Page 1

IBM TotalStorage™Network Attached Storage 200

Models 200 and 225

Hardware Installation Guide

Page 2

Page 3

IBM TotalStorage™Network Attached Storage 200

Models 200 and 225

Hardware Installation Guide

Page 4

NOTE

Before using this information and the product it supports, read “Appendix E. Notices” on page 117 and “Appendix B. Safety

and environmental notices” on page 73.

First Edition (June 2001)

This edition applies to the IBM TotalStorage Network Attached Storage 200 Model 200 and Model 225 and to all

subsequent releases and modifications until otherwise indicated in new editions.

Order publications through your IBM representative or the IBM branch office servicing your locality. Publications are

not stocked at the address below.

IBM welcomes your comments. A form for reader’s comments is provided at the back of this publication. If the form

has been removed, you may address your comments to:

International Business Machines Corporation

Design & Information Development

Department CGFA

PO Box 12195

Research Triangle Park, NC 27709–9990

U.S.A.

You can also submit comments to www.ibm.com/networking/support/feedback.nsf/docsoverall.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any

way it believes appropriate without incurring any obligation to you.

© Copyright International Business Machines Corporation 2001. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ............................v

Tables ............................vii

About this guide ........................ix

Who should read this guide ....................ix

Safety precautions ........................ix

Frequently used terms.......................x

Publications ..........................xi

Hardcopy publications shipped with the Network Attached Storage Models 200

and225..........................xi

Related publications ......................xi

Accessibility .........................xi

Web site ...........................xi

Chapter 1. Introduction to Network Attached Storage 200 hardware ....1

Standard features ........................1

Optional features ........................2

Specifications ..........................3

Dimensions .........................3

Weight ...........................3

Operating environment .....................3

Nonoperating (power-off) environment ................3

Heat output .........................3

Power requirements ......................3

Included software applications....................3

Chapter 2. Installation procedures .................5

Preinstallation checklist ......................5

Setting up the appliance ......................5

Setting up the Model 200 ....................5

Setting up the Model 225 ....................6

Setting up the Model 225 in a rack .................6

Installing optional features .....................11

Installing a 5194-EXU storage unit.................11

Installing a hot-swap hard drive ..................12

Installing memory modules (DIMMs) ................14

Cabling............................20

Starting the appliance ......................23

Performing initial configuration ...................25

Chapter 3. Adding and replacing components ............27

Before you begin ........................27

Safety information .......................27

System reliability considerations .................27

Working inside an appliance while power is on ............28

Major components of the Network Attached Storage 200 ........29

Adding or removing internal hardware components ...........40

Removing the cover (Model 200) .................40

Removing the cover (Model 225) .................41

Removing the door and bezel (Model 200)..............42

Removing the bezel (Model 225) .................43

Installing internal drives.....................43

© Copyright IBM Corp. 2001 iii

Page 6

Replacing hot-swap power supplies ................48

Replacing the ServeRAID controller ................52

Installing adapters.......................57

Installing or replacing a microprocessor ...............61

Replacing the battery .....................62

Replacing the cover, door, and bezel ................65

Connecting external options ....................68

Installation procedure .....................68

Input/output connector locations .................68

Input/output ports .......................69

Appendix A. Safety precautions ..................71

Appendix B. Safety and environmental notices ............73

Safety notices .........................73

General safety ........................73

Electrical safety........................74

Safety inspection guide .....................75

Handling electrostatic discharge-sensitive devices ...........76

Grounding requirements ....................77

Translated safety notices ....................77

Environmental notices ......................108

Electronic emission notices ...................108

Appendix C. Getting help, service, and information ..........111

Service support ........................111

Before you call for service ....................112

Getting customer support and service ................112

Getting help online: www.ibm.com/storage/support/nas .........112

Getting help by telephone ...................113

Appendix D. Purchasing additional services ............115

Warranty and repair services ...................115

Appendix E. Notices ......................117

Trademarks..........................118

Appendix F. Product warranties and notices ............119

Warranty Statements ......................119

IBM Statement of Limited Warranty for United States, Puerto Rico, and

Canada (Part 1 - General Terms) ................119

IBM Statement of Warranty Worldwide except Canada, Puerto Rico, Turkey,

United States (Part 1 – General Terms) .............122

Part2-Worldwide Country-Unique Terms .............124

Power cords .........................128

Index ............................131

iv IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 7

Figures

1. Front and back of the rack mounting template ....................7

2. Rack mounting instructions ...........................8

3. ServeRAID-4H channel connector locations .....................11

4. Installing a hot-swap hard drive .........................13

5. Removing the cover of the Model 200 .......................15

6. Removing the cover of the Model 225 .......................16

7. Installing a DIMM...............................18

8. Replacing the Model 200 cover .........................19

9. Replacing the Model 225 cover .........................20

10. Cabling the appliance .............................21

11. Routing cables through cable-management assembly .................22

12. Locations of the Information LED, System Error LED, POST Complete (OK) LED, and Power-on

LED ...................................23

13. Locations of major components .........................29

14. System-board options connectors.........................30

15. System-board internal cable connectors ......................31

16. System board external port connectors.......................32

17. System board switches and jumpers .......................33

18. System board LED locations ..........................34

19. Model 200 front view .............................35

20. Model 225 front view .............................36

21. Model 200 rear view .............................37

22. Model 225 rear view .............................38

23. Operator information panel ...........................39

24. Removing the cover of the Model 200 .......................40

25. Removing the cover of the Model 225 .......................41

26. Removing the appliance door of the Model 200 ...................42

27. Removing the bezel of the Model 225 .......................43

28. Installing internal drive bays for the Model 200 ....................44

29. Installing internal drive bays for the Model 225 ....................44

30. Installing a hot-swap drive ...........................45

31. Replacing a drive in a hot-swap drive bay in the Model 200 ...............46

32. Replacing a hot-swap power supply ........................48

33. Removing a hot-swap power supply ........................50

34. Installing a hot-swap power supply ........................51

35. ServeRAID-4H controller ............................52

36. ServeRAID-4L controller ............................53

37. Inserting a ServeRAID-4H controller into the PCI expansion slot .............54

38. Connecting a ServeRAID-4H controller internal channel connector ............55

39. Connecting a ServeRAID-4H controller external channel connector ............56

40. Location of the PCI expansion slots ........................58

41. Installing the adapter .............................60

42. Installing an additional microprocessor .......................61

43. Replacing the battery .............................64

44. Installing the battery..............................64

45. Replace the Model 200 cover ..........................65

46. Replacing the Model 225 cover .........................66

47. Replacing the Model 200 bezel .........................67

48. Replacing the Model 225 bezel .........................68

49. Input/output connectors (ports) and expansion slots ..................69

© Copyright IBM Corp. 2001 v

Page 8

vi IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 9

Tables

1. Standard Features of the Model 200 and Model 225 ..................1

2. Optional Features of Model 200 and Model 225 ....................2

3. Product Information ..............................5

4. Switches1-8................................33

5. Standard features of ServeRAID-4L and ServeRAID-4H ................59

6. IBM Web sites for help, services, and information ..................111

7. Telephone numbers for warranted help and information ................113

© Copyright IBM Corp. 2001 vii

Page 10

viii IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 11

About this guide

This guide provides information necessary to install the hardware for the IBM

TotalStorage™Network Attached Storage 200 appliance.

Who should read this guide

This guide is intended for anyone responsible for planning or performing Network

Attached Storage 200 hardware installations.

Safety precautions

Be sure to read all caution and danger statements in this publication before

performing any of the instructions.

Leia todas as instruções de cuidado e perigo antes de executar qualquer operação.

Prenez connaissance de toutes les consignes de type Attention et Danger avant de

procéder aux opérations décrites par les instructions.

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

© Copyright IBM Corp. 2001 ix

Page 12

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazione.

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a

cabo cualquier operación.

Frequently used terms

The following list of terms, used within this document, have these specific

meanings:

Term Definition in this document

Drive bay A receptacle into which you insert a hard disk drive in an appliance.

The bays could be physically located in a separate rack from the

appliance.

Engine The processor that responds to requests for data from clients. This

is where the operating software for the Network Attached Storage

200 appliance resides.

Storage unit Hardware that contains one or more drive bays, power supplies,

and a network interface. Some storage units contain a RAID

controller. There are no other components in a storage unit, and it

is accessed by a NAS appliance.

Notes These notices provide important tips, guidance, or advice.

Attention These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or

situation in which damage could occur.

Caution These notices indicate situations that can be potentially hazardous

to you. A caution notice is placed just before descriptions of

potentially hazardous procedure steps or situations.

Danger These notices indicate situations that can be potentially lethal or

extremely hazardous to you. A danger notice is placed just before

descriptions of potentially lethal or extremely hazardous procedure

steps or situations.

x IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 13

Publications

Hardcopy publications shipped with the Network Attached Storage Models 200 and 225

The following publications are shipped in hardcopy and are also provided in

softcopy form at www.ibm.com/storage/support/nas:

v IBM TotalStorage Network Attached Storage 200 Hardware Installation Guide,

GA27-4262

This publication provides procedures for setting up, cabling, and replacing

components of the IBM TotalStorage Network Attached Storage Models 200 and

225.

v Release Notes

This document provides any changes that were not available at the time this

publication was produced.

Related publications

The following publications contain additional information about the Network Attached

Storage 200:

v IBM TotalStorage Network Attached Storage 200 User’s Reference, GA27-4263

v IBM TotalStorage Network Attached Storage 200 Service Guide, GA27-0400

v Safety Information, 44L2247

Accessibility

Web site

The softcopy version of this guide and the other related publications are all

accessibility-enabled for the IBM Home Page Reader.

You can obtain complete FAQs, parts information, technical hints and tips, technical

publications, and downloadable files from:

www.ibm.com/storage/support/nas

About this guide xi

Page 14

xii IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 15

Chapter 1. Introduction to Network Attached Storage 200 hardware

The IBM TotalStorage™is designed for workgroups, departments, and solution

providers that have storage area network requirements across heterogeneous

Microsoft

The Model 200 is a tower unit that requires only power and network connections for

setup. For the Model 200, a conversion kit is available to convert the tower for rack

mounting. The Model 225 can be mounted in a 5U rack drawer. The Model 225 has

external SCSI connections for up to three 5194-EXU storage units for a total rack

requirement of 14U.

As an appliance with redundant power supplies, the appliance is shipped with three

power cords. It does not come with a mouse, keyboard, or monitor. The appliance

is already configured; aside from initial configuration to determine the IP address,

you do not need to configure hardware or install for the base model configurations.

The Model 200 requires two connections: power and network.

