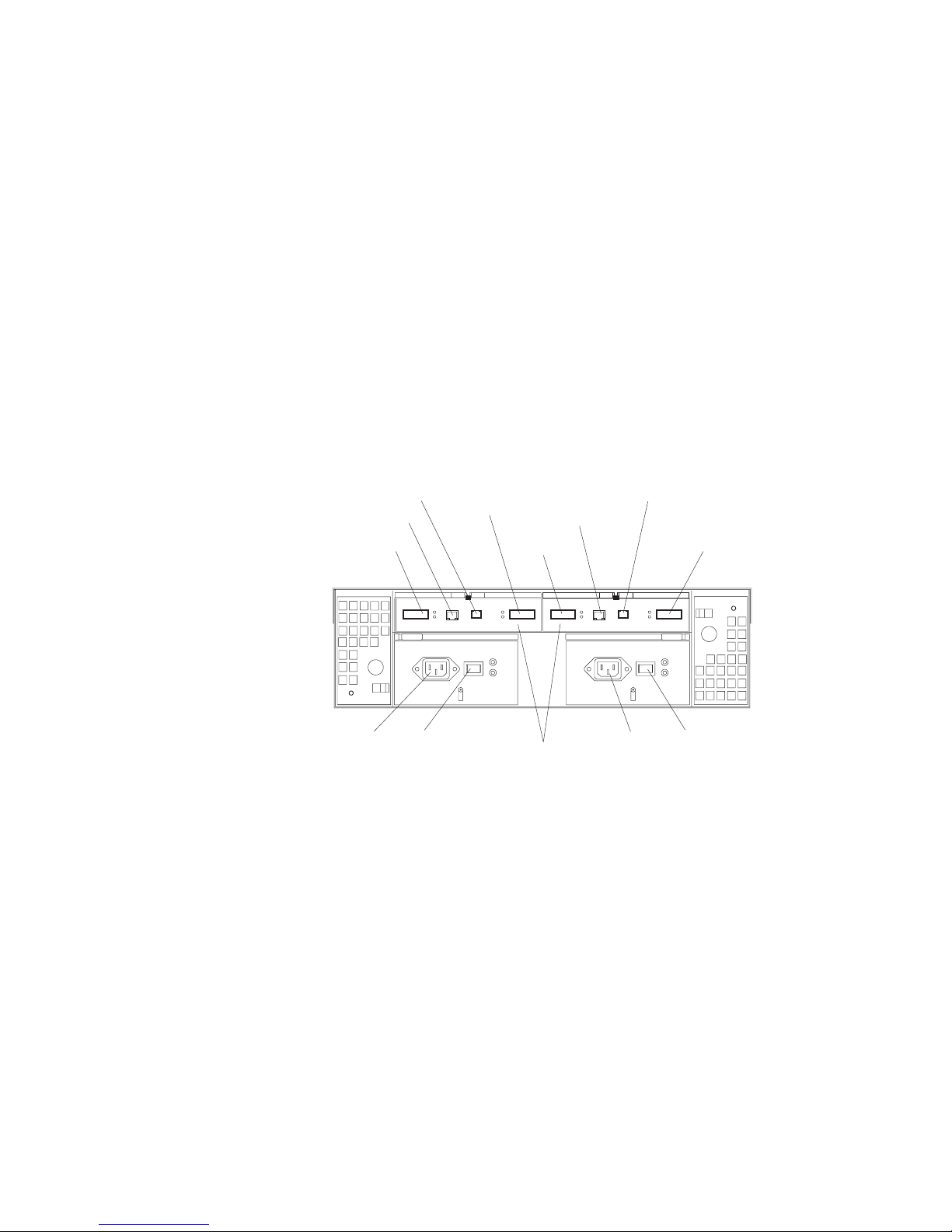

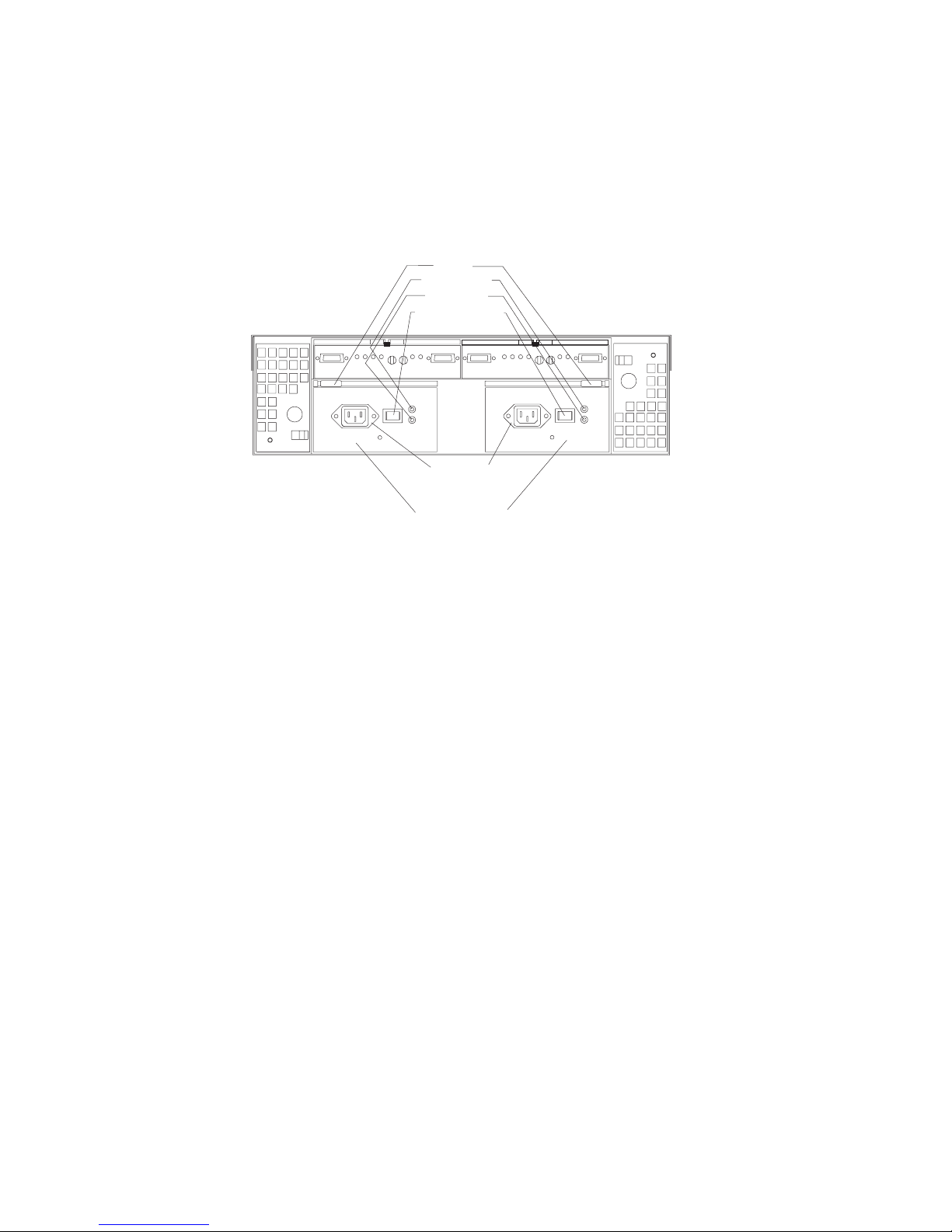

Interface ports and switches

The following illustration shows the ports and switches on the back of the RAID

controller.

Ethernet port

AC power

connector

RAID controller

Each RAID controller contains several connectors and LEDs. Each

controller has one host port and one expansion port for connecting the

storage server to hosts or expansion units. You first insert GBICs into the

ports and then connect the Fibre Channel cables.

Host port

The host port is used to connect a Fibre Channel cable from the IBM NAS

300 Fibre Channel hub. You first insert a GBIC into the port and then

connect a Fibre Channel cable.

RS-232 port

Host port

Expansion port

AC power

switch

Ethernet port

Host port

RAID controllers

RS-232 port

AC power

connector

Expansion port

AC power

switch

Ethernet port

The Ethernet port is for an RJ-45 10 BASE-T or 100 BASE-T Ethernet

connection. Use the Ethernet connection to directly manage storage

subsystems.

Expansion port

The expansion port is used to connect additional expansion units to the

RAID controllers. You first insert a GBIC into the port and then connect a

Fibre Channel cable.

8 IBM NAS 300 Service Guide

Page 19

Storage Unit

Features

RS-232 port

The RS-232 port is a TJ-6 modular jack and is used for an RS-232 serial

connection. The RS-232 port is used by service personnel to perform

diagnostic operations on the RAID controllers. An RS-232 cable comes with

the RAID storage controller.

The IBM NAS 300 storage unit is a compact unit that provides high-capacity, Fibre

Channel (FC) disk storage. It delivers fast, high-volume data transfer, retrieval, and

storage functions across multiple drives, to multiple hosts. The expansion enclosure

is designed for continuous, reliable service; the modular, redundant disk drives,

power supplies, ESM boards, and fans use hot-swap technology for easy

replacement without shutting down the system.

The storage unit supports redundant, dual-loop configurations. Optional external FC

cables and gigabit interface converters (GBICs) connect the RAID controller to the

storage unit.

By adding an additional RAID storage controller, you can add up to seven 10–drive

storage units to your IBM NAS 300.