Standard features

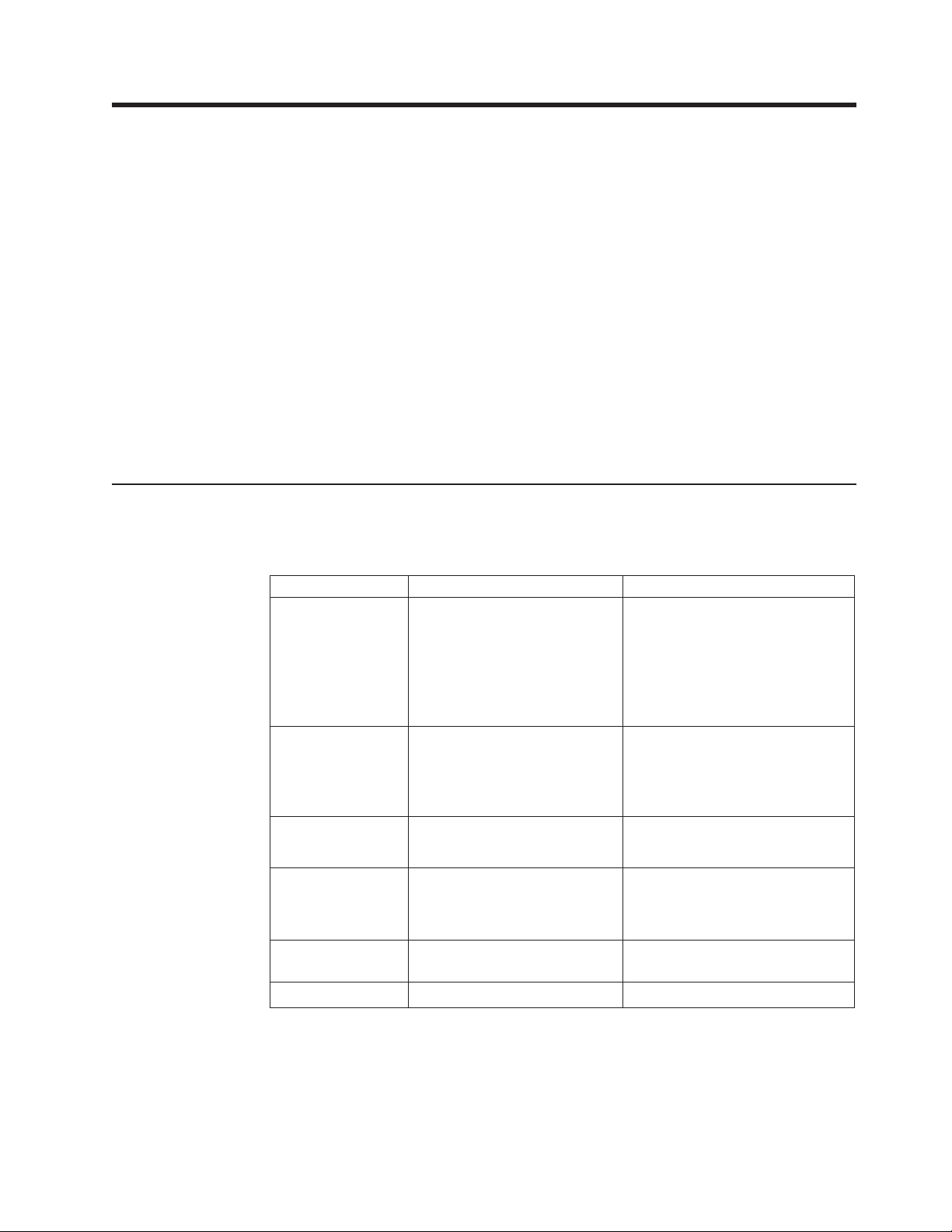

Table 1 lists the standard features of the Model 200 and Model 225.

Table 1. Standard Features of the Model 200 and Model 225

System

Memory

Expansion bays

Hot-swap hard

drives

RAID controller ServeRAID

Power Supplies Three 250 W (115-230 V) Three 250 W (115-230 V)

®

Windows NT®, Windows®2000, and Linux clients.

Hardware Model 200 Model 225

v One 800-MHz Intel Pentium

III with MMX™technology

and SIMD extensions

v 256 KB Level-2 cache

v Integrated 10/100 Ethernet

v Five PCI expansion slots

v 256 MB

v Type: 133-MHz, ECC,

SDRAM, registered DIMMs

v Maximum: 2 GB

v Hot-swap: six slim-high

v Non-hot-swap: two 5.25-inch

Three Ultra160 10000 rpm 36.4

GB

Total: 108 GB

™

-4L

16 MB cache

®

v Two 800-MHz Intel Pentium III

with MMX technology and SIMD

extensions

v 256 KB Level-2 cache

v Integrated 10/100 Ethernet

v Five PCI expansion slots

v 1GB

v Type: 133-MHz, ECC, SDRAM,

registered DIMMs

v Maximum: 2 GB

v Hot-swap: six slim-high

v Non-hot-swap: two 5.25-inch

Six Ultra160 10000 rpm 36.4 GB

Total: 216 GB

ServeRAID-4H

128 MB cache

© Copyright IBM Corp. 2001 1

Page 16

Optional features

Table 2 lists the optional features of the Models 200 and 225.

Optional features for Model 200 and Model 225 include:

v 10/100 Ethernet Adapter 2

v Gigabit Ethernet SX Adapter

v PCI Fast/Wide Ultra SCSI Adapter (for external tape backup)

v Advanced System Management PCI Adapter

v Up to four additional adapters: 10/100 Ethernet or Gigabit Ethernet SX Adapter

Table 2. Optional Features of Model 200 and Model 225

5194-EXU storage unit storage units, each

containing 14 Ultra160 36.4-GB hard drives

36.4 GB 10K-4 Ultra160 SCSI Hot-Swap SL HDD Option to add up

800/133FSB/256 Processor Upgrade Option Standard

Note: The memory listed below is the total system memory configuration that is available.

256 MB 133-MHz ECC SDRAM Standard N/A

512 MB 133-MHz ECC SDRAM Option N/A

1 GB 133-MHz ECC SDRAM Option Standard

2 GB 133-MHz ECC SDRAM Option Option

5600 Tower-to-Rack Kit Option Rack-mountable

Feature Model 200 Model 225

Not an option Option to add up

to three

additional units

Includes six

to three

additional units

standard units

(standard)

2 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 17

Specifications

Dimensions

Model 200 Model 225 Model EXU

Front 217.3 mm (8.6 in) 426.5 mm (16.8 in) 444.0 mm (17.5 in)

Side 659.3 mm (26.0 in) 629.3 mm (24.8 in) 519.0 mm (20.4 in)

Height 426.5 mm (16.8 in) 217.3 mm (8.6 in) 127.5 mm (5.0 in)

Weight

Model 200 Model 225 Model EXU

Approx. 26.6 kg (58.6 lb)

without extra hard drives

Approx. 37.5 kg (82.7 lb)

when fully configured

Approx. 25.2 kg (55.7 lb)

without extra hard drives

Approx. 36.2 kg (79.8 lb)

when fully configured

Approx.with all hard drives:

34.5 kg (76 lb)

Operating environment

Models 200 and 225

Air temperature

at altitudes up to 914 m (2999 ft.) 10° -35° C (50.0° - 95.0° F)

at altitudes from 914 m (2999 ft. to 2133 m (6998 ft) 10° -32° C (50.0° - 89.6° F).

Humidity 8% - 80%

Nonoperating (power-off) environment

Models 200 and 225

Temperature (at max. altitude of 2133 m [6998 ft]) 10° -43° C (50.0° - 109.4° F)

Humidity 8% - 80%

Heat output

Approximate heat output for Models 200 and 225:

Minimum configuration 683 BTU (200 watts)

Maximum configuration 2048 BTU (600 watts)

Power requirements

Voltage low range 100 - 127 V ac, 50 - 60 Hz

Voltage high range 200 - 240 V ac, 50 - 60 Hz

Power consumption 0.08 - 0.52 kVA

Included software applications

See IBM TotalStorage Network Attached Storage 200 User’s Guide for a list of

applications included for Network Attached Storage 200.

Chapter 1. Introduction to Network Attached Storage 200 hardware 3

Page 18

4 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 19

Chapter 2. Installation procedures

This chapter provides information about how to install the Models 200 and 225.

Preinstallation checklist

Before beginning installation, record your product information in Table 3. Refer to

this information when service is necessary.

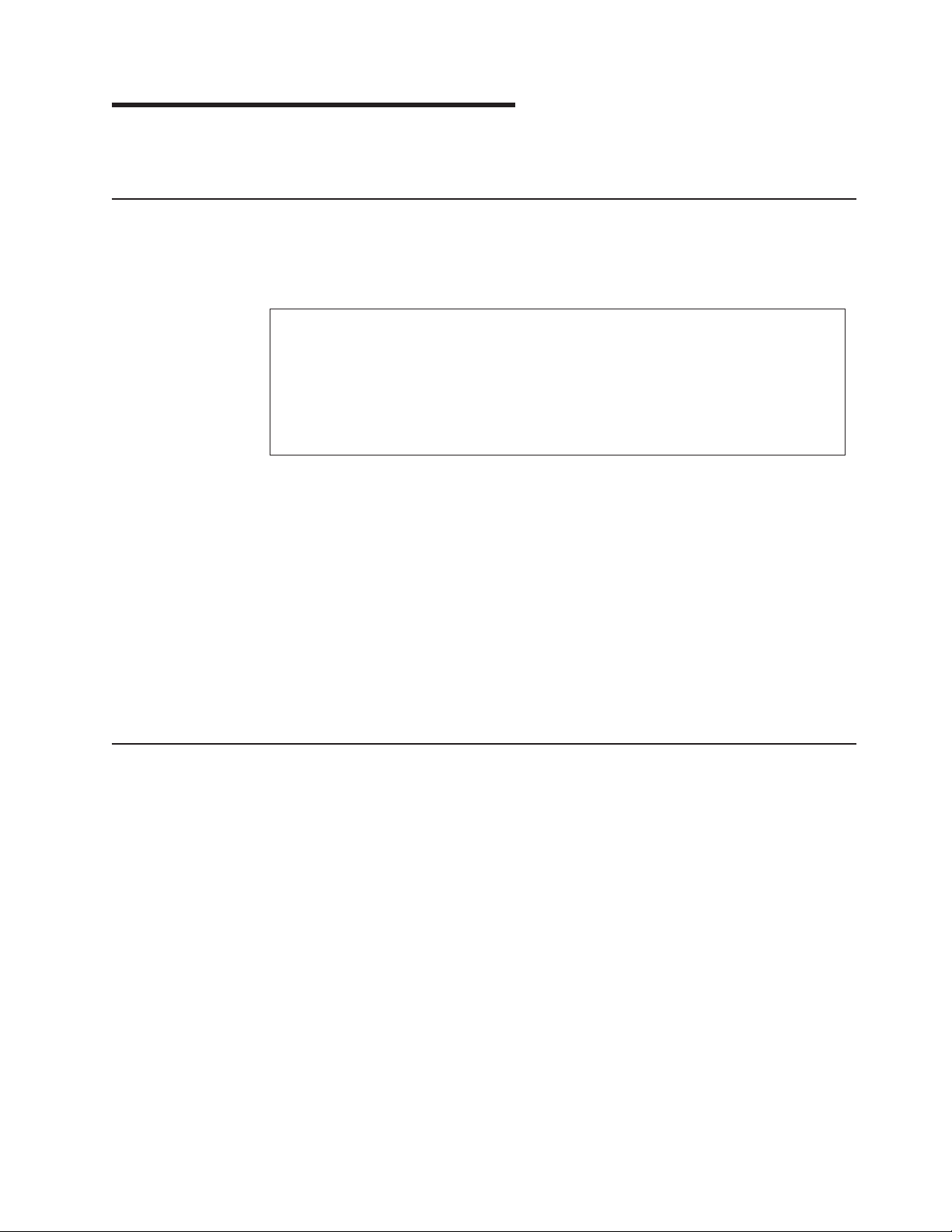

Table 3. Product Information

Record your product information in this table.

Product name _____________________________________________

Machine type _____________________________________________

Model number _____________________________________________

Serial number _____________________________________________

In addition to this IBM TotalStorage Network Attached Storage 200 Installation

Guide, make sure that you have the following items:

v Model 200 or Model 225

v Power cords (3)

v Recovery CD

v Rack-mounting kit (for Model 225)

v Safety Information, IBM Part Number 44L2247

If you ordered options for the appliance, this package might contain additional

hardware, , or publications for those options.

If an item is missing or damaged, contact your place of purchase.

Setting up the appliance

This section provides information about the initial installation and setup for the

Models 200 and 225.

Setting up the Model 200

The initial installation of the Model 200 consists of the following steps:

1. Installing optional features (see “Installing optional features” on page 11).

2. Connecting the power cords and communication cables (see “Cabling” on

page 20).

3. Starting the appliance and verifying that the power-on diagnostics completed

successfully (see “Starting the appliance” on page 23).

4. Performing the initial configuration (see “Performing initial configuration” on

page 25).

© Copyright IBM Corp. 2001 5

Page 20

Setting up the Model 225

The initial installation of a Model 225 consists of the following steps:

1. Installing in a rack (see “Setting up the Model 225 in a rack”).

2. Installing optional features (see “Installing optional features” on page 11 and

“Installing a 5194-EXU storage unit” on page 11).

3. Connecting the power cords and communication cables (see “Cabling” on

page 20).

4. Starting the appliance and verifying that the power-on diagnostics completed

successfully (see “Starting the appliance” on page 23).

5. Performing the initial configuration (see “Performing initial configuration” on

page 25).

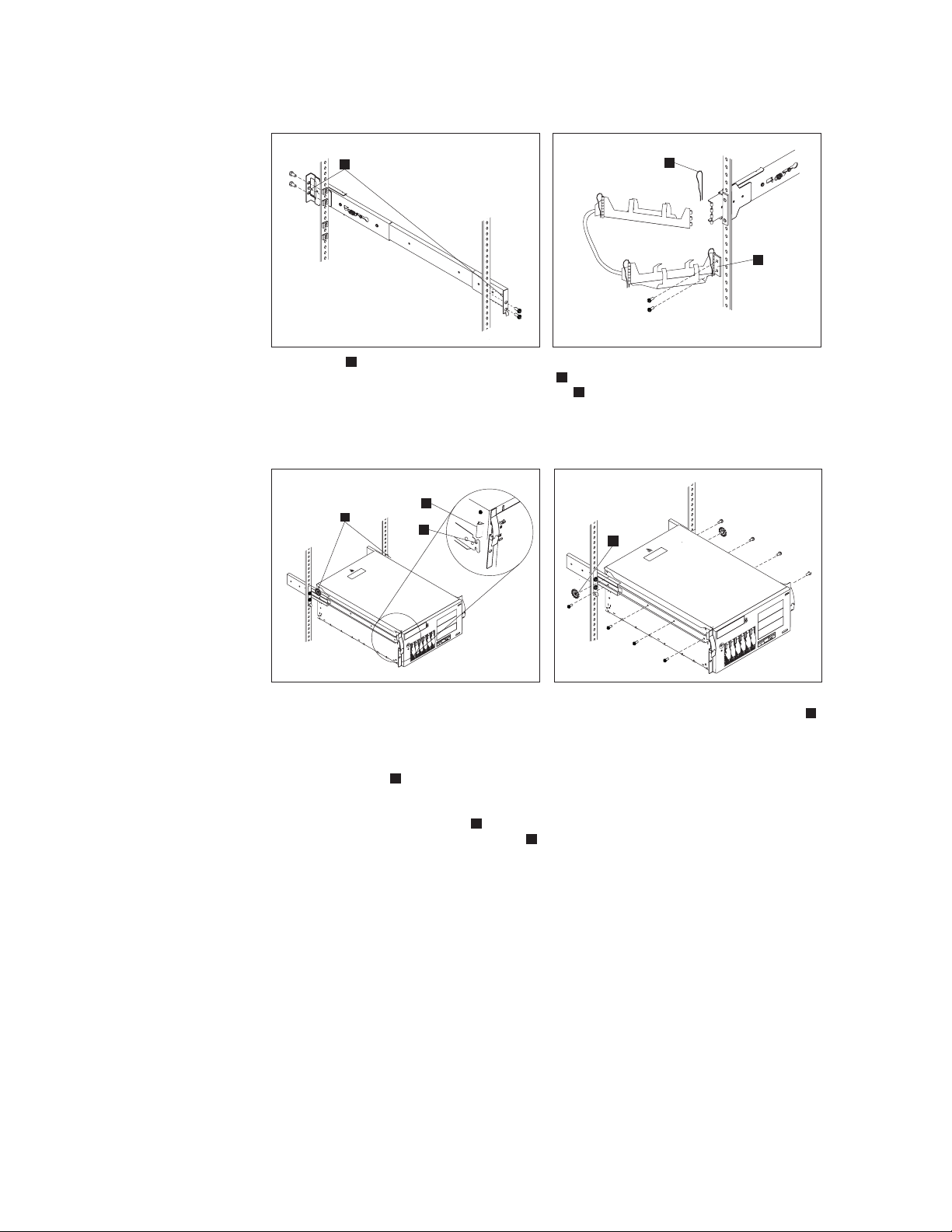

Setting up the Model 225 in a rack

For Model 225, you must first install the appliance in a rack, using the

rack-mounting kit provided.

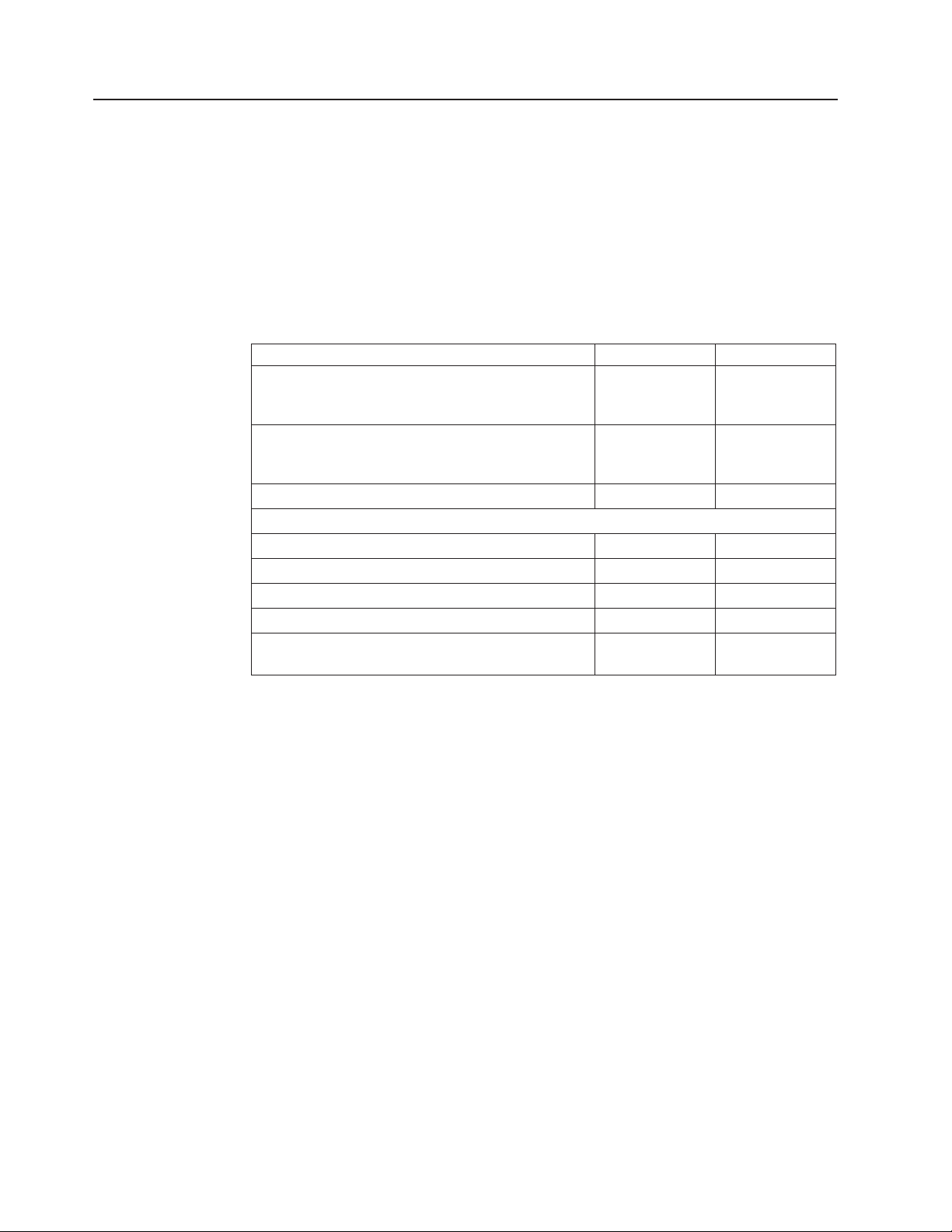

The following reduced-size illustration of the front and the back of the rack mounting

template shows where to place the clip nuts or cage nuts when installing your

appliance in a rack.