Each storage unit includes the following standard features:

v Dual ESM boards: The environmental services monitor (ESM) boards contain the

expansion unit controls, switches, and LEDs. Each ESM board has two GBIC

ports for connecting the storage unit to the RAID storage controller.

v 10 Fibre Channel 40–pin disk drives.

v Dual power supplies and dual modular cooling fan assemblies.

Table 2. storage unit features

General

v Modular components:

– High-capacity disk drives

– Environmental services monitor

(ESM) boards

– Power supplies

– Cooling fans

v Technology:

– Supports disk arrays

– Supports clustering

– Fibre Channel host interface

– Redundant data storage,

cooling system, power system,

and ESM boards

– Hot-swap technology for drives,

power supplies, fans, and ESM

boards

v User interface:

– Built-in power, activity, and fault

indicators

– Identification labeling CRUs,

rear indicator lights, switches,

and connectors

– Easy-to-replace drives, power

supplies, ESM boards, and fans

Disk drive storage

Maximum drives per storage unit:

10

ESM boards

v Technology and interfaces:

– Fibre Channel: 40-pin FC disk

drives

– Fibre Channel interface: Four,

GBICs connectors for incoming

and outgoing FC cables (two

GBICs on each ESM board)

Chapter 2. Introduction 9

Page 20

Components

The following sections describe the components of the storage unit.

Note: The hot-swap features of the IBM NAS 300 storage unit enable you to

remove and replace hard disk drives, power supplies, ESM boards, and fans

without turning off the storage unit. Therefore, you can maintain the

availability of your system while a hot-swap device is removed or replaced.

Storage unit CRUs

This section lists the storage unit CRUs.

Hot-swap drives: The following illustration shows the location of the hot-swap

drive bays accessible from the front of your expansion unit. The storage unit

contains 10 slim 40-pin FC hard disk drives. These drives come preinstalled in drive

trays. This drive-and-tray assembly is called a drive CRU (customer replaceable

unit).

Hot-swap drive bays

Attention: Never hot-swap a drive CRU when its green Activity LED is flashing.

Hot-swap a drive CRU only when its amber Fault LED is completely on and not

flashing or when the drive is inactive with the green Activity LED completely on and

not flashing.

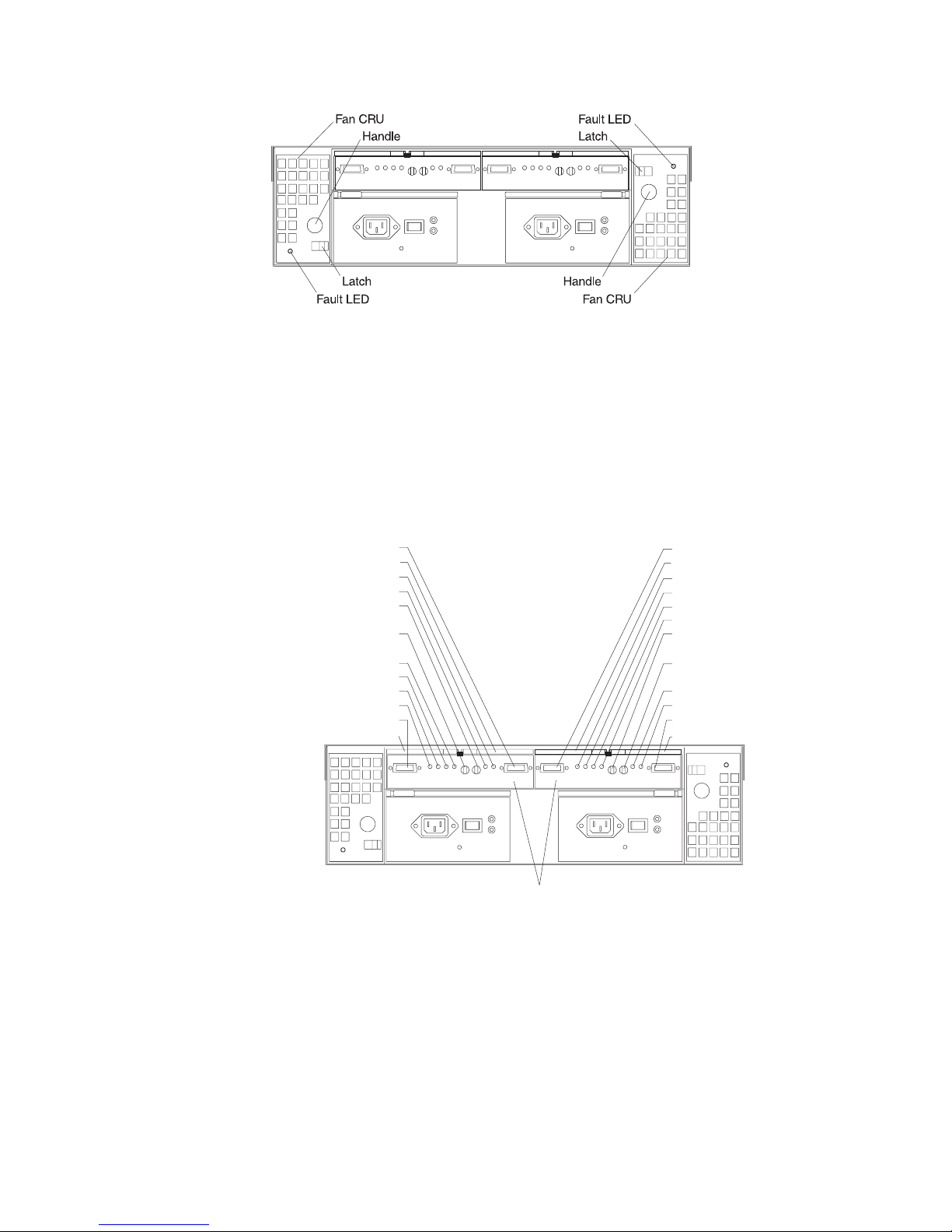

Fan, ESM, and power supply CRUs: The following illustration shows the location

of the hot-swap fan CRUs, the hot-swap ESM CRUs, and the hot-swap power

supply CRUs.

Hot-swap fan bays

ESM bays

Hot-swap power

supply bays

ESM CRUs

Your storage unit comes with two hot-swappable ESM boards. The ESM

boards provide a 1–Gb FC interface to the drives and monitors the overall

10 IBM NAS 300 Service Guide

Page 21

status of the storage unit. Each ESM board has two GBIC connector ports

for connecting your storage unit to the controller or connecting two or more

storage unit together. The ESM boards provide redundancy when both

boards are configured into redundant FC loops.

Hot-swap fan CRUs

Your storage unit has two interchangeable hot-swap and redundant fan

units. Each unit contains two fans. If one fan unit fails, the second fan unit

continues to operate. Both fan units must be installed to maintain proper

cooling within your expansion unit, even if one fan unit is not operational.

Hot-swap power supplies

Your storage unit comes with two hot-swap and redundant power supplies.

Both power supplies must be installed to maintain proper cooling within

your storage unit, even if one power supply is not operational.

Front controls and indicators

The primary controls on the front of the storage unit are shown in the following

illustration.

Power-on LED

General-systemerror LED

Hot-swap

drive CRU

Tray handle

Latch

Drive activity LED

Drive fault LED

Activity LED

Each drive CRU has an Activity LED. When flashing, this green LED

indicates drive activity. When completely on, this green LED indicates the

drive is properly installed.

Drive CRU

Your storage unit comes standard with 10 hot-swap drive CRUs. Each drive

CRU consists of a hard disk drive and tray.

Fault LED

Each drive CRU has a Fault LED. When lit, this amber LED indicates a

drive failure. When flashing, this amber LED indicates that a drive Identify

or Rebuild process is in progress.

General system error LED

When lit, this amber LED indicates that the unit has a fault, such as in a

power supply, fan unit, or hard disk drive.

Latch This multipurpose blue latch releases or locks the drive CRU in place.

Power-on LED

When lit, this green light indicates that the unit has good dc power.

Tray handle

You can use this multipurpose handle to insert and remove a drive CRU in

the bay.

Chapter 2. Introduction 11

Page 22

Rear controls, indicators, and connectors

Two hot-swap power supply CRUs, two hot-swap fan CRUs, and two ESM boards

are accessible from the back of the storage unit. These components contain several

controls, indicators, and connectors.

Power supply controls, indicators, and connectors:

Levers

Power LEDs

Fault LEDs

Power switches

AC power

connectors

Hot-swap power

supply bays

AC power connectors

The power cords for the power supplies connect here.