6 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 21

FRONT

Rack Mounting

Template

REAR

Rack Mounting

Template

Slide rail

()Front Left

Release-latch-bracket

assembly

()Front Left

Slide rail

()Front Right

Release-latch-bracket

assembly

()Front Right

Slide rail

()Rear Left

Slide rail

()Rear Right

Hinge bracket

()Rear Right

Figure 1. Front and back of the rack mounting template

Chapter 2. Installation procedures 7

Page 22

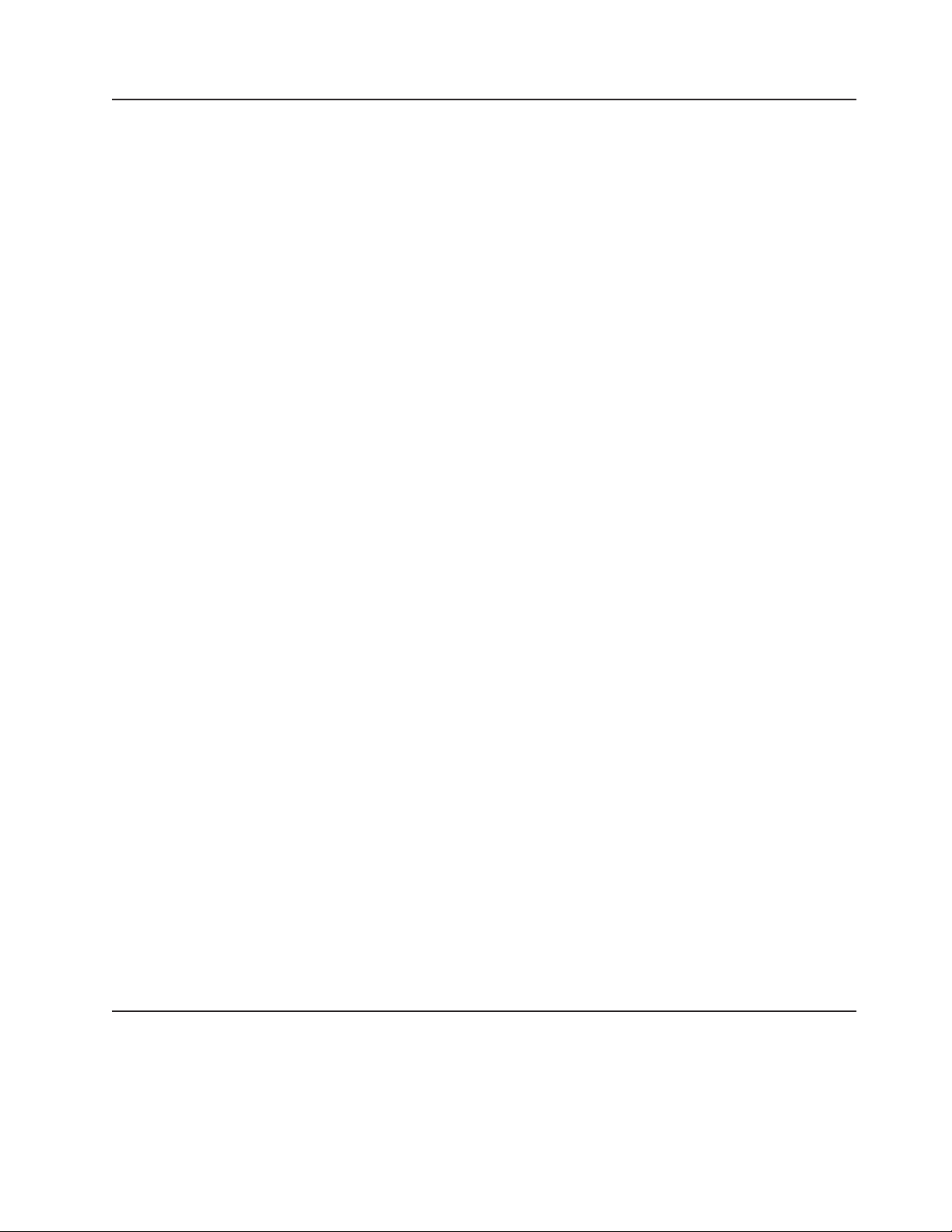

Rack Mounting Instructions

• Review the documentation that comes with your rack enclosure.

• Maintain 15 cm (6 in.) of clearance around your appliance for air circulation.

• Ensure the room air temperature is below 35°C(95°F).

• Plan the installation working from the bottom of the rack up.

• Remove the rack doors and the side panels during the installation, if necessary.

• Position the template to the rack so that the edges of the template do not

overlap any other devices to be installed.

• Connect all power cords on the and on other devices to properly wired

and grounded electrical outlets.

• Take precautions to prevent the rack from overloading the power outlets

when you install multiple devices in a rack.

The following is a list of items shipped in your rack installation kit. If any

items are missing or damaged, contact your place of purchase.

• Cable-management assembly

• Cable straps (7)

• Cable ties (10)

• Cage nuts (12)

appliance

appliance

• Do not place any object weighing more than 82kg

(180 lb) on top of rack-mounted devices.

• Use safe practices when lifting.

• Clip nuts (12)

• Screw packages (2)

• Slide rails (2)

32 kg (70.5 lb)82 kg (180 lb)

1

T

e

m

p

l

a

t

e

Use the attached stickers to mark the holes on

the front and the rear of the rack in the

locations indicated by the arrows on the

template.

Figure 2. Rack mounting instructions

2

Cage

nuts

Cage

nuts

Use a screwdriver or the cage-nut-insertion

tool to insert the cage nuts, or s

as required for your rack, into all the

nuts,

marked holes.

Clip

nuts

lide on the clip

8 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 23

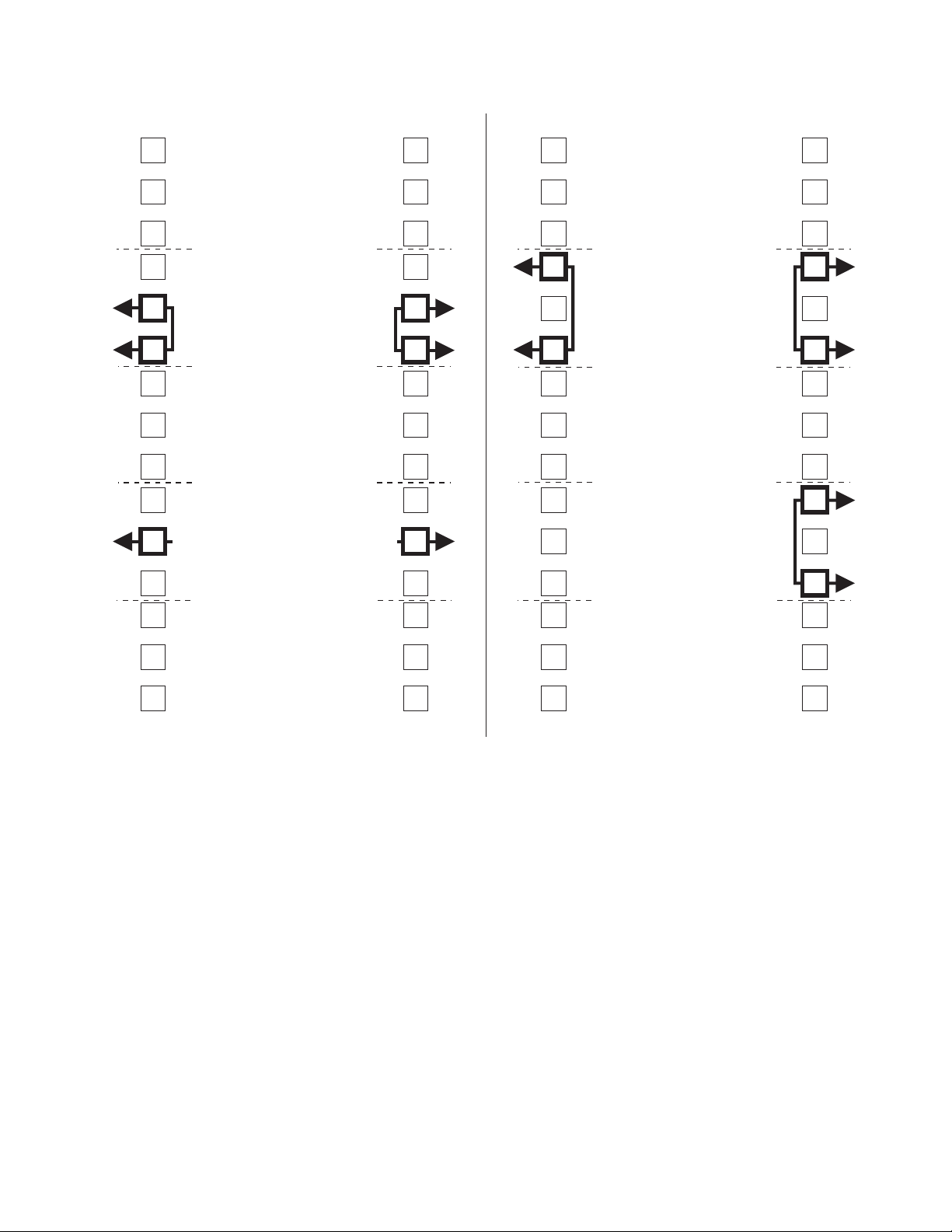

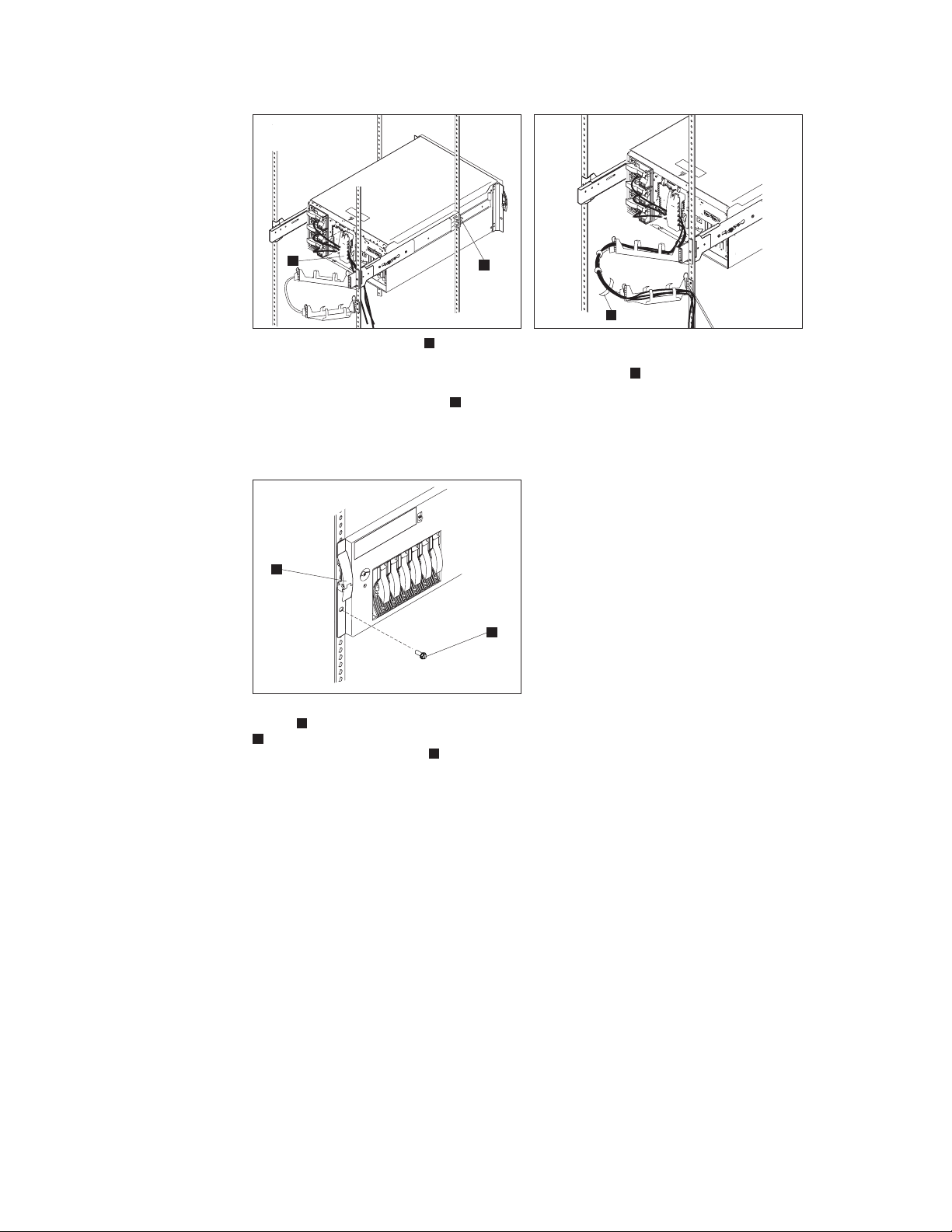

3

A

4

B

A

Use the pins on the slide rail to align the

slide rail to the rack. Use the M6 screws to

bolt the slide rail to the rack (left front of rack

shown here). Repeat this step for the other

slide rail.