Fault LEDs

These amber Fault LEDs light if a power supply failure occurs or if the

power supply is turned off.

Levers

Use these locking handles to remove or install a power supply.

Power LEDs

These green LEDs light when the storage unit is turned on and receiving ac

power.

Power supply CRUs

The two hot-swap power supplies are located here. Both power supply

CRUs must be installed, even if one power supply is not operational.

Power switches

Use these switches to turn the power supplies on and off. You must turn

both switches on to take advantage of the redundant power supplies.

Fan controls and indicators: The fans in your storage unit are hot-swappable

and redundant. This means that your storage unit will continue to operate if a fan

fails. It also means that you can remove and replace the fan while the storage unit

is on and accessing drives.

Attention: The fans in your storage unit draw in fresh air and force out hot air.

These fans are hot-swappable and redundant; however, when one fan fails, the fan

unit must be replaced within 48 hours in order to maintain redundancy and optimum

cooling. When you replace the failed unit, be sure to install the second fan within 10

minutes to prevent any overheating due to the lack of the additional fan unit.

12 IBM NAS 300 Service Guide

Page 23

Fan CRUs

The two fan CRUs are located here. These fans are hot-swappable and

redundant.

Fault LEDs

These amber LEDs light when a fan failure occurs.

Latches and handles

Use the latches and handles to remove or install the fan CRUs.

ESM boards user controls:

GBIC output port

Lever

Output bypass LED

ID conflict LED

Tray number

switch tens place (x10)

Tray number

switch ones place (x1)

Over-temperature LED

Fault LED

Power LED

Input bypass LED

GBIC input port

Lever

ESM boards

The environmental services monitor (ESM) boards contain the expansion

unit controls, switches, and LEDs. Each ESM board has two GBIC ports for

connecting the expansion unit to the controller.

ESM boards

GBIC input port

Lever

bypass LED

Input

Power LED

Fault LED

O

ver-temperature LED

Tray number

switch tens place (x10)

Tray number

switch ones place (x1)

ID conflict LED

Out put bypass LED

GBIC output port

Lever

Fault LEDs

GBIC input ports

These amber LEDs light when an ESM board failure occurs.

The two GBIC input ports are for attaching the optional GBICs to the

storage unit.

Chapter 2. Introduction 13

Page 24

GBIC output ports

The two GBIC output ports are for attaching the optional GBICs to the

storage unit.

The optional GBICs (input and output) are for attaching your optical cables

to the storage unit, then to the controller or additional storage unit. Insert

the GBICs in the expansion unit GBIC ports and attach your FC cables to

the GBICs, then connect the FC cables to the controller or additional

storage unit.

ID conflict LEDs

These amber LEDs light if the storage unit tray ID settings for the ESM

boards do not match. In this case, the storage unit uses the tray number of

the left ESM board.

Input/Output bypass LEDs

These amber LEDs light when no valid input signal is detected and when

no data is passed through the port. When no cable is connected to the port,

the LEDs also light. Both ports on the ESM board are bypassed and the

LEDs are lit in the event of an ESM board fault. In this case, the ESM Fault

LED is also lit.

Levers

Use these levers when removing and inserting the ESM boards.

Power LEDs

These green LEDs are lit when there is power to the ESM board.

Over-temperature LEDs

These amber LEDs light if the storage unit overheats.

Tray number switches

These switches assign the physical addresses of the disk drives and the

system management processors that are participating in the loop, and they

identify the storage unit. The base switch (x1) sets the IDs of the disk drives

on the loop. The settings of both the base ID switch (x1) and the extended

ID switch (x10) together is the storage unit ID. The switches set the storage

unit ID using values of 00 through 99. The base ID switch (x1) is for the

ones position and the extended ID switch (x10) is for the tens position.

Supported software applications

For a list of the pre-loaded and optional software applications that are supported by

your IBM NAS 300, refer to the IBM TotalStorage Network Attached Storage 300

User’s Reference.

14 IBM NAS 300 Service Guide

Page 25

Chapter 3. Troubleshooting

This chapter provides basic troubleshooting information to help you resolve some

common problems that might occur with your IBM NAS 300.

Note: The information is organized by IBM NAS 300 component (engines, Fibre

Channel hub, and so on); however, if a Fibre Channel hub or one or more

engines, RAID storage controllers, or storage units loses power to one power

supply, check the circuit breakers on the power distribution units (PDUs)

located inside the IBM NAS 300 left and right side covers.

Troubleshooting the engines

Diagnostic tools overview

The following tools are available to help you identify and resolve hardware-related

problems:

v POST beep codes, error messages, and error logs

The power-on self-test (POST) generates beep codes and messages to indicate

successful test completion or the detection of a problem. See “POST” on page 16

for more information.

v Diagnostic programs and error messages

The diagnostic programs are stored in upgradable read-only memory (ROM) on

the system board. These programs are the primary method of testing the major

components of your engine. See “Diagnostic programs and error messages” on

page 17 for more information.

Note: To view error messages, attach a monitor, keyboard, and mouse to the

each engine before it is powered-on.

v Light path diagnostics

Light-emitting diodes (LEDs) help you identify problems with engine components.

These LEDs are part of the light-path diagnostics that are built into your engine.

By following the path of lights, you can quickly identify the type of system error

that occurred. See “Light path diagnostics” for more information.

Identifying problems using LEDs

Each engine has LEDs to help you identify problems with some engine

components. These LEDs are part of the light path diagnostics built into the engine.

By following the path of lights, you can identify the type of system error that

occurred. See the following sections for more information.

Power supply LEDs

The ac and dc Power LEDs on the power supply provide status information about

the power supply. See “Power supply LED errors” on page 52.

Light path diagnostics

You can use the light path diagnostics to quickly identify the type of system error

that occurred. The diagnostics panel is under the ″wind tunnel.″ Each engine is

designed so that any LEDs that are On, remain On when the engine shuts down as

long as the ac power source is good and the power supplies can supply +5V dc

current to the engine. This feature helps isolate the problem if an error causes the

engine to shut down. See “Light path diagnostics table” on page 16.

© Copyright IBM Corp. 2001 15

Page 26

Diagnostics LED panel

DASD2

DASD1

VRM

PCI A

PCI B

CPU

MEM

FAN

TEMP

NMI

OVER

NON

PS3

PS2

PS1

The following illustration shows the LEDs on the diagnostics panel on the system

board. See “Light path diagnostics table” for information on identifying problems

using these LEDs.

Note: You need to remove the top cover (see “Removing the cover and bezel” on

page 70) to view these LEDs.

Light path diagnostics table

The System Error LED on the operator information panel is On when certain system

errors occur. If the System Error LED is On, use the following table to help

determine the cause of the error and the action to take. See table in “Information

panel system error LED” on page 48.

POST

When you power-on the engine, it performs a series of tests to check the operation

of its components and some of the options installed in the engine. This series of

tests is called the power-on self-test or POST.

If POST finishes without detecting any problems, one long beep and three short

16 IBM NAS 300 Service Guide

beeps sound.

If POST detects a problem, a series of beeps sound. See “Beep symptoms” on

page 45 and “POST error messages” on page 17 for more information.

Notes:

1. If you have a power-on password or administrator password set, you must type

the password and press Enter, when prompted, before POST will continue.

2. A single problem might cause several error messages. When this occurs, work

to correct the cause of the first error message. After you correct the cause of

the first error message, the other error messages usually will not occur the next

time you run the test.

Page 27

POST error messages

Note: To view POST error messages, attach a monitor, keyboard, and mouse to

each engine before it is powered-up.

The table,“POST error codes” on page 53, provides information about the POST

error messages that can appear during startup.

Event/error logs

The POST error log contains the three most recent error codes and messages that

the system generated during POST. The System Event/Error Log contains all error

messages issued during POST and all system status messages from the Advanced

System Management Processor. In event of a POST error, check the System

Event/Error Log as it may indicate the most recent errors commonly associated with

typical hardware failures. It may not detect all hardware failures but many times will

provide an indicator as to the nature of key failures.

To view the contents of the error logs, start the Configuration/Setup Utility program

(“Starting the Configuration/Setup Utility program” on page 111); then, select

Event/Error Logs from the main menu.

Diagnostic programs and error messages

The engine diagnostic programs are stored in upgradable read-only memory (ROM)

on the system board. These programs are the primary method of testing the major

components of your engine.

For a list of error messages and codes, see “Diagnostic error codes” on page 49.

Diagnostic error messages indicate that a problem exists; they are not intended to

be used to identify a failing part. Troubleshooting and servicing of complex

problems that are indicated by error messages should be performed by trained

service personnel.

Sometimes the first error to occur causes additional errors. In this case, the engine

displays more than one error message. Always follow the suggested action

instructions for the first error message that appears.

The following sections contain the error codes that might appear in the detailed test

log and summary log when running the diagnostic programs.

The error code format is as follows:

fff-ttt-iii-date-cc-text message

where:

fff is the three-digit function code that indicates the function being tested when

the error occurred. For example, function code 089 is for the

microprocessor.

ttt is the three-digit failure code that indicates the exact test failure that was

encountered.

iii is the three-digit device ID.

date is the date that the diagnostic test was run and the error recorded.

cc is the check digit that is used to verify the validity of the information.

Chapter 3. Troubleshooting 17

Page 28

text message

is the diagnostic message that indicates the reason for the problem.

Text messages

The diagnostic text message format is as follows:

Function Name: Result (test specific string)

where:

Function Name

is the name of the function being tested when the error occurred. This

corresponds to the function code (fff) given in the previous list.

Result

can be one of the following:

Test Specific String

This is additional information that you can use to analyze the problem.

Passed

This result occurs when the diagnostic test completes without any errors.

Failed This result occurs when the diagnostic test discovers an error.

User Aborted

This result occurs when you stop the diagnostic test before it is complete.

Not Applicable

This result occurs when you specify a diagnostic test for a device that is not

present.

Aborted

This result occurs when the test could not proceed because of the system

configuration.

Warning

This result occurs when a possible problem is reported during the

diagnostic test, such as when a device that is to be tested is not installed.

Starting the diagnostic programs

To start the diagnostic programs:

1. Ensure you have connected a monitor, keyboard, and mouse to each engine.

Notes:

a. When you do not have a monitor, keyboard, and mouse attached and the

engine passes POST, one long and three short beeps sound.

b. When you have a monitor, keyboard, and mouse attached and the engine

passes POST, one beep sounds. If the engine fails POST, a series of beeps

sound (see “Beep symptoms” on page 45 for more details) and an error

message appears on the monitor screen.

2. Power-on the engine and watch the screen.

3. When the message F2 for Diagnostics appears, press F2. If a POST error is

encountered, a series of beeps sound and an error message appears on the

monitor screen.

4. Type in the appropriate password; then, press Enter. If a system error is

encountered, the Configuration/Setup screen appears. Press Esc to start the

Diagnostic program.

Note: To run the diagnostic programs, you must start the engine with the

18 IBM NAS 300 Service Guide

highest level password that is set. That is, if an administrator password is

Page 29

set, you must enter the administrator password, not the power-on

password, to run the diagnostic programs.

5. Select either Extended or Basic from the top of the screen. (PC-Doctor 2.0 with

a copyright statement appears at the bottom of this screen.)

6. When the Diagnostic Programs screen appears, select the test you want to run

from the list that appears; then, follow the instructions on the screen.

Notes:

a. Press F1 while running the diagnostic programs to obtain Help information.

Also press F1 from within a help screen to obtain online documentation from

which you can select different categories. To exit Help and return to where

you left off, press Esc.

b. If the engine stops during testing and you cannot continue, restart the

engine and try running the diagnostic programs again.

c. If you run the diagnostic programs with either no mouse or a USB mouse

attached to your engine, you will not be able to navigate between test

categories using the Next Cat and Prev Cat buttons. All other functions

provided by mouse-selectable buttons are also available using the function

keys.

d. You can test the USB keyboard by using the regular keyboard test. The

regular mouse test can test a USB mouse. Also, you can run the USB hub

test only if there are no USB devices attached.

e. You can view engine configuration information (such as system

configuration, memory contents, interrupt request (IRQ) use, direct memory

access (DMA) use, device drivers, and so on) by selecting Hardware Info

from the top of the screen.

f. You cannot use the diagnostics program to test adapters. Use the procedure

outlined in “Running adapter diagnostics” on page 25.