5

Caution: To avoid injury, do not place your

fingers around the rack-support wheels when

lowering the onto the rails.appliance

Fully extend the slide rails out of the rack. Lift

the above the rails; then, rest the

appliance

rack-support wheels located on the rear of the

appliance

the onto the slide rails.

appliance

Note:

front of the fit securely on the tabs

located on the front of the slide rails.

A

A

on the slide rails. Lower the front of

Be sure the bracket notches on the

appliance

B

C

A

B

C

Use the M6 screws to attach the hinge bracket

A

to the rear of the rack. Then, use the hinge

B

pin to attach the cable-management

assembly to the slide rail. (Right rear of rack

shown here).

6

A

Use the M4 screws to secure the appliance to

the rails. Unscrew the rack-support wheels

and store them in a safe place.

A

Chapter 2. Installation procedures 9

Page 24

87

B

Press in on the safety latches and slide the

appliance

halfway into the rack. Attach the

A

A

power, keyboard, mouse, and monitor cables

(if required) to the and route them

through the cable restraint bracket . Then,

appliance

B

attach all other required cables to the

appliance.

9

A

B

Slide the into the rack until the release

latches snap shut. Then, insert the M6 screws

B

Note:

you are moving the rack or the rack is in a

vibration-prone area.

appliance

A

through the release-latch-bracket assembly.

Inserting the M6 screws is optional, unless

B

A

Route all the cables through the cablemanagement assembly as shown. Then, use

the cable straps or the cable ties to secure

A

the cables to the cable-management assembly.

10 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 25

Installing optional features

The appliance has several optional features available.

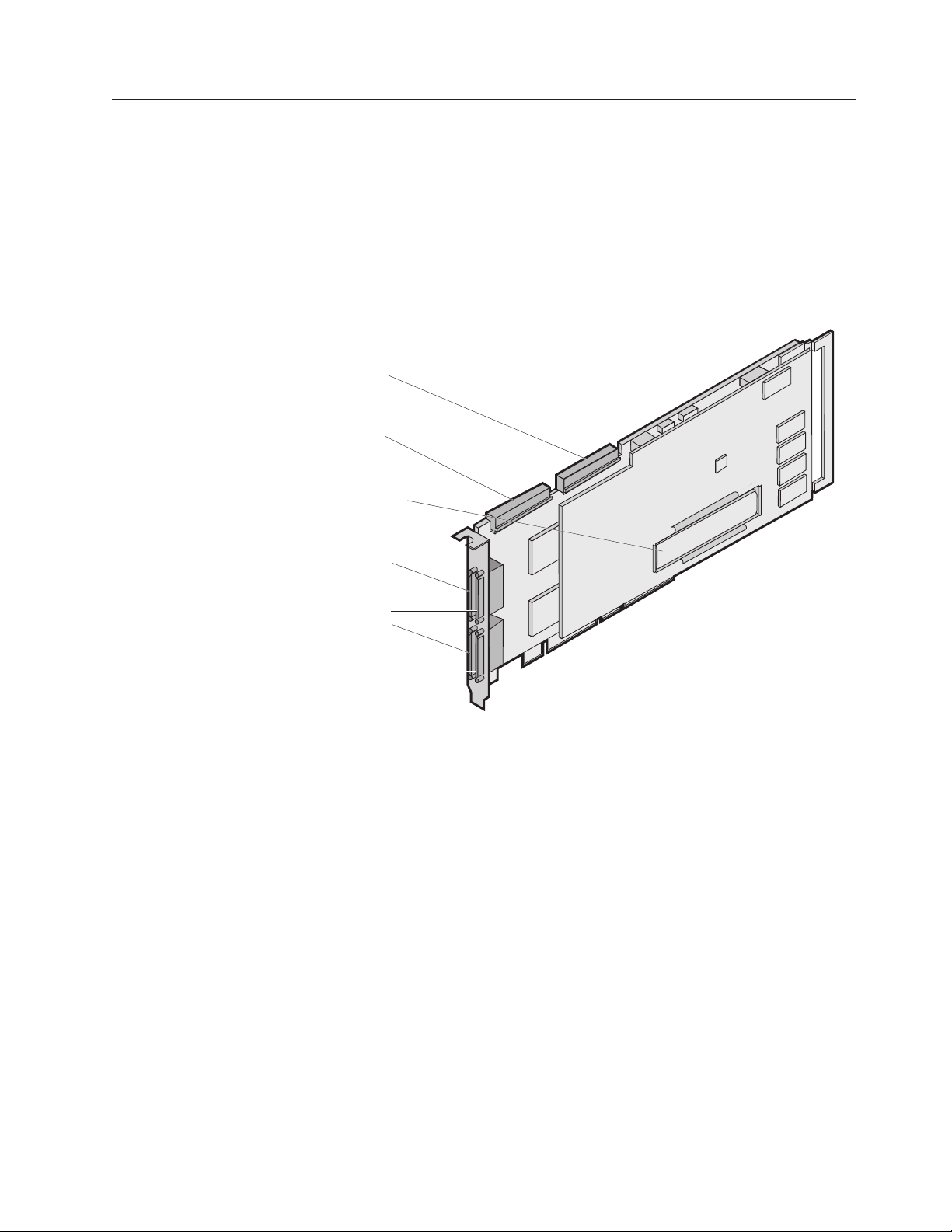

Installing a 5194-EXU storage unit

The Model 225 includes the option of installing up to three additional 5194-EXU

storage units, or Model EXUs. The internal hot-swap SCSI disks are connected

internally to Channel 1 for both the ServeRAID-4H and ServeRAID-4L adapters. You

cannot attach a 5194-EXU storage unit to a Model 200 because ServeRAID-4L has

only one channel connector.

Internal Channel 2

Internal Channel 1

Battery-backup cache

External Channel 1

External Channel 2

External Channel 3

External Channel 4

Figure 3. ServeRAID-4H channel connector locations

Important: When adding 5194-EXU storage units to the Model 225, connect the

first additional storage unit to Channel 2, the second to Channel 3, and

so forth.

Notes:

1. The ServeRAID-4L and ServeRAID-4H adapters do not support configurations

that use both the internal and external connectors on the same channel

concurrently. For example, you cannot use both external Channel 1 and internal

Channel 1.

2. The battery-backup cache protects the data stored in the ServeRAID cache

memory during a power outage or failure when using the write-back mode.

3. The ServeRAID-4H controller uses the module (part number 38L3386)

containing a lithium battery.

Chapter 2. Installation procedures 11

Page 26

Statement 2

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module

type made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Note: For translations of the safety notices that are included in this guide, refer to

Safety Information.

To connect 5194-EXU storage units to an external channel connector on the

ServeRAID-4H controller:

1. Connect one end of a 68-pin very high density connector interface (VHDCI)

SCSI cable to an external channel connector on the ServeRAID-4H adapter.

Note: See Figure 3 on page 11 for the channel connector locations.

2. Connect the other end of the SCSI cable to the 5194-EXU storage unit. For

detailed installation and cabling instructions for the 5194-EXU storage unit, refer

to the IBM TotalStorage Network Attached Storage 5194-EXU Storage Unit

Installation and User’s Guide.

Installing a hot-swap hard drive

You can install up to three hot-swap drives in the Model 200. (The Model 225

already has the maximum number of hot-swap drives allowed without adding a

5194-EXU storage unit.)

Each hot-swap drive that you plan to install must have a hot-swap-drive tray

attached. The drive must have a single connector attachment (SCA) connector.

Hot-swap-drive trays come with the hot-swap drives.

v Models 200 and 225 support six slim (1-inch) 3.5-inch hot-swap hard disk drives

in the hot-swap bays. The Model EXU supports 14 slim (1-inch) 3.5-inch

hot-swap hard disk drives.

v The hot-swap bays connect to the planar. The planar is the printed circuit board

behind the bay.

v The planar controls the SCSI IDs for the hot swap drives.

12 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 27

Slim filler

Filler panel

Hard disk drive

Drive tray

Drive tray handle

(in open position)

Figure 4. Installing a hot-swap hard drive

Attention:

v To maintain proper system cooling, do not operate the appliance for more than

two minutes without either a drive or a filler panel installed for each bay.

v You do not need to switch off the Models 200 and 225 or remove covers to install

or replace hot-swap power supplies or hot-swap hard drives.

v Back up all important data before you make changes to hard drives.

v When you handle electrostatic discharge-sensitive devices (ESDs), take

precautions to avoid damage from static electricity. For details on handling these

devices, refer to “Handling electrostatic discharge-sensitive devices” on page 76.

To install a hard disk drive in a hot-swap drive bay:

1. Review the safety precautions in “Safety precautions” on page ix.

2. Remove the filler panel from one of the empty hot-swap bays by inserting your

finger into the depression at the left side of the filler panel and pulling it away

from the appliance.

3. Install the hard disk drive in the hot-swap bay:

a. Ensure the tray handle is open (that is, perpendicular to the drive).

b. Align the rails on the drive assembly with the guide rails in the drive bay.

c. Gently push the drive assembly into the bay until the drive connects to the

planar.

d. Push the tray handle toward the closed position until it locks the drive in

place.

4. Check the hard disk drive status indicators to verify that the hard disk drives are

operating properly :

v When the amber LED is on continuously, the drive has failed.

v When the green LED flashes slowly (one flash per second), the drive is being

rebuilt.

v When the green LED flashes rapidly (three flashes per second), the controller

is identifying the drive.

Chapter 2. Installation procedures 13

Page 28

Installing memory modules (DIMMs)

You can install additional memory modules to the Model 200, which includes one

256-MB DIMM.

This section describes how to replace a memory module. It consists of four steps:

1. Prepare to install the memory module (see “Preparing to install a memory

module”).