When the tests have completed, you can view the Test Log by selecting Utility from

the top of the screen.

If the hardware checks out OK but the problem persists during normal engine

operations, a software error might be the cause. If you suspect a software problem,

refer to the information that comes with the software package.

Viewing the test log

The test log will not contain any information until after the diagnostic program has

run.

Note: If you already are running the diagnostic programs, begin with step 4

To view the test log:

1. Ensure a monitor, keyboard, and mouse is connected to each engine.

2. Power-on the engine and watch the screen.

If the engine is on, shut down your operating system and restart the engine.

3. When the message F2 for Diagnostics appears, press F2.

If a power-on password or administrator password is set, the engine prompts

you for it. Type in the appropriate password; then, press Enter.

4. When the Diagnostic Programs screen appears, select Utility from the top of

the screen.

5. Select View Test Log from the list that appears; then, follow the instructions on

the screen.

Chapter 3. Troubleshooting 19

Page 30

The system maintains the test-log data while the engine is powered-on. When

you power-off the power to the engine, the test log is cleared.

Diagnostic error message tables

For descriptions of the error messages that might appear when you run the

diagnostic programs see “Diagnostic error codes” on page 49.

Attention: If diagnostic error messages appear that are not listed in the tables,

make sure that your engine has the latest levels of BIOS, Advanced System.

Recovering BIOS

If your BIOS has become corrupted, such as from a power failure during a flash

update, you can recover your BIOS using the recovery boot block and a BIOS flash

diskette.

Note: You can obtain a BIOS flash diskette from one of the following sources:

v Download a BIOS flash diskette from the

website:www.storage.ibm.com/support/nas

v Contact your IBM service representative.

Troubleshooting the planar Ethernet controller

This section provides troubleshooting information for problems that might occur with

the 10/100 Mbps planar Ethernet controller.

Network connection problems

If the Ethernet controller cannot connect to the network, check the following:

v Ensure that you have the engine correctly connected to the Ethernet with a

verified cable that has been correctly built to the related Category 3, 4, or 5

unshielded twisted pair (UTP) standards.

The network cable must be securely attached at all connections. If the cable is

attached but the problem persists, try a different cable.

If you set the Ethernet controller to operate at 100 Mbps, you must use Category

5 cabling.

If you directly connect two workstations (without a hub), or if you are not using a

hub with X ports, use a crossover cable.

Note: To determine whether a hub has an X port, check the port label. If the

label contains an X, the hub has an X port.

v Ensure that heartbeat is inoperable on the adapter card or transceiver you are

using to connect to the Ethernet.

v If you are connecting through an Ethernet hub or repeater, validate that the

signal lights are operational while the device is on and connected to the LAN.

v Determine if the hub supports auto-negotiation. If not, try configuring the

integrated Ethernet controller manually to match the speed and duplex mode of

the hub.

v Check the Ethernet controller lights on the operator information panel.

These lights indicate whether a problem exists with the connector, cable, or hub.

– The Ethernet Link Status light is On when the Ethernet controller receives a

LINK pulse from the hub. If the light is Off, there might be a bad connector or

cable, or a problem with the hub.

– The Ethernet Transmit/Receive Activity light is On when the Ethernet controller

sends or receives data over the Ethernet Network. If the Ethernet

Transmit/Receive Activity light is Off, make sure that the hub and network are

operating and that the correct device drivers are loaded.

20 IBM NAS 300 Service Guide

Page 31

v Make sure that you are using the correct device drivers, supplied with your

engine.

v Check for operating system-specific causes for the problem.

v Make sure that the device drivers on the client and engine are using the same

protocol.

v Test the Ethernet controller by running the diagnostic program.

Ethernet controller troubleshooting chart

Use the following troubleshooting chart to find solutions to 10/100 Mbps Ethernet

controller problems that have definite symptoms.

Table 3. Ethernet troubleshooting chart

Ethernet controller problem Suggested Action

Ethernet Link Status light is

not On.

The Ethernet

Transmit/Receive Activity light

is not On.

Data is incorrect or sporadic. Check the following:

The Ethernet controller

stopped working when

another adapter was added to

the engine.

Check the following:

v Ensure that the hub is powered-on.

v Check all connections at the Ethernet controller and the hub.

v Check the cable. A crossover cable is required unless the hub has an X

designation.

v Use another port on the hub.

v If the hub does not support auto-negotiation, manually configure the Ethernet

controller to match the hub.

v If you manually configured the duplex mode, ensure that you also manually

configure the speed.

v Run diagnostics on the LEDs.

If the problem remains, go to “Starting the diagnostic programs” on page 18 to run

the diagnostic programs.

Check the following:

Note: The Ethernet Transmit/Receive Activity LED is On only when data is sent to or

by this Ethernet controller.

v Ensure that you have loaded the network device drivers.

v The network might be idle. Try sending data from this workstation.

v Run diagnostics on the LEDs.

v The function of this LED can be changed by device driver load parameters. If

necessary, remove any LED parameter settings when you load the device drivers.

v Ensure that you are using Category 5 cabling when operating the engine at 100

Mbps.

v Make sure that the cables do not run close to noise-inducing sources like

fluorescent lights.

Check the following:

v Ensure that the cable is connected to the Ethernet controller.

v Ensure that your PCI system BIOS is current.

v Reseat the adapter.

v Ensure that the adapter you are testing is supported by the engine.

Go to “Starting the diagnostic programs” on page 18 to run the diagnostic programs.

The Ethernet controller

stopped working without

apparent cause.

Check the following:

v Run diagnostics for the Ethernet controller.

v Try a different connector on the hub.

v Reinstall the device drivers. Refer to your operating-system documentation and to

If the problem remains, go to “Starting the diagnostic programs” on page 18 to run

the diagnostic programs.

the IBM NAS 300 User’s Reference information.

Chapter 3. Troubleshooting 21

Page 32

10/100 Ethernet Adapter troubleshooting chart

You can use the following troubleshooting chart to find solutions to 10/100 Mbps

Ethernet adapter problems that have definite symptoms.

Table 4. Ethernet troubleshooting chart

Ethernet adapter problem Suggested Action

The adapter cannot connect

to the network.

Diagnostics pass, but the

connection fails or errors

occur.

Check the following:

1. Ensure that the network cable is installed correctly. The cable must be securely

attached at both RJ-45 connections (adapter and hub). The maximum allowable

distance from adapter to the hub is 100 m (328 ft.). If the cable is attached and

the distance is within acceptable limits but the problem persists, try a different

cable. If you are directly connecting two computers without a hub or switch, make

sure you are using a crossover cable.

2. Check the LED lights on the adapter. The adapter has two diagnostic LEDs, one

on each side of the cable connector. These lights help you to determine whether

there is a problem with the connector, cable, switch, or hub.

ACT/LNK — On

v Adapter and switch is receiving power and cable connection between

them is good

ACT/LNK — Off

Check the following:

v Adapter not sending or receiving data

v Adapter or switch not receiving power

v Cable connection between adapter and switch is faulty

v Drivers not configured properly

ACT/LNK — Flashing

Normal operation. LED flashes when the adapter sends or receives data.

The frequency of the flashes varies with the amount of network traffic

100 — On

Adapter is operating at 100 Mbps

100 — Off

Adapter is operating at 10 Mbps

3. Ensure that you are using the correct drivers. Ensure that you are using the

drivers that come with this adapter. Drivers that support previous versions of this

adapter do not support this version of the adapter.

4. Ensure that the switch port and the adapter have the same duplex setting. If you

configured the adapter for full-duplex, ensure that the switch port is also

configured for full-duplex. Setting the wrong duplex mode can degrade

performance, cause data loss, or result in lost connections.

Check the following:

1. For 100 Mbps:

v Use Category 5 cabling and ensure that the network cable is securely

attached.

v Verify the adapter is seated firmly in the slot and connected to a 100BASE-TX

hub/switch (not 100BASE-T4).

2. Ensure the duplex mode setting on the adapter matches the setting on the switch

22 IBM NAS 300 Service Guide

Page 33

Table 4. Ethernet troubleshooting chart (continued)

Ethernet adapter problem Suggested Action

The LNK LED is not On. Check the following:

1. Ensure that you loaded the correct network drivers.

2. Check all connections at the adapter and the switch.

3. Try another port on the switch.

4. Ensure that the duplex mode setting on the adapter matches the setting on the

switch.

5. Ensure that you have the correct type of cable between the adapter and the hub.

100BASE-TX requires two pairs. Some hubs require a crossover cable while

others require a straight-through cable.

The ACT LED is not On. Check the following:

1. Ensure that you loaded the correct network drivers.

2. The network might be idle. Try accessing a server.

3. The adapter is not transmitting or receiving data. Try another adapter.

4. Ensure that you are using two-pair cable for TX wiring.

Adapter stops working without

apparent cause.

The LNK LED is not On when

you connect the power.

Check the following:

1. Run the diagnostics.

2. Try reseating the adapter in its slot, or try a different slot if necessary.

3. The network driver files might be corrupt or missing. Remove and then reinstall

the drivers.

Check the following:

Ensure that the network cable is securely attached at both ends.

Gigabit Ethernet SX adapter troubleshooting chart

Use the following troubleshooting chart to find solutions to gigabit Ethernet adapter

problems that have definite symptoms.

Chapter 3. Troubleshooting 23

Page 34

Table 5. Ethernet troubleshooting chart

Gigabit adapter problem Suggested Action

No Link or TX/RX Activity If you cannot link to your switch, check the following:

1. Check the following LED lights on the adapter:

TX — On

The adapter is sending data

RX — On

The adapter is receiving data.

Link — On

The adapter is connected to a valid link partner and is receiving link

pulses.

Link — Off

Link is inoperative.

v Check all connections at the adapter and link partner

v Make sure the link partner is set to 1000 Mbps and full-duplex

v Ensure the required drivers are loaded

PRO — Programmable LED

Identifies the adapter by blinking. Use the Identify Adapter push-button in

INTEL PROSet II to control blinking.

2. Ensure that the cable is installed correctly. The network cable must be securely

attached at all connections. If the cable is attached but the problem persists, try a

different cable.

Your engine cannot find the

Gigabit Ethernet SX adapter

Diagnostics pass but the

connection fails

Another adapter stopped

working after you installed

the Gigabit Ethernet SX

Adapter

The adapter stopped working

without apparent cause

LINK LED is not On Check the following:

Check the following:

1. Verify that the adapter is seated firmly in the slot

2. Try a different Gigabit Ethernet SX adapter

Check the following:

Ensure the network cable is securely attached

Check the following:

1. Verify that the cable is connected to the Gigabit Ethernet SX Adapter and not to

another adapter.

2. Check for a resource conflict

3. Ensure both adapters are seated firmly in the slot

4. Check all cables

Check the following:

1. Try reseating the adapter

2. The network driver files might be damaged or deleted. Reinstall the drivers

3. Try a different Gigabit Ethernet SX Adapter

1. Ensure that you have loaded the adapter driver

2. Check all connections at the adapter and the buffered repeater or switch

3. Try another port on the buffered repeater or switch

4. Ensure that the buffered repeater or switch port is configured for 1000 Mbps and

full-duplex.

5. Try changing the auto-negotiation setting on the link partner, if possible

24 IBM NAS 300 Service Guide

Page 35

Table 5. Ethernet troubleshooting chart (continued)

Gigabit adapter problem Suggested Action

RX or TX LED is no On Check the following:

1. Ensure that you have loaded the adapter driver

2. Network might be idle; try logging in from a workstation

3. The adapter is not transmitting or receiving data; try another adapter

Running adapter diagnostics

This section describes how to test the adapters using the diagnostics tools.