2. Remove the cover (see “Removing the cover” on page 15).

3. Install the memory module (see “Adding the memory module” on page 17).

4. Replace the cover (see “Replacing the cover” on page 19).

Preparing to install a memory module

Read these notes before installing a memory module.

Note:

v Become familiar with the safety and handling guidelines specified under

“Handling electrostatic discharge-sensitive devices” on page 76.

v The blue color on components and labels inside your Models 200 and 225

identifies touch points where a component can be gripped, a latch moved,

and so on. The only exception to this is the power supplies, which are

orange.

v Make sure that you have an adequate number of properly grounded

electrical outlets for Models 200 and 225 and any other options that you

intend to install.

v Have a small, flat-blade screwdriver available.

v Before you begin installing components, read the safety information found

in “Translated safety notices” on page 77.

v For translations of the safety notices that are included in this guide, refer

to Safety Information.

14 IBM TotalStorage

System reliability considerations: To help ensure proper cooling and system

reliability, make sure that:

v Each of the drive bays has either a drive or a filler panel installed.

v The cover is in place during normal operations, or is removed for no longer than

30 minutes while the appliance is operating.

Note: The front door (Model 200) can be removed permanently without affecting

system reliability.

v There is space around the appliance to allow the appliance cooling system to

work properly.

– For Model 200, leave about 127 mm (5 in.) of space around the front and rear

of the appliance.

– For Model 225, refer to the documentation that comes with the rack.

v A removed hot-swap drive is replaced within 2 minutes of removal.

v Cables for optional adapters are routed according to the instructions provided

with the adapters.

v A failed fan is replaced within 48 hours.

™

Network Attached Storage 200 Installation Guide

Page 29

Removing the cover

Removing the Model 200 cover:

Left-side cover

Cover

release

lever

Figure 5. Removing the cover of the Model 200

To remove the left-side cover of the Model 200:

1. Review the information in “Preparing to install a memory module” on page 14.

2. Switch off the appliance and all attached devices and disconnect all external

cables and power cords.

3. Slide the cover-release lever on the front of the appliance to release the cover;

then, slide the cover toward the rear of the appliance about 25 mm (1 in.). Move

the top edge of the cover out from the appliance; then, lift the cover off the

appliance. Set the cover aside.

Attention: For proper cooling and airflow, replace the cover before switching

on the appliance. Operating the appliance for extended periods of time (over 30

minutes) with the cover removed might damage appliance components.

Chapter 2. Installation procedures 15

Page 30

Removing the Model 225 cover:

Top cover

Right-side

latch

Cover release lever

Left-side latch

Figure 6. Removing the cover of the Model 225

To remove the appliance top cover:

1. Review the information in “Preparing to install a memory module” on page 14.

2. Switch OFF the appliance and all attached devices and disconnect all external

cables and power cords.

3. Release the left and right side latches and pull the appliance out of the rack

enclosure until both slide rails lock.

Note: When the appliance is in the locked position, you can reach the cables

on the back of the appliance.

4. Move the cover-release lever down while sliding the top cover toward the rear of

the appliance about 25 mm (1 in.). Lift the cover off the appliance and set the

cover aside.

Attention: For proper cooling and airflow, replace the cover before switching

on the appliance. Operating the appliance for extended periods of time (over 30

minutes) with the cover removed might damage appliance components.

16 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 31

Adding the memory module

Read these notes before adding the memory module.

Note: The Model 200 supports additional 256-MB, 512-MB, and 1-GB DIMMs. The

Model 225 supports additional 512-MB DIMMs. Both models support a

maximum of 2-GB of memory.

To install a memory module (DIMM):

Attention: When you handle electrostatic discharge-sensitive devices (ESDs),

take precautions to avoid damage from static electricity. For details on handling

these devices, refer to “Handling electrostatic discharge-sensitive devices” on

page 76.

1. Review the safety precautions listed in Statement 1 and Statement 5 in

“Translated safety notices” on page 77.

2. Review the documentation that comes with your option.

3. Switch off the appliance and peripheral devices and disconnect all external

cables and power cords.

4. Remove the cover.

5. Touch the static-protective package containing the DIMM to any unpainted metal

surface on the appliance. Then, remove the DIMM from the package.

Note: To avoid breaking the retaining clips or damaging the DIMM connectors,

handle the clips gently.

Chapter 2. Installation procedures 17

Page 32

6. Install the DIMM:

a. Turn the DIMM so that the pins align correctly with the connector.

b. Insert the DIMM into the connector by pressing on one edge of the DIMM

and then on the other edge of the DIMM. Be sure to press straight into the

connector. Be sure that the retaining clips snap into the closed positions.

c. Make sure the retaining clips are in the closed position. If a gap exists

between the DIMM and the retaining clips, the DIMM has not been properly

installed. In this case, open the retaining clips and remove the DIMM; then,

reinsert the DIMM.

DIMM 2

DIMM 1

DIMM connector 4 (J18)

DIMM connector 3 (J19)

DIMM connector 2 (J21)

DIMM connector 1 (J23)

Figure 7. Installing a DIMM

7. Install additional DIMMs in the order specified in the documentation that comes

with your option. (See Figure 7 for memory connector locations.)

8. Continue with “Replacing the cover” on page 19.

18 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 33

Replacing the cover

Replacing the Model 200 cover:

Slots

Left-side cover

Figure 8. Replacing the Model 200 cover

To replace the appliance left-side cover:

1. Align the cover with the left side of the appliance, about 25 mm (1 in.) from the

front of the appliance; place the bottom of the cover on the bottom rail of the

chassis.

2. Insert the tabs at the top of the cover into the slots at the top of the appliance.

3. Hold the cover against the appliance and slide the cover toward the front of the

appliance until the cover clicks into place.

4. Switch on the appliance.

5. The system displays a message indicating that the memory configuration has

changed. Start the Configuration/Setup Utility program and select Save

Settings.

6. Restart the appliance.

Chapter 2. Installation procedures 19

Page 34

Replacing the Model 225 cover:

Flange

Top cover

Flange

Side latches

Figure 9. Replacing the Model 225 cover

To replace the appliance top cover:

1. Align the top cover with the top of the appliance, about 25 mm (1 in.) from the

front of the appliance; the flanges on the left and right sides of the cover should

be on the outside of the appliance chassis.

2. Hold the cover against the appliance and slide the cover toward the front of the

appliance until the cover clicks into place.

3. Switch on the appliance.

4. The system displays a message indicating that the memory configuration has

changed. Start the Configuration/Setup Utility program and select Save

Settings.

5. Restart the appliance.

Cabling

20 IBM TotalStorage

For each of the three power supplies, connect one end of the power cord to the

power supply and the other end to an appropriate outlet. Connect one end of the

Gigabit Ethernet cable to the Gigabit Ethernet Adapter located in one of the

expansion slots (see Figure 10 on page 21) and the other to the system network.

Note: You may use a 10/100 Ethernet cable if your network does not support

Gigabit Ethernet.

When you cable the appliance, be sure to route the power and network cables

through the cable-restraint bracket on the rear of the appliance.

™

Network Attached Storage 200 Installation Guide

Page 35

Serial A

Keyboard

Service

Ethernet

Video

Figure 10. Cabling the appliance

Cable-restraint

bracket

ServeRAID

Gigabit Ethernet

Chapter 2. Installation procedures 21

Page 36

Additionally, for Model 225, be sure to thread the cables through the cable-restraint

bracket and then route the cables through the cable-management assembly on the

rack (see Figure 11).

Cable straps

Figure 11. Routing cables through cable-management assembly

22 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 37

Starting the appliance

Complete the installation by switching on the appliance and running the power-on

diagnostics. Each time the appliance is switched on, it runs a self-testing program

to ensure that it is running correctly. See Figure 12 for the locations of the

Information LED, System Error LED, POST Complete (OK) LED, and Power-on

LED.

Note: Depending on the system status, other LEDs may be on.

34

OK

100

MB

Figure 12. Locations of the Information LED, System Error LED, POST Complete (OK) LED,

and Power-on LED

1 Information LED

2 System Error LED

LINK

OK

TX

RX

3 Power-on LED

4 POST Complete (OK) LED

If a problem is detected during the diagnostics, refer to the IBM TotalStorage

Network Attached Storage Models 200 and 225 Service Guide.

After you plug the power cord of the appliance into the power supply and an

electrical outlet, start the appliance by pressing the power button on the front of the

appliance.

Note: After you plug the power cord of the appliance into an electrical outlet, wait

approximately 20 seconds before pressing the power button. During this

time, the system-management processor is initializing and the power button

does not respond.

Attention: The operating system undergoes a series of initialization operations

upon start up. The first time you start the appliance, a series of configuration and

system preparation programs that finish configuring the NOS are run automatically.

These programs must finish running before you use any included applications to

connect to or configure your appliance. Wait at least 5 minutes to connect to or

configure the appliance after the initial system start.

Chapter 2. Installation procedures 23

Page 38

Note: This notice applies only to the first time the appliance is started.

When switching off the appliance, be aware of the following safety precautions:

v Statement 5

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

Note: For translations of this safety notice, refer to Safety Information.

You can switch off the appliance as follows:

v Press the power button on the front of the appliance. This starts an orderly

shutdown of the operating system, if this feature is supported by your operating

system, and places the appliance in standby mode.

Note: After switching off the appliance, wait at least 5 seconds before you press

the power button to switch on the appliance again.

v Press and hold the power button for more than 4 seconds to cause an immediate

shutdown of the appliance and place the appliance in standby mode. You can

use this feature if the operating system ceases to function.

v Disconnect the appliance power cords from the electrical outlets to shut off all

power to the appliance.

Note: Wait about 15 seconds after disconnecting the power cords for your

system to stop running. Watch for the Power-on LED on the operator

information panel to stop blinking.

24 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 39

Performing initial configuration

Refer to the IBM TotalStorage Network Attached Storage Models 200 and 225

User’s Reference for software configuration and setup.

Chapter 2. Installation procedures 25

Page 40

26 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 41

Chapter 3. Adding and replacing components

This chapter instructs you on how to add and replace components, informs you

about safety and system reliability, and shows you the location of the major

components.

Before you begin

Before you begin to install options in your Models 200 and 225, read the following

information:

v Become familiar with the safety and handling guidelines specified under

“Handling electrostatic discharge-sensitive devices” on page 76.

v You do not need to switch off the Models 200 and 225 or remove covers to install

or replace hot-swap power supplies or hot-swap hard drives.

v The blue color on components and labels inside your Models 200 and 225

identifies touch points where a component can be gripped, a latch moved, and so

on.

v Make sure that you have an adequate number of properly grounded electrical

outlets for Models 200 and 225 and any other options that you intend to install.

v Back up all important data before you make changes to hard drives.

v Have a small, flat-blade screwdriver available.

Safety information

Before you begin installing components, read the safety information found in

“Translated safety notices” on page 77. For translations of the safety notices that

are included in this guide, refer to Safety Information.

System reliability considerations

Adding options to the base configurations could increase power requirements

beyond the limit for redundancy. To ensure that redundancy is maintained, check

the status of the NON LED on the system board after you install any option.

To help ensure proper cooling and system reliability, make sure that:

v Each of the drive bays has either a drive or a filler panel installed.

v The cover is in place during normal operations, or is removed for no longer than

30 minutes while the appliance is operating.

Note: The front door (Model 200) can be removed permanently without affecting

system reliability.

v There is space around the appliance to allow the appliance cooling system to

work properly.

– For Model 200, leave about 127 mm (5 in.) of space around the front and rear

of the appliance.

– For Model 225, refer to the documentation that comes with the rack.

v A removed hot-swap drive is replaced within 2 minutes of removal.

v Cables for optional adapters are routed according to the instructions provided

with the adapters.

v A failed fan is replaced within 48 hours.

© Copyright IBM Corp. 2001 27

Page 42

Working inside an appliance while power is on

Your appliance is designed to operate safely while switched on with the cover

removed. Follow these guidelines when you work inside an appliance that is

switched on:

v Avoid loose-fitting clothing on your forearms. Button long-sleeved shirts before

working inside the appliance; do not wear cuff links while you are working inside

the appliance.

v Do not allow your necktie or scarf to hang inside the appliance.

v Remove jewelry, such as bracelets, rings, necklaces, and loose-fitting wrist

watches.

v Remove items from your shirt pocket (such as pens or pencils) that could fall into

the appliance as you lean over it.

v Take care to avoid dropping any metallic objects, such as paper clips, hair pins,

or screws, into the appliance.

28 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 43

Major components of the Network Attached Storage 200

Figure 13 shows the locations of major components in your appliance.

Note: The illustrations in this document might differ slightly from your hardware.

Microprocessor

Adapter

retention

bracket

Adapter

support

bracket

Fan

Power supply

Terminator card

Memory module

Figure 13. Locations of major components

Fan (blower)

Chapter 3. Adding and replacing components 29

Page 44

System board

Figure 14 identifies system-board connectors for user-installable options.

PCI slot 5

64-bit

33 MHz (J44)

Battery

PCI slot 4

64-bit

33 MHz (J39)

PCI slot 3

64-bit

33 MHz (J34)

PCI slot 2

32-bit

33 MHz (J32)

PCI slot 1

32-bit

33 MHz (J27)

DIMM 1 (J23)

DIMM 2 (J21)

DIMM 3 (J19)

DIMM 4 (J18)

Microprocessor 2 (U17)

Microprocessor 1 (U3)

Voltage regulator

module (VRM2) (U29)

Figure 14. System-board options connectors

30 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 45

Figure 15 identifies system-board connectors for internal cables.

Fan 3 (J35)

Main power (J4)

Power-signal (J51)

DASD (SCSI) system

management (J5)

Power-system management

and signal (J12)

Diskette (J26)

IDE (J31)

On-Off/Reset

panel (J38)

Fan 2 (J60)

Figure 15. System-board internal cable connectors

Fan 1 (unused) (J59)

Operator information

panel (J50)

Chapter 3. Adding and replacing components 31

Page 46

Figure 16 identifies system-board connectors for external devices.

Video/Advanced

System Management

Processor port (J13)

Ethernet port (J9)

Keyboard/mouse port (J6)

Serial ports (J3)

Figure 16. System board external port connectors

32 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 47

Figure 17 identifies the switches and jumpers on the system board.

System board jumper blocks

Boot block

jumper (J37)

System board

switch block (SW1)

Figure 17. System board switches and jumpers

Diagnostics

panel

Any jumper blocks on the system board that are not shown in the illustration are

reserved. For normal operation of the system, no jumpers should be installed on

any of the jumper blocks. See Figure 17 for information about the boot block

jumper.

System board switch block

The switch block contains microswitches1-8.Switch 8 is at the top of the switch

block and switch 1 is at the bottom. The Off position for each switch is the side

nearer the diagnostics panel.

Table 4 describes the function for each switch.

Table 4. Switches 1 - 8

Switch

number

8 Bypass power-on password. The default setting is Off.

7 Reserved. The default setting is Off.

6 Clock frequency selection. The default setting is Off.

Switch

description

When toggled to the On position and back to Off, clears the power-on

password, if one is set.

When On, sets the host bus speed to 100 MHz. When Off, the host bus

speed is 133 MHz.

Chapter 3. Adding and replacing components 33

Page 48

Table 4. Switches 1 - 8 (continued)

Switch

number

Switch

description

5 Power-on override. The default setting is Off (disabled).

When On, overrides the power-on switch and forces power-on mode. The

system will always boot without the use of the power-on switch.

4 Reserved.

3 Reserved.

2 Reserved.

1 Reserved.

Figure 18 identifies system-board LEDs. You might need to refer to this figure when

troubleshooting a problem.

DIMM 4

failure (CR20)

DIMM 3

failure (CR18)

DIMM 2

failure (CR28)

DIMM 1

failure (CR21)

Microprocessor 2

failure (CR7)

Microprocessor 1

failure (CR1)

Voltage regulator module

(VRM2) failure (CR16)

Integrated voltage regulator

(VRM1) failure (CR4)

Power-on

(CR56)

Diagnostics panel

Advanced System

Management Processor

error (CR70)

Figure 18. System board LED locations

Note: The power-on indicator (CR56) is on when system power is present in the

appliance. When this LED flashes, the appliance is in standby mode (the

system power supply is turned off and current is present).

Diagnostics panel LEDs:

PS1 Power supply 1 failure.

PS2 Power supply 2 failure.

PS3 Power supply 3 failure.

NON Non-redundant power.

OVER Overspec. The system has exceeded the power capabilities of the installed

power supply units.

NMI Non-maskable-interrupt occurred.

TEMP System temperature exceeded maximum rating.

FAN A fan failed or is operating slowly.

MEM Memory failure. One or more memory DIMMS have failed.

CPU Microprocessor failure. One or both microprocessors have failed.

PCI A Error on PCI channel A or system board.

34 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 49

Note: PCI bus A is often referred to as PCI bus 0.

PCI B Error on PCI channel B or system board.

Note: PCI bus B is often referred to as PCI bus 1.

VRM Error on voltage regulator module or on integrated voltage regulator.

DASD1

A hot-swap disk drive, backplane, or other part of SCSI channel A has

failed.

DASD2

A SCSI device on SCSI channel B has failed.

Appliance controls and indicators

Figure 19, Figure 20 on page 36, Figure 21 on page 37, and Figure 22 on page 38

illustrate the various controls and indicators on the appliance models.

Note: The Model 200 is also known as the tower model. The Model 225 is also

known as the rack model.

Figure 19. Model 200 front view

1 Operator Information panel

2 Hard Drive Status LED

3 Hard Drive Activity LED

4 Serial Number

5 Cover Release Latch

6 Reset Button

7 Power Control Button

8 Power Control Button Shield (if installed)

Chapter 3. Adding and replacing components 35

Page 50

Figure 20. Model 225 front view

1 Cover-release latch

2 Serial Number

3 Hard Drive Status LED

4 Hard Drive Activity LED

5 Reset Button

6 Power Control Button

7 Power Control Button Shield (if installed)

8 Operator Information panel

Reset Button Press this button to reset the appliance and run the POST.

Attention: Press this button only when the appliance is hung.

Pressing this button when the appliance is booting up or operating

may make the appliance non-operational or corrupt the drives.

Operator Information panel

The LEDs on this panel give status information for your appliance.

See “Operator information panel” on page 39 for more information.

Hard Drive Status LED

Each of the hot-swap drives has a Hard Drive Status LED. When

this amber LED is on continuously, the drive has failed. When the

LED flashes slowly (one flash per second), the drive is being

rebuilt. When the LED flashes rapidly (three flashes per second),

the controller is identifying the drive.

36 IBM TotalStorage

Hard Drive Activity LED

Each of the hot-swap drives has a Hard Drive Activity LED. When

this green LED is flashing, the controller is accessing the drive.

™

Network Attached Storage 200 Installation Guide

Page 51

3

4

5

6

7

8

Figure 21. Model 200 rear view

1 AC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on.

2 DC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on.

3 Serial Port A

4 Mouse

5 Keyboard

6 Ethernet port

7 Video

8 Management

Chapter 3. Adding and replacing components 37

Page 52

4

3

Figure 22. Model 225 rear view

5

6

1 AC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on.

2 DC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on.

3 Serial Port A

4 Mouse

5 Keyboard

6 Ethernet port

7 Video

8 Management

8

7

38 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 53

Operator information panel

The operator information panel on the front of the appliance contains status LEDs.

OK

TX

LINK

100

OK

MB

Figure 23. Operator information panel

1 Information LED

2 System Error LED

3 Ethernet Transmit/Receive Activity (TX/RX) LED

4 Ethernet Link Status (LINK OK) LED

5 Ethernet Speed (100 MB) LED

6 Power-on LED

7 POST Complete (OK) LED

RX

8 SCSI Hard Drive In-use LED

Information LED

This amber LED is on when the information log contains information about

certain conditions in your appliance that might affect performance. For

example, the LED is on if your appliance does not have redundant power. A

LED on the diagnostic panel on the system board will also be on.

System Error LED

This amber LED is on when a system error occurs. A LED on the diagnostic

panel on the system board will also be on to further isolate the error.

Ethernet Transmit/Receive Activity LED

This green LED is on when there is transmit or receive activity to or from

the appliance on the Service Ethernet port.

Ethernet Link Status LED

This green LED is on when there is an active connection on the Service

Ethernet port.

Ethernet Speed LED

This green LED is on when the Service Ethernet LAN speed is 100 Mbps.

Power-on LED

This green LED is on when system power is present in the appliance.

When this LED flashes, the appliance is in standby mode (the system

power supply is turned off and AC current is present). If this LED is not on,

the power cord is not connected, the power supply has failed, or this LED

has failed.

Chapter 3. Adding and replacing components 39

Page 54

POST Complete LED

This green LED is on when the appliance completes the POST without any

errors.

SCSI Hard Drive In-use LED

This green LED is on when there is activity on a hard drive.

Adding or removing internal hardware components

This section describes how to add or remove internal hardware components.

Removing the cover (Model 200)

The following sections describe how to remove the cover, the door (for the Model

200), and the bezel.

Left-side cover

Cover

release

lever

Figure 24. Removing the cover of the Model 200

To remove the left-side cover of the Model 200:

1. Review the information in “Before you begin” on page 27.

2. If you are planning to install or remove any part other than a hot-swap hard disk

drive or hot-swap power supply, switch off the appliance and all attached

devices and disconnect all external cables and power cords.

3. Slide the cover-release lever on the front of the appliance to release the cover;

then, slide the cover toward the rear of the appliance about 25 mm (1 in.). Move

the top edge of the cover out from the appliance; then, lift the cover off the

appliance. Set the cover aside.

Attention: For proper cooling and airflow, replace the cover before switching

on the appliance. Operating the appliance for extended periods of time (over 30

minutes) with the cover removed might damage appliance components.