This section describes how to test the adapters using the diagnostics tools.

Testing the Ethernet adapters with Intel PROSet II

Each IBM NAS 300 engine comes with Intel PROSet II. You can use PROSet to

view the following:

v Adapter parameters such as MAC and IP addresses

v Network link status such as speed, duplex mode, and activity

v Device-driver level used for the adapter

You can also use PROSet II to test the 10/100 Ethernet and GB Ethernet PCI

adapters for any problems with the adapter hardware, cabling, or network

connections. PROSet performs a loopback test on the 10/100 Ethernet and GB

Ethernet PCI cards.

To access the PROSet II utility, go into Terminal Services. For instructions on how

to invoke Terminal Services. Within Terminal Services do the following steps:

1. Go to the Start menu, select Settings, then Control Panel.

2. Double-click the INTEL PROSet II icon in the Control Panel to start the INTEL

PROSet II utility.

3. In the INTEL PROSet II utility, select the Ethernet adapter you want to test

(Gigabit Ethernet PCI adapter or 10/100 Ethernet Adapter).

4. Select the Diagnostics tab. A list of available tests is displayed.

5. Select Run Tests. You can also select or deselect individual tests with the

check boxes. If an error is detected, information about the error is displayed.

6. Repeat Steps 3 through 5 for each Ethernet adapter installed.

For additional information about Intel PROSet, please refer to the online help that

accompanies the utility.

Testing the fibre-channel host adapter with FAStT Check

Note: Ensure that there is no adapter activity before running the test or data can

be lost.

The IBM NAS 300 engine also comes with FAStT Check for viewing the status of

the Fibre Channel connection as well as testing the adapter or cable. To use FAStT

Check, you should first go into Terminal Services.

You access FAStT Check by going into the IBM NAS Admin console, selecting NAS

Management → Storage → NAS Utilities → FAStT Check. Then, select Connect.A

diagnostic panel displays the following general information related to the Fibre

Channel adapter which can be useful if you need to place a support call:

Chapter 3. Troubleshooting 25

Page 36

v Node name

v Serial number (in hex)

v Loop ID

v BIOS version

v Firmware version number

v Device driver version number

v PCI slot number

FAStT Check also provides the engine’s world-wide name (WWN) as detailed in the

IBM NAS 300 User’s Reference..

To test the Fibre Channel adapter, select the adapter and then click the Diagnostic

button. FAStT Check can perform fibre loopback and data tests.

For additional information relating to FAStT Check diagnostic functions, refer to the

online help accessed from its panels.

Checking the FAStT host-bus adapter’s fibre-channel connectivity: In addition

to the above diagnostic function, you can use FAStT Check to determine if your

physical fibre channel connections are in place by doing the following steps:

1. Once Connected with FAStT as above, select the QLA2200 Adapter icon, and

verify that you see all Fibre Controllers that you are physically connected to. If

you see a red X on the QLA2200 Adapter icon, and the icon is yellow, the

adapter cannot register with the 3534 Fibre Channel hub. (A green icon means

connections are in place.) Check the fibre cable connections, and if the

QLA2200 adapter still does not connect, run the adapter and 3534 Fibre

Channel hub diagnostics.

2. If the icon is green, click on the plus sign (+) in front of the adapter icon to see

the state of the attached Fibre channel storage controllers. The absence of

controllers in the display indicates connection problems.

For additional information relating to FAStT Check diagnostic functions, refer to the

online help accessed from its panels.

Testing the Advanced System Management adapter

1. Insert the Advance System Management Utility CD-ROM into the CD-ROM drive

and restart the engine. If the engine does not boot from the CD-ROM, use

POST/BIOS setup to configure the CD-ROM drive as a boot device.

2. After your engine boots, the main option menu appears. The main menu

contains the following selections:

v Hardware Status and Information

v Configuration Settings

v Update System Management firmware

3. Use the up and down arrow keys to select Hardware Status and Information

and press Enter. The Hardware Status and Information menu contains the list

of Advanced System Management devices in the Gateway with the following

diagnostic test results:

26 IBM NAS 300 Service Guide

System Management Processor Communication : Passed

-> Built in Self Test Status ...... : Passed

Boot Sector Code Revision ... :6, Build ID: RIET62A

Main Application Code Revision :4, Build ID: ILET15A

Page 37

System Management Processor Communication : Passed

-> Built in Self Test Status ...... : Passed

Boot Sector Code Revision ... :6, Build ID: WMICT60A

Main Application Code Revision :4, Build ID: WMXT57A

4. Use the up and down arrow keys to select the device you want to look at in

more detail. Press Enter. You will see a list of tests and results on the device:

Current System Management Processor Status

Current BIST Results:

SRAM Memory Test: Passed

Serial Port 1 Test : Passed

Serial Port 2 Test: Passed

NVRAM Memory Test Passed

Realtime Clock Test Passed

Programmable Gate Array Test: Passed

I2C Interface Test: Passed

Main Application Checksum: Passed

Boot Sector Checksum: Passed

Current System Management Adapter Status

Current BIST Results:

SRAM Memory Test: Passed

Serial Port 1 Test : Passed

Serial Port 2 Test: Passed

NVRAM Memory Test Passed

Realtime Clock Test Passed

Programmable Gate Array Test: Passed

I2C Interface Test: Passed

Main Application Checksum: Passed

Boot Sector Checksum: Passed

Onboard Ethernet Hardware Test: Passed

PCI EEPROM Initialization Test: Passed

5. When you are finished viewing this information, press Esc to return to the main

option menu. Remove the CD then restart the engine.

Power checkout

Power problems can be difficult to troubleshoot. For example, a short circuit can

exist anywhere on any of the power distribution busses. Usually a short circuit

causes the power subsystem to shut down because of an overcurrent condition.

A general procedure for troubleshooting power problems is as follows:

1. Power-off the system and disconnect the ac cord(s).