40 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 55

Removing the cover (Model 225)

Figure 25. Removing the cover of the Model 225

To remove the appliance top cover:

1. Review the information in “Before you begin” on page 27.

2. If you are planning to install or remove any part other than a hot-swap hard disk

drive or hot-swap power supply, switch OFF the appliance and all attached

devices and disconnect all external cables and power cords.

3. Release the left and right side latches and pull the appliance out of the rack

enclosure until both slide rails lock.

Top cover

Right-side

latch

Cover release lever

Left-side latch

Note: When the appliance is in the locked position, you can reach the cables

on the back of the appliance.

4. Move the cover-release lever down while sliding the top cover toward the rear of

the appliance about 25 mm (1 in.). Lift the cover off the appliance and set the

cover aside.

Attention: For proper cooling and airflow, replace the cover before switching

on the appliance. Operating the appliance for extended periods of time (over 30

minutes) with the cover removed might damage appliance components.

Chapter 3. Adding and replacing components 41

Page 56

Removing the door and bezel (Model 200)

Bezel-release lever

Figure 26. Removing the appliance door of the Model 200

To remove the appliance door:

1. Unlock and open the appliance door.

2. Locate the flange on the top edge of the door.

3. Press down on the flange while pressing out on the door; then, lift the appliance

door up and off the hinge. Set the door aside in a safe place.

Door

Flange

To remove the bezel:

1. Move the blue bezel-release lever, following the curve of the lever opening.

2. Lift the bezel tabs out of the slots and pull the bezel away from the appliance

front. Store the bezel in a safe place.

42 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 57

Removing the bezel (Model 225)

Bezel-release lever

Bezel

Figure 27. Removing the bezel of the Model 225

To remove the bezel:

1. Move the blue bezel-release lever, following the curve of the lever opening.

2. Lift the bezel tabs out of the slots and pull the bezel away from the appliance

front. Store the bezel in a safe place.

Installing internal drives

You can install a tape drive to store more data. You can see a list of supported tape

drives at www.storage.ibm.com.

Installing internal drive bays

Internal hard drives are installed in bays. The drive bays of the Network Attached

Storage 200 are in the front of the appliance, as shown in the following illustrations.

Attention: If you are going to install additional hard drives in the non-hot-swap

drive bays, you must install the power supply backplane option and additional

power supplies.

Chapter 3. Adding and replacing components 43

Page 58

Model 200:

Non-hot-swap

bay A

Non-hot-swap

bay B

Non-hot-swap

bay C

Hot-swap bays

Non-hot-swap

bay D

SCSI ID 0

Hard disk

activity light

Hard disk

status light

SCSI ID 2

SCSI ID 3

SCSI ID 4

SCSI ID 8

SCSI ID 9

Figure 28. Installing internal drive bays for the Model 200

Note: The SCSI IDs for the slim-high and half-high hot-swap hard drives are on a

label on the bezel, immediately adjacent to the hot-swap hard drive bays.

Model 225:

SCSI ID 0

SCSI ID 1

SCSI ID 4

SCSI ID 3

Hot-swap bays

SCSI ID 5

SCSI ID 9

Non-hot-swap

bay A

Non-hot-swap

bay B

Non-hot-swap

bay C

Non-hot-swap

bay D

Hard disk

activity light

Hard disk

status light

44 IBM TotalStorage

Figure 29. Installing internal drive bays for the Model 225

Installing and replacing hot-swap hard drives

Your appliance contains hardware that lets you continue to operate your system

while a hard drive is removed or installed. These hard drives are known as

hot-swappable hard drives. They are also referred to as hot-swap hard drives.

™

Network Attached Storage 200 Installation Guide

Page 59

Each hot-swap hard drive that you plan to install must have a hot-swap hard drive

tray attached. The hard drive must have a single connector attachment (SCA)

connector. Hot-swap hard drive trays come with the hot-swap drives.

v Your appliance supports up to six slim 25-mm (1-in.) hot-swap hard drives in the

hot-swap bays.

v The hot-swap hard drive bays connect to a SCSI backplane. This backplane is

the printed circuit board behind the bay.

v The backplane controls the SCSI IDs for the hot-swap hard drives.

Installing a hot-swap hard drive:

Slim filler

Filler panel

Hard disk drive

Drive tray

Drive tray handle

(in open position)

Figure 30. Installing a hot-swap drive

To install a drive in a hot-swap hard drive bay:

Attention:

v To maintain proper system cooling, do not operate the appliance for more than

two minutes without either a hard drive or a filler panel installed for each bay.

Therefore, if you are replacing a defective hot-swap drive, either leave the

defective drive in place or put in a filler panel until you have a replacement drive.

v When you handle electrostatic discharge-sensitive devices (ESDs), take

precautions to avoid damage from static electricity. For details on handling these

devices, refer to “Handling electrostatic discharge-sensitive devices” on page 76.

1. Remove the filler panel from one of the empty hot-swap drive bays by inserting

your finger into the depression at the left side of the filler panel and pulling it

away from the appliance.

2. Install the hard drive in the hot-swap drive bay:

a. Ensure the tray handle is open (that is, perpendicular to the hard drive).

b. Align the rails on the hard drive assembly with the guide rails in the drive

bay.

c. Gently push the hard drive assembly into the drive bay until the hard drive

connects to the backplane.

d. Push the tray handle toward the closed position until it locks the hard drive

in place.

3. Check the hard drive status indicators to verify that the hard drives are

operating properly (the Hard Drive Status LED is immediately to the right of the

hard disk drive).

v When the amber LED is on continuously, the hard drive has failed.

Chapter 3. Adding and replacing components 45

Page 60

v When the green LED flashes slowly (one flash per second), the hard drive is

being rebuilt.

v When the green LED flashes rapidly (three flashes per second), the controller

is identifying the hard drive.

4. Refer to the Network Attached Storage 200 User’s Reference for information

about using the ServeRAID utility to configure the hot-swap drive.

Replacing a hot-swap hard drive: You do not have to switch off the appliance to

remove or install the hot-swap hard drives.

Attention:

1. Before you replace a hot-swap hard drive, check the Hard Drive Status LED on

the front of the drive to see if the drive is defective (if the drive is defective, the

LED will be amber). If you partially or completely remove a good drive instead

of a defective one, you might lose valuable data.

This situation is especially relevant because your appliance has a RAID adapter

installed. The RAID adapter can rebuild the data that you need, provided that

certain conditions are met.

2. Before you remove a hot-swap hard drive that is not defective, back up all

important data.

3. To avoid damage to a hard drive, pull on the release lever to disengage the

hard drive connector from the backplane at the back of the drive bay, wait

approximately 30 seconds to allow the hard drive to spin down, and then

completely remove it from the bay.

Refer to Figure 31 while you perform the steps in this procedure.

Slim filler

Filler panel

Hard disk drive

Drive tray

Drive tray handle

(in open position)

Figure 31. Replacing a drive in a hot-swap drive bay in the Model 200

To replace a drive in a hot-swap drive bay:

1. Before you begin, read the documentation that comes with your hard drive.

2. If your appliance is a Model 200, unlock and open the appliance door.

Attention: To maintain proper system cooling, do not operate the appliance

for more than two minutes without either a hard drive or a filler panel installed

for each drive bay.

3. Locate the defective hard drive (look for an amber Hard Drive Status LED on

the front of the drive).

46 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 61

4. Remove the defective hard drive: move the handle on the hard drive to the

open position (perpendicular to the hard drive) and pull the hot-swap hard drive

assembly from the drive bay.

5. Install the replacement hard drive in the hot-swap drive bay:

a. Ensure the tray handle is open (that is, perpendicular to the hard drive).

b. Align the rails on the hard drive assembly with the guide rails in the drive

bay.

c. Gently push the hard drive assembly into the drive bay until the hard drive

connects to the backplane.

d. Push the tray handle toward the closed position until it locks the hard drive

in place.

6. Check the hard drive status indicators to verify that the hard drive is installed

properly (the Hard Drive Status LED is located to the immediate right of the

hard disk drive).

v When the amber LED is on continuously, the hard drive has failed.

v When the green LED flashes slowly (one flash per second), the hard drive is

being rebuilt.

v When the green LED flashes rapidly (three flashes per second), the controller

is identifying the hard drive.

7. If your appliance is a Model 200, close and lock the appliance door.

Chapter 3. Adding and replacing components 47

Page 62

Replacing hot-swap power supplies

Your appliance comes with three hot-swap power supplies, installed in bays 1, 2,

and 3. The third power supply provides additional redundancy. Each power supply

has two status indicators; see the following illustration for information about the

status indicators and power supply bay locations.

Power supply 1 Power supply 2 Power supply 3

DC power

LED

AC power

LED

Figure 32. Replacing a hot-swap power supply

Power Supply 1

LED PS1 on the system board diagnostics panel refers to this power

supply. See Figure 18 on page 34 for more information about the

diagnostics panel.

Power Supply 2

LED PS2 on the system board diagnostics panel refers to this power

supply. See Figure 18 on page 34 for more information about the

diagnostics panel.

Power Supply 3

LED PS3 on the system board diagnostics panel refers to this power

supply. See Figure 18 on page 34 for more information about the

diagnostics panel.

AC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on. Refer to the

Power Supply LEDs section in the IBM TotalStorage IP Storage 200i

Administrator’s Guide for more information.

DC Power LED

This LED provides status information about the power supply. During

normal operation, both the AC and DC Power LEDs are on. Refer to the

Power Supply LEDs section in the IBM TotalStorage IP Storage 200i

Administrator’s Guide for more information.

48 IBM TotalStorage

™

Network Attached Storage 200 Installation Guide

Page 63

Removing a hot swap power supply

Statement 8

CAUTION:

Never remove the cover on a power supply or any part that has the following label

attached.

Hazardous voltage, current, and energy levels are present inside any component that has

this label attached. There are no serviceable parts inside these components. If you

suspect a problem with one of these parts, contact a service technician.

Note: For translations of this safety notice, refer to Safety Information.

Attention: If you remove a power supply while the system is running, when you

do not have power redundancy, your system will abruptly cease to function.

To remove a hot swap power supply

1. Check the LEDs on the power supplies to determine which power supply has

failed. If a power supply has failed, go to step 4 on page 50.

2. Remove the engine covers.

3. Check the LEDs on the diagnostics panel on the system board.

a. If the NON (non-redundant) LED is on, you do not have redundancy: switch

OFF the appliance and peripheral devices; then, continue with step 4 on

page 50.

Note: The Information LED on the operator information panel on the front of

the appliance also will be on. See “Appliance controls and indicators”

on page 35 for the location and contents of the operator information

panel.

b. If the NON LED is not lit, you have redundancy and do not need to switch

off the appliance. Continue with step 4 on page 50.

Chapter 3. Adding and replacing components 49

Page 64

Diagnostics panel

Figure 33. Removing a hot-swap power supply

4. Unplug the power cord from the power supply.